Sustainable Biomass Functional Monomer-Modified Polycarboxylate Superplasticizers Enable the Creation of High-Performance Cement Pastes

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

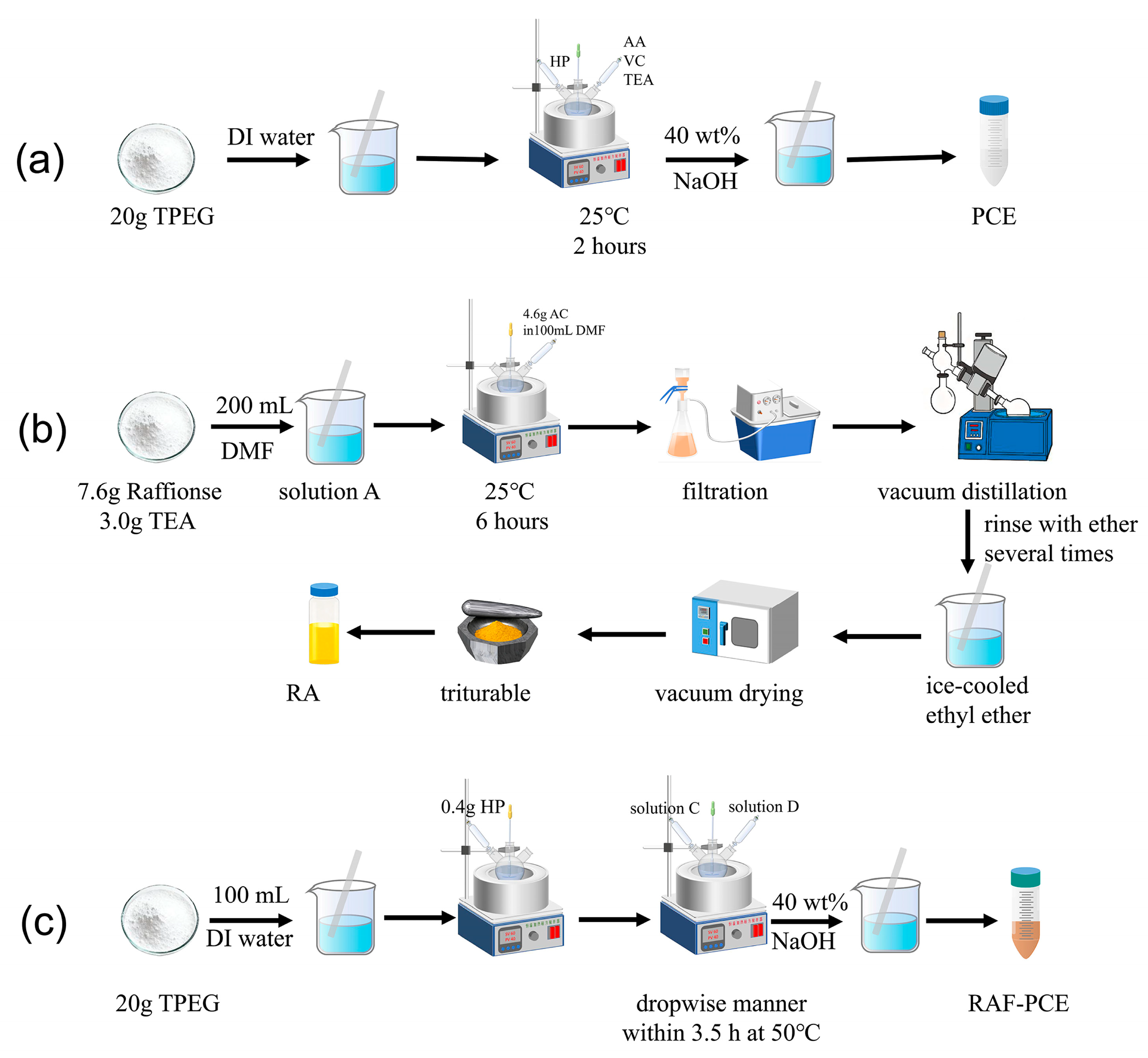

2.2. Synthesis Process

2.2.1. Synthesis of PCE

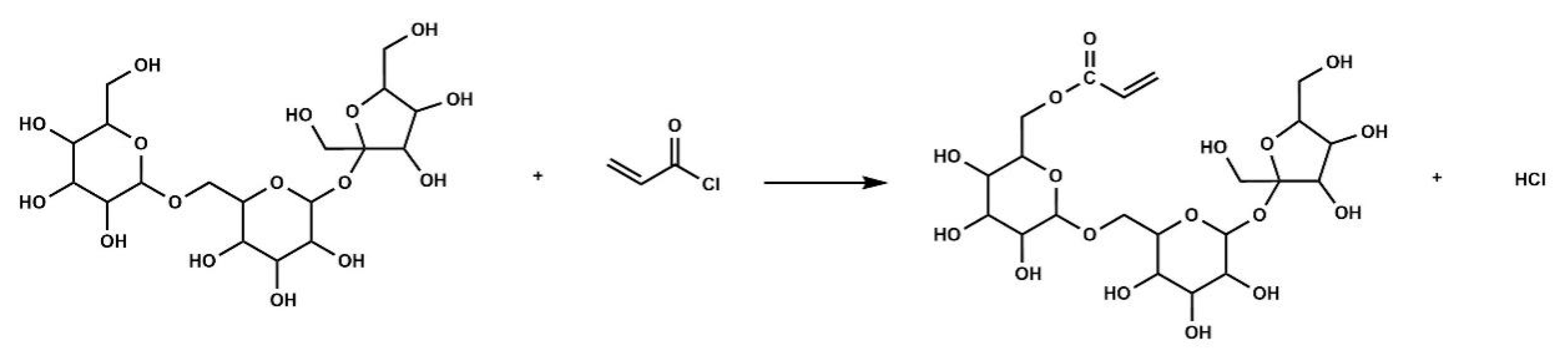

2.2.2. Synthesis of RA

2.2.3. Synthesis of RAF-PCE

