Abstract

The Chengyang City (城阳城) site in Xinyang, Henan Province, China, was a significant northern military stronghold of the Chu state during the Warring States period (475/403–221 BCE). The lacquered armor unearthed from Tomb M18 provides critical material evidence for studying ancient military technology and lacquer craftsmanship. In this study, a comprehensive analytical approach combining ultra-depth optical microscopy, Fourier-transform infrared spectroscopy (FTIR), confocal micro-Raman spectroscopy, scanning electron microscopy coupled with energy-dispersive X-ray spectroscopy (SEM-EDS) and pyrolysis–gas chromatography/mass spectrometry (Py-GC/MS) were employed to systematically characterize the structural and compositional features of the armor samples. The results indicate that the armor was constructed with a leather substrate and lacked any lacquer ash layer, while the surface exhibited multiple layers of mixed laccol and urushiol-based lacquer coatings. Cinnabar (HgS) was identified as the primary red pigment, and no carbon black or iron-based blackening agents were detected in the dark lacquer layers. Notably, the presence of laccol suggests that such lacquer resources may have also been produced in mainland China, offering new perspectives on the prevailing view that associates laccol exclusively with “Vietnamese lacquer.” This study elucidates the technological characteristics of mid-Warring States period lacquered armor, provides scientific insights into ancient lacquering techniques, and contributes valuable data for the conservation and restoration of similar cultural heritage artifacts.

1. Introduction

Lacquerware represents a distinctive category of organic composite materials within East Asian traditional culture, with origins that can be traced back to the Neolithic period (circa 6000 BCE) [1]. China is recognized as the earliest civilization to invent and systematically utilize natural lacquer [2,3,4], gradually establishing a sophisticated lacquering tradition over thousands of years. Lacquer technology was extensively applied across diverse domains, including daily utensils, ritual vessels, religious artifacts, and military equipment [5,6,7]. In the context of military protective gear, the application of lacquer not only substantially enhanced the durability and decorative qualities of objects but also conveyed functions related to identity [8,9,10], hierarchical status, and cultural symbolism, reaching its zenith during the Warring States period and the Han dynasty. Among these applications, lacquered armor stood out as an exemplary artifact that combined structural integrity, protective functionality, and aesthetic refinement, reflecting the profound integration of lacquering techniques with military practices (Figure 1).

Figure 1.

Lacquered leather armor from the Warring States Chu state, excavated from the Tomb of Marquis Yi of Zeng (Hubei Provincial Museum, China).

Compared with the systematic research on wooden-body and fabric-laminated lacquerware (jiazhutai, 夹纻胎), scientific analyses of lacquered armor constructed with leather and other organic substrates remain relatively limited. On the one hand, such artifacts are highly susceptible to deterioration during prolonged burial, which often leads to severe structural fragmentation and severely compromised preservation. These conditions pose considerable challenges for both sample acquisition and analytical investigation. On the other hand, lacquered leather armor displays distinctive technological characteristics, including complex layering sequences, specific material compositions, pigment selection strategies, and particular requirements for substrate identification. These features necessitate comprehensive characterization through advanced scientific methodologies. Furthermore, recent studies have shown that the catechol composition within lacquer films can serve as a robust chemical proxy for tracing the provenance of lacquer resources, laying a promising foundation for the development of archaeological lacquer chemistry as an emerging subfield. This approach offers critical indicators for evaluating ancient manufacturing practices, technological systems, and the circulation of raw materials [11,12].

This study focuses on a relatively well-preserved fragment of lacquered leather armor (sample no. 103-12) excavated from Tomb M18 at the Chengyang City site in Xinyang, Henan Province, central China [13,14,15,16]. A comprehensive suite of analytical techniques—including ultra-depth optical microscopy, scanning electron microscopy coupled with energy-dispersive X-ray spectroscopy (SEM-EDS), Fourier-transform infrared spectroscopy (FTIR), confocal micro-Raman spectroscopy (Raman), and pyrolysis–gas chromatography/mass spectrometry (Py-GC/MS)—were employed to systematically characterize the stratigraphic structure of the lacquer layers, material composition, pigment types, and catechol profiles. The sample measures 11.8 cm in length and 7.4 cm in width, with multiple circular perforations visible on its surface (Figure 2). The findings of this study not only enhance the technological understanding of lacquered armor production during the Warring States period in China but also provide valuable empirical evidence for reconstructing lacquer resource provenance and advancing conservation strategies for organic cultural heritage materials.

