Polymer Coating Effects: Study of Material Properties and Architectural Application Characteristics of Aluminum Template

Abstract

1. Introduction

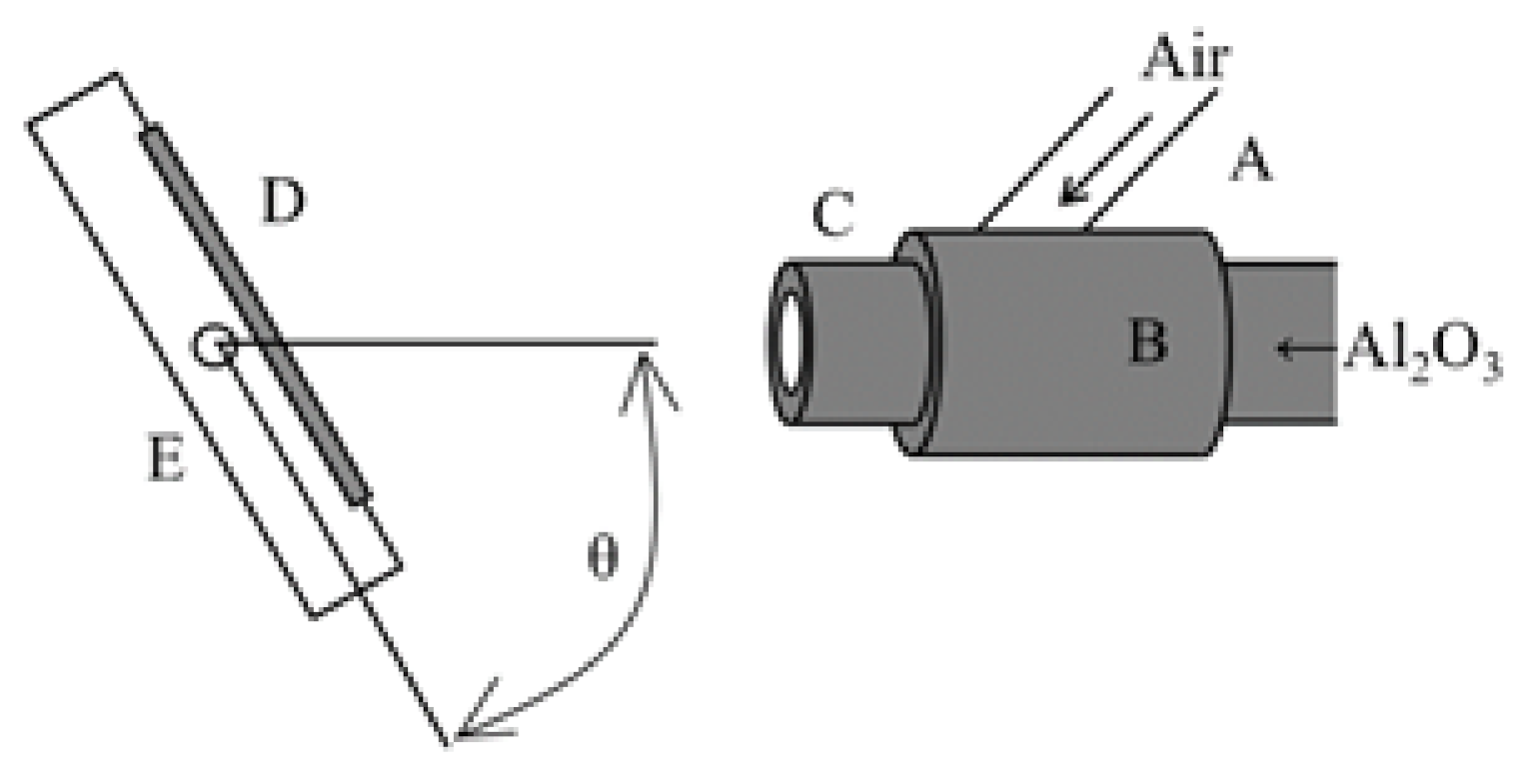

2. Experimental Procedure

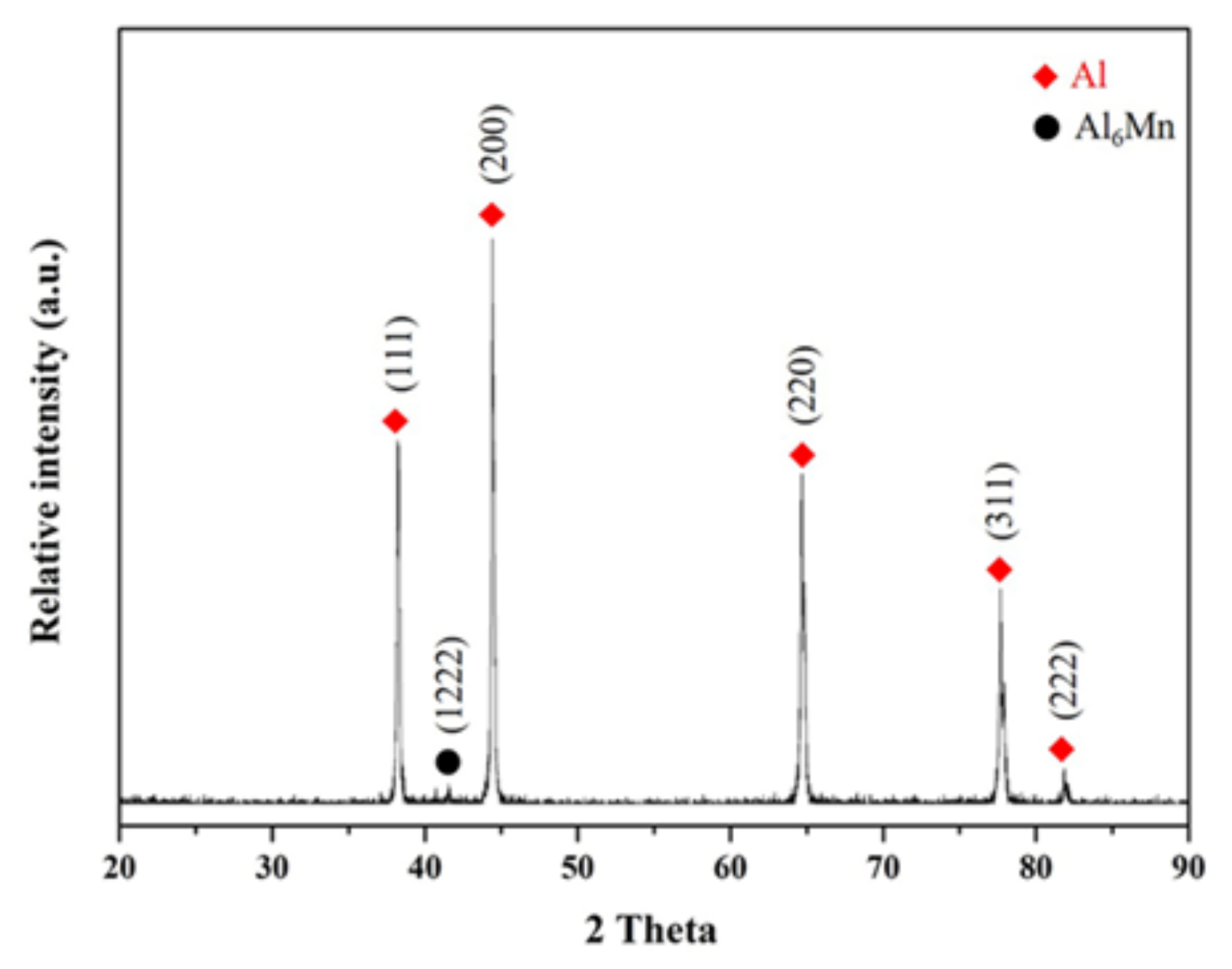

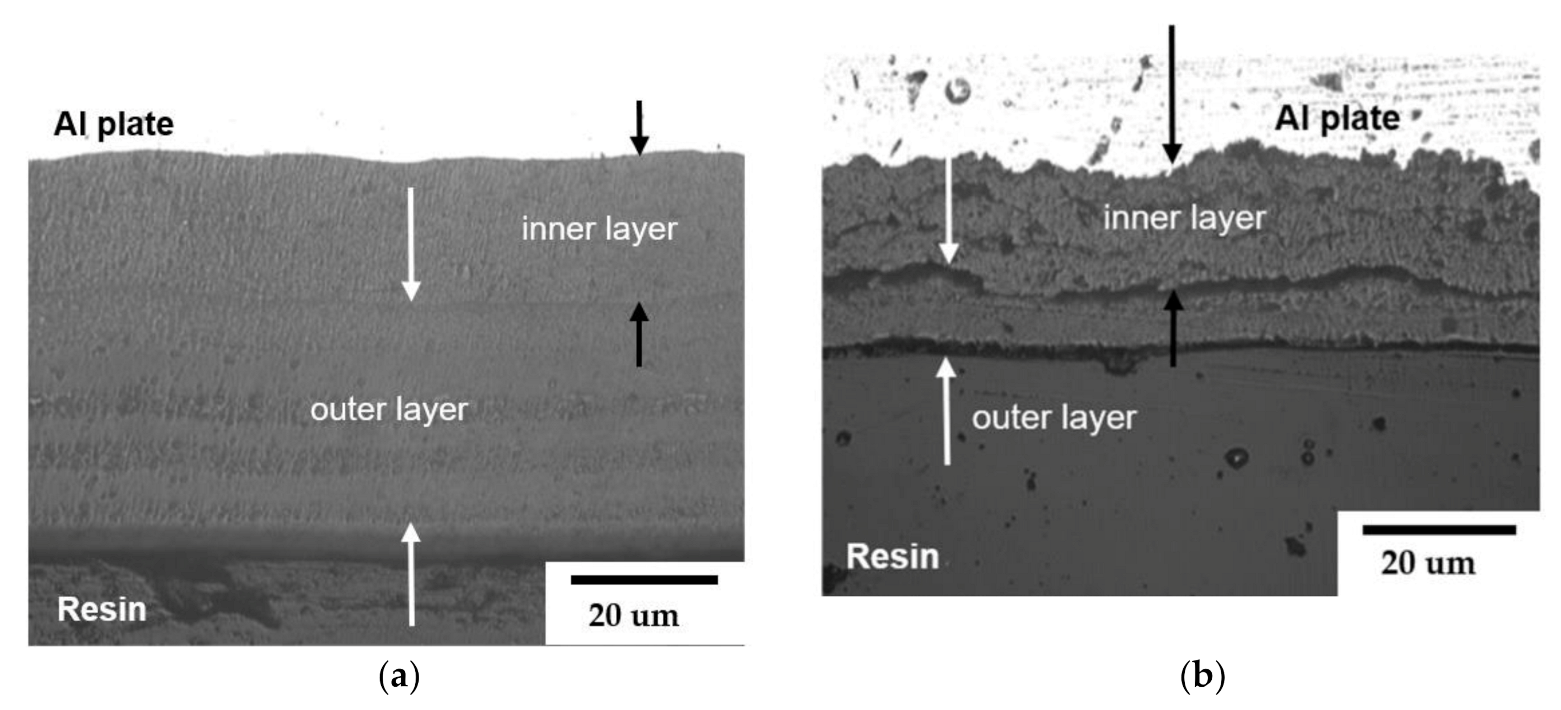

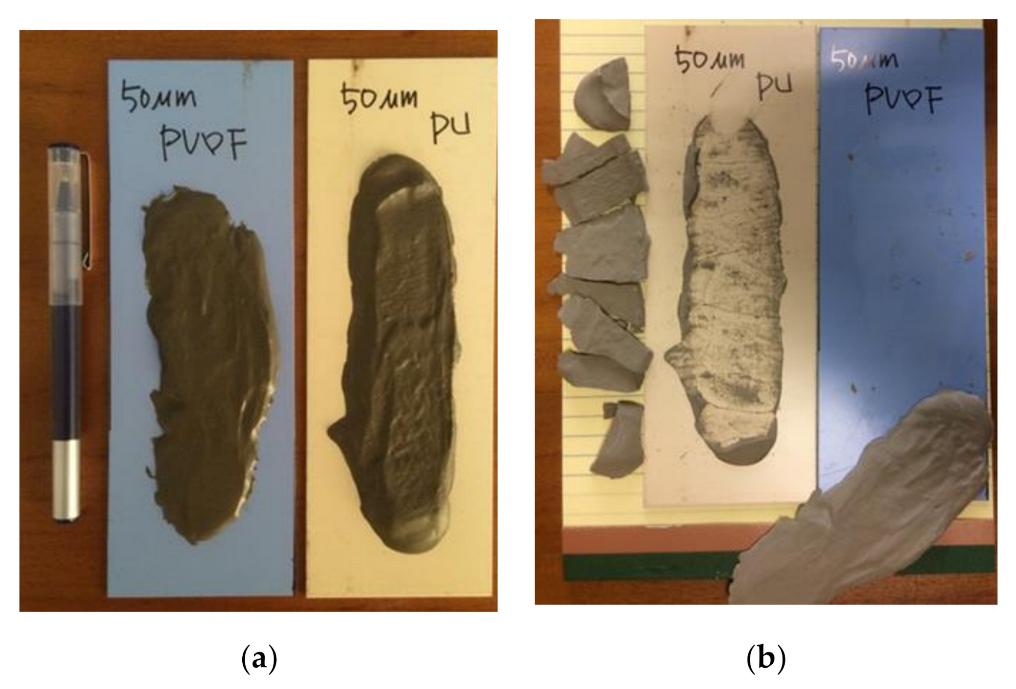

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guillon, O.; Roizard, X.; Belliard, P. Experimental