Investigation of the Structure and Properties of MoS2 Coatings Obtained by Electrospark Alloying

Abstract

1. Introduction

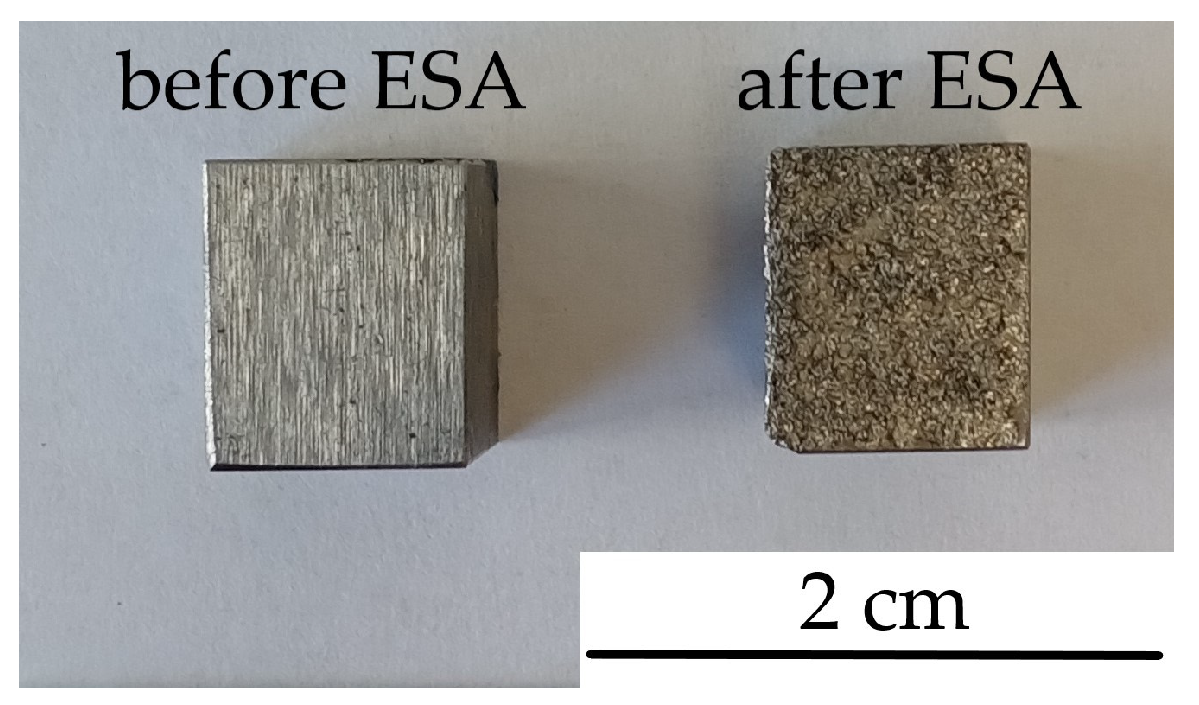

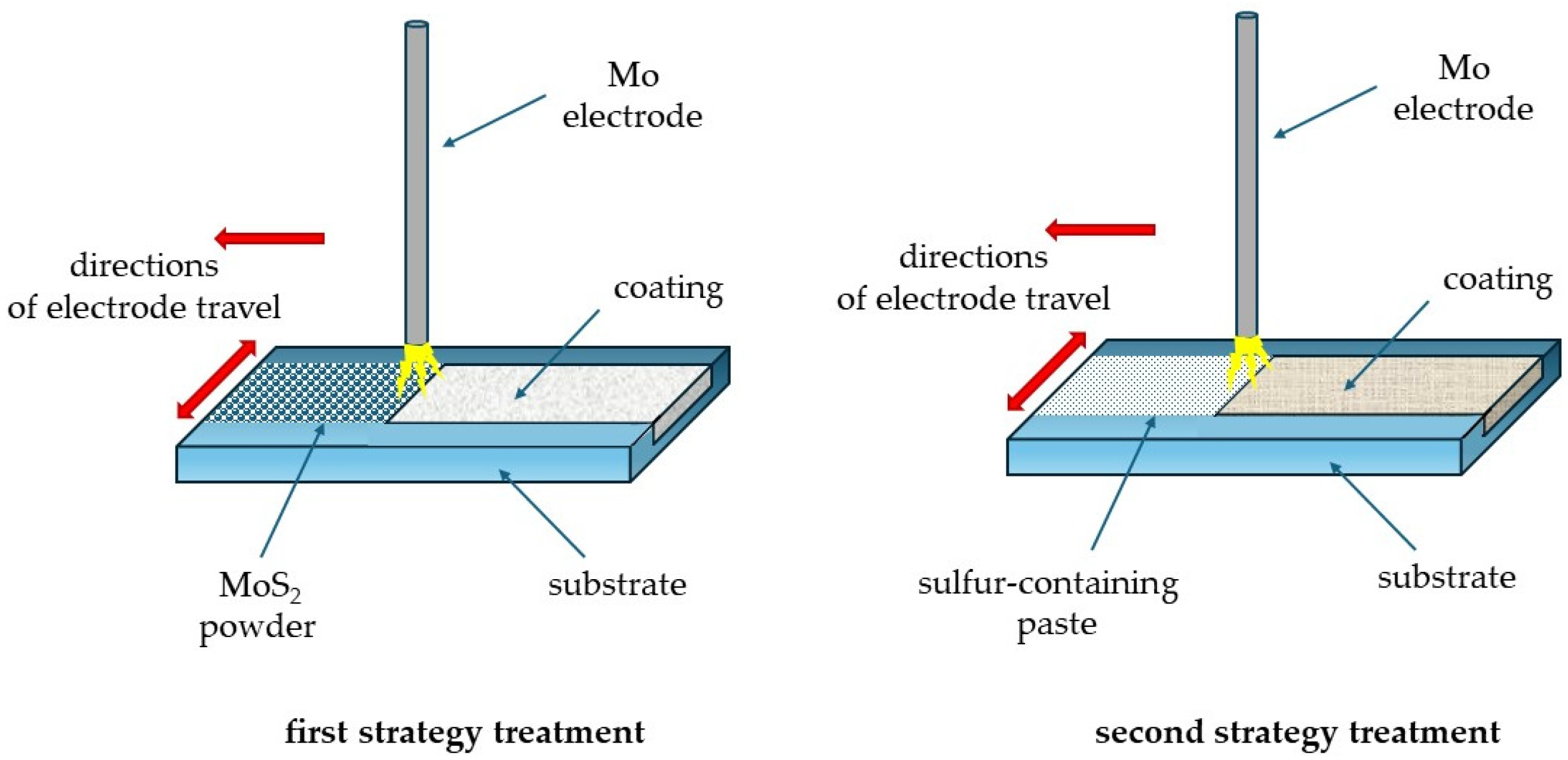

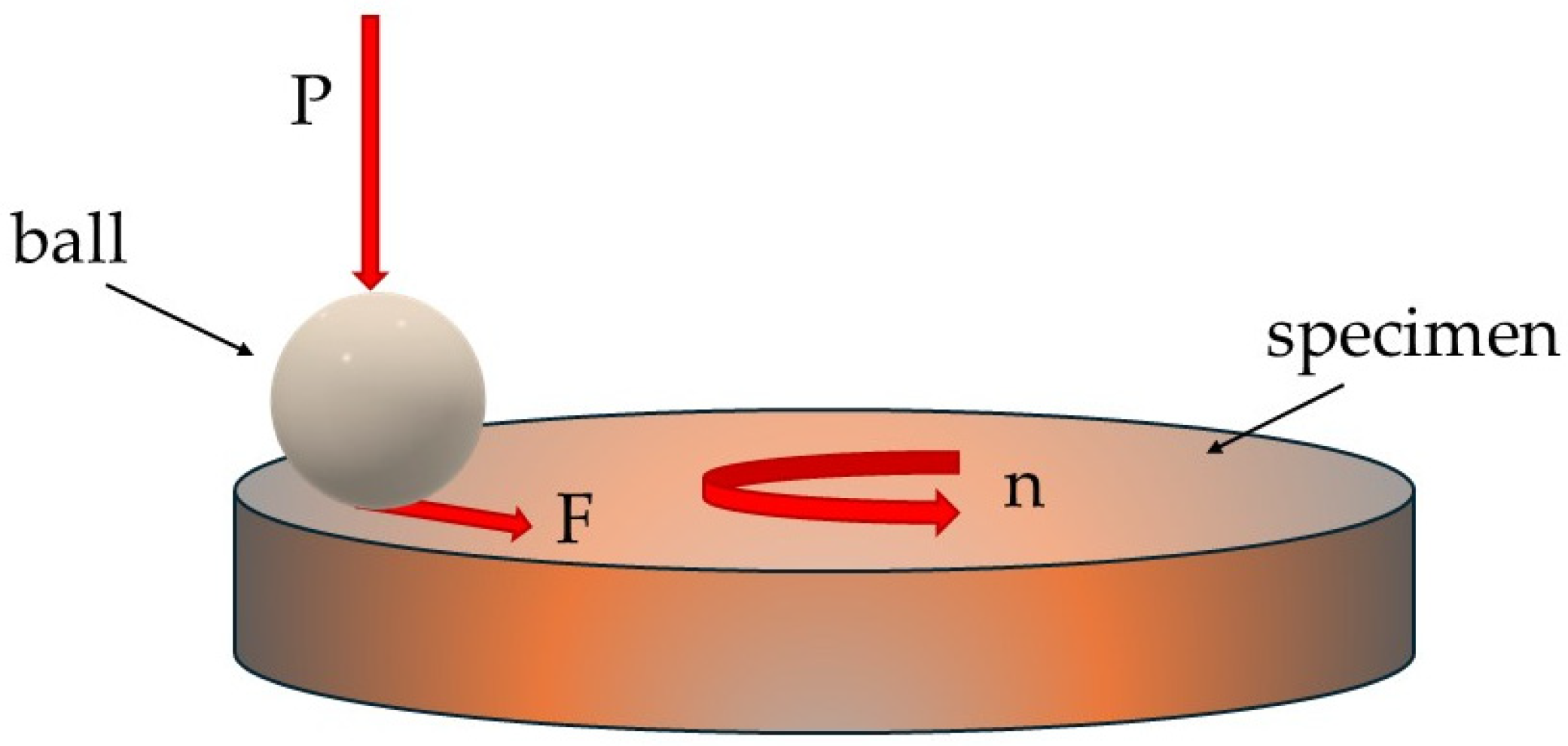

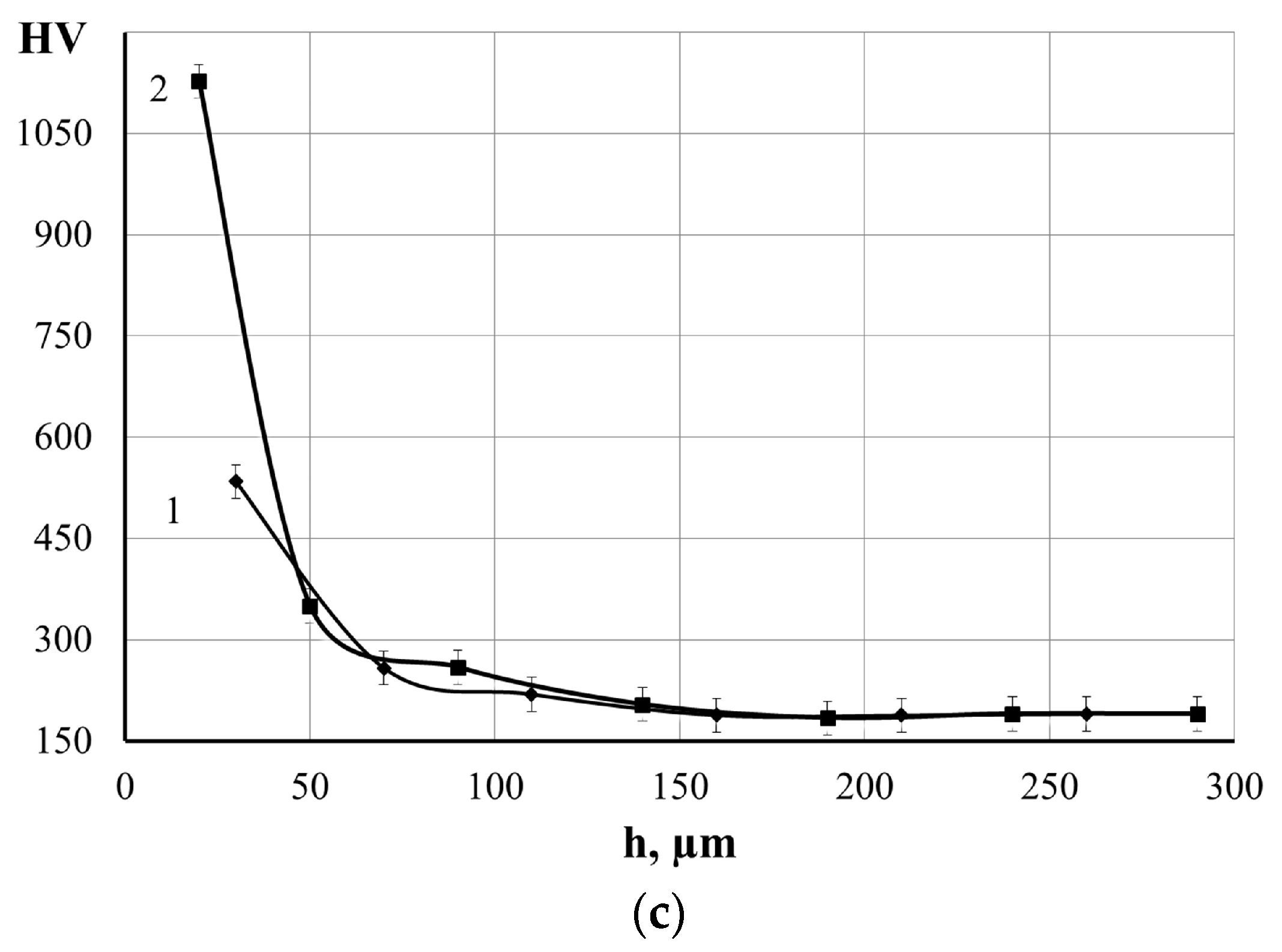

