Influence of Multiple Firings on the Color Stability and Surface Roughness of Gingival Pink Feldspathic Ceramic

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation and Grouping of Specimens

2.2. Color Change (ΔE) Assessments

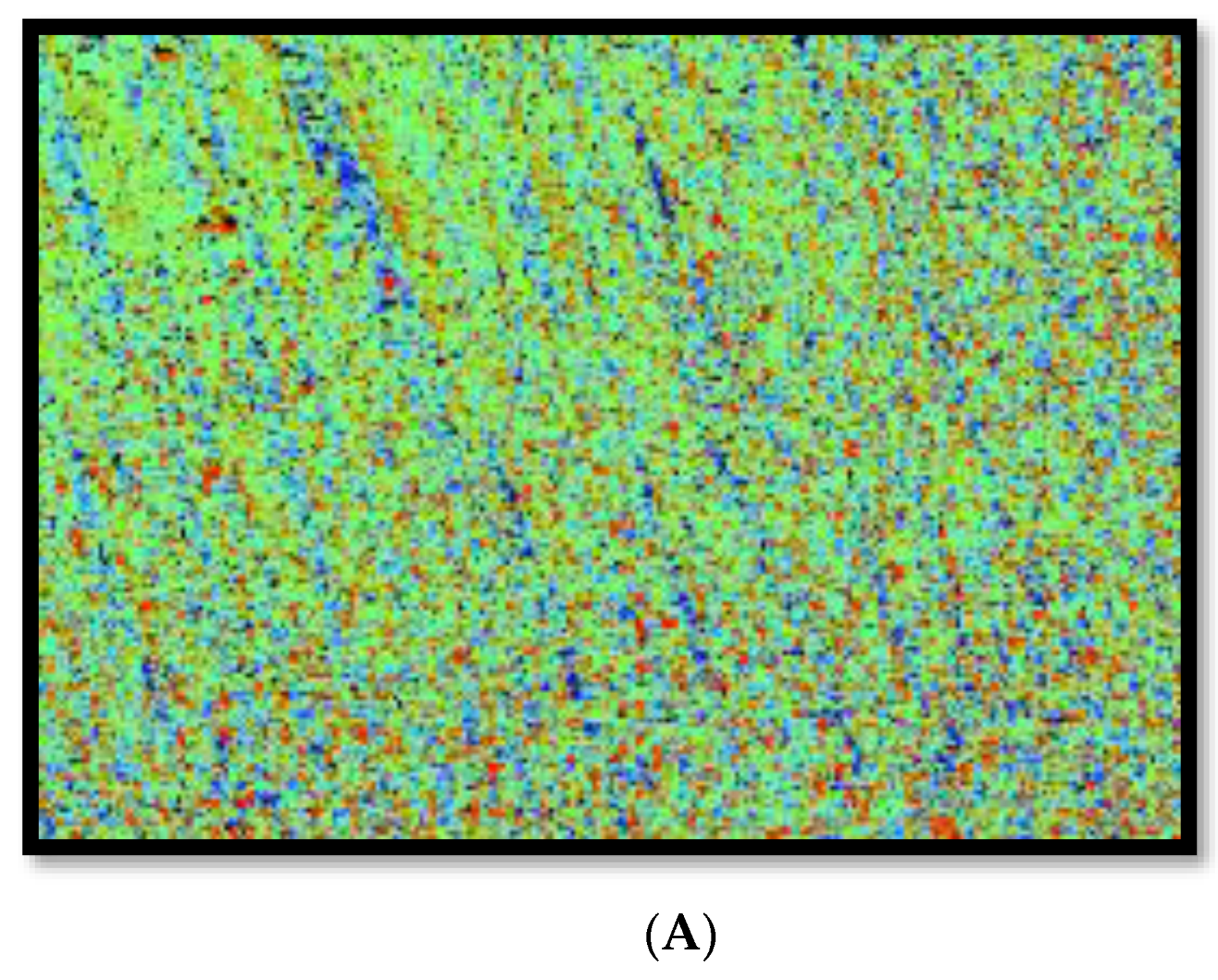

