Study on the Electrical, Structural, Chemical and Optical Properties of PVD Ta(N) Films Deposited with Different N2 Flow Rates

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

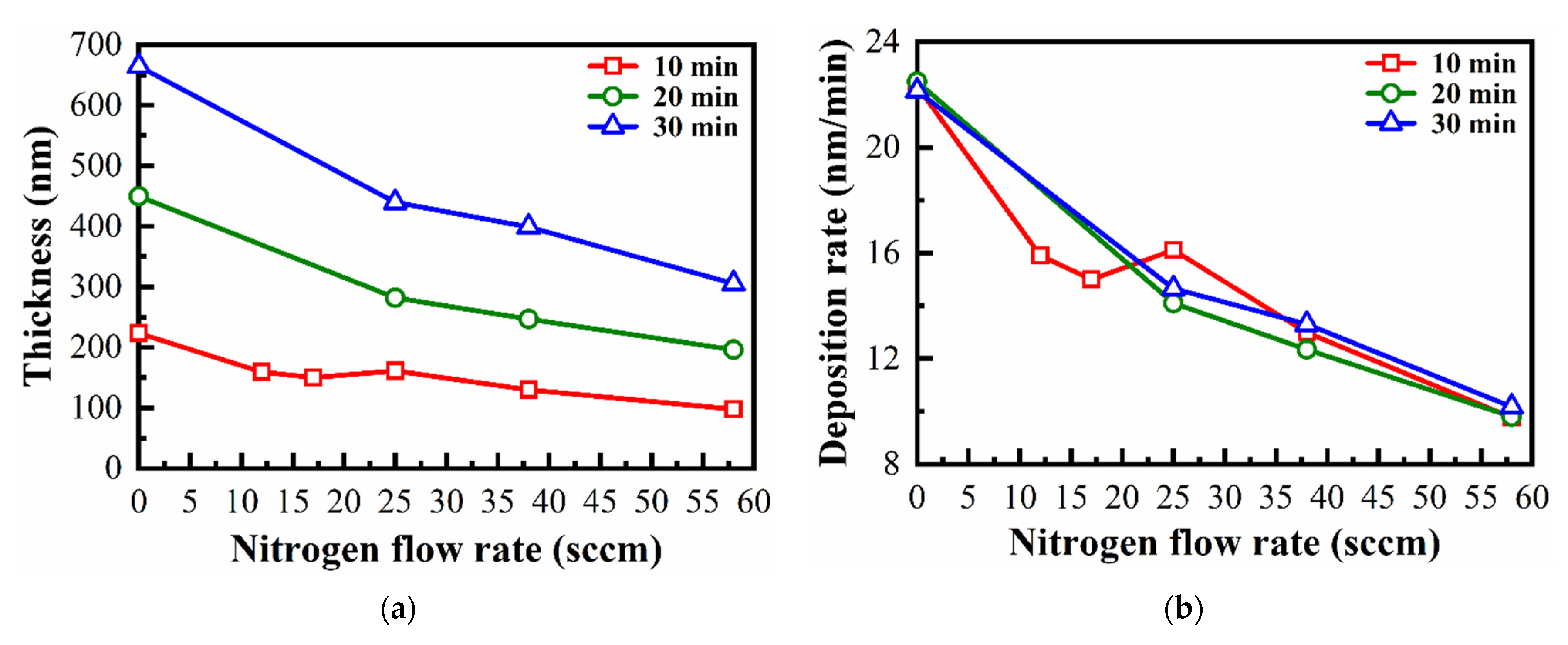

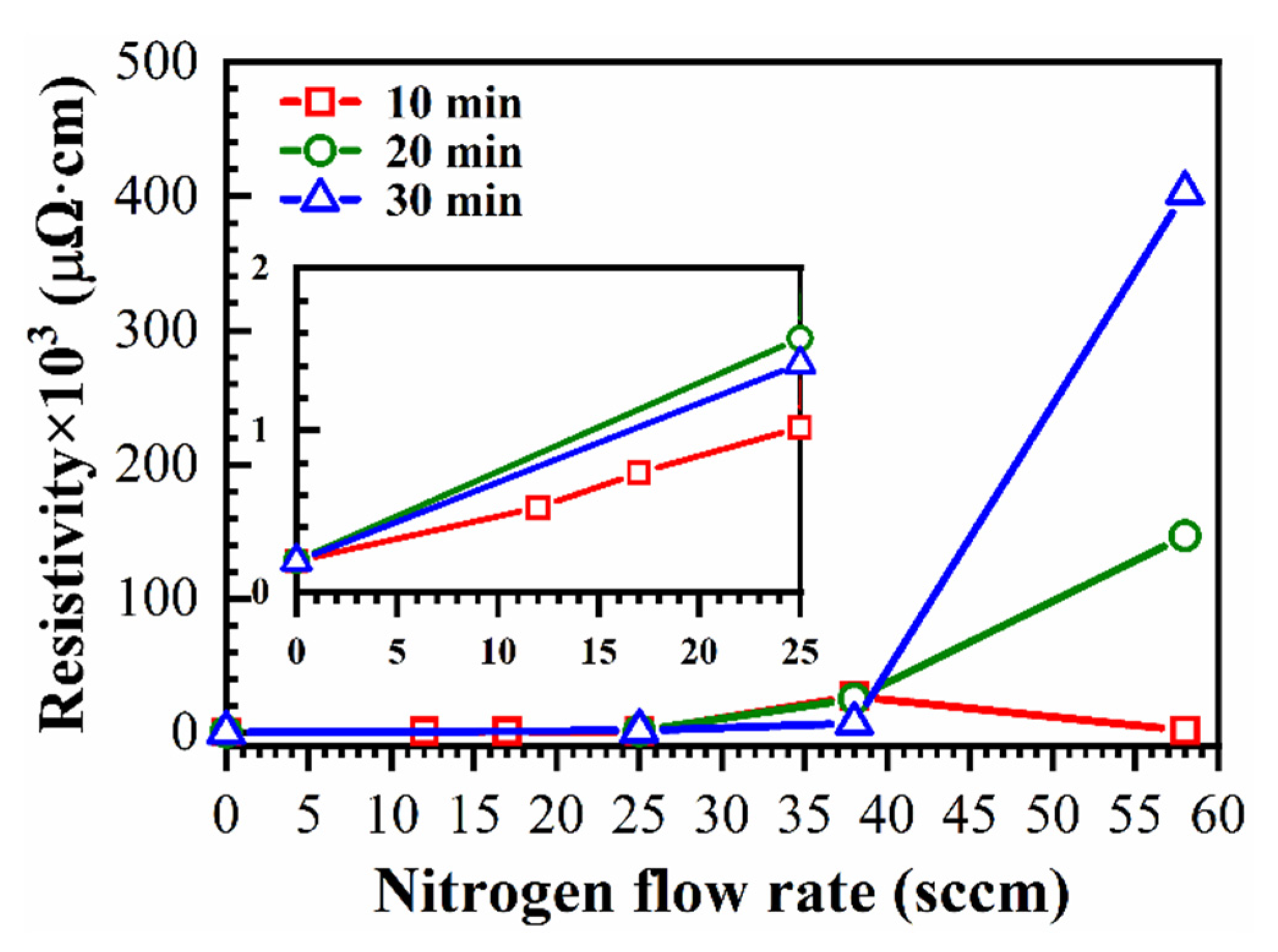

3.1. Deposition Rate and Resistivity

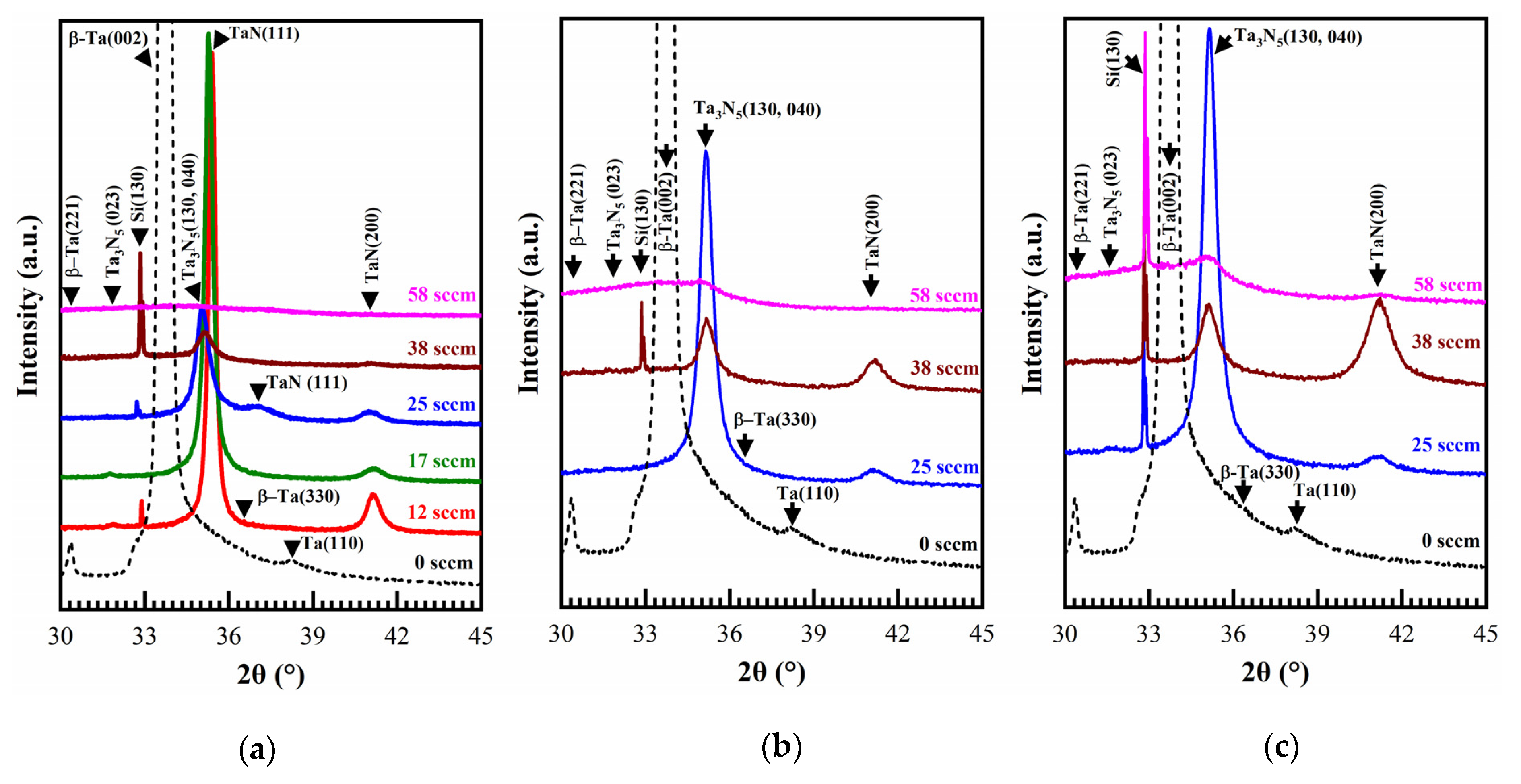

3.2. Structural Properties (XRD Analysis)

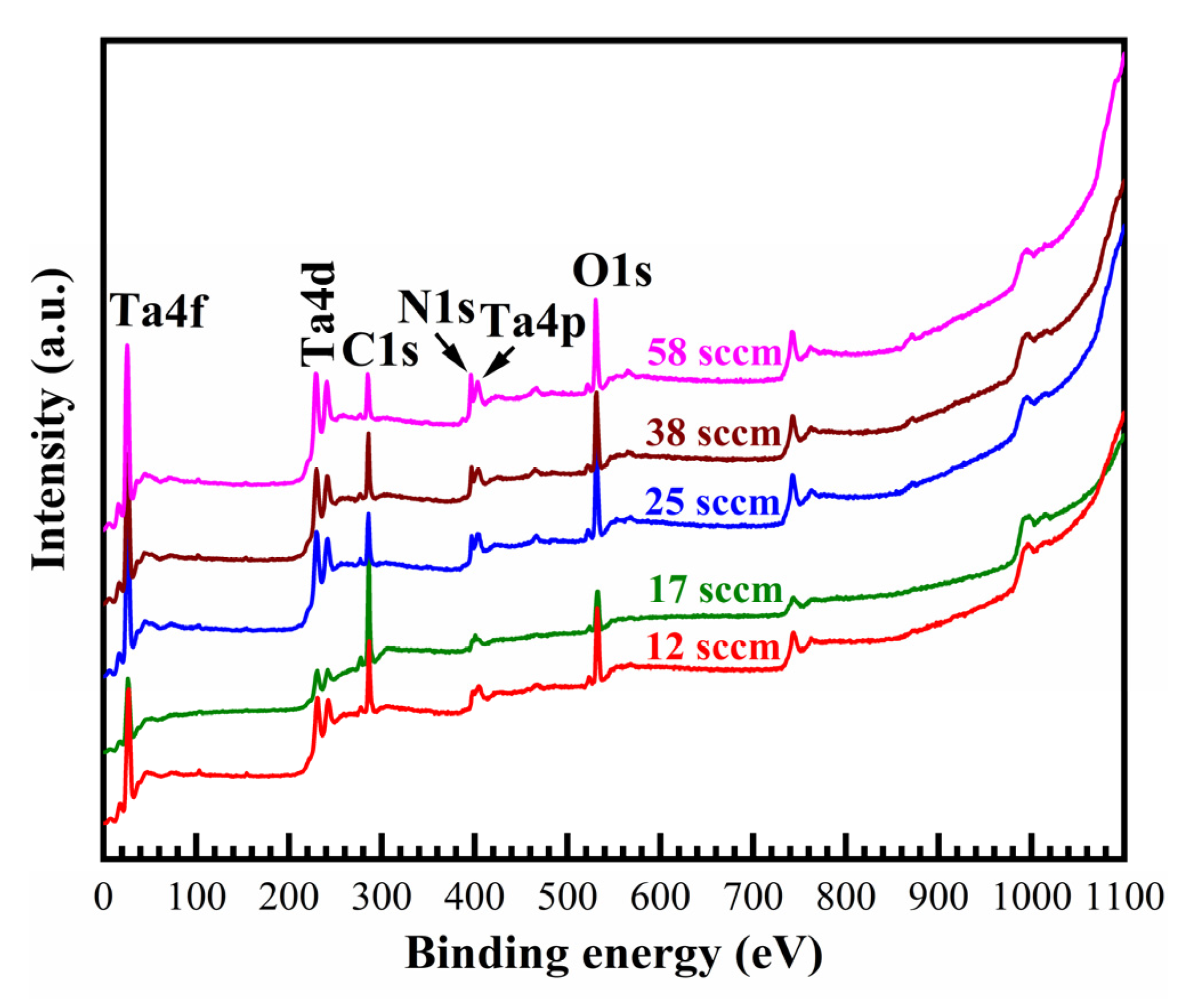

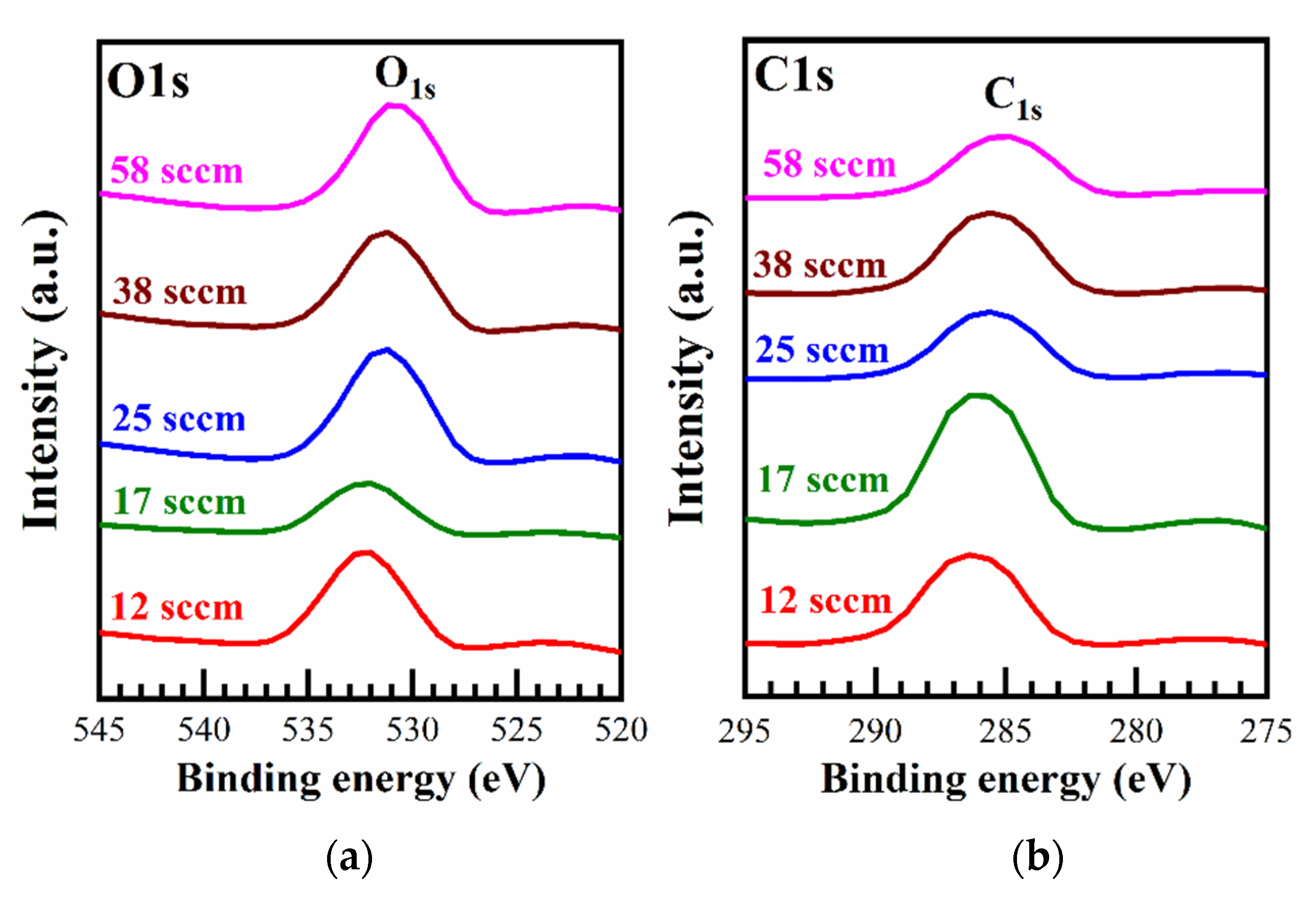

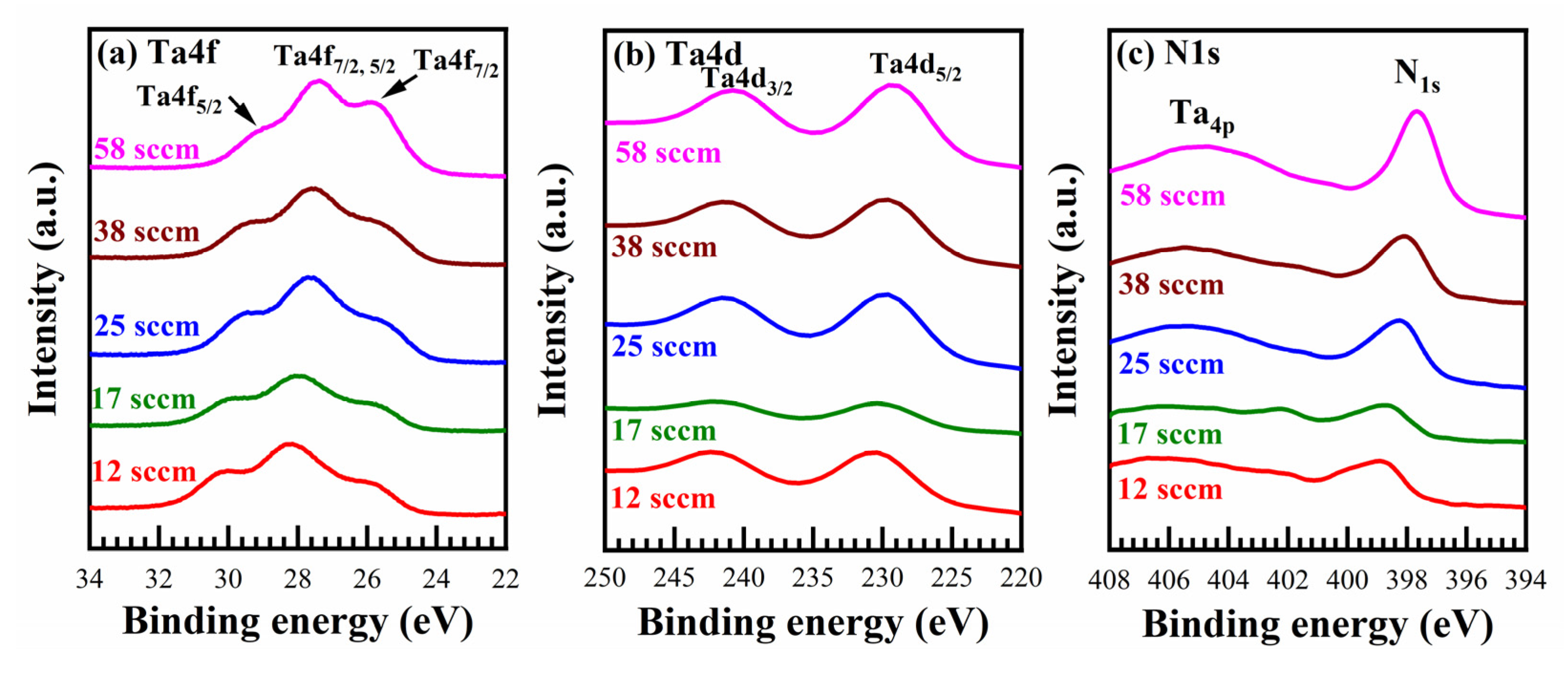

3.3. Elemental Composition (XPS Studies)

