1. Introduction

Chinese lacquer (urushi) has been widely used as a traditional coating material in East Asia for more than 7000 years, representing a unique cultural and artistic achievement in human civilization [

1]. It is primarily derived from the sap of the lacquer tree (

Toxicodendron vernicifluum), consisting of urushiol (a mixture of catechol derivatives with long unsaturated side chains, typically C15–C17), polysaccharides, glycoproteins, laccase enzymes, and water [

2]. The unique chemical structure of urushiol, which undergoes enzymatic oxidative polymerization catalyzed by laccase, gives rise to a dense cross-linked polymer network, accounting for the excellent durability, gloss, and resistance of lacquer films. Owing to its excellent durability, gloss, and resistance to water and insects, lacquer has been extensively applied to furniture, artworks, and architectural decorations, and has been recognized as part of the world’s intangible cultural heritage [

3].

However, lacquer coatings are highly sensitive to environmental conditions such as light, temperature, and humidity. Long-term exposure to ultraviolet (UV) radiation can lead to photo-oxidation, chain scission, and cross-linking reactions in urushiol components, causing discoloration, cracking, and loss of mechanical integrity [

4,

5]. Pigments traditionally mixed with lacquer, such as cinnabar (HgS), carbon black, and iron oxides, orpiment (As

2S

3), and lapis lazuli (lazurite, (Na,Ca)

8(AlSiO

4)

6(S,SO

4,Cl)

2), can further influence its stability by affecting light absorption and degradation pathways [

6]. For example, cinnabar is known for its relative stability under light exposure, whereas orpiment is highly sensitive to photodecomposition, and lapis lazuli can undergo complex structural changes that influence its chromatic stability. Previous studies using spectroscopic techniques (FTIR, Raman, Py-GC/MS) have revealed that photo-aging induces chemical modifications in functional groups such as C=O, C=C, and O–H [

2,

3], but most investigations have been limited to clear lacquer or a single pigment type, and the comparative role of different mineral pigments in modulating photoaging behavior remains insufficiently addressed.

Recent studies have focused predominantly on artificial UV or lamp-based aging of lacquer films, whereas comparatively fewer investigations have examined natural sunlight exposure; several reports indicate that degradation pathways and kinetics under natural sunlight or broad-spectrum illumination may differ from those observed under accelerated UV sources [

2,

7,

8]. This knowledge gap limits the development of scientific conservation guidelines for lacquered artifacts.

Current conservation strategies for lacquered cultural relics mainly rely on empirical restoration methods or modern synthetic coatings, but their compatibility and long-term stability remain controversial [

9,

10]. For example, artificial resins used in restoration often show different aging behaviors compared to natural lacquer, which can accelerate deterioration rather than prevent it [

11].

Therefore, the present study aims to investigate the surface chemical changes in Chinese lacquer coatings of different colors during natural light aging using Fourier-transform infrared spectroscopy (FTIR). By combining visual appearance, colorimetric parameters (ΔL*, ΔC*, and ΔE), gloss and roughness analysis, FTIR, and scanning electron microscopy (SEM), this study systematically evaluates the photoaging behavior of red, yellow, and blue lacquer coatings. By analyzing the variations in functional groups and comparing the influence of different mineral pigments, this research provides new insights into the mechanisms of photo-oxidative degradation in lacquer coatings. The findings are expected to contribute to the scientific preservation and restoration of lacquerware cultural heritage, offering a valuable reference for conservators in both museum and field contexts.

2. Materials and Methods

2.1. Materials

The substrate material employed in this study was rubberwood (Hevea brasiliensis), obtained from the Chinese Academy of Tropical Agricultural Sciences. Specimens were cut into standardized panels with dimensions of 7 cm × 7 cm × 0.5 cm, corresponding to the radial section of the wood, in order to ensure consistency in anatomical orientation and minimize variability caused by grain direction [

12]. Prior to coating, the wood was kiln-dried to achieve a moisture content of approximately 10% and subsequently conditioned for 14 days under controlled laboratory conditions (20 ± 1 °C, 55 ± 2% relative humidity, RH) to equilibrate moisture and stabilize the substrate.

Three traditional Chinese lacquer formulations were selected, each incorporating different mineral pigments to investigate the influence of pigment type on photoaging behavior. The red lacquer was pigmented with cinnabar (HgS, analytical grade, purity ≥ 99%, Sinopharm Chemical Reagent Co., Ltd., Shanghai, China), a mercury sulfide mineral historically used in East Asian art for its brilliant and stable red hue [

13,

14]. The yellow lacquer was pigmented with orpiment (As

2S

3, analytical grade, purity ≥ 98%, Aladdin Reagent Co., Ltd., Shanghai, China), an arsenic sulfide mineral known for its intense yellow coloration but relatively poor stability under light exposure [

15]. The blue lacquer was pigmented with lapis lazuli, represented by the complex aluminosilicate mineral lazurite ((Na,Ca)

8(AlSiO

4)

6(S,SO

4,Cl)

2), artist-grade, pigment quality, Kremer Pigmente GmbH, Aichstetten, Germany), valued for its deep ultramarine shade [

4]. All lacquer resins (urushiol-based) were purchased from the Xi’an Chinese Lacquer Research Institute, and mixed with mineral pigments at a weight ratio of 10 wt% pigment to lacquer, which ensured adequate coloration without affecting film formation.