2.3. Testing and Characterization

2.3.1. FTIR

2.3.2. Fluidity Test

2.3.3. Water Reduction Rate Test

2.3.4. Gel Permeation Chromatography

2.3.5. Adsorption Capacity Test

2.3.6. Zeta-Potential Measurement

2.3.7. Hydration Heat Measurement

2.3.8. Flexural Strength and Compressive Strength

2.3.9. X-Ray Diffraction Analysis

2.3.10. SEM Test

3. Results and Discussion

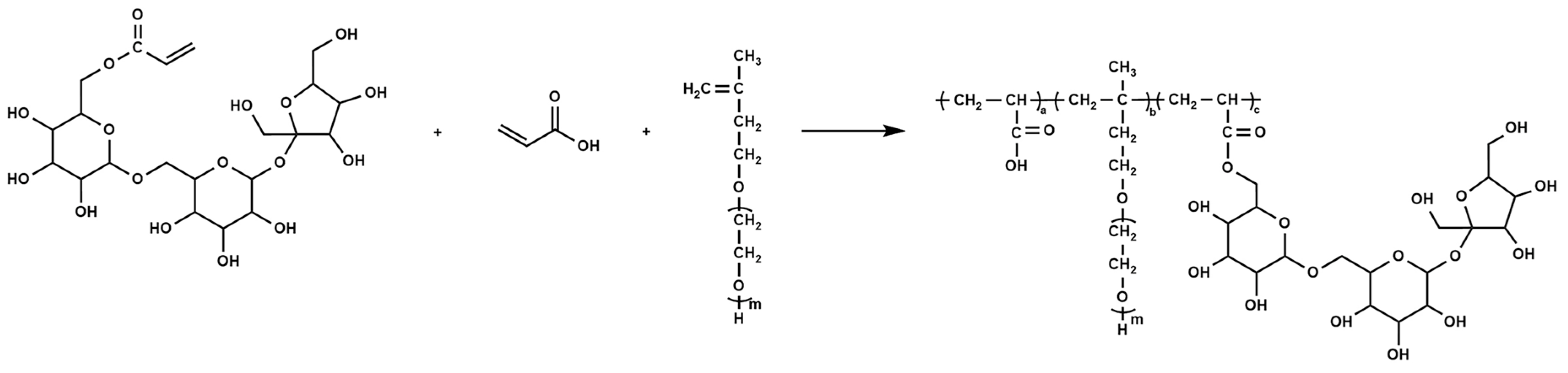

3.1. FTIR Analysis

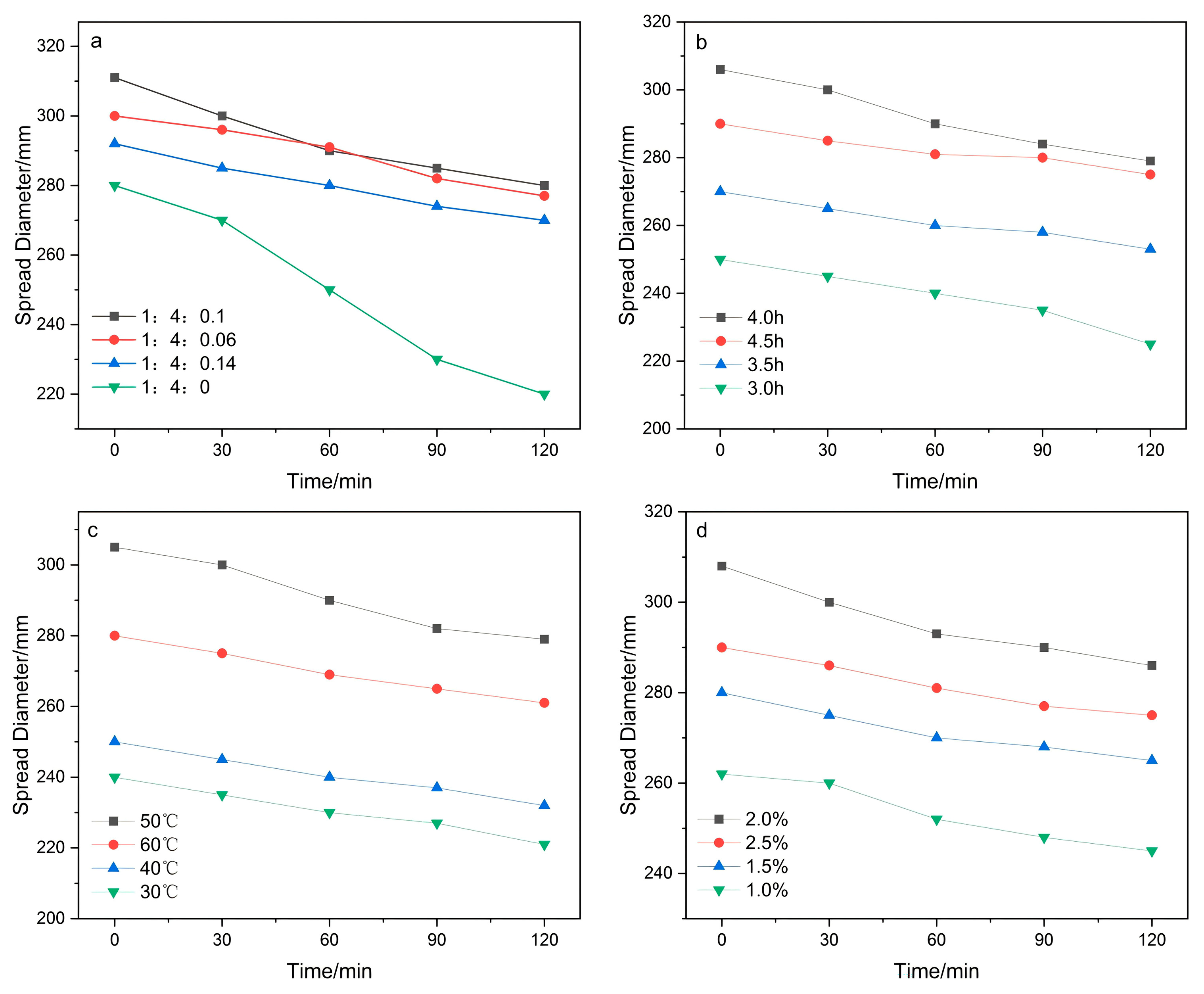

3.2. Fluidity of Cement Paste

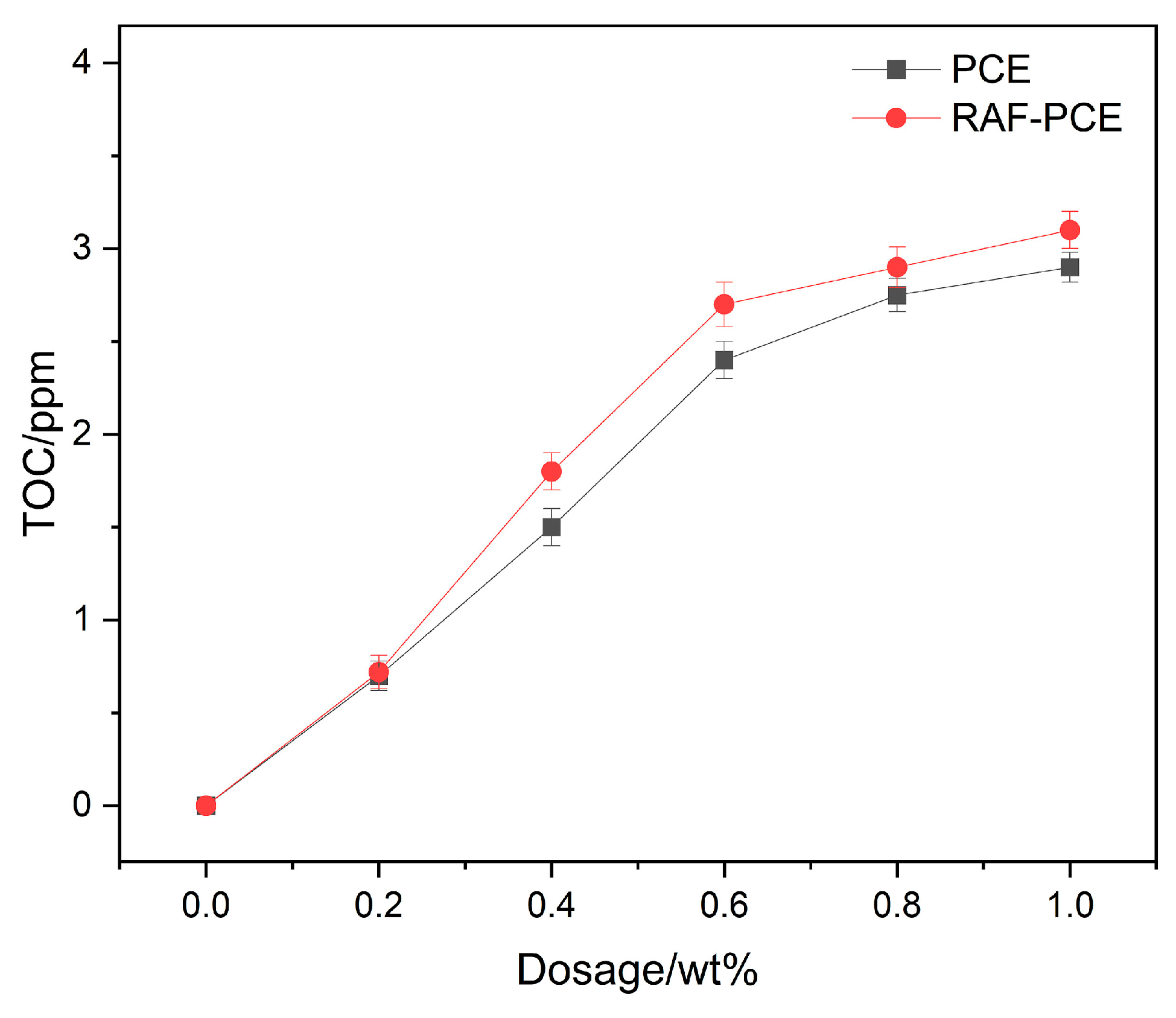

3.3. Adsorption Capacity

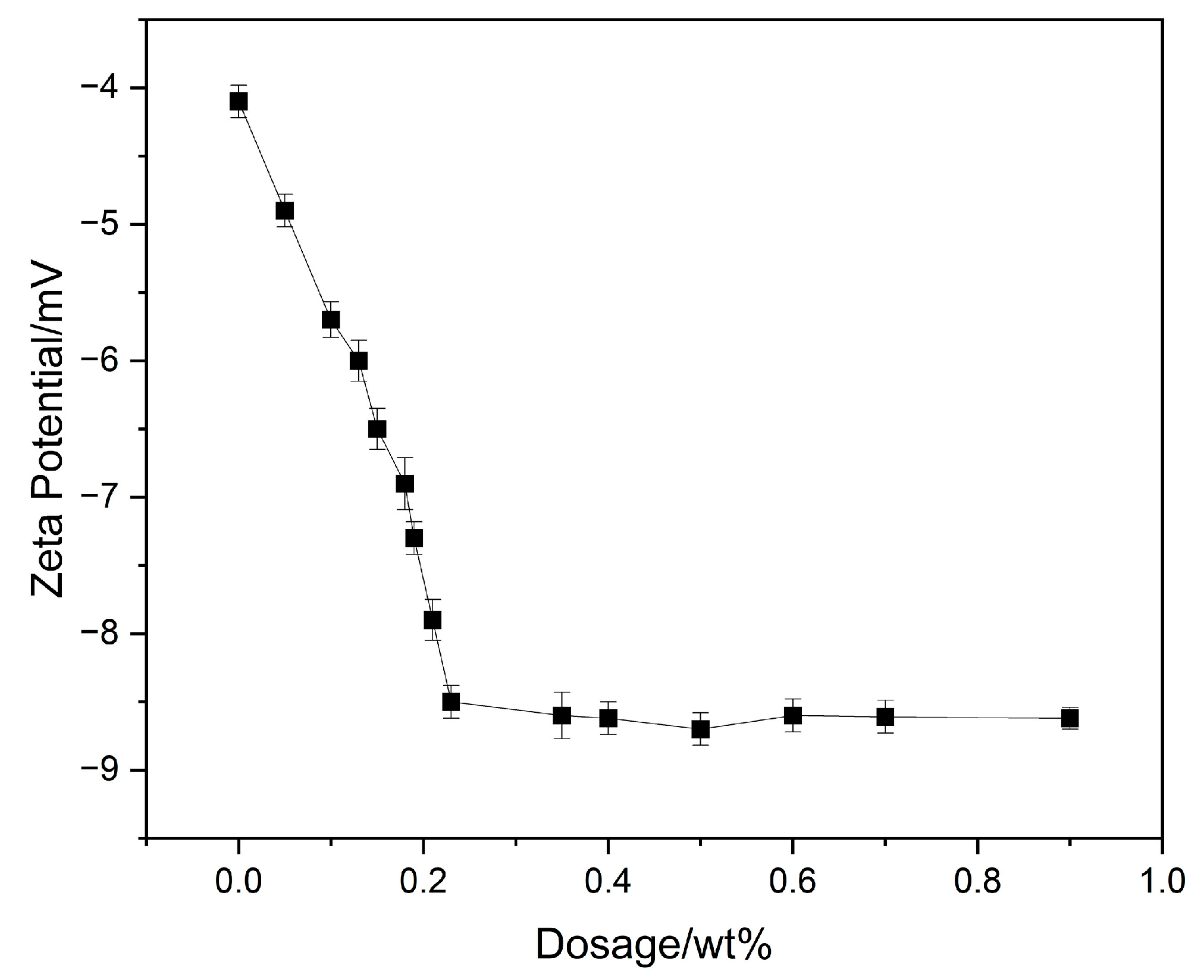

3.4. Zeta-Potential Test

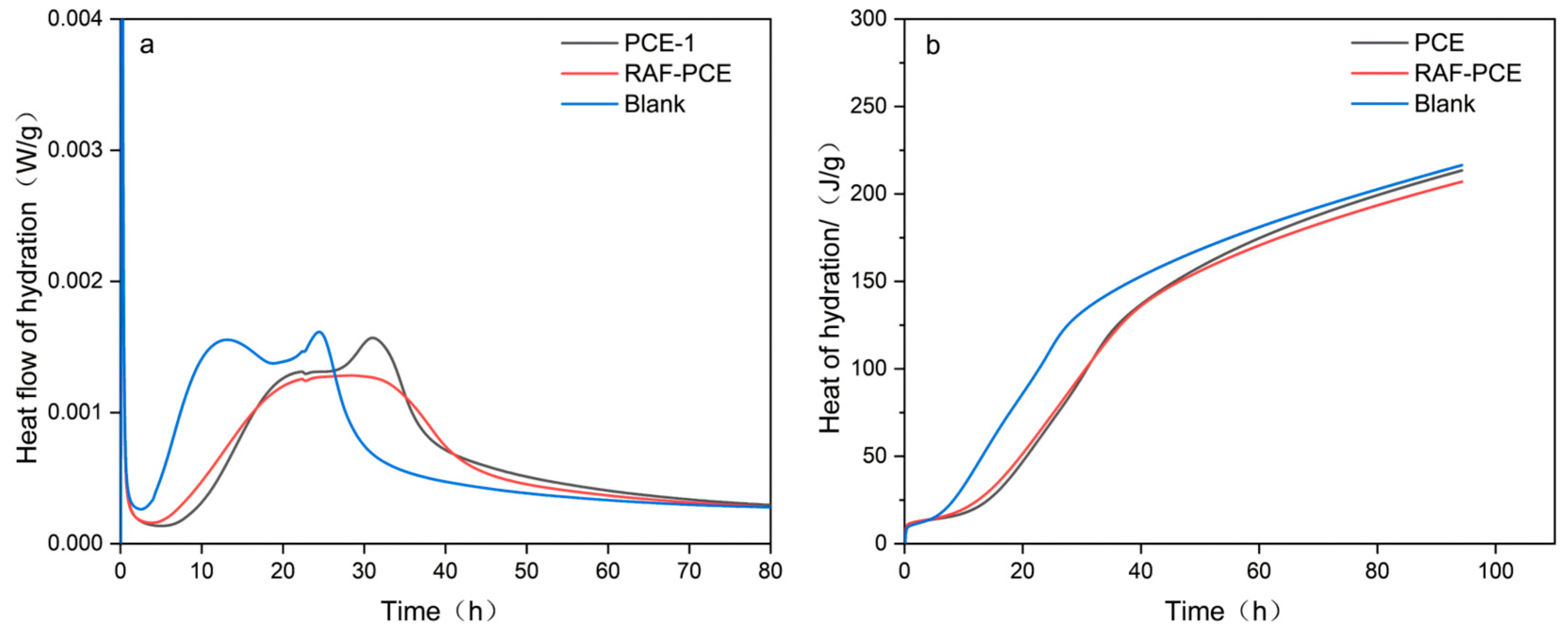

3.5. Hydration Heat Test

3.6. Setting Time

