Hydrostatic Bearing Characteristics Investigation of a Spherical Piston Pair with an Annular Orifice Damper in Spherical Pump

Abstract

:1. Introduction

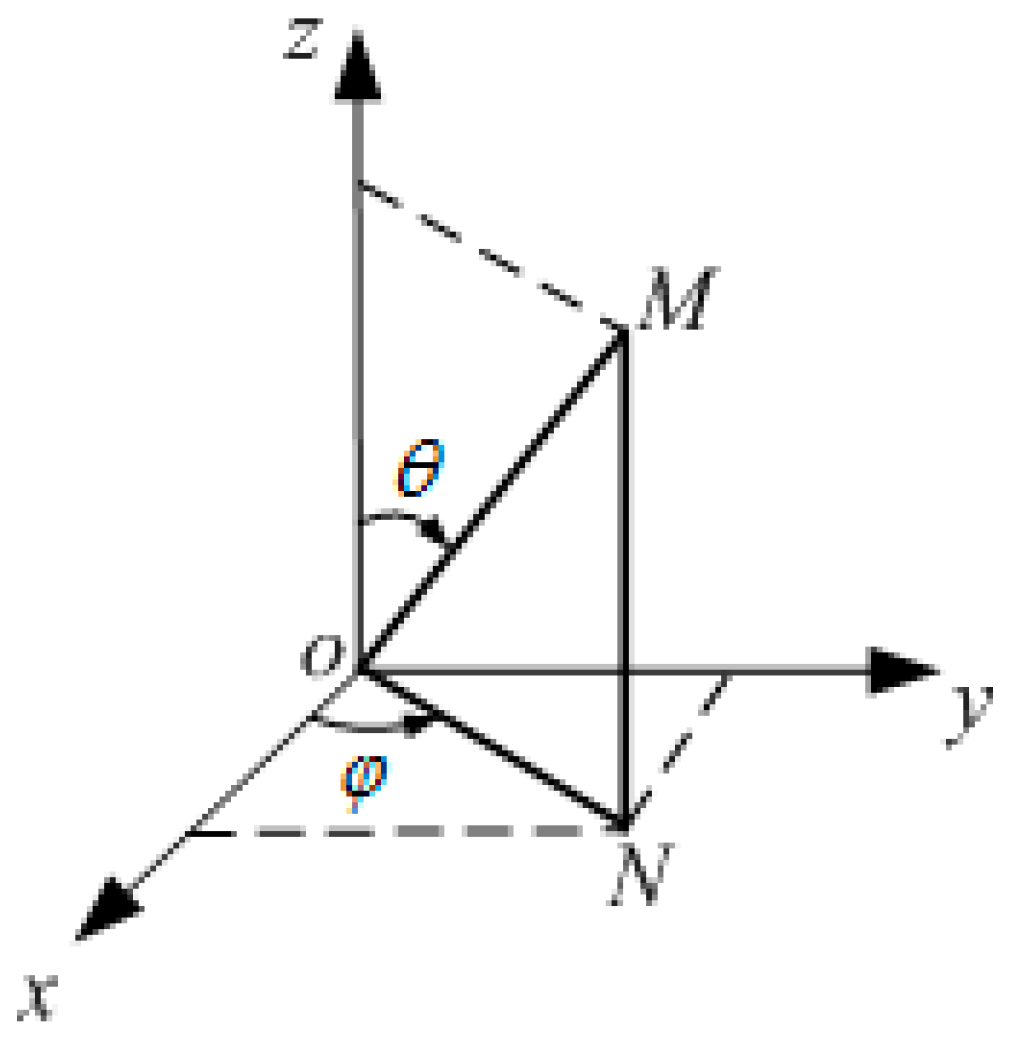

2. Hydrostatic Bearing Model for Spherical Cylinder–Piston Pair

2.1. Theoretical Analysis

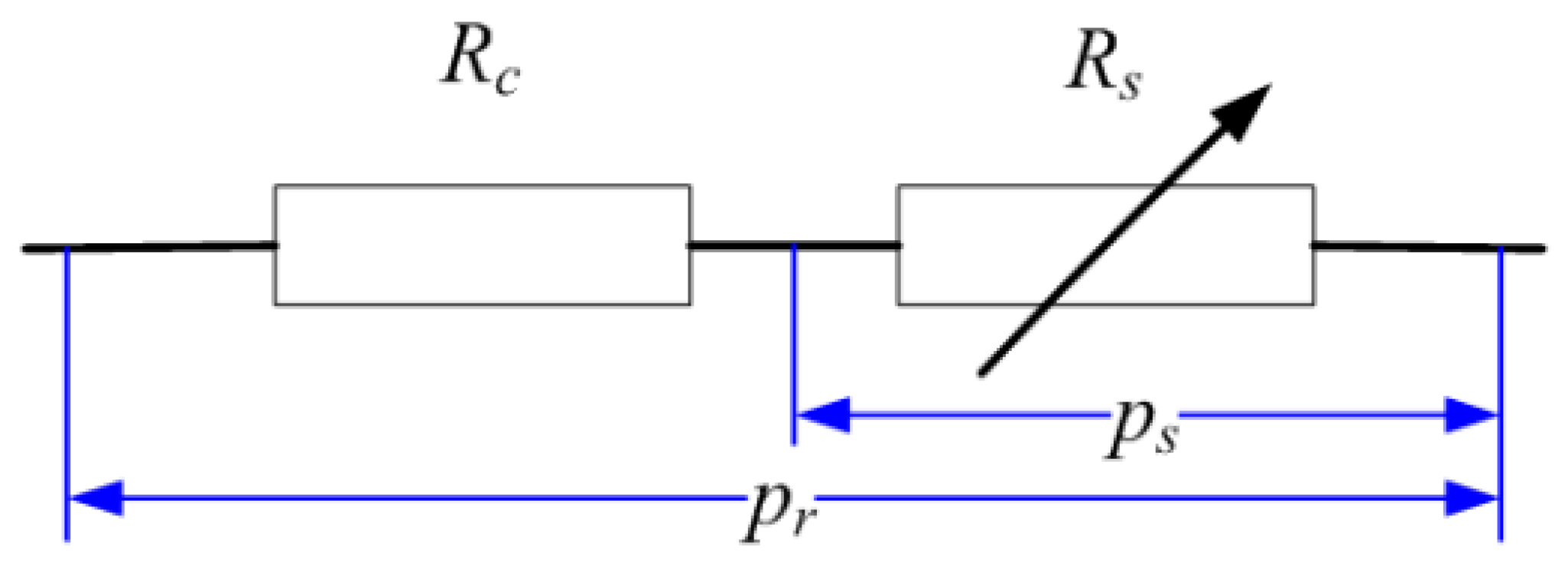

2.2. Modeling of the Piston–Cylinder Hydrostatic Bearing