By selecting pigments with distinct chemical compositions and historical significance, this study aimed to systematically evaluate how different mineral pigments modulate the optical and chemical stability of Chinese lacquer under natural photoaging conditions.

2.2. Preparation of Coated Specimens

The lacquer coatings were applied using a wire-bar applicator, with a wet film thickness of approximately 20 μm per layer, and three layers in total. The pigment–lacquer mixtures were mechanically stirred for 30 min at room temperature (25 °C) to ensure uniform dispersion before coating. Wet film thickness was verified using a wet-film comb gauge. After each coating application, specimens were cured in a climate chamber at 30 ± 1 °C and 80 ± 2% RH for 7 days. Between each layer, surfaces were sanded with 360- and 600-grit waterproof abrasive paper to improve adhesion and smoothness. The final layer was left unsanded, resulting in a total dry film thickness of approximately 50 μm.

2.3. Natural Light Aging Test

The natural light aging experiment was conducted from 26 November 2024, to 12 March 2025, at the Chinese Academy of Tropical Agricultural Sciences (20°01′07″ N, 110°20′56″ E). Seven replicates of each coating type were vertically mounted inside a custom-designed natural aging chamber (1500 × 500 × 685 mm) at a height of 450 mm above ground (21 specimens in total;

Figure 1 shows representative specimens). To minimize the effects of rainfall, the front, back, sides, and top of the chamber were covered with tempered glass, allowing exposure primarily to sunlight. The tempered glass exhibited a UV transmittance of approximately 75% in the UVA range (315–400 nm) and 15% in the UVB range (280–315 nm), which was considered in the analysis of photoaging behavior. Surface properties of the specimens were evaluated at 7-day intervals to assess the degree of aging.

2.4. Evaluation of Aging Performance of Lacquer Coatings

2.4.1. Appearance and Color Measurement

The surface appearance of the specimens was documented using a high-resolution flatbed scanner to provide a visual record of macroscopic changes during the aging process. Colorimetric measurements were carried out using a portable spectrophotometer (CM-700d, Konica Minolta, Tokyo, Japan), operating under the CIE standard illuminant D65 with a 10° standard observer angle. The CIE Lab* color space values (L*, a*, b*) were recorded at each time interval. Chroma (C*) was calculated according to the equation:

The total color difference (ΔE) was used to quantify the overall perceptible color change, calculated as:

where ΔL*, Δa*, and Δb* represent the differences in L*, a*, and b* values between the aged samples and the control [

16], respectively.

2.4.2. Surface Roughness and Gloss Measurement

Surface roughness (Ra) was measured using a surface roughness tester (SJ-410, Mitutoyo, Kawasaki, Japan). Each specimen was measured at three different positions, and the mean ± standard deviation was reported. Gloss was determined using a glossmeter (Novo-Gloss 60°, Rhopoint, East Sussex, UK) at a 60° incidence angle to evaluate changes in surface reflectance.

2.4.3. Surface Chemical Composition Analysis

Fourier-transform infrared spectroscopy (FTIR) analysis was conducted using a Nicolet iS10 spectrometer (Thermo Fisher Scientific, Waltham, MA, USA) equipped with an attenuated total reflection (ATR) accessory. Spectra were recorded in the range of 4000–400 cm

−1, with a resolution of 4 cm

−1 and 32 scans per sample. These measurements provided insights into the chemical changes in lacquer coatings induced by natural photoaging [

17].

2.4.4. Microscopic Morphology Observation

Microscopic surface morphology was investigated using scanning electron microscopy (SEM, SU8010, Hitachi, Tokyo, Japan). Prior to observation, all specimens were sputter-coated with a thin layer of gold to ensure conductivity. Images were obtained at an accelerating voltage of 15 kV to evaluate surface defects such as crack formation, pigment dispersion, and microstructural degradation caused by prolonged light exposure.

2.5. Statistical Analysis

All experimental data were expressed as mean ± standard deviation (SD) based on seven replicates per coating type. Statistical analyses were conducted using one-way analysis of variance (ANOVA) to assess the effect of aging time on colorimetric parameters (ΔL*, ΔC*, ΔE), gloss, and surface roughness. Post hoc multiple comparisons were performed using Tukey’s HSD test to determine pairwise differences. A significance level of p < 0.05 was adopted to evaluate statistical significance. All statistical computations were carried out using SPSS Statistics 26.0 (IBM Corp., Armonk, NY, USA).

