Aluminium-Based Dissimilar Alloys Surface Composites Reinforced with Functional Microparticles Produced by Upward Friction Stir Processing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

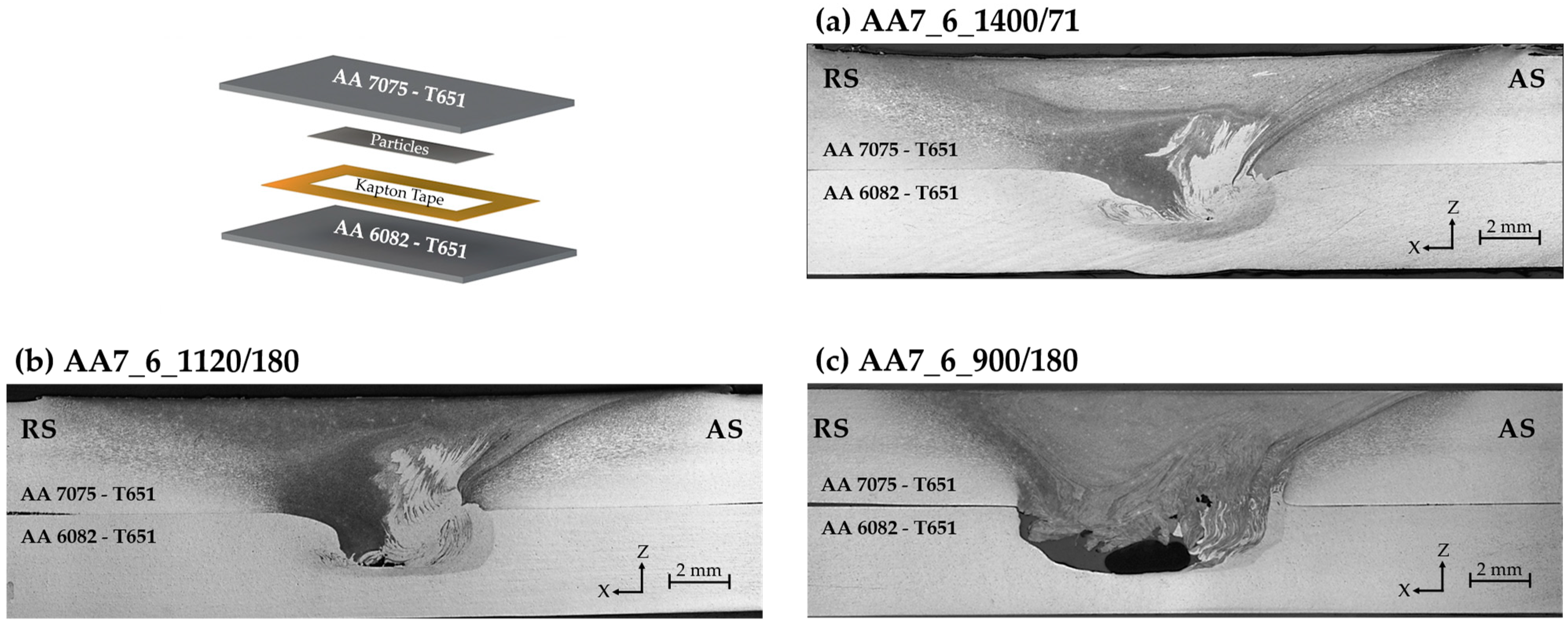

