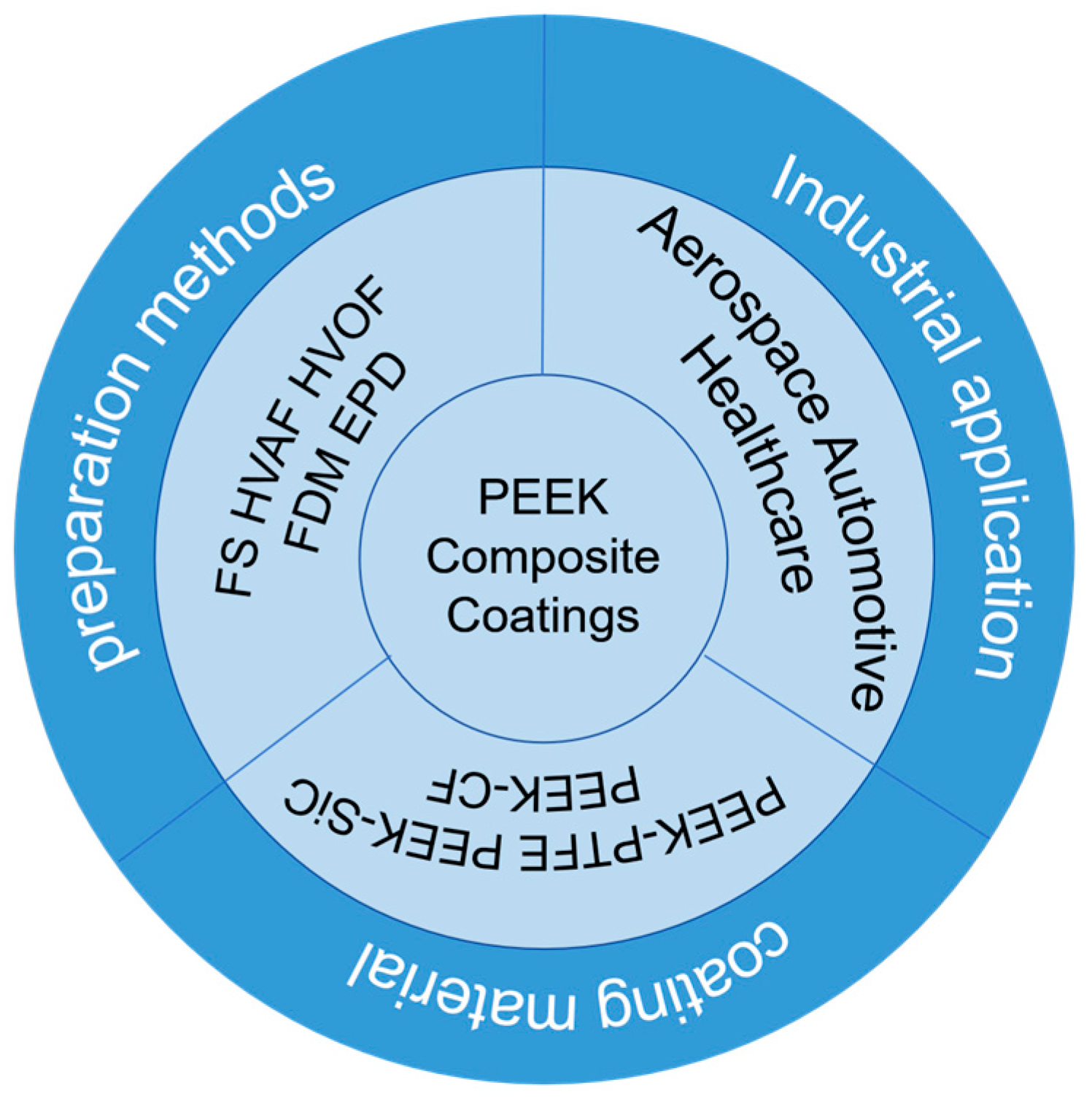

Research Progress on Polyether Ether Ketone (PEEK) Composite Coatings: A Review

Abstract

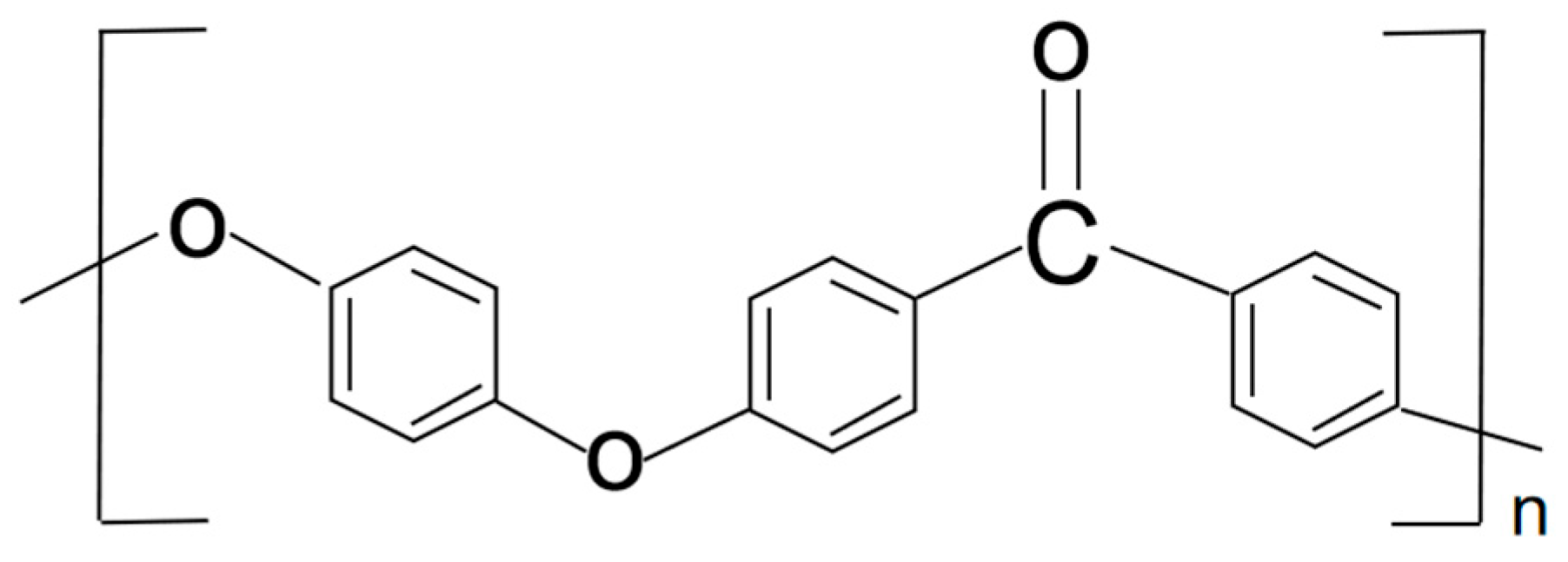

1. Introduction

2. Preparation of PEEK Composite Coatings

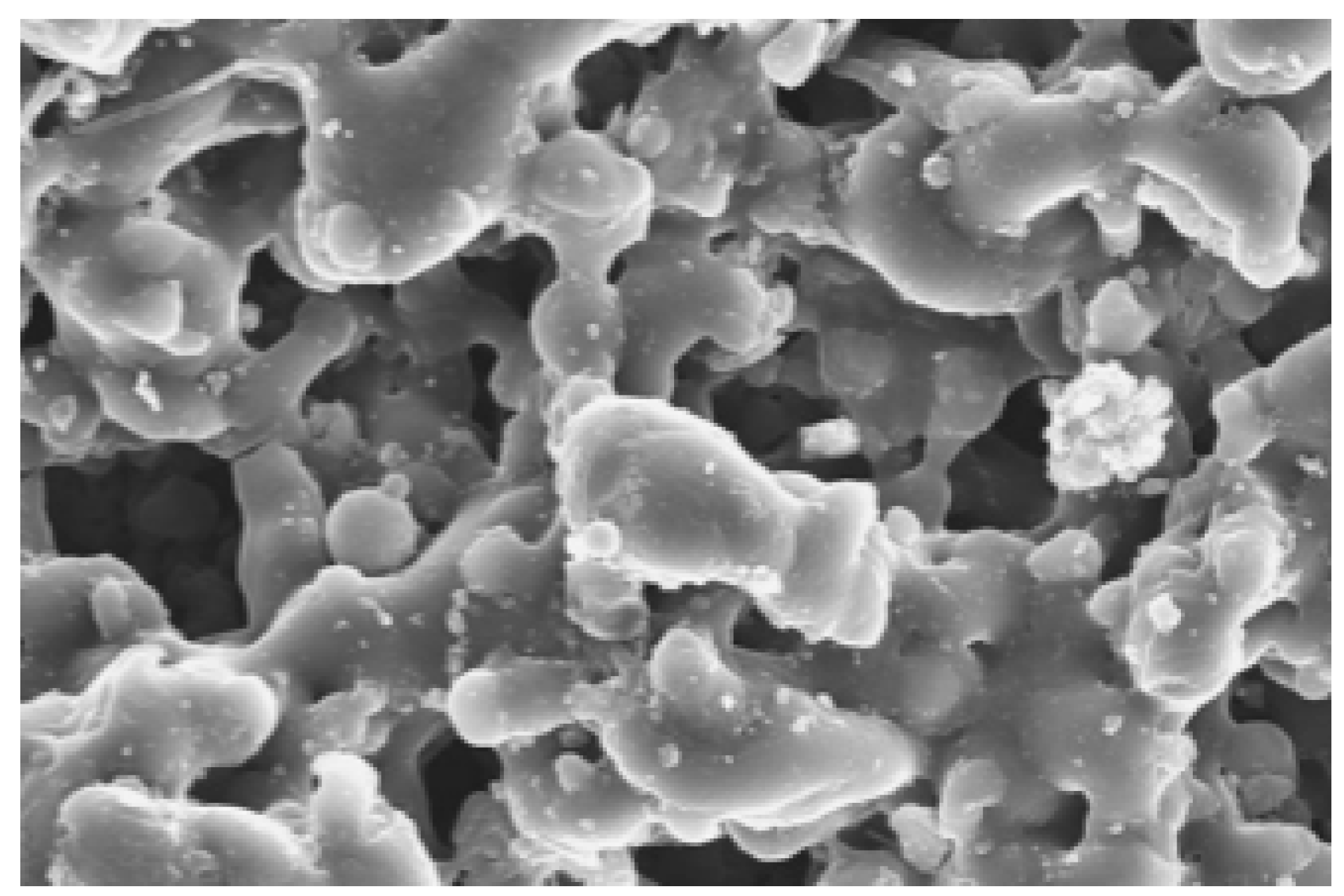

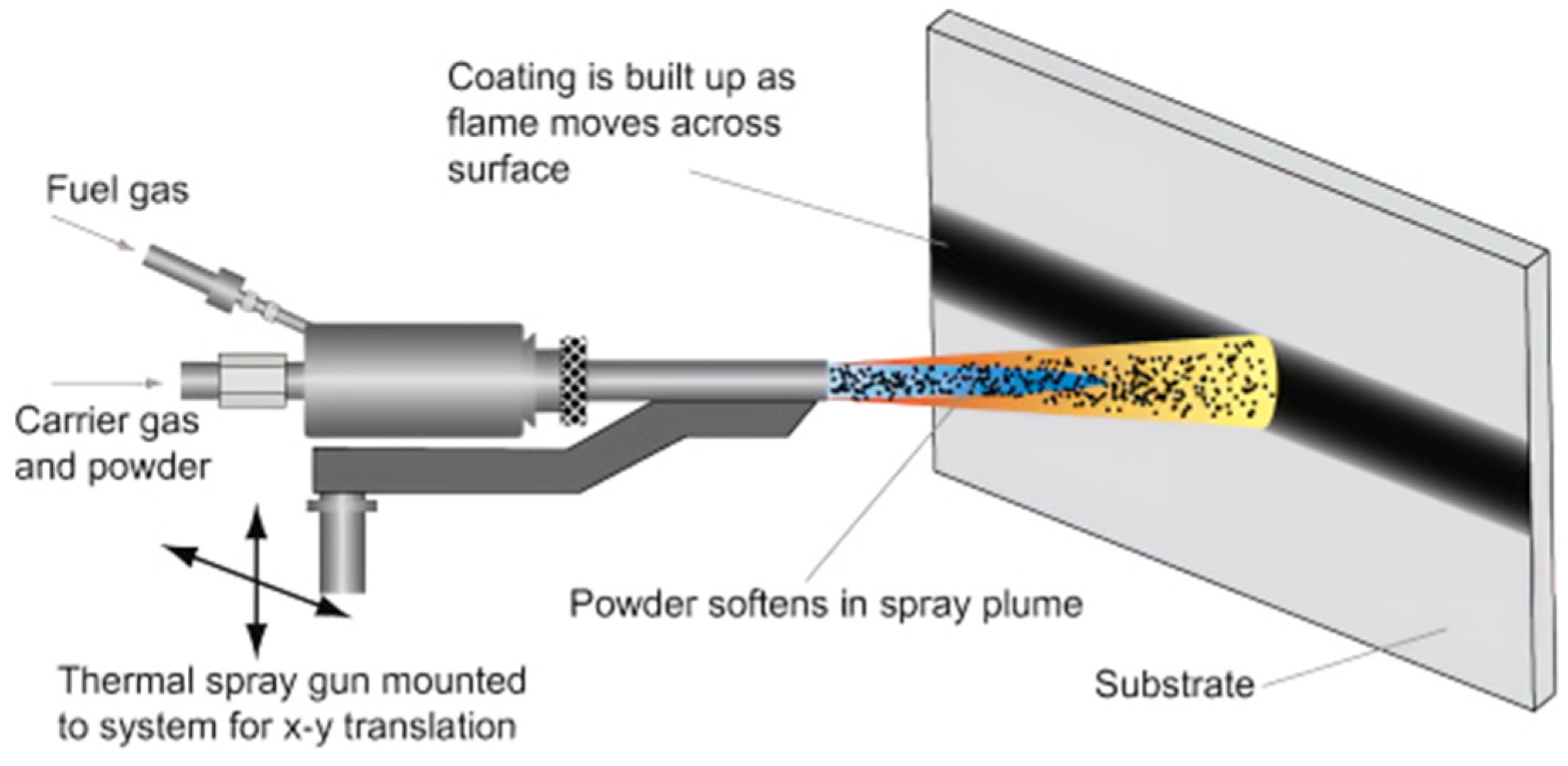

2.1. Preparation of PEEK Coatings by Thermal Spray Technology

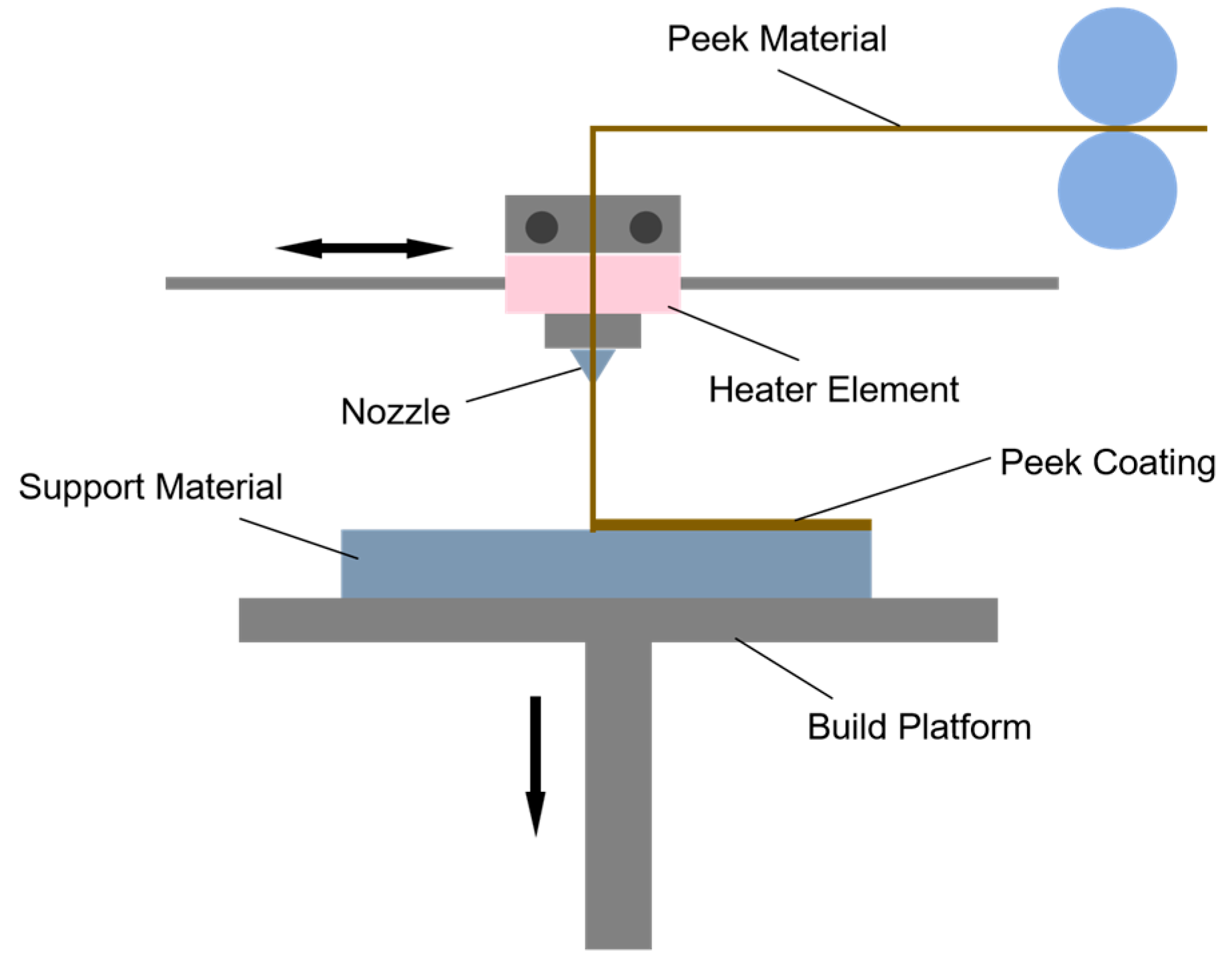

2.2. Additive Manufacturing Technology for PEEK Coating Preparation

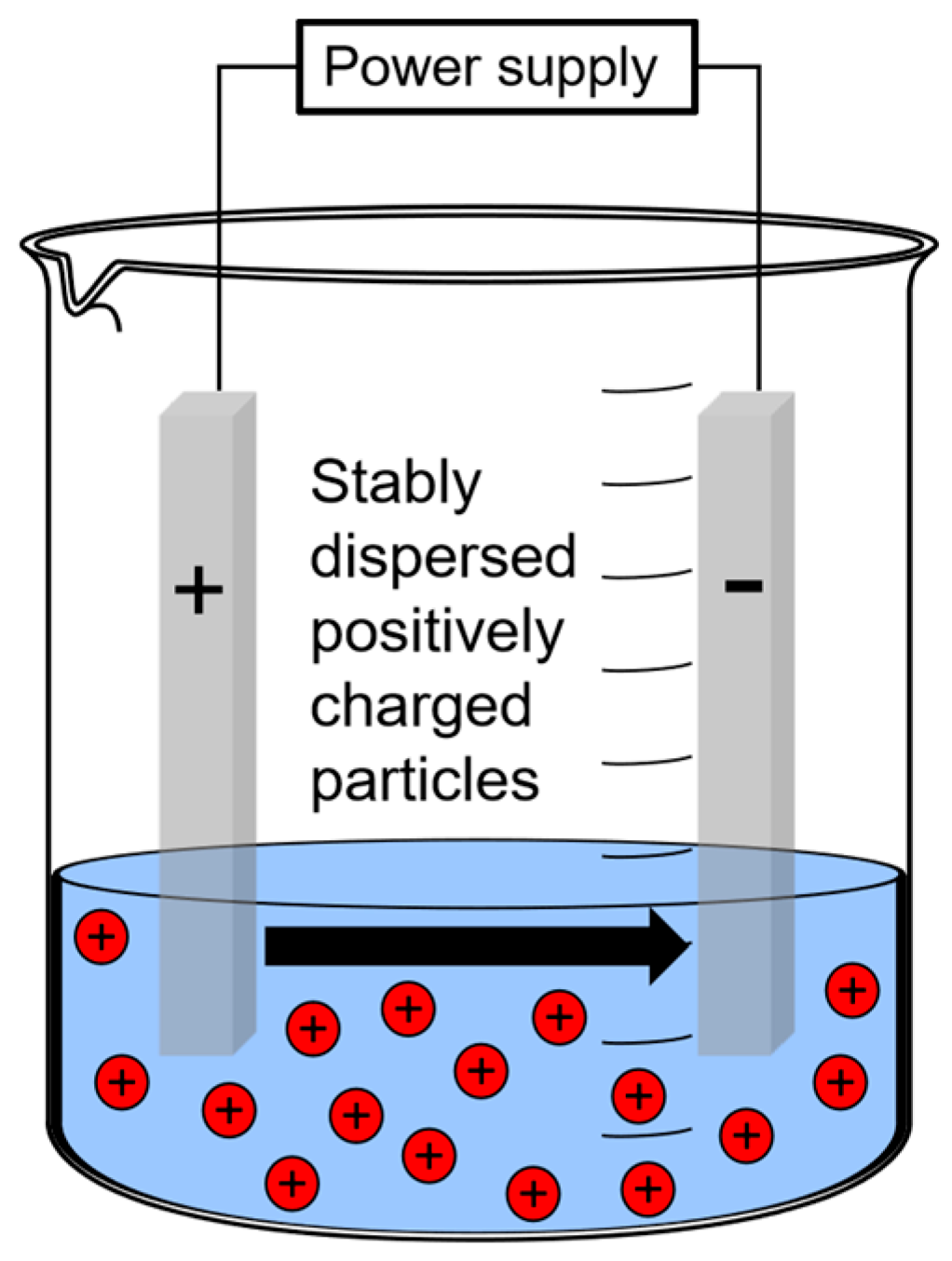

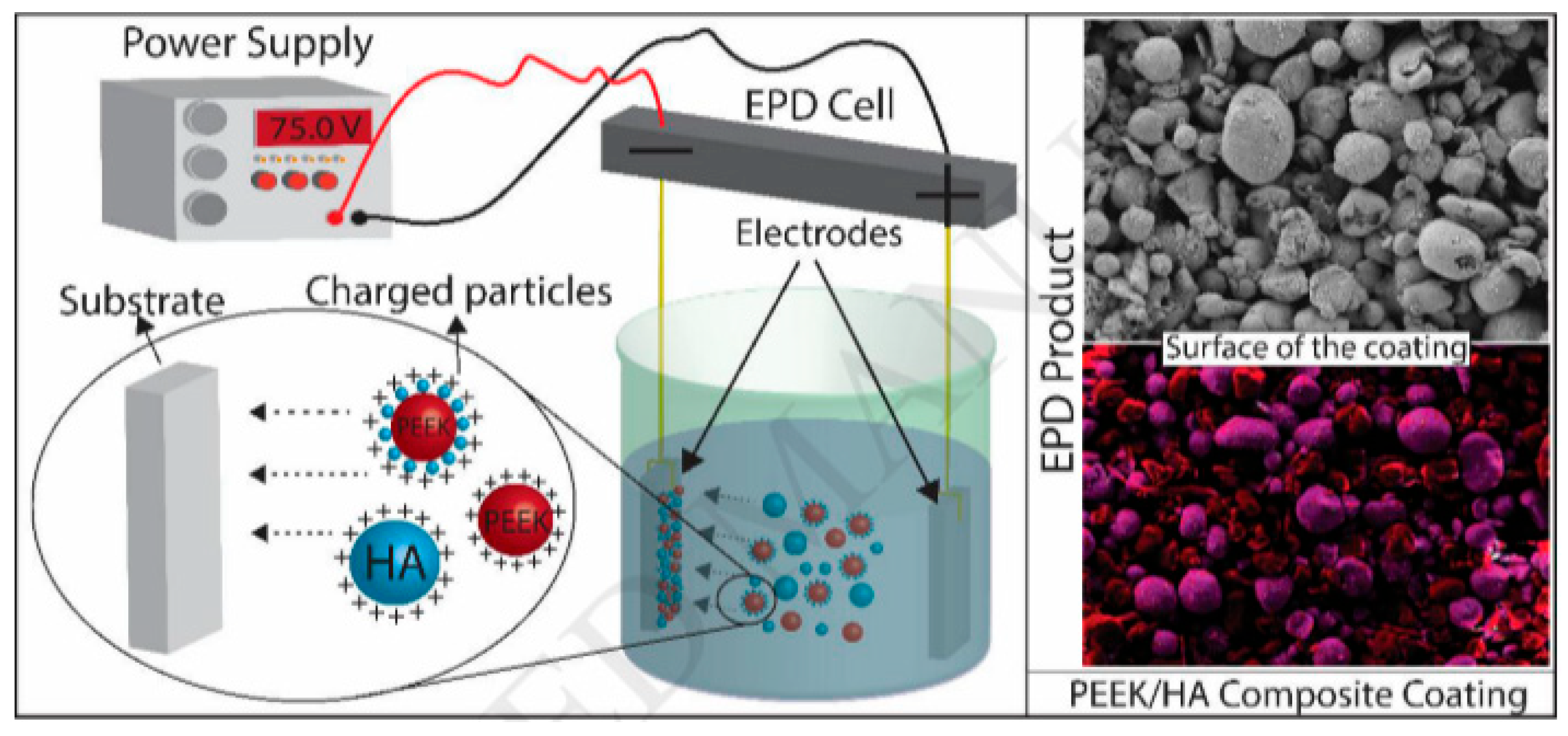

2.3. Electrophoretic Deposition (EPD) Technology for PEEK Coating Preparation

3. Factors Affecting the Performance of PEEK Composite Coatings

3.1. Influence of Substrate Roughness and Temperature on Coating Properties

3.2. Effect of Coating Thickness and Lubrication on Coating Performance

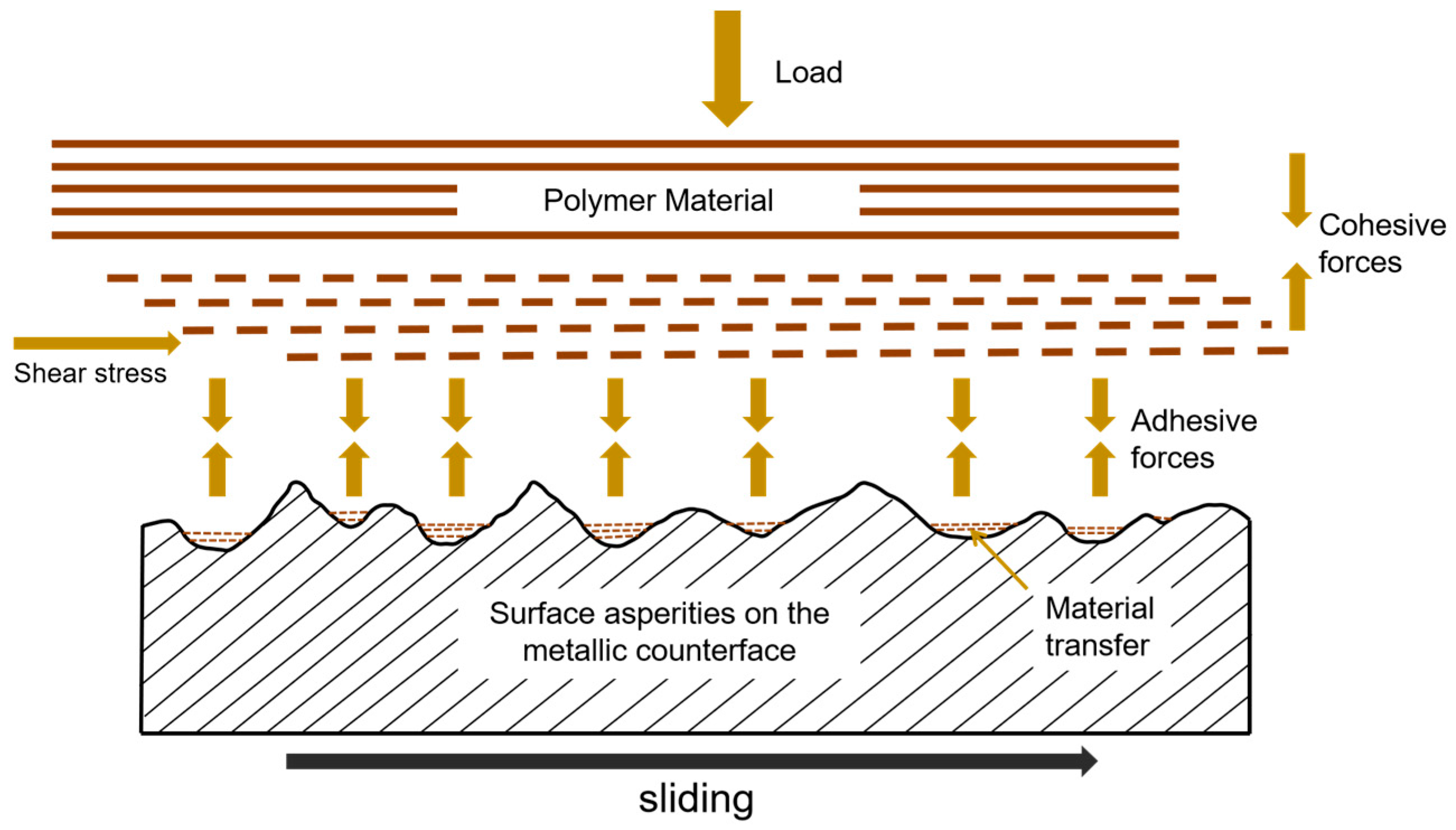

4. Current Status of Research on Friction-Modulated PEEK Composite Coatings