3. Results

3.1. Color Evolution of Chinese Lacquer Coatings During Natural Photoaging

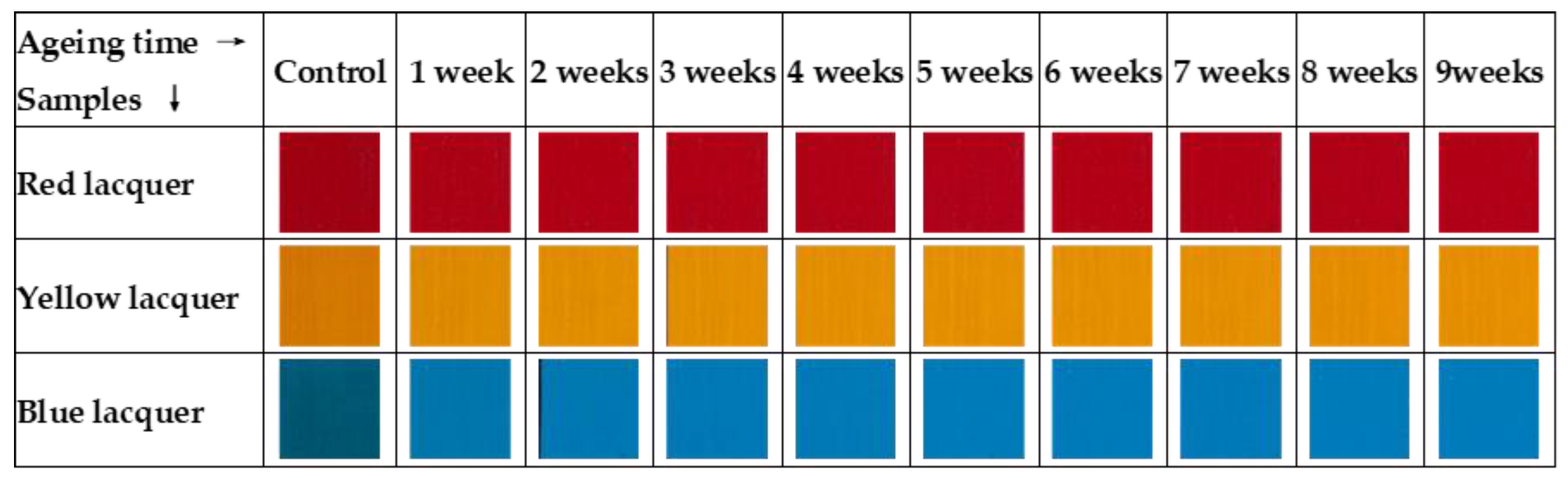

Visual inspection of the scanned specimens clearly indicated that all types of lacquer coatings, regardless of their pigment composition, experienced a progressive enhancement in surface brightness and color vividness when subjected to natural light aging (

Figure 2). This visual improvement, particularly characterized by increasingly saturated color appearance, was consistently supported by quantitative instrumental color measurements, demonstrating the reliability of the observed phenomena [

18,

19].

Detailed analysis of the colorimetric data (comprehensively presented in

Table 1,

Table 2 and

Table 3) revealed that the most significant transformations occurred in the lightness (L) and chroma (C) parameters, while variations in hue-related coordinates (a* and b) demonstrated distinct patterns specific to each pigment type [

20]. In the red lacquer coatings, L values showed a steady increase from 36.6 to 41.7 over the nine-week exposure period, while C* values rose substantially from 37.83 to approximately 50.01, collectively indicating a markedly brighter and more vivid visual appearance. The concurrent increases in both redness (a) and yellowness (b) values contributed to the development of a more saturated and intense red hue [

21]. The yellow lacquer exhibited even more pronounced changes, with L* values increasing from 57.87 to 67.48 and C* values expanding from 47.96 to 67.08, accompanied by a particularly remarkable elevation in b* values from 46.64 to 66.26, reflecting not only substantial brightening but also significantly enhanced yellowness and color purity [

22]. For the blue lacquer, L* values showed an initial increase from 38.09 to 46.19 during the early stages of exposure before exhibiting slight fluctuations in subsequent measurements, while C* values demonstrated a sharp rise from 12.96 to 36.56. The negative b* values became substantially more pronounced, changing from −11.65 to −34.81, indicating the development of a deeper and more intense blue tone, although some irregular fluctuations observed at week 7 and week 9 suggested possible pigment instability or measurement variability under certain conditions.

Comparative analysis across all three pigment types highlighted that while all coatings exhibited measurable increases in both brightness and chroma, the specific magnitude and directional characteristics of color changes were distinctly pigment-dependent. The red lacquer consistently evolved toward a more saturated red appearance with slight yellow undertones, the yellow lacquer progressed toward a noticeably brighter and purer yellow coloration, and the blue lacquer developed toward a more intense and pure blue hue with greater depth.