methodology to study tribological aspects of deep drawing application to aluminum alloy sheets and tool coatings. Tribol. Int. 2001, 34, 757–766. [Google Scholar] [CrossRef]

- Yang, C.-W.; Hung, F.-Y.; Lui, T.-S.; Chen, L.-H.; Juo, J.-Y. Weibull Statistics for Evaluating Failure Behaviors and Joining Reliability of Friction Stir Spot Welded 5052 Aluminum Alloy. Mater. Trans. 2009, 50, 145–151. [Google Scholar] [CrossRef]

- Ozturk, F.; Esener, E.; Toros, S.; Picu, C.R. Effects of aging parameters on formability of 6061-O alloy. Mater. Des. 2010, 31, 4847–4852. [Google Scholar] [CrossRef]

- Barnwal, V.K.; Raghavan, R.; Tewari, A.; Narasimhan, K.; Mishra, S.K. Effect of microstructure and texture on forming behavior of AA-6061 aluminum alloy sheet. Mater. Sci. Eng. A. 2017, 679, 56–65. [Google Scholar] [CrossRef]

- Ding, L.; Jia, Z.; Nie, J.-F.; Weng, Y.; Cao, L.; Chen, H.; Wu, X.; Liu, Q. The structural and compositional evolution of precipitates in Al-Mg-Si-Cu alloy. Acta Mater. 2018, 145, 437–450. [Google Scholar] [CrossRef]

- Hung, F.-S. Material Application of a Transformer Box: A Study on the Electromagnetic Shielding Characteristics of Al–Ta Coating Film with Plasma-Spray Process. Coatings 2019, 9, 495. [Google Scholar] [CrossRef]