3.7. Strength of Cement Mortar

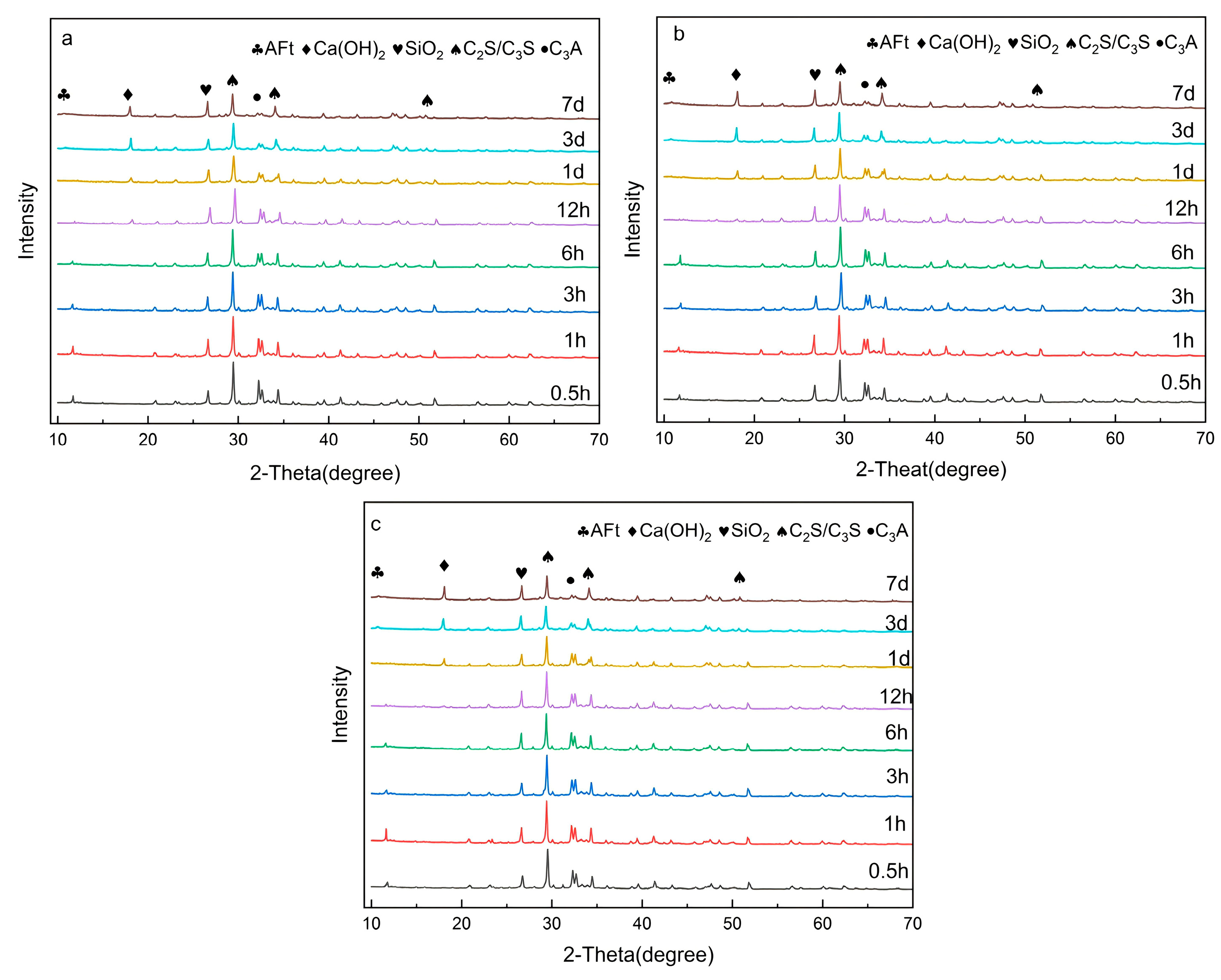

3.8. XRD

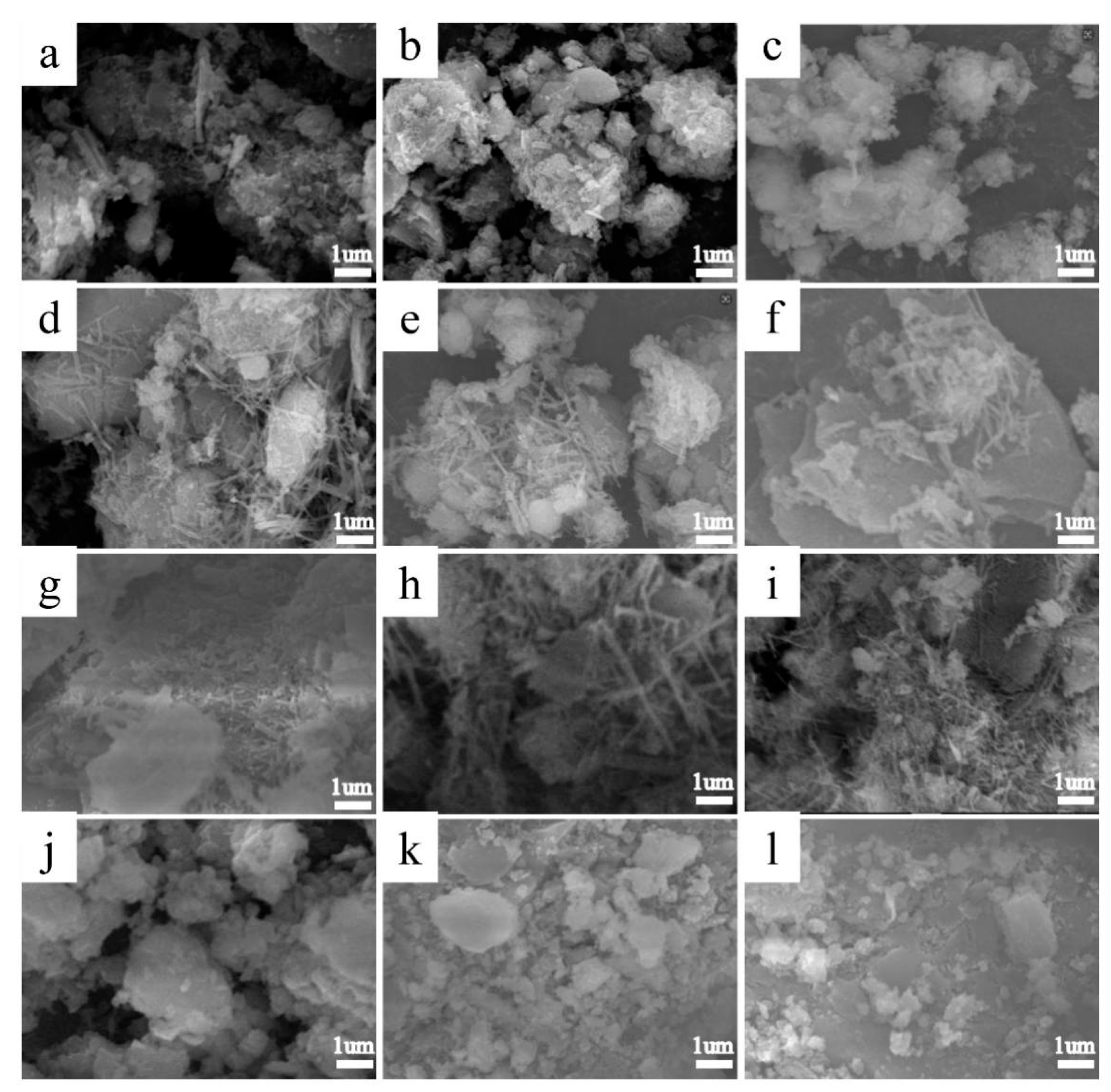

3.9. SEM

3.10. Environmental and Sustainability Assessment

- (1)

- Raffinose is extracted from agricultural by-products (such as beet molasses and cottonseed), which reduces reliance on fossil-derived monomers, promotes high-value utilization of waste resources, and reflects the sustainability of raw materials.

- (2)

- The synthesis process of RAF-PCE is green and environmentally friendly. Esterification and free radical polymerization reactions are carried out at low temperatures (≤50 °C) without toxic catalysts. Compared with traditional PCE chemical modification methods, energy consumption can be effectively reduced.