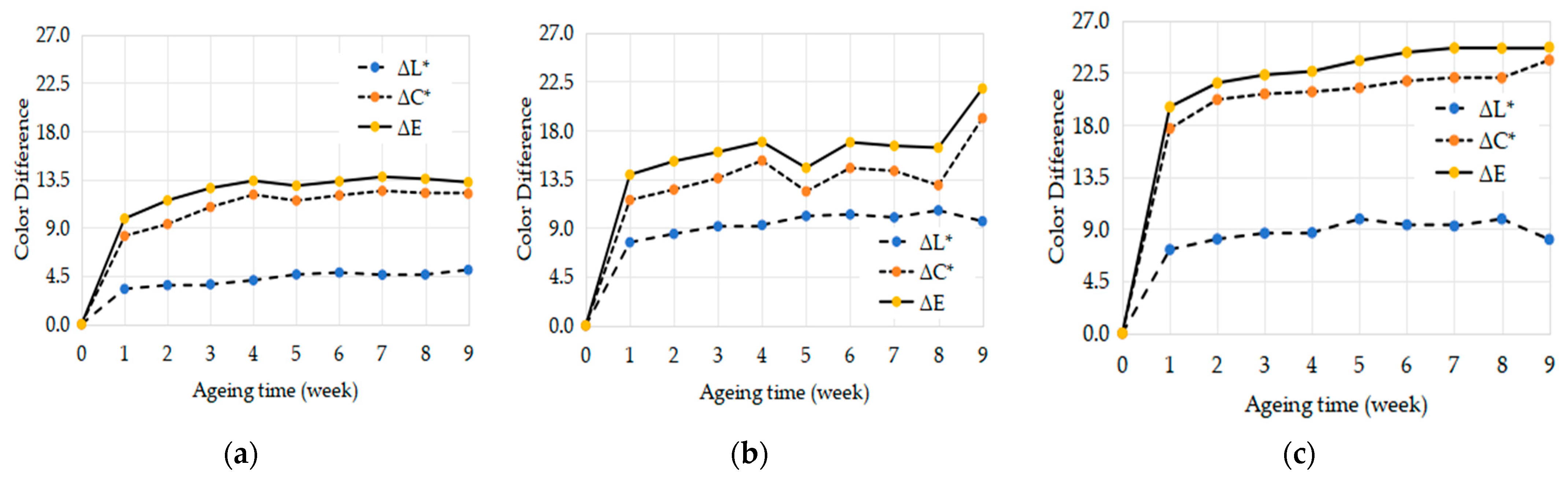

As clearly demonstrated in

Figure 3, the ΔL, ΔC, and ΔE* values collectively indicate that all three lacquer coatings underwent their most pronounced optical transformations during the initial week of natural photoaging, followed by more gradual but continuing variations throughout the subsequent weeks of exposure. For the red lacquer, ΔL* values increased progressively from 0 to 5.07 and ΔC* values expanded from 0 to 12.18, resulting in a final ΔE* value of 13.25 at week 9; the most substantial change occurred during the first week (ΔE* = 9.85), after which the rate of change noticeably stabilized. The yellow lacquer exhibited greater sensitivity to photoaging, with ΔL* values rising to 10.61 and ΔC* values reaching 15.12, culminating in a ΔE* of 19.86 by week 9, with the most rapid transformations observed during the first two weeks (ΔE* = 13.91 and 15.15, respectively). The blue lacquer showed the most dramatic response to light exposure, with ΔL* values fluctuating within the 8–10 range, ΔC* values increasing continuously to 23.60, and ΔE* values peaking at 24.71 by week 9.

Among the three coating systems, the blue lacquer exhibited the greatest perceptible color change according to ΔE* values, followed by the yellow lacquer, while the red lacquer remained relatively more stable throughout the aging process. Overall, the data conclusively confirm that the most significant photoinduced alterations occurred during the initial exposure period, after which the rate of change considerably slowed, indicating that the coatings gradually reached a relatively stable state of color evolution under continued light exposure.