Figure 2.

Photograph of the lacquered leather armor samples: (a) lacquer film side; (b) leather substrate side.

2. Materials and Methods

2.1. Sample Preparation

Fragments of lacquered leather armor from Tomb M18 were cleaned in an ultrasonic bath with ultrapure water for 10 min; this process was repeated three times until the solution was clear. They were rinsed, air-dried, and stored overnight in a freezer below 0 °C. The next day, samples were freeze-dried in a DYYB-18 vacuum freeze dryer (Shanghai Deyang Yibang Instrument Co., Ltd., Shanghai, China) for ~48 h. Dried samples were sealed in labeled polyethylene bags and kept in a desiccator.

Epoxy resin and curing agent (Buehler, EpoThin 2, Epoxy Resin: 20-3440-128, Epoxy Hardener: 20-3442-064) were mixed at a 2:1 ratio and degassed under vacuum. Samples were placed in molds and embedded with the mixture, then cured for 24 h and demolded. Cross-sections were ground with 800-grit paper to expose the layers, followed by sequential polishing with 1000-, 1500-, 2000-, and 3000-grit papers (each applied twice). A polishing cloth was used for final finishing until the surface was smooth and free of scratches.

2.2. Analytical Methods

2.2.1. Microscopic Observation

A Zeiss Smartzoom 5 ultra-depth optical microscope (Zeiss, Jena, Germany) was used to examine the surfaces, backs, and cross-sections of the lacquer film. Observations were conducted at 34×–300× magnification with a transmitted LED stage light and ring illumination.

2.2.2. SEM-EDS Analysis

Lacquer film samples were analyzed using an Apreo S scanning electron microscope (Thermo Scientific, Waltham, MA, USA) coupled with an X-MAX20 energy-dispersive spectrometer (Oxford Instruments, Oxfordshire, UK). Dried lacquer film samples (≤1.0 cm × 1.0 cm) were sputter-coated with gold for 15 s. SEM-EDS was performed at 10 kV accelerating voltage in low-vacuum mode, with a working distance of 10–10.8 mm and 4 nm resolution. High-magnification images and elemental maps were obtained to document microstructure and composition.

2.2.3. FTIR Analysis

Fourier transform infrared (FT-IR) spectroscopy was conducted to analyze the molecular structural characteristics of the lacquer film samples using a LUMOS FT-IR spectrometer (Bruker, Bremen, Germany). A small amount of lacquer was mixed with KBr (1:200), ground, and pressed into pellets for transmission FTIR. ATR measurements were also conducted on the red lacquer of Sample 3. Residual material from the back of Sample 2 (a-1, a-2) was analyzed for comparison. Conditions: 4000–600 cm−1 range, 4 cm−1 resolution, 16 scans.

2.2.4. Raman Spectroscopy

An InVia micro-Raman spectrometer (Renishaw, Gloucestershire, UK) was employed for this purpose. Confocal micro-Raman spectra were collected on red and dark brown lacquer surfaces. Parameters: 50× objective, 785 nm laser, 1200 L/mm grating, 100–2000 cm−1 range, 10 s exposure, 1 accumulation. The laser power was set to 0.5% of the maximum output (300 mW), and the actual laser power reaching the sample surface was approximately 450 μW.

2.2.5. Py-GC/MS Analysis

Pyrolysis was performed with a PY-3030D pyrolyzer (Frontier Lab, Funabashi, Japan) coupled to a GCMS-QP2010Ultra (Shimadzu, Kyoto, Japan) using a DB-5MS UI column (20 m × 0.18 mm, 0.18 μm film). Pyrolysis furnace: 590 °C; injector and interface: 290 °C; split ratio: 1:20. Oven program: 35 °C initial, ramped to 100 °C at 60 °C/min, to 250 °C at 14 °C/min, and to 315 °C at 6 °C/min (hold 5 min). Helium carrier gas at 145.3 kPa. EI ionization at 70 eV, scanning m/z 35–500. About 0.2 mg sample with 3 μL 25% TMAH methanol was pyrolyzed after solvent absorption.