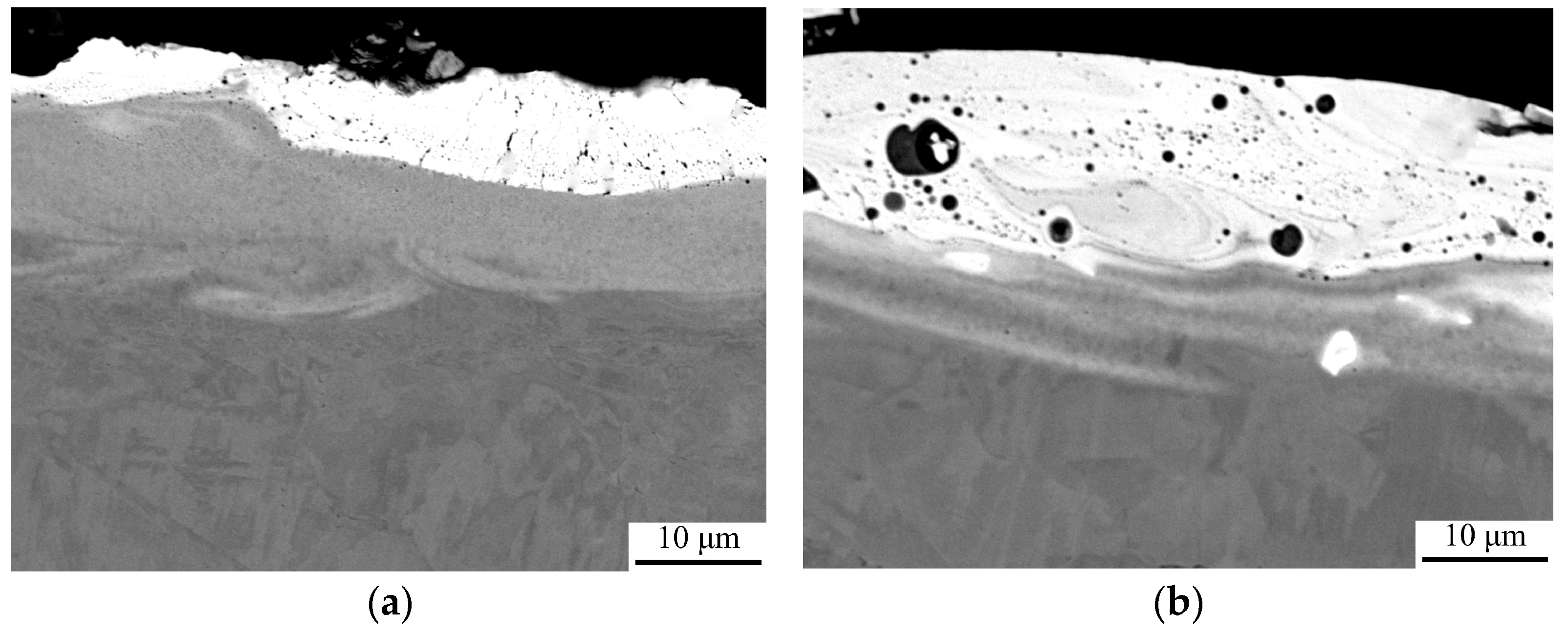

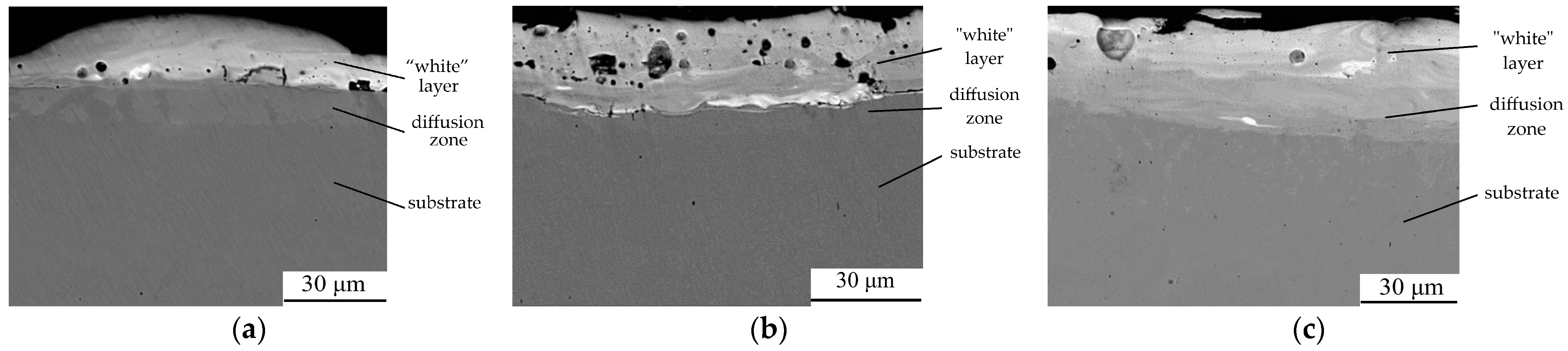

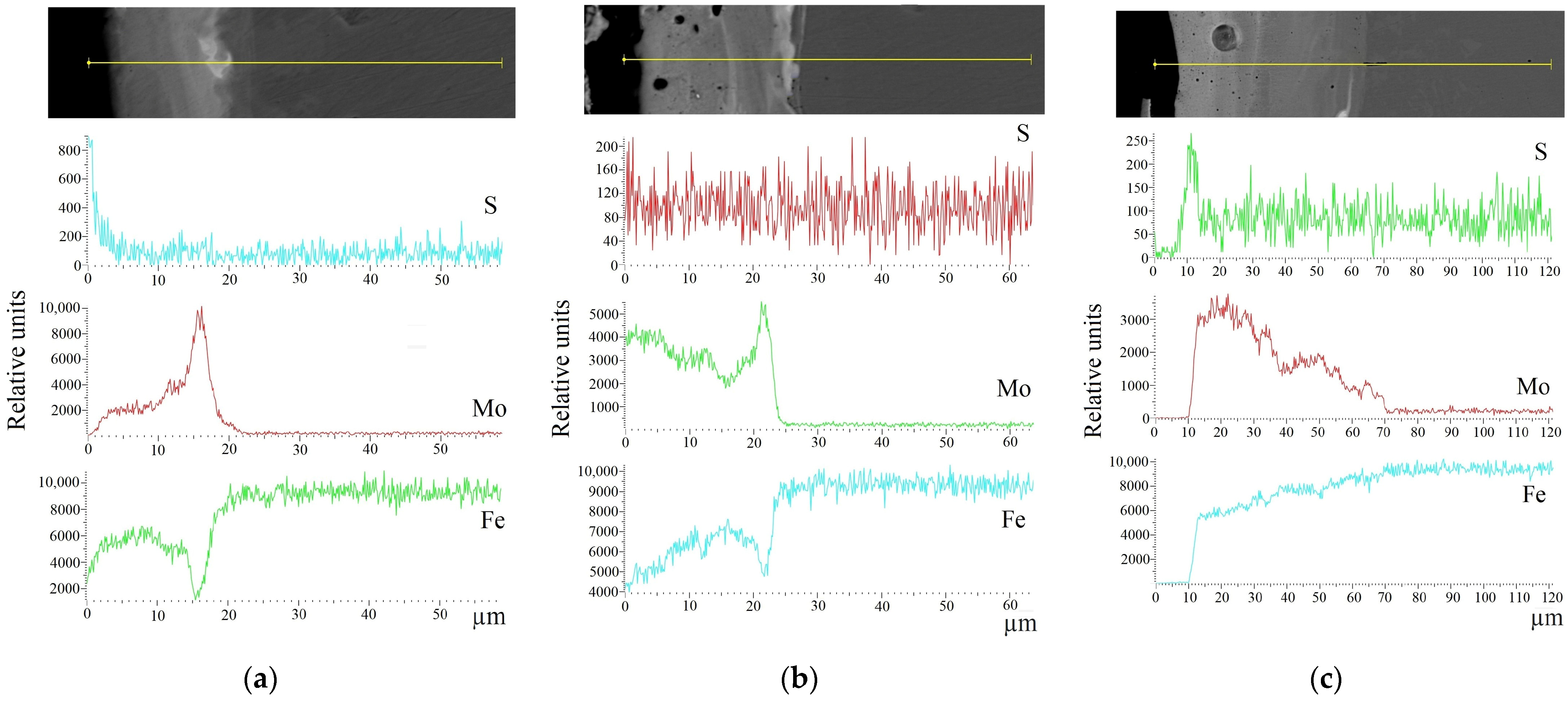

2. Materials and Methods

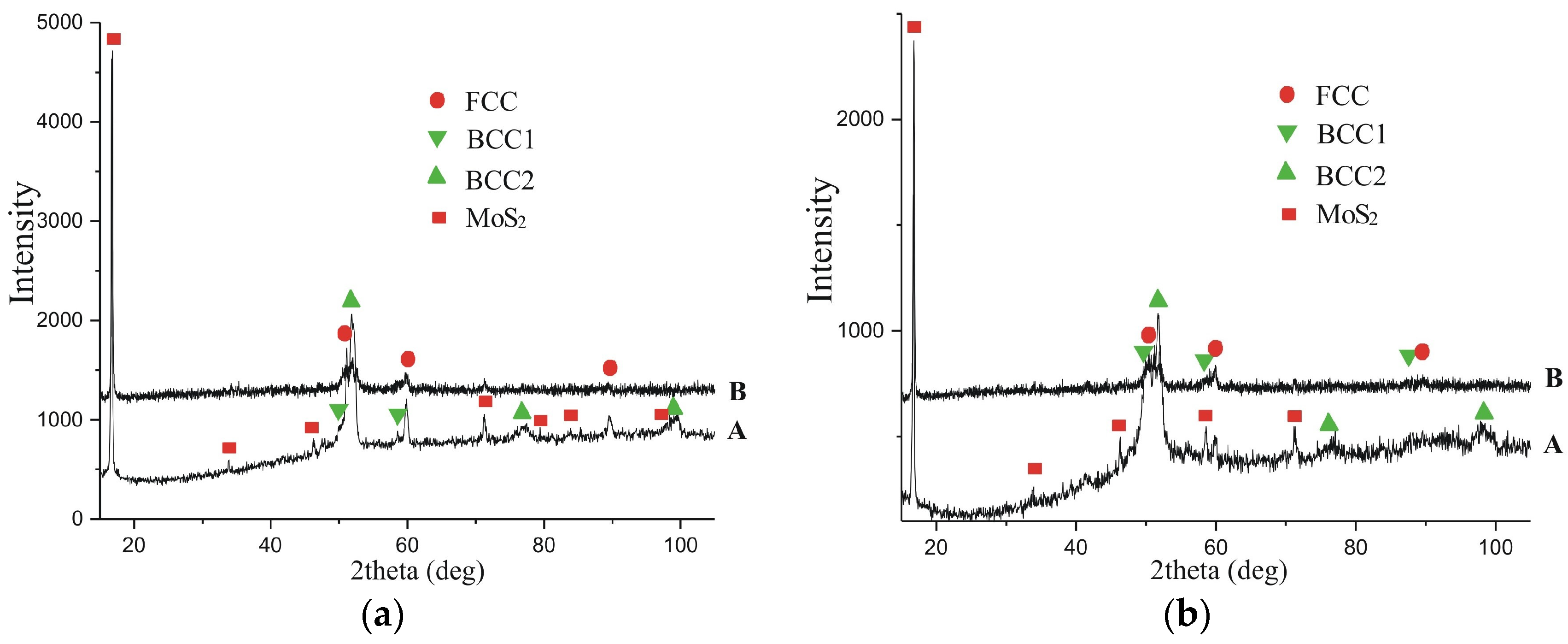

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Roik, T.A.; Gavrysh, O.A.; Vitsiuk, I.I.; Kholiavko, V.V. Wear-Resistant Composites Produced from Tool Steel Waste for Contact Joints of High-Speed Printing Machines. Powder Metall. Met. Ceram. 2023, 62, 215–224. [Google Scholar] [CrossRef]

- Hlushkova, D.B.; Bagrov, V.A.; Volchuk, V.M.; Murzakhmetova, U.A. Influence of structure and phase composition on wear resistance of sparingly alloyed alloys. Funct. Mater. 2023, 30, 74–78. [Google Scholar] [CrossRef]

- Martsinkovsky, V.; Yurko, V.; Tarelnik, V.; Filonenko, Y. Designing radial sliding bearing equipped with hydrostatically suspended pads. Procedia Eng. 2012, 39, 157–167. [Google Scholar] [CrossRef]

- Tarelnyk, V.; Konoplianchenko, I.; Martsynkovskyy, V.; Zhukov, A.; Kurp, P. Comparative tribological tests for face impulse seals sliding surfaces formed by various methods. In Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2019; pp. 382–391. [Google Scholar] [CrossRef]

