Improvement of Load Carrying Capacity of Concrete Pavement Slabs Using Macro Synthetic Fibers

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

2.1.1. Cement

2.1.2. Aggregate

2.1.3. Water and Superplasticizer (SP)

2.1.4. Fibers

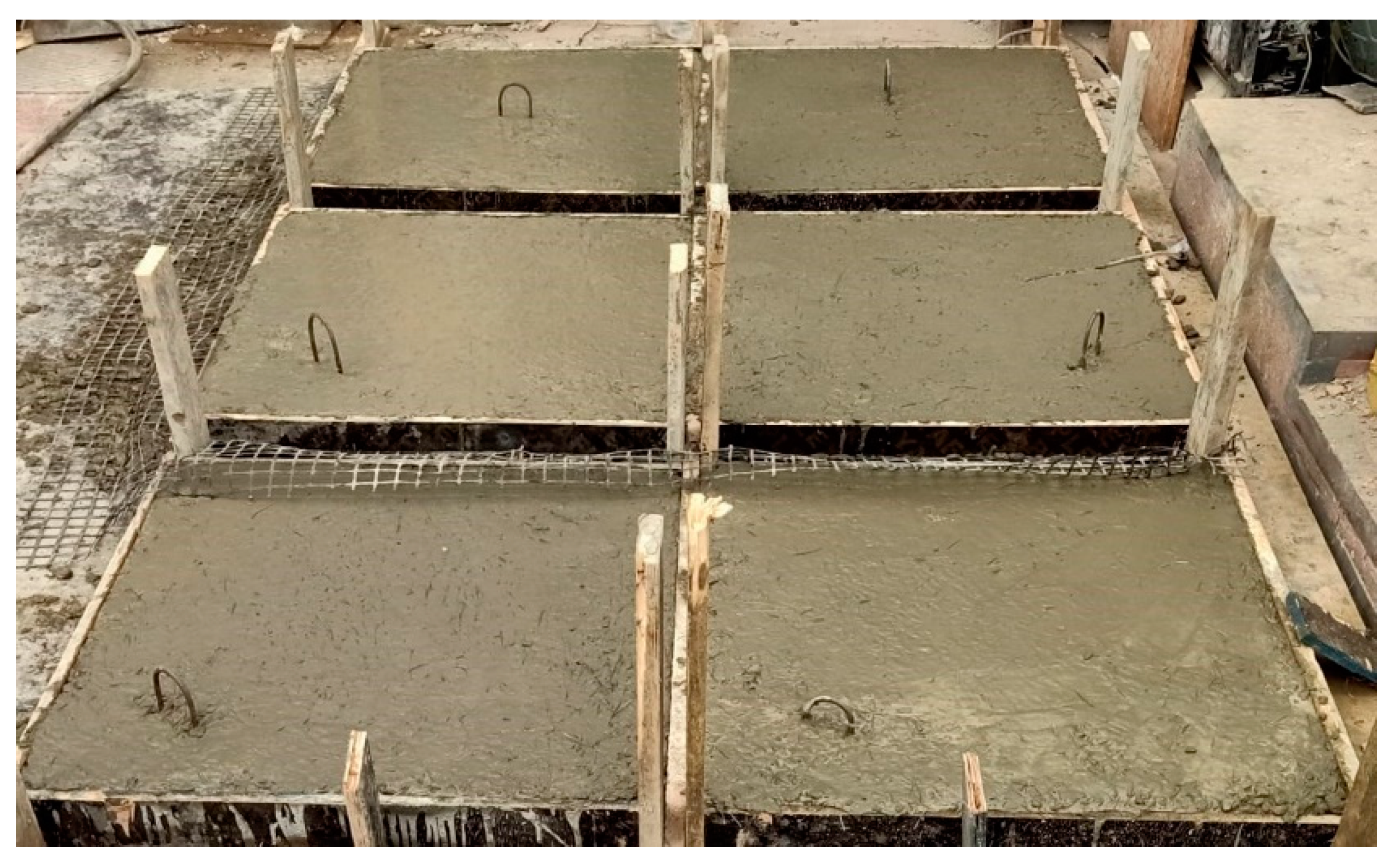

2.2. Mixing, Casting and Curing Procedure

3. Test Procedures

3.1. Fresh Properties

3.2. Compressive Strength Test

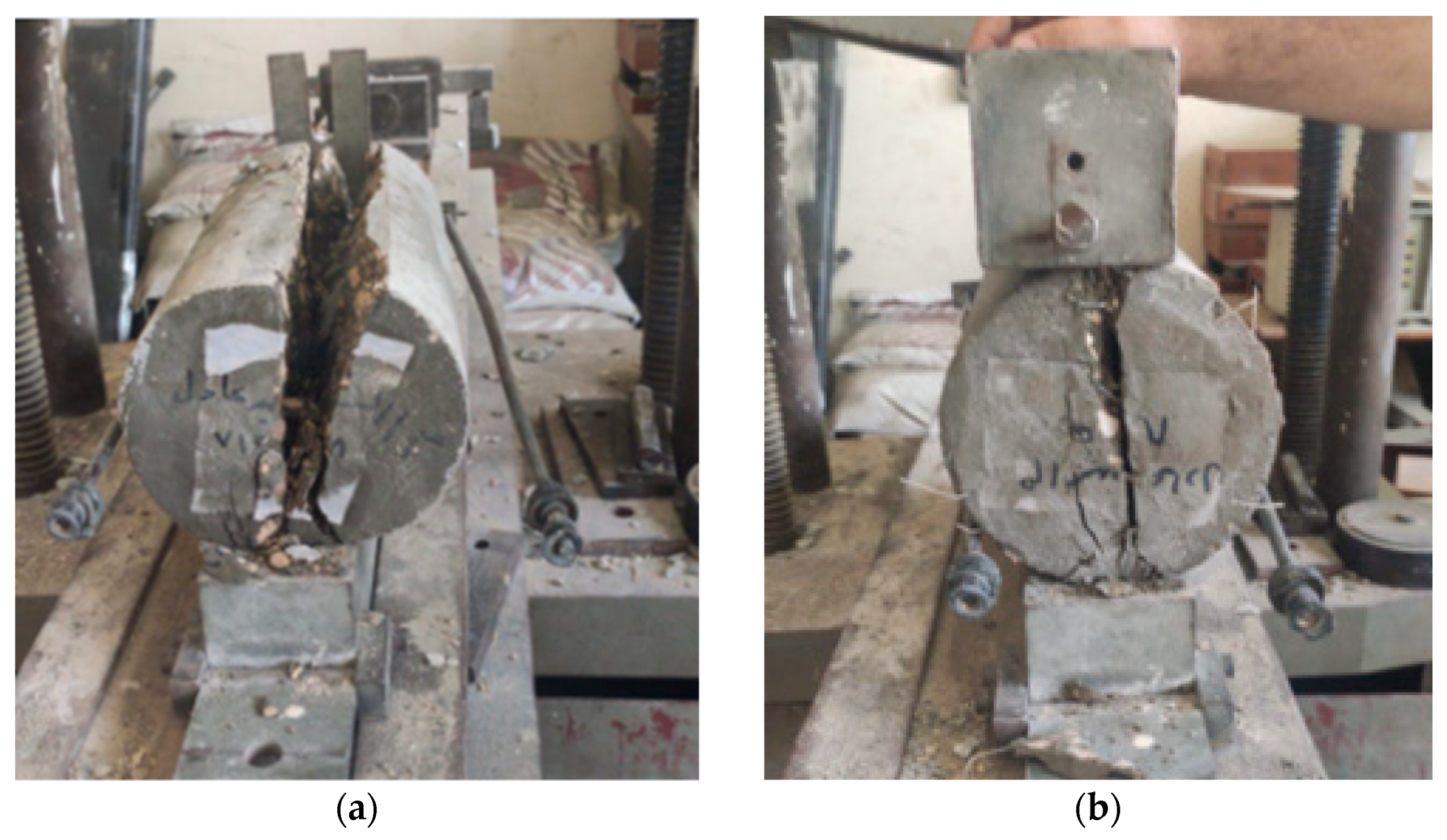

3.3. Splitting Tensile Strength Test