3. Results and Discussion

3.1. Structural Analysis of the Lacquered Armor

Optical microscopy revealed that the surface of the sample was covered by a relatively smooth and glossy brown lacquer film with areas of red decorative painting. The reverse side exhibited an unevenly colored, fibrous brownish network with a loose, interwoven structure and weak cohesion between the fibers, consistent with residual substrate material from the original armor. Cross-sectional observations showed that the lacquer film had a total thickness of approximately 0.27 mm. In addition to the brown residues on the back and an adjacent thicker lacquer layer (~0.07 mm), the stratigraphy comprised seven alternating brown and black layers of varying thicknesses. The thicker layers measured approximately 0.03–0.05 mm, while the thinner layers were about 0.01 mm (Figure 3). Based on these stratigraphic characteristics, it can be inferred that the armor was produced by directly applying multiple layers of lacquer onto the substrate without the use of an intermediate lacquer ash layer.

Figure 3.

Cross-section of the armor sample under (a) visible and (b) UV light; (c) labeled layers.

3.2. Analysis of the Substrate Material

The reverse side of the lacquer film exhibited unevenly distributed yellowish-brown residues with a porous, loosely bonded structure, morphologically consistent with degraded fibrous bundles. These features suggest that the material is likely residual leather substrate (Figure 4). In certain areas, the brownish residue showed substantial collagen loss, exposing a darker underlying layer with a rough, grooved surface (Figure 4).

Figure 4.

Microscopic image of brownish residue on the reverse side of the lacquer film.

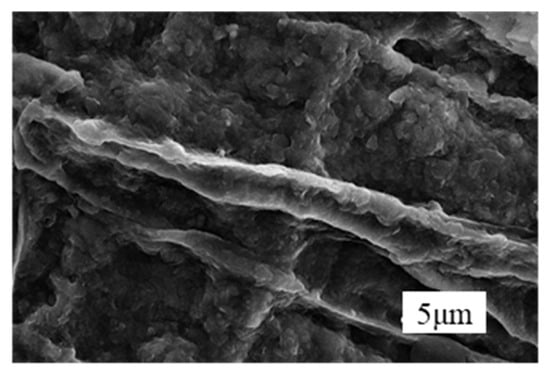

Scanning electron microscopy revealed a network of intersecting fibrous strands forming rope-like bundles, with irregular groove-like microstructures and rough concave surfaces. The fibers exhibited distinct edges and natural torsional patterns, further supporting the identification of an organic origin (Figure 5).

Figure 5.

SEM image of the brownish residue on the reverse side of the lacquer film.

FTIR analysis of residue sample displayed characteristic absorption bands at 3423 cm−1, 2973 cm−1, 2925 cm−1, and 1636 cm−1, corresponding, respectively, to O–H and N–H stretching vibrations, asymmetric stretching of C–H bonds in methyl groups, and the amide I band (Figure 6). These spectral features are partially consistent with proteinaceous materials. Although aging typically reduces the intensity of amide bands, the amide I band remains dominant in most aged protein samples. Thus, despite extensive degradation, the spectral evidence suggests the presence of protein-based components within the residue [17,18].

Figure 6.

FTIR absorption spectrum of the armor substrate.

Integrating the microscopic and spectroscopic results, it is inferred that the observed residues are derived from aged leather, confirming the use of a leather substrate in the original armor fabrication.

3.3. Lacquer Film Analysis

The FTIR spectrum of the sample’s lacquer surface (Figure 7) exhibits distinct absorption bands at 3436 cm−1, 2918 cm−1, 2850 cm−1, 1633 cm−1, and 1027 cm−1. These peaks correspond to the stretching vibrations of hydroxyl groups (O–H), methylene groups (–CH2), C=C bonds in aromatic rings, and C–O bonds, respectively (Table 1). A weaker band at 1456 cm−1 may be attributed to the deformation vibration of methylene groups on the side chains of urushiol molecules. These spectral features collectively indicate that the lacquer film was produced using raw lacquer (urushiol) [9,19].

Figure 7.

FTIR absorption spectrum of the coating lacquer.

Table 1.

FTIR spectral analysis of lacquer.