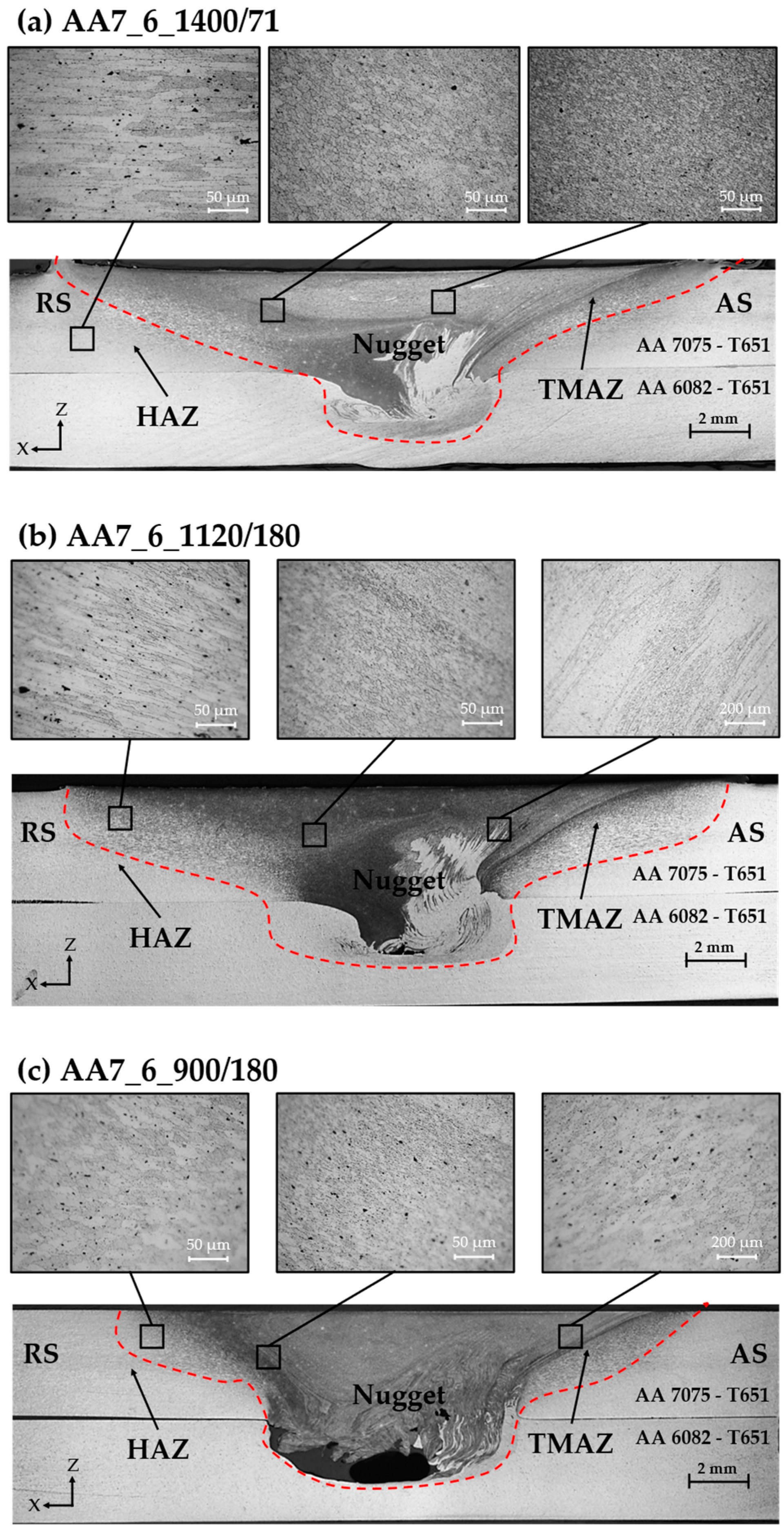

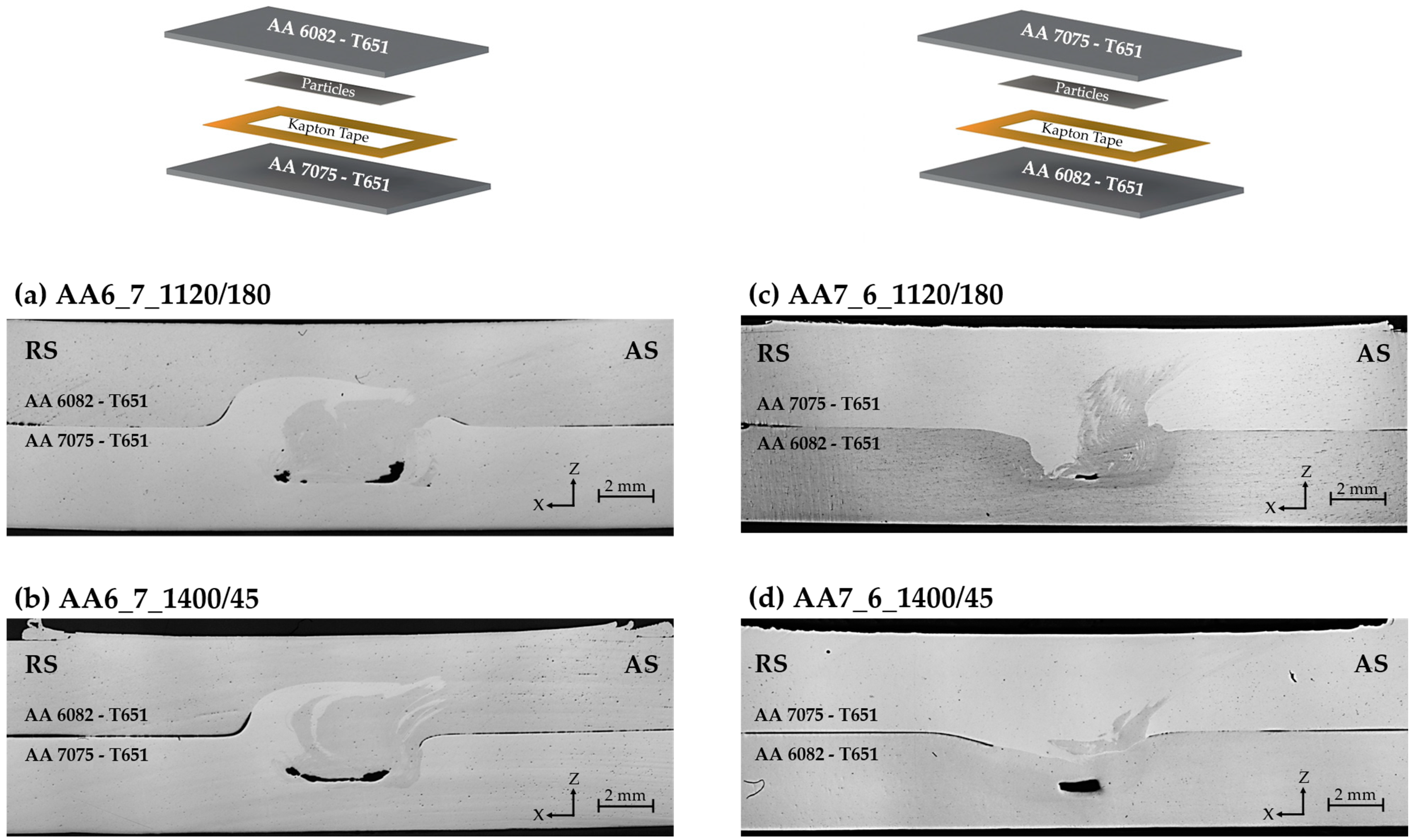

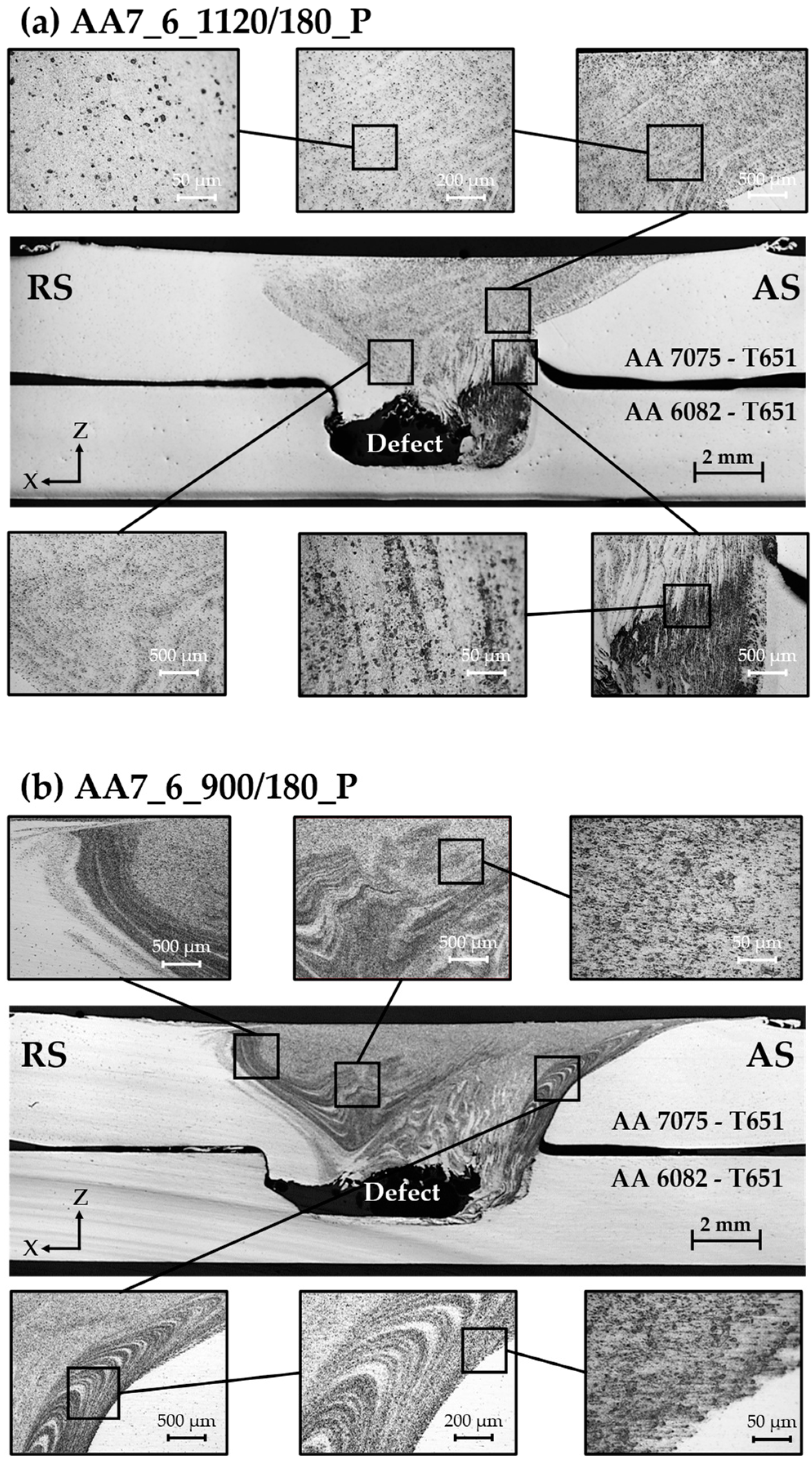

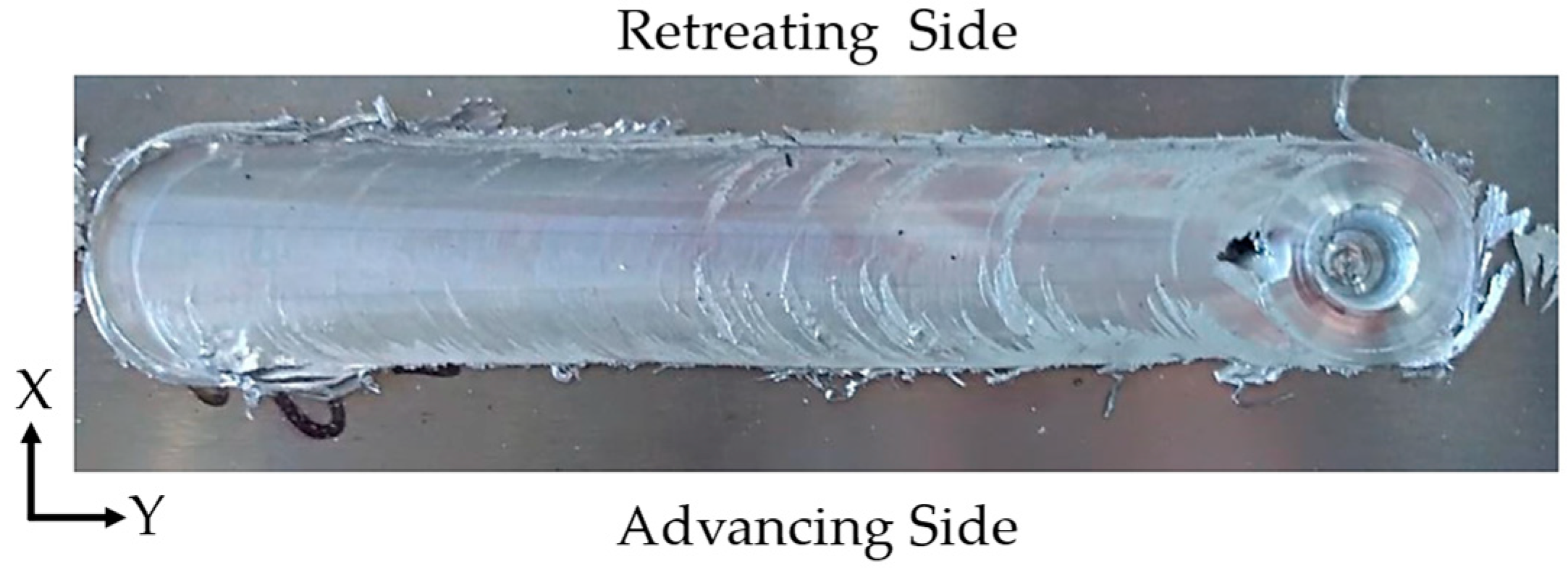

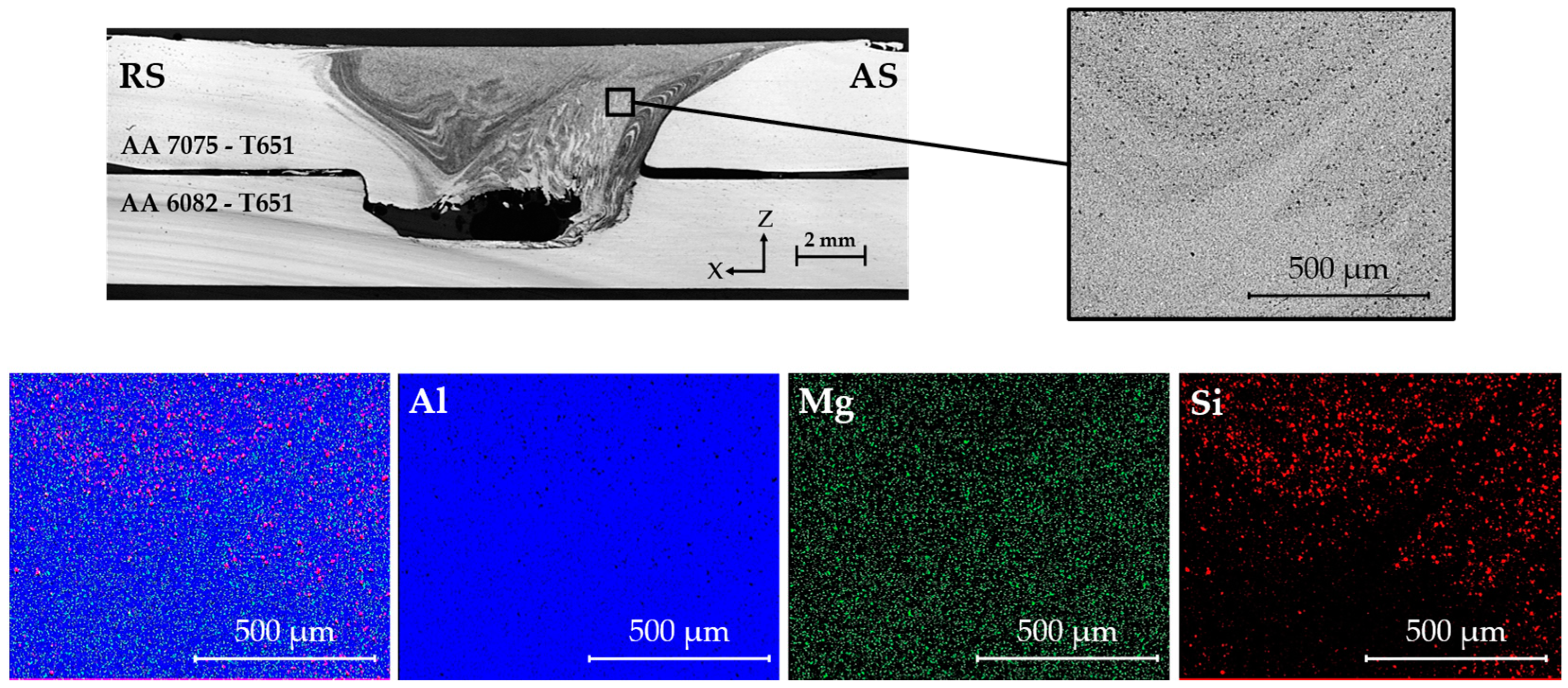