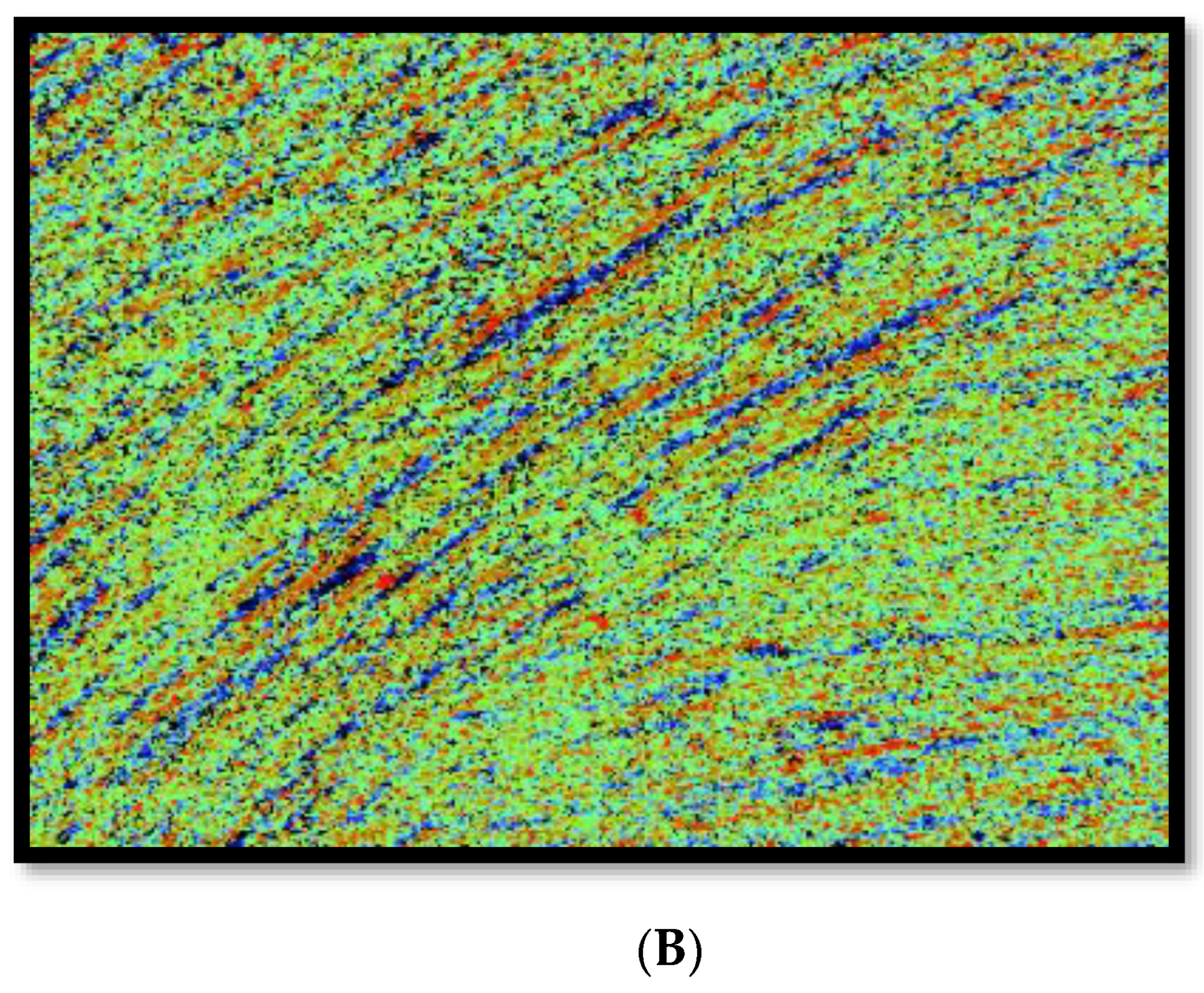

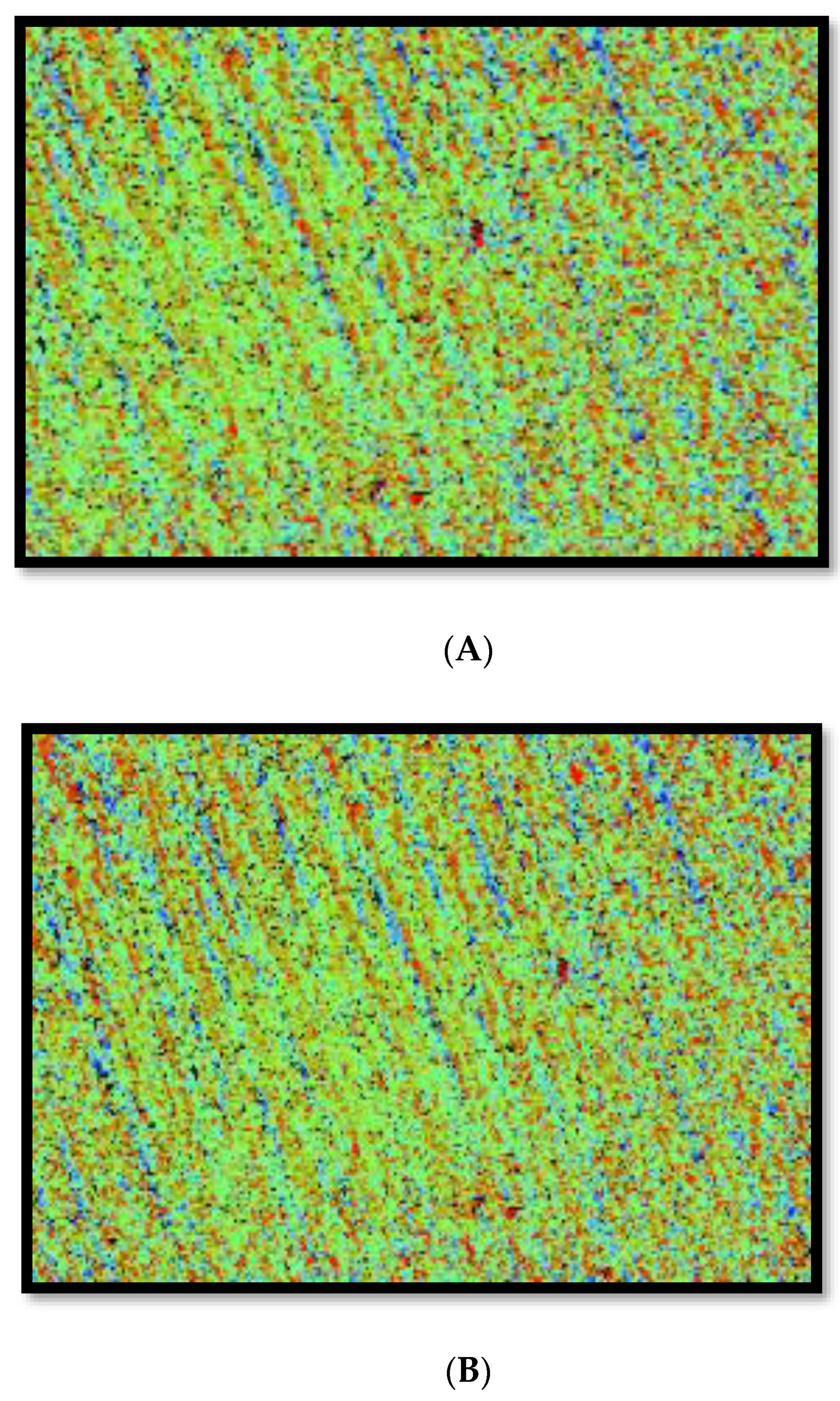

2.3. Ra Analysis

2.4. Statistical Analysis

3. Results

3.1. ∆E Assessment Results

3.2. Ra Analysis Results

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maawadh, A.M.; Almohareb, T.; Al-Hamdan, R.S.; Al Deeb, M.; Naseem, M.; Alhenaki, A.M.; Vohra, F.; Abduljabbar, T. Repair strength and surface topography of lithium disilicate and hybrid resin ceramics with LLLT and photodynamic therapy in comparison to hydrofluoric acid. J. App. Biomat. Func. Mater. 2020, 18, 2280800020966938. [Google Scholar] [CrossRef] [PubMed]