Lacquer soup is a milky-white natural emulsion exuded from the phloem of the Toxicodendron vernicifluum. It primarily comprises urushiol, laccase, polysaccharides, glycoproteins, water, and trace metal ions, forming a reactive water-in-oil biobased composite system. To optimize its physicochemical properties and application performance, lacquer soup is typically subjected to dehydration and oxidative maturation. During traditional lacquer preparation, various additives are incorporated—including tung oil (a drying oil), rosin (a natural resin), and wheat flour (a saccharide-based thickener)—which, through a series of complex polymerization and cross-linking reactions, ultimately yield a robust, three-dimensional lacquer film.

In the FTIR spectra of lacquerware, the absorption bands observed within the 1300–1000 cm−1 region are attributed to C–O stretching vibrations. The spectral intensity in this region is predominantly influenced by three major functional groups: (1) phenolic hydroxyl groups (C–OH) originating from urushiol; (2) ether linkages (C–O–C) formed through oxidative polymerization; and (3) glycosidic bonds (C–O–C) associated with lacquer polysaccharides. These characteristic vibrations provide valuable molecular-level insights into the composition and curing mechanisms of traditional lacquer films [20,21,22].

Py-GC/MS analysis further confirms urushiol as the main lacquer component, with catechols dominated by heptadecylcatechol (C17) (Figure 8a), a chemical marker typically associated with Vietnamese lacquer [23]. This is particularly notable, as the artifact was excavated from the ancient Chu state—a known lacquer-producing region of China—where the use of imported lacquer would be unexpected given the superior quality and local abundance of Chinese urushi. Additionally, evidence of wax additives was also detected (Figure 8b).

Figure 8.

RAdICAL analysis of the surface lacquer by Py-GC/MS: (a) lacquer components; (b) wax additives.

Elemental analysis of the lacquer surface via SEM-EDS revealed that carbon and oxygen together accounted for over 90% of the elemental composition, with minor amounts of Na, Ca, and Mg, further supporting the organic nature of the lacquer (Table 2). No iron was detected. Raman spectroscopy of the red and dark brown lacquer layers showed strong diagnostic peaks at 255, 288, and 345 cm−1 in the red areas, consistent with cinnabar (HgS) as the red pigment (Figure 9). In contrast, Raman spectra from the dark brown lacquer exhibited no peaks at ~1320 cm−1 and ~1580 cm−1, which are characteristic of carbon black, and instead presented smooth spectral curves, indicating the absence of added black pigments. The dark coloration is therefore attributed to the natural color of the urushiol-based lacquer rather than intentional pigmentation.

Table 2.

SEM–EDS elemental composition of the black lacquer surface.

Figure 9.

Raman spectra of cinnabar (HgS) identified in the red lacquer layer.

3.4. Technological Reconstruction

Based on the results of the aforementioned analyses, the manufacturing process of the lacquered armor unearthed from Tomb M18 at the Chengyang City site in Henan Province can be preliminarily reconstructed. The substrate was identified as animal leather, while the lacquer layers were primarily composed of natural raw lacquer (urushi). The brown and black lacquer coatings did not contain carbon-based black pigments, such as carbon black, indicating that the coloration was due to the inherent tone of urushiol. In contrast, cinnabar (HgS) was detected in the red lacquer layer, confirming its use as a red pigment.

In terms of structural layering, except for localized areas with red lacquer decoration, the sample generally featured multiple alternating applications of brown and black lacquer directly onto the leather substrate. These lacquer layers varied in thickness and surface roughness but were consistently formed using natural urushi. This multilayer lacquering method is consistent with archaeological observations of other lacquered armor pieces from the early Warring States period, suggesting a certain degree of technological continuity and standardization in lacquer armor production during this time.

