Comparison of Microstructure and Properties of CoCrMo Coatings Prepared by High-Speed and Conventional Laser Cladding

Abstract

1. Introduction

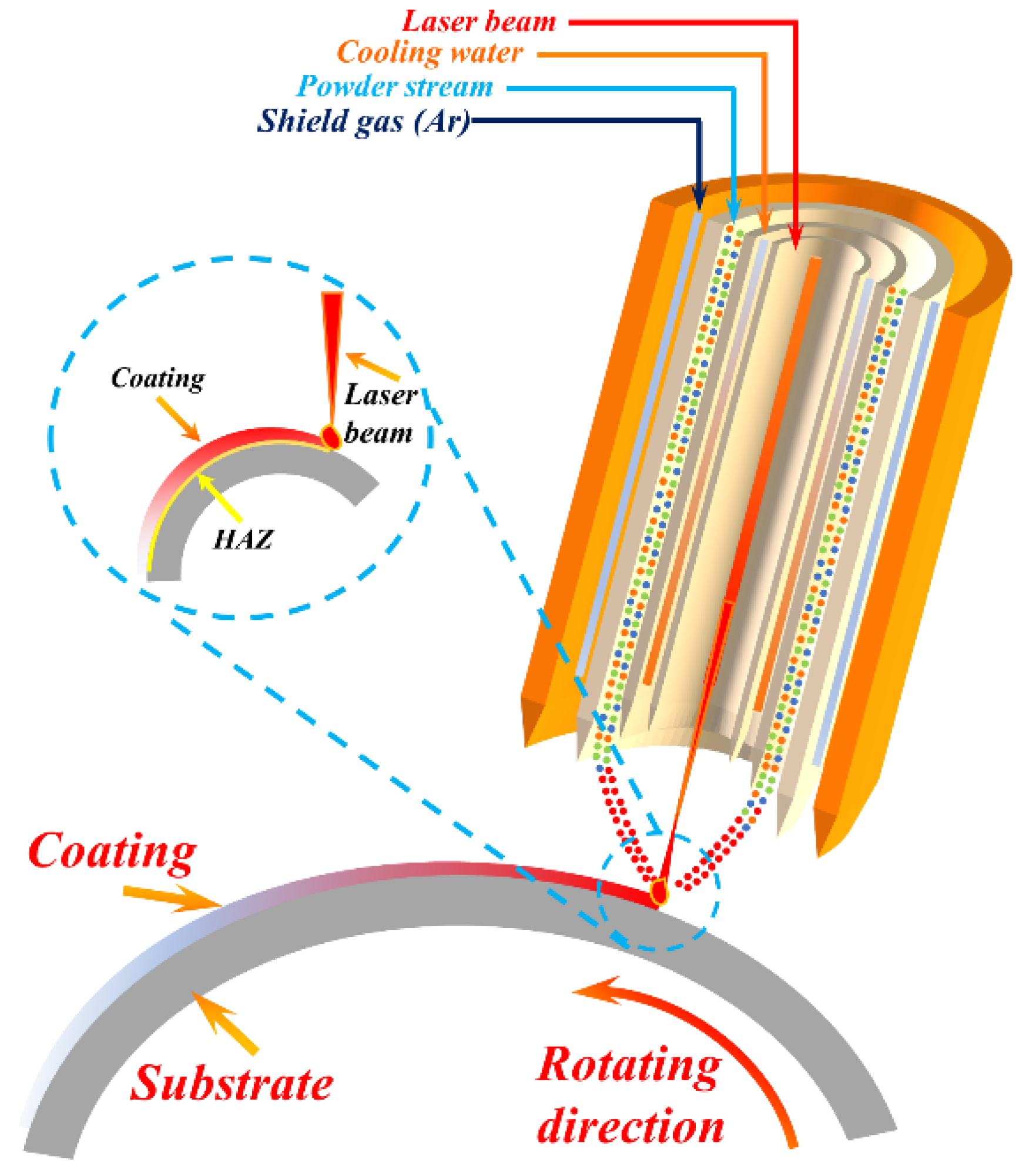

2. Experimental Materials and Methods

2.1. Materials and Preparation

2.2. Metallographic Preparation and Characterization

2.3. Nano-Indentation and Wear Behavior Testing

3. Results and Discussion

3.1. Phase Composite

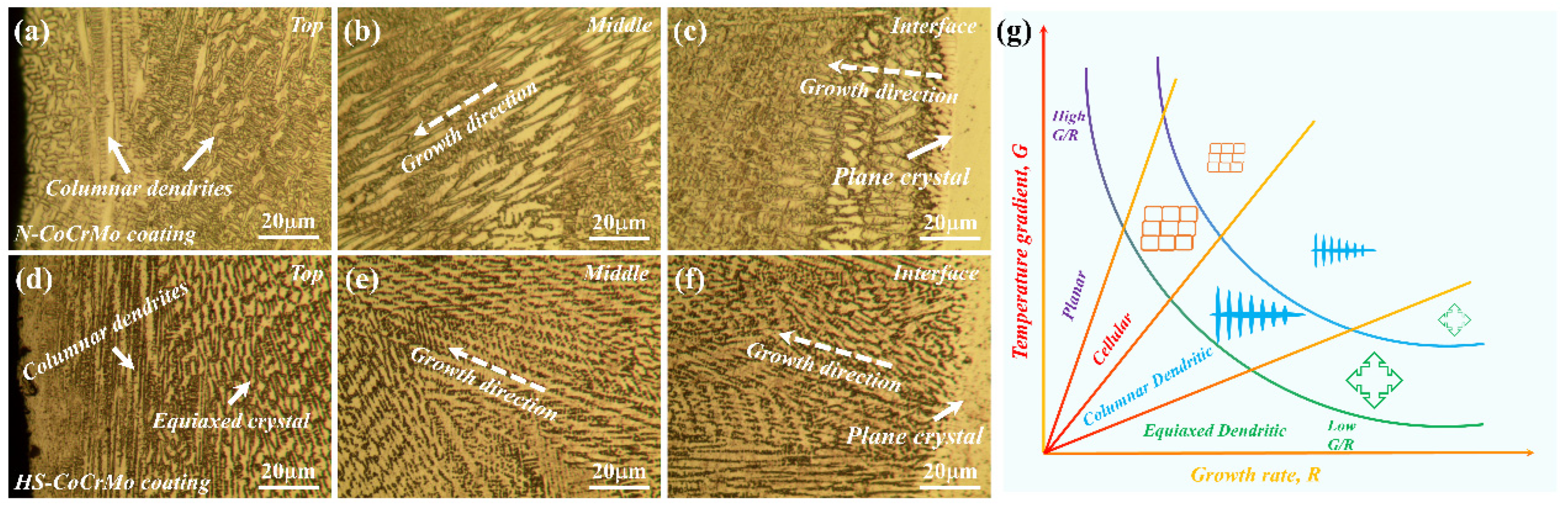

