The Influence of the Preheating Temperature of the (−2 0 1) β-Ga2O3 Substrates on c-Plane GaN Epitaxial Growth

Abstract

1. Introduction

2. Materials and Methods

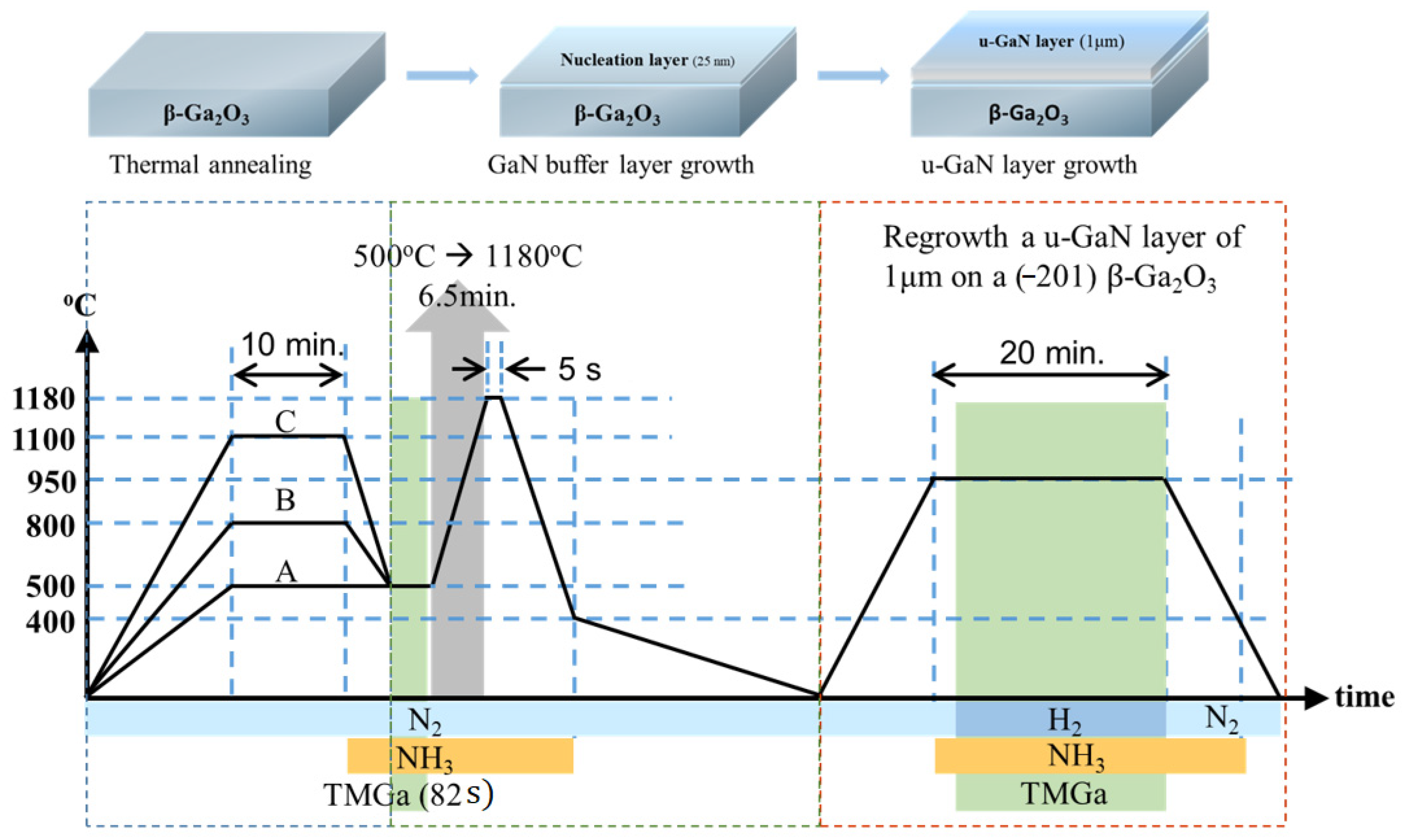