3.2. Changes in Gloss and Surface Roughness

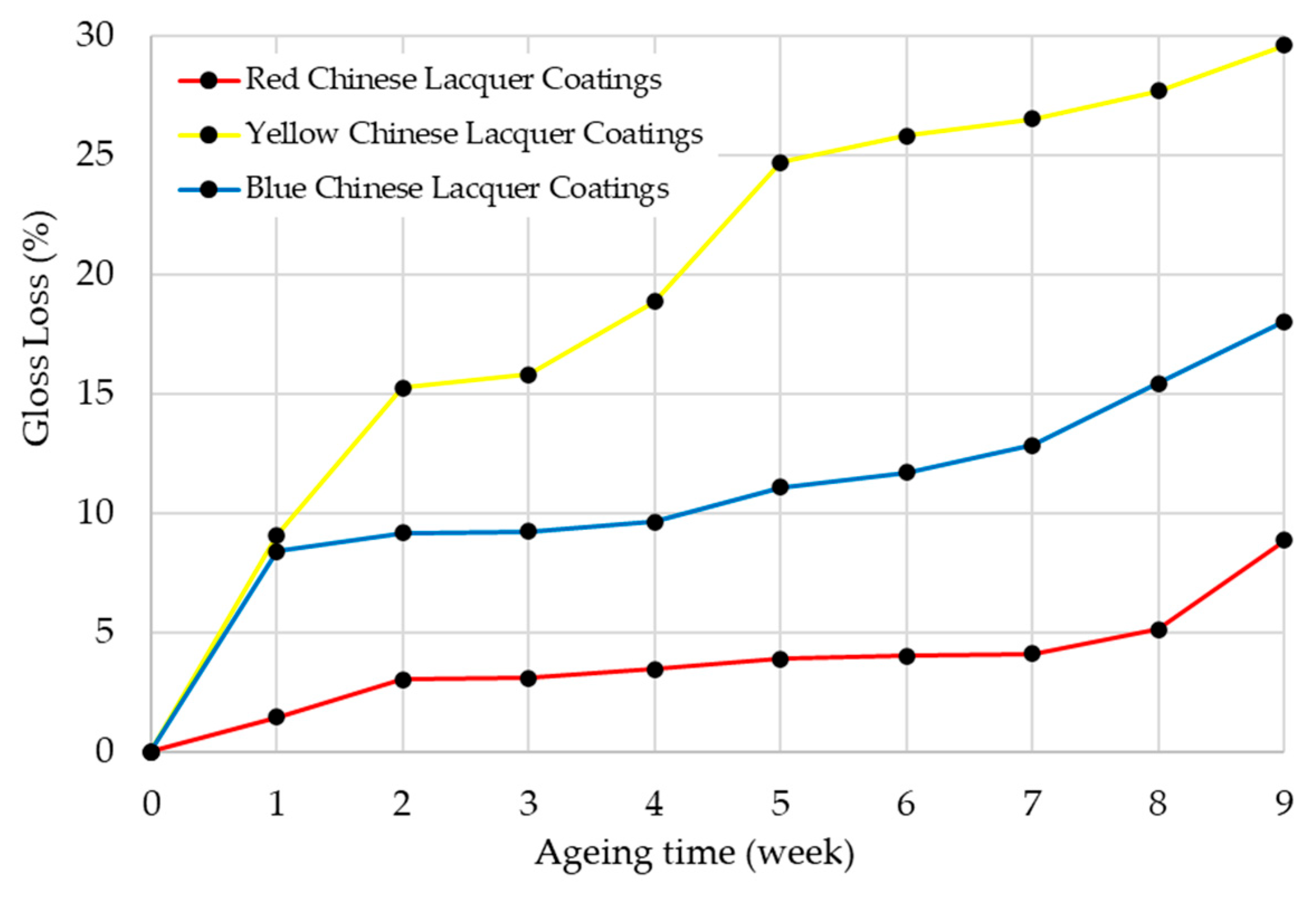

Figure 4 illustrates the percentage gloss loss observed for the red, yellow, and blue lacquer coatings throughout the natural photoaging process. All three coating types exhibited a progressive yet distinct decline in gloss from their respective initial values, demonstrating the impact of light-induced degradation on surface optical properties. The yellow coating, which started from an initial gloss value of 33.64, experienced the most severe gloss degradation, losing nearly 30% of its original specular reflection capability. The blue coating, despite having the highest initial gloss value of 69.58, showed a considerable reduction of approximately 18%, indicating that even initially high-gloss surfaces undergo significant optical deterioration. In contrast, the red coating, with a moderate initial gloss value of 41.43, demonstrated the best gloss retention performance among the three, with a total loss of less than 9% over the exposure period. These results clearly indicate distinct sensitivities to light-induced gloss degradation among the different pigments, with yellow-pigmented lacquer being particularly vulnerable to photodegradation effects.