- (3)

- Cement is the cornerstone of buildings and public infrastructure, and its manufacturing process is characterized by energy-intensive and high carbon dioxide (CO2) emissions, estimated to account for 7.5% of global emissions [44]. The RAF-PCE in this paper has a high water reduction rate (31%), which can greatly reduce the amount of cement used while ensuring strength. In other words, the use of polycarboxylate superplasticizer with high water reduction rate can indirectly reduce In other words, using polycarboxylate superplasticizers with high water-reducing efficiency can indirectly reduce carbon dioxide emissions by reducing cement consumption, thereby helping to achieve the global “dual carbon” goals.

4. Conclusions

- (1)

- A novel biomass-based polycarboxylate superplasticizer (RAF-PCE) was successfully synthesized by incorporating a raffinose-derived monomer. RAF-PCE exhibits superior dispersing ability and significantly improves the fluidity retention of cement paste compared to conventional PCE, effectively addressing the issue of rapid slump loss.

- (2)

- RAF-PCE effectively delays cement hydration, as evidenced by calorimetry and setting time measurements. This retarding effect is attributed to the combined action of the strong adsorption of its hydroxyl groups onto cement particles and the complexation of its functional groups with Ca2+ ions in the pore solution, which inhibits the nucleation and growth of early hydration products.

- (3)

- The incorporation of RAF-PCE promotes the formation of a more homogeneous and compact microstructure in hardened cement paste, with reduced porosity and fewer cracks. This microstructural refinement directly translates to enhanced mechanical properties, resulting in higher compressive and flexural strength at all curing ages. The 28-day compressive strength reaches 79.2 MPa.

- (4)

- This research presents a feasible and eco-friendly strategy for developing high-performance superplasticizers by utilizing renewable biomass resources. RAF-PCE not only delivers excellent comprehensive performance but also paves the way for the green and sustainable development of the concrete industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PCE | polycarboxylate superplasticizer |

| RAF-PCE | raffinose monomer modified polycarboxylate superplasticizer |

| PEG | polyethylene glycol |

| TPEG | isopentenol polyoxyethylene ether |

| Mw | molecular weight |

| AA | acrylic acid |

| HP | hydrogen peroxide |

| VC | ascorbic acid |

| MPA | 3-mercaptopropionic |

| NaOH | sodium hydroxide |

| TEA | triethylamine |

| DMF | N,N-Dimethylformamide |

| RA | synthesis of raffinose acrylate |

| AC | acryloyl chloride |

| DI | deionized |

| FTIR | Fourier transform infrared spectroscopy |

| TOC | total organic carbon |

| GPC | gel permeation chromatography |

| XRD | X-ray diffraction |

| SEM | scanning electron microscope |

| CH | calcium hydroxide |

| AFt | ettringite |

| C3S | tricalcium silicate |

| C2S | dicalcium silicate |

| C3A | tricalcium aluminate |

| C4AF | tetracalcium ferroaluminate |

References

- Huang, H.; Qian, C.; Zhao, F.; Qu, J.; Guo, J.; Danzinger, M. Improvement on microstructure of concrete by polycarboxylate superplasticizer (PCE) and its influence on durability of concrete. Constr. Build. Mater. 2016, 110, 293–299. [Google Scholar] [CrossRef]

- Tutal, A.; Partschefeld, S.; Schneider, J.; Osburg, A. Effects of bio-based plasticizers, made from starch, on the properties of fresh and hardened metakaolin-geopolymer mortar: Basic investigations. Clays Clay Miner. 2020, 68, 413–427. [Google Scholar] [CrossRef]

- Li, X.; Peng, Z.; Feng, Q.; Zheng, Y.; Zhang, X.; Zhang, H.; Long, Y.; Zhang, Y.; Zhou, J. Preparation of Zwitterionic Polycarboxylate Dispersant and its Influence on Rheological Properties and Dispersion Mechanism of Oil Well Cement. Silicon 2025, 17, 3355–3374. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Lee, L.-S. Future Research Trends in High-performance Concrete: Cost-effective Considerations. Transp. Res. Rec. 1997, 1574, 49–55. [Google Scholar] [CrossRef]

- Kulkarni, V.R. High performance concrete for high-rise buildings: Some crucial issues. Int. J. Res. Eng. Technol. 2016, 5, 26–33. [Google Scholar] [CrossRef]

- Feng, P.; Zhang, G.; Zhang, W.; Cui, H.; Xin, T. Comparison of ester-based slow-release polycarboxylate superplasticizers with their polycarboxylate counterparts. Colloids Surf. A 2022, 633, 127878. [Google Scholar] [CrossRef]

- Plank, J.; Sakai, E.; Miao, C.; Yu, C.; Hong, J. Chemical admixtures—Chemistry, applications and their impact on concrete microstructure and durability. Cem. Concr. Res. 2015, 78, 81–99. [Google Scholar] [CrossRef]

- Yang, Y.; Tan, Y.; Li, Z.; Zhou, G.; Yu, X.; Xu, D.; Yong, Q.; Zhao, H.; Xie, Z. Interaction mechanisms between polycarboxylate superplasticizers and cement, and the influence of functional groups on superplasticizer performance: A review. Polym. Bull. 2024, 81, 10415–10438. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, P.; Chan, H.K.; Han, Z.; Liu, B.; Lei, L. Design of a Novel Starch-Modified MPEG PCE for Enhanced Slump Retention in Alkali-Activated Slag Binder. Cem. Concr. Compos. 2026, 165, 106358. [Google Scholar] [CrossRef]

- Sun, Y.; Yu, R.; Shui, Z.; Wang, X.; Qian, D.; Rao, B.; Huang, J.; He, Y. Understanding the porous aggregates carrier effect on reducing autogenous shrinkage of Ultra-High Performance Concrete (UHPC) based on response surface method. Constr. Build. Mater. 2019, 222, 130–141. [Google Scholar] [CrossRef]

- Zhang, M.; Gao, W.; Zhang, F.; Mi, Y.; Wang, W.; An, Q.; Wang, J.; Ma, X.; Miao, J.; Hu, Z. Efficient ternary non-fullerene polymer solar cells with PCE of 11.92% and FF of 76.5%. Energy Environ. Sci. 2018, 11, 841–849. [Google Scholar] [CrossRef]

- Yang, D.; Yang, R.; Priya, S.; Liu, S. Recent advances in flexible perovskite solar cells: Fabrication and applications. Angew. Chem. Int. Ed. 2019, 58, 4466–4483. [Google Scholar] [CrossRef] [PubMed]

