Low-Temperature Epitaxial Growth of AlN Thin Films on a Mo Electrode/Sapphire Substrate Using Reactive Sputtering

Abstract

1. Introduction

2. Experimental

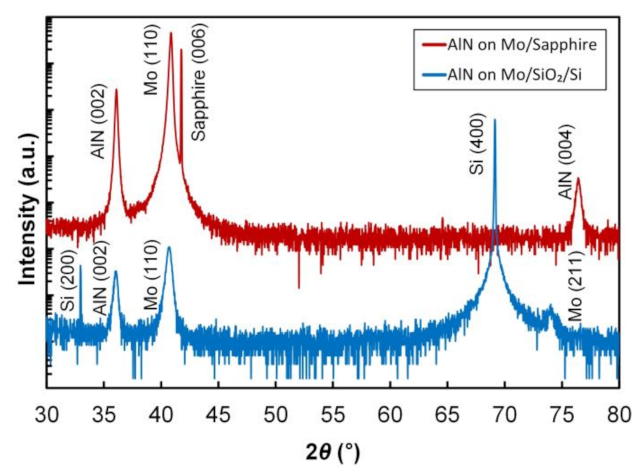

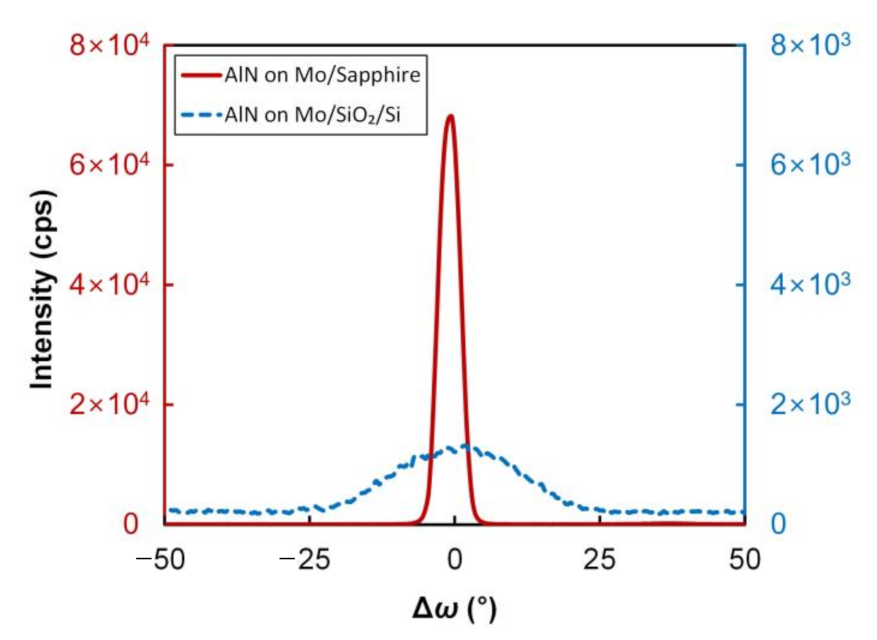

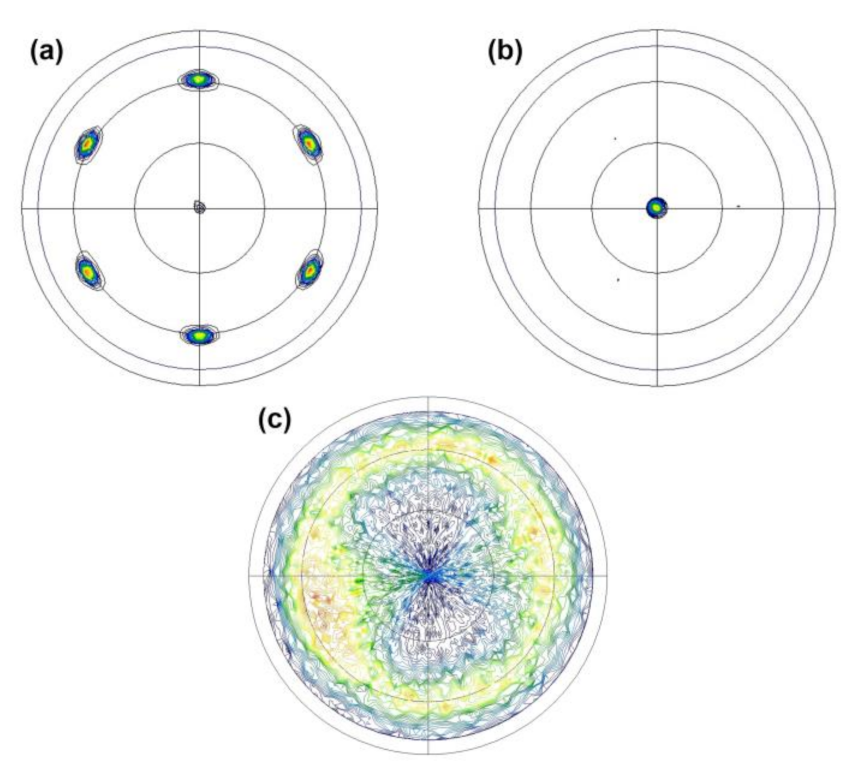

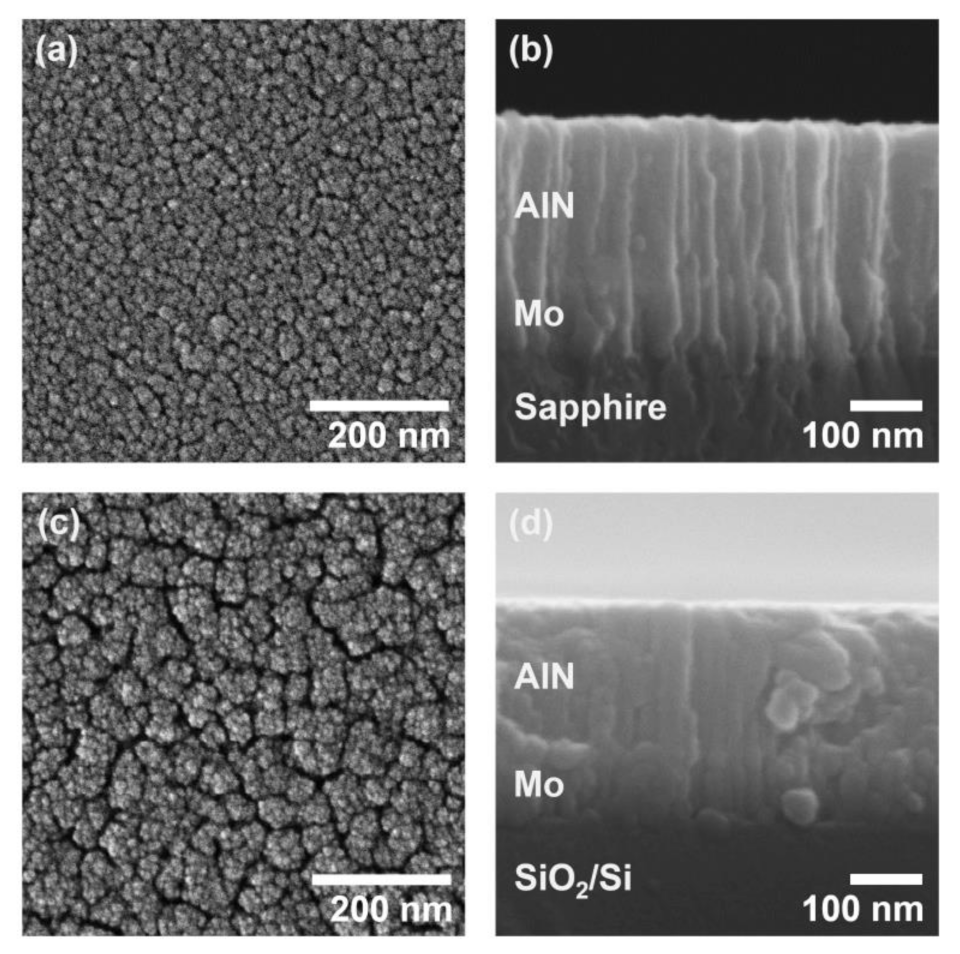

3. Results and Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bairagi, S.; Järrendahl, K.; Eriksson, F.; Hultman, L.; Birch, J.; Hsiao, C. Glancing Angle Deposition and Growth Mechanism of Inclined AlN Nanostructures using Reactive Magnetron Sputtering. Coatings 2020, 10, 768. [Google Scholar] [CrossRef]

- Bayerl, D.; Islam, S.M.; Jones, C.M.; Protasenko, V.; Jena, D.; Kioupakis, E. Deep Ultraviolet Emission from Ultra-Thin GaN/AlN Heterostructures. Appl. Phys. Lett. 2016, 109, 241102. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, Y.; Zhang, H.; Xie, L.; Xing, Z.; Cheng, Z.; Li, H.; Xiao, Y.; Liang, H.; Liu, H. Ultraviolet Optical Properties Analysis of Wurtzite AlN Films Grown by Vapor Phase Epitaxy. Opt. Mater. 2021, 111, 110678. [Google Scholar] [CrossRef]