3.4. Flexural Strength Test

3.5. Modulus of Elasticity Test

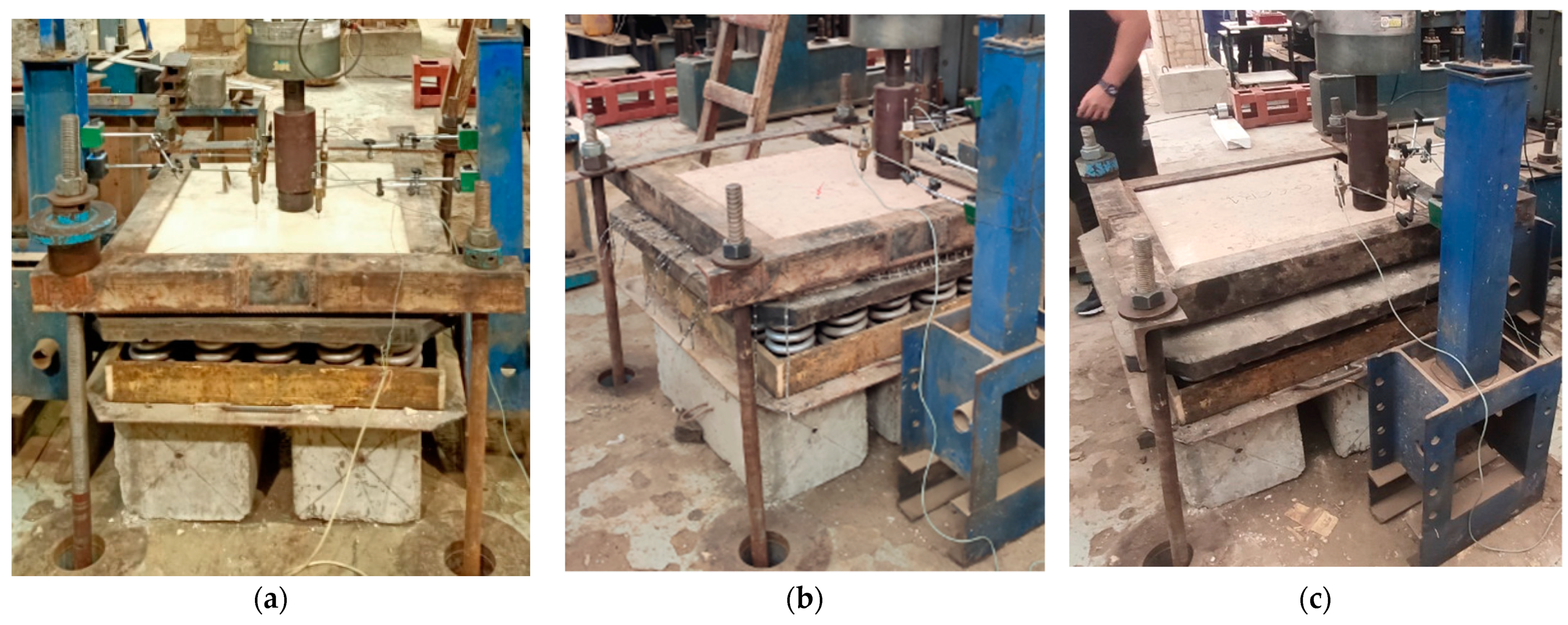

3.6. Slabs Loading Test

4. Test Results and Discussion

4.1. Fresh Concrete Properties

4.2. Compressive Strength