- Martsinkovsky, V.; Yurko, V.; Tarelnik, V.; Filonenko, Y. Designing thrust sliding bearings of high bearing capacity. Procedia Eng. 2012, 39, 148–156. [Google Scholar] [CrossRef]

- Halchuk, T.N.; Povstyanoy, O.Y.; Bembenek, M.; Redko, R.G.; Chetverzhuk, T.I.; Polinkevych, R.M. Impact of technological system’s characteristics on the machining accuracy of bearing rings. J. Eng. Sci. 2023, 10, A22–A30. [Google Scholar] [CrossRef] [PubMed]

- Wasilczuk, M.; Wodtke, M. Experimental study on the feasibility of alternative materials for tilting pad thrust bearings operating in transition to mixed friction. Friction 2024, 12, 812–822. [Google Scholar] [CrossRef]

- Joseph, A.; Vijayan, A.S.; Shebeeb, M.C.; Akshay, K.S.; Mathew, K.P.J.; Sajith, V. A review on tailoring the corrosion and oxidation properties of MoS2-based coatings. J. Mater. Chem. A 2023, 7, 3172–3209. [Google Scholar] [CrossRef]

- Antoszewski, B.; Kurp, P. Effect of Surface Texture on the Sliding Pair Lubrication Efficiency. Lubricants 2022, 10, 80. [Google Scholar] [CrossRef]

- Bouti, S.; Antonova, M.N.; Hamouda, K.; Babichev, A.P.; Sayah, T. Structure and Mechanochemical Properties of the MoS2 Solid Lubricant Using Vibration Wave Treatment. Mater. Sci. 2018, 53, 739–749. [Google Scholar] [CrossRef]

- Martin, P.M. Handbook of Deposition Technologies for Films and Coatings; William Andrew Publishing: Boston, MA, USA, 2010; pp. 1–912. [Google Scholar]

- Seynstahl, A.; Köbrich, M.; Rosnitschek, T.; Göken, M.; Tremmel, S. Enhancing the lifetime and vacuum tribological performance of PVD-MoS2 coatings by nitrogen modification. Surf. Coat. Technol. 2024, 477, 130343. [Google Scholar] [CrossRef]

- Altuntepe, A.; Erkan, S.; Karadeniz, G. Large-scale synthesis of homogeneous WS2 films by physical vapor deposition. Eurasian J. Sci. Eng. Technol. 2023, 4, 36–41. [Google Scholar] [CrossRef]

- Bozheyev, F.; Friedrich, D.; Nie, M.; Rengachari, M.; Ellmer, K. Preparation of highly (001)-oriented photoactive tungsten diselenide (WSe2) films an amorphous solid-liquidcrystalline solid (aSLcS) rapid-crystallization process. Phys. Status Solidi A 2014, 211, 2013–2019. [Google Scholar] [CrossRef]

- Nozhenkov, M.V. The Ultra-Low Friction of Layer Structures. Mech. Eng. Res. 2013, 3, 73–89. [Google Scholar] [CrossRef][Green Version]

- Poyraz, M.; Tunay, R.F. The effect of different sputtering parameters on coating thickness and hardness in MoS2 coated films with and without interlayer. Int. J. Surf. Sci. Eng. 2020, 14, 117–134. [Google Scholar] [CrossRef]

- Lu, X.; Sui, X.; Zhang, X.; Yan, Z.; Hao, J. Influence of V doping on the microstructure, chemical stability, mechanical and tribological properties of MoS2 coatings. Ind. Lubr. Tribol. 2024, 76, 29–40. [Google Scholar] [CrossRef]

- Torres, H.; Vuchkovb, T.; Slawikc, S.; Gachotd, C.; Prakashb, B.; Ripoll, M.R. Self-lubricating laser claddings for reducing friction and wear from room temperature to 600 °C. Wear 2018, 408–409, 22–33. [Google Scholar] [CrossRef]

- Yao, Y.H.; Wu, Y.C.; Zhang, Z.Y.; Zhu, H.; Hu, M.N.; Xu, K.; Liu, Y. Enhancement of frictional properties of Ni-MoS2 self-lubricating composite coatings by microgroove arrays. Appl. Surf. Sci. 2022, 605, 154635. [Google Scholar] [CrossRef]

- Li, S.; Zhao, X.; An, Y.; Liu, D.; Zhou, H.; Chen, J. YSZ/MoS2 self-lubricating coating fabricated by thermal spraying and hydrothermal reaction. Ceram. Int. 2018, 44, 17864–17872. [Google Scholar] [CrossRef]

- Liu, T.X.; Guo, C.A.; Lu, F.S.; Zhang, X.Y.; Zhang, L.; Wang, Z.J.; Xu, Z.Y.; Zhu, G.L. Influence of deposition voltage on tribological properties of W-WS2 coatings deposited by electrospark deposition. Chalcogenide Lett. 2023, 20, 741–749. [Google Scholar] [CrossRef]

- Yue, M.; Zhao, W.; Wang, S.; Li, J.; Zhu, C.; Jin, H.; Guo, C. Tribological properties of electrospark depositing Ni-WS2 self-lubricating coating. Chalcogenide Lett. 2021, 18, 557–564. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, M.; Dai, S.; Zhu, L. Research Progress in Electrospark Deposition Coatings on Titanium Alloy Surfaces: A Short Review. Coatings 2023, 13, 1473. [Google Scholar] [CrossRef]

