Data Analysis of Two-Phase Flow Simulation Experiment of Array Optical Fiber and Array Resistance Probe

Abstract

:1. Introduction

2. Experiment and Interpolation Algorithm Analysis

2.1. Test Instrument and Response Principle

2.2. Experimental Program and Instrument Comparison

2.3. Data Type Analysis

3. Experimental Data Analysis and Data Selection

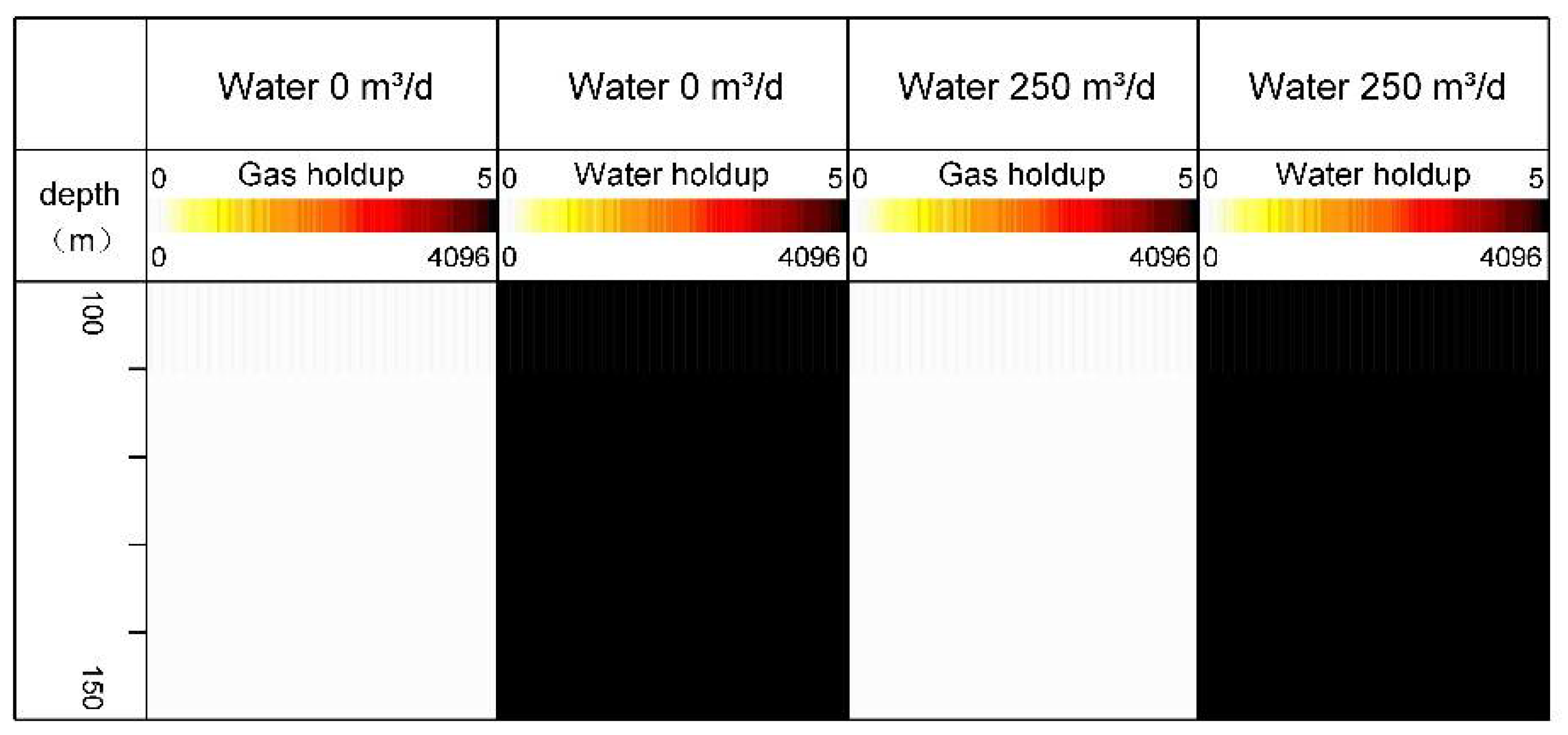

3.1. Data Measurement Response Analysis

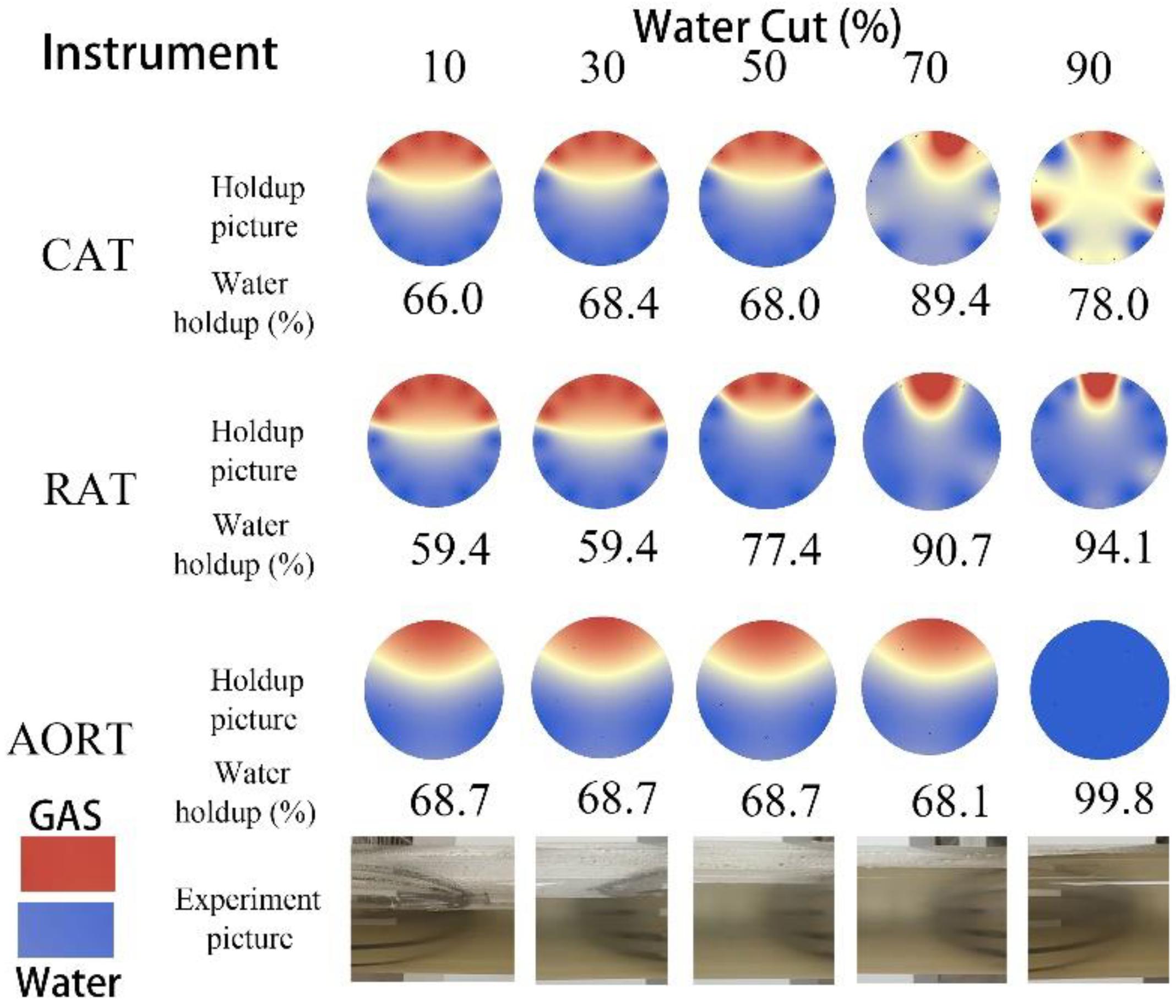

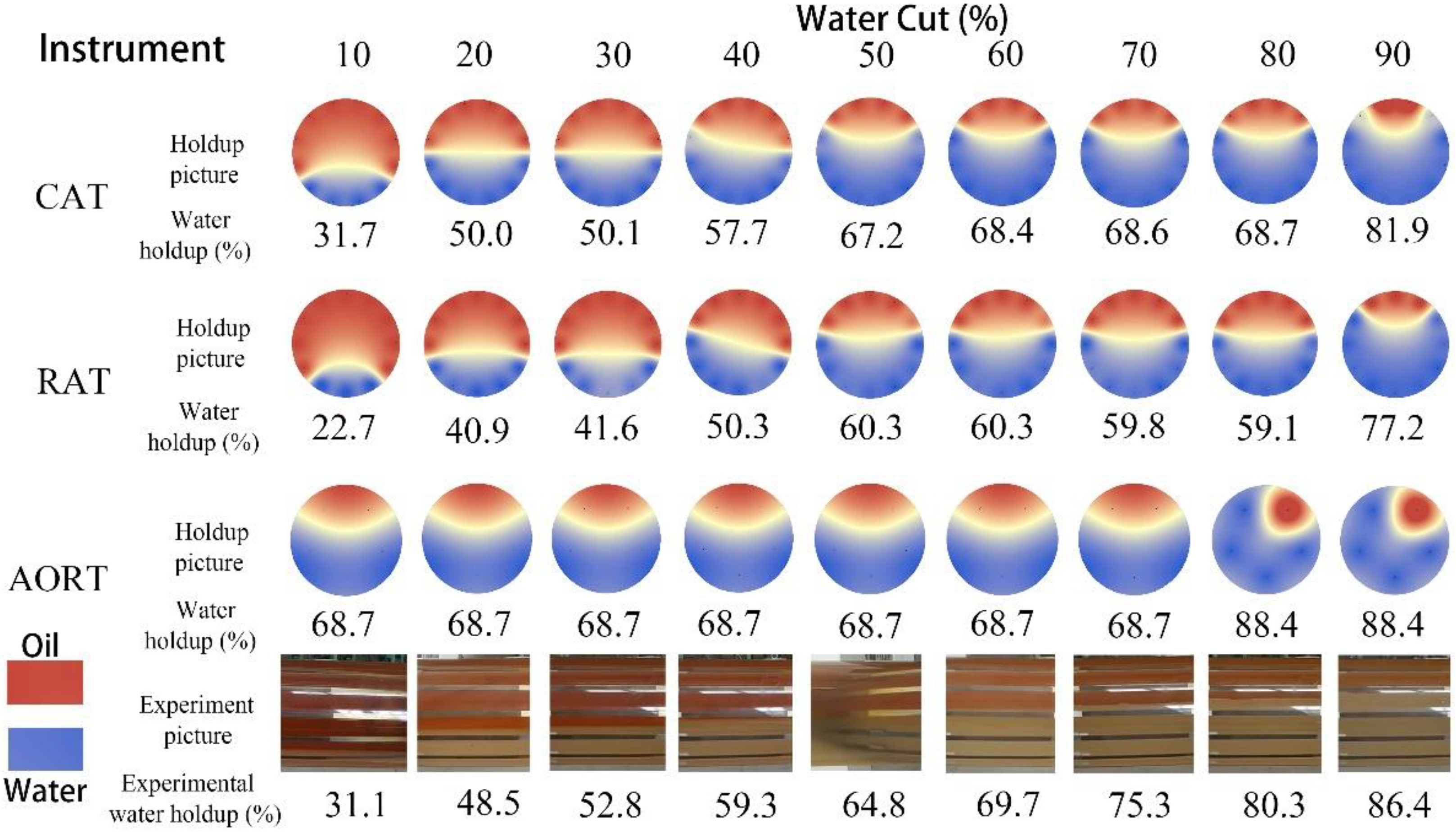

3.2. Data Interpolation Imaging Analysis

4. Discussion

5. Conclusions

- (1)

- According to the calibration results in pure gas, pure water and pure oil, it can be seen that the fiber probe can accurately identify the gas, the resistance probe can accurately identify the water, and both of them have low identification accuracy for oil. Based on this response relationship, the combination of an optical