2.1. Growth Sequence of the GaN Epilayer

2.1.1. Substrate Preheating

2.1.2. GaN Nucleation Layer Growth

2.1.3. Growth of the Undoped GaN Layer

2.2. Measurements

3. Results and Discussions

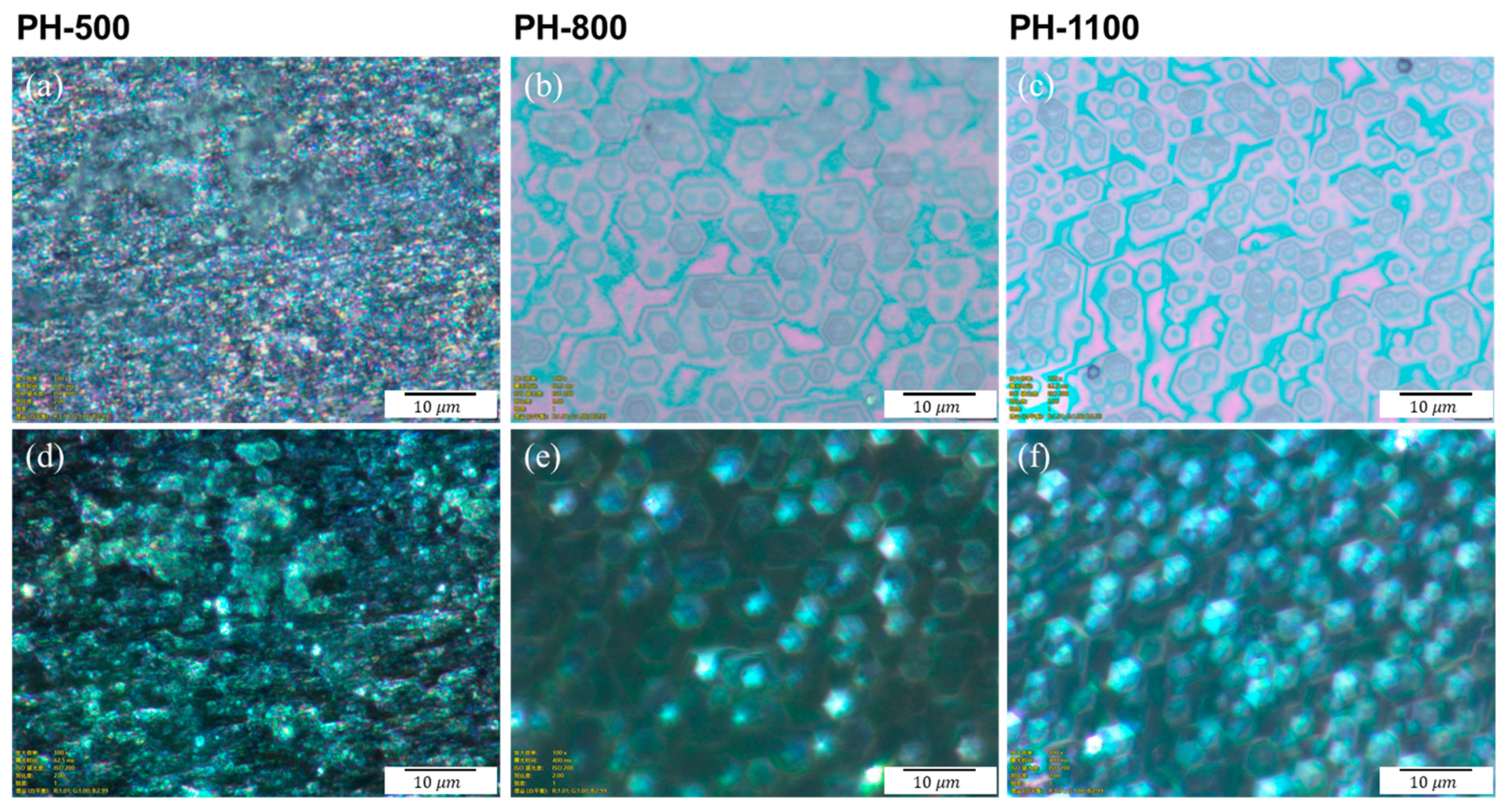