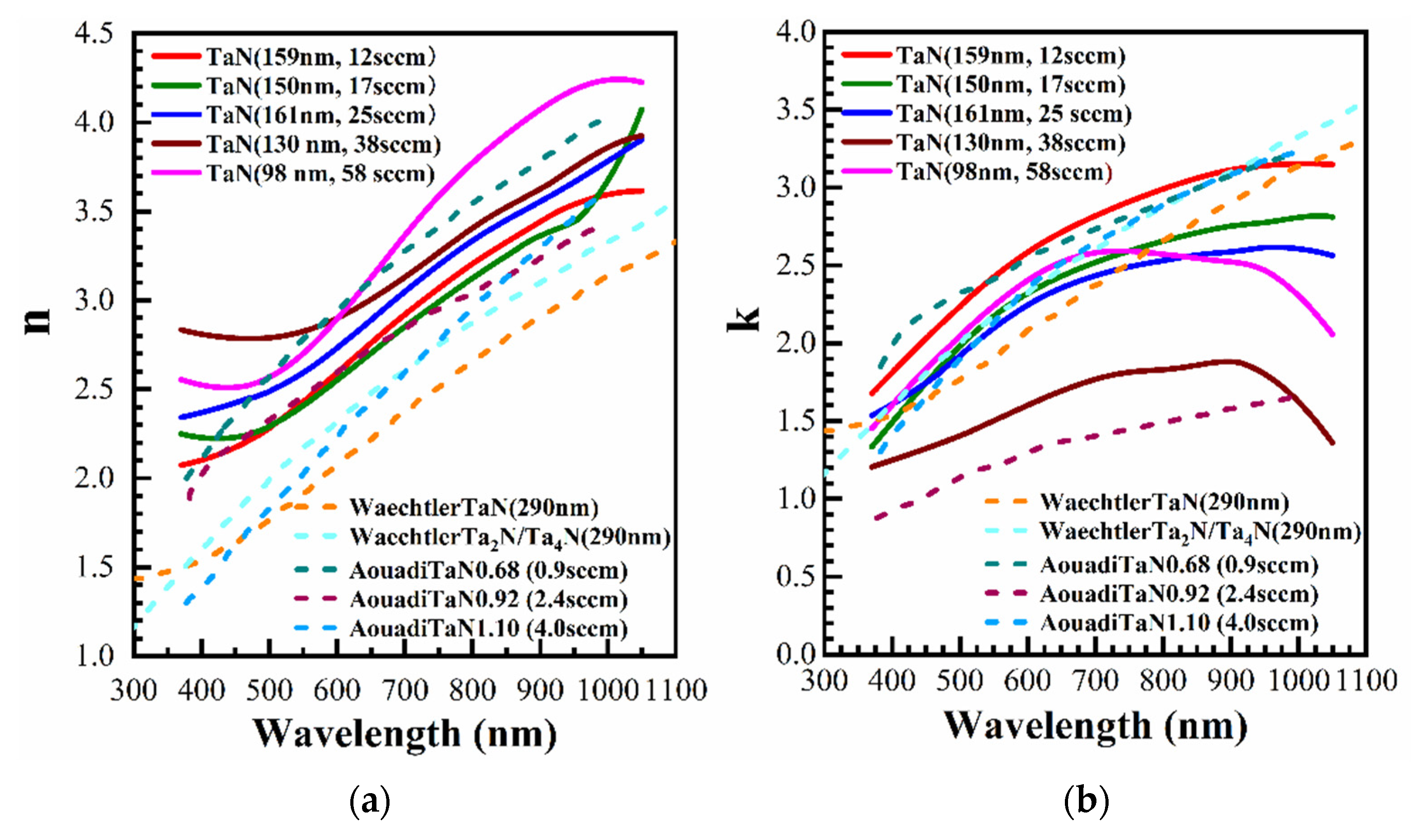

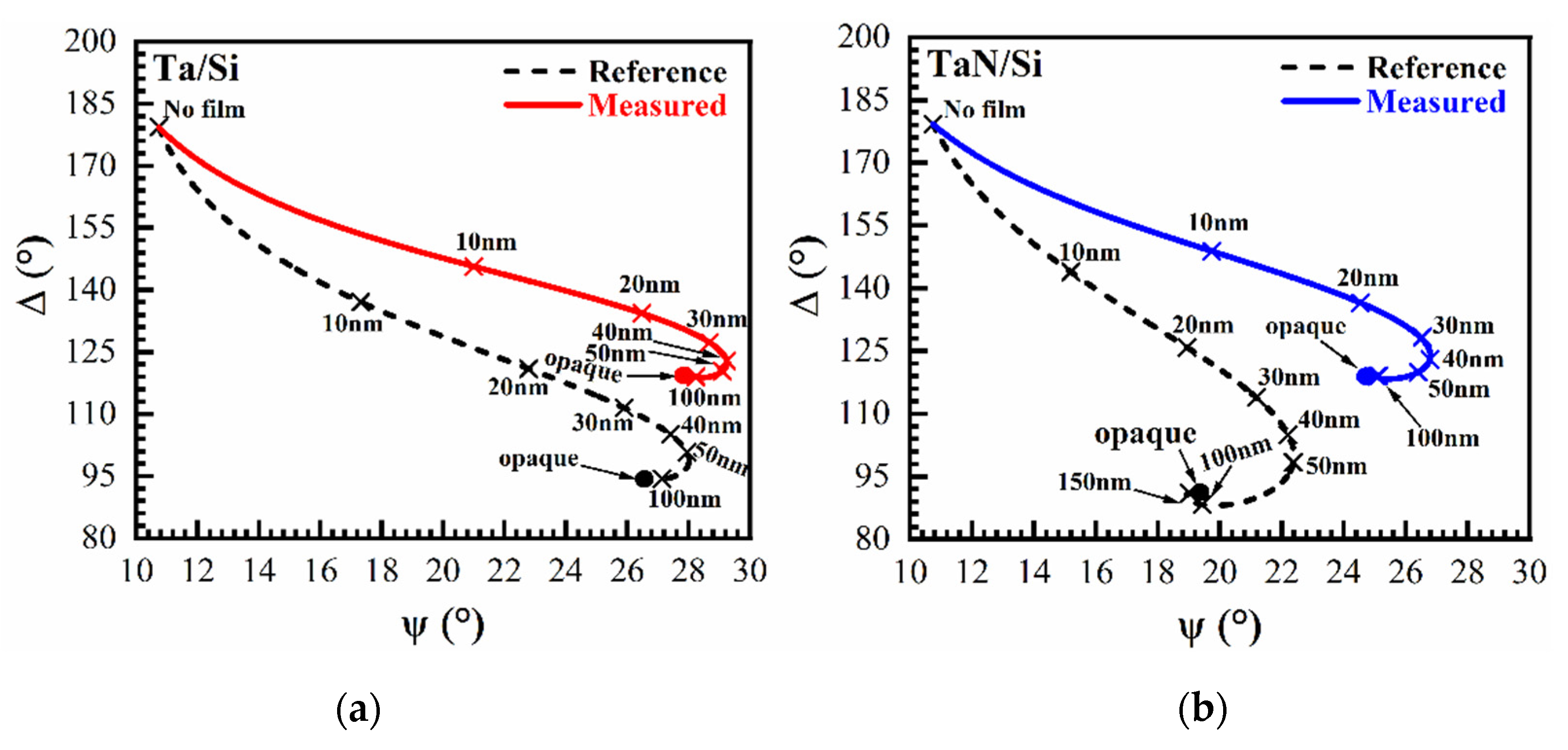

3.4. Optical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, J.H.; Kim, H.Y.; Lee, S.C.; Kim, D.H.; Park, B.K.; Park, J.-S.; Jeon, D.J.; Chung, T.-M.; Kim, C.G. Growth of tantalum nitride film as a Cu diffusion barrier by plasma-enhanced atomic layer deposition from bis((2-(dimethylamino)ethyl) (methyl)amido)methyl(tert-butylimido)tantalum complex. Appl. Surf. Sci. 2016, 362, 176–181. [Google Scholar] [CrossRef]