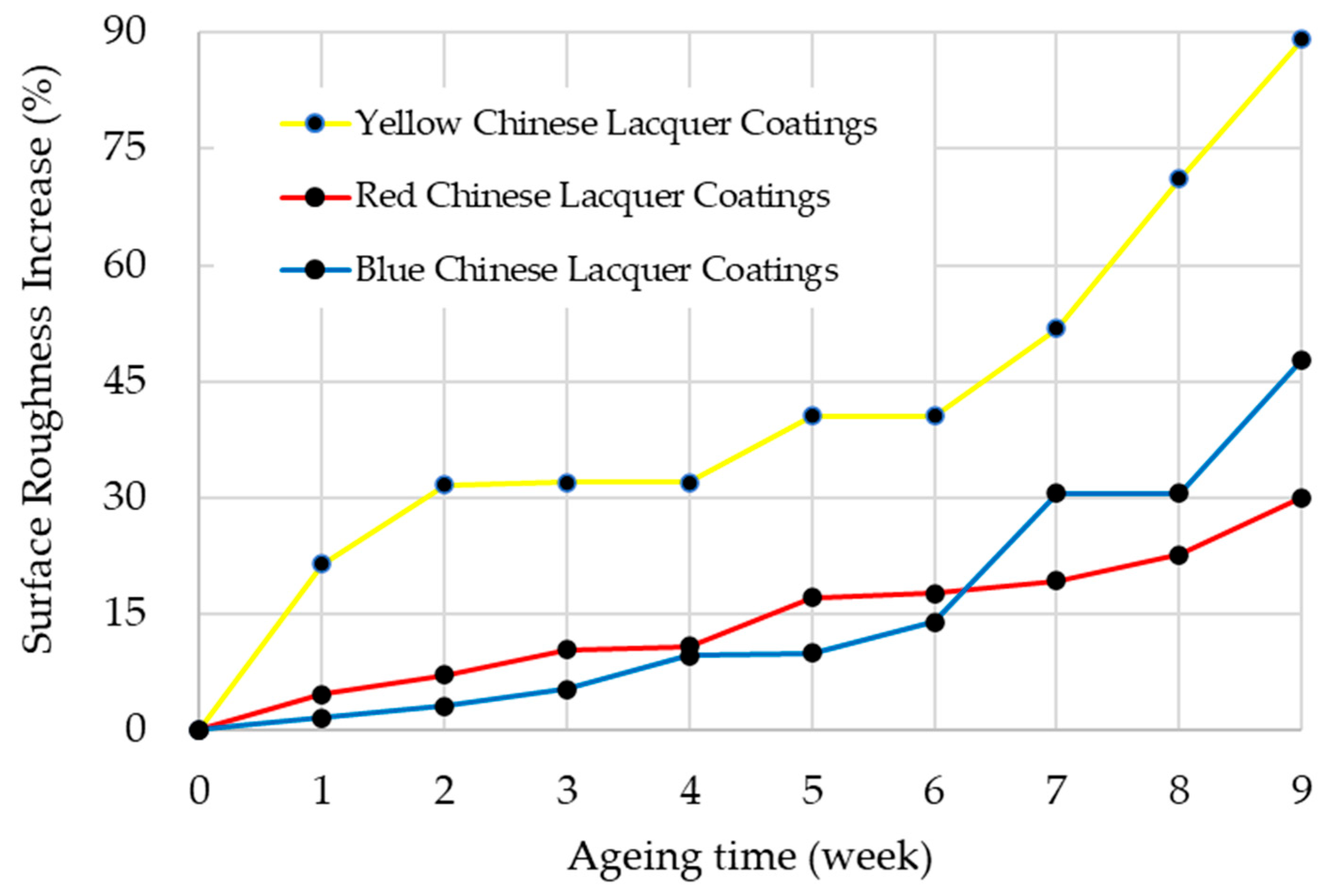

The evolution of surface roughness, expressed as the percentage increase in Ra values, is presented in

Figure 5. A substantial and progressive increase in surface roughness was observed for all coating types throughout the aging duration, directly correlating with the period of light exposure. The yellow coating again displayed the most pronounced morphological change, with its Ra value increasing by approximately 89% from an initial value of 0.676 µm, indicating significant surface deterioration. The blue coating’s roughness increased by about 48% from a relatively low initial Ra of 0.324 µm, representing a substantial relative change despite starting from a smoother initial condition. The red coating showed a measurable but more moderate increase in surface roughness of around 30%, starting from an initial Ra of 0.549 µm. This widespread and consistent rise in Ra values across all three coating systems confirms that surface morphological deterioration represents a fundamental consequence of natural light aging for these traditional lacquer materials [

23].

A strong negative correlation is clearly evident between the increase in surface roughness (

Figure 5) and the corresponding loss of gloss (

Figure 4). As the surface topography became progressively rougher due to aging-induced microcracks, pitting, and general coarsening of texture, its capacity for specular reflection diminished significantly according to established optical principles [

24,

25]. This relationship was most extreme in the case of the yellow coating, where the largest relative increase in surface roughness (approximately 89%) corresponded directly with the greatest percentage loss in gloss (approximately 30%), demonstrating a clear coupling between morphological degradation and optical deterioration. The red and blue coatings followed the same fundamental trend, though with lesser magnitude, maintaining the consistent negative correlation between surface roughness and gloss retention. This comprehensive analysis demonstrates that the degradation of surface microstructure serves as the primary driver behind the reduction in optical gloss during photoaging, providing important insights into the degradation mechanisms of traditional Chinese lacquer coatings under light exposure conditions.