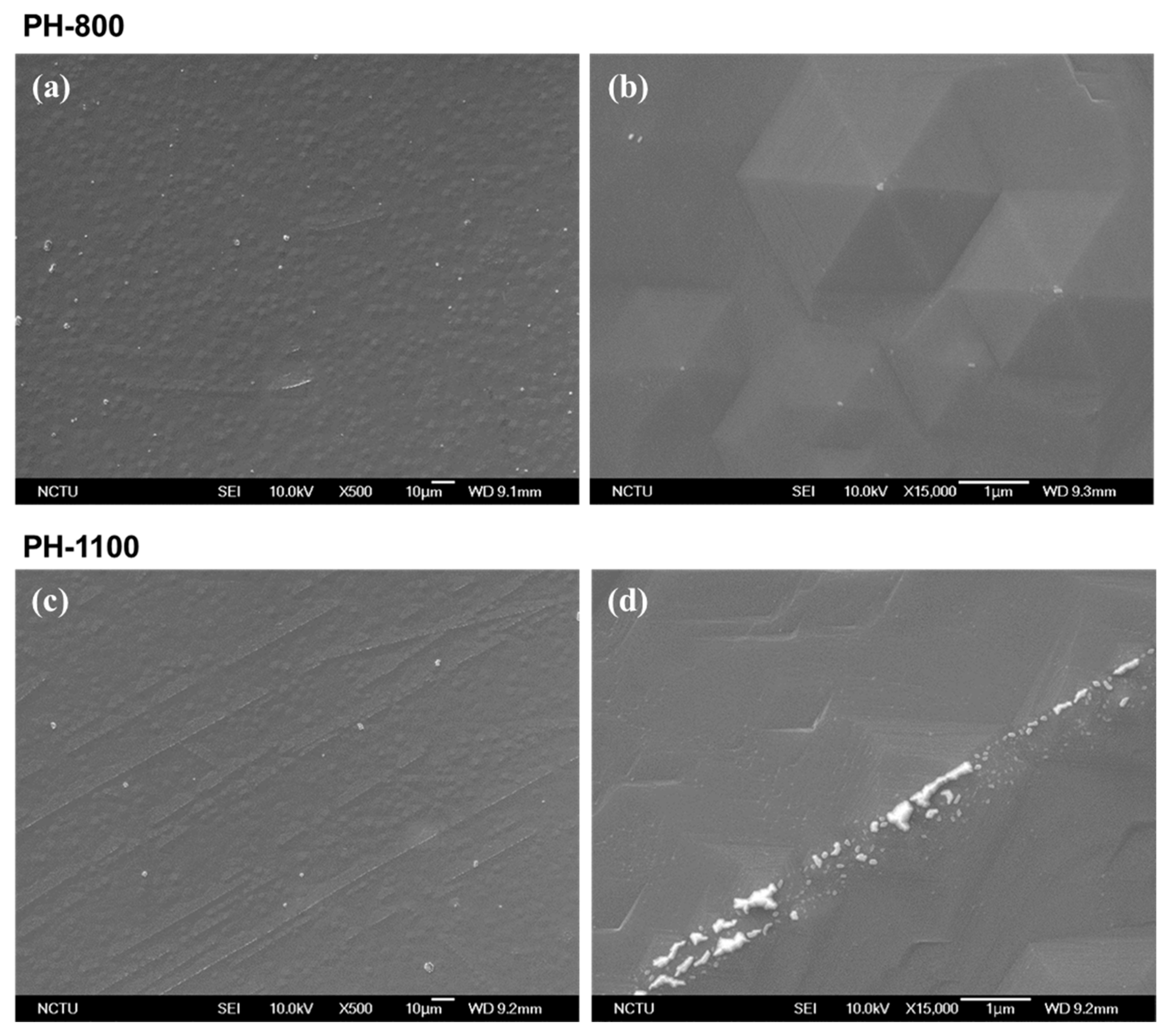

3.1. Surface Morphology of the Substrate Versus Preheating Temperature

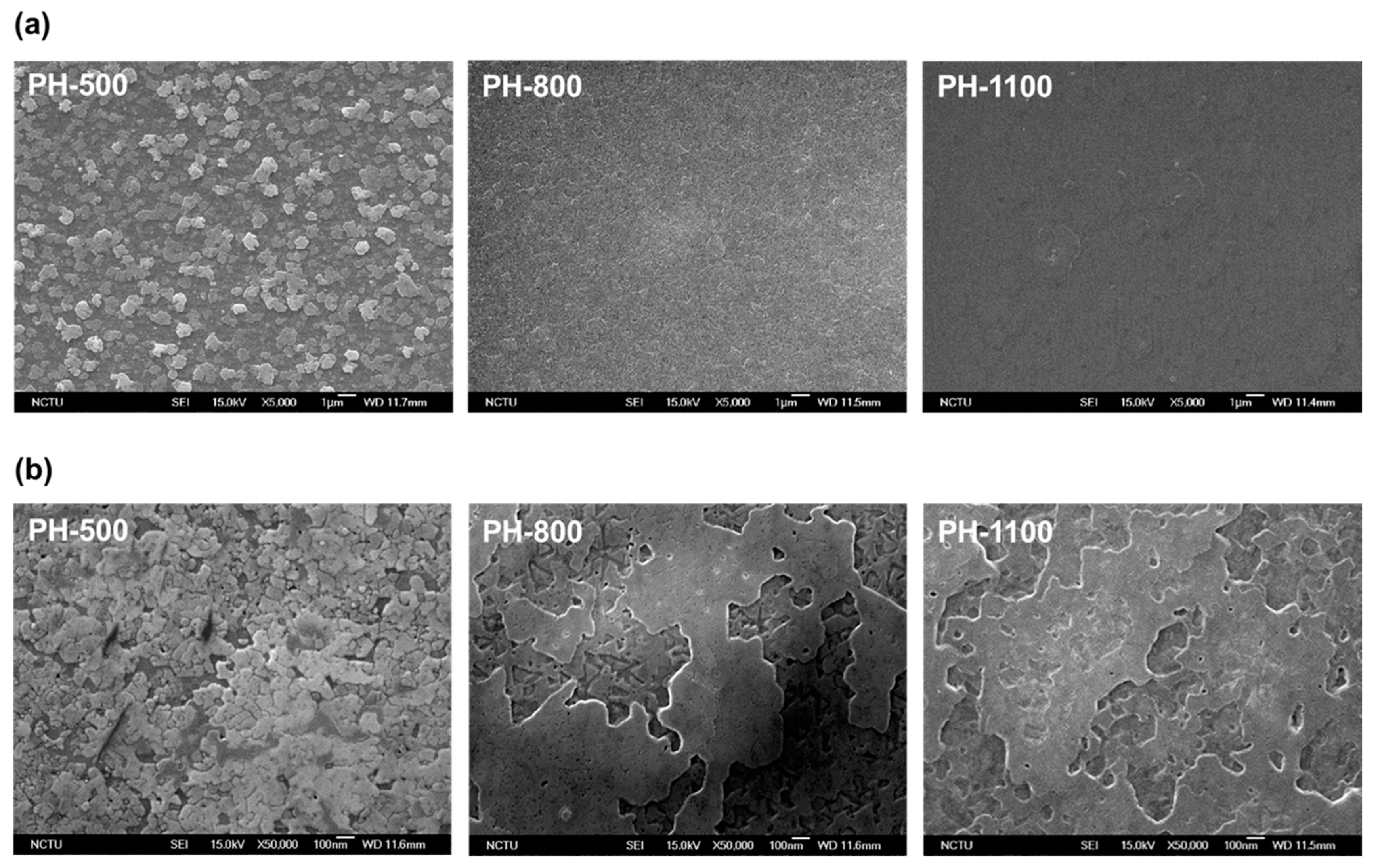

3.2. GaN Nuclear Layer Versus Preheating Temperature