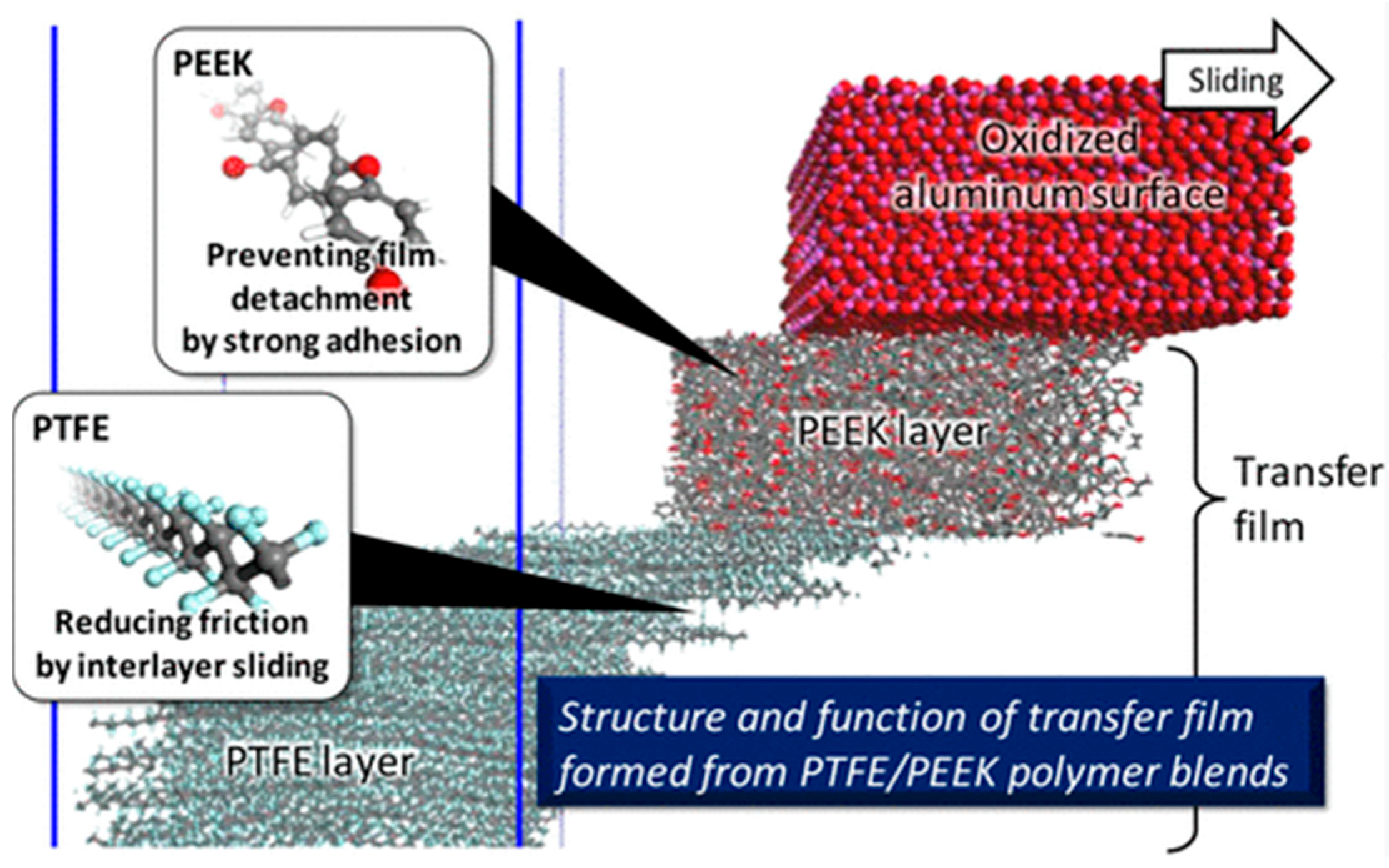

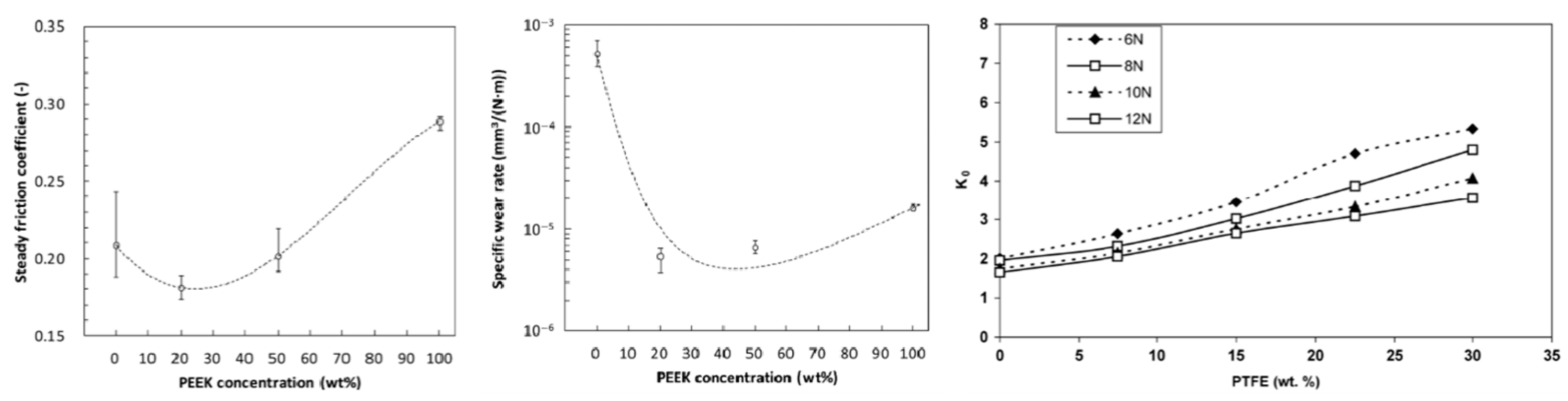

4.1. Frictional Wear Mechanism of PEEK-PTFE Composite Coatings

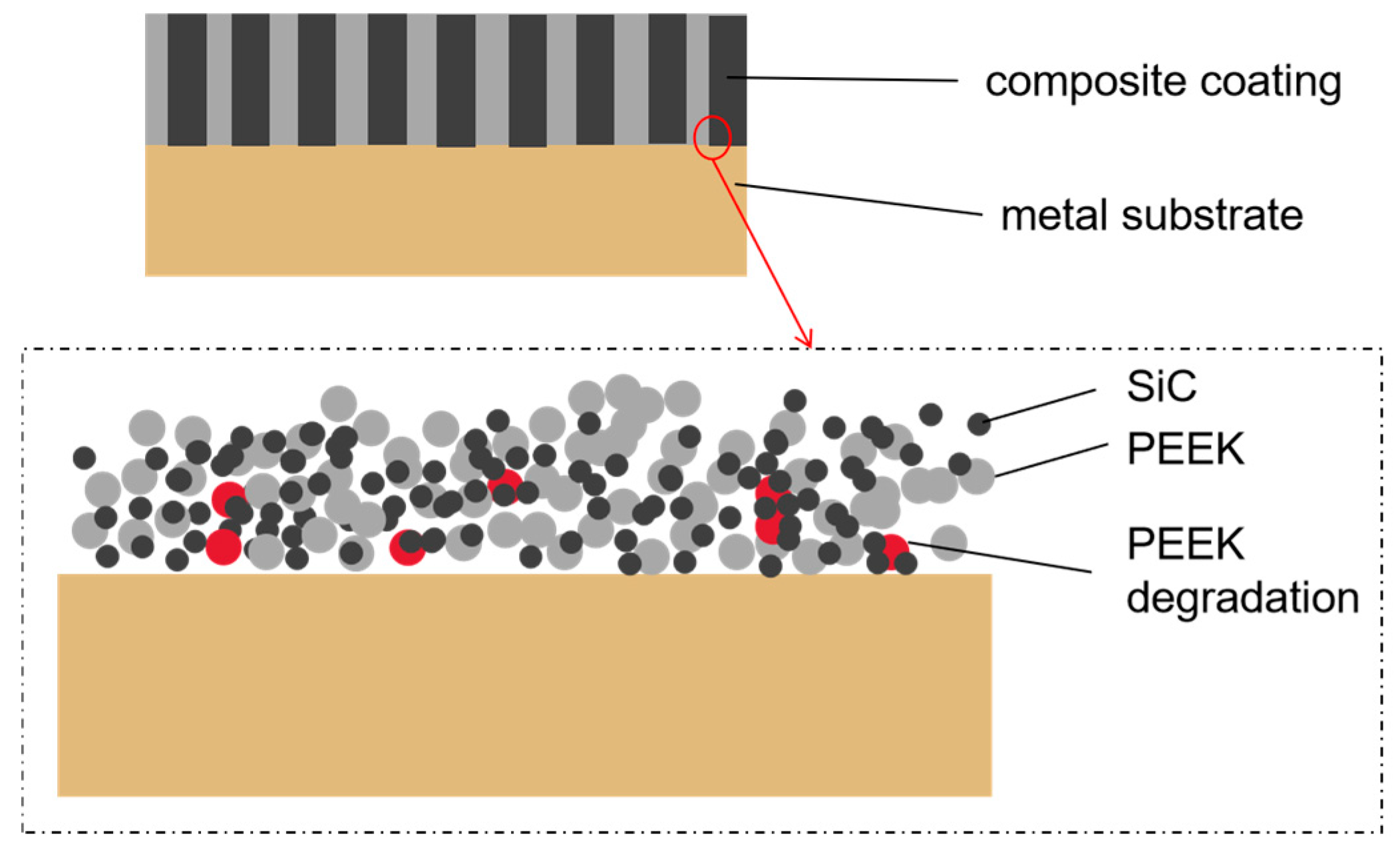

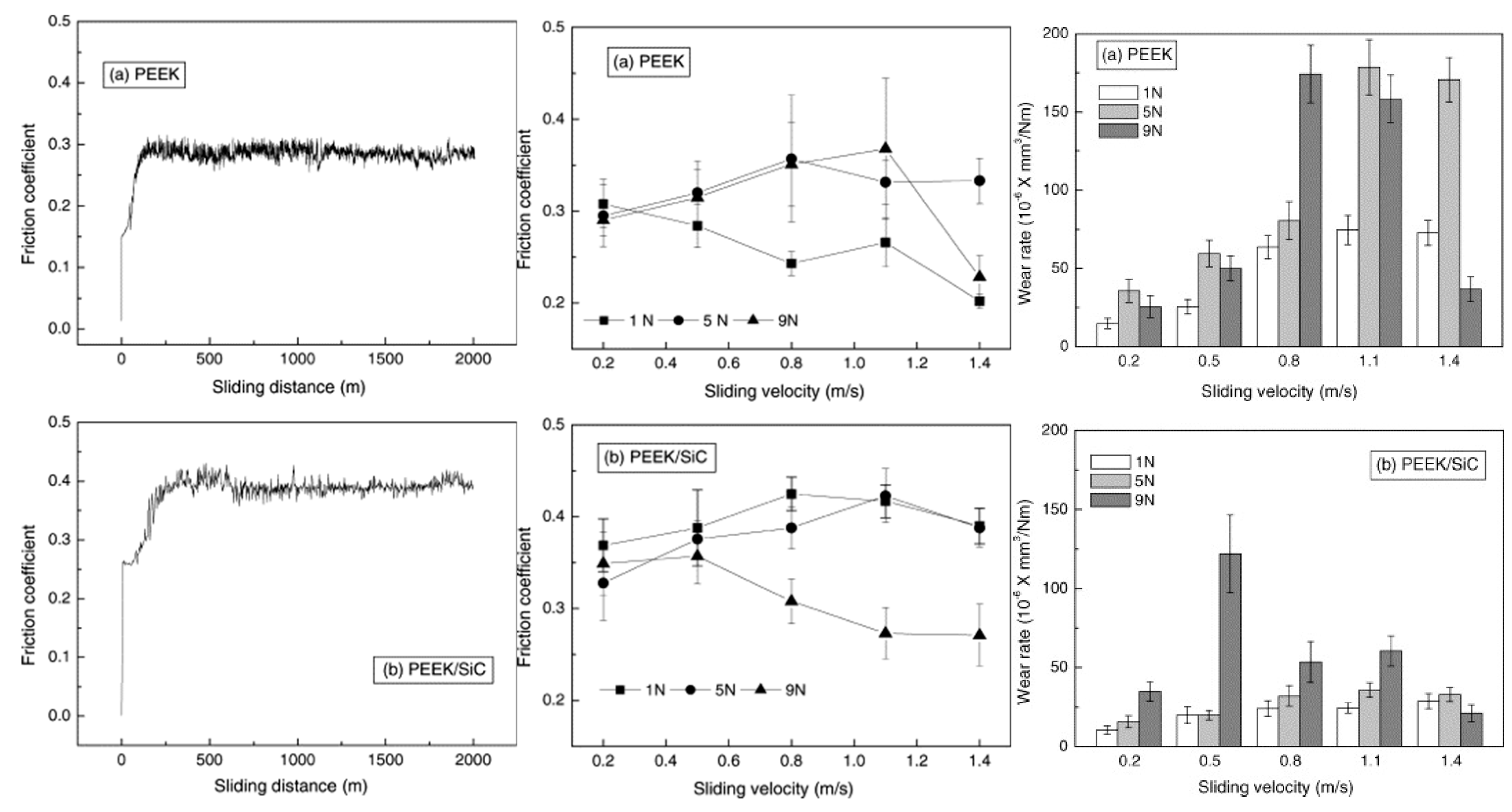

4.2. Frictional Wear Mechanism of PEEK-SiC Composite Coatings

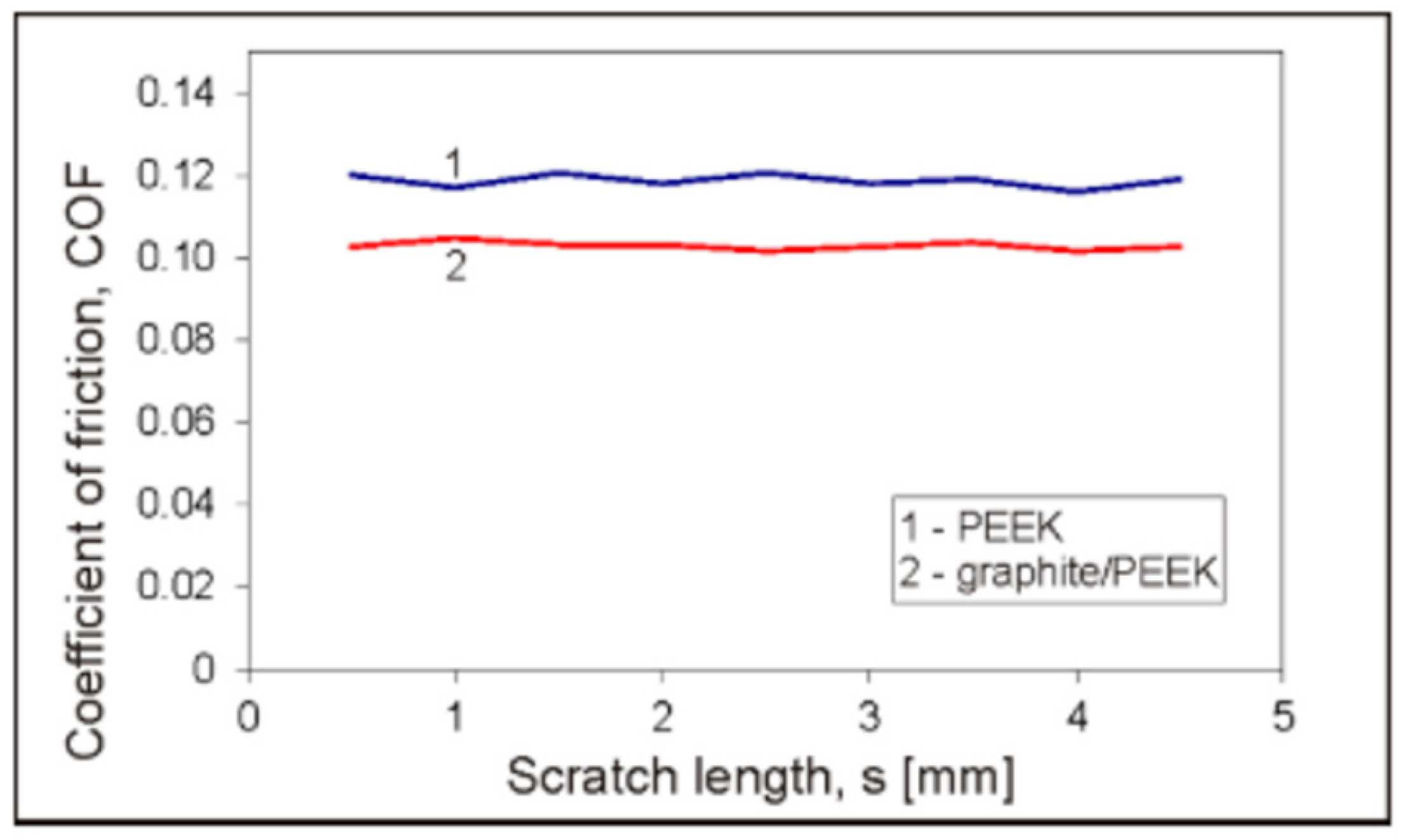

4.3. Tribological Mechanisms of Other PEEK Composite Coatings

5. Conclusions and Future Research Directions

Funding

Conflicts of Interest

References

- Thiruchitrambalam, M.; Bubesh Kumar, D.; Shanmugam, D.; Jawaid, M. A Review on PEEK Composites—Manufacturing Methods, Properties and Applications. Mater. Today Proc. 2020, 33, 1085–1092. [Google Scholar] [CrossRef]

- Xu, J.; Huang, X.; Davim, J.P.; Ji, M.; Chen, M. On the machining behavior of carbon fiber reinforced polyimide and PEEK thermoplastic composites. Polym. Compos. 2020, 41, 3649–3663. [Google Scholar] [CrossRef]