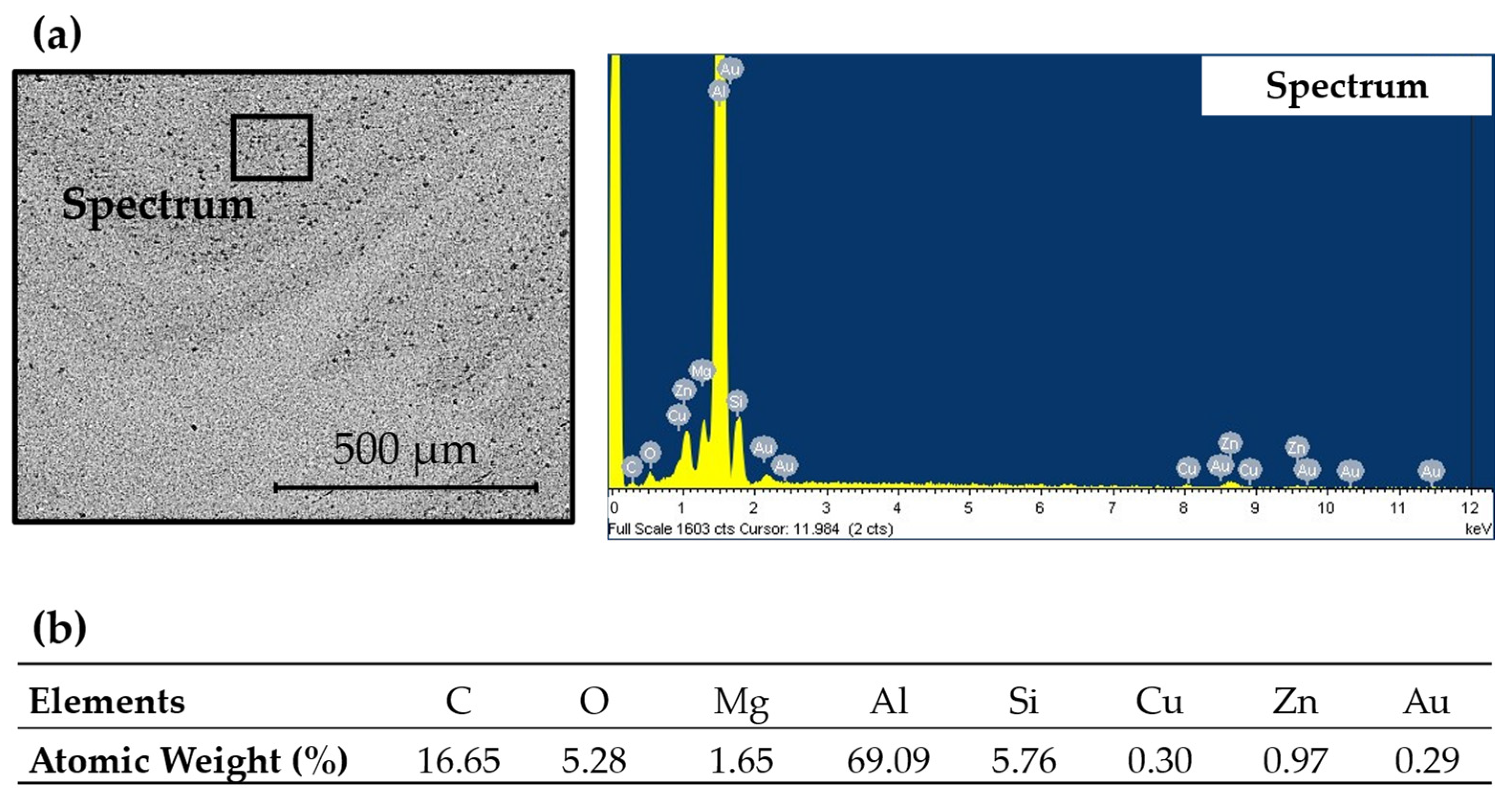

3.1. Aluminium-Based Dissimilar Alloys Surface Composites

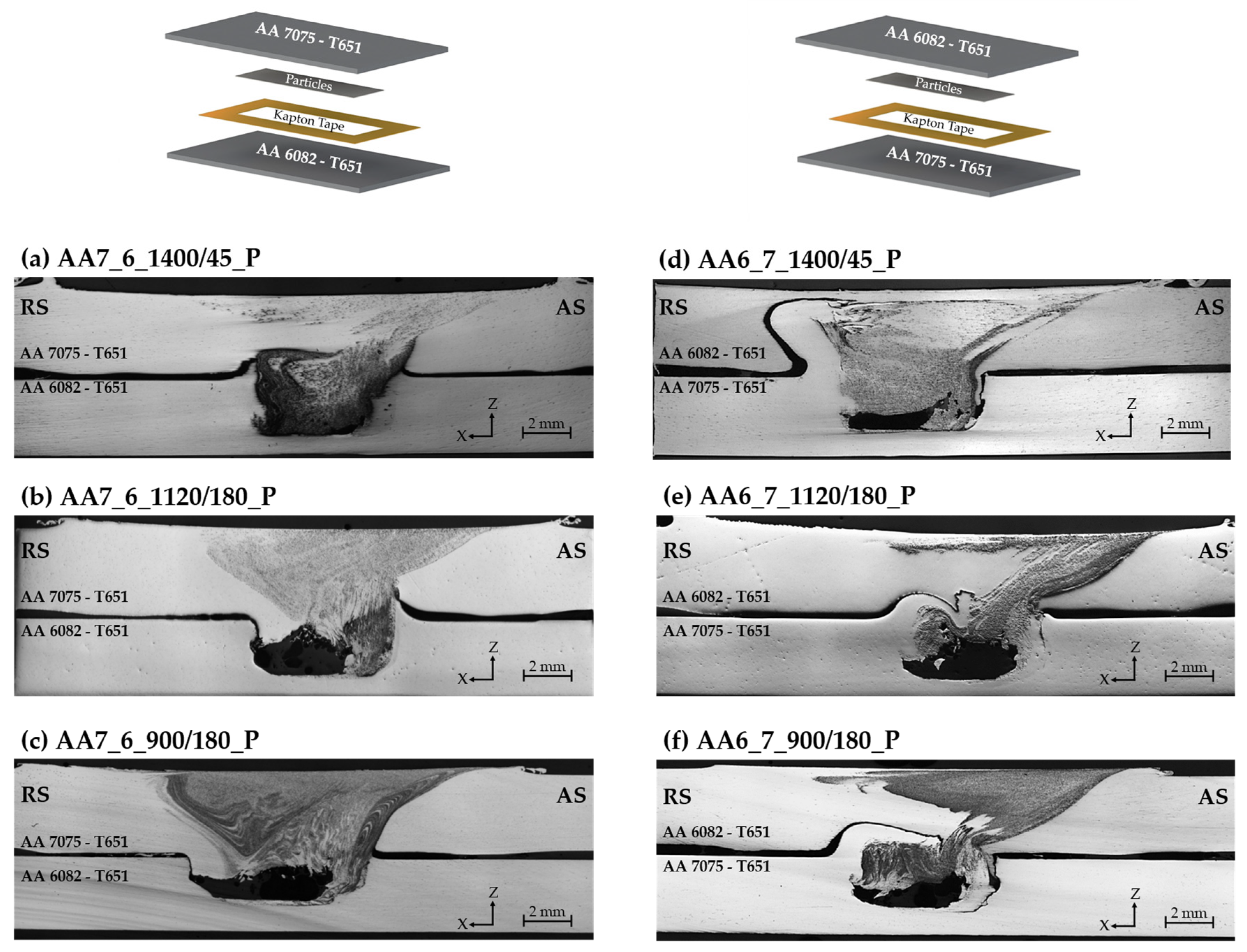

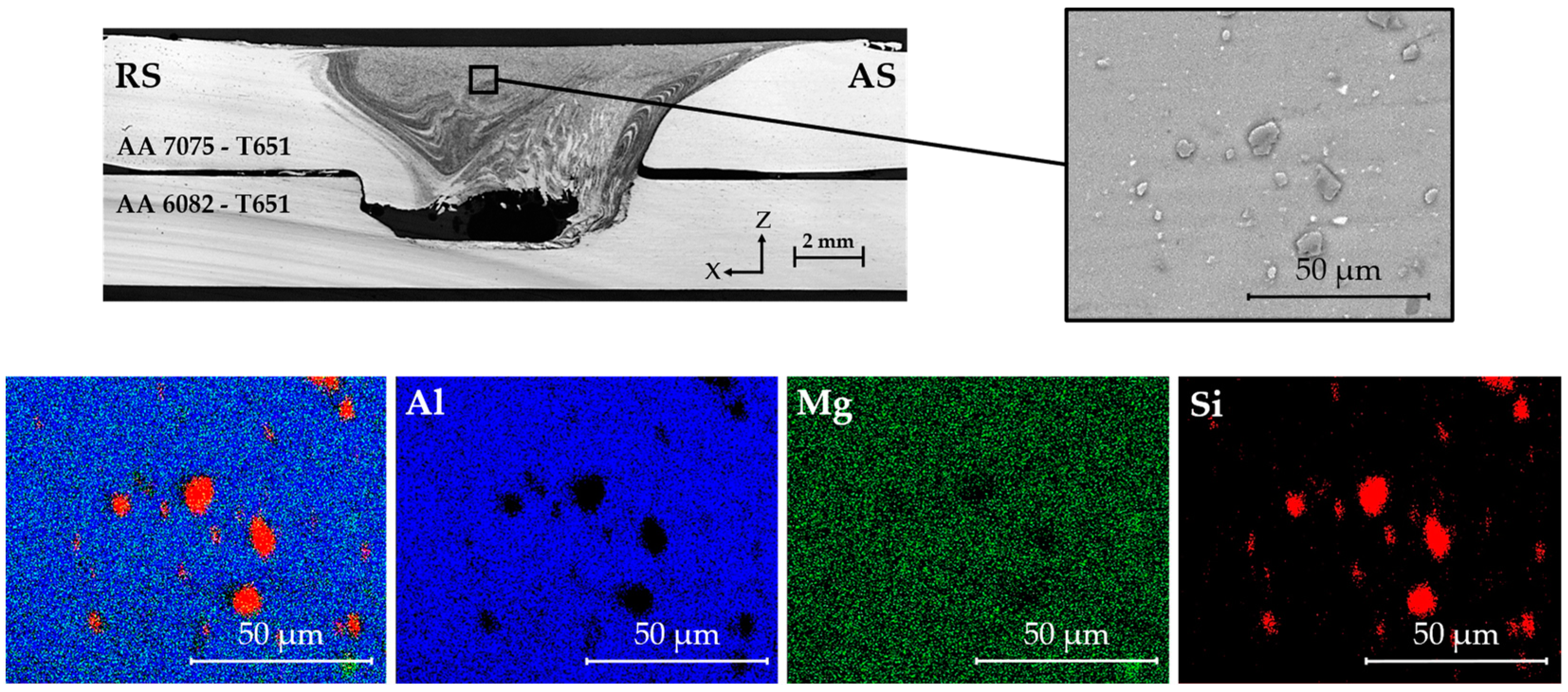