- Awad, M.M.; Al Jeaidi, Z.A.; Almutairi, N.; Vohra, F.; Özcan, M.; Alrahlah, A. Effect of self-etching ceramic primer on bond strength of zirconia-reinforced lithium silicate ceramics. J. Adhes. Sci. Technol. 2020, 34, 91–101. [Google Scholar] [CrossRef]

- Gracis, S.; Thompson, V.P.; Ferencz, J.L.; Silva, N.R.; Bonfante, E.A. A new classification system for all-ceramic and ceramic-like restorative materials. Int. J. Prosthodont. 2015, 28, 227–235. [Google Scholar] [CrossRef] [PubMed]

- Ruales-Carrera, E.; Dal Bó, M.; das Neves, W.F.; Fredel, M.C.; Volpato, C.A.M.; Hotza, D. Chemical tempering of feldspathic porcelain for dentistry applications: A review. Open Ceram. 2022, 9, 100201. [Google Scholar] [CrossRef]

- Nistor, L.; Grădinaru, M.; Rîcă, R.; Mărășescu, P.; Stan, M.; Manolea, H.; Ionescu, A.; Moraru, I. Zirconia Use in Dentistry—Manufacturing and Properties. Curr. Health Sci. J. 2019, 25, 28–35. [Google Scholar]

- Vohra, F.; Labban, N.; Al-Hussaini, A.; Al-Jarboua, M.; Zawawi, R.; Alrahlah, A.; Naseem, M. Influence of Er; Cr: YSGG laser on shear bond strength and color stability of lithium disilicate ceramics: An in vitro study. Photobiomodul. Photomed. Laser Surg. 2019, 37, 483–488. [Google Scholar] [CrossRef]

- AlHamdan, E.M.; Bashiri, A.; Alnashmi, F.; Al-Saleh, S.; Al-shahrani, K.; Al-shahrani, S.; Alsharani, A.; Alzahrani, K.M.; Alqarawi, F.K.; Vohra, F.; et al. Evaluation of Smart Chromatic Technology for a Single-Shade Dental Polymer Resin: An In Vitro Study. Appl. Sci. 2020, 11, 10108. [Google Scholar] [CrossRef]

- Alqutub, M.N.; Mukhtar, A.H.; Alali, Y.; Vohra, F.; Abduljabbar, T. Osteogenic Differentiation of Periodontal Ligament Stem Cells Seeded on Equine-Derived Xenograft in Osteogenic Growth Media. Medicina 2022, 58, 1518. [Google Scholar] [CrossRef]

- Petropoulou, A.; Pappa, E.; Pelekanos, S. Esthetic considerations when replacing maxillary incisors with implants: A clinical report. J. Prosthet. Dent. 2013, 109, 140–144. [Google Scholar] [CrossRef]

- Sonune, S.J.; Kumar, S.; Jadhav, M.S.; Martande, S. Gingival-colored Porcelain: A Clinical Report of an Esthetic-prosthetic Paradigm. Int. J. Appl. Basic Med. Res. 2017, 7, 275–277. [Google Scholar] [CrossRef]

- Kalman, L.; MacIntosh, K. The Use of Pink Porcelain to Manage a Malposed Anterior Implant: Case Report. J. Can. Dent. Assoc. 2013, 79, d117. [Google Scholar] [PubMed]

- Papaspyridakos, P.; Amin, S.; El-Rafie, K.; Weber, H.P. Technique to Match Gingival Shade when Using Pink Ceramics for Anterior Fixed Implant Prostheses. J. Prosthodont. 2018, 27, 311–313. [Google Scholar] [CrossRef] [PubMed]

- Wisniewska, K.; Pichor, W.; Klosek-Wawrzyn, E. Influence of Firing Temperature on Phase Composition and Color Properties of Ceramic Tile Bodies. Materials 2021, 14, 6380. [Google Scholar] [CrossRef] [PubMed]

- Fehmi, G.; Ersan, Ç.; Caner, Ö. Influence of repeated firings on the color parameters of two different all-ceramic materials. Color Res. Appl. 2017, 43, 606–611. [Google Scholar] [CrossRef]