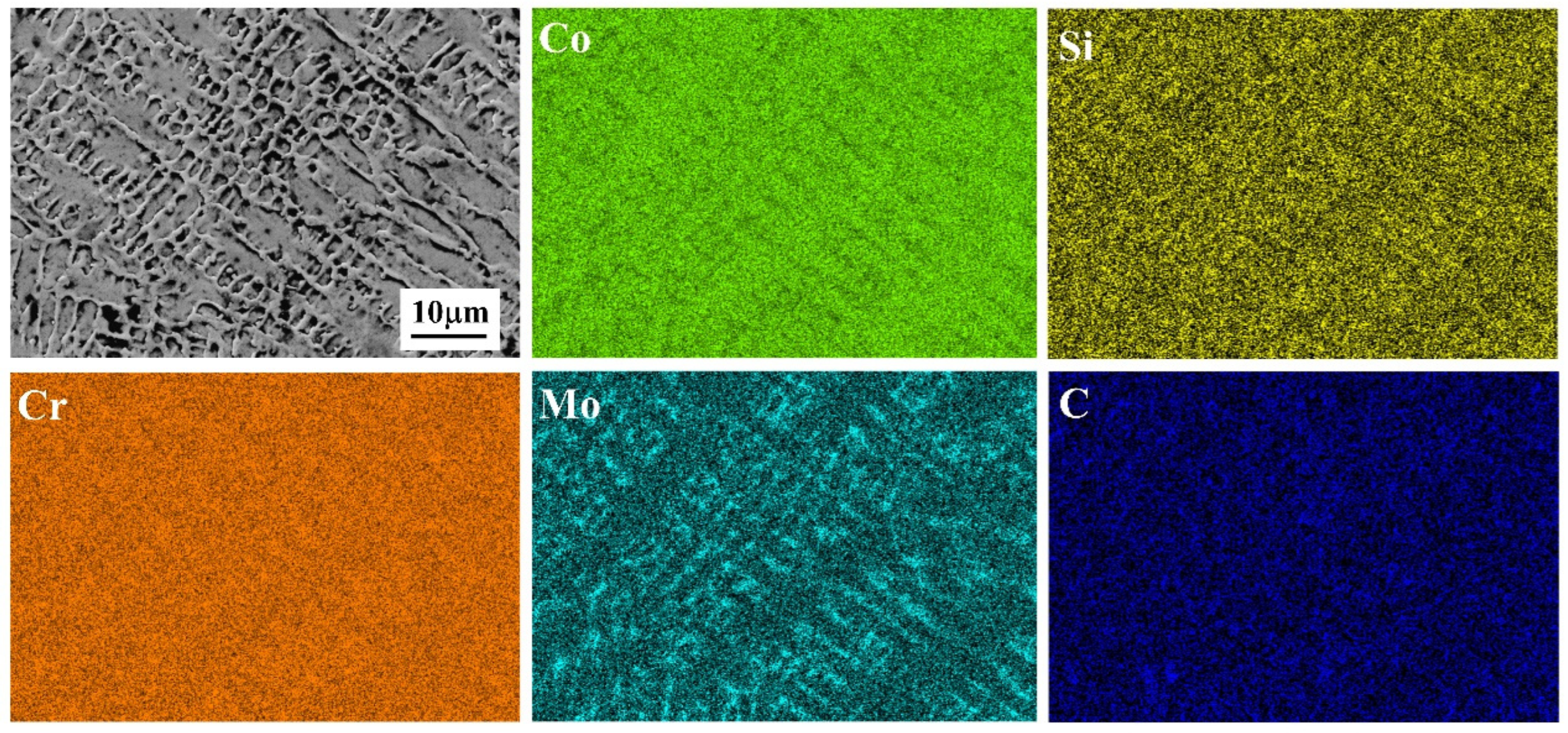

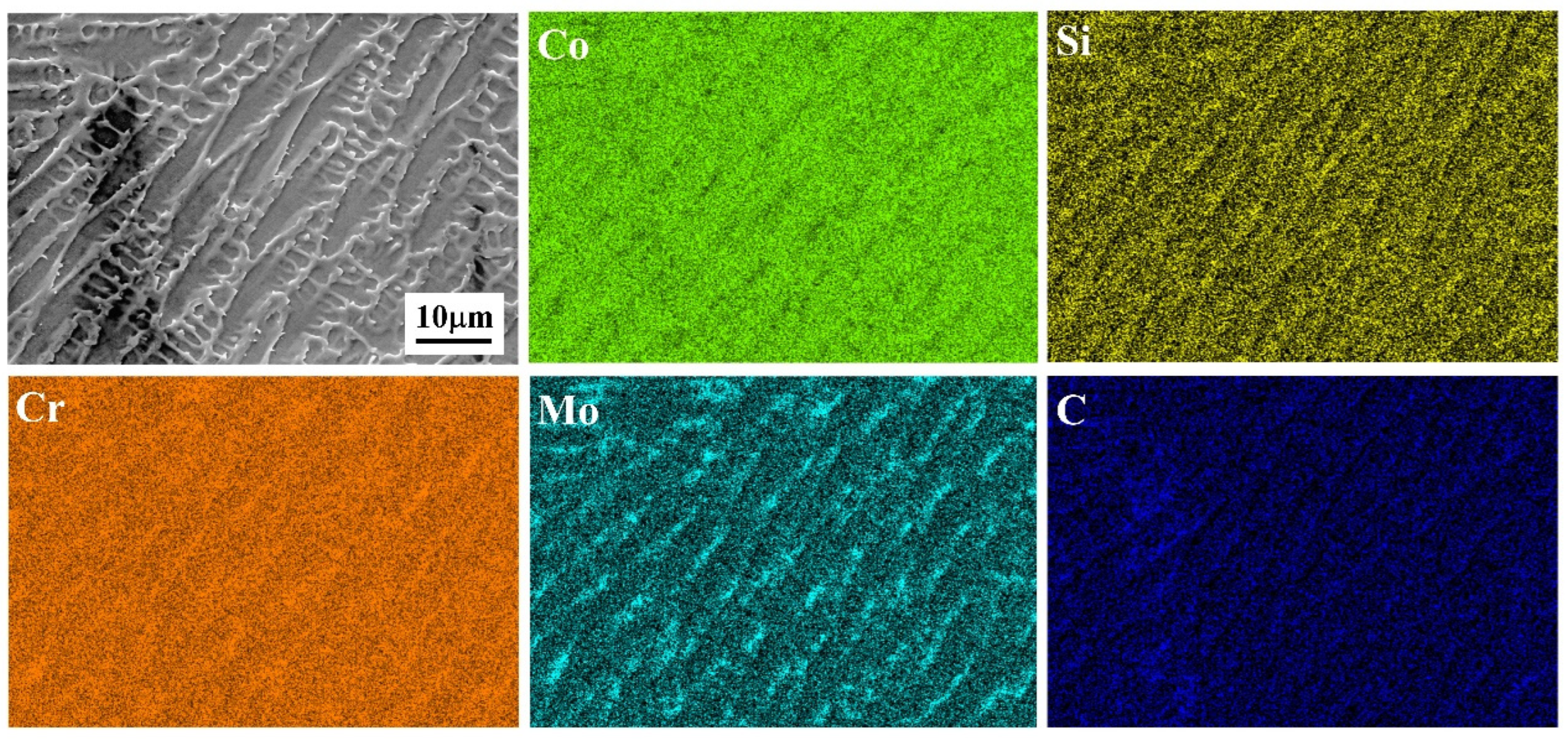

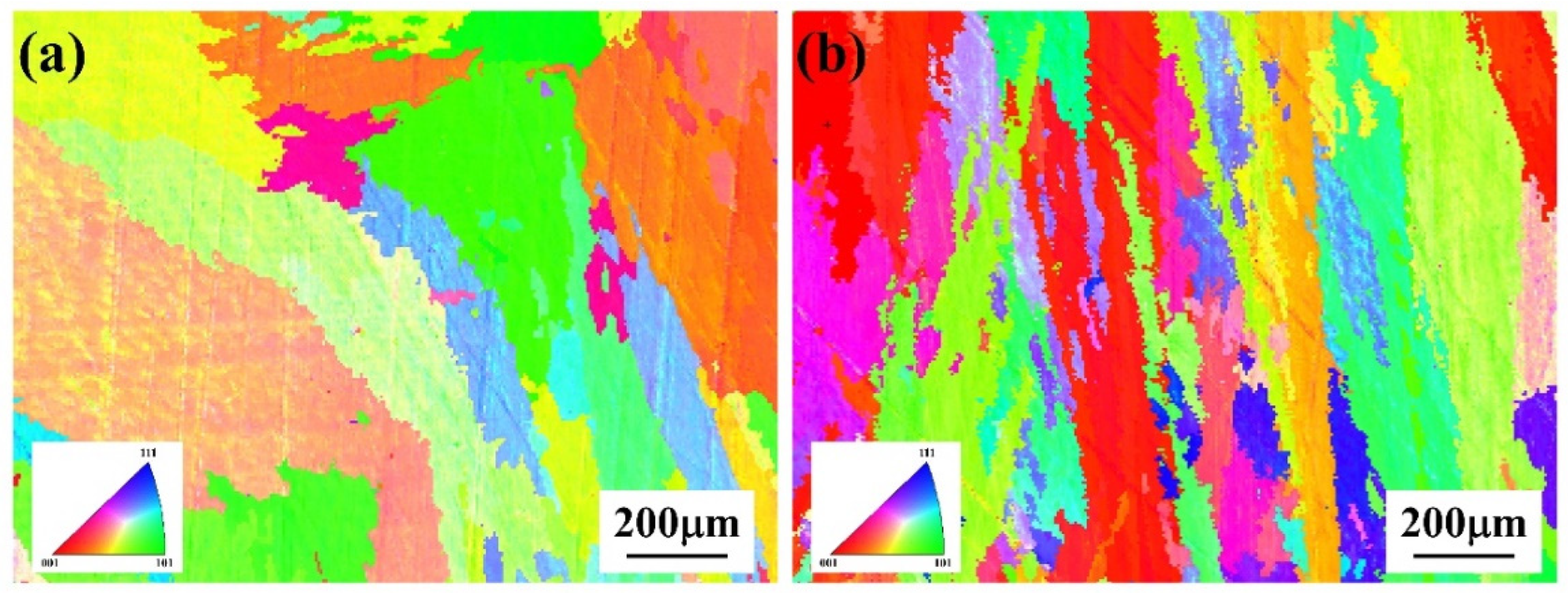

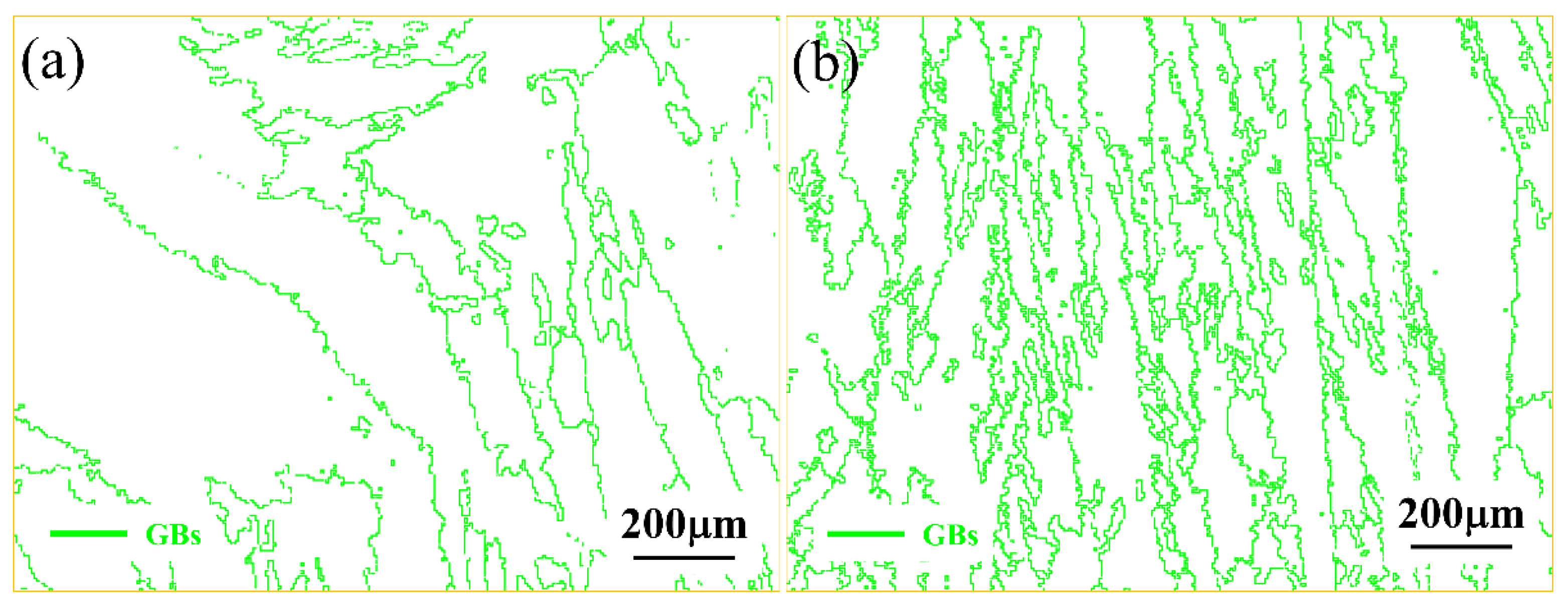

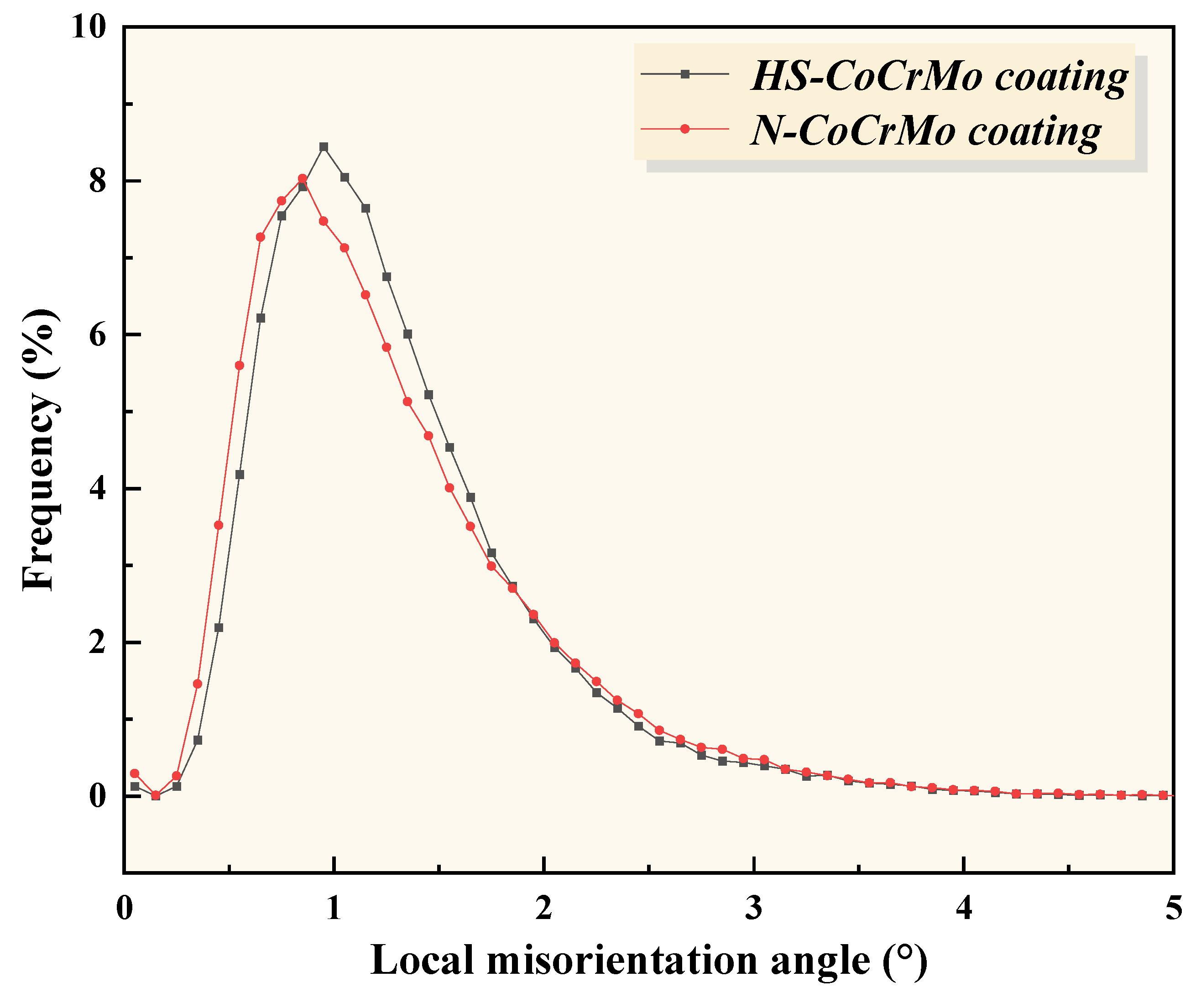

3.2. Microstructure and Crystal Structure

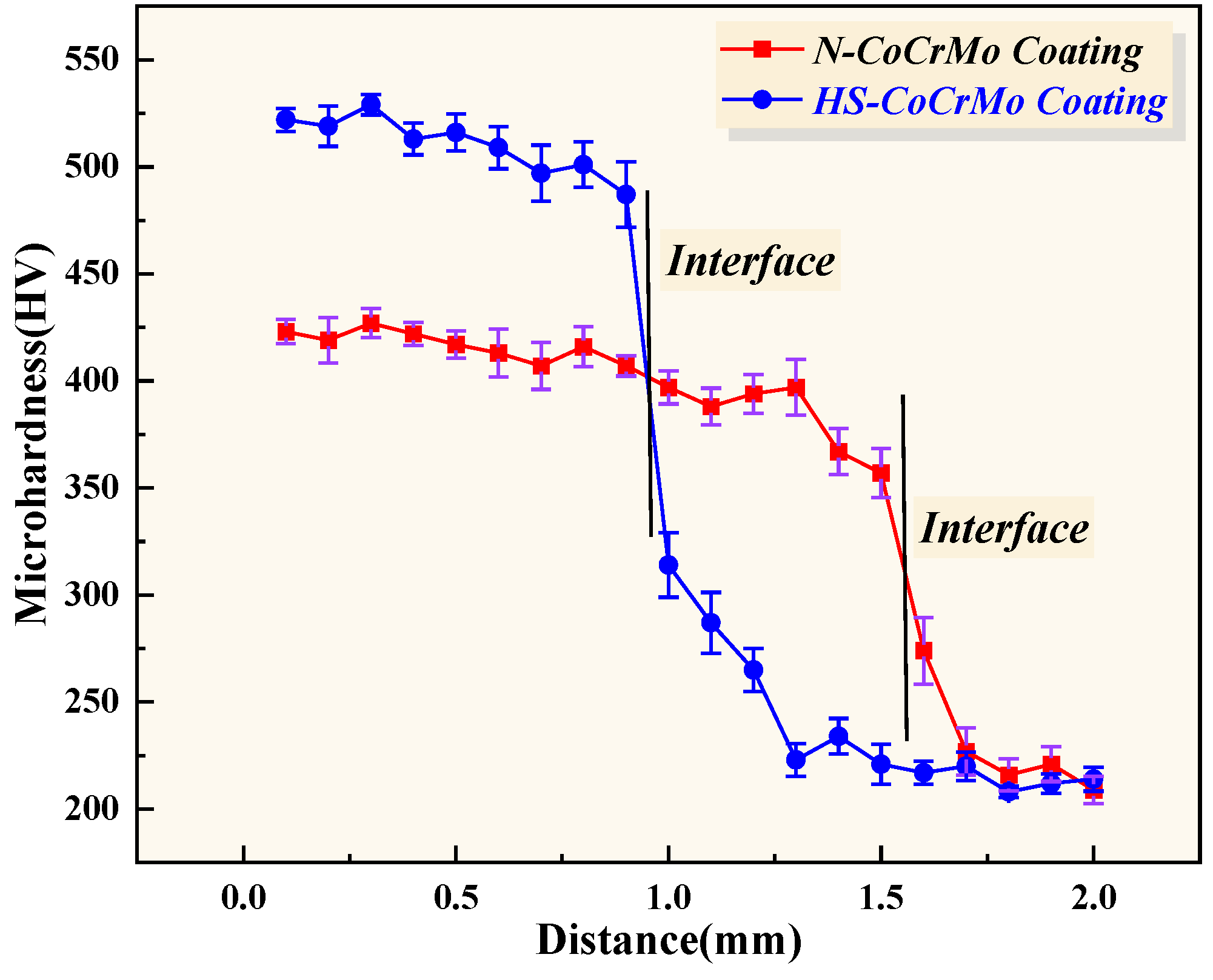

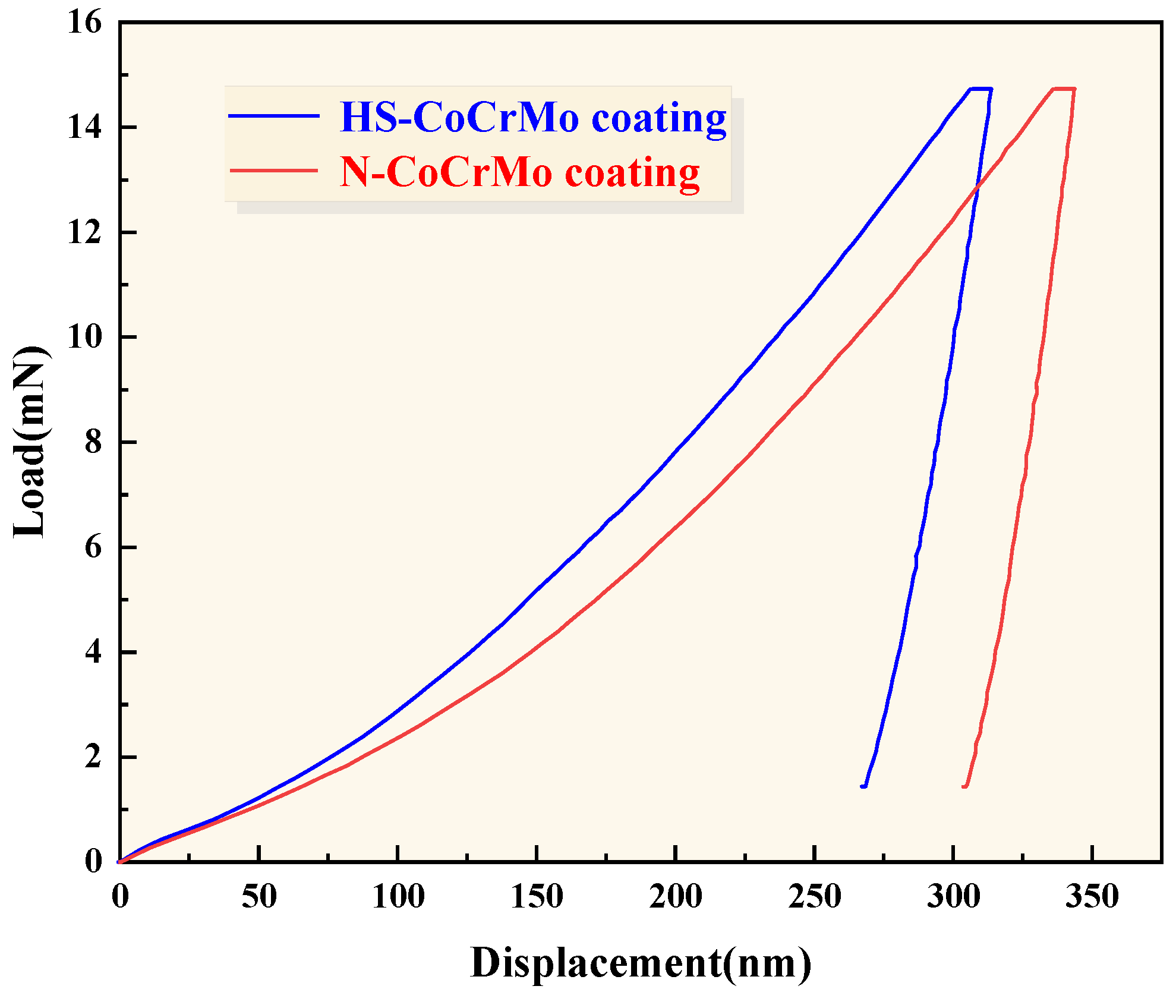

3.3. Microhardness Nano-Indentation Behavior

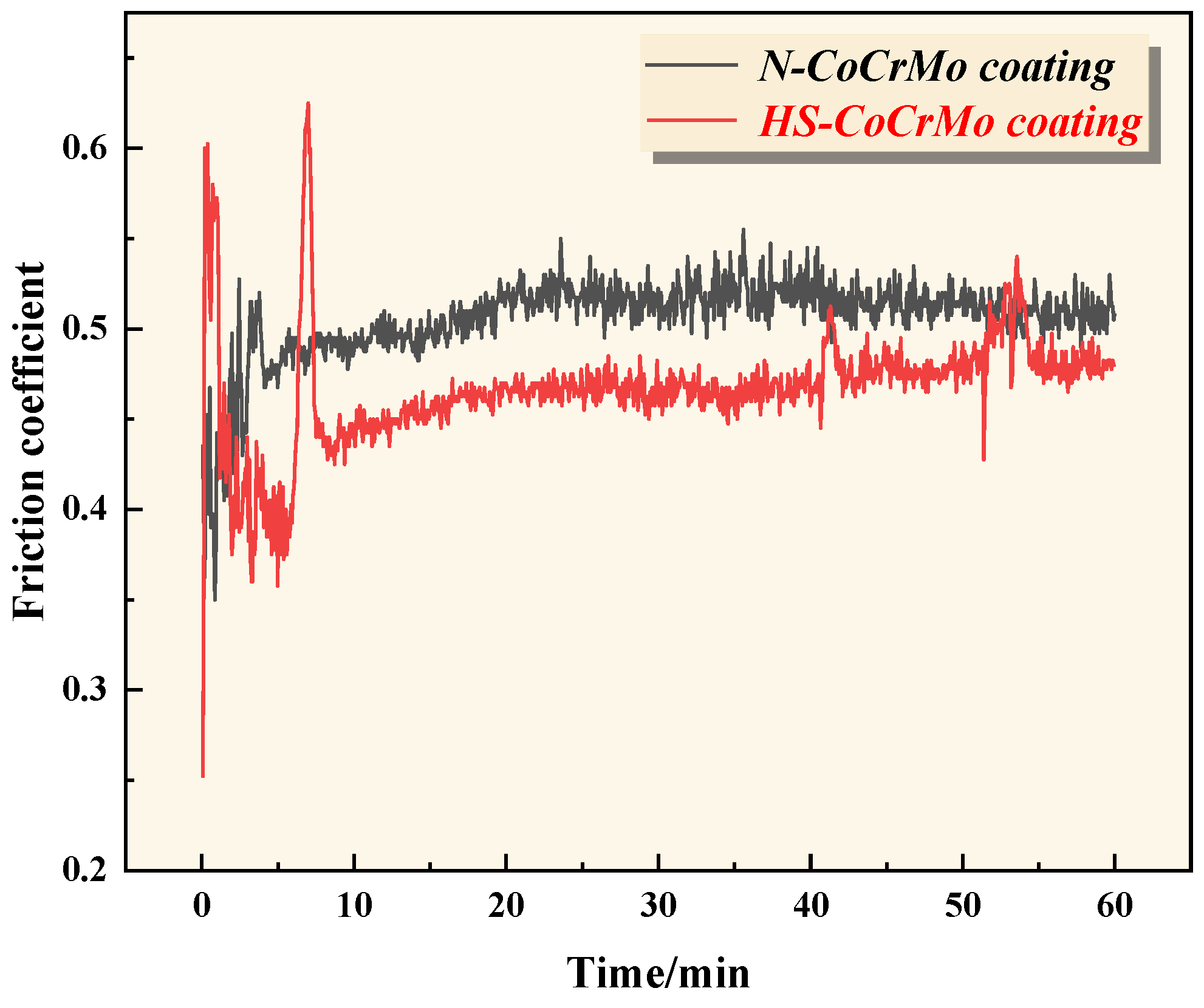