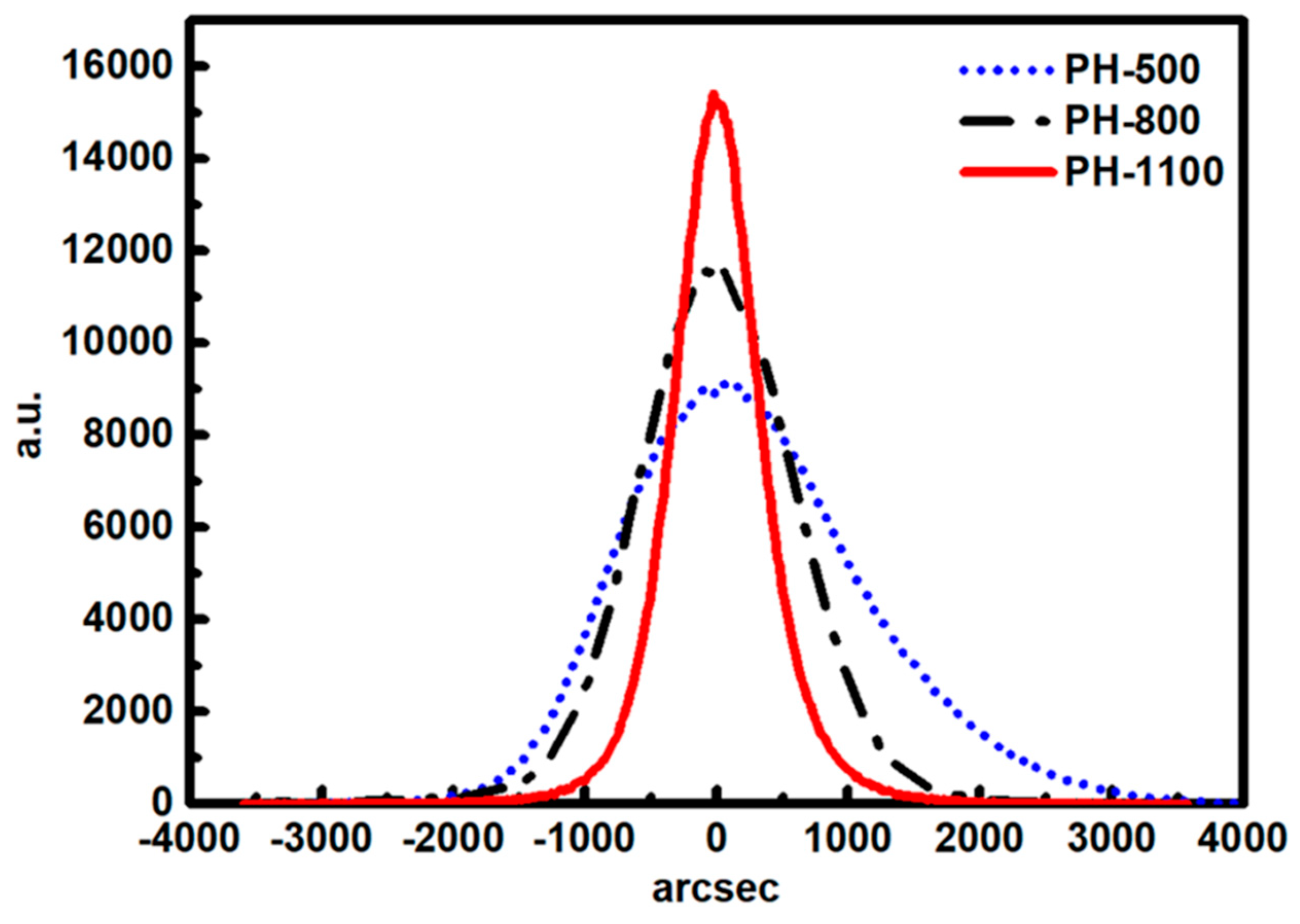

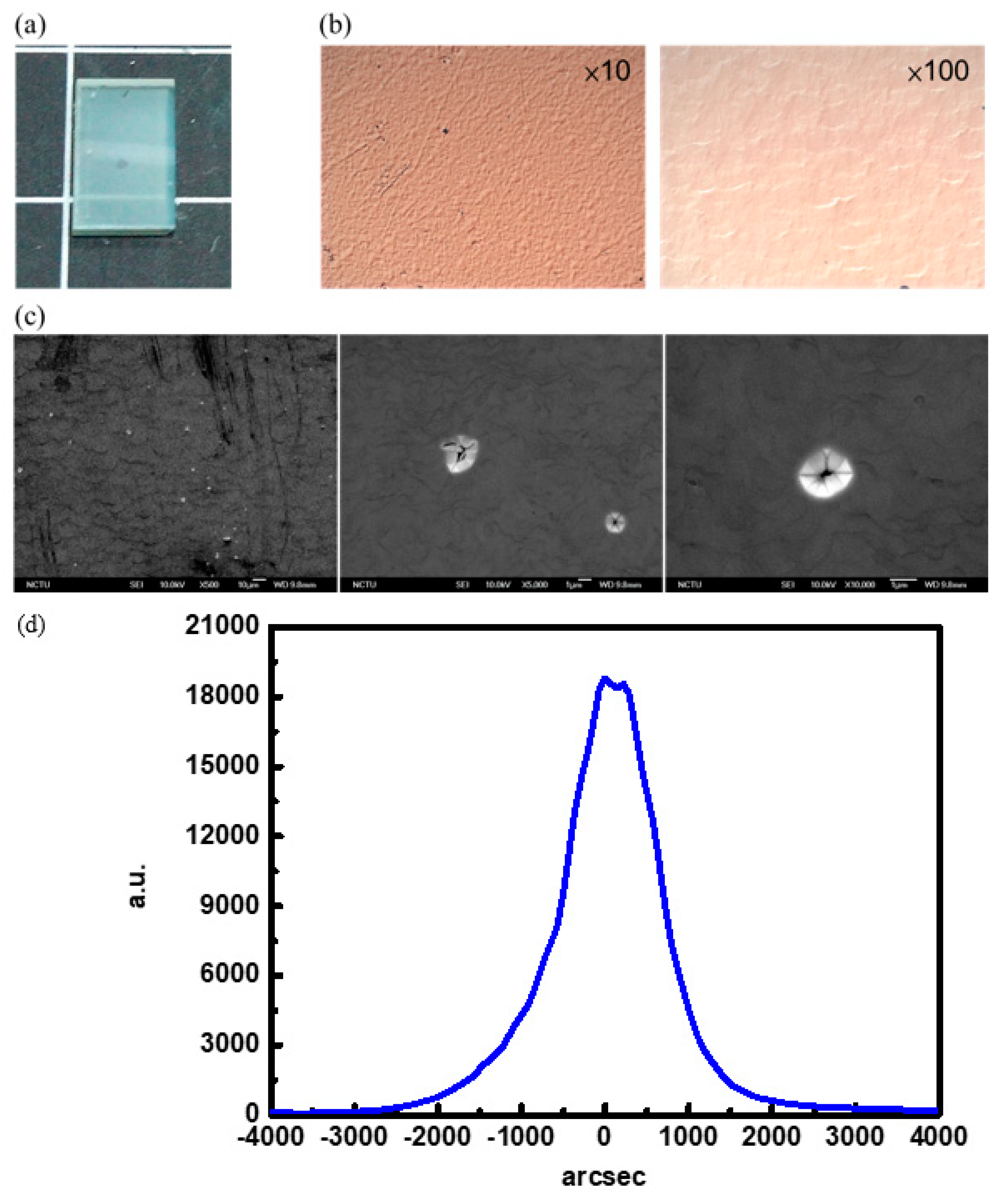

3.3. Crystalline Quality of the GaN Film

3.4. Power-Dependent Photoluminescence

3.5. 2-μm-thick GaN Film Growth on Substrate without Preheating

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mishra, U.K.; Shen, L.; Kazior, T.E.; Wu, Y.-F. GaN-Based RF Power Devices and Amplifiers. Proc. IEEE 2008, 96, 287–305. [Google Scholar] [CrossRef]

