First Approach to Doping Silver into CrB2 Thin Films Deposited by DC/HiPIMS Technology in Terms of Mechanical and Tribological Properties

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Chemical Composition of Studied Thin Films

3.2. XRD Structure of Ag–CrB2+x Thin Films

3.3. Cross-Section of Ag–CrB2+x Thin Films

3.4. Mechanical Properties of Ag–CrB2+x Thin Films

3.5. Adhesion Properties of Ag–CrB2+x Thin Films

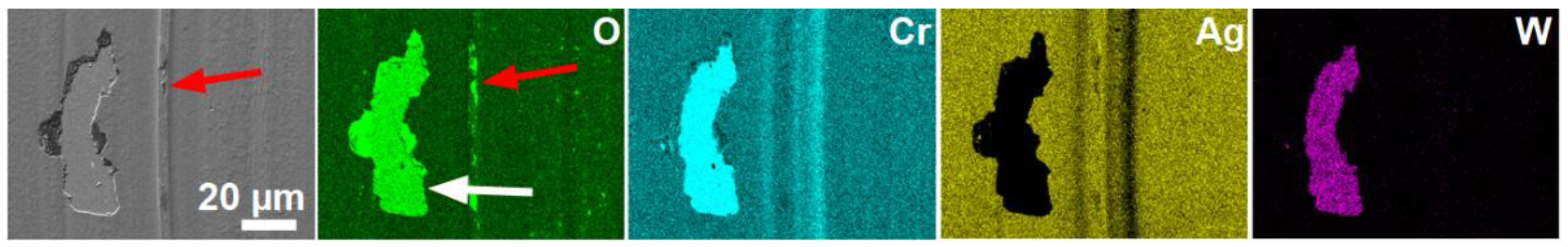

3.6. Tribological Response of Silver-Doped CrB2+x Thin Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Goncharov, A.A.; Dub, S.N.; Agulov, A.V.; Petukhov, V.V. Structure, Composition, and Mechanical Properties of Thin Films of Transition Metals Diborides. J. Superhard Mater. 2015, 37, 422–428. [Google Scholar] [CrossRef]

- Mitterer, C. Borides in Thin Film Technology. J. Solid State Chem. 1997, 133, 279–291. [Google Scholar] [CrossRef]

- Thörnberg, J.; Palisaitis, J.; Hellgren, N.; Klimashin, F.F.; Ghafoor, N.; Zhirkov, I.; Azina, C.; Battaglia, J.-L.; Kusiak, A.; Sortica, M.A.; et al. Microstructure and Materials Properties of Understoichiometric TiBx Thin Films Grown by HiPIMS. Surf. Coat. Technol. 2020, 404, 126537. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Mitterer, C.; Wen, J.G.; Greene, J.E.; Petrov, I. Self-Organized Nanocolumnar Structure in Superhard TiB2 Thin Films. Appl. Phys. Lett. 2005, 86, 131909. [Google Scholar] [CrossRef]

- Munro, R.G. Material Properties of Titanium Diboride. J. Res. Natl. Inst. Stand. Technol. 2000, 105, 709–720. [Google Scholar] [CrossRef]

- Palisaitis, J.; Dahlqvist, M.; Hall, A.J.; Thörnberg, J.; Persson, I.; Nedfors, N.; Hultman, L.; Greene, J.E.; Petrov, I.; Rosen, J.; et al. Where Is the Unpaired Transition Metal in Substoichiometric Diboride Line Compounds? Acta Mater. 2021, 204, 116510. [Google Scholar] [CrossRef]

- Emiliani, M.L. Characterization and Oxidation Resistance of Hot-Pressed Chromium Diboride. Mater. Sci. Eng. A 1993, 172, 111–124. [Google Scholar] [CrossRef]

- Audronis, M.; Kelly, P.J.; Arnell, R.D.; Valiulis, A.V. Pulsed Magnetron Sputtering of Chromium Boride Films from Loose Powder Targets. Surf. Coat. Technol. 2006, 200, 4166–4173. [Google Scholar] [CrossRef]