3.5. Conservation Considerations

During the course of sampling and instrumental analysis, the lacquered armor specimen exhibited progressive dehydration, accompanied by observable stratification between individual lacquer layers. These signs suggest the onset of structural instability and potential future deterioration if left unaddressed. Given the fragile and dynamic state of such waterlogged organic artifacts, it is essential to consider appropriate conservation measures alongside technological investigations. Accordingly, this section outlines the current challenges and potential strategies for the preventive stabilization of lacquered leather armors post-excavation. Lacquered leather armors are typically excavated in a highly waterlogged condition, with the original organic substrate—primarily leather—often severely degraded or entirely disintegrated, rendering accurate identification and retrieval challenging. These artifacts, having been buried for extended periods in low-oxygen, high-humidity environments, exist in a state of fragile equilibrium. Upon exposure to ambient conditions, they undergo rapid and irreversible physical and chemical deterioration, particularly due to moisture loss, leading to structural collapse, lacquer delamination, surface deformation, and powdering. Immediate post-excavation intervention is therefore critical to control the drying rate and reinforce structural integrity, thereby mitigating further degradation.

Traditional conservation approaches have employed glutaraldehyde as a cross-linking agent to stabilize organic matrices by enhancing their mechanical strength. However, issues related to limited reversibility and potential chemical residues have prompted the exploration of alternative consolidants. In recent years, advanced materials specifically designed for the conservation of organic cultural heritage—such as moisture-curable polyurethane (MCPU) [24,25,26,27] and acrylic-metal complexes (AMC)—have been developed [28,29,30]. These materials exhibit improved compatibility, flexibility, and long-term stability, and have demonstrated encouraging results in preliminary applications on excavated organic artifacts.

Future work should focus on systematic evaluation of the physicochemical properties, aging behavior, and field applicability of these novel materials. Furthermore, the establishment of a standardized conservation framework tailored to the diverse material states of organic archaeological objects will be essential for improving the scientific rigor and effectiveness of conservation practices.

4. Conclusions

This study conducted detailed morphological observations and material analyses on a lacquered armor fragment unearthed from Tomb M18 at the Chengyang City site in Xinyang, Henan Province. The following conclusions can be drawn:

- (1)

- The lacquered armor sample is generally well-preserved in shape; however, the lacquer surface exhibits typical signs of aging, including warping, blistering, fragmentation, and cracking, indicating significant physical deterioration during burial.

- (2)

- The substrate was identified as animal leather. The remaining fibrous material on the reverse side shows uneven coloration, a loose and degraded structure, and a rough, furrowed appearance at the base lacquer layer, all of which point to a high degree of degradation.

- (3)

- The brown and black lacquer layers display coloration consistent with the natural tone of raw lacquer (urushi), with no evidence of added carbon-based black pigments. Cinnabar (HgS) was identified as the red pigment in localized red lacquer layers. Combined results from FTIR, Raman spectroscopy, and Py-GC/MS confirm that natural raw lacquer was the primary film-forming material.

- (4)

- Structurally, the armor was produced by repeatedly applying alternating brown and black lacquer layers directly onto the leather substrate. The lacquer layers differ in thickness and texture, with selective application of red decorative coatings. This multilayer lacquering approach not only enhanced the mechanical strength and protective function of the armor but also reflects a high degree of technological continuity and standardization in lacquered armor production during the Warring States period.

The lacquered armor sample analyzed in this study revealed a catechol profile dominated by C17 dihydroxybenzenes, a chemical signature commonly regarded as indicative of Vietnamese lacquer. However, considering the archaeological context and the abundance of native lacquer resources in the Chu region, it is unlikely that this artifact was produced using lacquer imported from Vietnam. Therefore, this study questions the general validity of C17 catechols as definitive markers of Vietnamese lacquer and proposes further systematic research on regional lacquer chemotaxonomy to refine the provenance identification framework for ancient lacquer materials.

Author Contributions

Conceptualization, X.L., Z.W. and Y.Q.; methodology, X.L.; software, M.C. and Z.C.; validation, Z.W. and M.C.; investigation, L.G. and Z.Z.; resources, Z.W. and Y.Q.; data curation, M.C., Z.C. and K.F.; writing—original draft preparation, X.L.; writing—review and editing, Z.W. and Y.Q.; visualization, X.L.; supervision, Y.Q.; project administration, Y.Q.; funding acquisition, X.L. and Y.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key R&D Program of China (Grant No. 2022YFF0904100), the National Social Science Fund of China (Project No. 22BKG015), the National Natural Science Foundation of China (Grant No. 52203126), Archaeological Talent Promotion Program of China (2025-207), Major Science and Technology Project of Gansu Province (25ZDFA014) and the Shaanxi Province Youth Science and Technology Rising Star Project (Grant No. 2024ZC-KJXX-033).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets used and analysed during the current study are available from the first author upon reasonable request.