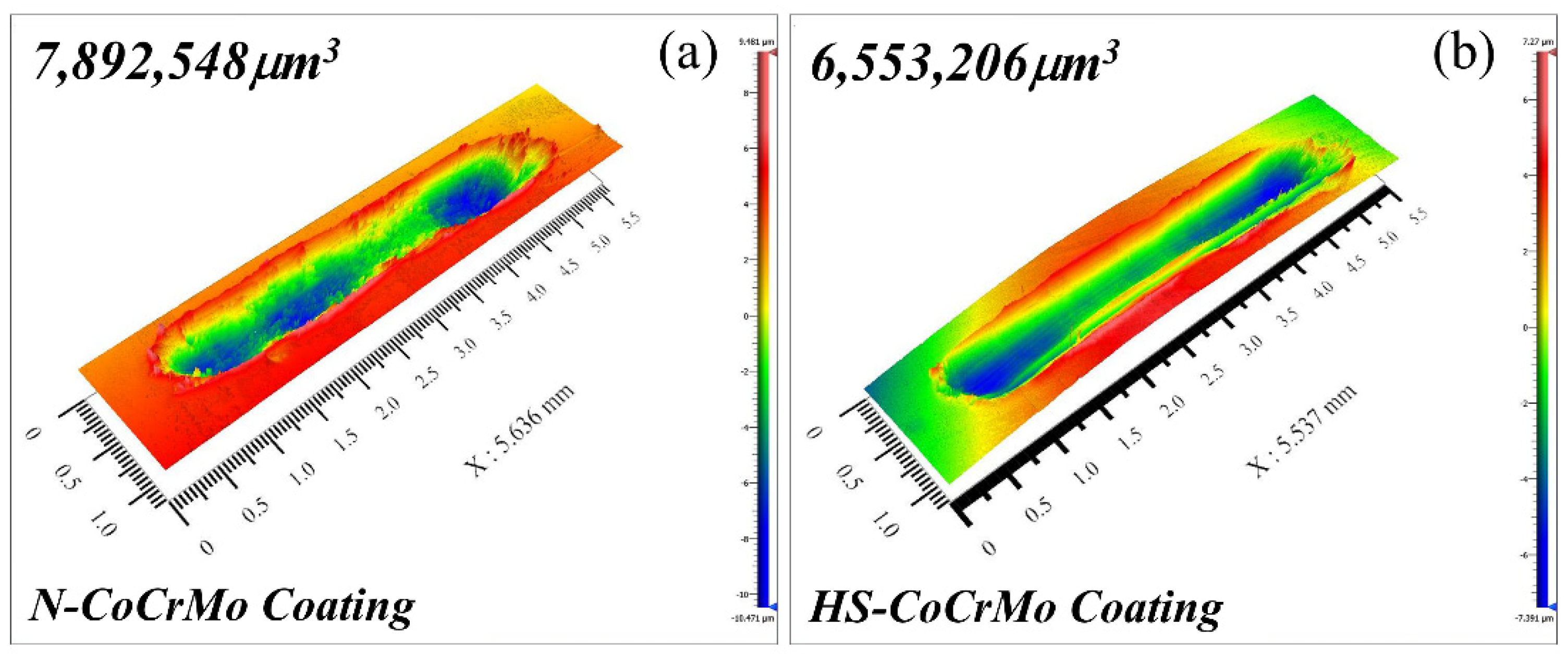

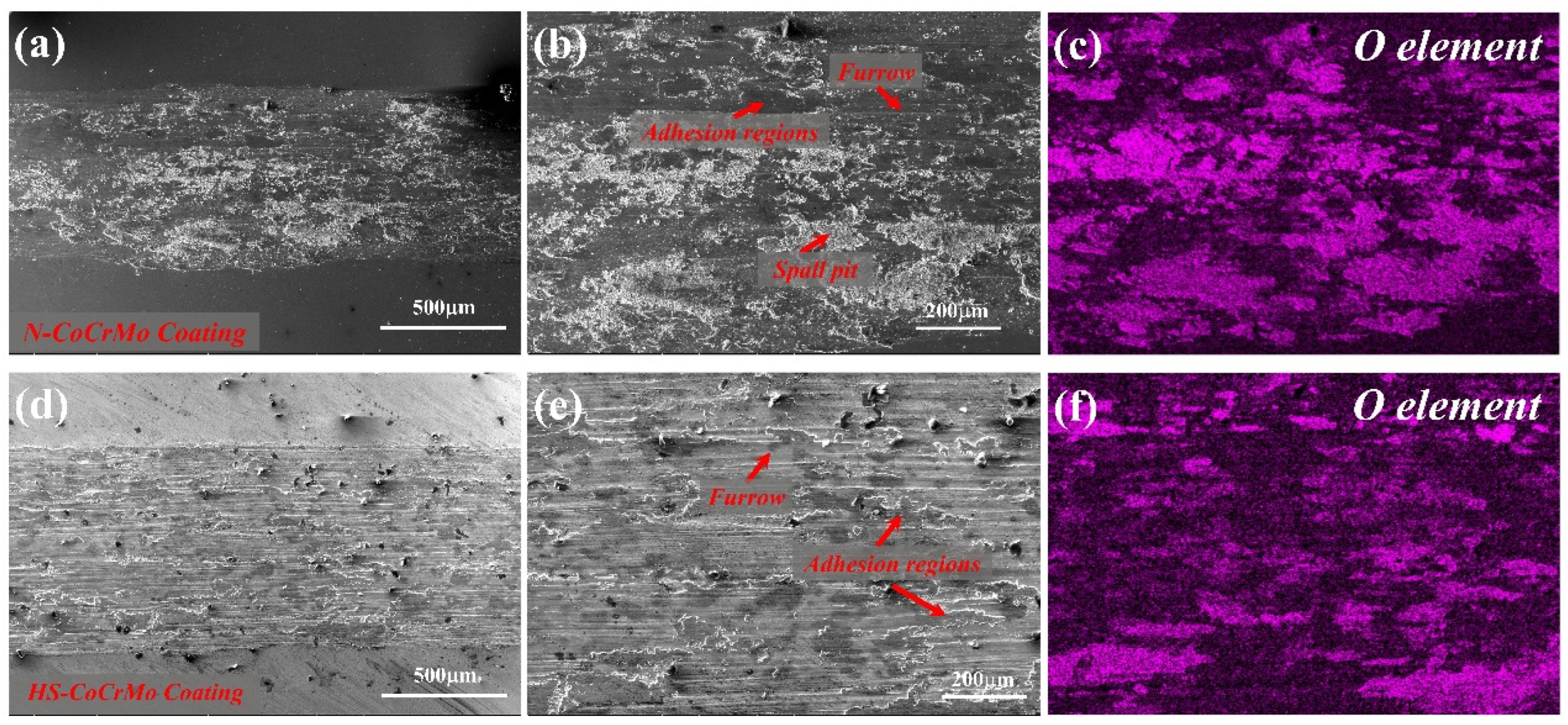

3.4. Wear Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jian, Y.; Liu, Y.; Qi, H.; He, P.; Huang, G.; Huang, Z. Effects of scanning speed on the microstructure, hardness and corrosion properties of high-speed laser cladding Fe-based stainless coatings. J. Mater. Res. Technol. 2024, 29, 3380–3392. [Google Scholar] [CrossRef]