- Aouadi, S.M.; Debessai, M. Optical properties of tantalum nitride films fabricated using reactive unbalanced magnetron sputtering. J. Vac. Sci. Technol. A Vac. Surf. Film 2004, 22, 1975–1979. [Google Scholar] [CrossRef]

- Kang, S.M.; Yoon, S.G.; Suh, S.J.; Yoon, D.H. Control of electrical resistivity of TaN thin films by reactive sputtering for embedded passive resistors. Thin Solid Films 2008, 516, 3568–3571. [Google Scholar] [CrossRef]

- Lovejoy, M.L.; Patrizi, G.A.; Roger, D.J.; Barbour, J.C. Thin-film tantalum-nitride resistor technology for phosphide-based optoelectronics. Thin Solid Films 1996, 290–291, 513–517. [Google Scholar] [CrossRef]

- Shin, C.-S.; Kim, Y.-W.; Hellgren, N.; Gall, D.; Petrov, I.; Greene, J.E. Epitaxial growth of metastable δ-TaN layers on MgO(001) using low-energy, high-flux ion irradiation during ultrahigh vacuum reactive magnetron sputtering. J. Vac. Sci. Technol. A Vac. Surf. Film 2002, 20, 2007. [Google Scholar] [CrossRef] [Green Version]

- Shin, C.-S.; Gall, D.; Kim, Y.-W.; Hellgren, N.; Petrov, I.; Greene, J.E. Development of preferred orientation in polycrystalline NaCl-structure δ-TaN layers grown by reactive magnetron sputtering: Role of low-energy ion surface interactions. J. Appl. Phys. 2002, 92, 5084–5093. [Google Scholar] [CrossRef]

- Patel, A.; Gladczuk, L.; Paur, C.S.; Sosnowski, M. Tantalum Nitride Seed Layers for Bcc Tantalum Coatings Deposited on Steel by Magnetron Sputtering. MRS Proc. 2002, 750, 523. [Google Scholar] [CrossRef]

- Dalili, N.; Liu, Q.; Ivey, D.G. Thermal and electrical stability of TaNx diffusion barriers for Cu metallization. J. Mater. Sci. 2013, 48, 489–501. [Google Scholar] [CrossRef]