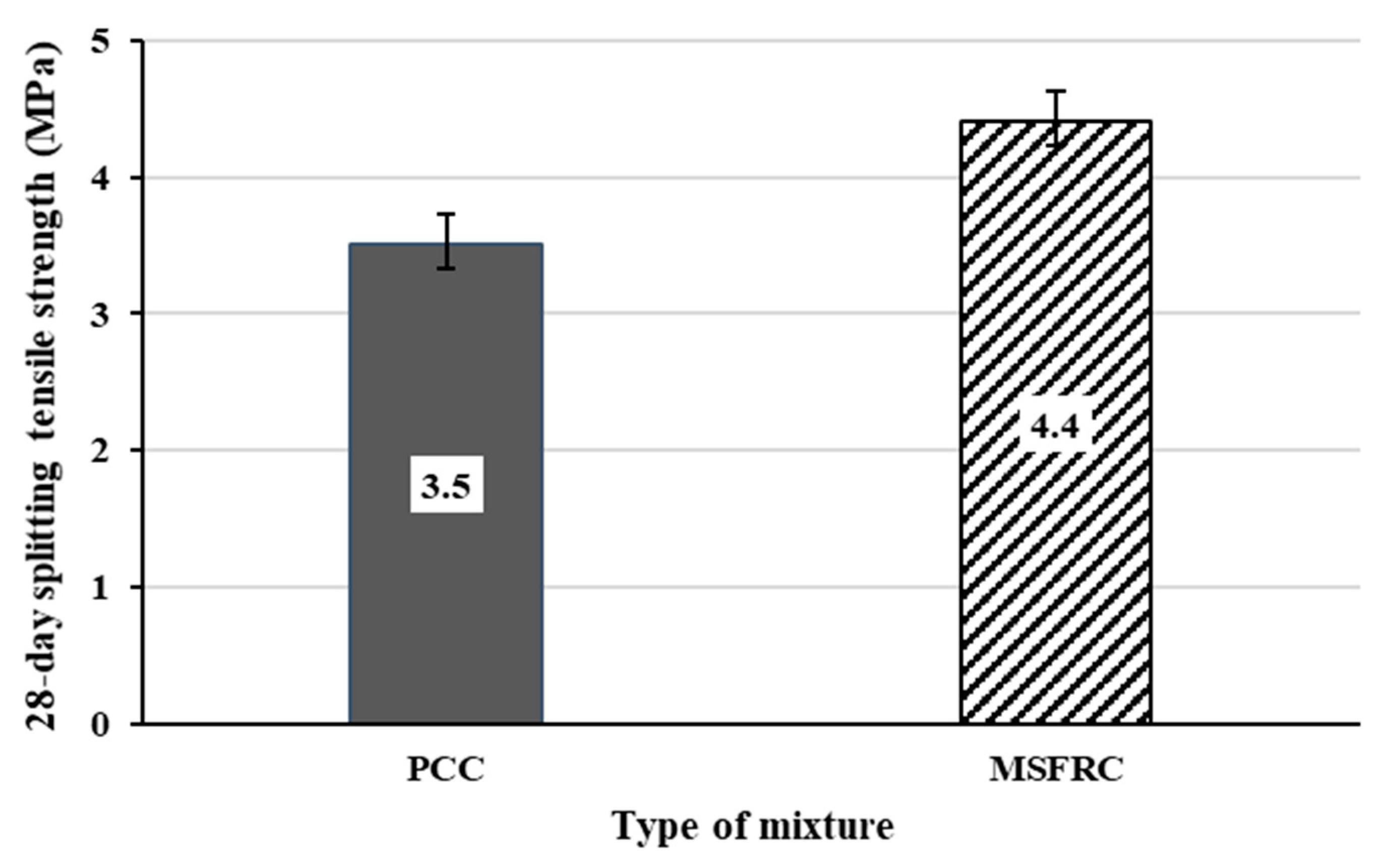

4.3. Splitting Tensile Strength

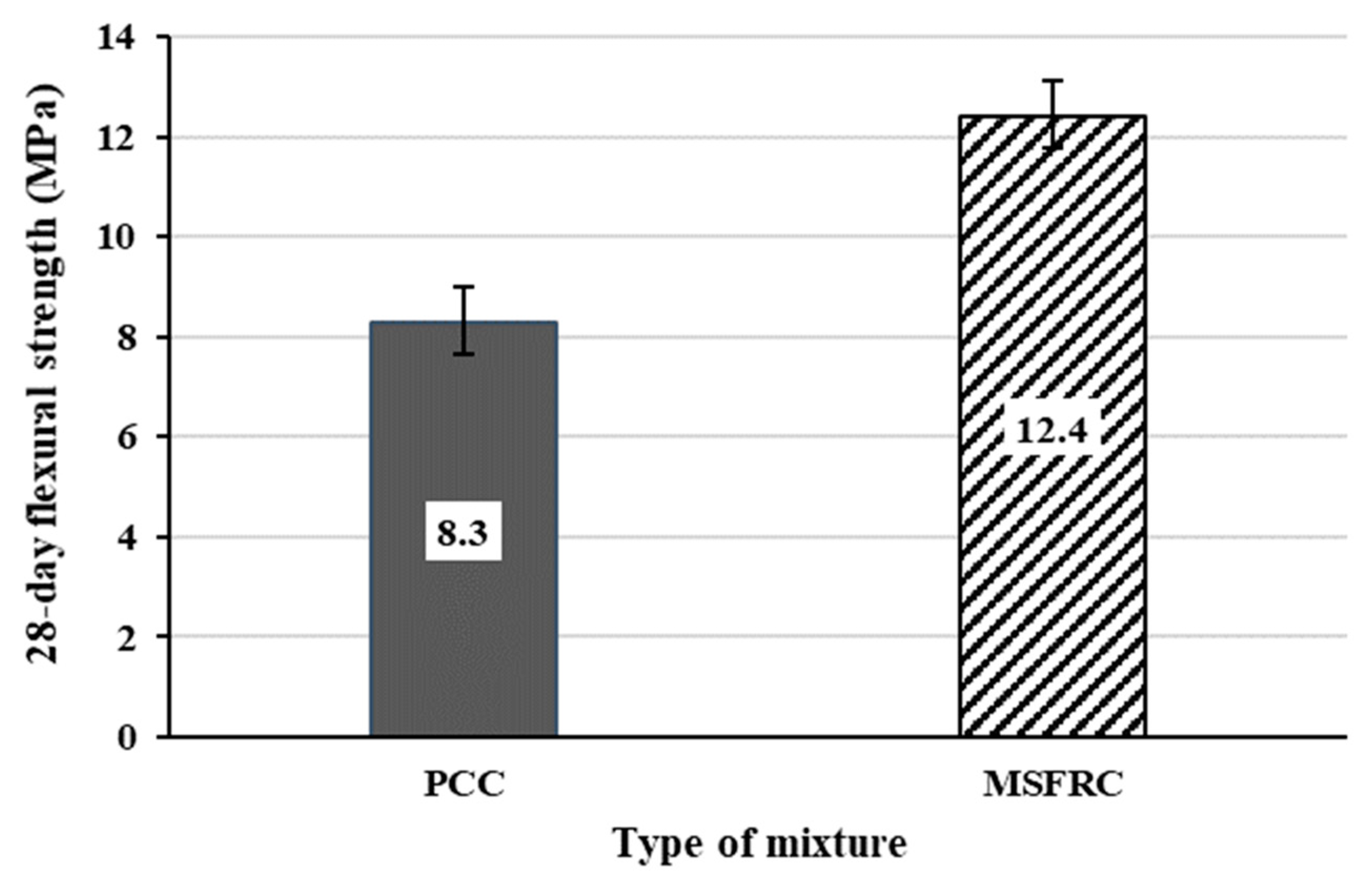

4.4. Flexural Strength

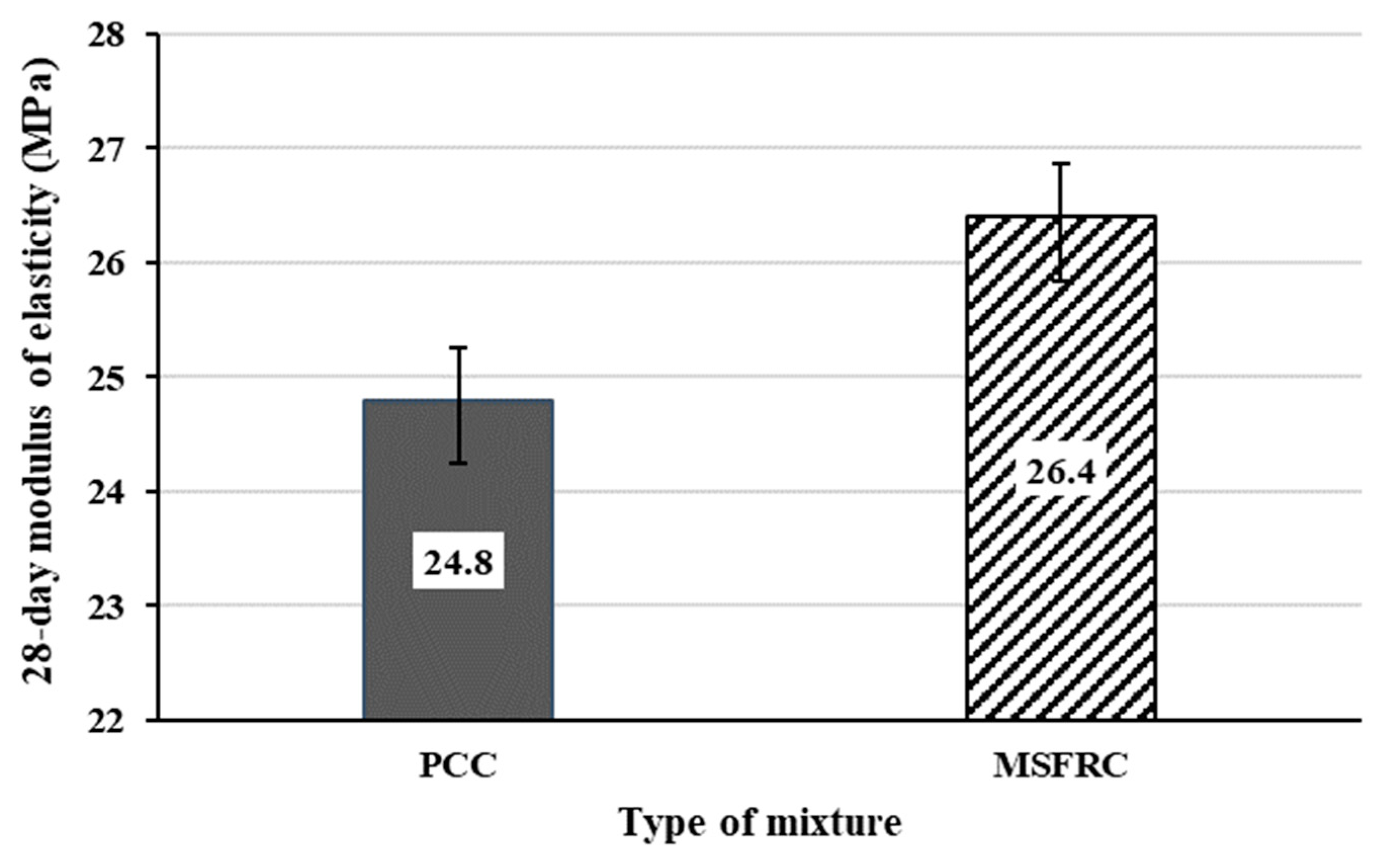

4.5. Modulus of Elasticity