- Audronis, M.; Rosli, Z.M.; Leyland, A.; Kelly, P.J.; Matthews, A. Tribological Behaviour of Pulsed Magnetron Sputtered CrB2 Coatings Examined by Reciprocating Sliding Wear Testing against Aluminium Alloy and Steel. Surf. Coat. Technol. 2008, 202, 1470–1478. [Google Scholar] [CrossRef]

- Dorri, M.M.; Thörnberg, J.; Hellgren, N.; Palisaitis, J.; Petruhins, A.; Klimashin, F.F.; Hultman, L.; Petrov, I.; Persson, P.O.Å.; Rosen, J. Synthesis and Characterization of CrB2 Thin Films Grown by DC Magnetron Sputtering. Scr. Mater. 2021, 200, 113915. [Google Scholar] [CrossRef]

- Marka, S.; Menaka; Ganguli, A.K.; Krishna, M.G. Effect of Substrate and Film Thickness on the Growth, Structure, Mechanical and Optical Properties of Chromium Diboride Thin Films. Surf. Coat. Technol. 2012, 209, 23–31. [Google Scholar] [CrossRef]

- Dahm, K.L.; Jordan, L.R.; Haase, J.; Dearnley, P.A. Magnetron Sputter Deposition of Chromium Diboride Coatings. Surf. Coat. Technol. 1998, 108–109, 413–418. [Google Scholar] [CrossRef]

- Bhatt, B.; Murthy, T.S.R.C.; Limaye, P.K.; Nagaraj, A.; Singh, K.; Sonber, J.K.; Sairam, K.; Sashanka, A.; Rao, G.V.S.N.; Rao, T.S. Tribological Studies of Monolithic Chromium Diboride against Cemented Tungsten Carbide (WC–Co) under Dry Condition. Ceram. Int. 2016, 42, 15536–15546. [Google Scholar] [CrossRef]

- Cheng, C.-H.; Lee, J.-W.; Ho, L.-W.; Chen, H.-W.; Chan, Y.-C.; Duh, J.-G. Microstructure and Mechanical Property Evaluation of Pulsed DC Magnetron Sputtered Cr–B and Cr–B–N Films. Surf. Coat. Technol. 2011, 206, 1711–1719. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Z.; Guo, P.; Ke, P.; Odén, M.; Wang, A. Temperature Induced Superhard CrB 2 Coatings with Preferred (001) Orientation Deposited by DC Magnetron Sputtering Technique. Surf. Coat. Technol. 2017, 322, 134–140. [Google Scholar] [CrossRef]

- Choi, H.S.; Park, B.; Lee, J.J. CrB2 Coatings Deposited by Inductively Coupled Plasma Assisted DC Magnetron Sputtering. Surf. Coat. Technol. 2007, 202, 982–986. [Google Scholar] [CrossRef]

- Nedfors, N.; Primetzhofer, D.; Wang, L.; Lu, J.; Hultman, L.; Jansson, U. Characterization of magnetron sputtered Cr-B and Cr-B-C thin films for electrical contact applications. Surf. Coat. Technol. 2015, 266, 167–176. [Google Scholar] [CrossRef]

- Sliney, H.E. The Use of Silver in Self-Lubricating Coatings for Extreme Temperatures. ASLE Trans. 1986, 29, 370–376. [Google Scholar] [CrossRef]

- Bilek, P.; Jurci, P.; Novak, M.; Hudakova, M.; Caplovic, L. Tribological and Mechanical Properties of Cr 2 N–11Ag-Coatings Deposited on Cr–V Ledeburitic Steel. Wear 2015, 340–341, 47–52. [Google Scholar] [CrossRef]