- Volpi, F.; Cadix, L.; Berthomé, G.; Coindeau, S.; Encinas, T.; Jourdan, N.; Blanquet, E. Impact of silica-substrate chemistry on tantalum nitride thin films deposited by atomic layer deposition: Microstructure, chemistry and electrical behaviors. Thin Solid Films 2019, 669, 392–398. [Google Scholar] [CrossRef]

- Liu, C.H.; Liu, W.; Wang, Y.H.; Wang, Y.; An, Z.; Song, Z.X.; Xu, K.W. Interface stability and microstructure of an ultrathin α-Ta/graded Ta(N)/TaN multilayer diffusion barrier. Microelectron. Eng. 2012, 98, 80–84. [Google Scholar] [CrossRef]

- Witt, C.; Yeap, K.B.; Lesniewska, A.; Wan, D.; Jordan, N.; Ciofi, I.; Wu, C.; Tokei, Z. Testing The Limits of TaN Barrier Scaling. In Proceedings of the 2018 IEEE International Interconnect Technology Conference (IITC), Santa Clara, CA, USA, 4–7 June 2018; pp. 54–56. [Google Scholar]

- Leng, Y.; Sun, H.; Yang, P.; Chen, J.; Wang, J.; Wan, G.; Huang, N.; Tian, X.; Wang, L.; Chu, P. Biomedical properties of tantalum nitride films synthesized by reactive magnetron sputtering. Thin Solid Films 2001, 398–399, 471–475. [Google Scholar] [CrossRef]

- Shostachenko, S.A.; Zakharchenko, R.V.; Ryzhuk, R.V.; Leshchev, S.V. Thermal stability of tantalum nitride based thin film resistors. IOP Conf. Ser. Mater. Sci. Eng. 2019, 498, 012014. [Google Scholar] [CrossRef]

- Ayerdi, I.; Castaño, E.; García-Alonso, A.; Gracia, J. High-temperature ceramic pressure sensor. Sens. Actuators A Phys. 1997, 60, 72–75. [Google Scholar] [CrossRef]

- Kundu, A.; Yang, X.; Ma, J.; Feng, T.; Carrete, J.; Ruan, X.; Madsen, G.K.H.; Li, W. Ultrahigh Thermal Conductivity of θ-Phase Tantalum Nitride. Phys. Rev. Lett. 2021, 126, 115901. [Google Scholar] [CrossRef] [PubMed]

- Aouadi, S.M. Structural and mechanical properties of TaZrN films: Experimental and ab initio studies. J. Appl. Phys. 2006, 99, 053507. [Google Scholar] [CrossRef] [Green Version]

- Aouadi, S.M.; Bohnhoff, A.; Amriou, T.; Williams, M.; Hilfiker, J.N.; Singh, N.; Woollam, J.A. Vacuum ultra-violet spectroscopic ellipsometry study of single- and multi-phase nitride protective films. J. Phys. Condens. Matter 2006, 18, S1691–S1701. [Google Scholar] [CrossRef]

- Nazon, J.; Sarradin, J.; Flaud, V.; Tedenac, J.C.; Fréty, N. Effects of processing parameters on the properties of tantalum nitride thin films deposited by reactive sputtering. J. Alloys Compd. 2008, 464, 526–531. [Google Scholar] [CrossRef]

- Tsukimoto, S.; Moriyama, M.; Murakami, M. Microstructure of amorphous tantalum nitride thin films. Thin Solid Films 2004, 460, 222–226. [Google Scholar] [CrossRef]

- Bernoulli, D.; Müller, U.; Schwarzenberger, M.; Hauert, R.; Spolenak, R. Magnetron sputter deposited tantalum and tantalum nitride thin films: An analysis of phase, hardness and composition. Thin Solid Films 2013, 548, 157–161. [Google Scholar] [CrossRef]

- Lee, W.-H.; Lin, J.-C.; Lee, C. Characterization of tantalum nitride films deposited by reactive sputtering of Ta in N2/Ar gas mixtures. Mater. Chem. Phys. 2001, 68, 266–271. [Google Scholar] [CrossRef]

- Wang, J.H.; Chen, L.J.; Lu, Z.C.; Hsiung, C.S.; Hsieh, W.Y.; Yew, T.R. Ta and Ta–N diffusion barriers sputtered with various N2/Ar ratios for Cu metallization. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2002, 20, 1522. [Google Scholar] [CrossRef]

- Lee, T.; Watson, K.; Fen, C.; Gill, J.; Harmon, D.; Sullivan, T.; Li, B. Characterization and reliability of TaN thin film resistors. In Proceedings of the 2004 IEEE International Reliability Physics Symposium, Phoenix, AZ, USA, 25–29 April 2004; pp. 502–508. [Google Scholar]

- Hantehzadeh, M.R.; Mortazavi, S.H.; Faryadras, S.; Ghoranneviss, M. The effect of temperature on the structure of tantalum nitride (TaN) thin films deposited by DC plasma. J. Fusion Energy 2012, 31, 84–88. [Google Scholar] [CrossRef]

- Chen, S.-F.; Wang, S.-J.; Yang, T.-H.; Yang, Z.-D.; Bor, H.-Y.; Wei, C.-N. Effect of nitrogen flow rate on TaN diffusion barrier layer deposited between a Cu layer and a Si-based substrate. Ceram. Int. 2017, 43, 12505–12510. [Google Scholar] [CrossRef]

- Zaman, A.; Meletis, E. Microstructure and Mechanical Properties of TaN Thin Films Prepared by Reactive Magnetron Sputtering. Coatings 2017, 7, 209. [Google Scholar] [CrossRef] [Green Version]

- Waechtler, T.; Gruska, B.; Zimmermann, S.; Schulz, S.; Gessner, T. Characterization of Sputtered Ta and TaN Films by Spectroscopic Ellipsometry. In Proceedings of the 2006 8th International Conference on Solid-State and Integrated Circuit Technology, Shanghai, China, 23–26 October 2006; pp. 2184–2186. [Google Scholar]

- Ma, Q.; Shi, X.; Bi, L.; Li, J.; Zhou, Q.; Zhu, B. Influence of the deposition temperature on the optical and electrical properties of TiN film by spectroscopic ellipsometry. Superlattices Microstruct. 2021, 151, 106815. [Google Scholar] [CrossRef]

- Johs, B.D.; Hale, J.; Ianno, N.J.; Herzinger, C.M.; Tiwald, T.E.; Woollam, J.A. Recent developments in spectroscopic ellipsometry for in situ applications. In Optical Metrology Roadmap for the Semiconductor, Optical, and Data Storage Industries II.; Duparre, A., Singh, B., Eds.; International Society for Optics and Photonics: Bellingham, WA, USA, 2001; Volume 4449, pp. 41–57. [Google Scholar]