- Darmawan, A.S.; Siswanto, W.A.; Purboputro, P.I.; Anggono, A.D.; Masyrukan; Hamid, A. Effect of Increasing Salinity to Corrosion Resistance of 5052 Aluminum Alloy in Artificial Seawater. Mater. Sci. Forum 2019, 961, 107–111. [Google Scholar] [CrossRef]

- Rasouli, S.A.; Behnagh, R.; Dadvand, A.; Saleki-Haselghoubi, N. Improvement in corrosion resistance of 5083 aluminum alloy via friction stir processing. Proc. Inst. Mech. Eng. Part. L J. Mater. Des. Appl. 2014, 230, 142–150. [Google Scholar] [CrossRef]

- Shen, X.; Liu, H.; Cheng, X.-B.; Yan, C.; Huang, J.-Q. Beyond lithium ion batteries: Higher energy density battery systems based on lithium metal anodes. Energy Storage Mater. 2018, 12, 161–175. [Google Scholar] [CrossRef]

- Vanesa, C.B.; Joshua, K. Energy access is needed to maintain health during pandemics. Nat. Energy 2020, 5, 419–421. [Google Scholar]

- Weber, R.; Genovese, M.; Louli, A.J.; Hames, S.; Martin, C.; Hill, I.G.; Dahn, J.R. Long cycle life and dendrite-free lithium morphology in anode-free lithium pouch cells enabled by a dual-salt liquid electrolyte. Nat. Energy 2019, 4, 683–689. [Google Scholar] [CrossRef]

- Jang, J.Y.; Do, J.Y. Synthesis and evaluation of thermoplastic polyurethanes as thermo-optic waveguide materials. Polym. J. 2014, 46, 349–354. [Google Scholar] [CrossRef]

- Wang, C.-H.; Hou, G.-G.; Du, Z.-Z.; Cong, W.; Sun, J.-F.; Xu, Y.-Y.; Liu, W.-S. Synthesis, characterization and antibacterial properties of polyurethane material functionalized with quaternary ammonium salt. Polym. J. 2015, 48, 259–265. [Google Scholar] [CrossRef]

- Chen, Q.; Mangadlao, J.D.; Wallat, J.; De Leon, A.; Pokorski, J.K.; Advincula, R.C. 3D Printing Biocompatible Polyurethane/Poly(lactic acid)/Graphene Oxide Nanocomposites: Anisotropic Properties. ACS Appl. Mater. Interfaces 2017, 9, 4015–4023. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Kong, Q.; Kong, F.; Liu, T.; Qian, H. Synthesis and surface properties of novel fluorinated polyurethane base on F-containing chain extender. Polym. Adv. Technol. 2019, 31, 616–629. [Google Scholar] [CrossRef]

- Zhao, B.; Jia, R.; Zhang, Y.; Liu, D.; Zheng, X. Design and synthesis of antibacterial waterborne fluorinated polyurethane. J. Appl. Polym. Sci. 2019, 136, 46923. [Google Scholar] [CrossRef]

- Oprea, S. Effect of Composition and Hard-segment Content on Thermo-mechanical Properties of Cross-linked Polyurethane Copolymers. High. Perform. Polym. 2008, 21, 353–370. [Google Scholar] [CrossRef]

- Lee, S.R.; Kim, M.R.; Jo, E.H.; Yoon, K.-B. Synthesis of very low birefringence polymers using fluorinated macromers for polymeric waveguides. High. Perform. Polym. 2015, 28, 131–139. [Google Scholar] [CrossRef]

- Wu, C.; Chiu, S.; Lee, H.; Suen, M. Synthesis and properties of biodegradable polycaprolactone/polyurethanes using fluoro chain extenders. Polym. Adv. Technol. 2015, 27, 665–676. [Google Scholar] [CrossRef]

- Kerr, S.; Naumkin, F.Y. Noncovalently bound complexes of polar molecules: Dipole-inside-of-dipole vs. dipole–dipole systems. New J. Chem. 2017, 41, 13576–13584. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, W.; Hao, L.; Wang, S.; Pei, M.; Wang, X. Synthesis of novel cationic fluoroalkyl-terminated hyperbranched polyurethane latex and morphology, physical properties of its latex film. Prog. Org. Coatings 2018, 121, 209–217. [Google Scholar] [CrossRef]