- Ionescu, R.N.; Totan, A.R.; Imre, M.M.; Țâncu, A.M.C.; Pantea, M.; Butucescu, M.; Farcașiu, A.T. Prosthetic materials used for implant-supported restorations and their biochemical oral interactions: A narrative review. Materials 2022, 15, 1016. [Google Scholar] [CrossRef] [PubMed]

- Shrivastava, S.P.; Dable, R.; Raj, A.P.N.; Mutneja, P.; Srivastava, S.B.; Haque, M. Comparison of mechanical properties of PEEK and PMMA: An in vitro study. J. Contemp. Dent. Pract. 2021, 22, 179–183. [Google Scholar] [CrossRef]

- Otto, M.; Fiołek, A.; Zimowski, S. Influence of a Steel Substrate Surface Roughness on the Mechanical Properties of a Peek Coating Deposited with the Electrophoretic Method. Tribologia 2022, 300, 33–44. [Google Scholar] [CrossRef]

- Nunez, E.E.; Gheisari, R.; Polycarpou, A.A. Tribology Review of Blended Bulk Polymers and Their Coatings for High–Load Bearing Applications. Tribol. Int. 2019, 129, 92–111. [Google Scholar] [CrossRef]

- Corni, I.; Neumann, N.; Eifler, D.; Boccaccini, A.R. Polyetheretherketone (PEEK) Coatings on Stainless Steel by Electrophoretic Deposition. Adv. Eng. Mater. 2008, 10, 559–564. [Google Scholar] [CrossRef]

- Puhan, D.; Wong, J.S.S. Properties of Polyetheretherketone (PEEK) Transferred Materials in a PEEK–Steel Contact. Tribol. Int. 2019, 135, 189–199. [Google Scholar] [CrossRef]

- Patel, K.; Doyle, C.S.; James, B.J.; Hyland, M.M. Valence Band XPS and FT-IR Evaluation of Thermal Degradation of HVAF Thermally Sprayed PEEK Coatings. Polym. Degrad. Stab. 2010, 95, 792–797. [Google Scholar] [CrossRef]

- Dai, Z.; Zhu, S.; Liu, S.; Guan, S. Preparation and Properties of High-Performance Polyethersulfone Composites Reinforced by Modified Silicon Nitride. High Perform. Polym. 2012, 24, 609–615. [Google Scholar] [CrossRef]

- Bonnheim, N.; Ansari, F.; Regis, M.; Bracco, P.; Pruitt, L. Effect of Carbon Fiber Type on Monotonic and Fatigue Properties of Orthopedic Grade PEEK. J. Mech. Behav. Biomed. Mater. 2019, 90, 484–492. [Google Scholar] [CrossRef]