- Li, T.; Wang, F.; Lin, R.; Xie, W.; Li, Y.; Zheng, W.; Huang, F. In-Plane Enhanced Epitaxy for Step-Flow AlN Yielding a High-Performance Vacuum-Ultraviolet Photovoltaic Detector. CrystEngComm 2020, 22, 654–659. [Google Scholar] [CrossRef]

- Motamedi, P.; Cadien, K. XPS Analysis of AlN Thin Films Deposited by Plasma Enhanced Atomic Layer Deposition. Appl. Surf. Sci. 2014, 315, 104–109. [Google Scholar] [CrossRef]

- Kim, T.; Kim, J.; Dalmau, R.; Schlesser, R.; Preble, E.; Jiang, X. High-Temperature Electromechanical Characterization of AlN Single Crystals. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 62, 1880–1887. [Google Scholar] [CrossRef] [PubMed]

- Tonisch, K.; Cimalla, V.; Foerster, C.; Romanus, H.; Ambacher, O.; Dontsov, D. Piezoelectric Properties of Polycrystalline AlN Thin Films for MEMS Application. Sens. Actuators A Phys. 2006, 132, 658–663. [Google Scholar] [CrossRef]

- Ababneh, A.; Alsumady, M.; Seidel, H.; Manzaneque, T.; Hernando-García, J.; Sánchez-Rojas, J.L.; Bittner, A.; Schmid, U. C-Axis Orientation and Piezoelectric Coefficients of AlN Thin Films Sputter-Deposited on Titanium Bottom Electrodes. Appl. Surf. Sci. 2012, 259, 59–65. [Google Scholar] [CrossRef]

- Musa, I.; Qamhieh, N.; Said, K.; Mahmoud, S.T.; Alawadhi, H. Fabrication and Characterization of Aluminum Nitride Nanoparticles by RF Magnetron Sputtering and Inert Gas Condensation Technique. Coatings 2020, 10, 411. [Google Scholar] [CrossRef]

- Jackson, N.; Keeney, L.; Mathewson, A. Flexible-CMOS and Biocompatible Piezoelectric AlN Material for MEMS Applications. Smart Mater. Struct. 2013, 22, 115033. [Google Scholar] [CrossRef]

- Galca, A.C.; Stan, G.E.; Trinca, L.M.; Negrila, C.C.; Nistor, L.C. Structural and Optical Properties of C-Axis Oriented Aluminum Nitride Thin Films Prepared at Low Temperature by Reactive Radio-Frequency Magnetron Sputtering. Thin Solid Films 2012, 524, 328–333. [Google Scholar] [CrossRef]

- Iriarte, G.F.; Rodríguez, J.G.; Calle, F. Synthesis of C-Axis Oriented AlN Thin Films on Different Substrates: A Review. Mater. Res. Bull. 2010, 45, 1039–1045. [Google Scholar] [CrossRef]

- Imran, S.; Yuan, J.; Yin, G.; Ma, Y.; He, S. Influence of Metal Electrodes on C-axis Orientation of AlN Thin Films Deposited by DC Magnetron Sputtering. Surf. Interface Anal. 2017, 49, 885–891. [Google Scholar] [CrossRef]

- Pawar, S.; Singh, K.; Sharma, S.; Pandey, A.; Dutta, S.; Kaur, D. Growth Assessment and Scrutinize Dielectric Reliability of C-Axis Oriented Insulating AlN Thin Films in MIM Structures for Microelectronics Applications. Mater. Chem. Phys. 2018, 219, 74–81. [Google Scholar] [CrossRef]

- Alizadeh, M.; Mehdipour, H.; Ganesh, V.; Ameera, A.N.; Goh, B.T.; Shuhaimi, A.; Rahman, S.A. Plasma-Assisted Hot Filament Chemical Vapor Deposition of AlN Thin Films on ZnO Buffer Layer: Toward Highly C-Axis-Oriented, Uniform, Insulative Films. Appl. Phys. A 2014, 117, 2217–2224. [Google Scholar] [CrossRef]

- Tavsanoglu, T. Synthesis of C-Axis Oriented AlN Thin Films at Room Temperature. Surf. Eng. 2017, 33, 249–254. [Google Scholar] [CrossRef]

- Jiang, J.; Peng, B.; Zhang, W.; Wang, Y.; Shu, L.; Wang, R. Growth of C-Axis Oriented AlN Thin Films on Titanium Alloy Substrate by Middle Frequency Magnetron Sputtering. J. Vac. Sci. Technol. A Vac. Surf. Film. 2015, 33, 041509. [Google Scholar] [CrossRef]

- Monteagudo-Lerma, L.; Naranjo, F.B.; González-Herráez, M.; Fernández, S. Influence of Substrate Biasing on the Growth of C-axis Oriented AlN Thin Films by RF Reactive Sputtering in Pure Nitrogen. Phys. Status Solidi C 2012, 9, 1074–1078. [Google Scholar] [CrossRef]