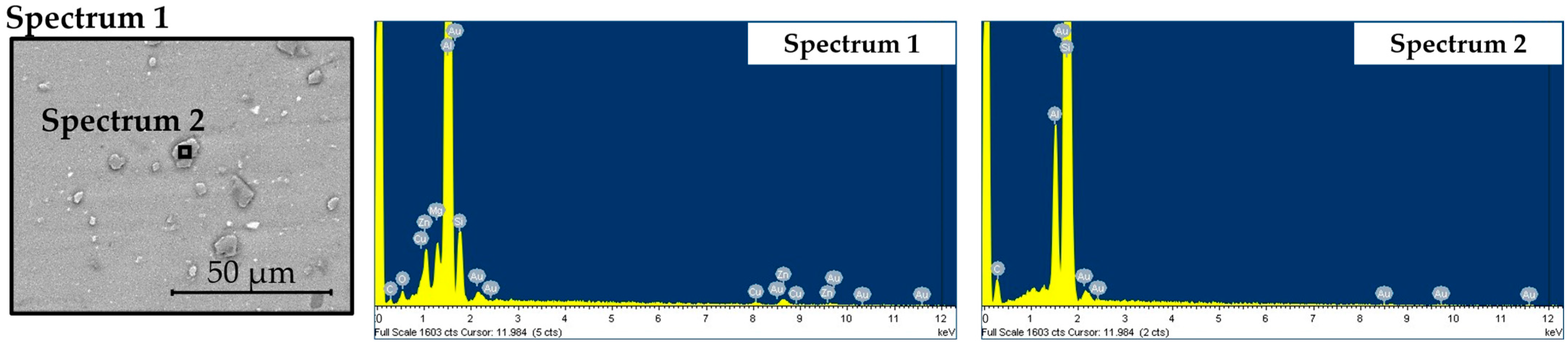

3.2. Aluminium-Based Dissimilar Alloys Surface Composites Reinforced with SiC Particles

4. Conclusions

- A reduction of approximately 20 HV 0.5 in hardness was observed in the stirred zone when compared to the base material. This reduction can be attributed to the weakening effect caused by low-temperature annealing during UFSP, which reduces the strengthening effect induced by the T651 heat treatment.