- Yuan, C.; Li, D.; Yuan, X.; Liu, L.; Huang, Y. Preparation of Semi-Aliphatic Polyimide for Organic-Solvent-Free Sizing Agent in CF/PEEK Composites. Compos. Sci. Technol. 2021, 201, 108490. [Google Scholar] [CrossRef]

- Wang, T.; Jiao, Y.; Mi, Z.; Wang, C.; Wang, D.; Zhao, X.; Zhou, H.; Chen, C. Improving the Interfacial Adhesion of Carbon Fiber/Polyether Ether Ketone Composites by Polyimide Coating. Chem. Sel. 2020, 5, 5507–5514. [Google Scholar] [CrossRef]

- Yuan, X.; Jiang, J.; Wei, H.; Yuan, C.; Wang, M.; Zhang, D.; Liu, L.; Huang, Y.; Gao, G.-L.; Jiang, Z. PAI/MXene Sizing-Based Dual Functional Coating for Carbon Fiber/PEEK Composite. Compos. Sci. Technol. 2021, 201, 108496. [Google Scholar] [CrossRef]

- Wang, S.; Wang, T.; Zhang, S.; Dong, Z.; Chevali, V.S.; Yang, Y.; Wang, G.; Wang, H. Enhancing Fiber-Matrix Interface in Carbon Fiber/Poly Ether Ether Ketone (CF/PEEK) Composites by Carbon Nanotube Reinforcement of Crystalline PEEK Sizing. Compos. Part B Eng. 2023, 251, 110470. [Google Scholar] [CrossRef]

- Lomonaco, P.; Weiller, S.; Feki, I.; Debray, A.; Delloro, F.; Jeandin, M.; Favini, B.; Rossignol, C. Cold Spray Technology to Promote Conductivity of Short Carbon Fiber Reinforced Polyether-Ether-Ketone (PEEK). Key Eng. Mater. 2019, 813, 459–464. [Google Scholar] [CrossRef]

- Yan, T.; Yan, F.; Li, S.; Li, M.; Liu, Y.; Zhang, M.; Jin, L.; Shang, L.; Liu, L.; Ao, Y. Interfacial Enhancement of CF/PEEK Composites by Modifying Water-Based PEEK-NH2 Sizing Agent. Compos. Part B Eng. 2020, 199, 108258. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Z.; Lai, M.; Jiang, L.; Zhang, Y.; Zhou, H. Highly Enhancing the Interfacial Strength of CF/PEEK Composites by Introducing PAIK onto Diazonium Functionalized Carbon Fibers. Appl. Surf. Sci. 2020, 510, 145400. [Google Scholar] [CrossRef]

- Hanafi, I.; Khamlichi, A.; Cabrera, F.M.; Almansa, E.; Jabbouri, A. Optimization of Cutting Conditions for Sustainable Machining of PEEK-CF30 Using TiN Tools. J. Clean. Prod. 2012, 33, 1–9. [Google Scholar] [CrossRef]

- Lyu, H.; Jiang, N.; Li, Y.; Zhang, D. Enhancing CF/PEEK Interfacial Adhesion by Modified PEEK Grafted with Carbon Nanotubes. Compos. Sci. Technol. 2021, 210, 108831. [Google Scholar] [CrossRef]

- Bijwe, J.; Sen, S.; Ghosh, A. Influence of PTFE Content in PEEK-PTFE Blends on Mechanical Properties and Tribo-Performance in Various Wear Modes. Wear 2005, 258, 1536–1542. [Google Scholar] [CrossRef]

- Attwood, T.E.; Dawson, P.C.; Freeman, J.L.; Hoy, L.R.J.; Rose, J.B.; Staniland, P. Synthesis and properties of polyaryletherketones. Polymer 1981, 22, 1096–1103. [Google Scholar] [CrossRef]

- Brockett, C.L.; Carbone, S.; Abdelgaied, A.; Fisher, J.; Jennings, L.M. Influence of Contact Pressure, Cross-Shear and Counterface Material on the Wear of PEEK and CFR-PEEK for Orthopaedic Applications. J. Mech. Behav. Biomed. Mater. 2016, 63, 10–16. [Google Scholar] [CrossRef]

- Zhao, W.; Yu, R.; Dong, W.; Luan, J.; Wang, G.; Zhang, H.; Zhang, M. The Influence of Long Carbon Fiber and Its Orientation on the Properties of Three-Dimensional Needle-Punched CF/PEEK Composites. Compos. Sci. Technol. 2021, 203, 108565. [Google Scholar] [CrossRef]

- Stübinger, S.; Drechsler, A.; Bürki, A.; Klein, K.; Kronen, P.; von Rechenberg, B. Titanium and Hydroxyapatite Coating of Polyetheretherketone and Carbon Fiber-reinforced Polyetheretherketone: A Pilot Study in Sheep. J. Biomed. Mater. Res. Part B Appl. Biomater. 2015, 104, 1182–1191. [Google Scholar] [CrossRef]

- Devine, D.M.; Hahn, J.; Richards, R.G.; Gruner, H.; Wieling, R.; Pearce, S.G. Coating of Carbon Fiber-reinforced Polyetheretherketone Implants with Titanium to Improve Bone Apposition. J. Biomed. Mater. Res. Part B Appl. Biomater. 2012, 101B, 591–598. [Google Scholar] [CrossRef]

- Hassan, E.A.M.; Yang, L.; Elagib, T.H.H.; Ge, D.; Lv, X.; Zhou, J.; Yu, M.; Zhu, S. Synergistic Effect of Hydrogen Bonding and π-π Stacking in Interface of CF/PEEK Composites. Compos. Part B Eng. 2019, 171, 70–77. [Google Scholar] [CrossRef]

- Hassan, E.A.M.; Ge, D.; Yang, L.; Zhou, J.; Liu, M.; Yu, M.; Zhu, S. Highly Boosting the Interlaminar Shear Strength of CF/PEEK Composites via Introduction of PEKK onto Activated CF. Compos. Part A Appl. Sci. Manuf. 2018, 112, 155–160. [Google Scholar] [CrossRef]

- Miyazaki, T.; Matsunami, C.; Shirosaki, Y. Bioactive Carbon–PEEK Composites Prepared by Chemical Surface Treatment. Mater. Sci. Eng. C 2017, 70, 71–75. [Google Scholar] [CrossRef]

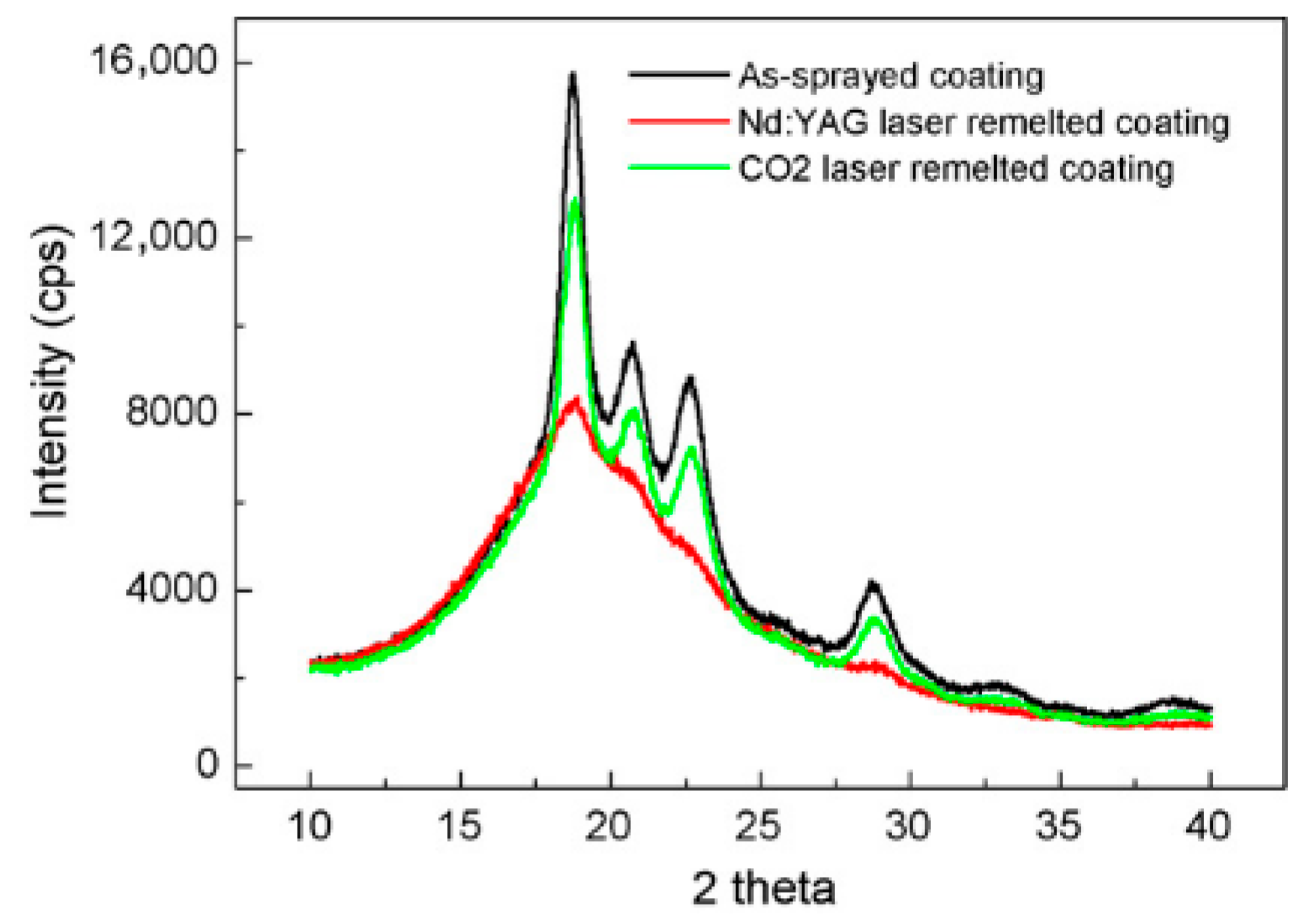

- Zhang, C.; Zhang, G.; JI, V.; Liao, H.; Costil, S.; Coddet, C. Microstructure and Mechanical Properties of Flame-Sprayed PEEK Coating Remelted by Laser Process. Prog. Org. Coat. 2009, 66, 248–253. [Google Scholar] [CrossRef]

- Choudhury, S.S.; Pandey, M.; Bhattacharya, S. Recent developments in surface modification of PEEK polymer for industrial applications: A critical review. Rev. Adhes. Adhes. 2021, 9, 410–433. [Google Scholar] [CrossRef]

- Zhang, G.; Li, W.-Y.; Cherigui, M.; Zhang, C.; Liao, H.; Bordes, J.-M.; Coddet, C. Structures and Tribological Performances of PEEK (Poly-Ether-Ether-Ketone)-Based Coatings Designed for Tribological Application. Prog. Org. Coat. 2007, 60, 39–44. [Google Scholar] [CrossRef]

- Li, J.; Liao, H.; Coddet, C. Friction and wear behavior of flame-sprayed PEEK coatings. Wear 2002, 252, 824–831. [Google Scholar] [CrossRef]

- Guo, R.Q.; Zhang, C.; Chen, Q.; Yang, Y.; Li, N.; Liu, L. Study of Structure and Corrosion Resistance of Fe-Based Amorphous Coatings Prepared by HVAF and HVOF. Corros. Sci. 2011, 53, 2351–2356. [Google Scholar] [CrossRef]

- Zhang, G.; Liao, H.; Yu, H.; Ji, V.; Huang, W.; Mhaisalkar, S.G.; Coddet, C. Correlation of Crystallization Behavior and Mechanical Properties of Thermal Sprayed PEEK Coating. Surf. Coat. Technol. 2006, 200, 6690–6695. [Google Scholar] [CrossRef]

- Gillet, V.; Aubignat, E.; Costil, S.; Courant, B.; Langlade, C.; Casari, P.; Knapp, W.; Planche, M.P. Development of Low Pressure Cold Sprayed Copper Coatings on Carbon Fiber Reinforced Polymer (CFRP). Surf. Coat. Technol. 2019, 364, 306–316. [Google Scholar] [CrossRef]

- Soveja, A.; Costil, S.; Liao, H.; Sallamand, P.; Coddet, C. Remelting of Flame Spraying PEEK Coating Using Lasers. J. Therm. Spray Technol. 2009, 19, 439–447. [Google Scholar] [CrossRef]