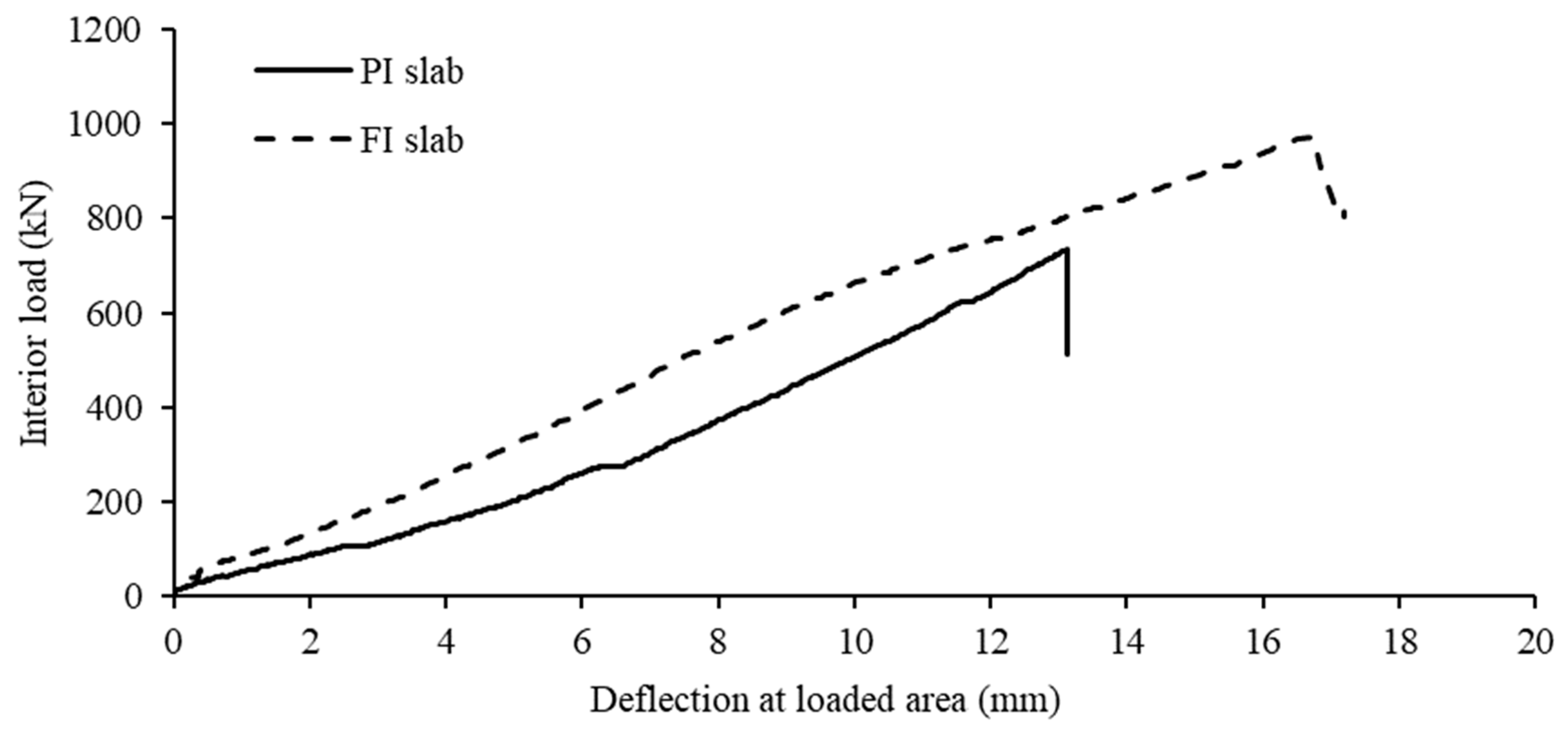

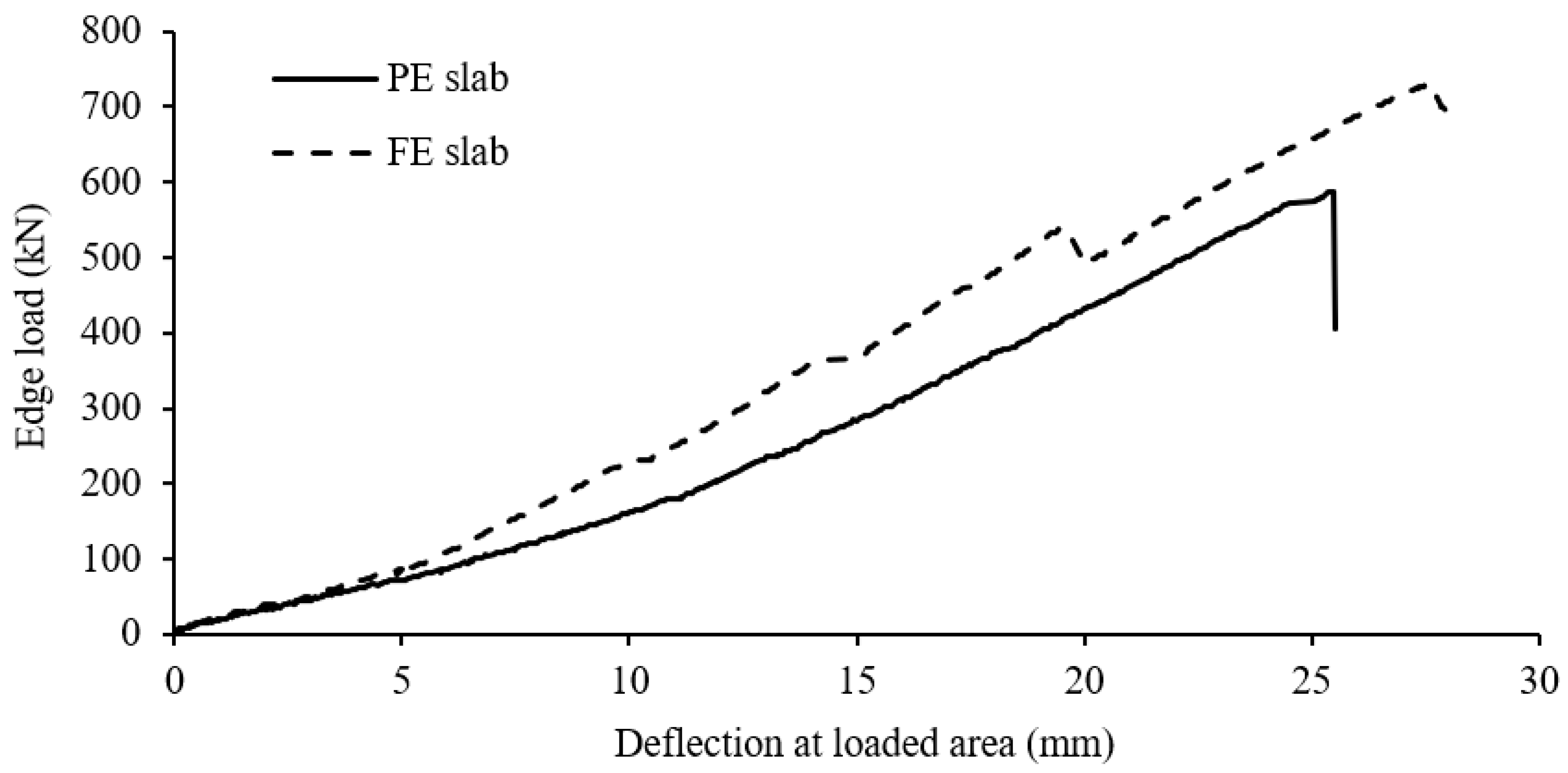

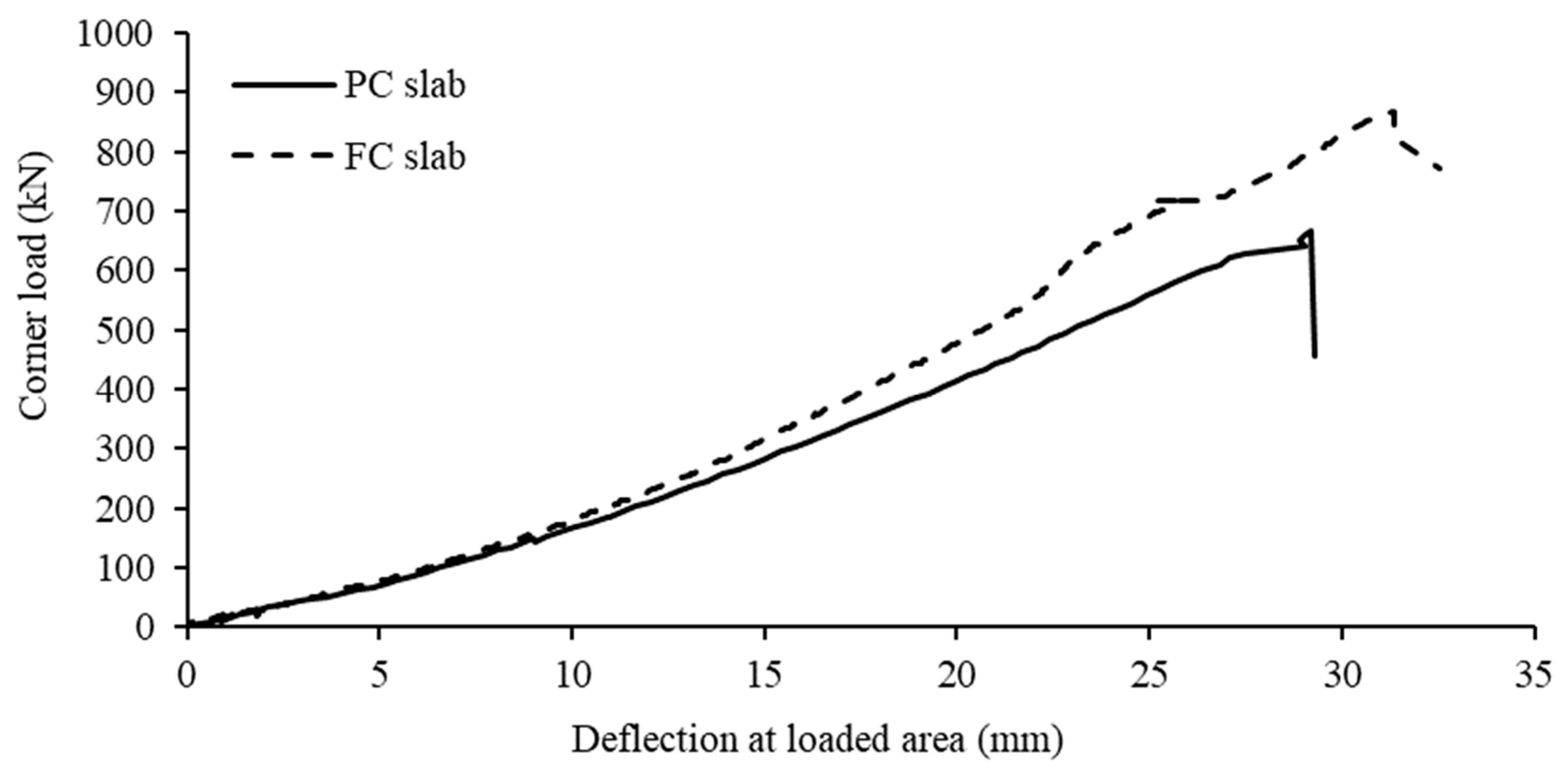

4.6. Slabs Loading

5. Conclusions

- Adding MSF to the concrete mixture led to reduced workability of the fresh concrete.