- The presence of particles did not influence the surface composites’ hardness in the stirred zone.

- The findings from the eddy currents tests are in good agreement with the hardness profiles obtained.

- The lower plate was not found to be a merely sacrificial plate. Despite significant internal defects observed after processing, SEM analyses revealed evidence of merging of the lower alloy into the upper zone.

- The production of bimetallic composites through UFSP may offer advantages over composites produced from a monometallic matrix as there were significant changes in the chemical composition of the upper plate.

- The results of the eddy currents testing and microhardness measurements were consistent with the SEM/EDS analyses.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ferreira, P.M.; Machado, M.A.; Carvalho, M.S.; Vidal, C. Granting Sensorial Properties to Metal Parts through Friction Stir Processing. Meas. J. Int. Meas. Confed. 2023, 207, 112405. [Google Scholar] [CrossRef]

- Sunil, B.R.; Reddy, G.P.K.; Patle, H.; Dumpala, R. Magnesium Based Surface Metal Matrix Composites by Friction Stir Processing. J. Magnes. Alloy. 2016, 4, 52–61. [Google Scholar] [CrossRef]

- Sharma, V.; Prakash, U.; Kumar, B.V.M. Surface Composites by Friction Stir Processing: A Review. J. Mater. Process. Technol. 2015, 224, 117–134. [Google Scholar] [CrossRef]

- Khan, M.A.; Butola, R.; Gupta, N. A Review of Nanoparticle Reinforced Surface Composites Processed by Friction Stir Processing. J. Adhes. Sci. Technol. 2023, 37, 565–601. [Google Scholar] [CrossRef]

- Omotehinse, I.S.; Abioye, T.E.; Anasyida, A.S.; Omiyale, B.O. Review of Parametric Strategies for Enhancing the Mechanical and Wear Properties of Friction Stir Processed Aluminium Alloys Composites. Trans. Indian Inst. Met. 2023, 76. [Google Scholar] [CrossRef]

- Bharti, S.; Ghetiya, N.D.; Patel, K.M. A Review on Manufacturing the Surface Composites by Friction Stir Processing. Mater. Manuf. Process. 2021, 36, 135–170. [Google Scholar] [CrossRef]

- Das, S.S.; Raja, A.R.; Nautiyal, H.; Gautam, R.K.S.; Jha, P.; Sharma, J.; Singh, S. A Review on Aluminum Matrix Composites Synthesized by FSP. Macromol. Symp. 2023, 407, 2200119. [Google Scholar] [CrossRef]

- Vasava, A.; Singh, D. Influence of Various Tool Shoulder Design on Hybrid Surface Composite of AA7075-T651/SiC/Graphene through Friction Stir Processing. Can. Metall. Q 2023, 62, 1–19. [Google Scholar] [CrossRef]

- Liao, Z.; Abdelhafeez, A.; Li, H.; Yang, Y.; Diaz, O.G.; Axinte, D. State-of-the-Art of Surface Integrity in Machining of Metal Matrix Composites. Int. J. Mach. Tools Manuf. 2019, 143, 63–91. [Google Scholar] [CrossRef]

- Singh, L.; Singh, B.; Saxena, K.K. Manufacturing Techniques for Metal Matrix Composites (MMC): An Overview. Adv. Mater. Process. Technol. 2020, 6, 441–457. [Google Scholar] [CrossRef]

- Kumar Sharma, A.; Bhandari, R.; Aherwar, A.; Rimašauskienė, R.; Pinca-Bretotean, C. A Study of Advancement in Application Opportunities of Aluminum Metal Matrix Composites. Mater. Today Proc. 2020, 26, 2419–2424. [Google Scholar] [CrossRef]

- Ferreira, P.M.; Machado, M.A.; Carvalho, M.S.; Vidal, C. Embedded Sensors for Structural Health Monitoring: Methodologies and Applications Review. Sensors 2022, 22, 8320. [Google Scholar] [CrossRef]

- Singh, R.K.; Gilbert, D.R.; Fitz-Gerald, J.; Lee, D.G. Surface Composites: Novel Method to Fabricate Adherent Interfaces. Surf. Eng. 1997, 13, 389–392. [Google Scholar] [CrossRef]

- Riabkina-Fishman, M.; Rabkin, E.; Levin, P.; Frage, N.; Dariel, M.; Weisheit, A.; Galun, R.; Mordike, B. Laser Produced Functionally Graded Tungsten Carbide Coatings on M2 High-Speed Tool Steel. Mater. Sci. Eng. A 2001, 302, 106–114. [Google Scholar] [CrossRef]

- Ayers, J.D.; Tucker, T.R. Particulate-TiC-Hardened Steel Surfaces by Laser Melt Injection. Thin Solid Films 1980, 73, 201–207. [Google Scholar] [CrossRef]

- Farayibi, P.K.; Folkes, J.A.; Clare, A.T. Laser Deposition of Ti-6Al-4V Wire with WC Powder for Functionally Graded Components. Mater. Manuf. Process. 2013, 28, 514–518. [Google Scholar] [CrossRef]

- Wang, X.H.; Zhang, M.; Du, B.S. Fabrication of Multiple Ceramic Particle Reinforced Iron Matrix Coating by Laser Cladding. Mater. Manuf. Process. 2013, 28, 509–513. [Google Scholar] [CrossRef]

- Mehdi, H.; Mishra, R.S. Consequence of Reinforced SiC Particles on Microstructural and Mechanical Properties of AA6061 Surface Composites by Multi-Pass FSP. J. Adhes. Sci. Technol. 2022, 36, 1279–1298. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Siddiquee, A.N.; Maheshwari, S. Investigation on the Effects of Silicon Carbide and Cooling Medium during Multi-Pass FSP of Al-Mg/ SiC Surface Composites. Silicon 2019, 11, 2149–2157. [Google Scholar] [CrossRef]

- Patel, K.; Ghetiya, N.D.; Bharti, S. Effect of Single and Double Pass Friction Stir Processing on Microhardness and Wear Properties of AA5083/Al2O3 Surface Composites. Mater. Today Proc. 2022, 57, 38–43. [Google Scholar] [CrossRef]