- Li, Y.; Man, Z.; Lin, X.; Wei, L.; Wang, H.; Lei, M. Role of Well-Dispersed Carbon Nanotubes and Limited Matrix Degradation on Tribological Properties of Flame-Sprayed PEEK Nanocomposite Coatings. J. Tribol. 2021, 144. [Google Scholar] [CrossRef]

- Yang, Q.; Li, R.; Liu, Z.; Shi, M.; Luo, X.; Zhang, T. Compositional Dependence of Microstructure and Tribological Properties of Plasma Sprayed Fe-Based Metallic Glass Coatings. Sci. China Technol. Sci. 2012, 55, 1335–1342. [Google Scholar] [CrossRef]

- Zhang, G.; Liao, H.; Yu, H.; Costil, S.; Mhaisalkar, S.G.; Bordes, J.-M.; Coddet, C. Deposition of PEEK Coatings Using a Combined Flame Spraying–Laser Remelting Process. Surf. Coat. Technol. 2006, 201, 243–249. [Google Scholar] [CrossRef]

- Pei, X.-Q.; Bennewitz, R.; Schlarb, A.K. Mechanisms of Friction and Wear Reduction by Carbon Fiber Reinforcement of PEEK. Tribol. Lett. 2015, 58, 42. [Google Scholar] [CrossRef]

- Garcia-Alonso, D.; Serres, N.; Demian, C.; Costil, S.; Langlade, C.; Coddet, C. Pre-/During-/Post-Laser Processes to Enhance the Adhesion and Mechanical Properties of Thermal-Sprayed Coatings with a Reduced Environmental Impact. J. Therm. Spray Technol. 2011, 20, 719–735. [Google Scholar] [CrossRef]

- Dupuis, A.; Ho, T.H.; Fahs, A.; Lafabrier, A.; Louarn, G.; Bacharouche, J.; Airoudj, A.; Aragon, E.; Chailan, J.-F. Improving Adhesion of Powder Coating on PEEK Composite: Influence of Atmospheric Plasma Parameters. Appl. Surf. Sci. 2015, 357, 1196–1204. [Google Scholar] [CrossRef]

- Fauchais, P. Understanding Plasma Spraying. J. Phys. D Appl. Phys. 2004, 37, R86–R108. [Google Scholar] [CrossRef]

- Sharma, M.; Bijwe, J.; Mitschang, P. Wear Performance of PEEK–Carbon Fabric Composites with Strengthened Fiber–Matrix Interface. Wear 2011, 271, 2261–2268. [Google Scholar] [CrossRef]

- Tang, W.; Zhang, J.; Li, Y.; Yu, B.; Zhao, J. Numerical Simulation of the Cold Spray Deposition of Copper Particles on Polyether Ether Ketone (PEEK) Substrate. J. Therm. Spray Technol. 2021, 30, 1792–1809. [Google Scholar] [CrossRef]

- Kim, H.; Praveen, K.; Lee, M.W.; Lee, J. Performance-Tunable Thermal Barrier Coating for Carbon Fiber-Reinforced Plastic Composites via Flame Spraying. Compos. Part B Eng. 2024, 287, 111842. [Google Scholar] [CrossRef]

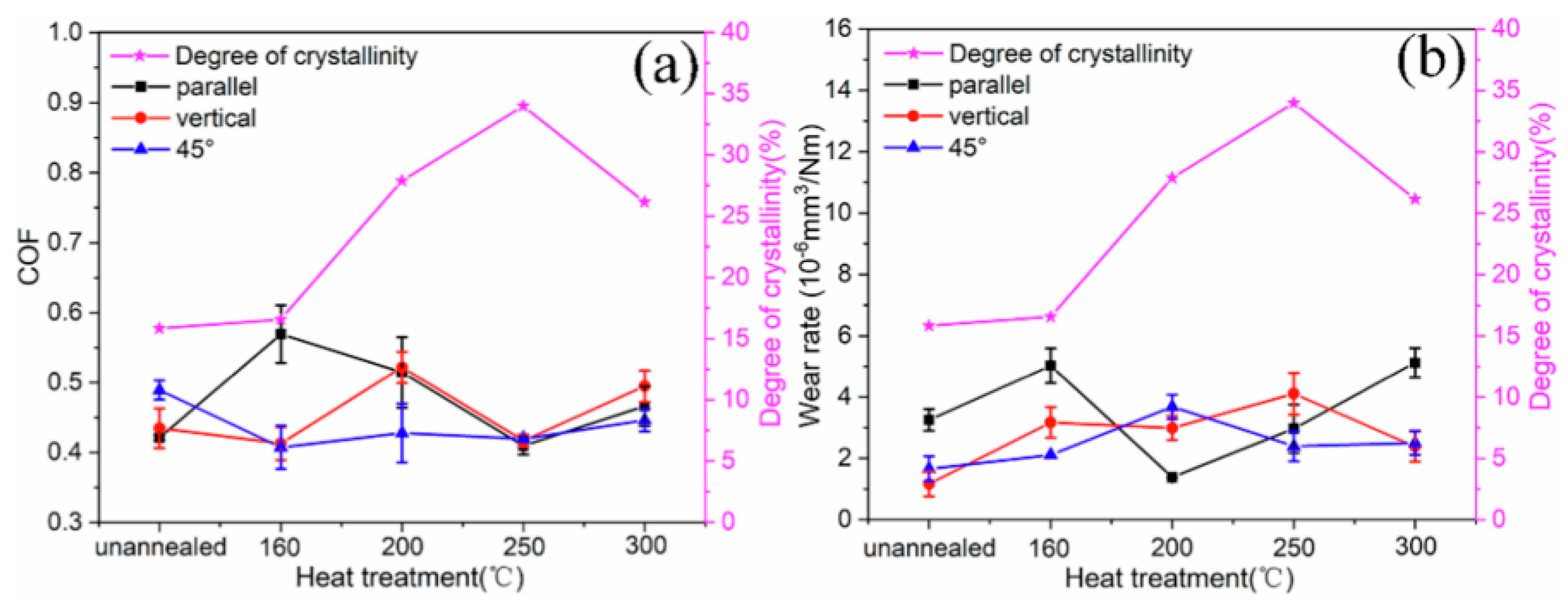

- He, Y.; Shen, M.; Wang, Q.; Wang, T.; Pei, X. Effects of FDM Parameters and Annealing on the Mechanical and Tribological Properties of PEEK. Compos. Struct. 2023, 313, 116901. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, K.; Li, Y.; Chen, F. Mechanical Characterization of Biocompatible PEEK by FDM. J. Manuf. Process. 2020, 56, 28–42. [Google Scholar] [CrossRef]

- Wu, L.; Meng, L.; Wang, Y.; Lv, M.; Ouyang, T.; Wang, Y.; Zeng, X. Fabrication of Polyetheretherketone (PEEK)-Based 3D Electronics with Fine Resolution by a Hydrophobic Treatment Assisted Hybrid Additive Manufacturing Method. Int. J. Extrem. Manuf. 2023, 5, 035003. [Google Scholar] [CrossRef]

- Lin, L.; Ecke, N.; Huang, M.; Pei, X.-Q.; Schlarb, A.K. Impact of Nanosilica on the Friction and Wear of a PEEK/CF Composite Coating Manufactured by Fused Deposition Modeling (FDM). Compos. Part B Eng. 2019, 177, 107428. [Google Scholar] [CrossRef]

- Chen, Y.; Ni, H.; Park, J.-J.; Lv, S. A Review of the Preparation, Modification, and Applications of Polyetheretherketone Coating. Coatings 2024, 14, 1451. [Google Scholar] [CrossRef]

- Chatterton, S.; Gheller, E.; Vania, A.; Pennacchi, P.; Dang, P.V. Investigation of PEEK Lined Pads for Tilting-Pad Journal Bearings. Machines 2022, 10, 125. [Google Scholar] [CrossRef]

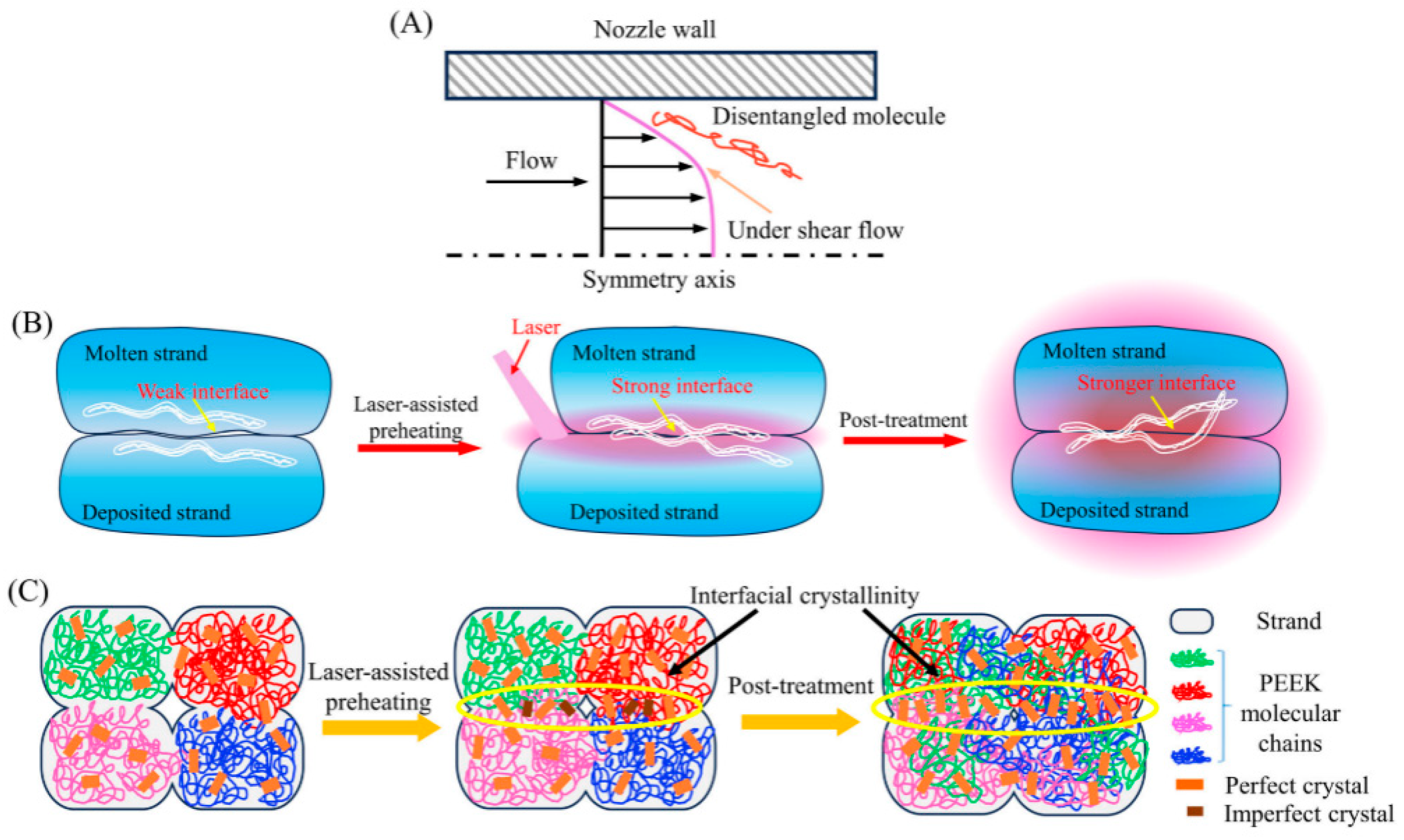

- Huang, C.; Lv, D.; Zhu, Y.; Chen, G.; Chen, M.; Zhang, Y.; Han, Y.; Wu, H. Influences of heat treatment on mechanical properties of SCF/PEEK composites in FDM-3D printing process with UV laser assistance. Polym. Compos. 2024, 45, 12597–12610. [Google Scholar] [CrossRef]

- Sikder, P.; Challa, B.T.; Gummadi, S.K. A Comprehensive Analysis on the Processing-Structure-Property Relationships of FDM-Based 3-D Printed Polyetheretherketone (PEEK) Structures. Materialia 2022, 22, 101427. [Google Scholar] [CrossRef]

- Francis, J.N.; Banerjee, I.; Chugh, A.; Singh, J. Additive Manufacturing of Polyetheretherketone and Its Composites: A Review. Polym. Compos. 2022, 43, 5802–5819. [Google Scholar] [CrossRef]

- Massocchi, D.; Riboni, G.; Lecis, N.; Chatterton, S.; Pennacchi, P. Tribological Characterization of Polyether Ether Ketone (PEEK) Polymers Produced by Additive Manufacturing for Hydrodynamic Bearing Application. Lubricants 2021, 9, 112. [Google Scholar] [CrossRef]