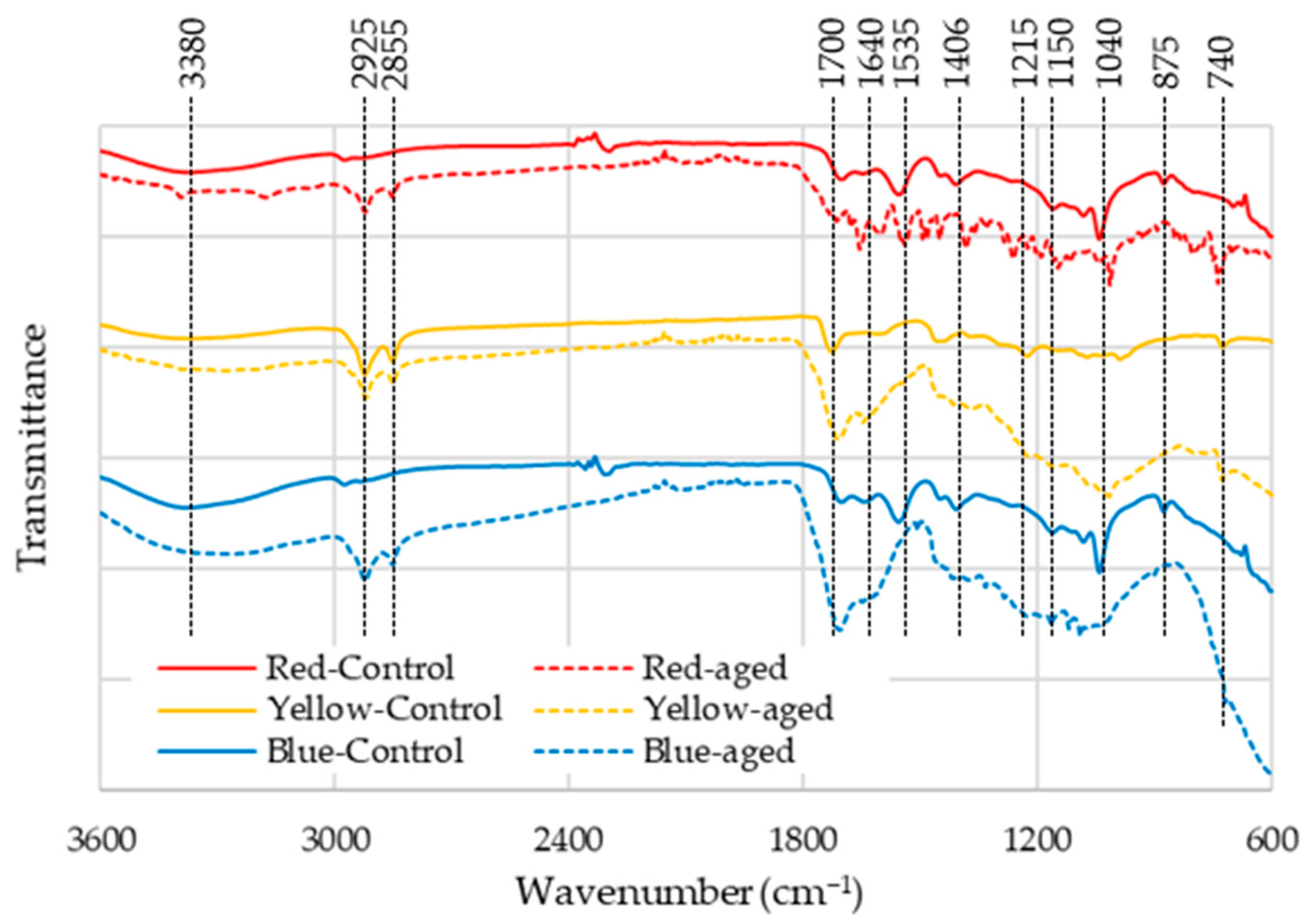

3.3. Evaluation of Surface Chemical Changes in Chinese Lacquer by FTIR

Figure 6 presents the FTIR spectra of three colored Chinese lacquer coatings before and after 9 weeks of natural light aging. A comparison of the pre-aging spectra shows that their overall profiles are generally consistent, with characteristic absorption peaks observed at 3380, 2925, 2855, 1700, 1640, 1040, 875, and 740 cm

−1. Specifically, the band at 3380 cm

−1 corresponds to the stretching vibration of hydroxyl groups (–OH), 2925 cm

−1 and 2855 cm

−1 are attributed to the symmetric and asymmetric stretching of –CH

2 and –CH

3 groups, 1700 cm

−1 is assigned to the stretching vibration of carbonyl groups (C=O), and 1640 cm

−1 is associated with aromatic ring skeleton vibrations or C=C stretching [

26,

27]. The band at 1040 cm

−1 relates to C–O stretching, while 875 cm

−1 and 740 cm

−1 correspond to out-of-plane bending of aromatic C–H [

28]. Although the peak positions remain unchanged among the three lacquer samples, their relative intensities differ, which can be attributed to the influence of different mineral pigments.

After 9 weeks of natural light exposure, the spectra exhibited pronounced changes. Notably, the absorption peaks at 1700 cm

−1 and 1640 cm

−1 increased in intensity, likely due to photo-oxidation reactions of the lacquer matrix [

3,

29,

30]. Moreover, new peaks emerged, indicating the formation of oxidation or degradation products during the aging process. These findings suggest that natural light aging induces significant chemical alterations in lacquer coatings and that mineral pigments may modulate the photochemical pathways and degradation mechanisms [

31].

3.4. Evaluation of Surface Microstructural Changes in Chinese Lacquer by SEM

After natural light aging, significant changes occurred in the surface microstructure of the lacquer coatings, which were systematically evaluated using scanning electron microscopy (SEM).

Figure 7 shows the microstructural comparison of a black lacquer coating before and after 9 weeks of UV exposure (magnification: 2000×). It was observed that all colored coatings—red, yellow, and blue—exhibited varying degrees of surface cracking after photoaging.

Before aging, the blue lacquer coating displayed the smoothest and most refined surface. However, after 9 weeks of natural light aging, the yellow lacquer coating showed the most severe surface damage, with pronounced cracking and structural loosening. These microscopic changes were highly consistent with the degradation of macroscopic properties: the yellow coating had the highest percentage gloss loss (approximately 30%) and the largest increase in surface roughness (Ra, ≈89%). In contrast, the red coating exhibited relatively better stability, with minimal microstructural alterations, the lowest gloss loss (<9%), and a moderate increase in roughness (≈30%).