- Wistrela, E.; Schneider, M.; Bittner, A.; Schmid, U. Impact of the Substrate Dependent Polarity Distribution in C-Axis Oriented AlN Thin Films on the Etching Behaviour and the Piezoelectric Properties. Microsyst. Technol. 2016, 22, 1691–1700. [Google Scholar] [CrossRef]

- Pandey, A.; Kaushik, J.; Dutta, S.; Kapoor, A.K.; Kaur, D. Electrical and Structural Characteristics of Sputtered C-Oriented AlN Thin Films on Si (100) and Si (110) Substrates. Thin Solid Films 2018, 666, 143–149. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, F.J.; Wang, J.M.; He, C.G.; Zhang, L.S.; Huang, J.; Cheng, J.P.; Qin, Z.X.; Yang, X.L.; Tang, N. Epitaxial Growth of AlN Films on Sapphire via a Multilayer Structure Adopting a Low-and High-Temperature Alternation Technique. CrystEngComm 2015, 17, 7496–7499. [Google Scholar] [CrossRef]

- Paduano, Q.S.; Weyburne, D.W.; Jasinski, J.; Liliental-Weber, Z. Effect of Initial Process Conditions on the Structural Properties of AlN Films. J. Cryst. Growth 2004, 261, 259–265. [Google Scholar] [CrossRef]

- Yang, J.; Jiao, X.; Zhang, R.; Zhong, H.; Shi, Y.; Du, B. Growth of AlN Films as a Function of Temperature on Mo Films Deposited by Different Techniques. J. Electron. Mater. 2014, 43, 369–374. [Google Scholar] [CrossRef]

- Kamohara, T.; Akiyama, M.; Ueno, N.; Kuwano, N. Improvement in Crystal Orientation of AlN Thin Films Prepared on Mo Electrodes using AlN Interlayers. Ceram. Int. 2008, 34, 985–989. [Google Scholar] [CrossRef]

- Chauhan, S.S.; Joglekar, M.M.; Manhas, S.K. Influence of Process Parameters and Formation of Highly C-Axis Oriented AlN Thin Films on Mo by Reactive Sputtering. J. Electron. Mater. 2018, 47, 7520–7530. [Google Scholar] [CrossRef]

- Seo, H.; Petrov, I.; Kim, K. Structural Properties of AlN Grown on Sapphire at Plasma Self-Heating Conditions using Reactive Magnetron Sputter Deposition. J. Electron. Mater. 2010, 39, 1146–1151. [Google Scholar] [CrossRef]

- Six, S.; Gerlach, J.W.; Rauschenbach, B. Epitaxial Aluminum Nitride Films on Sapphire Formed by Pulsed Laser Deposition. Thin Solid Films 2000, 370, 1–4. [Google Scholar] [CrossRef]

- Okamoto, M.; Mori, Y.; Sasaki, T. Epitaxial Growth of AlN Thin Films on Sapphire by Pulsed Laser Deposition and Effect of N2 Ambient on Crystallinity. Jpn. J. Appl. Phys. 1999, 38, 2114. [Google Scholar] [CrossRef]

- He, C.; Zhao, W.; Wu, H.; Zhang, S.; Zhang, K.; He, L.; Liu, N.; Chen, Z.; Shen, B. High-Quality AlN Film Grown on Sputtered AlN/Sapphire Via Growth-Mode Modification. Cryst. Growth Des. 2018, 18, 6816–6823. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, K.; Ai, Y.; Zhang, L.; Niu, X.; Lv, H.; Zhang, Y. Crystal Quality Improvement of Sputtered AlN Film on Sapphire Substrate by High-Temperature Annealing. J. Mater. Sci. Mater. Electron. 2018, 29, 13766–13773. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J. Low-Temperature Epitaxial Growth of AlN Thin Films on a Mo Electrode/Sapphire Substrate Using Reactive Sputtering. Coatings 2021, 11, 443. https://doi.org/10.3390/coatings11040443

Kim J. Low-Temperature Epitaxial Growth of AlN Thin Films on a Mo Electrode/Sapphire Substrate Using Reactive Sputtering. Coatings. 2021; 11(4):443. https://doi.org/10.3390/coatings11040443

Chicago/Turabian StyleKim, Jihong. 2021. "Low-Temperature Epitaxial Growth of AlN Thin Films on a Mo Electrode/Sapphire Substrate Using Reactive Sputtering" Coatings 11, no. 4: 443. https://doi.org/10.3390/coatings11040443

APA StyleKim, J. (2021). Low-Temperature Epitaxial Growth of AlN Thin Films on a Mo Electrode/Sapphire Substrate Using Reactive Sputtering. Coatings, 11(4), 443. https://doi.org/10.3390/coatings11040443