3. Bearing Properties Analysis

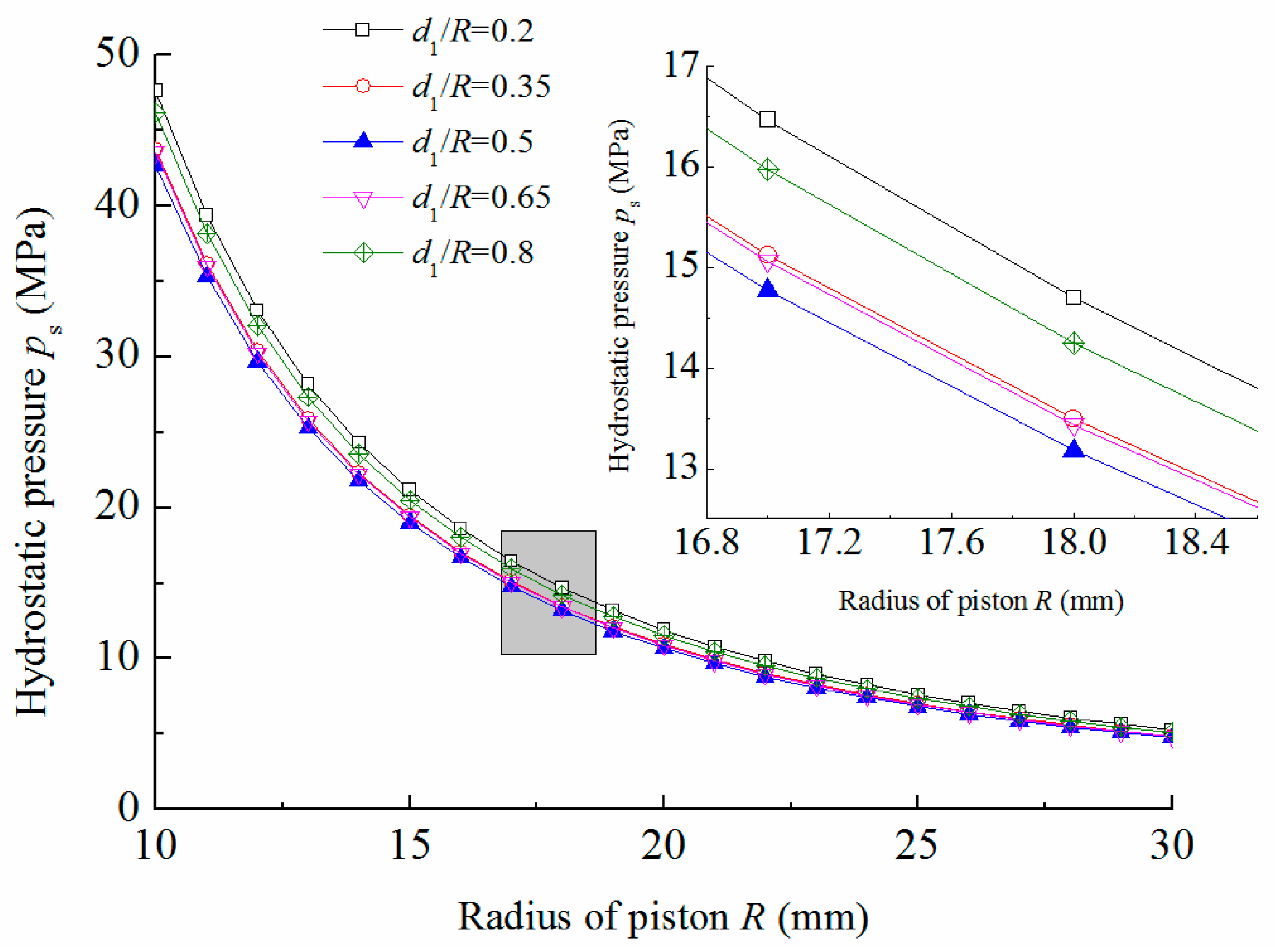

3.1. Variation in Hydrostatic Pressure

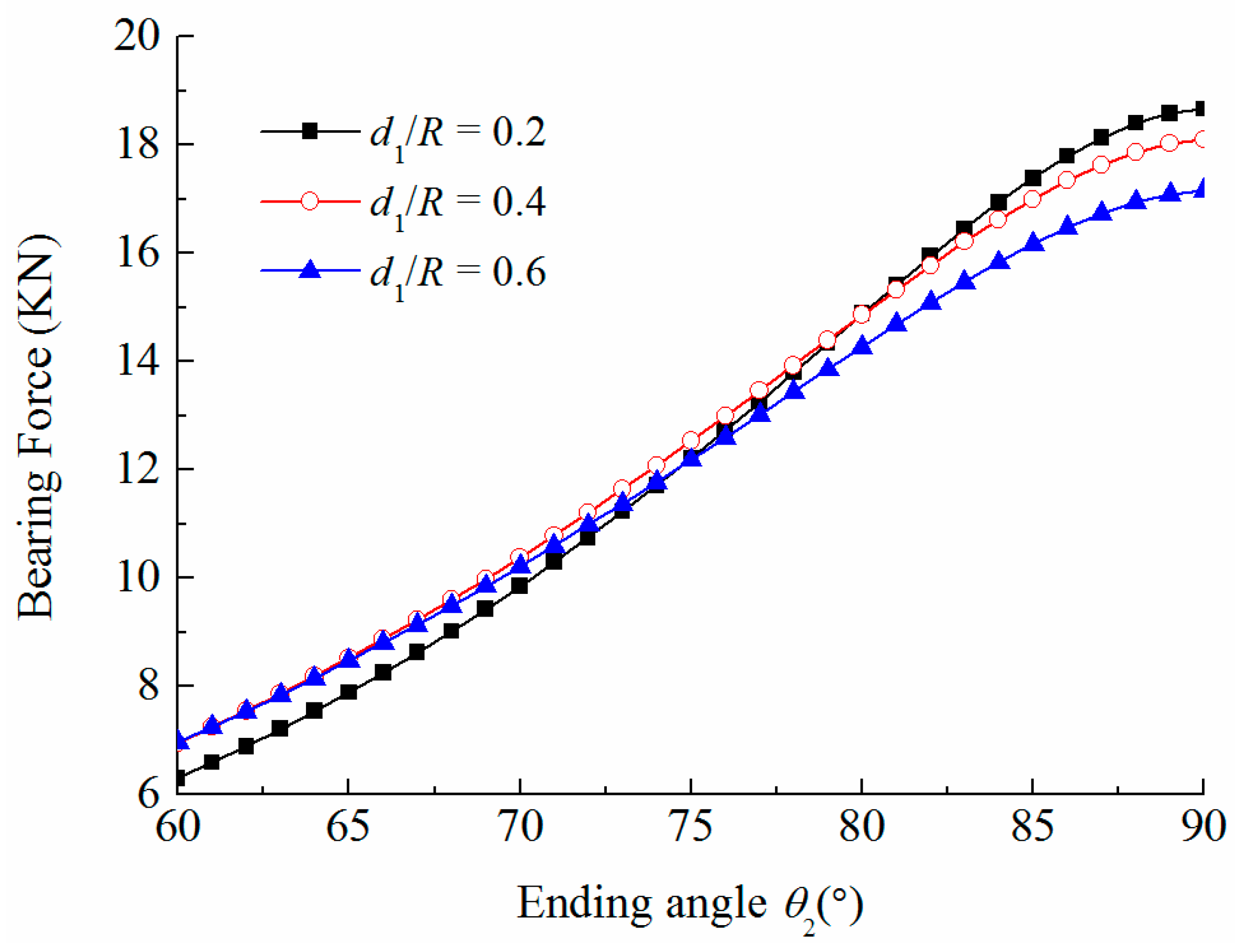

3.2. Variation in Bearing Force

3.3. Variation in Pressure Drop Coefficient

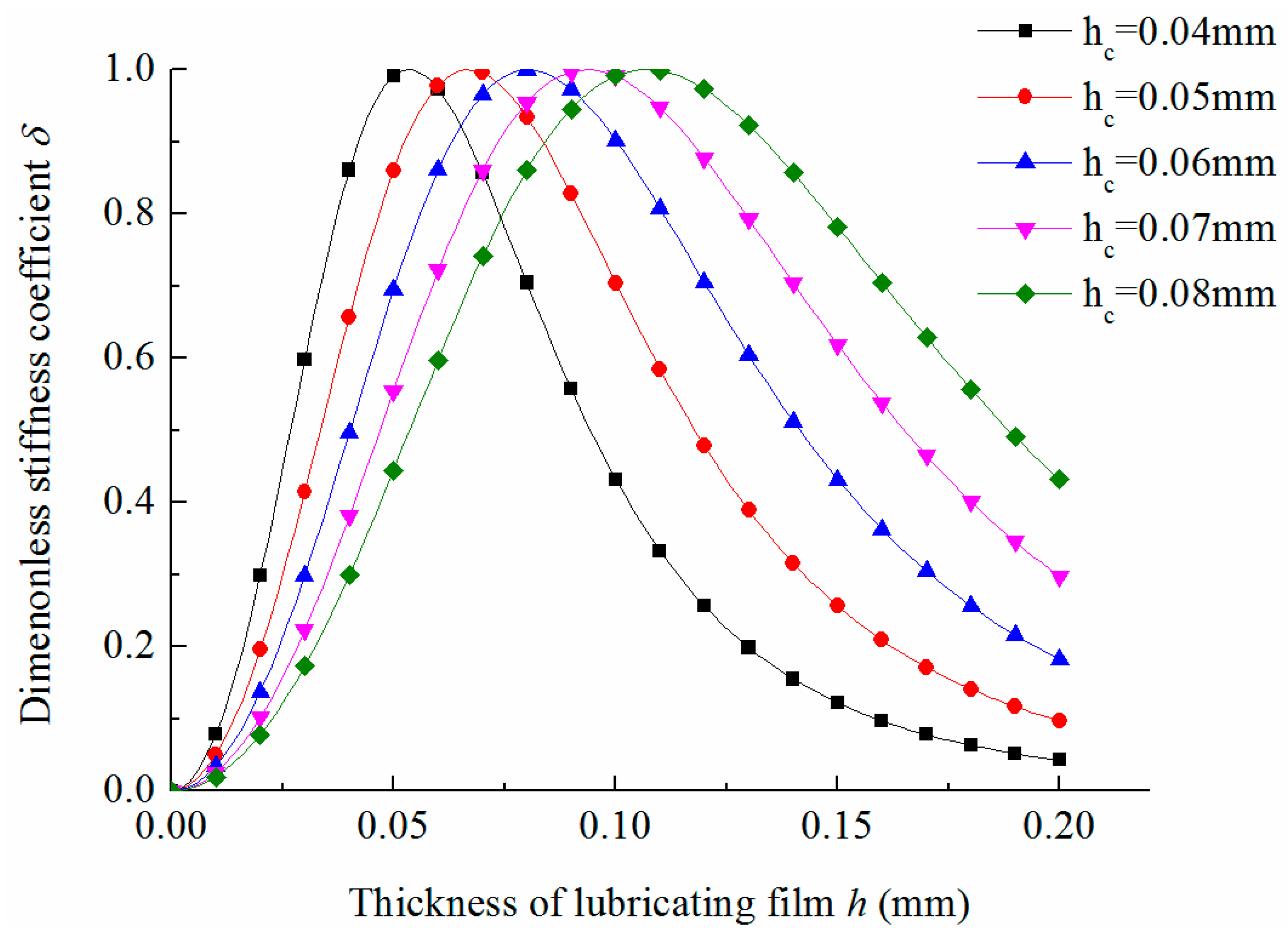

3.4. Lubricating Film Stiffness Analysis

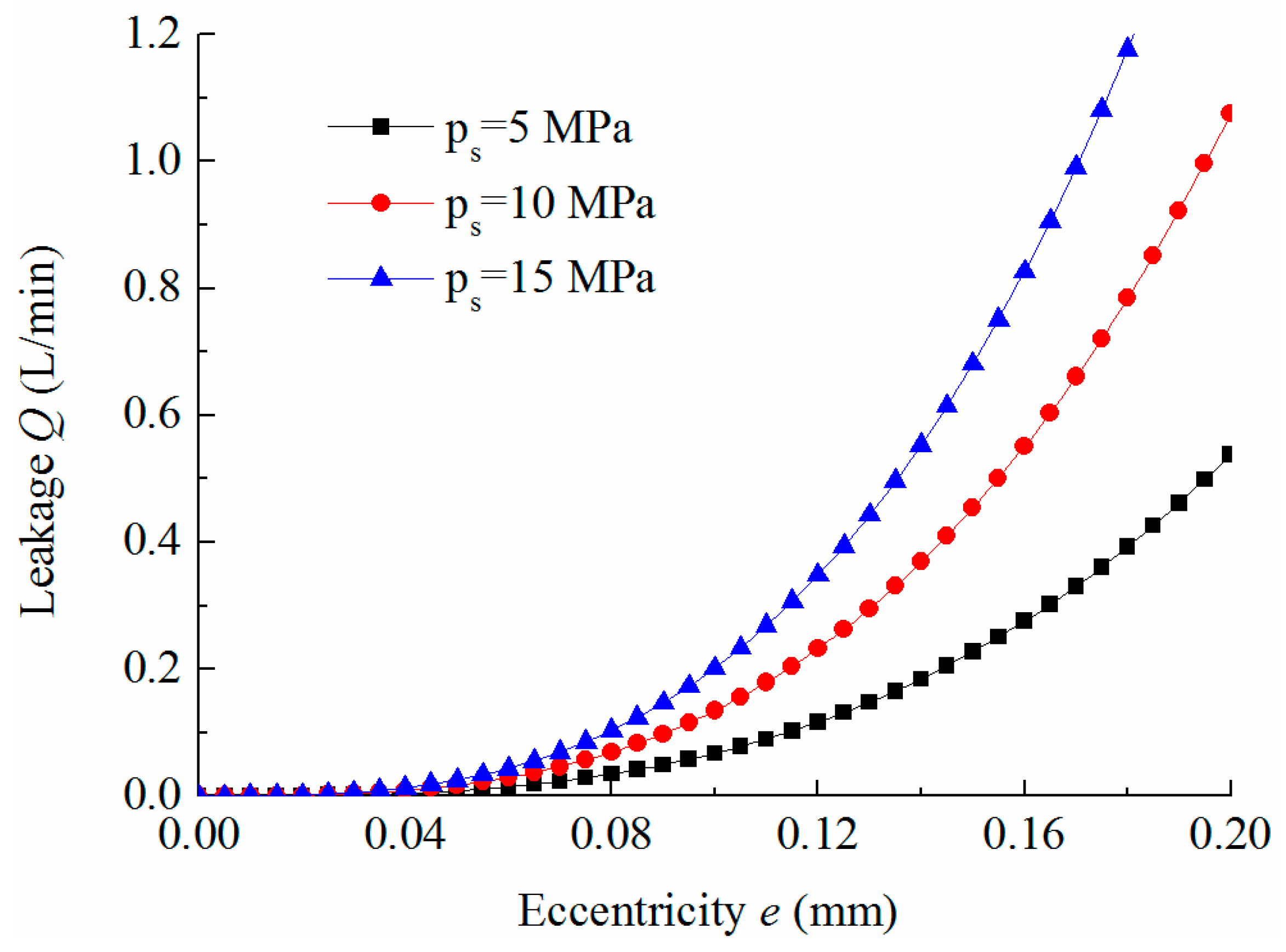

3.5. Leakage Analysis