- Cherfi, D.E.; Guemmaz, M.; Bourahli, M.E.H.; Ouadfel, M.A.; Maabed, S. Effects of Nitrogen Flow Rate on the Structural, Morphological and Optical Properties of TaN Thin Films Grown by the DC Magnetron Sputtered Technique. Acta Phys. Pol. A 2019, 136, 849–854. [Google Scholar] [CrossRef]

- Xu, H.; Hu, Z.-J.; Qu, X.-P.; Wan, H.; Yan, S.-S.; Li, M.; Chen, S.-M.; Zhao, Y.-H.; Zhang, J.; Baklanov, M.R. Effect of thickness scaling on the permeability and thermal stability of Ta(N) diffusion barrier. Appl. Surf. Sci. 2019, 498, 143887. [Google Scholar] [CrossRef]

- Shamiryan, D.; Baklanov, M.R.; Maex, K. Diffusion barrier integrity evaluation by ellipsometric porosimetry. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2003, 21, 220. [Google Scholar] [CrossRef]

- Kondoh, E. Ellipsheet: Spreadsheet Ellipsometry (Excel Ellipsometer). Available online: http://www.ccn.yamanashi.ac.jp/~kondoh/ellips.html (accessed on 1 January 2021).

- Lee, K.; Lee, K. Optical Properties and X-ray Photoelectron Spectroscopy Study ofReactive-sputtered Ta-N Thin Films. J. Korean Phys. Soc. 2009, 55, 966–970. [Google Scholar] [CrossRef]

- Arshi, N.; Lu, J.; Joo, Y.K.; Yoon, J.H.; Koo, B.H. Effects of nitrogen composition on the resistivity of reactively sputtered TaN thin films. Surf. Interface Anal. 2015, 47, 154–160. [Google Scholar] [CrossRef]

- Cheviot, M.; Gouné, M.; Poulon-Quintin, A. Monitoring tantalum nitride thin film structure by reactive RF magnetron sputtering: Influence of processing parameters. Surf. Coatings Technol. 2015, 284, 192–197. [Google Scholar] [CrossRef]

- Schauer, A.; Roschy, M.R.F. sputtered β-tantalum and b.c.c. tantalum films. Thin Solid Films 1972, 12, 313–317. [Google Scholar] [CrossRef]

- Cuong, N.D.; Kim, D.-J.; Kang, B.-D.; Kim, C.S.; Yu, K.-M.; Yoon, S.-G. Characterization of Tantalum Nitride Thin Films Deposited on SiO2/Si Substrates Using dc Magnetron Sputtering for Thin Film Resistors. J. Electrochem. Soc. 2006, 153, G164. [Google Scholar] [CrossRef]

- Arshi, N.; Lu, J.; Lee, C.G.; Koo, B.H.; Ahmed, F. Effects of Nitrogen Content on the Phase and Resistivity of TaN Thin Films Deposited by Electron Beam Evaporation. JOM 2014, 66, 1893–1899. [Google Scholar] [CrossRef]

- Rossnagel, S.M. Characteristics of ultrathin Ta and TaN films. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2002, 20, 2328. [Google Scholar] [CrossRef]

- Lu, Y.; Weng, R.; Hwang, W.; Yang, Y. Study of phase transition and electrical resistivity of tantalum nitride films prepared by DC magnetron sputtering with OES detection system. Thin Solid Films 2001, 398–399, 356–360. [Google Scholar] [CrossRef]

- Oku, T.; Kawakami, E.; Uekubo, M.; Takahiro, K.; Yamaguchi, S.; Murakami, M. Diffusion barrier property of TaN between Si and Cu. Appl. Surf. Sci. 1996, 99, 265–272. [Google Scholar] [CrossRef]

- Willmott, D.J. Effect of nitrogen on the electrical and structural properties of triode-sputtered tantalum films. J. Appl. Phys. 1972, 43, 4865–4871. [Google Scholar] [CrossRef]

- Nie, H.B.; Xu, S.Y.; Wang, S.J.; You, L.P.; Yang, Z.; Ong, C.K.; Li, J.; Liew, T.Y.F. Structural and electrical properties of tantalum nitride thin films fabricated by using reactive radio-frequency magnetron sputtering. Appl. Phys. A Mater. Sci. Process. 2001, 73, 229–236. [Google Scholar] [CrossRef] [Green Version]

- Riekkinen, T.; Molarius, J.; Laurila, T.; Nurmela, A.; Suni, I.; Kivilahti, J. Reactive sputter deposition and properties of TaxN thin films. Microelectron. Eng. 2002, 64, 289–297. [Google Scholar] [CrossRef]

- Sun, X.; Kolawa, E.; Chen, J.-S.; Reid, J.S.; Nicolet, M.-A. Properties of reactively sputter-deposited Ta–N thin films. Thin Solid Films 1993, 236, 347–351. [Google Scholar] [CrossRef]

- Stampfl, C.; Freeman, A.J. Stable and metastable structures of the multiphase tantalum nitride system. Phys. Rev. B 2005, 71, 024111. [Google Scholar] [CrossRef] [Green Version]

- Ishikawa, A.; Takata, T.; Matsumura, T.; Kondo, J.N.; Hara, M.; Kobayashi, H.; Domen, K. Oxysulfides Ln2Ti2S2O5 as Stable Photocatalysts for Water Oxidation and Reduction under Visible-Light Irradiation. J. Phys. Chem. B 2004, 108, 2637–2642. [Google Scholar] [CrossRef]

- Fang, Z.; Aspinall, H.C.; Odedra, R.; Potter, R.J. Atomic layer deposition of TaN and Ta3N5 using pentakis(dimethylamino)tantalum and either ammonia or monomethylhydrazine. J. Cryst. Growth 2011, 331, 33–39. [Google Scholar] [CrossRef]

- Stampfl, C.; Freeman, A.J. Metallic to insulating nature of TaNx: Role of Ta and N vacancies. Phys. Rev. B 2003, 67, 064108. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Hisatomi, T.; Minegishi, T.; Nakabayashi, M.; Shibata, N.; Katayama, M.; Domen, K. Thin film transfer for the fabrication of tantalum nitride photoelectrodes with controllable layered structures for water splitting. Chem. Sci. 2016, 7, 5821–5826. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hashizume, T.; Saiki, A.; Terayama, K. Fabrication of Tantalum nitride thin film using the low vacuum magnetron sputtering system. IOP Conf. Ser. Mater. Sci. Eng. 2011, 18, 092032. [Google Scholar] [CrossRef]