- Jones, E.A.; Wang, F.F.; Costinett, D. Review of Commercial GaN Power Devices and GaN-Based Converter Design Challenges. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 707–719. [Google Scholar] [CrossRef]

- Nakamura, S. Current Status of GaN-Based Solid-State Lighting. MRS Bull. 2009, 34, 101–107. [Google Scholar] [CrossRef]

- Akasaki, I. Key Inventions in the History of Nitride-Based Blue LED and LD. J. Cryst. Growth 2007, 300, 2–10. [Google Scholar] [CrossRef]

- Nakamura, S.; Fasol, G. The Blue Laser Diode: GaN Based Light Emitters and Lasers; Springer-Verlag: Berlin/Heidelberg, Germany, 1997; ISBN 978-3-662-03462-0. [Google Scholar]

- Jarndal, A.; Arivazhagan, L.; Nirmal, D. On the Performance of GaN-on-Silicon, Silicon-Carbide, and Diamond Substrates. Int. J. RF Microw. Comput. Aided Eng. 2020, 30, e22196. [Google Scholar] [CrossRef]

- Boles, T. GaN-on-Silicon Present Challenges and Future Opportunities. In Proceedings of the 2017 12th European Microwave Integrated Circuits Conference (EuMIC), Nuremberg, Germany, 8–10 October 2017; pp. 21–24. [Google Scholar]

- Zhu, D.; Wallis, D.J.; Humphreys, C.J. Prospects of III-Nitride Optoelectronics Grown on Si. Rep. Prog. Phys. 2013, 76, 106501. [Google Scholar] [CrossRef] [PubMed]

- Jang, H.W.; Ryu, S.W.; Yu, H.K.; Lee, S.; Lee, J.-L. The Role of Reflective P-Contacts in the Enhancement of Light Extraction in Nanotextured Vertical InGaN Light-Emitting Diodes. Nanotechnology 2009, 21, 025203. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.H.; Lee, H.K.; Yu, J.S.; Bae, S.J.; Choi, J.H.; Kim, D.H.; Ju, I.C.; Song, K.M.; Kim, J.M.; Shin, C.S. Temperature and Thermal Characteristics of InGaN/GaN Vertical Light-Emitting Diodes on Electroplated Copper. Semicond. Sci. Technol. 2011, 26, 055014. [Google Scholar] [CrossRef]

- Na, S.-I.; Ha, G.-Y.; Han, D.-S.; Kim, S.-S.; Kim, J.-Y.; Lim, J.-H.; Kim, D.-J.; Min, K.-I.; Park, S.-J. Selective Wet Etching of P-GaN for Efficient GaN-Based Light-Emitting Diodes. IEEE Photonics Technol. Lett. 2006, 18, 1512–1514. [Google Scholar] [CrossRef]

- Yamada, M.; Mitani, T.; Narukawa, Y.; Shioji, S.; Niki, I.; Sonobe, S.; Deguchi, K.; Sano, M.; Mukai, T. InGaN-Based Near-Ultraviolet and Blue-Light-Emitting Diodes with High External Quantum Efficiency Using a Patterned Sapphire Substrate and a Mesh Electrode. Jpn. J. Appl. Phys. 2002, 41, L1431–L1433. [Google Scholar] [CrossRef]

- Feng, Z.H.; Qi, Y.D.; Lu, Z.D.; Lau, K.M. GaN-Based Blue Light-Emitting Diodes Grown and Fabricated on Patterned Sapphire Substrates by Metalorganic Vapor-Phase Epitaxy. J. Cryst. Growth 2004, 272, 327–332. [Google Scholar] [CrossRef]

- Lee, Y.J.; Hwang, J.M.; Hsu, T.C.; Hsieh, M.H.; Jou, M.J.; Lee, B.J.; Lu, T.C.; Kuo, H.C.; Wang, S.C. Enhancing the Output Power of GaN-Based LEDs Grown on Wet-Etched Patterned Sapphire Substrates. IEEE Photonics Technol. Lett. 2006, 18, 1152–1154. [Google Scholar] [CrossRef]

- Wuu, D.S.; Wang, W.K.; Shih, W.C.; Horng, R.H.; Lee, C.E.; Lin, W.Y.; Fang, J.S. Enhanced Output Power of Near-Ultraviolet InGaN-GaN LEDs Grown on Patterned Sapphire Substrates. IEEE Photonics Technol. Lett. 2005, 17, 288–290. [Google Scholar] [CrossRef]

- Lee, J.-H.; Oh, J.T.; Kim, Y.C.; Lee, J.-H. Stress Reduction and Enhanced Extraction Efficiency of GaN-Based LED Grown on Cone-Shape-Patterned Sapphire. IEEE Photonics Technol. Lett. 2008, 20, 1563–1565. [Google Scholar] [CrossRef]

