Nanoscale ITO Films for Plasmon Resonance-Based Optical Sensors

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

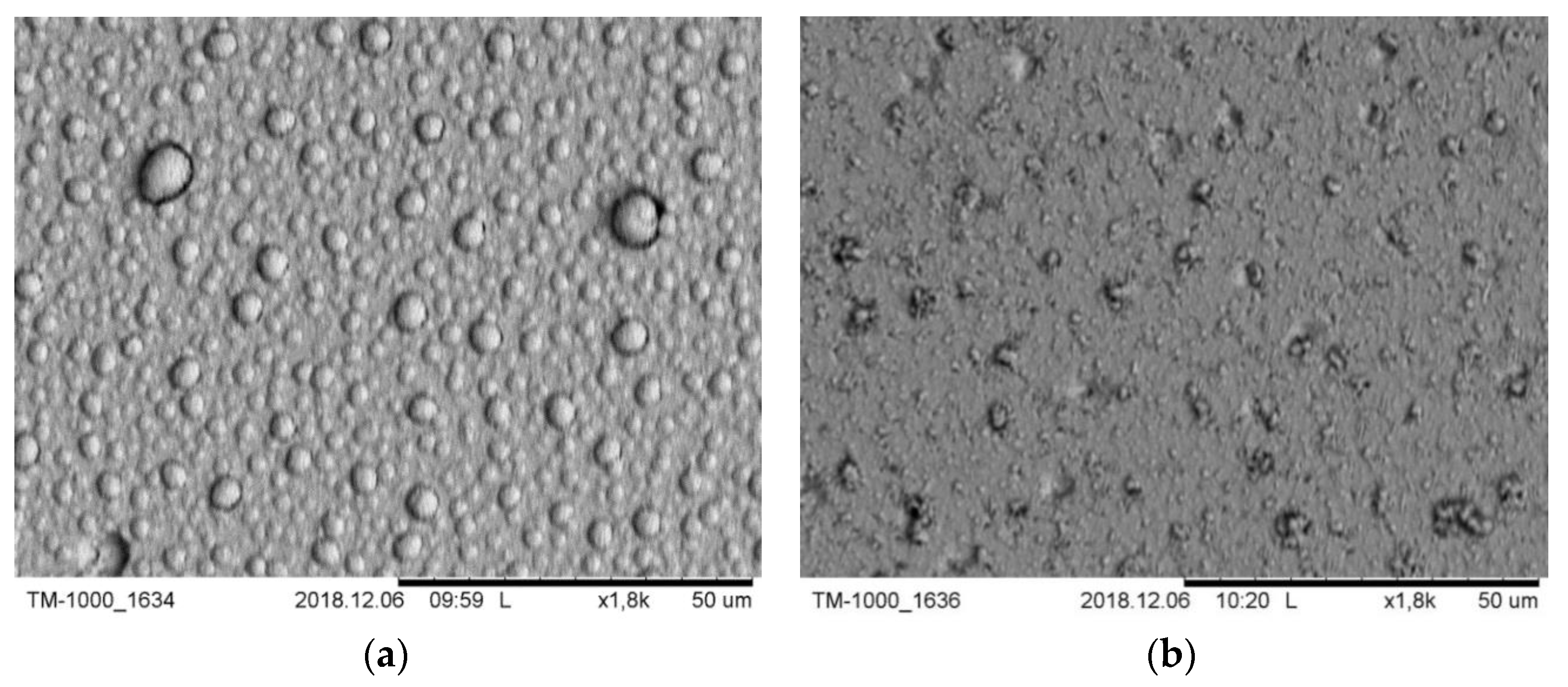

3.1. ITO Film Deposition Technology

3.2. Study of Optical Mode Excitation and Plasmon Resonance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, C.; Lü, J.; Liu, W.; Wang, F.; Chu, P.K. Overview of refractive index sensors comprising photonic crystal fibers based on the surface plasmon resonance effect [Invited]. Chin. Opt. Lett. 2021, 19, 102202. [Google Scholar] [CrossRef]

- Nguyen, H.H.; Park, J.; Kang, S.; Kim, M. Surface Plasmon Resonance: A Versatile Technique for Biosensor Applications. Sensors 2015, 15, 10481–10510. [Google Scholar] [CrossRef] [PubMed]

- Homola, J. Surface Plasmon Resonance Based Sensors; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar] [CrossRef]

- Noguez, C. Surface Plasmons on Metal Nanoparticles: The Influence of Shape and Physical Environment. J. Phys. Chem. C 2007, 111, 3806–3819. [Google Scholar] [CrossRef]

- Anker, J.; Hall, W.; Lyandres, O.; Shah, N.C.; Zhao, J.; Van Duyne, R.P. Biosensing with plasmonic nanosensors. Nat. Mater. 2008, 7, 442–453. [Google Scholar] [CrossRef] [PubMed]