Acknowledgments

The authors have reviewed and edited the output and take full responsibility for the content of this publication. The authors sincerely thank Zhao Xing from the School of Cultural Heritage, Northwest University, and Associate Research Fellow Wang Na from the Palace Museum for their valuable guidance and technical support during the course of this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, Z.; Li, X.; Yu, J.; Sun, Y.; Geng, J.; Zhao, X. The Lacquer Craft of the Corridor Coffin (徼道棺) from Tomb No. 2 of Tushan in Eastern Han Dynasty, Xuzhou. Coatings 2024, 14, 1222. [Google Scholar] [CrossRef]

- Zhai, K.; Sun, G.; Zheng, Y.; Wu, M.; Zhang, B.; Zhu, L.; Hu, Q. The earliest lacquerwares of China were discovered at Jingtoushan site in the Yangtze River Delta. Archaeometry 2022, 64, 218–226. [Google Scholar] [CrossRef]

- Hidaka, K.; Werhahn, S.Y. Lacquerware as a Global Commodity: Distribution and Imitation of Maki-e. In Japanese Art—Transcultural Perspectives; Brill: Leiden, The Netherlands, 2024; pp. 279–303. [Google Scholar]

- Sangchel, S. A study on the inflow routes and utilization of East Asian lacquerware in the art market of France during the 17th and 18th centuries. Misuljaryo-Natl. Mus. Korea Art J. 2022, 102, 38–64. [Google Scholar]

- Hong, S. A review of a century of archaeological research on ancient Chinese lacquerware. South. Cult. Relics 2021, 4, 48–54. [Google Scholar]

- Romero, R.; Illán, A.; Bondía, C. Three studies of luxury Mexican lacquer objects from the 16th to the 19th centuries: Analysis of materials and pictorial techniques. Heritage 2023, 6, 3590–3605. [Google Scholar] [CrossRef]

- Wu, F.; Zhang, L.; Chen, J. A study on the manufacturing process of Song Dynasty lacquerware with circle-overlapping method. In Collection of Papers on Museum Scientific Research; Chengyuan, M., Ed.; Shanghai Science and Technology Literature Press: Shanghai, China, 1996; p. 460. [Google Scholar]

- Lu, R.; Honda, T.; Kamiya, Y.; Yoshida, K.; Miyakoshi, T. Analysis of Japanese Jōmon lacquerware by pyrolysis-gas chromatography/mass spectrometry. J. Anal. Appl. Pyrolysis 2013, 103, 68–72. [Google Scholar] [CrossRef]

- Park, J.; Choi, J.; Lee, U.; Kang, M.; Kim, S. Lacquer techniques in the late Joseon dynasty. J. Korean Wood Sci. Technol. 2023, 51, 69–80. [Google Scholar] [CrossRef]

- Norman, J. Lacquer: Technology and Conservation: A Comprehensive Guide to the Technology and Conservation of Asian and European Lacquer; Archetype Publications: London, UK, 2006. [Google Scholar]

- He, H.P.; Hu, T. Exploration on the Development of Ancient Armor; Capital Museum Forum: Beijing, China, 2014; pp. 9–15. [Google Scholar]

- Zhang, Y.; Xu, J.J. Analysis of the manufacturing technology of Warring States lacquered leather armor unearthed in Nanyang, Henan. Jianghan Archaeol. 2014, S1, 135–143. [Google Scholar]

- Rong, B.; Zhao, Q.; Wu, Z.-J.; Zheng, H.; Zhao, J.; Luo, H.-J.; Li, Q.; Ma, Y.-R. Scientific research on painted pottery from the Warring States Chu tomb at Chengyangcheng site, Xinyang, Henan. Sci. Conserv. Archaeol. 2018, 30, 9–14. [Google Scholar]

- Feng, D.J.; Wu, Z.J.; Zhao, J.F.; Li, J.J. Study on wood materials from Tomb No. 8 at Chengyangcheng site, Xinyang, Henan. J. Northwest For. Univ. 2017, 32, 245–248. [Google Scholar]