- Dilip, J.J.S.; Babu, S.; Rajan, S.V.; Rafi, K.H.; Ram, G.D.J.; Stucker, B.E. Use of Friction Surfacing for Additive Manufacturing. Mater. Manuf. Process. 2013, 28, 189–194. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.; Lei, L.; Hu, W. Fabrication and Evaluation of Ti3Alp/Ti–6Al–4V Surface Layer via Additive Friction-Stir Processing. Mater. Manuf. Process. 2014, 29, 412–417. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.; Hu, W. Friction-Stir Nitriding of Titanium Alloy Surface Layer. Mater. Manuf. Process. 2014, 29, 493–497. [Google Scholar] [CrossRef]

- Akinlabi, E.T.; Andrews, A.; Akinlabi, S.A. Effects of Processing Parameters on Corrosion Properties of Dissimilar Friction Stir Welds of Aluminium and Copper. Trans. Nonferrous Met. Soc. China 2014, 24, 1323–1330. [Google Scholar] [CrossRef]

- Zheng, Q.; Feng, X.; Shen, Y.; Huang, G.; Zhao, P. Effect of Plunge Depth on Microstructure and Mechanical Properties of FSW Lap Joint between Aluminum Alloy and Nickel-Base Alloy. J. Alloys Compd. 2017, 695, 952–961. [Google Scholar] [CrossRef]

- Beygi, R.; Mehrizi, M.Z.; Verdera, D.; Loureiro, A. Influence of Tool Geometry on Material Flow and Mechanical Properties of Friction Stir Welded Al-Cu Bimetals. J. Mater. Process. Technol. 2018, 255, 739–748. [Google Scholar] [CrossRef]

- Vasava, A.; Singh, D. Effect of Different Volume Ratios of SiC and TiO2 Reinforcement Particles on Mono and Hybrid Surface Composites of AA7075-T651 through Friction Stir Processing. J. Adhes. Sci. Technol. 2023, 4, 1–20. [Google Scholar] [CrossRef]

- Khan, N.Z.; Siddiquee, A.N.; Khan, Z.A.; Mukhopadhyay, A.K. Mechanical and Microstructural Behavior of Friction Stir Welded Similar and Dissimilar Sheets of AA2219 and AA7475 Aluminium Alloys. J. Alloys Compd. 2017, 695, 2902–2908. [Google Scholar] [CrossRef]

- Leitão, C.; Louro, R.; Rodrigues, D.M. Analysis of High Temperature Plastic Behaviour and Its Relation with Weldability in Friction Stir Welding for Aluminium Alloys AA5083-H111 and AA6082-T6. Mater. Des. 2012, 37, 402–409. [Google Scholar] [CrossRef]

- Gungor, B.; Kaluc, E.; Taban, E.; Sik, A. Mechanical, Fatigue and Microstructural Properties of Friction Stir Welded 5083-H111 and 6082-T651 Aluminum Alloys. Mater. Des. 2014, 56, 84–90. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; Sheikhi, S.; dos Santos, J.F.; Bolfarini, C. Preliminary Study on the Microstructure and Mechanical Properties of Dissimilar Friction Stir Welds in Aircraft Aluminium Alloys 2024-T351 and 6056-T4. J. Mater. Process. Technol. 2008, 206, 132–142. [Google Scholar] [CrossRef]

- Moradi, M.M.; Jamshidi Aval, H.; Jamaati, R.; Amirkhanlou, S.; Ji, S. Microstructure and Texture Evolution of Friction Stir Welded Dissimilar Aluminum Alloys: AA2024 and AA6061. J. Manuf. Process. 2018, 32, 1–10. [Google Scholar] [CrossRef]

- Farhang, M.; Mohammadreza Farahani, M.N.; Sam-Daliri, O. Experimental Correlation Between Microstructure, Residual Stresses and Mechanical Properties of Friction Stir Welded 2024-T6 Aluminum Alloys. Int. J. Adv. Des. Manuf. Technol. 2022, 15, 1–9. [Google Scholar] [CrossRef]

- Çavuşoğlu, N. Effect of Friction Welding Parameters on the Mechanical and Microstructural Properties of Dissimilar IN713C-AISI 4140 Joints. J. Mater. Eng. Perform. 2022, 31, 4035–4048. [Google Scholar] [CrossRef]

- Farhang, M.; Sam-Daliri, O.; Farahani, M.; Vatani, A. Effect of Friction Stir Welding Parameters on the Residual Stress Distribution of Al-2024-T6 Alloy. J. Mech. Eng. Sci. 2021, 15, 7684–7694. [Google Scholar] [CrossRef]

- Guo, J.F.; Chen, H.C.; Sun, C.N.; Bi, G.; Sun, Z.; Wei, J. Friction Stir Welding of Dissimilar Materials between AA6061 and AA7075 Al Alloys Effects of Process Parameters. Mater. Des. 2014, 56, 185–192. [Google Scholar] [CrossRef]

- Sahu, P.K.; Pal, S.; Pal, S.K.; Jain, R. Influence of Plate Position, Tool Offset and Tool Rotational Speed on Mechanical Properties and Microstructures of Dissimilar Al/Cu Friction Stir Welding Joints. J. Mater. Process. Technol. 2016, 235, 55–67. [Google Scholar] [CrossRef]

- Cavaliere, P.; De Santis, A.; Panella, F.; Squillace, A. Effect of Welding Parameters on Mechanical and Microstructural Properties of Dissimilar AA6082–AA2024 Joints Produced by Friction Stir Welding. Mater. Des. 2009, 30, 609–616. [Google Scholar] [CrossRef]

- Dinaharan, I.; Kalaiselvan, K.; Vijay, S.J.; Raja, P. Effect of Material Location and Tool Rotational Speed on Microstructure and Tensile Strength of Dissimilar Friction Stir Welded Aluminum Alloys. Arch. Civ. Mech. Eng. 2012, 12, 446–454. [Google Scholar] [CrossRef]

- Prasad, B.L.; Neelaiah, G.; Krishna, M.G.; Ramana, S.V.V.; Prakash, K.S.; Sarika, G.; Reddy, G.P.K.; Dumpala, R.; Sunil, B.R. Joining of AZ91 Mg Alloy and Al6063 Alloy Sheets by Friction Stir Welding. J. Magnes. Alloy. 2018, 6, 71–76. [Google Scholar] [CrossRef]

- Fu, B.; Qin, G.; Li, F.; Meng, X.; Zhang, J.; Wu, C. Friction Stir Welding Process of Dissimilar Metals of 6061-T6 Aluminum Alloy to AZ31B Magnesium Alloy. J. Mater. Process. Technol. 2015, 218, 38–47. [Google Scholar] [CrossRef]