- Saigusa, M.; Tsuboi, K.; Konosu, Y.; Ashizawa, M.; Tanioka, A.; Matsumoto, H. Highly sensitive local surface plasmon resonance in anisotropic Au nanoparticles deposited on nanofibers. J. Nanomater. 2015, 37, 829273. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, C.Z. Screening sensitive nanosensors via the investigation of shape-dependent localized surface plasmon resonance of single Ag nanoparticles. Nanoscale 2013, 5, 7458–7466. [Google Scholar] [CrossRef]

- Chung, H.Y.; Chen, C.C.; Wu, P.C.; Tseng, M.L.; Lin, W.C.; Chen, C.W.; Chiang, H.P. Enhanced sensitivity of surface plasmon resonance phase-interrogation biosensorby using oblique deposited silver nanorods. Nanoscale Res. Lett. 2014, 9, 476–480. [Google Scholar] [CrossRef]

- Su, W.; Zheng, G.; Li, X. Design of a highly sensitive surface plasmon resonance sensor using aluminum based diffraction grating. Opt. Commun. 2012, 285, 4603–4607. [Google Scholar] [CrossRef]

- Sang, X.Z.; Zhang, D.W. Research on the SPR properties of copper thin film with regulation of titanium dioxide. Spectrosc. Spectr. Anal. 2016, 36, 2027–2030. [Google Scholar]

- Usha, S.P.; Mishra, S.K.; Gupta, B.D. Fabrication and characterization of a SPR-based fibre-optic sensor for the detection of chlorine gas using silver and zinc oxide. Materials 2015, 8, 2204–2216. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; Chen, K. Indium–Tin–Oxide Nanostructures for Plasmon-Enhanced Infrared Spectroscopy: A Numerical Study. Micromachines 2019, 10, 241. [Google Scholar] [CrossRef] [PubMed]

- Kamakura, R.; Takeishi, T.; Murai, S.; Fujita, K.; Tanaka, K. Surface-Enhanced Infrared Absorption for the Periodic Array of Indium Tin Oxide and Gold Microdiscs: Effect of in-Plane Light Diffraction. ACS Photonics 2018, 5, 2602–2608. [Google Scholar] [CrossRef]

- Li, S.Q.; Guo, P.; Zhang, L.; Zhou, W.; Odom, T.W.; Seideman, T.; Ketterson, J.B.; Chang, R.P.H. Infrared Plasmonics with Indium–Tin-Oxide Nanorod Arrays. ACS Nano 2011, 5, 9161–9170. [Google Scholar] [CrossRef] [PubMed]

- Abb, M.; Wang, Y.; Papasimakis, N.; de Groot, C.H.; Muskens, O.L. Surface-Enhanced Infrared Spectroscopy Using Metal Oxide Plasmonic Antenna Arrays. Nano Lett. 2014, 14, 346–352. [Google Scholar] [CrossRef]

- Kim, J.; Dutta, A.; Memarzadeh, B.; Kildishev, A.V.; Mosallaei, H.; Boltasseva, A. Zinc Oxide Based Plasmonic Multilayer Resonator: Localized and Gap Surface Plasmon in the Infrared. ACS Photonics 2015, 2, 1224–1230. [Google Scholar] [CrossRef]

- Jiang, H.; Zhou, Y.-R.; Liu, F.-Z.; Zhou, Y.-Q. Effect of annealing treatment on characteristics of surface plasmon resonance for indium tin oxide. Acta Phys. Sin.-Chin. Ed. 2018, 67, 177802. [Google Scholar] [CrossRef]

- Korotkova, K.; Bainov, D.; Smirnov, S.; Yunusov, I.; Zhidik, Y. Electrical Conductivity and Optical Properties of Nanoscale Titanium Films on Sapphire for Localized Plasmon Resonance-Based Sensors. Coatings 2020, 10, 1165. [Google Scholar] [CrossRef]

- Ching-Wei, C.; Yen-Cheng, L.; Chia-Hua, C.; Peichen, Y.; Jia-Min, S.; Ci-Ling, P. Frequency-dependent complex conductrivities and dielectric recponses of indium tin oxide thin films from the visible to the far-infrared. IEEE J. Quantum Electron. 2010, 46, 1746–1754. [Google Scholar] [CrossRef]

- Seeger, K. Lattice Reflection in Polar Semiconductors. In Semiconductor Physics, 8th ed.; Hubertus von Riedesel, Ed.; Springer: Heidelberg, Germany, 2002; pp. 352–354. [Google Scholar] [CrossRef]