- Yilmaz, K.; Gonuldas, F.; Ozturk, C. The effect of repeated firings on the color change of dental ceramics using different glazing methods. J. Adv. Prosthodont. 2014, 6, 427–433. [Google Scholar] [CrossRef]

- Ozturk, O.; Uludag, B.; Usumez, A.; Sahin, V.; Celik, G. The effect of ceramic thickness and number of firings on the color of two all-ceramic systems. J. Prosthet. Dent. 2008, 100, 99–106. [Google Scholar] [CrossRef]

- Bayindir, F.; Ozbayram, O. Effect of number of firings on the color and translucency of ceramic core materials with veneer ceramic of different thicknesses. J. Prosthet. Dent. 2018, 119, 152–158. [Google Scholar] [CrossRef]

- Hasssija, J.; Hegde, V.; Sridhar, N. An In Vitro Study on Effect of Ceramic Thickness and Multiple Firings on Colour of Metal Ceramic Restorations. J. Indian Prosthodont. Soc. 2014, 14 (Suppl. 1), 86–92. [Google Scholar] [CrossRef]

- Sert, M.; Subasi, M.G.; Donmez, M.B.; Cakmak, G.; Yilmaz, B. Effect of firing cycle and aging on long-term chemical degradation of monolithic CAD-CAM ceramics. J. Prosthet. Dent. 2022, 128, 89 e1–89 e10. [Google Scholar] [CrossRef]

- Filho, H.L.; Maia, L.H.; Araújo, M.V.; Eliast, C.N.; Ruellas, A.C. Colour stability of aesthetic brackets: Ceramicand plastic. Aust. Orthod. J. 2013, 29, 13–20. [Google Scholar]

- Ibrahim, M.; Farghaly, E.; Badih, R. A comparison of color stability between hybrid ceramic and veneers: An in vitro study. Int. Arab J. Dent. 2019, 10, 25–30. [Google Scholar] [CrossRef]

- Javali, M.A.; Abdul Khader, M.; Alqahtani, R.M.; Almufarrij, M.J.; Alqahtani, T.M.; Addas, M.K. Spectrophotometric Analysis of Dental Enamel Staining to Antiseptic and Dietary Agents: In Vitro Study. Int. J. Dent. 2020, 2020, 5429725. [Google Scholar] [CrossRef] [PubMed]

- Alzahrani, K.M.; Alhaqbani, M.M.; Basalem, S.A.; Alsubaie, F.; AlRabiah, M.; Alzahrani, A.; AlAali, K.A.; Farooq, I.; Vohra, F.; Abduljabbar, T. Effect of Staining Drinks on the Color Stability of Grit Blasted and Non-Grit Blasted Monolithic Zirconia: An In Vitro Study. Crystals 2022, 12, 1331. [Google Scholar] [CrossRef]

- Alnassar, T.M. Color Stability of Monolithic Zirconia in Various Staining Liquids: An In Vitro Study. App. Sci. 2022, 12, 9752. [Google Scholar] [CrossRef]

- Gomez-Polo, C.; Portillo Munoz, M.; Lorenzo Luengo, M.C.; Vicente, P.; Galindo, P.; Martin Casado, A.M. Comparison of the CIELab and CIEDE2000 color difference formulas. J. Prosthet. Dent. 2016, 115, 65–70. [Google Scholar] [CrossRef] [PubMed]

- Colombo, M.; Cavallo, M.; Miegge, M.; Dagna, A.; Beltrami, R.; Chiesa, M.; Poggio, C. Color stability of CAD/CAM Zirconia ceramics following exposure to acidic and staining drinks. J. Clin. Exp. Dent. 2017, 9, e1297–e1303. [Google Scholar] [CrossRef]

- Inokoshi, S.; Burrow, M.F.; Kataumi, M.; Yamada, T.; Takatsu, T. Opacity and color changes of tooth-colored restorative materials. Oper. Dent. 1996, 21, 73–80. [Google Scholar]

- Bachhav, V.C.; Aras, M.A. The effect of ceramic thickness and number of firings on the color of a zirconium oxide based all ceramic system fabricated using CAD/CAM technology. J. Adv. Prosthodont. 2011, 3, 57–62. [Google Scholar] [CrossRef]