- Yun, S.; Qin, Y.; Uhl, A.R.; Vlachopoulos, N.; Yin, M.; Li, D.; Han, X.; Hagfeldt, A. New-generation integrated devices based on dye-sensitized and perovskite solar cells. Energy Environ. Sci. 2018, 11, 476–526. [Google Scholar] [CrossRef]

- Li, Z.; Klein, T.R.; Kim, D.H.; Yang, M.; Berry, J.J.; Van Hest, M.F.; Zhu, K. Scalable fabrication of perovskite solar cells. Nat. Rev. Mater. 2018, 3, 18017. [Google Scholar] [CrossRef]

- Huang, F.; Li, M.; Siffalovic, P.; Cao, G.; Tian, J. From scalable solution fabrication of perovskite films towards commercialization of solar cells. Energy Environ. Sci. 2019, 12, 518–549. [Google Scholar] [CrossRef]

- Zhang, L.; Miao, X.; Kong, X.; Zhou, S. Retardation effect of PCE superplasticizers with different architectures and their impacts on early strength of cement mortar. Cem. Concr. Compos. 2019, 104, 103369. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Y.; Wang, G.; Liu, J.; Cao, Z.; Yong, Q.; Zhao, H. Interaction Between Polycarboxylate Superplasticizer and Clay in Cement and Its Sensitivity Inhibition Mechanism: A Review. Materials. 2025, 18, 2662. [Google Scholar] [CrossRef]

- Arzu, S. Organizational commitment turnover intentions and the influence of cultural values. J. Occup. Organ. Psychol. 2010, 76, 303–321. [Google Scholar]

- Tian, H.; Kong, X.; Su, T.; Wang, D. Comparative study of two PCE superplasticizers with varied charge density in Portland cement and sulfoaluminate cement systems. Cem. Concr. Res. 2019, 115, 43–58. [Google Scholar] [CrossRef]

- Allcock, H.; Morozowich, R. Bioerodible polyphospha zenes and their medical potential. Polym. Chem. 2012, 3, 57–58. [Google Scholar] [CrossRef]

- Maki, H.; Tsujito, M.; Yamada, T. Intrinsic 31P NMR Chemical Shifts and the Basicities of Phosphate Groups in a Short-Chain Imino Polyphosphate. J. Solut. Chem. 2013, 42, 27–43. [Google Scholar] [CrossRef]

- Miao, C.; Ran, Q.; Liu, J.; Mao, Y.; Shang, Y.; Sha, J. New generation amphoteric comb-like copolymer superplasticizer and its properties. Polym. Polym. Compos. 2011, 19, 1–8. [Google Scholar] [CrossRef]

- Chen, M.; Ma, J.; Feng, Y.; Yuan, Q.; Wu, Y.; Liu, Y.; Hu, G.; Liu, X. Advancing aqueous zinc-ion batteries with carbon dots: A comprehensive review. EcoEnergy 2025, 3, 254–295. [Google Scholar] [CrossRef]

- Vandamme, E.; Soetaert, W. Biotechnical modification of carbohydrates. FEMS Microbiol. Rev. 1995, 16, 163–186. [Google Scholar] [CrossRef]

- Webster, C.D.; Lim, C. Introduction to fish nutrition. In Nutrient Requirements and Feeding of Finfish for Aquaculture; CABI Publishing: Wallingford, UK, 2002; pp. 1–27. [Google Scholar]

- Rodén, L. Biosynthesis of acidic glycosaminoglycans (mucopolysaccharides). Metab. Conjug. Metab. Hydrolys. 1970, 2, 345–442. [Google Scholar]

- Wigglesworth, V. Digestion and nutrition. In The Principles of Insect Physiology; Springer: Berlin/Heidelberg, Germany, 1972; pp. 476–552. [Google Scholar]

- GB/T 8076-2008; Concrete Admixtures. Standardization Administration of PRC: Beijing, China, 2008.

- Benzaazoua, M.; Fall, M.; Belem, T. A contribution to understanding the hardening process of cemented pastefill. Miner. Eng. 2004, 17, 141–152. [Google Scholar] [CrossRef]

- GB/T 8077-2023; Methods for Testing Uniformity of Concrete Admixtures. State Administration for Market Regulation, China National Standardization Administration: Beijing, China, 2023.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). Standardization Administration of the People’s Republic of China: Beijing, China, 2021.

- Plank, J.; Hirsch, C. Impact of zeta potential of early cement hydration phases on superplasticizer adsorption. Cem. Concr. Res. 2007, 37, 537–542. [Google Scholar] [CrossRef]

- Zhang, Q.; Shu, X.; Yang, Y.; Wang, X.; Liu, J.; Ran, Q. Preferential adsorption of superplasticizer on cement/silica fume and its effect on rheological properties of UHPC. Constr. Build. Mater. 2022, 359, 129519. [Google Scholar] [CrossRef]

- John, E.; Lothenbach, B. Cement hydration mechanisms through time—A review. J. Mater. Sci. 2023, 58, 9805–9833. [Google Scholar] [CrossRef]

- Cheung, J.; Jeknavorian, A.; Roberts, L.; Silva, D. Impact of admixtures on the hydration kinetics of Portland cement. Cem. Concr. Res. 2011, 41, 1289–1309. [Google Scholar] [CrossRef]

- Beaudoin, J.; Odler, I. Hydration, setting and hardening. In Lea’s Chemistry of Cement and Concrete; Elsevier: Amsterdam, The Netherlands, 2019; p. 157. [Google Scholar]

- Glasser, F. Fundamental aspects of cement solidification and stabilisation. J. Hazard. Mater. 1997, 52, 151–170. [Google Scholar] [CrossRef]

- Sha, S.; Wang, M.; Shi, C.; Xiao, Y. Influence of the structures of polycarboxylate superplasticizer on its performance in cement-based materials-A review. Constr. Build. Mater. 2020, 233, 117257. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, X.; Liu, Y.; Ge, C.; Guo, L.; Shu, X.; Liu, J. Synergistic effects of silica nanoparticles/polycarboxylate superplasticizer modified graphene oxide on mechanical behavior and hydration process of cement composites. RSC Adv. 2017, 7, 16688–16702. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, J.; Xu, W.; Yang, J.; Li, M. Synthesis and characterization of SSS/MA/NVCL copolymer as high temperature oil well cement retarder. J. Dispers. Sci. Technol. 2022, 43, 1405–1415. [Google Scholar] [CrossRef]