- Wang, X.; Ren, X.; Xue, Y.; Luan, B. Investigation on microstructure and high-temperature wear properties of high-speed laser cladding Inconel 625 alloy. J. Mater. Res. Technol. 2024, 30, 626–639. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, L.; Ma, G.; Li, G.; Zhao, H.; Wang, H. Microstructure and excellent arc ablation resistance of Ni–8Al coating on copper substrate by high-speed laser cladding. J. Mater. Res. Technol. 2024, 31, 606–617. [Google Scholar] [CrossRef]

- Wei, R.; Mao, M.; Liang, J.; Zhao, C.; Ouyang, C.; Bai, Q. Repair feasibility and performance enhancement analysis of Fe-based alloy coating on ductile iron surface by high-speed laser cladding. Mater. Today Commun. 2024, 39, 108638. [Google Scholar] [CrossRef]

- Bu, X.; Xu, X.; Lu, H.; Liang, Y.; Bian, H.; Luo, K.; Lu, J. Effect of overlap rate on the microstructure and properties of Cr-rich stainless steel coatings prepared by extreme high-speed laser cladding. Surf. Coat. Technol. 2024, 487, 131025. [Google Scholar] [CrossRef]

- Du, J.L.; Deng, W.W.; Xu, X.; Wu, Y.J.; Luo, K.Y.; Zhang, H.M.; Lu, J.Z. Improvement of microstructure and performance of an extreme-high-speed laser cladding CoCrFeMnNi coating through laser shock peening. J. Alloys Compd. 2024, 1002, 175520. [Google Scholar] [CrossRef]