- Sung, Y.-M.; Kim, H.-J. Optimum substrate bias condition for TiN thin film deposition using an ECR sputter system. Surf. Coatings Technol. 2003, 171, 75–82. [Google Scholar] [CrossRef]

- Chang, C.-C.; Jeng, J.; Chen, J. Microstructural and electrical characteristics of reactively sputtered Ta-N thin films. Thin Solid Films 2002, 413, 46–51. [Google Scholar] [CrossRef]

- Chuang, J.; Chen, M. Passivation of Cu by Sputter-Deposited Ta and Reactively Sputter-Deposited Ta-Nitride Layers. J. Electrochem. Soc. 1998, 145, 3170–3177. [Google Scholar] [CrossRef]

- Liu, X.; Ma, G.J.; Sun, G.; Duan, Y.P.; Liu, S.H. Effect of deposition and annealing temperature on mechanical properties of TaN film. Appl. Surf. Sci. 2011, 258, 1033–1037. [Google Scholar] [CrossRef]

- Sreenivasan, R.; Sugawara, T.; Saraswat, K.C.; McIntyre, P.C. High temperature phase transformation of tantalum nitride films deposited by plasma enhanced atomic layer deposition for gate electrode applications. Appl. Phys. Lett. 2007, 90, 102101. [Google Scholar] [CrossRef]

- Chun, W.-J.; Ishikawa, A.; Fujisawa, H.; Takata, T.; Kondo, J.N.; Hara, M.; Kawai, M.; Matsumoto, Y.; Domen, K. Conduction and Valence Band Positions of Ta2O5, TaON, and Ta3N5 by UPS and Electrochemical Methods. J. Phys. Chem. B 2003, 107, 1798–1803. [Google Scholar] [CrossRef]

- Bertóti, I. Characterization of nitride coatings by XPS. Surf. Coat. Technol. 2002, 151–152, 194–203. [Google Scholar] [CrossRef]

- Nyholm, R.; Berndtsson, A.; Martensson, N. Core level binding energies for the elements Hf to Bi (Z=72-83). J. Phys. C Solid State Phys. 1980, 13, L1091–L1096. [Google Scholar] [CrossRef]

- Tian, X.; Gong, C.; Huang, Y.; Jiang, H.; Yang, S.; Fu, R.K.Y.; Chu, P.K. Ion trajectories in plasma ion implantation of slender cylindrical bores using a small inner end source. Appl. Phys. Lett. 2008, 93, 191501. [Google Scholar] [CrossRef]

- Azzam, R.M.A.; Bashara, N.M. Ellipsometry and Polarized Light, 1st ed.; North-Holland Pub. Co.: Amsterdam, The Netherlands, 1977; pp. 1–529. [Google Scholar]

- Tompkins, H.G.; Zhu, T.; Chen, E. Determining thickness of thin metal films with spectroscopic ellipsometry for applications in magnetic random-access memory. J. Vac. Sci. Technol. A Vac. Surf. Film 1998, 16, 1297–1302. [Google Scholar] [CrossRef]

| Film | Sputtering Time (min) | Argon Flow (sccm) | N2 Flow (sccm) | Thickness (nm) | Sheet Resistance (Ω/sq) | Resistivity (µΩ·cm) |

|---|---|---|---|---|---|---|

| Ta | 10 | 58 | 0 | 223.18 | 8.67 | 193.5 |

| 20 | 449.63 | 4.39 | 197.4 | |||

| 30 | 664.35 | 2.92 | 193.9 | |||

| TaN | 10 | 58 | 12 | 159.00 | 33.03 | 524.00 |

| TaN | 10 | 58 | 17 | 150.00 | 47.18 | 738.00 |

| TaN | 10 | 58 | 25 | 161.07 | 63.23 | 1018.4 |

| 20 | 282.08 | 55.57 | 1567.5 | |||

| 30 | 439.51 | 32.10 | 1410.8 | |||

| TaN | 10 | 58 | 38 | 129.84 | 2090.0 | 27,136.6 |

| 20 | 246.84 | 1020.0 | 25,177.7 | |||

| 30 | 399.00 | 174.83 | 6975.7 | |||

| TaN | 10 | – | – | 97.64 | 160.70 | 1568.9 |

| 20 | 58 | 58 | 195.93 | 7480 | 146,555.6 | |

| 30 | – | – | 305.19 | 13,200 | 402,850.8 |

| Flow Rate of N2 (sccm) | Peaks | Peak Position, 2θ (deg) | FWHM, θ (deg) | Average Crystalline size (±0.5 nm) |

|---|---|---|---|---|

| 0 | β-Ta(002) | 33.72 | 0.266 | 31.22 |

| 12 | TaN(111) | 35.40 | 0.340 | 24.54 |

| 17 | TaN(111) | 35.28 | 0.394 | 21.15 |

| 25 | Ta3N5(130,040) | 35.04 | 0.543 | 15.34 |

| 38 | Ta3N5(130,040) | 35.12 | 0.890 | 9.37 |

| 58 | Ta3N5(130,040) | 34.24 | 3.394 | 2.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Rasadujjaman, M.; Wang, Y.; Zhang, J.; Yan, J.; Baklanov, M.R. Study on the Electrical, Structural, Chemical and Optical Properties of PVD Ta(N) Films Deposited with Different N2 Flow Rates. Coatings 2021, 11, 937. https://doi.org/10.3390/coatings11080937

Hu Y, Rasadujjaman M, Wang Y, Zhang J, Yan J, Baklanov MR. Study on the Electrical, Structural, Chemical and Optical Properties of PVD Ta(N) Films Deposited with Different N2 Flow Rates. Coatings. 2021; 11(8):937. https://doi.org/10.3390/coatings11080937

Chicago/Turabian StyleHu, Yingying, Md Rasadujjaman, Yanrong Wang, Jing Zhang, Jiang Yan, and Mikhail R. Baklanov. 2021. "Study on the Electrical, Structural, Chemical and Optical Properties of PVD Ta(N) Films Deposited with Different N2 Flow Rates" Coatings 11, no. 8: 937. https://doi.org/10.3390/coatings11080937

APA StyleHu, Y., Rasadujjaman, M., Wang, Y., Zhang, J., Yan, J., & Baklanov, M. R. (2021). Study on the Electrical, Structural, Chemical and Optical Properties of PVD Ta(N) Films Deposited with Different N2 Flow Rates. Coatings, 11(8), 937. https://doi.org/10.3390/coatings11080937