- Shin, H.-Y.; Kwon, S.K.; Chang, Y.I.; Cho, M.J.; Park, K.H. Reducing Dislocation Density in GaN Films Using a Cone-Shaped Patterned Sapphire Substrate. J. Cryst. Growth 2009, 311, 4167–4170. [Google Scholar] [CrossRef]

- Huang, H.W.; Lin, C.H.; Huang, J.K.; Lee, K.Y.; Lin, C.F.; Yu, C.C.; Tsai, J.Y.; Hsueh, R.; Kuo, H.C.; Wang, S.C. Investigation of GaN-Based Light Emitting Diodes with Nano-Hole Patterned Sapphire Substrate (NHPSS) by Nano-Imprint Lithography. Mater. Sci. Eng. B 2009, 164, 76–79. [Google Scholar] [CrossRef]

- Cheng, J.-H.; Wu, Y.S.; Liao, W.-C.; Lin, B.-W. Improved Crystal Quality and Performance of GaN-Based Light-Emitting Diodes by Decreasing the Slanted Angle of Patterned Sapphire. Appl. Phys. Lett. 2010, 96, 051109. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Tzou, A.-J.; Lin, B.-C.; Lan, Y.-P.; Chiu, C.-H.; Chi, G.-C.; Chen, C.-H.; Kuo, H.-C.; Lin, R.-M.; Chang, C.-Y. Efficiency Improvement of GaN-Based Ultraviolet Light-Emitting Diodes with Reactive Plasma Deposited AlN Nucleation Layer on Patterned Sapphire Substrate. Nanoscale Res. Lett. 2014, 9, 505. [Google Scholar] [CrossRef][Green Version]

- Liu, L.; Edgar, J.H. Substrates for Gallium Nitride Epitaxy. Mater. Sci. Eng. R Rep. 2002, 37, 61–127. [Google Scholar] [CrossRef]

- Yoshida, S.; Misawa, S.; Gonda, S. Improvements on the Electrical and Luminescent Properties of Reactive Molecular Beam Epitaxially Grown GaN Films by Using AlN-coated Sapphire Substrates. Appl. Phys. Lett. 1983, 42, 427–429. [Google Scholar] [CrossRef]

- Amano, H.; Sawaki, N.; Akasaki, I.; Toyoda, Y. Metalorganic Vapor Phase Epitaxial Growth of a High Quality GaN Film Using an AlN Buffer Layer. Appl. Phys. Lett. 1986, 48, 353–355. [Google Scholar] [CrossRef]

- Tippins, H.H. Optical Absorption and Photoconductivity in the Band Edge of β-Ga2O3. Phys. Rev. 1965, 140, A316–A319. [Google Scholar] [CrossRef]

- Víllora, E.G.; Shimamura, K.; Yoshikawa, Y.; Aoki, K.; Ichinose, N. Large-Size β-Ga2O3 Single Crystals and Wafers. J. Cryst. Growth 2004, 270, 420–426. [Google Scholar] [CrossRef]

- Aida, H.; Nishiguchi, K.; Takeda, H.; Aota, N.; Sunakawa, K.; Yaguchi, Y. Growth of β-Ga2O3 Single Crystals by the Edge-Defined, Film Fed Growth Method. Jpn. J. Appl. Phys. 2008, 47, 8506–8509. [Google Scholar] [CrossRef]

- Víllora, E.G.; Shimamura, K.; Kitamura, K.; Aoki, K.; Ujiie, T. Epitaxial Relationship between Wurtzite GaN and β-Ga2O3. Appl. Phys. Lett. 2007, 90, 234102. [Google Scholar] [CrossRef]

- Muhammed, M.M.; Peres, M.; Yamashita, Y.; Morishima, Y.; Sato, S.; Franco, N.; Lorenz, K.; Kuramata, A.; Roqan, I.S. High Optical and Structural Quality of GaN Epilayers Grown on (01) β-Ga2O3. Appl. Phys. Lett. 2014, 105, 042112. [Google Scholar] [CrossRef]

- Ajia, I.A.; Yamashita, Y.; Lorenz, K.; Muhammed, M.M.; Spasevski, L.; Almalawi, D.; Xu, J.; Iizuka, K.; Morishima, Y.; Anjum, D.H.; et al. GaN/AlGaN Multiple Quantum Wells Grown on Transparent and Conductive (−201)-Oriented β-Ga2O3 Substrate for UV Vertical Light Emitting Devices. Appl. Phys. Lett. 2018, 113, 082102. [Google Scholar] [CrossRef]

- Li, D.; Hoffmann, V.; Richter, E.; Tessaro, T.; Galazka, Z.; Weyers, M.; Tränkle, G. MOVPE Growth of Violet GaN LEDs on β-Ga2O3 Substrates. J. Cryst. Growth 2017, 478, 212–215. [Google Scholar] [CrossRef]