- Mohamed, S.A.; Ahmed, A.F.; Mekkawi, W.O. Effect of Repeated Firings on the Color Change and Surface Roughness of Two All-ceramic Systems. Al-Azhar Dent. J. Girls 2020, 7, 345–354. [Google Scholar] [CrossRef]

- Talibi, M.; Kaur, K.; Parmar, H. Do you know your ceramics? Part 2: Feldspathic ceramics. Br. Dent. J. 2022, 232, 80–83. [Google Scholar] [CrossRef]

- Dong-Dong, Q.; Lei, Z.; Xiaoping, L.; Wenli, C. Effect of repeated sintering on the color and translucency of dental lithium disilicate-based glass ceramic. Hua Xi Kou Qiang Yi Xue Za Zhi 2015, 33, 50–53. [Google Scholar] [PubMed]

- Fathi, A.; Farzin, M.; Giti, R.; Kalantari, M.H. Effects of number of firings and veneer thickness on the color and translucency of 2 different zirconia-based ceramic systems. J. Prosthet. Dent. 2019, 122, 565 e1–565 e7. [Google Scholar] [CrossRef] [PubMed]

- Yilmaz, K.; Ozkan, P. Profilometer evaluation of the effect of various polishing methods on the surface roughness in dental ceramics of different structures subjected to repeated firings. Quintessence Int. 2010, 41, e125–e131. [Google Scholar] [PubMed]

- Barghi, N. Color and glaze: Effects of repeated firings. J. Prosthet. Dent. 1982, 47, 393–395. [Google Scholar] [CrossRef]

- Denry, I.; Holloway, J.A. Ceramics for Dental Applications: A Review. Materials 2010, 3, 351–368. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Ozcan, M.; Hallmann, L.; Ender, A.; Mehl, A.; Hämmerlet, C.H. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin. Oral Investig. 2013, 17, 269–274. [Google Scholar] [CrossRef]

- Kulvarangkun, A.; Panyayong, W.; Pumpaluk, P. Experimental study of surface roughness of dental ceramics after polishing with three types of polishing systems. J. Int. Soc. Prev. Communit Dent. 2022, 12, 540–546. [Google Scholar]

- Rashid, H. The effect of surface roughness on ceramics used in dentistry: A review of literature. Eur. J. Dent. 2014, 8, 571–579. [Google Scholar] [CrossRef]