3.6. Effect of Temperature on Leakage Properties

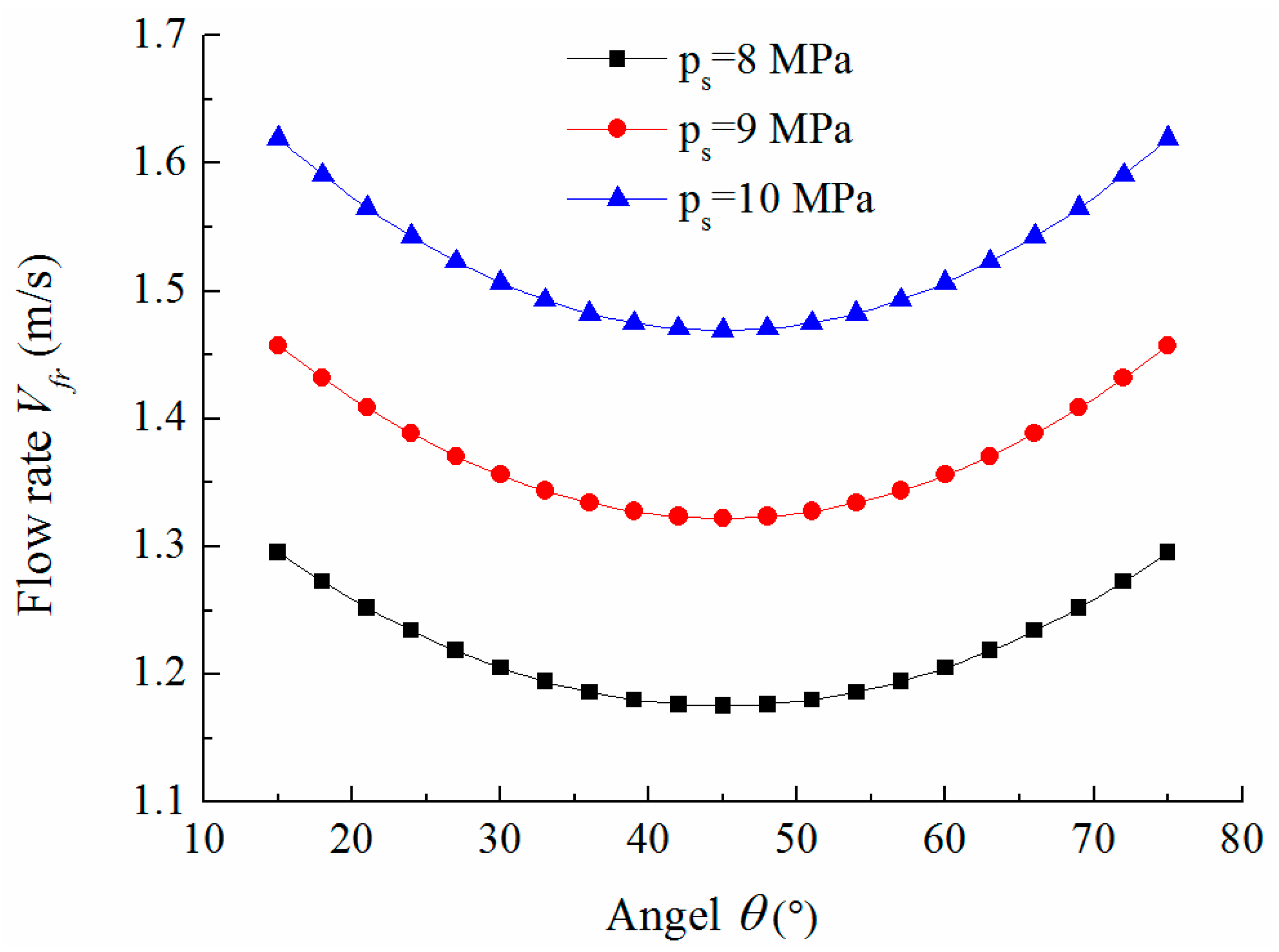

3.7. Flow Rate Characteristics of Leakage Medium

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| integral constants | |

| piston pin diameter | |

| cylinder hole diameter | |

| eccentricity | |

| , , | body force in three coordinate directions |

| bearing force | |

| clearance between the piston and the internal surface of the cylinder body | |

| revolute joint clearance | |

| maximum lubricating film thickness | |

| lubricating film stiffness | |

| maximum lubricating film stiffness | |

| structural parameters | |

| axial length of revolute joint | |

| lubricating fluid flow | |

| pressure of lubrication fluid | |

| revolute joint pressure drop | |

| injected lubricating fluid pressure | |

| lubricating pair pressure drop | |

| piston radius | |

| revolute joint fluid resistance | |

| bearing pair fluid resistance | |

| effective bearing area | |

| specific surface area | |

| temperature | |

| , , | fluid velocities in three coordinate directions |

| specific surface flow rate | |

| hydrostatic bearing pressure drop ratio | |

| dimensionless stiffness coefficient | |

| density of lubrication fluid | |

| film (piston) beginning angle | |

| film (piston) ending angle | |

| dynamic viscosity coefficient |

References

- Agrawal, N.; Sharma, S.C. Effect of the ER lubricant behaviour on the performance of spherical recessed hydrostatic thrust bearing. Tribol. Int. 2021, 153, 106621. [Google Scholar] [CrossRef]