- Fu, J.; Gui, W.; Qin, J.; Lin, J.; Ren, X.; Luan, B. High-speed laser-clad 3533-00 Fe-based cemented carbide coatings on nuclear power valve sealing surface to enhanced wear and corrosion resistance. Surf. Coat. Technol. 2024, 480, 130594. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, Y.; Wan, Y.; Jeyaprakash, N.; Wang, Y.; Ma, K.; Yang, J. Influence of scanning speed on microstructure and corrosion resistance of Fe-based amorphous coatings by high-speed laser cladding. Surf. Coat. Technol. 2024, 479, 130449. [Google Scholar] [CrossRef]

- Yu, Y.; Li, Y.; Tan, N.; Mou, H.; Tong, Y.; Xing, Z.; Cai, Z.; Wang, H. Influence of cBN on the microstructure and tribology properties of (CoCrNi)94Al3Ti3 medium-entropy alloy coating prepared by high-speed laser cladding: The evolution and strengthening mechanism of cBN. Ceram. Int. 2024, 50, 22041–22049. [Google Scholar] [CrossRef]

- An, Y.; Pang, X.; Liu, G.; Zheng, S.; Wang, Y.; Pu, J. Effect of h-BN on corrosion behavior of nickel-copper alloy coatings prepared by high-speed laser cladding. J. Mater. Res. Technol. 2024, 28, 4065–4075. [Google Scholar] [CrossRef]

- Chen, C.; Bai, Q.; Zhao, C.; Li, Q.; Zhang, S. Effect of ultrasonic high-frequency micro-forging on the wear resistance of a Fe-base alloy coating deposited by high-speed laser cladding process. Vacuum 2024, 221, 112934. [Google Scholar] [CrossRef]

- Liu, J.; Cui, X.; Jin, G.; Wen, X.; Li, D.; Jing, Y.; Li, Y.; Qi, Y. A novel strategy for preparation of ZrB2–SiC self-transpiration cooling coating by dilution effect of high speed laser cladding. Ceram. Int. 2024, 50, 18075–18079. [Google Scholar] [CrossRef]

- Georgiou, E.P.; Drees, D.; Timmermans, G.; Zoikis-Karathanasis, A.; Pérez-Fernández, M.; Magagnin, L.; Celis, J.-P. High performance accelerated tests to evaluate hard Cr replacements for hydraulic cylinders. Coatings 2021, 11, 1511. [Google Scholar] [CrossRef]

- Liang, Y.; Liao, Z.Y.; Zhang, L.L.; Cai, M.W.; Wei, X.S.; Shen, J. A review on coatings deposited by extreme high-speed laser cladding: Processes, materials, and properties. Opt. Laser Technol. 2023, 164, 109472. [Google Scholar] [CrossRef]

- Lv, H.; Liu, Y.; Chen, H.; Zhang, W.; Lv, S.; He, D. Temperature field simulation and microstructure evolution of Fe-based coating processed by extreme high-speed laser cladding for re-manufacturing locomotive axle. Surf. Coat. Technol. 2023, 464, 129529. [Google Scholar] [CrossRef]

- Yuan, W.; Li, R.; Chen, Z.; Gu, J.; Tian, Y. A comparative study on microstructure and properties of traditional laser cladding and high-speed laser cladding of Ni45 alloy coatings. Surf. Coat. Technol. 2021, 405, 126582. [Google Scholar] [CrossRef]

- Yang, J.; Bai, B.; Ke, H.; Cui, Z.; Liu, Z.; Zhou, Z.; Xu, H.; Xiao, J.; Liu, Q.; Li, H. Effect of metallurgical behavior on microstructure and properties of FeCrMoMn coatings prepared by high-speed laser cladding. Opt. Laser Technol. 2021, 144, 107431. [Google Scholar] [CrossRef]

- Du, J.L.; Xu, X.; Zhang, H.M.; Lu, M.W.; Sun, J.F.; Luo, K.Y.; Lu, J.Z. Microstructure and wear resistance of CoCrFeNiMn coatings prepared by extreme-high-speed laser cladding. Surf. Coat. Technol. 2023, 470, 129821. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.; Huang, F.; Dong, J.; Wang, C.; Yuan, J.; Fu, Q. Experimental study of corrosion resistance of 431M2 stainless steel coatings in a CO2-saturated NaCl solution deposited by extreme high-speed laser cladding. Mater. Today Commun. 2024, 38, 108202. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, Y.; Hu, D.; Lv, H.; Yang, Q. Experimental and numerical simulation studies of the flow characteristics and temperature field of Fe-based powders in extreme high-speed laser cladding. Opt. Laser Technol. 2024, 170, 110317. [Google Scholar] [CrossRef]

- Cui, C.; Wu, M.; Miao, X.; Gong, Y.; Zhao, Z. The effect of laser energy density on the geometric characteristics, microstructure and corrosion resistance of Co-based coatings by laser cladding. J. Mater. Res. Technol. 2021, 15, 2405–2418. [Google Scholar] [CrossRef]

- Smoqi, Z.; Toddy, J.; Halliday, H.; Shield, J.E.; Rao, P. Process-structure relationship in the directed energy deposition of cobalt-chromium alloy (Stellite 21) coatings. Mater. Des. 2021, 197, 109229. [Google Scholar] [CrossRef]

- Zhang, N.; Xu, Y.-f.; Wang, M.-h.; Hou, X.-d.; Du, B.-r.; Ge, X.-y.; Shi, H.; Xie, X. M2 coating prepared by ultra-high speed laser cladding: Microstructure and interfacial residual stress. Mater. Today Commun. 2023, 35, 105638. [Google Scholar] [CrossRef]

- Xu, T.Z.; Zhang, S.; Wang, L.; Du, Y.; Wu, C.L.; Zhang, C.H.; Sun, X.Y.; Chen, H.T.; Chen, J. Influence of scanning speed on the microstructure, nanoindentation characteristics and tribological behavior of novel maraging steel coatings by laser cladding. Mater. Charact. 2023, 205, 113335. [Google Scholar] [CrossRef]

- Verchère, L.; Aubert, I.; Devos, O. Influence of the crystallographic orientation on the electrochemical reactivity measured by Scanning Electrochemical Microscopy on nickel-based alloy 600. Electrochim. Acta 2019, 313, 292–302. [Google Scholar] [CrossRef]

- Wu, T.; Degener, S.; Tinkloh, S.; Liehr, A.; Zinn, W.; Nobre, J.P.; Tröster, T.; Niendorf, T. Characterization of residual stresses in fiber metal laminate interfaces—A combined approach applying hole-drilling method and energy-dispersive X-ray diffraction. Compos. Struct. 2022, 299, 116071. [Google Scholar] [CrossRef]

- Wang, H.; An, Y.; Xu, X.; Guo, X.; Hu, Y. Rapid solidification microstructure evolution and grain refinement of deeply undercooled nickel alloys. Mater. Charact. 2020, 170, 110703. [Google Scholar] [CrossRef]

- Limmaneevichitr, C.; Kou, S. Experiments to simulate effect of Marangoni convection on weld pool shape. Weld. J. 2000, 79, 231-237-S. [Google Scholar]

- Liang, Y.-J.; Cheng, X.; Li, J.; Wang, H.-M. Microstructural control during laser additive manufacturing of single-crystal nickel-base superalloys: New processing–microstructure maps involving powder feeding. Mater. Des. 2017, 130, 197–207. [Google Scholar] [CrossRef]