- It was observed that concrete density was not mainly affected by the addition of MSF.

- The addition of MSF caused a slight increase in air content as compared to the PCC.

- The addition of MSF did not have a considerable effect on compressive strength, as by adding MSF to the concrete mix, a 4% decrease in compressive strength was observed.

- The splitting tensile strength, flexural strength and elastic modulus of MSFRC at 28 days were increased by 20.5%, 33% and 6%, respectively, compared with that of PPC.

- The load carrying capacity of the PCC slab was improved considerably by the addition of MSF.

- The load carrying capacity of the MSFRC slab was higher than the PCC slab by about 24% for interior loading, 20% for edge loading and 23% for corner loading.

- The ductility of the MSFRC slab was higher than the PCC slab by about 43% for interior loading, 26% for edge loading and 33% for corner loading.

- In general, the results obtained and the observations made in this study proposed that concrete incorporating MSF could be used with satisfactory mechanical properties to increase the load carrying capacity and ductility of rigid pavement slabs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tunç, A. Yol Malzemeleri ve Uygulamaları; Atlas Yayınevi: Istanbul, Turkey, 2001. [Google Scholar]

- Kim, Y.K.; Lee, S.W. Performance evaluation of bonded concrete overlay. Constr. Build. Mater. 2013, 49, 464–470. [Google Scholar] [CrossRef]

- Lee, Y.-H. Corner stress analysis of jointed concrete pavements. Transp. Res. Rec. J. Transp. Res. Board 1996, 1525, 44–56. [Google Scholar] [CrossRef]

- Lee, Y.H.; Yen, S.T.; Lee, C.T.; Bair, J.H.; Lee, Y.M. Development of new stress analysis and thickness design procedures for jointed concrete pavements. In Proceedings of the 6th International Conference of Concrete Pavements, Purdue University, West Lafayette, IN, USA, 18–21 November 1997. [Google Scholar]

- Setyawan, A.; Zoorob, S.; Hasan, K. Investigating and comparing traffic induced and restrained temperature stresses in a conventional rigid pavement and semi-rigid layers. Procedia Eng. 2013, 54, 875–884. [Google Scholar] [CrossRef] [Green Version]

- Tang, T.; Zollinger, D.G.; Senadheera, S. Analysis of concave curling in concrete slabs. J. Transp. Eng. 1993, 119, 618–633. [Google Scholar] [CrossRef]

- Nobili, A.; Lanzoni, L.; Tarantino, A.M. Experimental investigation and monitoring of a polypropylene-based fiber reinforced concrete road pavement. Constr. Build. Mater. 2013, 47, 888–895. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Cen, G.; Cui, Y. Comparative study on the effect of synthetic fiber on the preparation and durability of airport pavement concrete. Constr. Build. Mater. 2018, 184, 34–44. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Singh, S.P.; Kaushik, K.S. Properties of steel fibrous concrete containing mixed fibres in fresh and hardened state. Constr. Build. Mater. 2008, 22, 956–965. [Google Scholar] [CrossRef]

- Yazıcı, Ş.; İnan, G.; Tabak, V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build. Mater. 2007, 21, 1250–1253. [Google Scholar] [CrossRef]

- Thomas, J.; Ramaswamy, A. Mechanical properties of steel fiber-reinforced concrete. J. Mater. Civ. Eng. 2007, 19, 385–392. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef] [Green Version]

- Altoubat, S.A.; Roesler, J.R.; Lange, D.A.; Rieder, K.A. Simplified method for concrete pavement design with discrete structural fibers. Constr. Build. Mater. 2008, 22, 384–393. [Google Scholar] [CrossRef]

- Daniel, J.I.; Gopalaratnam, V.S.; Galinat, M.A. State-of-the-Art Report on Fiber Reinforced Concrete; ACI Committee 544, Report 544, 1R-96; American Concrete Institute: Detroit, MI, USA, 2002. [Google Scholar]

- Zheng, Z.; Feldman, D. Synthetic fibre-reinforced concrete. Prog. Polym. Sci. 1995, 20, 185–210. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- American Concrete Institute (ACI). Guide for Specifying, Proportioning, and Production of Fiber-Reinforced Concrete; ACI 544.3R-08; ACI: Farmington Hills, MI, USA, 2008. [Google Scholar]

- Rossi, P. High performance multimodal fiber reinforced cement composites (HPMFRCC): The LCPC experience. Mater. J. 1997, 6, 478–783. [Google Scholar]

- Navas, F.O.; Navarro-Gregori, J.; Herdocia, G.L.; Serna, P.; Cuenca, E. An experimental study on the shear behaviour of reinforced concrete beams with macro-synthetic fibres. Constr. Build. Mater. 2018, 169, 888–899. [Google Scholar] [CrossRef]

- Yang, J.-M.; Min, K.-H.; Shin, H.; Yoon, Y.-S. Effect of steel and synthetic fibers on flexural behavior of high-strength concrete beams reinforced with FRP bars. Compos. Part B Eng. 2012, 43, 1077–1086. [Google Scholar] [CrossRef]

- Roesler, J.R.; Lange, D.A.; Altoubat, S.A.; Rieder, K.A.; Ulreich, G.R. Fracture of plain and fiber-reinforced concrete slabs under monotonic loading. J. Mater. Civ. Eng. 2004, 16, 452–460. [Google Scholar] [CrossRef]

- Roesler, J.R.; Altoubat, S.A.; Lange, D.A.; Rieder, K.A.; Ulreich, G.R. Effect of synthetic fibers on structural behavior of concrete slabs-on-ground. ACI Mater. J. 2006, 103, 3–10. [Google Scholar]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Bolat, H.; Şimşek, O.; Çullu, M.; Durmuş, G.; Can, Ö. The effects of macro synthetic fiber reinforcement use on physical and mechanical properties of concrete. Compos. Part B Eng. 2014, 61, 191–198. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Ozbakkaloglu, T. Synthetic fibers for cementitious composites: A critical and in-depth review of recent advances. Constr. Build. Mater. 2019, 207, 491–518. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Alhozaimy, A.; Soroushian, P.; Mirza, F.; Alhozaimy, A.; Soroushian, P.; Mirza, F. Mechanical properties of polypropylene fiber reinforced concrete and the effects of pozzolanic materials. Cem. Concr. Compos. 1996, 18, 85–92. [Google Scholar] [CrossRef]

- Patel, P.A.; Desai, A.K.; Desai, J.A. Evaluation of engineering properties for polypropylene fibre reinforced concrete. Int. J. Adv. Eng. Technol. 2012, 3, 42–45. [Google Scholar]