- Du, J.; Liang, G. Performance comparative analysis of hydrostatic bearings lubricated with low-viscosity cryogenic fluids. Tribol. Int. 2019, 137, 139–151. [Google Scholar] [CrossRef]

- Yousefzadeh, S.; Jafari, A.; Mohammadzadeh, A. Effect of hydrostatic pressure on vibrating functionally graded circular plate coupled with bounded fluid. Appl. Math. Model. 2018, 60, 435–446. [Google Scholar] [CrossRef]

- Manring, N.D.; Johnson, R.E.; Cherukuri, H.P. The impact of linear deformations on stationary hydrostatic thrust bearings. J. Tribol. 2002, 124, 874–877. [Google Scholar] [CrossRef]

- Nie, S.; Huang, G.; Li, Y. Tribological study on hydrostatic slipper bearing with annular orifice damper for water hydraulic axial piston motor. Tribol. Int. 2005, 39, 1342–1354. [Google Scholar] [CrossRef]

- Shen, H.; Zhou, Z.; Guan, D.; Liu, Z.; Jing, L.; Zhang, C. Dynamic contact analysis of the piston and slipper pair in axial piston pump. Coatings 2020, 10, 1217. [Google Scholar] [CrossRef]

- Guan, D.; Wu, J.H.; Jing, L.; Hilton, H.H.; Lu, K. Kinematic modeling, analysis and test on a quiet spherical pump. J. Sound Vib. 2016, 383, 146–155. [Google Scholar] [CrossRef]

- Guan, D.; Jing, X.; Shen, H.; Jing, L.; Gong, J. Test and simulation the failure characteristics of twin tube shock absorber. Mech. Syst. Signal Process. 2019, 122, 707–719. [Google Scholar] [CrossRef]

- Guan, D.; Jing, L.; Hilton, H.H.; Gong, J. Dynamic lubrication analysis for a spherical pump. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 233, 18–29. [Google Scholar] [CrossRef]

- Guan, D.; Liu, R.; Fei, C.; Zhao, S.; Jing, L. Fluid–structure coupling model and experimental validation of interaction between pneumatic soft actuator and lower limb. Soft Robot. 2020, 7, 627–638. [Google Scholar] [CrossRef]

- Guan, D.; Jing, L.; Gong, J.; Yang, Z.; Shen, H. Friction and wear modeling of rotary disc in spherical pump. Ind. Lubr. Tribol. 2019, 71, 420–425. [Google Scholar] [CrossRef]

- Guan, D.; Jing, L.; Hilton, H.H.; Gong, J.; Yang, Z. Tangential contact analysis of spherical pump based on fractal theory. Tribol. Int. 2018, 119, 531–538. [Google Scholar] [CrossRef]

- Guan, D.; Jing, L.; Gong, J.; Shen, H.; Hilton, H.H. Normal contact analysis for spherical pump based on fractal theory. Tribol. Int. 2018, 124, 117–123. [Google Scholar] [CrossRef]

- Guan, D.; Hilton, H.H.; Yang, Z.; Jing, L.; Lu, K. Lubrication regime analysis for spherical pump. Ind. Lubr. Tribol. 2018, 70, 1437–1446. [Google Scholar] [CrossRef]

- Pang, Z.; Zhai, W.; Shun, J. The Study of Hydrostatic Lubrication of the Slipper in a High-Pressure Plunger Pump. Tribol. Trans. 1993, 36, 316–320. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Matsuoka, H. A mixed lubrication model applicable to bearing/seal parts of hydraulic equipment. J. Tribol. 1992, 114, 116–121. [Google Scholar] [CrossRef]

- Kazama, T.; Yamaguchi, A. Application of a mixed lubrication model for hydrostatic thrust bearings of hydraulic equipment. J. Tribol. 1993, 115, 686–691. [Google Scholar] [CrossRef]

- Kazama, T.; Yamaguchi, A. Optimum design of bearing and seal parts for hydraulic equipment. Wear 1993, 161, 161–171. [Google Scholar] [CrossRef]