- Zhao, J.; Zhu, W.; Yan, W.; Wang, X.; Liu, L.; Yu, J.; Ding, B. Tailoring waterproof and breathable properties of environmentally friendly electrospun fibrous membranes by optimizing porous structure and surface wettability. Compos. Commun. 2019, 15, 40–45. [Google Scholar] [CrossRef]

- Hung, F.-S. Design of lightweight aluminum alloy building materials for corrosion and wear resistance. Emerg. Mater. Res. 2020, 9, 750–757. [Google Scholar] [CrossRef]

- Hung, F.; Chen, L.; Lui, T. A study on erosion of upper bainitic ADI and PDI. Wear 2006, 260, 1003–1012. [Google Scholar] [CrossRef]

| Al | Mg | Si | Mn | Cr | Cu | Fe |

|---|---|---|---|---|---|---|

| Bal. | 4.22 | 0.48 | 0.72 | 0.16 | 1.28 | 0.25 |

| Probes | YS (MPa) | UTS(MPa) | UE (%) | TE (%) |

|---|---|---|---|---|

| 5089 | 224 | 340 | 12.8 | 18.0 |

| PVDF | 229 | 349 | 12.3 | 18.2 |

| PU | 204 | 333 | 12.1 | 19.5 |

| hr (s) | YS (MPa) | UTS (MPa) | UE (%) | TE (%) |

|---|---|---|---|---|

| 0 | 229 | 349 | 12.3 | 18.2 |

| 625 | 221 | 341 | 11.1 | 17.3 |

| 1250 | 220 | 333 | 10.8 | 15.3 |

| hr(s) | YS (MPa) | UTS (MPa) | UE (%) | TE (%) |

|---|---|---|---|---|

| 0 | 204 | 333 | 12.1 | 19.5 |

| 625 | 198 | 325 | 11.4 | 19.2 |

| 1250 | 185 | 302 | 9.8 | 18.5 |

| Hardness | PVDF | PU |

|---|---|---|

| HK 0.01 (MPa) | 86.3 | 81.9 |

| Conversion to HRF (MPa) | 71.7 | 68.4 |

| Test piece | Test name and Method | Result |

|---|---|---|

| PVDF | 1. Bending 2. Specifications: ASTM-D1737 | (1) Tests were all normal (2) No cracks on the surface. |

| PU | ||

| PVDF | 1. Adhesion Resistance 2. Specifications: ASTM-D3359 | (1) Tests were all normal (2) 1 mm square 100% adhesion. |

| PU | ||

| PVDF | 1. Alkali resistance 2. Specifications: ASTM-D1308 3. Times:500 hrs | (1) Tests were all normal (2) No discoloration, corrosion and blistering. |

| PU | ||

| PVDF | 1. Acid Resistance 2. Specifications:ASTM-D1308 3. Times:500 hrs | (1) Tests were all normal (2) No discoloration, corrosion and blistering. |

| PU |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, F.S. Polymer Coating Effects: Study of Material Properties and Architectural Application Characteristics of Aluminum Template. Coatings 2021, 11, 240. https://doi.org/10.3390/coatings11020240

Hung FS. Polymer Coating Effects: Study of Material Properties and Architectural Application Characteristics of Aluminum Template. Coatings. 2021; 11(2):240. https://doi.org/10.3390/coatings11020240

Chicago/Turabian StyleHung, Fei Shuo. 2021. "Polymer Coating Effects: Study of Material Properties and Architectural Application Characteristics of Aluminum Template" Coatings 11, no. 2: 240. https://doi.org/10.3390/coatings11020240

APA StyleHung, F. S. (2021). Polymer Coating Effects: Study of Material Properties and Architectural Application Characteristics of Aluminum Template. Coatings, 11(2), 240. https://doi.org/10.3390/coatings11020240