- Muhammed, M.M.; Alwadai, N.; Lopatin, S.; Kuramata, A.; Roqan, I.S. High-Efficiency InGaN/GaN Quantum Well-Based Vertical Light-Emitting Diodes Fabricated on β-Ga2O3 Substrate. ACS Appl. Mater. Interfaces 2017, 9, 34057–34063. [Google Scholar] [CrossRef]

- Shimamura, K.; Villora, E.G.; Aoki, K.; Ichinose, N. Growth and Characterization of Beta-Ga2O3 Single Crystals as Transparent Conductive Substrates for GaN (Invited Paper). In Physics and Simulation of Optoelectronic Devices XIII; Osinski, M., Henneberger, F., Amano, H., Eds.; SPIE: Bellingham, WA, USA, 2005; Volume 5722, pp. 380–391. [Google Scholar]

- Ito, S.; Takeda, K.; Nagata, K.; Aoshima, H.; Takehara, K.; Iwaya, M.; Takeuchi, T.; Kamiyama, S.; Akasaki, I.; Amano, H. Growth of GaN and AlGaN on (100) β-Ga2O3 Substrates. Phys. Status Solidi C 2012, 9, 519–522. [Google Scholar] [CrossRef]

- Víllora, E.G.; Arjoca, S.; Shimamura, K.; Inomata, D.; Aoki, K. β-Ga2O3 and Single-Crystal Phosphors for High-Brightness White LEDs and LDs, and β-Ga2O3 Potential for next Generation of Power Devices. In Oxide-Based Materials and Devices V; Teherani, F.H., Look, D.C., Rogers, D.J., Eds.; SPIE: Bellingham, WA, USA, 2014; Volume 8987, p. 89871U. [Google Scholar]

- Lee, H.J.; Shin, T.I.; Yoon, D.H. Influence of NH3 Gas for GaN Epilayer on β-Ga2O3 Substrate by Nitridation. Surf. Coat. Technol. 2008, 202, 5497–5500. [Google Scholar] [CrossRef]

- Kachel, K.; Korytov, M.; Gogova, D.; Galazka, Z.; Albrecht, M.; Zwierz, R.; Siche, D.; Golka, S.; Kwasniewski, A.; Schmidbauer, M.; et al. A New Approach to Free-Standing GaN Using β-Ga2O3 as a Substrate. CrystEngComm 2012, 14, 8536–8540. [Google Scholar] [CrossRef]

- Chiu, C.-H.; Hsu, L.-H.; Lee, C.-Y.; Lin, C.-C.; Lin, B.-W.; Tu, S.-J.; Chen, Y.-H.; Liu, C.-Y.; Hsu, W.-C.; Lan, Y.-P.; et al. Light Extraction Enhancement of GaN-Based Light-Emitting Diodes Using Crown-Shaped Patterned Sapphire Substrates. IEEE Photonics Technol. Lett. 2012, 24, 1212–1214. [Google Scholar] [CrossRef]

- Teisseyre, H.; Perlin, P.; Suski, T.; Grzegory, I.; Porowski, S.; Jun, J.; Pietraszko, A.; Moustakas, T.D. Temperature Dependence of the Energy Gap in GaN Bulk Single Crystals and Epitaxial Layer. J. Appl. Phys. 1994, 76, 2429–2434. [Google Scholar] [CrossRef]

- Reshchikov, M.A.; Morkoç, H. Luminescence Properties of Defects in GaN. J. Appl. Phys. 2005, 97, 061301. [Google Scholar] [CrossRef]

- Reshchikov, M.A.; Vorobiov, M.; Grabianska, K.; Zajac, M.; Iwinska, M.; Bockowski, M. Defect-Related Photoluminescence from Ammono GaN. J. Appl. Phys. 2021, 129, 095703. [Google Scholar] [CrossRef]

- Singh, R.; Molnar, R.J.; Ünlü, M.S.; Moustakas, T.D. Intensity Dependence of Photoluminescence in GaN Thin Films. Appl. Phys. Lett. 1994, 64, 336–338. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, Y.-P. The Influence of the Preheating Temperature of the (−2 0 1) β-Ga2O3 Substrates on c-Plane GaN Epitaxial Growth. Coatings 2021, 11, 824. https://doi.org/10.3390/coatings11070824

Lan Y-P. The Influence of the Preheating Temperature of the (−2 0 1) β-Ga2O3 Substrates on c-Plane GaN Epitaxial Growth. Coatings. 2021; 11(7):824. https://doi.org/10.3390/coatings11070824

Chicago/Turabian StyleLan, Yu-Pin. 2021. "The Influence of the Preheating Temperature of the (−2 0 1) β-Ga2O3 Substrates on c-Plane GaN Epitaxial Growth" Coatings 11, no. 7: 824. https://doi.org/10.3390/coatings11070824

APA StyleLan, Y.-P. (2021). The Influence of the Preheating Temperature of the (−2 0 1) β-Ga2O3 Substrates on c-Plane GaN Epitaxial Growth. Coatings, 11(7), 824. https://doi.org/10.3390/coatings11070824