- Yew, M.C.; Bin Mahmud, H.; Ang, B.C. Influence of different types of polypropylene fibre on the mechanical properties of high-strength oil palm shell lightweight concrete. Constr. Build. Mater. 2015, 90, 36–43. [Google Scholar] [CrossRef]

- Nurdian, I.I.; Jalan, P.L. The prospects of using polypropylene fibers as an additive in high quality concrete. Fiber Mesh 1990, 3–16. [Google Scholar]

- Yap, S.P.; Alengaram, U.J.; Jumaat, M.Z. Enhancement of mechanical properties in polypropylene– and nylon–fibre reinforced oil palm shell concrete. Mater. Des. 2013, 49, 1034–1041. [Google Scholar] [CrossRef]

- Labib, W.; Eden, N. An Investigation into the Use of Fibers in Concrete Industrial Ground-Floor Slabs; School of the Built Environment, Liverpool John Moores University: Liverpool, UK, 2006. [Google Scholar]

- Khan, M.; Ali, K. Effectiveness of hair and wave polypropylene fibers for concrete roads. Constr. Build. Mater. 2018, 166, 581–591. [Google Scholar] [CrossRef]

- Gali, S.; Subramaniam, K.V. Cohesive stress transfer and shear capacity enhancements in hybrid steel and macro-polypropylene fiber reinforced concrete. Theor. Appl. Fract. Mech. 2019, 103, 102250. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- British Standards Institution (BSI). Cement: Composition, Specifications and Conformity Criteria for Common Cements; BS EN 197-1; BSI: London, UK, 2011. [Google Scholar]

- Egyptian Standard Specification (ESS). Composition, Specifications and Conformity Criteria for Common Cements; 4576-1; Egyptian Organization for Standards and Quality (EOS): Cairo, Egypt, 2009. [Google Scholar]

- ECP 203-2018. Egyptian Code of Practice for Design and Construction of Reinforced Concrete Structures; Ministry of Housing, Utilities and Urban Communities: Cairo, Egypt, 2018. [Google Scholar]

- ASTM C494/C494M. Standard Specification for Chemical Admixtures for Concrete; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- ASTM C1116/C1116M-10a. Standard Specification for Chemical Admixtures for Concrete; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- British Standards Institution (BSI). Fibres for Concrete: Polymer Fibres—Definitions, Specifications and Conformity; BS EN 14889-2; BSI: London, UK, 2006. [Google Scholar]

- BASF-The Chemical Company. MasterFiber-249 Macrosynthetic Fiber-Product Data Sheet. 2020. Available online: https://www.master-builders-solutions.com/en-ng/products/masterfiber/masterfiber-249 (accessed on 31 August 2020).

- Richardson, A.; Coventry, K.; Lamb, T.; MacKenzie, D. The addition of synthetic fibres to concrete to improve impact/ballistic toughness. Constr. Build. Mater. 2016, 121, 612–621. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C.; Picazo, A. Recent advances in structural fibre-reinforced concrete focused on polyolefin-based macro-synthetic fibres. Mater. Constr. 2020, 70, 206. [Google Scholar] [CrossRef] [Green Version]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.; Agrawal, V. Fibre distribution and orientation of macro-synthetic polyolefin fibre reinforced concrete elements. Constr. Build. Mater. 2016, 122, 505–517. [Google Scholar] [CrossRef]

- Alberti, M.; Enfedaque, A.; Gálvez, J. On the mechanical properties and fracture behavior of polyolefin fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2014, 55, 274–288. [Google Scholar] [CrossRef]

- El-Newihy, A.; Azarsa, P.; Gupta, R.; Biparva, A. Effect of polypropylene fibers on self-healing and dynamic modulus of elasticity recovery of fiber reinforced concrete. Fibers 2018, 6, 9. [Google Scholar] [CrossRef] [Green Version]

- Rooholamini, H.; Hassani, A.; Aliha, M. Evaluating the effect of macro-synthetic fibre on the mechanical properties of roller-compacted concrete pavement using response surface methodology. Constr. Build. Mater. 2018, 159, 517–529. [Google Scholar] [CrossRef]

- Soutsos, M.; Le, T.; Lampropoulos, A. Flexural performance of fibre reinforced concrete made with steel and synthetic fibres. Constr. Build. Mater. 2012, 36, 704–710. [Google Scholar] [CrossRef]

- ASTM C143/C143M. Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM C231/C231M-17a. Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM C138/C138M-17a. Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- British Standards Institution (BSI). Testing Hardened Concrete: Compressive Strength of Test Specimens; BS EN 12390-3; BSI: London, UK, 2009. [Google Scholar]

- Boulekbache, B.; Hamrat, M.; Chemrouk, M.; Amziane, S. Failure mechanism of fibre reinforced concrete under splitting test using digital image correlation. Mater. Struct. 2014, 48, 2713–2726. [Google Scholar] [CrossRef]

- ASTM C496/C496M. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM C293/C293M. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading); ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Hesami, S.; Hikouei, I.S.; Emadi, S.A.A. Mechanical behavior of self-compacting concrete pavements incorporating recycled tire rubber crumb and reinforced with polypropylene fiber. J. Clean. Prod. 2016, 133, 228–234. [Google Scholar] [CrossRef]

- ASTM C469/C469M. Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Hammons, M.I. Advanced Pavement Design: Finite Element Modeling for Rigid Pavement Joints. Report II: Model Development; MS 39180-6199; U.S. Army Engineer Waterways Experiment Station: Vicksburg, VA, USA, 1998. [Google Scholar]

- Al-Hedad, A.S.A.; Hadi, M.N.S. Effect of geogrid reinforcement on the flexural behaviour of concrete pavements. Road Mater. Pavement Des. 2018, 20, 1005–1025. [Google Scholar] [CrossRef]

- PCA. US Portland Cement Association. Thickness Design for Concrete Highway and Street Pavements. Engineering Bulletin EB109P; Portland Cement Association: Skokie, IL, USA, 1984. [Google Scholar]

- Memon, N.A.; Sumadi, S.R.; Ramli, M. Performance of high wokability slag-cement mortar for ferrocement. Build. Environ. 2007, 42, 2710–2717. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Contribution of hybrid fibers on the properties of the high-strength lightweight concrete having good workability. Cem. Concr. Res. 2005, 35, 913–917. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Mechanical, durability, and microstructural properties of macro synthetic polypropylene (PP) fiber-reinforced rubber concrete. J. Clean. Prod. 2019, 234, 1351–1364. [Google Scholar] [CrossRef]

- Alsaif, A.; Koutas, L.; Bernal, S.A.; Guadagnini, M.; Pilakoutas, K. Mechanical performance of steel fibre reinforced rubberised concrete for flexible concrete pavements. Constr. Build. Mater. 2018, 172, 533–543. [Google Scholar] [CrossRef]

- Sahoo, D.R.; Solanki, A.; Kumar, A. Influence of steel and polypropylene fibers on flexural behavior of rc beams. J. Mater. Civ. Eng. 2015, 27, 04014232. [Google Scholar] [CrossRef]