- Granqvist, C.G.; Hultaker, A. Transparent and conducting ITO films: New developments and applications. Thin Solid Films 2002, 411, 1–5. [Google Scholar] [CrossRef]

- Untila, G.G.; Kost, T.N.; Chebotareva, A.B.; Timofeev, M.A. Effect of the tin content on the composition and optical and electrical properties of ITO films deposited onto silicon and glass by ultrasonic spray pyrolysis. Semiconductors 2012, 46, 984–990. [Google Scholar] [CrossRef]

- Facchetti, A.; Marks, T.J. Transparent Electronics: From Synthesis to Applications, 1st ed.; Wiley: Hoboken, NJ, USA, 2010; p. 452. [Google Scholar]

- Amosova, L.P. Electrooptical properties and structural features of amorphous ITO. Semiconductors 2015, 49, 414–418. [Google Scholar] [CrossRef]

- Zhidik, Y.S.; Troyan, P.E.; Kozik, V.V.; Kozyukhin, S.A.; Zabolotskaya, A.V.; Kuznetsova, S.A. Investigation of Electrophysical Properties of ITO Films. Russ. Phys. J. 2020, 63, 1139–1143. [Google Scholar] [CrossRef]

- Troyan, P.E.; Zhidik, Y.S.; Sakharov, Y.V. Synthesis of conducting films In2O3:Sn with the method of magnetron sputtering and their electrophysical properties. In Proceedings of the 15th International Conference of Young Specialists on Micro/Nanotechnologies and Electron Devices, Novosibirsk, Russia, 30 June–4 July 2014. [Google Scholar] [CrossRef]

- Oka, N.; Kawase, Y.; Shigesato, Y. High-rate deposition of high-quality Sn-doped In2O3 films by reactive magnetron sputtering using alloy targets. Thin Solid Films 2012, 520, 4101–4105. [Google Scholar] [CrossRef]

- Pasquarelli, R.M.; Ginley, D.S.; O’Hayre, R. Solution processing of transparent conductors: From flask to film. Chem. Soc. Rev. 2011, 40, 5406–5441. [Google Scholar] [CrossRef]

- Xia, G.; Zhou, C.; Jin, S.; Huang, C.; Xing, J.; Liu, Z. Sensitivity Enhancement of Two-Dimensional Materials Based on Genetic Optimization in Surface Plasmon Resonance. Sensors 2019, 19, 1198. [Google Scholar] [CrossRef]

- Mrozek, P.; Gorodkiewicz, E.; Falkowski, P.; Hościło, B. Sensitivity Analysis of Single- and Bimetallic Surface Plasmon Resonance Biosensors. Sensors 2021, 21, 4348. [Google Scholar] [CrossRef] [PubMed]

| Sample Series No | Oxygen in the Gas Mixture | ρS before Annealing, Ohm/□ | ρS after Annealing, Ohm/□ |

|---|---|---|---|

| 1 | 20% | 2475 | 661 |

| 2 | 18% | 1107 | 85.2 |

| 3 | 16% | 1021 | 78.9 |

| 4 | 14% | 873 | 49.4 |

| 5 | 12% | 639 | 13.0 |

| 6 | 10% | 316 | 8.6 |

| 7 | 8% | 594 | 24.5 |

| 8 | 6% | 681 | 37.3 |

| ρV, Ohm·cm | n, cm−3 | μ, cm2/(V·s) | |

|---|---|---|---|

| Before annealing | 3.16 × 10−3 | 7.33 × 1020 | 2.7 |

| After annealing | 8.6 × 10−5 | 2.25 × 1021 | 32.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhidik, Y.; Ivanova, A.; Smirnov, S.; Zhuk, K.; Yunusov, I.; Troyan, P. Nanoscale ITO Films for Plasmon Resonance-Based Optical Sensors. Coatings 2022, 12, 1868. https://doi.org/10.3390/coatings12121868

Zhidik Y, Ivanova A, Smirnov S, Zhuk K, Yunusov I, Troyan P. Nanoscale ITO Films for Plasmon Resonance-Based Optical Sensors. Coatings. 2022; 12(12):1868. https://doi.org/10.3390/coatings12121868

Chicago/Turabian StyleZhidik, Yury, Anna Ivanova, Serafim Smirnov, Klavdiya Zhuk, Igor Yunusov, and Pavel Troyan. 2022. "Nanoscale ITO Films for Plasmon Resonance-Based Optical Sensors" Coatings 12, no. 12: 1868. https://doi.org/10.3390/coatings12121868

APA StyleZhidik, Y., Ivanova, A., Smirnov, S., Zhuk, K., Yunusov, I., & Troyan, P. (2022). Nanoscale ITO Films for Plasmon Resonance-Based Optical Sensors. Coatings, 12(12), 1868. https://doi.org/10.3390/coatings12121868