fiber probe and a resistance probe can realize an accurate identification of oil, gas and water, to determine whether the fluid at the probe is gas, water, or oil.

- (2)

- Through the data analysis and verification of gas–water and oil–water two-phase flow, the AORT instrument can accurately identify and distinguish oil, gas and water. Due to the small number of probes, there is a certain error in the measurement of holdup. Through comparative analysis with the data of RAT and CAT, it was determined to be better to use a combination of AORT and RAT for gas–water two-phase flow; while a combination of AORT and CAT is preferred for oil–water two-phase flow. Through the current experimental analysis, the advantages and disadvantages of the AORT instrument were found. According to the analysis of the experimental results, the combination of instruments were superior for use in the oil–water and gas–water two phase flow, providing a reference for subsequent instrument improvement and experiments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, H.M. Introduction to Production Logging, 2nd ed.; Petroleum Industry Press: Beijing, China, 2010. [Google Scholar]

- Guo, H.M.; Dai, J.C.; Chen, K.G. Production Logging Principle and Data Interpretation; Petroleum Industry Press: Beijing, China, 2007. [Google Scholar]

- Parijat, M.; Zouhir, Z.; Hugh, R. The Role of Enhanced Production Logging Measurements in Challenging Openhole Horizontal Completions. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 24–27 September 2006; Volume 102198, pp. 1–7. [Google Scholar]

- Vu-Hoang, D.; Faur, M.; Marcus, R.; Cadenhead, J.; Besse, F.; Haus, J.; Di-Pierro, E.; Wadjiri, A.; Gabon, P.; Hofmann, A. A novel approach to production logging in multiphase horizontal wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004; pp. 1–11. [Google Scholar]