- Abdel–Aty, Y.Y.; Mahmoud, H.S.; Al-Zahrani, A.A. Experimental evaluation of consolidation techniques of fossiliferous limestone in masonry walls of heritage buildings at historic Jeddah, Kingdom of Saudi Arabia. Adv. Res. Conserv. Sci. 2020, 1, 16–33. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, Y.; Liu, S.; Liu, Q.; Chen, Y.; Zha, F. Strength and micro-structure evolution of compacted soils modified by admixtures of cement and metakaolin. Appl. Clay Sci. 2016, 127, 44–51. [Google Scholar] [CrossRef]

- Balonis, M.; Glasser, F.P. The density of cement phases. Cem. Concr. Res. 2009, 39, 733–739. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, R.; Ma, Y.; Hu, Y.; Zhang, X.; Wang, Y.; Li, W. Carbon emission reduction in cement production catalyzed by steel solid waste. Natl. Sci. Rev. 2025, 12, nwaf109. [Google Scholar] [CrossRef]

| Classification | Characteristic Functional Groups | Water Reduction Rate | Retardation Effect | Compressive Strength |

|---|---|---|---|---|

| Polyester-type | Carboxylate (-COO−), Ester bond (-COO−) The backbone incorporates both anionic (carboxylate) and cationic monomer units. | 25%–35% | Relatively weak or slightly promotes coagulation | Significant enhancement of early-age strength |

| Polyether-type | Carboxylate (-COO−), Ether bond (-C-O-C-), Poly(ethylene oxide) (PEO) side chains Amide/imide groups on the backbone or side chains allow precise control over side-chain density and length. | 25%–40% | Neutral or extremely slight delay in coagulation | Significant strength enhancement at all stages with balanced development |

| Amide/Imide-type | Amide (-CONH-) or Imide (-CO-N-CO-) backbone (e.g., polyacrylate) grafted with polyether long side chains. | 20%–30% | Significant delay in coagulation | Stable and continuous strength growth in later stages |

| Zwitterionic-type | Carboxylate (-COO−), Cationic group Backbone (e.g., polymaleic anhydride) grafted with polyester long side chains. | 20%–30% | A significant effect in delaying coagulation | Steady strength enhancement at all stages |

| Our work | Carboxyl group (-COO−), ether bond (-C-O-C-), sugar ring hydroxyl group (-OH) | 25%–31% | A significant effect in delaying coagulation: the initial setting time extended by 2.92 h and the final setting time extended by 4.95 h | 3-day average compressive strength 51.9 MPa; 7-day average compressive strength 67.2 MPa; 28-day average compressive strength 79.2 MPa |

| Type | Dosage of Initiator | Molecular Weight (g/mol) | Initial Fluidity (mm) | Water Reduction Ration (%) |

|---|---|---|---|---|

| RAF-PCE 1 | 1.0% | 34,122 | 250 | 25% |

| RAF-PCE 2 | 1.5% | 32,135 | 270 | 27% |

| RAF-PCE 3 | 2.0% | 28,063 | 310 | 31% |

| RAF-PCE 4 | 2.5% | 25,054 | 300 | 30% |

| RAF-PCE 5 | 3.0% | 24,976 | 280 | 28% |

| Initial | Final | Interval Time (h) | |||

|---|---|---|---|---|---|

| Initial Time (h) | Change in Initial Setting Time (h) | Final Times (h) | Change in Final Setting Time (h) | ||

| Blank | 2.91 ± 0.12 | 0 | 5.03 ± 0.18 | 0 | 2.12 ± 0.09 |

| PCE | 4.15 ± 0.15 | +1.24 | 7.20 ± 0.21 | +2.17 | 3.05 ± 0.12 |

| RAF-PCE | 5.83 ± 0.21 | +2.92 | 9.98 ± 0.32 | +4.95 | 4.15 ± 0.15 |

| Samples | Flexural Strength/MPa | Compressive Strength/MPa | ||||

|---|---|---|---|---|---|---|

| 3 d | 7 d | 28 d | 3 d | 7 d | 28 d | |

| Blank | 5.5 ± 0.3 | 6.7 ± 0.2 | 8.2 ± 0.4 | 37.1 ± 1.5 | 49.4 ± 1.8 | 65.6 ± 2.1 |

| PCE | 6.7 ± 0.2 | 8.4 ± 0.3 | 9.7 ± 0.3 | 50.5 ± 1.6 | 60.1 ± 1.7 | 75.1 ± 2.0 |

| RAF-PCE | 6.9 ± 0.3 | 8.9 ± 0.2 | 10.3 ± 0.4 | 51.9 ± 1.2 | 67.2 ± 1.5 | 79.2 ± 1.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Y.; Du, Q.; Diao, W.; Wang, C.; Wang, L.; Lv, S.; Kong, L.; Zhang, L.; Xi, Y.; Wang, H. Sustainable Biomass Functional Monomer-Modified Polycarboxylate Superplasticizers Enable the Creation of High-Performance Cement Pastes. Coatings 2025, 15, 1459. https://doi.org/10.3390/coatings15121459

Yan Y, Du Q, Diao W, Wang C, Wang L, Lv S, Kong L, Zhang L, Xi Y, Wang H. Sustainable Biomass Functional Monomer-Modified Polycarboxylate Superplasticizers Enable the Creation of High-Performance Cement Pastes. Coatings. 2025; 15(12):1459. https://doi.org/10.3390/coatings15121459

Chicago/Turabian StyleYan, Yu, Qifei Du, Wanyue Diao, Chao Wang, Liyan Wang, Sa Lv, Lingwei Kong, Liping Zhang, Yuanzhang Xi, and Huan Wang. 2025. "Sustainable Biomass Functional Monomer-Modified Polycarboxylate Superplasticizers Enable the Creation of High-Performance Cement Pastes" Coatings 15, no. 12: 1459. https://doi.org/10.3390/coatings15121459

APA StyleYan, Y., Du, Q., Diao, W., Wang, C., Wang, L., Lv, S., Kong, L., Zhang, L., Xi, Y., & Wang, H. (2025). Sustainable Biomass Functional Monomer-Modified Polycarboxylate Superplasticizers Enable the Creation of High-Performance Cement Pastes. Coatings, 15(12), 1459. https://doi.org/10.3390/coatings15121459