- Inácio, P.L.; Nogueira, F.; Ferreira, F.B.; Vidal, C.; Schell, N.; Tero, T.; Vilaça, P.; Oliveira, J.P.; Santos, T.G. Functionalized Material Production via Multi-Stack Upward Friction Stir Processing (UFSP). Mater. Manuf. Process. 2022, 37, 11–24. [Google Scholar] [CrossRef]

- Vidal, C.; Alves, P.; Alves, M.M.; Carmezim, M.J.; Fernandes, M.H.; Grenho, L.; Inácio, P.L.; Ferreira, F.B.; Santos, T.G.; Santos, C. Fabrication of a Biodegradable and Cytocompatible Magnesium/Nanohydroxyapatite/Fluorapatite Composite by Upward Friction Stir Processing for Biomedical Applications. J. Mech. Behav. Biomed. Mater. 2022, 129, 105137. [Google Scholar] [CrossRef]

- Milosan, I.; Bedő, T.; Gabor, C.; Munteanu, D.; Pop, M.A.; Catana, D.; Cosnita, M.; Varga, B. Characterization of Aluminum Alloy–Silicon Carbide Functionally Graded Materials Developed by Centrifugal Casting Process. Appl. Sci. 2021, 11, 1625. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.; Sued, K.; Clucas, D. Development of Metallographic Etchants for the Microstructure Evolution of A6082-T6 BFSW Welds. Metals 2017, 7, 423. [Google Scholar] [CrossRef]

- Zamani, M.H.; Divandari, M.; Tamizifar, M. On the Characteristics of Friction Stir Welding Lap Joint of Magnesium and Aluminum. Iran. J. Mater. Sci. Eng. 2018, 15, 64–77. [Google Scholar] [CrossRef]

- Gao, Y.; Morisada, Y.; Fujii, H.; Liao, J. Dissimilar Friction Stir Lap Welding of Magnesium to Aluminum Using Plasma Electrolytic Oxidation Interlayer. Mater. Sci. Eng. A 2018, 711, 109–118. [Google Scholar] [CrossRef]

- Grimm, A.; Schulze, S.; Silva, A.; Göbel, G.; Standfuss, J.; Brenner, B.; Beyer, E.; Füssel, U. Friction Stir Welding of Light Metals for Industrial Applications. Mater. Today Proc. 2015, 2, S169–S178. [Google Scholar] [CrossRef]

- Sorger, G.L.; Oliveira, J.P.; Inácio, P.L.; Enzinger, N.; Vilaça, P.; Miranda, R.M.; Santos, T.G. Non-Destructive Microstructural Analysis by Electrical Conductivity: Comparison with Hardness Measurements in Different Materials. J. Mater. Sci. Technol. 2019, 35, 360–368. [Google Scholar] [CrossRef]

| Elements | AA 7075-T651 | AA 6082-T651 |

|---|---|---|

| Al | 87.1–91.4 | 95.4–98.3 |

| Mg | 2.1–2.9 | 0.6–1.2 |

| Zn | 5.1–6.1 | 0.2 |

| Cu | 1.2–2.0 | 0.1 |

| Si | 0.4 | 0.7–1.3 |

| Mn | 0.3 | 0.4–1 |

| Fe | 0.5 | 0.5 |

| Ti | 0.2 | 0.1 |

| Cr | - | 0.25 |

| Properties | AA 7075-T651 | AA 6082-T651 |

|---|---|---|

| Density [g/cm3] | 2.83 | 2.70 |

| Melting point [C] | 475 | 555 |

| Electrical conductivity [W m−1 K−1] | 153 | 170 |

| Modulus of elasticity [GPa] | 72.0 | 70.0 |

| Vickers hardness [HV0.5] | 180 | 118 |

| Ultimate tensile strength [MPa] | 550 | 290 |

| Yield tensile strength [MPa] | 490 | 250 |

| Elongation at fracture [%] | 8 | 10 |

| Schematic | Samples without Particles AA7_6_ | Samples with Particles AA7_6_ | No. Processing Passes | Tool Geometry | ||

|---|---|---|---|---|---|---|

| 1400/45 | 1400/45_P | 1400 | 45 | 3 | Triflute left-hand threaded conical pin with a 4.8/5.5 mm length |

| 1400/71 | 1400/71_P | 71 | ||||

| 1400/180 | 1400/180_P | 180 | ||||

| 1120/45 | 1120/45_P | 1120 | 45 | |||

| 1120/71 | 1120/71_P | 71 | ||||

| 1120/180 | 1120/180_P | 180 | ||||

| 900/180 | 900/180_P | 900 | 180 |

| Schematic | Samples without Particles AA6_7_ | Samples with Particles AA6_7_ | No. Processing Passes | Tool Geometry | ||

|---|---|---|---|---|---|---|

| 1400/45 | 1400/45_P | 1400 | 45 | 3 | Triflute left-hand threaded conical pin with a 4.8/5.5 mm length |

| 1400/71 | 1400/71_P | 71 | ||||

| 1400/180 | 1400/180_P | 180 | ||||

| 1120/45 | 1120/45_P | 1120 | 45 | |||

| 1120/71 | 1120/71_P | 71 | ||||

| 1120/180 | 1120/180_P | 180 | ||||

| 900/180 | 900/180_P | 900 | 180 |

| Elements | Al | Mg | Zn | Cu | O | Si | C | Au |

|---|---|---|---|---|---|---|---|---|

| Atomic Weight (%) | 69.64 | 1.55 | 1.18 | 0.33 | 4.31 | 6.29 | 16.42 | 0.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreira, F.; Ferreira, P.M.; Silva, R.J.C.; Santos, T.G.; Vidal, C. Aluminium-Based Dissimilar Alloys Surface Composites Reinforced with Functional Microparticles Produced by Upward Friction Stir Processing. Coatings 2023, 13, 962. https://doi.org/10.3390/coatings13050962

Moreira F, Ferreira PM, Silva RJC, Santos TG, Vidal C. Aluminium-Based Dissimilar Alloys Surface Composites Reinforced with Functional Microparticles Produced by Upward Friction Stir Processing. Coatings. 2023; 13(5):962. https://doi.org/10.3390/coatings13050962

Chicago/Turabian StyleMoreira, Filipe, Pedro M. Ferreira, Rui J. C. Silva, Telmo G. Santos, and Catarina Vidal. 2023. "Aluminium-Based Dissimilar Alloys Surface Composites Reinforced with Functional Microparticles Produced by Upward Friction Stir Processing" Coatings 13, no. 5: 962. https://doi.org/10.3390/coatings13050962

APA StyleMoreira, F., Ferreira, P. M., Silva, R. J. C., Santos, T. G., & Vidal, C. (2023). Aluminium-Based Dissimilar Alloys Surface Composites Reinforced with Functional Microparticles Produced by Upward Friction Stir Processing. Coatings, 13(5), 962. https://doi.org/10.3390/coatings13050962