- Kelly, P.J.; Li, H.; Benson, P.S.; Whitehead, K.A.; Verran, J.; Arnell, R.D.; Iordanova, I. Comparison of the Tribological and Antimicrobial Properties of CrN/Ag, ZrN/Ag, TiN/Ag, and TiN/Cu Nanocomposite Coatings. Surf. Coat. Technol. 2010, 205, 1606–1610. [Google Scholar] [CrossRef]

- Mulligan, C.P.; Blanchet, T.A.; Gall, D. CrN–Ag Nanocomposite Coatings: Effect of Growth Temperature on the Microstructure. Surf. Coat. Technol. 2008, 203, 584–587. [Google Scholar] [CrossRef]

- Mulligan, C.P.; Blanchet, T.A.; Gall, D. CrN–Ag Nanocomposite Coatings: High-Temperature Tribological Response. Wear 2010, 269, 125–131. [Google Scholar] [CrossRef]

- 9 Solid Lubrication and Surface Treatments. In Tribology Series; Engineering Tribology; Stachowiak, G.W., Batchelor, A.W., Eds.; Elsevier: Amsterdam, The Netherlands, 1993; Volume 24, pp. 485–526. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing. Available online: https://www.astm.org/c1624-05.html (accessed on 1 February 2023).

- Musil, J.; Zeman, P.; Baroch, P. Hard Nanocomposite Coatings. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; pp. 325–353. ISBN 978-0-08-096533-8. [Google Scholar]

- Mulligan, C.P.; Blanchet, T.A.; Gall, D. CrN–Ag Nanocomposite Coatings: Tribology at Room Temperature and during a Temperature Ramp. Surf. Coat. Technol. 2010, 204, 1388–1394. [Google Scholar] [CrossRef]

- Sonber, J.K.; Raju, K.; Murthy, T.S.R.C.; Sairam, K.; Nagaraj, A.; Majumdar, S.; Kain, V. Friction and Wear Properties of Zirconium Diboride in Sliding against WC Ball. Int. J. Refract. Met. Hard Mater. 2018, 76, 41–48. [Google Scholar] [CrossRef]

- Ashby, M.F.; Abulawi, J.; Kong, H.S. Temperature Maps for Frictional Heating in Dry Sliding. Tribol. Trans. 1991, 34, 577–587. [Google Scholar] [CrossRef]

- Yalamanchili, K.; Jiménez-Piqué, E.; Pelcastre, L.; Bakoglidis, K.D.; Roa, J.J.; Johansson Jöesaar, M.P.; Prakash, B.; Ghafoor, N.; Odén, M. Influence of Microstructure and Mechanical Properties on the Tribological Behavior of Reactive Arc Deposited Zr-Si-N Coatings at Room and High Temperature. Surf. Coat. Technol. 2016, 304, 393–400. [Google Scholar] [CrossRef]

- Polcar, T.; Martinez, R.; Vítů, T.; Kopecký, L.; Rodriguez, R.; Cavaleiro, A. High Temperature Tribology of CrN and Multilayered Cr/CrN Coatings. Surf. Coat. Technol. 2009, 203, 3254–3259. [Google Scholar] [CrossRef]

- Wu, F.; Yu, L.; Ju, H.; Asempah, I.; Xu, J. Structural, Mechanical and Tribological Properties of NbCN-Ag Nanocomposite Films Deposited by Reactive Magnetron Sputtering. Coatings 2018, 8, 50. [Google Scholar] [CrossRef]

- Erdemir, A.; Busch, D.E.; Erck, R.A.; Fenske, G.R.; Lee, R. Ion-Beam-Assisted Deposition of Silver Films on Zirconia Ceramics for Improved Tribological Behavior; Argonne National Lab. (ANL): Argonne, IL, USA, 1990. [Google Scholar]