- Karahan, O.; Atis, C. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Olivito, R.; Zuccarello, F. An experimental study on the tensile strength of steel fiber reinforced concrete. Compos. Part B Eng. 2010, 41, 246–255. [Google Scholar] [CrossRef]

- Hasan, M.J.; Afroz, M.; Mahmud, H.M.I. An experimental investigation on mechanical behavior of macro synthetic fiber reinforced concrete. Int. J. Civ. Environ. Eng. 2011, 11, 18–23. [Google Scholar]

- Chorzepa, M.G.; Masud, M. Performance of multiscale, including nanoscale, fibres in concrete. Emerg. Mater. Res. 2017, 6, 198–209. [Google Scholar] [CrossRef]

- Saadun, A.; Mutalib, A.A.; Hamid, R.; Mussa, M.H. Behaviour of polypropylene fiber reinforced concrete under dynamic impact load. J. Eng. Sci. Technol. 2016, 11, 684–693. [Google Scholar]

- Hsie, M.; Tu, C.; Song, P. Mechanical properties of polypropylene hybrid fiber-reinforced concrete. Mater. Sci. Eng. A 2008, 494, 153–157. [Google Scholar] [CrossRef]

- Berndt, M.L. Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 2606–2613. [Google Scholar] [CrossRef]

- Foti, D. Preliminary analysis of concrete reinforced with waste bottles PET fibers. Constr. Build. Mater. 2011, 25, 1906–1915. [Google Scholar] [CrossRef]

- Gao, J.; Sun, W.; Morino, K. Mechanical properties of steel fiber-reinforced, high-strength, lightweight concrete. Cem. Concr. Compos. 1997, 19, 307–313. [Google Scholar] [CrossRef]

- Wu, F.; Liu, C.; Diao, Z.; Feng, B.; Sun, W.; Li, X.; Zhao, S. Improvement of mechanical properties in polypropylene- and glass-fibre-reinforced peach shell lightweight concrete. Adv. Mater. Sci. Eng. 2018, 2018, 6250941. [Google Scholar] [CrossRef] [Green Version]

- Sabih, G.; Tarefder, R.A. Impact of variability of mechanical and thermal properties of concrete on predicted performance of jointed plain concrete pavements. Int. J. Pavement Res. Technol. 2016, 9, 436–444. [Google Scholar] [CrossRef] [Green Version]

- Kamel, M.A. Quantification of benefits of steel fiber reinforcement for rigid pavement. Am. J. Civ. Eng. Archit. 2016, 4, 189–198. [Google Scholar]

| Property | Value | Specifications [37] |

|---|---|---|

| Soundness | 1.0 | ≤10 |

| Initial setting time (min) | 150 | ≥60 |

| Final setting time (min) | 195 | - |

| Specific surface area (m2/kg) | 385 | - |

| Flexural strength @ 2 days (MPa) | 4.8 | - |

| Flexural strength @ 28 days (MPa) | 7.6 | - |

| Compressive strength @ 2 days (MPa) | 19.5 | ≥10 |

| Compressive strength @ 28 days (MPa) | 48.3 | 42.5 ≤ X ≤ 62.5 |

| Property | Crushed Stone Aggregate | Fine Aggregate | Specifications [38] |

|---|---|---|---|

| Bulk density (g/cm3) | 1.65 | 1.56 | - |

| Fine particles percent (%) | 1.2 | 1.1 | ≤2.5% |

| Water absorption (%) | 1.6 | 1.39 | ≤2.5% |

| LA abrasion (%) | 23.7 | - | ≤30% (for crushed stone) |

| Shape index (%) | 8.4 | - | ≤25% |

| Flakiness index (%) | 12.4 | - | ≤25% |

| Properties | Value |

|---|---|

| Material | Polyolefin 100% |

| Design | Monofilament |

| Specific gravity | 0.91 |

| Equivalent diameter | 0.85 mm |

| Length | 48 mm |

| Aspect ratio | 56.6 |

| Tensile strength | 400 MPa |

| Modulus of elasticity | 4.7 GPa |

| Water absorption | Nil |

| Shape | Elliptical |

| Melting point | 160 °C |

| Ignition point | 350 °C |

| Type of Mixture | Cement | Sand | Agg. #10 | Agg. #20 | Water | SP | Fiber |

|---|---|---|---|---|---|---|---|

| PCC | 400 | 740 | 530 | 530 | 175 | 5.7 | - |

| MSFRC | 400 | 740 | 530 | 530 | 175 | 5.7 | 6 |

| Slab Type | Loading Position | Slab Label | Dimensions (mm) | Restraints |

|---|---|---|---|---|

| PCC | Interior | PI | 800 × 800 × 50 | Springs with k = 37 MPa/m |

| Edge | PE | |||

| Corner | PC | |||

| MSFRC | Interior | FI | 800 × 800 × 50 | Springs with k = 37 MPa/m |

| Edge | FE | |||

| Corner | FC |

| Mixture ID | Slump (mm) | Air Content (%) | Density (kg/m3) |

|---|---|---|---|

| PCC | 112 | 1.7 | 2389 |

| MSFRC | 81 | 1.9 | 2332 |

| Slab Label | Pref. (kN) | PFRC (kN) | Δref. (mm) | ΔFRC (mm) | {(PFRC/Pref.) − 1} × 100 (%) | Ductility (%) |

|---|---|---|---|---|---|---|

| PI | 735 | - | 13.1 | - | - | - |

| PE | 587 | - | 25.5 | - | - | - |

| PC | 668 | - | 29.2 | - | - | - |

| FI | - | 971 | - | 16.7 | 24 | 43 |

| FE | - | 732 | - | 27.6 | 20 | 26 |

| FC | - | 868 | - | 31.3 | 23 | 33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eisa, M.S.; Basiouny, M.E.; Youssef, A.M. Improvement of Load Carrying Capacity of Concrete Pavement Slabs Using Macro Synthetic Fibers. Coatings 2021, 11, 833. https://doi.org/10.3390/coatings11070833

Eisa MS, Basiouny ME, Youssef AM. Improvement of Load Carrying Capacity of Concrete Pavement Slabs Using Macro Synthetic Fibers. Coatings. 2021; 11(7):833. https://doi.org/10.3390/coatings11070833

Chicago/Turabian StyleEisa, Mohamed S., Mohamed E. Basiouny, and Ahmed M. Youssef. 2021. "Improvement of Load Carrying Capacity of Concrete Pavement Slabs Using Macro Synthetic Fibers" Coatings 11, no. 7: 833. https://doi.org/10.3390/coatings11070833

APA StyleEisa, M. S., Basiouny, M. E., & Youssef, A. M. (2021). Improvement of Load Carrying Capacity of Concrete Pavement Slabs Using Macro Synthetic Fibers. Coatings, 11(7), 833. https://doi.org/10.3390/coatings11070833