- Jia, L.M.; Wu, Z.J.; Zhang, L.; Lu, H.W.; Ma, M. Major achievements of archaeological work at Chengyangcheng site, Xinyang City, Henan from 2009 to 2011. Huaxia Archaeol. 2014, 2, 3–9. [Google Scholar]

- Wu, Z.J.; Nie, F.; Ren, X.; Ma, M.; Kou, J.; Jia, L. Excavation brief of Tomb No. 8 at Chengyangcheng site, Xinyang City, Henan. Huaxia Archaeol. 2020, 4, 24–45. [Google Scholar]

- Li, Y.H.; Yang, L.; Ge, R.C. Interaction and stability of protein-based mixed adhesives in painted cultural relics. Spectrosc. Spectr. Anal. 2024, 44, 1946–1951. [Google Scholar]

- Zhang, C.; Ge, R.; Yang, J.; Huang, J.; Dou, H.; Li, X.; Yang, L. The forgotten framework: Analysis of organic residues on Bronze Harness Ornaments of Shang and Western Zhou Dynasties unearthed at Xitou site in Shaanxi, China. npj Herit. Sci. 2025, 13, 9. [Google Scholar] [CrossRef]

- Wang, R.; Nie, F.; Chen, J.M.; Zhu, Y. Studies on lacquerwares from between the mid-Warring States period and the mid-Western Han dynasty excavated in the Changsha region. Archaeometry 2017, 59, 547–565. [Google Scholar] [CrossRef]

- Colomban, P.; Mancini, D. Lacquerware pigment identification with fixed and mobile raman microspectrometers: A potential technique to differentiate original/fake artworks. Arts 2013, 2, 111–123. [Google Scholar] [CrossRef]

- Niimura, N.; Miyakoshi, T. Structural study of oriental lacquer films during the hardening process. Talanta 2006, 70, 146–152. [Google Scholar] [CrossRef]

- Frade, J.C.; Ribeiro, M.I.; Graça, J.; Rodrigues, J. Applying pyrolysis-gas chromatography/mass spectrometry to the identification of oriental lacquers: Study of two lacquered shields. Anal. Bioanal. Chem. 2009, 395, 2167–2174. [Google Scholar] [CrossRef]

- Ebert, B.; Schilling, R.M. A technical analysis of paint media used in twentieth-century Vietnamese lacquer paintings. Stud. Conserv. 2016, 61 (Suppl. S3), 52–67. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, L.; Guo, L.; Ma, Y.; Wang, Z.; Niu, Q.; Zheng, L. Synthesis and thermal decomposition kinetics of moisture curable polyurethane films as a reinforcing material for cultural relics. Sci. Rep. 2020, 10, 21724. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, L.; Guo, L.; Ma, Y.; Wang, Z.; Niu, Q. The effect of a hindered amine light stabilizer on the aging behavior of moisture-curable polyurethane as a cultural relics consolidant. Polimery 2020, 65, 297–303. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, L.; Zhao, X.; Qian, Y.; Tang, Y.; Dong, X. Synthesis, testing and application of moisture-curable polyurethane as a consolidant for fragile organic cultural objects. J. Adhes. Sci. Technol. 2018, 32, 2421–2428. [Google Scholar] [CrossRef]

- Zhao, X.; Li, X.Z.; Xie, X.W.; Wang, L.Q.; Guo, L.; Leng, X.; Niu, Q. Performance characterization of moisture-curable polyurethane for cultural relic reinforcement. Appl. Chem. Ind. 2025, 54, 821–825. [Google Scholar]

- Huang, X.; Chen, J.C.; Chen, S.Y.; Shen, C.Y. Microstructure and interaction of soil matrix reinforced by a novel material. Appl. Mech. Mater. 2012, 174–177, 954–957. [Google Scholar] [CrossRef]

- Chen, J.; Mai, Y.; Chen, L.; Zhang, L.; Cui, X.; Liu, X. Evaluation of Surface Stabilization and Reinforcement Effect of Fragile Bronzes. J. Phys. Conf. Ser. 2024, 2706, 012019. [Google Scholar]

- Chen, J.C.; Huang, X.; Liu, H.W.; Zhu, R.S. Reinforcement experiment of Dazu Grotto sandstone samples with acrylate complex sol. Cult. Herit. Conserv. 2015, 38–42. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).