- Kalin, M. Influence of Flash Temperatures on the Tribological Behaviour in Low-Speed Sliding: A Review. Mater. Sci. Eng. A 2004, 374, 390–397. [Google Scholar] [CrossRef]

| Film Sample | EDS | Deposition Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ratio B/Cr | Ag [at.%] | ICrB2 [A] | UCrB2 [V] | PCrB2 [kW] | fCrB2 [Hz] | ptCrB2 [µs] | PAg [W] | Ib [A] | Thickness [µm] | |

| CrB2.3 | 2.30 | 0 | 70 | 1300 | 78 | 100 | 250 | - | 1.5 | 1.1 |

| Ag 3% | 2.20 | 3 ± 1 | 78 | 30 | 1.4 | 1.2 | ||||

| Ag 8% | 2.20 | 8 ± 1 | 73 | 40 | 1.5 | 1.3 | ||||

| Ag 13% | 2.18 | 13 ± 1 | 71 | 50 | 1.5 | 1.3 | ||||

| Ag 17% | 2.15 | 17 ± 1 | 71 | 60 | 1.5 | 1.4 | ||||

| Ag 18% | 2.05 | 18 ± 1 | 77 | 70 | 1.6 | 1.5 | ||||

| Ag 29% | 2.30 | 29 ± 1 | 77 | 110 | 1.6 | 1.9 | ||||

| Ag | - | 100 | - | - | - | - | - | 110 | 0.1 | 1.4 |

| H [GPa] | E [GPa] | COF | Specific Wear Rate [m3/Nm] | |

|---|---|---|---|---|

| CrB2.3 | 26.6 ± 1.1 | 362 ± 11 | 0.72 | 1.61 × 10−13 |

| Ag 3% | 22.1 ± 0.8 | 325 ± 8 | 0.71 | 9.51 × 10−14 |

| Ag 8% | 18.3 ± 1.2 | 299 ± 9 | 0.49 | 8.38 × 10−14 |

| Ag 13% | 15.0 ± 0.6 | 268 ± 12 | 0.48 | 1.09 × 10−13 |

| Ag 17% | 13.1 ± 0.2 | 245 ± 5 | 0.29 | 1.12 × 10−13 |

| Ag 18% | 11.4 ± 0.1 | 231 ± 5 | 0.32 | 1.27 × 10−13 |

| Ag 29% | 7.8 ± 0.1 | 187 ± 4 | 0.36 | 1.39 × 10−13 |

| Ag | 1.2 ± 0.5 | 97 ± 27 | 0.39 | 6.10 × 10−15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Truchlý, M.; Haršáni, M.; Frkáň, A.; Fiantok, T.; Sahul, M.; Roch, T.; Kúš, P.; Mikula, M. First Approach to Doping Silver into CrB2 Thin Films Deposited by DC/HiPIMS Technology in Terms of Mechanical and Tribological Properties. Coatings 2023, 13, 824. https://doi.org/10.3390/coatings13050824

Truchlý M, Haršáni M, Frkáň A, Fiantok T, Sahul M, Roch T, Kúš P, Mikula M. First Approach to Doping Silver into CrB2 Thin Films Deposited by DC/HiPIMS Technology in Terms of Mechanical and Tribological Properties. Coatings. 2023; 13(5):824. https://doi.org/10.3390/coatings13050824

Chicago/Turabian StyleTruchlý, Martin, Marián Haršáni, Adam Frkáň, Tomáš Fiantok, Martin Sahul, Tomáš Roch, Peter Kúš, and Marián Mikula. 2023. "First Approach to Doping Silver into CrB2 Thin Films Deposited by DC/HiPIMS Technology in Terms of Mechanical and Tribological Properties" Coatings 13, no. 5: 824. https://doi.org/10.3390/coatings13050824

APA StyleTruchlý, M., Haršáni, M., Frkáň, A., Fiantok, T., Sahul, M., Roch, T., Kúš, P., & Mikula, M. (2023). First Approach to Doping Silver into CrB2 Thin Films Deposited by DC/HiPIMS Technology in Terms of Mechanical and Tribological Properties. Coatings, 13(5), 824. https://doi.org/10.3390/coatings13050824