- Stepashkin, A.A.; Chukov, D.I.; Senatov, F.S. 3D-printed PEEK-carbon fiber (CF) composites: Structure and thermal properties. Compos. Sci. Technol. 2018, 164, 319–326. [Google Scholar] [CrossRef]

- Dhakal, N.; Espejo, C.; Morina, A. Tribological performance of 3D printed neat and carbon fiber reinforced PEEK composites. Tribol. Int. 2024, 193, 109356. [Google Scholar] [CrossRef]

- Jung, H.-D.; Jang, T.-S.; Lee, J.E.; Park, S.J.; Son, Y.; Park, S.-H. Enhanced Bioactivity of Titanium-Coated Polyetheretherketone Implants Created by a High-Temperature 3D Printing Process. Biofabrication 2019, 11, 045014. [Google Scholar] [CrossRef]

- Tseng, J.-W.; Liu, C.-Y.; Yen, Y.-K.; Belkner, J.; Bremicker, T.; Liu, B.H.; Sun, T.-J.; Wang, A.-B. Screw Extrusion-Based Additive Manufacturing of PEEK. Mater. Des. 2018, 140, 209–221. [Google Scholar] [CrossRef]

- Liu, C.Y.; Hsieh, Y.W.; Sun, T.J.; Zeng, J.W.; Wang, A.B.; Lee, N.T.; Chau, S.W.; Wei, W.C.; Liu, B.H.; Luo, R.C. Design and Test of Additive Manufacturing for Coating Thermoplastic PEEK Material. In Proceedings of the 2016 IEEE International Conference on Industrial Technology (ICIT), Taipei, Taiwan, 14–17 March 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1158–1162. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Zahedi, S.A.; Ismail, S.O.; Omigbodun, F.T. 3D Printing of PEEK and Its Composite to Increase Biointerfaces as a Biomedical Material- A Review. Colloids Surf. B Biointerfaces 2021, 203, 111726. [Google Scholar] [CrossRef]

- Chen, J.; Wang, K.; Zhao, Y. Enhanced Interfacial Interactions of Carbon Fiber Reinforced PEEK Composites by Regulating PEI and Graphene Oxide Complex Sizing at the Interface. Compos. Sci. Technol. 2018, 154, 175–186. [Google Scholar] [CrossRef]

- Zhang, K.; Yuan, X.; Li, D. Mechanical properties of solution-blended graphene nanoplatelets/polyether-ether-ketone nanocom-posites. J. Phys. Chem. B 2021, 5, 10597–10609. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Yang, D.; Yang, C.; Spintzyk, S.; Scheideler, L.; Li, P.; Li, D.; Geis-Gerstorfer, J.; Rupp, F. Carbon Fiber Reinforced PEEK Composites Based on 3D-Printing Technology for Orthopedic and Dental Applications. J. Clin. Med. 2019, 8, 240. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Deng, T.; Peng, Y.; Qin, Z.; Ramalingam, M.; Pan, Y.; Chen, C.; Zhao, F.; Cheng, L.; Liu, J. Effect of Surface Modification of PEEK Artificial Phalanx by 3D Printing on Its Biological Activity. Coatings 2023, 13, 400. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Zahedi, S.A. Improving Bioactivity and Strength of PEEK Composite Polymer for Bone Application. Mater. Chem. Phys. 2021, 266, 124485. [Google Scholar] [CrossRef]

- Ur Rehman, M.A.; Bastan, F.E.; Nawaz, A.; Nawaz, Q.; Wadood, A. Electrophoretic Deposition of PEEK/Bioactive Glass Composite Coatings on Stainless Steel for Orthopedic Applications: An Optimization for in Vitro Bioactivity and Adhesion Strength. Int. J. Adv. Manuf. Technol. 2020, 108, 1849–1862. [Google Scholar] [CrossRef]

- Fiołek, A.; Zimowski, S.; Kopia, A.; Łukaszczyk, A.; Moskalewicz, T. Electrophoretic Co-Deposition of Polyetheretherketone and Graphite Particles: Microstructure, Electrochemical Corrosion Resistance, and Coating Adhesion to a Titanium Alloy. Materials 2020, 13, 3251. [Google Scholar] [CrossRef]

- Batool, S.A.; Wadood, A.; Hussain, S.W.; Yasir, M.; Ur Rehman, M.A. A Brief Insight to the Electrophoretic Deposition of PEEK-, Chitosan-, Gelatin-, and Zein-Based Composite Coatings for Biomedical Applications: Recent Developments and Challenges. Surfaces 2021, 4, 205–239. [Google Scholar] [CrossRef]

- Seuss, S.; Subhani, T.; Kang, M.Y.; Okudaira, K.; Aguilar Ventura, I.E.; Boccaccini, A.R. Electrophoretic Deposition of PEEK-TiO2 Composite Coatings on Stainless Steel. Key Eng. Mater. 2012, 507, 127–133. [Google Scholar] [CrossRef]

- Baştan, F.E.; Atiq Ur Rehman, M.; Avcu, Y.Y.; Avcu, E.; Üstel, F.; Boccaccini, A.R. Electrophoretic Co-Deposition of PEEK-Hydroxyapatite Composite Coatings for Biomedical Applications. Colloids Surf. B Biointerfaces 2018, 169, 176–182. [Google Scholar] [CrossRef]

- Atiq Ur Rehman, M.; Bastan, F.E.; Haider, B.; Boccaccini, A.R. Electrophoretic Deposition of PEEK/Bioactive Glass Composite Coatings for Orthopedic Implants: A Design of Experiments (DoE) Study. Mater. Des. 2017, 130, 223–230. [Google Scholar] [CrossRef]

- Kruk, A.; Zimowski, S.; Łukaszczyk, A.; Cieniek, Ł.; Moskalewicz, T. The Influence of Heat Treatment on the Microstructure, Surface Topography and Selected Properties of PEEK Coatings Electrophoretically Deposited on the Ti-6Al-4V Alloy. Prog. Org. Coat. 2019, 133, 180–190. [Google Scholar] [CrossRef]

- Wu, J.; Munroe, P.R.; Withy, B.; Hyland, M.M. Study of the Splat-Substrate Interface for a PEEK Coating Plasma-Sprayed onto Aluminum Substrates. J. Therm. Spray Technol. 2009, 19, 42–48. [Google Scholar] [CrossRef]

- Henriques, B.; Sampaio, M.; Buciumeanu, M.; Souza, J.C.M.; Gomes, J.R.; Silva, F.; Carvalho, O. Laser Surface Structuring of Ti6Al4V Substrates for Adhesion Enhancement in Ti6Al4V-PEEK Joints. Mater. Sci. Eng. C 2017, 79, 177–184. [Google Scholar] [CrossRef]

- Sändker, H.; Stollenwerk, J.; Loosen, P. Laser-Based Process for Polymeric Tribological Coatings on Lightweight Components. Surf. Coat. Technol. 2017, 332, 391–398. [Google Scholar] [CrossRef]

- Zhang, G.; Yu, H.; Zhang, C.; Liao, H.; Coddet, C. Temperature Dependence of the Tribological Mechanisms of Amorphous PEEK (Polyetheretherketone) under Dry Sliding Conditions. Acta Mater. 2008, 56, 2182–2190. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Jordan, P.; Schmidlin, P.R.; Roos, M.; Eichberger, M.; Gernet, W.; Keul, C. PEEK Surface Treatment Effects on Tensile Bond Strength to Veneering Resins. J. Prosthet. Dent. 2014, 112, 1278–1288. [Google Scholar] [CrossRef] [PubMed]

- Patel, K.; Doyle, C.S.; Yonekura, D.; James, B.J. Effect of Surface Roughness Parameters on Thermally Sprayed PEEK Coatings. Surf. Coat. Technol. 2010, 204, 3567–3572. [Google Scholar] [CrossRef]

- Wang, Y.; Terrell, E.J. Influence of Coating Thickness and Substrate Elasticity on the Tribological Performance of PEEK Coatings. Wear 2013, 303, 255–261. [Google Scholar] [CrossRef]

- Almasi, D.; Izman, S.; Assadian, M.; Ghanbari, M.; Abdul Kadir, M.R. Crystalline Ha Coating on Peek via Chemical Deposition. Appl. Surf. Sci. 2014, 314, 1034–1040. [Google Scholar] [CrossRef]

- Zhang, G.; Wetzel, B.; Wang, Q. Tribological Behavior of PEEK-Based Materials under Mixed and Boundary Lubrication Conditions. Tribol. Int. 2015, 88, 153–161. [Google Scholar] [CrossRef]

- Onodera, T.; Nunoshige, J.; Kawasaki, K.; Adachi, K.; Kurihara, K.; Kubo, M. Structure and Function of Transfer Film Formed from PTFE/PEEK Polymer Blend. J. Phys. Chem. C 2017, 121, 14589–14596. [Google Scholar] [CrossRef]

- Vail, J.R.; Krick, B.A.; Marchman, K.R.; Sawyer, W.G. Polytetrafluoroethylene (PTFE) Fiber Reinforced Polyetheretherketone (PEEK) Composites. Wear 2011, 270, 737–741. [Google Scholar] [CrossRef]

- Dearn, K.D.; Hoskins, T.J.; Petrov, D.G.; Reynolds, S.C.; Banks, R. Applications of Dry Film Lubricants for Polymer Gears. Wear 2013, 298–299, 99–108. [Google Scholar] [CrossRef]

- Sun, W.; Ye, J.; Song, Q.; Feng, Y.; Liu, X. Ultralow Friction PTFE/PEEK Heterolayer: A New Solid Lubrication Approach toward Simplicity. Friction 2023, 12, 120–135. [Google Scholar] [CrossRef]

- Sun, W.; Chen, T.; Liu, X.; Jiao, Y.; Zhu, Y.; Ye, J. Microstructure-Armored Surface and Its Tribological Effects on Ultralow-Wear PEEK/PTFE Composites. Polymer 2024, 291, 126599. [Google Scholar] [CrossRef]

- Li, S.; Gao, C.; Duan, C.; Zhang, S.; Zhang, P.; Zhang, Z. Achieving Oil-Based Superlubricity with near-Zero Wear via Synergistic Effect between PEEK-PTFE and PAO40 Containing DDP-Cu Nanoparticles. Tribol. Int. 2025, 208, 110645. [Google Scholar] [CrossRef]

- Liao Y, Cao L, Wang Q Enhanced tribological properties of PEEK-based composite coatings reinforced by PTFE and graphite. J. Appl. Polym. Sci. 2022, 13, 51878. [CrossRef]

- Yeo, S.M.; Polycarpou, A.A. Micromechanical Properties of Polymeric Coatings. Tribol. Int. 2013, 60, 198–208. [Google Scholar] [CrossRef]

- Lan, P.; Meyer, J.L.; Vaezian, B.; Polycarpou, A.A. Advanced Polymeric Coatings for Tilting Pad Bearings with Application in the Oil and Gas Industry. Wear 2016, 354–355, 10–20. [Google Scholar] [CrossRef]

- Lo, K.H.; Qu, S.; Wang, S.S. A Mechanism-Based General Theory for Friction of PTFE/PEEK Composite: Effects of PTFE Morphology and Composite Microstructure. J. Tribol. 2022, 144, 081702. [Google Scholar] [CrossRef]

- Luo, H.; Li, Y.; Huan, D.; Zhu, C.; Wang, J.; Zeng, D. Efficient Fabrication of Wear-Resistant PEEK Matrix Composite Coating with Superhydrophobicity for Self-Cleaning and Anti-Icing Applications. Polym.-Plast. Technol. Mater. 2021, 60, 1106–1121. [Google Scholar] [CrossRef]

- Qu, S.; Lo, K.H.; Wang, S.S. Effect of Transfer Films on Friction of PTFE/PEEK Composite. J. Tribol. 2020, 143, 041401. [Google Scholar] [CrossRef]

- Zhang, G.; Leparoux, S.; Liao, H.; Coddet, C. Microwave Sintering of Poly-Ether-Ether-Ketone (PEEK) Based Coatings Deposited on Metallic Substrate. Scr. Mater. 2006, 55, 621–624. [Google Scholar] [CrossRef]

- Kadiyala, A.K.; Bijwe, J.; Kalappa, P. Investigations on Influence of Nano and Micron Sized Particles of SiC on Performance Properties of PEEK Coatings. Surf. Coat. Technol. 2018, 334, 124–133. [Google Scholar] [CrossRef]

- Zhang, G.; Liao, H.; Li, H.; Mateus, C.; Bordes, J.-M.; Coddet, C. On Dry Sliding Friction and Wear Behaviour of PEEK and PEEK/SiC-Composite Coatings. Wear 2006, 260, 594–600. [Google Scholar] [CrossRef]