- Kazama, T.; Yamaguchi, A. Experiment on mixed lubrication of hydrostatic thrust bearings for hydraulic equipment. J. Tribol. 1995, 117, 399–402. [Google Scholar] [CrossRef]

- Wang, X.; Yamaguchi, A. Characteristics of hydrostatic bearing/seal parts for water hydraulic pumps and motors. Part 1: Experiment and theory. Tribol. Int. 2002, 35, 425–433. [Google Scholar] [CrossRef]

- Wang, X.; Yamaguchi, A. Characteristics of hydrostatic bearing/seal parts for water hydraulic pumps and motors. Part 2: On eccentric loading and power losses. Tribol. Int. 2002, 35, 435–442. [Google Scholar] [CrossRef]

- Greenwood, J.; Williamson, J.P. Contact of nominally flat surfaces. In Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences; The Royal Society: London, UK, 1966; pp. 300–319. [Google Scholar]

- Patir, N.; Cheng, H. Application of average flow model to lubrication between rough sliding surfaces. J. Lubr. Technol. 1979, 101, 220–229. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication. J. Lubr. Technol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Koç, E.; Hooke, C.J. Considerations in the design of partially hydrostatic slipper bearings. Tribol. Int. 1997, 30, 815–823. [Google Scholar] [CrossRef]

- Li, K.; Hooke, C. A note on the lubrication of composite slippers in water-based axial piston pumps and motors. Wear 1991, 147, 431–437. [Google Scholar] [CrossRef]

- Hooke, C.; Li, K. The lubrication of slippers in axial piston pumps and motors—the effect of tilting couples. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1989, 203, 343–350. [Google Scholar] [CrossRef]

- Hooke, C.J.; Li, K.Y. The lubrication of overclamped slippers in axial piston pumps—centrally loaded behaviour. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1988, 202, 287–293. [Google Scholar] [CrossRef]

- Goenka, P.; Booker, J. Spherical bearings: Static and dynamic analysis via the finite element method. J. Lubr. Technol. 1980, 2, 308–318. [Google Scholar] [CrossRef]

- Xu, C.; Jiang, S. Analysis of static and dynamic characteristic of hydrostatic spherical hinge. J. Tribol. 2015, 137, 021701. [Google Scholar] [CrossRef]

- Xu, C.; Jiang, S. Analysis of the static characteristics of a self-compensation hydrostatic spherical hinge. J. Tribol. 2015, 137, 044503. [Google Scholar] [CrossRef]

- Yacout, A.W.; Ismaeel, A.S.; Kassab, S.Z. The combined effects of the centripetal inertia and the surface roughness on the hydrostatic thrust spherical bearings performance. Tribol. Int. 2007, 40, 522–532. [Google Scholar] [CrossRef]

- Dowson, D.; Taylor, C.M. Fluid-inertia effects in spherical hydrostatic thrust bearings. Asle Trans. 1967, 10, 316–324. [Google Scholar] [CrossRef]

- Seeton, C.J. Viscosity–temperature correlation for liquids. Tribol. Lett. 2006, 22, 67–78. [Google Scholar] [CrossRef]

- Arrhenius, S. Über die dissociationswärme und den einfluss der temperatur auf den dissociationsgrad der elektrolyte. Z. Phys. Chem. 1889, 4, 96–116. [Google Scholar] [CrossRef] [Green Version]

- Qian, D.; Liao, R. A Nonisothermal fluid-structure interaction analysis on the piston/cylinder interface leakage of high-pressure fuel pump. J. Tribol. 2014, 136, 021704. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, D.; Zhou, Z.; Zhang, C. Hydrostatic Bearing Characteristics Investigation of a Spherical Piston Pair with an Annular Orifice Damper in Spherical Pump. Coatings 2021, 11, 1007. https://doi.org/10.3390/coatings11081007

Guan D, Zhou Z, Zhang C. Hydrostatic Bearing Characteristics Investigation of a Spherical Piston Pair with an Annular Orifice Damper in Spherical Pump. Coatings. 2021; 11(8):1007. https://doi.org/10.3390/coatings11081007

Chicago/Turabian StyleGuan, Dong, Zhuxin Zhou, and Chun Zhang. 2021. "Hydrostatic Bearing Characteristics Investigation of a Spherical Piston Pair with an Annular Orifice Damper in Spherical Pump" Coatings 11, no. 8: 1007. https://doi.org/10.3390/coatings11081007

APA StyleGuan, D., Zhou, Z., & Zhang, C. (2021). Hydrostatic Bearing Characteristics Investigation of a Spherical Piston Pair with an Annular Orifice Damper in Spherical Pump. Coatings, 11(8), 1007. https://doi.org/10.3390/coatings11081007