| NBS Unit | Color Change Remarks | Clinical Interpretation |

|---|---|---|

| 0.0–0.5 | Trace | Extremely slight change |

| 0.5–1.5 | Slight | Slight change |

| 1.5–3.0 | Noticeable | Perceivable |

| 3.0–6.0 | Appreciable | Marked change |

| 6.0–12.0 | Much | Extremely marked changed |

| >12.0 | Very much | Change to another color |

| L* | a* | b* | ΔE | NBS Units | |

|---|---|---|---|---|---|

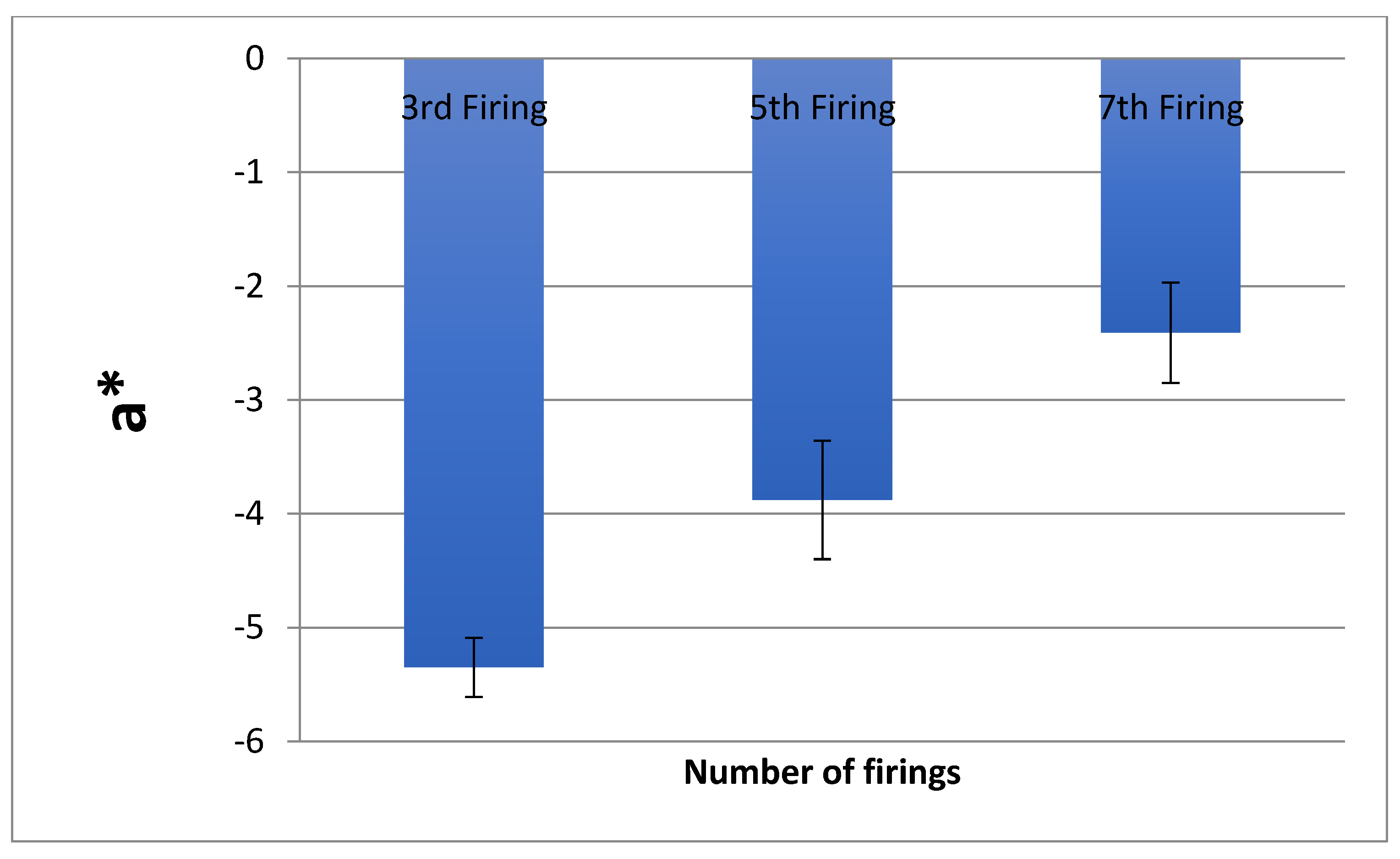

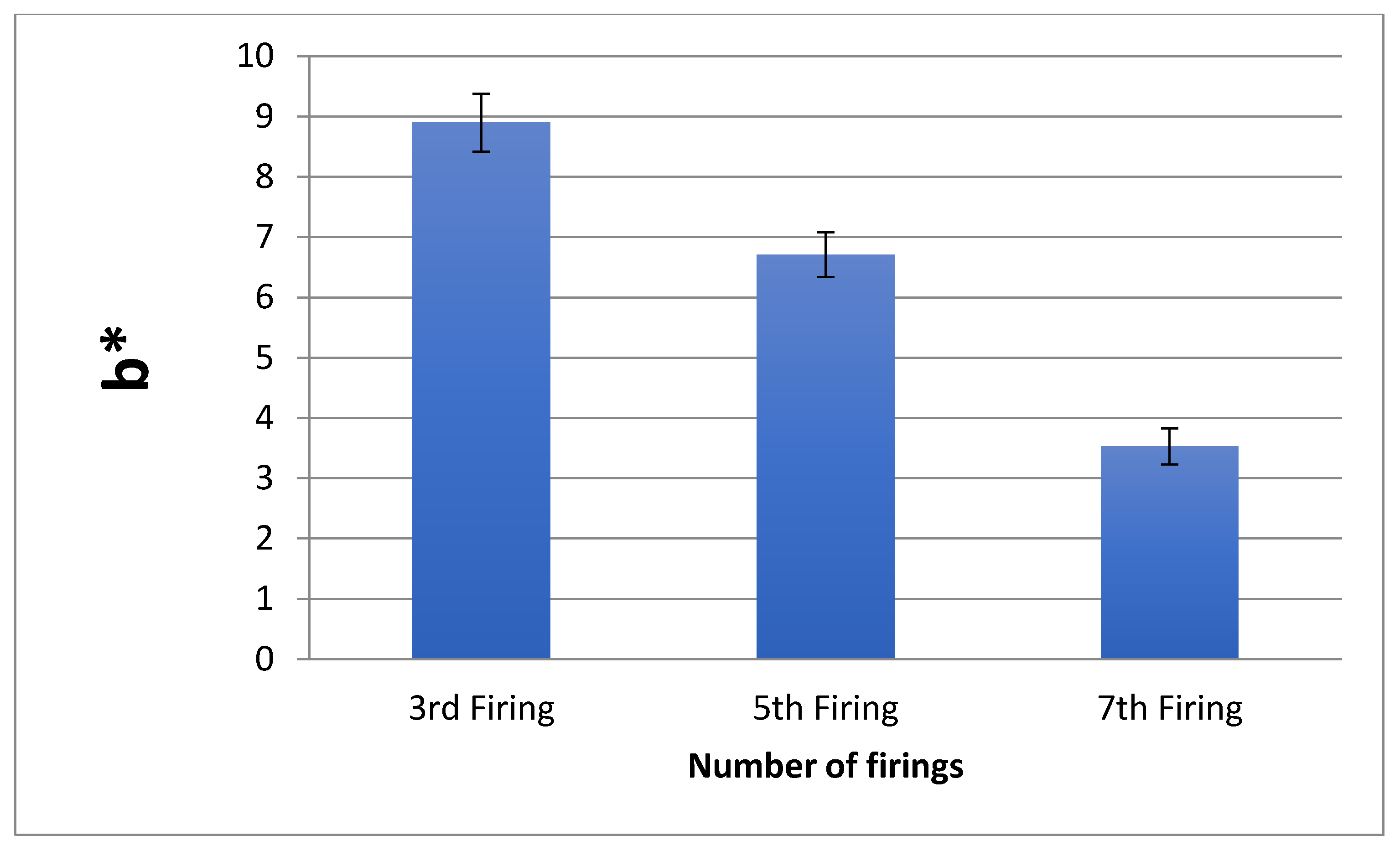

| No. of firing | Mean ± SD | Mean ± SD | Mean ± SD | Mean ± SD | |

| Third | 68.01 ± 1.30 | −5.35 ± 0.26 | 8.90 ± 0.48 | 2.61 A ± 1.20 | 2.40 |

| Fifth | 70.42 ± 1.40 | −3.88 ± 0.52 | 6.71 ± 0.37 | 3.93 B ± 1.66 | 3.61 |

| Seventh | 73.63 ± 1.40 | −2.41 ± 0.44 | 3.53 ± 0.30 | 6.86 C ± 2.18 | 6.31 |

| No. of Firings | Mean ± SD | ANOVA |

|---|---|---|

| First | 1.130 A ± 0.241 | <0.01 * |

| Third | 0.617 B ± 0.144 | |

| Fifth | 0.477 C ± 0.121 | |

| Seventh | 0.425 C ± 0.146 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnassar, T.M. Influence of Multiple Firings on the Color Stability and Surface Roughness of Gingival Pink Feldspathic Ceramic. Coatings 2022, 12, 1870. https://doi.org/10.3390/coatings12121870

Alnassar TM. Influence of Multiple Firings on the Color Stability and Surface Roughness of Gingival Pink Feldspathic Ceramic. Coatings. 2022; 12(12):1870. https://doi.org/10.3390/coatings12121870

Chicago/Turabian StyleAlnassar, Talal M. 2022. "Influence of Multiple Firings on the Color Stability and Surface Roughness of Gingival Pink Feldspathic Ceramic" Coatings 12, no. 12: 1870. https://doi.org/10.3390/coatings12121870

APA StyleAlnassar, T. M. (2022). Influence of Multiple Firings on the Color Stability and Surface Roughness of Gingival Pink Feldspathic Ceramic. Coatings, 12(12), 1870. https://doi.org/10.3390/coatings12121870