- Yin, X.; Jin, J.; Chen, X.; Rosenkranz, A.; Luo, J. Ultra-Wear-Resistant MXene-Based Composite Coating via in Situ Formed Nanostructured Tribofilm. ACS Appl. Mater. Interfaces 2019, 11, 32569–32576. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Y.; Wang, S.; Yan, X.; Zhang, W.; Ding, X. Interfacial Effects on Thermal Conductive Properties in Peek Composites. Int. J. Heat Mass Transf. 2025, 246, 127037. [Google Scholar] [CrossRef]

- Caglar, I.; Ates, S.M.; Yesil Duymus, Z. An In Vitro Evaluation of the Effect of Various Adhesives and Surface Treatments on Bond Strength of Resin Cement to Polyetheretherketone. J. Prosthodont. 2018, 28, e342–e349. [Google Scholar] [CrossRef]

- Weißbacher, C.; Kiefel, A.; Blumenthal, H.; Marheineke, J.; Piton, S. Performance of a Direct Bonded Sub-Millimeter Peek Coating for Hydrodynamic Plain Bearings. J. Tribol. 2021, 143, 101801. [Google Scholar] [CrossRef]

- Tharajak, J.; Palathai, T.; Sombatsompop, N. Morphological and Physical Properties and Friction/Wear Behavior of h-BN Filled PEEK Composite Coatings. Surf. Coat. Technol. 2015, 273, 20–29. [Google Scholar] [CrossRef]

- Tharajak, J.; Palathai, T.; Sombatsompop, N. Scratch Resistance and Adhesion Properties of PEEK Coating Filled with H-BN Nanoparticles. Adv. Mater. Res. 2013, 747, 303–306. [Google Scholar] [CrossRef]

- Lin, L.; Schlarb, A.K. Effect of the Varied Load Conditions on the Tribological Performance and the Thermal Characteristics of PEEK-Based Hybrid Composites. Tribol. Int. 2016, 101, 218–225. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, P.; Li, S.J.; Wang, Q.W.; Zeng, D.H.; Yu, C.Y.; Li, Q.-Y.; Liao, Y.-W.; Lin, Z.-D.; Li, W. Effects of TaN nanoparticles on microstructure, mechanical properties and tribological performance of PEEK coating prepared by electrophoretic deposition. Trans. Nonferrous Met. Soc. China 2022, 32, 3334–3348. [Google Scholar] [CrossRef]

- Xue, L.; Xu, Q.; Meng, C.; Lei, S.; Zhang, G.; Tang, M.; Zhai, W.; Yu, H.; Liu, X.; Du, C.-F. Achieving the Ultra-Low Friction and Wear Rate of PEEK-PTFE Composites by Ti3C2Tx MXene Reinforcement. Tribol. Int. 2024, 199, 110030. [Google Scholar] [CrossRef]

- Puértolas, J.A.; Castro, M.; Morris, J.A.; Ríos, R.; Ansón-Casaos, A. Tribological and Mechanical Properties of Graphene Nanoplatelet/PEEK Composites. Carbon 2019, 141, 107–122. [Google Scholar] [CrossRef]

| Flame Spraying Parameters | |

|---|---|

| Acetylene flow rate (L/min) | 6 |

| O2 flow rate (L/min) | 16 |

| Flux rate of compressed air (L/min) | 230 |

| Flux rate of carrier gas (N2, L/min) | 35 |

| Spraying distance (mm) | 180 |

| Powder feed rate (g/min) | 12 |

| Preparation Method | Principle of the Process | Post-Processing Requirements | Quality of the Coating | Equipment and Cost | References |

|---|---|---|---|---|---|

| Flame spraying technology | Gas flame heating of powder, low-speed particle deposition | Annealing/laser remelting required to improve structure | High porosity, poor density, Weak interfacial bonding | Simple equipment, low cost | [32,43] |

| HVAF Thermal Spray Technology | High-velocity air-fuel combustion, high particle kinetic energy | Optional annealing to further improve density | Significant densification, low porosity, Strong bonding, good toughness | Complex equipment, moderate cost | [9,34] |

| HVOF Thermal Spray Technology | High-velocity oxy-fuel combustion, high particle kinetic energy | Optional annealing to reduce oxidation effects | Significant densification, but prone to oxidation, Strong bonding, but may be affected by oxidation | Complex equipment, moderate cost | |

| Plasma spraying technology | Plasma arc heating of powder, high-temperature deposition | Required heat treatment to reduce porosity | High density, Improved bonding, but with a risk of thermal cracking | Expensive equipment, requires plasma source | [32,35] |

| Additive Manufacturing Processes | Heating and melting PEEK filament, layer-by-layer stacking | Annealing/laser-assisted optimization of crystallinity and interlayer bonding | Layered structure, significant porosity and interlayer cracking, Interlayer bonding strength depends on temperature and cooling rate | Simple equipment, low cost | [48,63] |

| Electrophoretic deposition process | Electric field-driven deposition of charged particles on the electrode | Heat treatment can improve crystallinity and hardness | High coating uniformity, good particle dispersion, Excellent interfacial bonding, further enhanced after annealing | Simple equipment, higher cost | [7,49,69,73,74] |

| Type of Composite | Optimal Component | Coating Function | Friction Mechanism | References |

|---|---|---|---|---|

| PEEK-PTFE | 7.5% PTFE | Enhanced impact strength of coatings (abrasive wear) | formation of a low-friction transfer film | [11,96,108] |

| 20%–30% PTFE | Increased wear resistance (low amplitude oscillatory wear) | |||

| Incorporation of 8% micronized SiO2 particles | Superhydrophobicity of the coating | |||

| Addition of Ti3C2TX material | Improvement of coating hardness | |||

| PEEK-SiC | - | Enhances coating compactness and improves its hardness, and retards the rate of increase in the coefficient of friction. (Shearing of interfacial molecular bonds) | Enhancement of interfacial shear resistance, suppression of polymer chain mobility, and mitigation of the plowing effect | [32,97,99] |

| PEEK101 | 89% PEEK, 10% perfluoroalkanes, 1% graphite | Increased yield strength, better shape stability, very low wear rate | constructing a synergistic lubrication network | [103] |

| PEEK-TaN | - | Increases coating thickness, improves coating hardness and scratch resistance, and reduces shear and furrow forces. | Enhancement of interfacial bonding strength and suppression of crack propagation | [107] |

| PEEK-h-BN | Addition of hexagonal boron nitride | Increased coating hardness | Solid lubrication effect, hardness enhancement, and crystallinity variation induced by particle size regulation | [104,105] |

| Type of Composite | Friction Coefficient | Wear Rates (mm3/(N·M)) | Typical Application Scenarios | Experimental Conditions | Years | References |

|---|---|---|---|---|---|---|

| Pure PEEK | 0.29 | 1.6 × 10−5 | - | - | - | - |

| PEEK-PTFE | 0.18–0.29 | 5.4 × 10−6 | Car air conditioning compressor piston ring, oil-free bearing sleeve | Pin-on-disk dry friction test | 2017 | [85] |

| 0.015–0.44 | 1 × 10−7 | Low amplitude oscillating wear | 2005 | [11] | ||

| 0.373–0.22 | - | Pin-on-disk dry friction test | 2021 | [96] | ||

| PEEK-SiC | 0.28–0.3 | 1 × 10−5–2.5 × 10−5 | Extreme environment electronic packaging, seawater lubricated bearings | Under a 1 N load | 2006 | [99] |

| 2.5 × 10−5–7.5 × 10−5 | Under a 5 N load | |||||

| 2.5 × 10−5–1.25 × 10−4 | Under a 9 N load | |||||

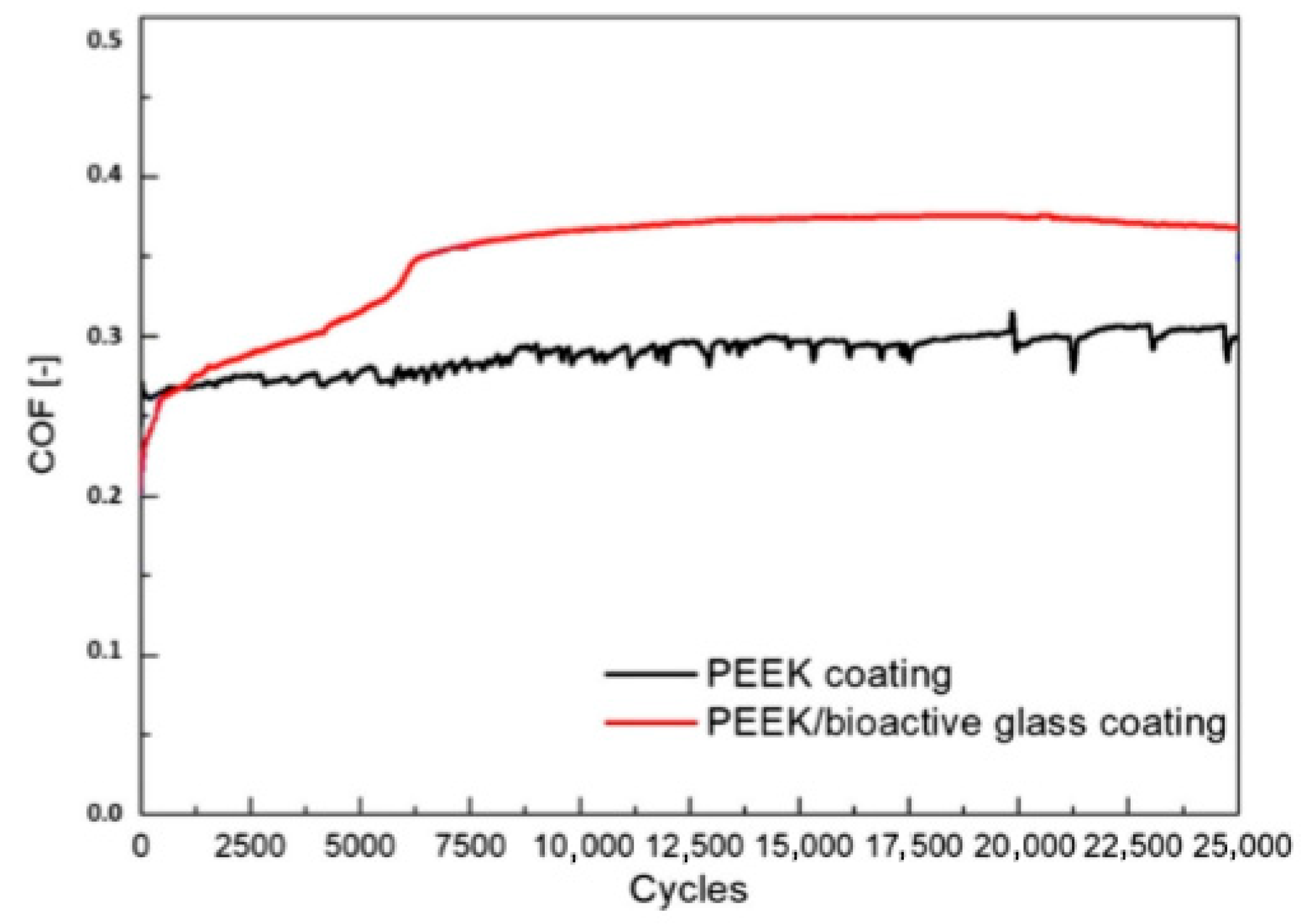

| PEEK-BG | 0.21–0.36 | - | Medical devices | Electrophoretic deposition fabrication | 2020 | [69] |

| PEEK-graphite | 0.09–0.11 | - | Medical devices | Electrophoretic deposition fabrication | 2020 | [70,109] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Sun, R.; Xiao, B.; Zhang, B.; Shi, T.; Zhao, W.; Cui, L.; Liaw, P.K. Research Progress on Polyether Ether Ketone (PEEK) Composite Coatings: A Review. Coatings 2025, 15, 1128. https://doi.org/10.3390/coatings15101128

Wang X, Sun R, Xiao B, Zhang B, Shi T, Zhao W, Cui L, Liaw PK. Research Progress on Polyether Ether Ketone (PEEK) Composite Coatings: A Review. Coatings. 2025; 15(10):1128. https://doi.org/10.3390/coatings15101128

Chicago/Turabian StyleWang, Xin, Rongyu Sun, Bingjie Xiao, Bo Zhang, Tingting Shi, Wenqi Zhao, Li Cui, and Peter K. Liaw. 2025. "Research Progress on Polyether Ether Ketone (PEEK) Composite Coatings: A Review" Coatings 15, no. 10: 1128. https://doi.org/10.3390/coatings15101128

APA StyleWang, X., Sun, R., Xiao, B., Zhang, B., Shi, T., Zhao, W., Cui, L., & Liaw, P. K. (2025). Research Progress on Polyether Ether Ketone (PEEK) Composite Coatings: A Review. Coatings, 15(10), 1128. https://doi.org/10.3390/coatings15101128