- Abbassi, L.; Tavernier, E.; Donzier, E.; Gysen, A.; Gysen, M.; Chen, C.K.; Zied, A.; Cedillo, G. Efficiency improvements in production profiling using ultracompact flow array sensing technology. Petrophysics 2018, 59, 457–488. [Google Scholar] [CrossRef]

- Ojukwu, K.I.; Khalil, M.I.; Clark, J.; Sharji, H.; Edwards, J.; Chang, T.K. Production logging low flow rate wells with high water cut. In Proceedings of the IPTC 2007: International Petroleum Technology Conference, Dubai, United Arab Emirates, 4–6 December 2007; pp. 1–11. [Google Scholar]

- Liu, J.F.; Xu, Y.Z.; Wu, Q.X. Flow imaging analysis of capacitive and resistive annular array probes. Prog. Geophys. 2018, 33, 2141–2147. [Google Scholar]

- Qin, H.; Dai, J.C.; Qin, M.J.; Pei, Y.; Wang, Z.T. Experimental study on the array water holdup meter for low-yield horizontal wells. Well Logging Technol. 2017, 41, 637–641, 647. [Google Scholar]

- Meng, X. Imaging Study of Horizontal Well Oil-Water Two-Phase Flow Based on MAPS. Master’s Thesis, Yangtze University, Wuhan, China, June 2019. [Google Scholar]

- Yin, G.P.; Liu, H.; Zou, Y.Y.; Chen, H.X. Application of production logging array imager in horizontal wells. Pet. Tubing Tools 2016, 2, 59–62. [Google Scholar] [CrossRef]

- Cui, S.F.; Liu, J.F.; Chen, X.L.; Li, Q.Z. Experimental Analysis of Gas Holdup Measured by Gas Array Tool in Gas–Water Two Phase of Horizontal Well. Coatings 2021, 11, 343. [Google Scholar] [CrossRef]

- Dukler, A.E.; Taitel, Y. Flow pattern transitions in gas–liquid systems: Measurement and modeling. Multiph. Sci. Technol. 1986, 2, 1–94. [Google Scholar] [CrossRef]

- Zhai, L.S.; Bian, P.; Han, Y.F.; Gao, Z.K.; Jin, N.D. The measurement of gas–liquid two phase flows in a small diameter pipe using a dual-sensor multi-electrode conductance probe. Meas. Sci. Technol. 2016, 27, 045101. [Google Scholar] [CrossRef]

- Liu, X.L. Study on imaging logging method of oil-water two phase flow in horizontal wells based on array probe. Pet. Tubing Tools 2018, 4, 70–73. [Google Scholar]

- Yan, C. Research on the Measurement Method of Stratified Flow Interface Characteristics of Horizontal Oil-Water Two-Phase Flow. Master’s Thesis, Tianjin University, Tianjin, China, June 2018. [Google Scholar]

| Fluid Nature | Total Flowrate (m3/d) | Instrument | Water Cut (%) |

|---|---|---|---|

| Oil | 0 and 250 | CAT + RAT + AORT | 100 |

| Water | 0 and 250 | 0 | |

| Gas | 0 and 250 | 0 | |

| Gas-Water | 300 | 10, 30, 50, 70, 90 | |

| Oil-Water | 300 | 10, 20, 30, 40, 50, 60, 70, 80, 90 |

| Instrument | Probe Type | Holdup | Quantity | Distribution Method |

|---|---|---|---|---|

| CAT | Capacitance | Water holdup | 12 | Circular distribution |

| RAT | Resistance | Water holdup | 12 | |

| AORT | Optical | Gas holdup | 5 | |

| Resistance | Water holdup | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, S.; Liu, J.; Li, K.; Li, Q. Data Analysis of Two-Phase Flow Simulation Experiment of Array Optical Fiber and Array Resistance Probe. Coatings 2021, 11, 1420. https://doi.org/10.3390/coatings11111420

Cui S, Liu J, Li K, Li Q. Data Analysis of Two-Phase Flow Simulation Experiment of Array Optical Fiber and Array Resistance Probe. Coatings. 2021; 11(11):1420. https://doi.org/10.3390/coatings11111420

Chicago/Turabian StyleCui, Shuaifei, Junfeng Liu, Kui Li, and Qinze Li. 2021. "Data Analysis of Two-Phase Flow Simulation Experiment of Array Optical Fiber and Array Resistance Probe" Coatings 11, no. 11: 1420. https://doi.org/10.3390/coatings11111420

APA StyleCui, S., Liu, J., Li, K., & Li, Q. (2021). Data Analysis of Two-Phase Flow Simulation Experiment of Array Optical Fiber and Array Resistance Probe. Coatings, 11(11), 1420. https://doi.org/10.3390/coatings11111420