- Antoszewski, B.; Gaponova, O.P.; Tarelnyk, V.B.; Myslyvchenko, O.M.; Kurp, P.; Zhylenko, T.I.; Konoplianchenko, I. Assessment of Technological Capabilities for Forming Al-C-B System Coatings on Steel Surfaces by Electrospark Alloying Method. Materials 2021, 14, 739. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.L.; Chen, X.M.; Chen, L.; Wang, Z.J.; Hou, G.C.; Guo, C.A.; Zhang, J. Influence of temperature on tribological behavior of AlCoCrFeNi coatings prepared by electrospark deposition. Dig. J. Nanomater. Biostructures 2023, 18, 145. [Google Scholar] [CrossRef]

- Tarelnyk, V.B.; Gaponova, O.P.; Loboda, V.B.; Konoplyanchenko, E.V.; Martsinkovskii, V.S.; Semirnenko, Y.I.; Tarelnyk, N.V.; Mikulina, M.A.; Sarzhanov, B.A. Improving Ecological Safety when Forming Wear-Resistant Coatings on the Surfaces of Rotation Body Parts of 12Kh18N10T Steel Using a Combined Technology Based on Electrospark Alloying. J. Surf. Eng. Appl. Electrochem. 2021, 2, 173–184. [Google Scholar] [CrossRef]

- Geng, C.X.; Zhang, H.X.; Li, X.J.; Geng, H.B. Elevated temperature tensile behaviour of 5183 aluminium alloy made by electrospark deposition additive manufacturing. Mater. Sci. Eng. A 2023, 868, 144746. [Google Scholar] [CrossRef]

- Myslyvchenko, O.M.; Gaponova, O.P.; Tarelnyk, V.B.; Krapivka, M.O. The Structure Formation and Hardness of High-Entropy Alloy Coatings Obtained by Electrospark Deposition. Powder Metall. Met. Ceram. 2020, 59, 201–208. [Google Scholar] [CrossRef]

- Cao, T.; Lei, S.; Zhang, M. The friction and wear behavior of Cu/Cu-MoS2 self-lubricating coating prepared by electrospark deposition. Surf. Coat. Technol. 2015, 270, 24–32. [Google Scholar] [CrossRef]

- Guo, C.; Kong, F.; Zhao, S.; Yan, X.; Yang, J.; Zhang, J. Performance of friction and wear of electrospark deposited ni-MoS2 self-lubricating coating. Chalcogenide Lett. 2019, 16, 309–315. [Google Scholar]

- Kiryukhantsev-Korneev, P.V.; Sheveyko, A.N.; Shvindina, N.V.; Levashov, E.A.; Shtansky, D.V. Comparative study of Ti-C-Ni-Al, Ti-C-Ni-Fe, and Ti-C-Ni-Al/Ti-C-Ni-Fe coatings produced by magnetron sputtering, electro-spark deposition, and a combined two-step process. Ceram. Int. 2018, 44, 7637–7646. [Google Scholar] [CrossRef]

- Tarelnyk, N. The Method of Eliminating Adhesion of Electrodes during Electrospark Alloying of Steel Parts of Equipment Subject to Radiation Exposure. Patent of Ukraine for Utility Model No. 155134: MPK (2006), B23P 6/00, B23H 1/00, C23C 28/00, 17 January 2024. Bull. No. 3. Available online: https://base.uipv.org/searchINV/search.php?action=viewdetails&IdClaim=287836 (accessed on 15 February 2024).

- Wang, J.M.; Liu, G.H.; Fang, Y.L.; Li, W.K. Marangoni effect in nonequilibrium multiphase system of material processing. Rev. Chem. Eng. 2016, 32, 551–585. [Google Scholar] [CrossRef]

- Tuo, Y.; Yang, Z.; Guo, Z.; Chen, Y.; Hao, J.; Zhao, Q.; Kang, Y.; Zhang, Y.; Zhao, Y. Pore structure optimization of MoS2/Al2O3 self-lubricating ceramic coating for improving corrosion resistance. Vacuum 2023, 207, 111687. [Google Scholar] [CrossRef]

- Borysov, Y.S.; Vihilianska, N.V.; Burlachenko, O.M.; Olevska, L.P.; Lopata, V.M. Analysis of modern experience in development of sealing coatings for parts of gas turbine engines (Review). Autom. Weld. 2022, 4, 41–49. (In Ukraine) [Google Scholar] [CrossRef]

- Boichyshyn, L.; Kovbuz, M.; Kulyk, Y.; Nosenko, V. Influence of the melt cooling rate of the structure on the alloyed iron based amorphous alloys with different form. Proc. Shevchenko Sci. Soc. Chem. Sci. 2015, 42, 101–108. [Google Scholar]

- Houserová, J.; Vřešťál, J.; Šob, M. Phase diagram calculations in the Co–Mo and Fe–Mo systems using first-principles results for the sigma phase. Calphad 2005, 29, 133–139. [Google Scholar] [CrossRef]

- Wang, W.; Du, M.; Zhang, X.; Luan, C.; Tian, Y. Preparation and Properties of Mo Coating on H13 Steel by Electro Spark Deposition Process. Materials 2021, 14, 3700. [Google Scholar] [CrossRef] [PubMed]