The cracking of the lacquer films is primarily attributed to oxidation reactions during photoaging, which damage the cross-linked structure and break molecular chains, leading to the formation of micro-defects and macro-cracks. The increase in surface roughness significantly reduces the film’s ability to specularly reflect light, thereby diminishing gloss. As the yellow coating underwent the most pronounced microstructural degradation, it also exhibited the most severe deterioration in optical properties and surface morphology. The results indicate a strong correlation between gloss reduction, roughness increase, and microstructural changes, confirming that the degradation of surface microstructure is the fundamental cause of macroscopic performance failure in lacquer coatings during photoaging.

4. Discussion

The natural light aging experiments revealed that the degradation of Chinese lacquer coatings is strongly pigment-dependent. While all samples exhibited noticeable color changes, cinnabar-based red lacquer demonstrated superior stability, consistent with its well-documented lightfastness [

32]. By contrast, orpiment-containing yellow lacquer underwent rapid brightening and yellowing, reflecting the intrinsic photo-instability of arsenic sulfide minerals and their tendency to release reactive sulfur species that accelerate lacquer oxidation [

33]. The blue lacquer, colored with lapis lazuli, showed pronounced decreases in b* values, indicating chromatic shifts associated with photoreduction and structural instability of lazurite [

34]. These results confirm that mineral pigments influence not only the visual appearance but also the chemical reactivity of lacquer films under illumination.

Statistical analysis (one-way ANOVA) further confirmed that natural light aging had significant effects on most parameters, including ΔL*, ΔC*, ΔE, gloss, and surface roughness (p < 0.05). However, the degree of significance varied among pigments: blue lacquer exhibited the highest differences in ΔE across aging stages (p < 0.001), yellow lacquer showed highly significant changes in both gloss and roughness (p < 0.01), while red lacquer, though also significant, displayed comparatively lower variation (p < 0.05). These findings indicate that the extent of photoinduced degradation is pigment-dependent, with instability most pronounced in lapis- and orpiment-based lacquers.

The evolution of gloss and roughness further illustrated the interplay between surface morphology and optical properties. Increased roughness caused by photodegradation correlated strongly with gloss loss, in line with optical scattering theory [

35]. Among the coatings, yellow lacquer exhibited the most severe deterioration, while red lacquer retained smoother surfaces and higher gloss, supporting the stabilizing role of cinnabar. SEM observations confirmed microcrack formation and surface pitting, especially in yellow and blue coatings, which provide a mechanistic explanation for the observed macroscopic changes [

36,

37]. These findings suggest that pigment stability directly affects the extent of physical deterioration, linking chromatic shifts with structural breakdown.

FTIR analysis provided direct evidence of chemical transformations during photoaging. The increase in carbonyl (1700 cm

−1) and aromatic C=C (1640 cm

−1) bands after nine weeks indicates oxidation of urushiol side chains and disruption of crosslinked networks, consistent with previous reports [

38,

39]. The stronger oxidation signals in yellow lacquer suggest catalytic effects from orpiment degradation products, whereas the weaker changes in red lacquer underscore cinnabar’s stabilizing influence. Together with colorimetric and morphological results, these observations highlight that natural light aging is a multifaceted process involving pigment-dependent optical, chemical, and structural transformations. From a conservation perspective, cinnabar-based lacquers are comparatively resilient, while orpiment- and lapis-colored coatings are particularly vulnerable and require protective strategies [

40].

5. Conclusions

This study systematically investigated the natural light aging behavior of Chinese lacquer coatings prepared with three traditional mineral pigments—cinnabar (red), orpiment (yellow), and lapis lazuli (blue). The results demonstrated that pigment type plays a decisive role in modulating the optical, chemical, and structural stability of lacquer films under outdoor exposure. Colorimetric analyses revealed that all coatings underwent rapid changes during the initial stages of aging, followed by slower transformations, with cinnabar-based red lacquer showing the highest chromatic stability, while orpiment- and lapis-colored lacquers exhibited severe discoloration.

Surface gloss and roughness measurements, supported by SEM observations, confirmed that photoaging induces significant morphological degradation. Yellow lacquer, in particular, suffered the greatest gloss loss and roughness increase due to extensive microcrack formation, whereas red lacquer retained smoother surfaces and better gloss performance. FTIR spectra further revealed oxidation of urushiol side chains and disruption of aromatic structures, with pigment-dependent differences in reaction intensity, suggesting that orpiment accelerates oxidative pathways while cinnabar provides relative stabilization.

Overall, this study highlights that natural photoaging of Chinese lacquer is governed by the intrinsic properties of mineral pigments, which determine the extent of visual, structural, and chemical deterioration. These findings provide new insights into the degradation mechanisms of traditional lacquer coatings and underline the necessity of pigment-specific conservation strategies. In particular, cinnabar-based lacquers exhibit relatively high resilience, whereas orpiment- and lapis-colored lacquers are highly vulnerable and require priority protection in cultural heritage conservation practices.