- Shi, L.; Jiang, L.; Gao, M. Numerical research on melt pool dynamics of oscillating laser-arc hybrid welding. Int. J. Heat Mass Transf. 2022, 185, 122421. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Dobara, K.; Todoroki, H.; Nam, C.; Morishita, K.; Yasuda, H. In-Situ Measurements of Solute Partition Coefficients Between Solid and Liquid Phases in Fe–Cr–Ni–Mo–Cu Alloys During Solidification. ISIJ Int. 2020, 60, 276–285. [Google Scholar] [CrossRef]

- Fu, K.; Zhong, C.; Zhang, L.; Wang, X.; Nie, B.; Xue, Y.; Gui, W.; Luan, B. Effect of multiple thermal cycling on the microstructure and microhardness of Inconel 625 by high-speed laser cladding. J. Mater. Res. Technol. 2023, 24, 1093–1107. [Google Scholar] [CrossRef]

- TXu, Z.; Zhang, S.; Du, Y.; Wu, C.L.; Zhang, C.H.; Sun, X.Y.; Chen, H.T.; Chen, J. Development and characterization of a novel maraging steel fabricated by laser additive man-ufacturing. Mater. Sci. Eng. A 2024, 891, 145975. [Google Scholar]

- Xu, T.Z.; Wang, T.; Wang, M.S.; Zhang, S.; Zhang, C.H.; Wu, C.L.; Sun, X.Y.; Chen, H.T.; Chen, J. Influence of solid solution time on microstructure and precipitation strengthening of novel maraging steels. Mater. Sci. Eng. A 2025, 920, 147535. [Google Scholar]

- Kubin, L.P.; Mortensen, A. Geometrically necessary dislocations and strain-gradient plasticity: A few critical issues. Scr. Mater. 2003, 48, 119–125. [Google Scholar] [CrossRef]

- Xu, T.Z.; Wang, T.; Wang, R.; Zhang, S.; Zhang, C.H.; Wu, C.L.; Sun, X.Y.; Chen, H.T.; Chen, J. Influence of various heat treatment processes behavior of a novel maraging steel coating process on the microstructure, nanoindentation pattern, and wear. Surf. Coat. Technol. 2024, 487, 130984. [Google Scholar] [CrossRef]

- Xu, T.Z.; Zhang, S.; Wang, Z.Y.; Zhang, C.H.; Zhang, D.X.; Wang, M.; Wu, C.L. Wear behavior of graphite self-lubricating Babbitt alloy composite coating on 20 steel prepared by laser cladding. Eng. Fail. Anal. 2022, 141, 106698. [Google Scholar] [CrossRef]

- Li, K.; Zhan, J.; Yang, T.; To, A.C.; Tan, S.; Tang, Q.; Cao, H.; Murr, L.E. Homogenization timing effect on microstructure and precipitation strengthening of 17–4PH stainless steel fabricated by laser powder bed fusion. Addit. Manuf. 2022, 52, 102672. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength. Scr. Mater. 2006, 54, 1321–1326. [Google Scholar] [CrossRef]

- Li, N.; Wang, Q.; Niu, W.; Han, P.; Guo, N.; Li, S. Microstructure and wear behaviors of 17-4 PH stainless steel fabricated by laser cladding with post laser shock peening treatment. Wear 2024, 538, 205207. [Google Scholar] [CrossRef]

- Roy, M.; Whiteside, L.; Xu, J.; Katerberg, B. Diamond-like carbon coatings enhance the hardness and resilience of bearing surfaces for use in joint arthroplasty. Acta Biomater. 2010, 6, 1619–1624. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Sha, C.; Zhou, Z.; Xie, Z.; Munroe, P. High entropy alloy FeMnNiCoCr coatings: Enhanced hardness and damage-tolerance through a dual-phase structure and nanotwins. Surf. Coat. Technol. 2020, 385, 125435. [Google Scholar] [CrossRef]

- Guan, S.; Wan, D.; Solberg, K.; Berto, F.; Welo, T.; Yue, T.M.; Chan, K. Additive manufacturing of fine-grained and dislocation-populated CrMnFeCoNi high entropy alloy by laser engineered net shaping. Mater. Sci. Eng. A 2019, 761, 138056. [Google Scholar] [CrossRef]

- Deng, G.; Tieu, A.K.; Su, L.; Wang, P.; Wang, L.; Lan, X.; Cui, S.; Zhu, H. Investigation into reciprocating dry sliding friction and wear properties of bulk CoCrFeNiMo high entropy alloys fabricated by spark plasma sintering and subsequent cold rolling processes: Role of Mo element concentration. Wear 2020, 460, 203440. [Google Scholar] [CrossRef]

- Miao, J.; Guo, T.; Ren, J.; Zhang, A.; Su, B.; Meng, J. Optimization of mechanical and tribological properties of FCC CrCoNi multi-principal element alloy with Mo addition. Vacuum 2018, 149, 324–330. [Google Scholar] [CrossRef]

- Popov, V. Generalized archard law of wear based on rabinowicz criterion of wear particle formation. Facta Univ. Ser. Mech. Eng. 2019, 17, 39–45. [Google Scholar] [CrossRef]

- Telliskivi, T. Simulation of wear in a rolling–sliding contact by a semi-Winkler model and the Archard’s wear law. Wear 2004, 256, 817–831. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Cr | Ni | Mo | Co | Fe |

|---|---|---|---|---|---|---|---|---|

| Wt% | 0.35 | 1.0 | 1.0 | 26.5 | 1.0 | 4.5 | Bal. | 1.0 |

| Sample | Laser Power (W) | Scanning Speed (m/min) | Laser Spot Diameter (mm) | Overlapping Rate | Powder Flow Rate (g/min) |

|---|---|---|---|---|---|

| HS-CoCrMo | 2000 | 1 | 3 | 50% | 16 |

| N-CoCrMo | 2800 | 3 | 3 | 70% | 24 |

| Sample | H (GPa) | E (GPa) | dmax (nm) | HU (GPa) | H/E | H3/E2 | 1/E2H(Gpa−3) × 106 |

|---|---|---|---|---|---|---|---|

| HSLC | 5.18 ± 0.23 | 213.367 | 312.83 | 0.687 | 0.0243 | 0.0031 | 4.255 |

| LC | 4.22 ± 0.17 | 226.459 | 342.96 | 0.627 | 0.0187 | 0.0015 | 4.640 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Li, Q.; Huo, F.; Chen, H.; Xu, T. Comparison of Microstructure and Properties of CoCrMo Coatings Prepared by High-Speed and Conventional Laser Cladding. Coatings 2025, 15, 1200. https://doi.org/10.3390/coatings15101200

Wang T, Li Q, Huo F, Chen H, Xu T. Comparison of Microstructure and Properties of CoCrMo Coatings Prepared by High-Speed and Conventional Laser Cladding. Coatings. 2025; 15(10):1200. https://doi.org/10.3390/coatings15101200

Chicago/Turabian StyleWang, Tianyu, Qingquan Li, Fengping Huo, Haitao Chen, and Tongzhou Xu. 2025. "Comparison of Microstructure and Properties of CoCrMo Coatings Prepared by High-Speed and Conventional Laser Cladding" Coatings 15, no. 10: 1200. https://doi.org/10.3390/coatings15101200

APA StyleWang, T., Li, Q., Huo, F., Chen, H., & Xu, T. (2025). Comparison of Microstructure and Properties of CoCrMo Coatings Prepared by High-Speed and Conventional Laser Cladding. Coatings, 15(10), 1200. https://doi.org/10.3390/coatings15101200