- Gaponova, O.P.; Antoszewski, B.; Tarelnyk, V.B.; Kurp, P.; Myslyvchenko, O.M.; Tarelnyk, N.V. Analysis of the Quality of Sulfomolybdenum Coatings Obtained by Electrospark Alloying Methods. Materials 2021, 14, 6332. [Google Scholar] [CrossRef] [PubMed]

| Discharge Energy (Wp), J | Capacity of the Capacitor Battery (C), µF | Output Voltage (U), V | Vibrator Oscillation Frequency, Hz |

|---|---|---|---|

| 0.13 | 300 | 35 | 50 |

| 0.55 | 300 | 75 | 50 |

| 3.4 | 1560 | 100 | 50 |

| Strategies Treatment | Substrate | Type of Processing |

|---|---|---|

| 1 | AISI 321 | ESA-processed by Mo-electrode with the use of MoS2-containing powder |

| 2 | ESA-processed by Mo-electrode with the use of S-containing paste | |

| - | ESA-processed by Mo-electrode |

| Discharge Energy, Wp, J | Roughness, Ra, μm | Strengthened “White” Layer | ||

|---|---|---|---|---|

| HV | h, μm | Continuity, % | ||

| 0.55 | 1.2 | 534 | 20–30 | 65 |

| 3.4 | 3.2 | 1127 | 50–60 | 80 |

| Energy Discharge, J | Phase | Lattice Period, a, nm | Phase Content, % (wt.) |

|---|---|---|---|

| 0.55 | BCC1 solid solution on α-Fe | 2.8700 | 14.0 |

| BCC2 solid solution on α-Fe | 2.8900 | 15.0 | |

| FCC solid solution on γ-Fe | 3.5900 | 25.0 | |

| MoS2 | a = 3.1612 c = 12.2985 | 46.0 | |

| 3.4 | BCC1 solid solution on α-Fe | 2.8700 | 24.0 |

| BCC2 solid solution on α-Fe | 2.8900 | 25.0 | |

| FCC solid solution on γ-Fe | 3.6500 | 24.0 | |

| MoS2 | a = 3.1612 c = 12.2985 | 27.0 |

| Discharge Energy, Wp, J | Roughness, Ra, μm | Layer of Low Microhardness | Strengthened “White Layer” | |||

|---|---|---|---|---|---|---|

| HV | h, μm | HV | h, μm | Continuity, % | ||

| C20 Steel | ||||||

| 0.13 | 0.6 | 111.2 | 20 | 514.7 | 20 | 65 |

| 0.55 | 1.9 | 136.8 | 30 | 715.0 | 30 | 75 |

| 3.4 | 5.5 | 166.6 | 40 | 1059.6 | 50 | 90 |

| C40 Steel | ||||||

| 0.13 | 0.8 | 132.0 | 10 | 547.4 | 25 | 75 |

| 0.55 | 2.0 | 167.0 | 20 | 783.2 | 40 | 90 |

| 3.4 | 5.7 | 204.0 | 30 | 1073.1 | 70 | 95 |

| AISI 321 Steel | ||||||

| 0.13 | 0.9 | 146.4 | 10 | 651.4 | 20 | 80 |

| 0.55 | 2.2 | 173.2 | 15 | 882.7 | 30 | 90 |

| 3.4 | 6.2 | 240.3 | 20 | 1137.3 | 55 | Up to 100 |

| Sample Series | Substrate | Load, P, N | Maximum Frictional Force, Fmax, N | Friction Force Average Value Faverage, N | Average Coefficient of Friction, μaverage |

|---|---|---|---|---|---|

| Mo | AISI 321 steel | 20 | 16.79 | 12.938 | 0.6469 ± 0.0257 |

| 40 | 23.06 | 19.97 | 0.4999 ± 0.0074 | ||

| Mo + S | 20 | 0.41 | 0.31 | 0.0156 ± 0.0059 | |

| 40 | 0.43 | 0.31 | 0.0078 ± 0.0001 | ||

| Mo + MoS2 | 20 | 1.83 | 1.20 | 0.0630 ± 0.0001 | |

| 40 | 2.51 | 2.00 | 0.0510 ± 0.0031 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haponova, O.; Tarelnyk, V.; Mościcki, T.; Tarelnyk, N.; Półrolniczak, J.; Myslyvchenko, O.; Adamczyk-Cieślak, B.; Sulej-Chojnacka, J. Investigation of the Structure and Properties of MoS2 Coatings Obtained by Electrospark Alloying. Coatings 2024, 14, 563. https://doi.org/10.3390/coatings14050563

Haponova O, Tarelnyk V, Mościcki T, Tarelnyk N, Półrolniczak J, Myslyvchenko O, Adamczyk-Cieślak B, Sulej-Chojnacka J. Investigation of the Structure and Properties of MoS2 Coatings Obtained by Electrospark Alloying. Coatings. 2024; 14(5):563. https://doi.org/10.3390/coatings14050563

Chicago/Turabian StyleHaponova, Oksana, Viacheslav Tarelnyk, Tomasz Mościcki, Nataliia Tarelnyk, Joanna Półrolniczak, Oleksandr Myslyvchenko, Bogusława Adamczyk-Cieślak, and Joanna Sulej-Chojnacka. 2024. "Investigation of the Structure and Properties of MoS2 Coatings Obtained by Electrospark Alloying" Coatings 14, no. 5: 563. https://doi.org/10.3390/coatings14050563

APA StyleHaponova, O., Tarelnyk, V., Mościcki, T., Tarelnyk, N., Półrolniczak, J., Myslyvchenko, O., Adamczyk-Cieślak, B., & Sulej-Chojnacka, J. (2024). Investigation of the Structure and Properties of MoS2 Coatings Obtained by Electrospark Alloying. Coatings, 14(5), 563. https://doi.org/10.3390/coatings14050563