Surface Topography of PVD Hard Coatings

Abstract

:1. Introduction

2. Materials and Methods

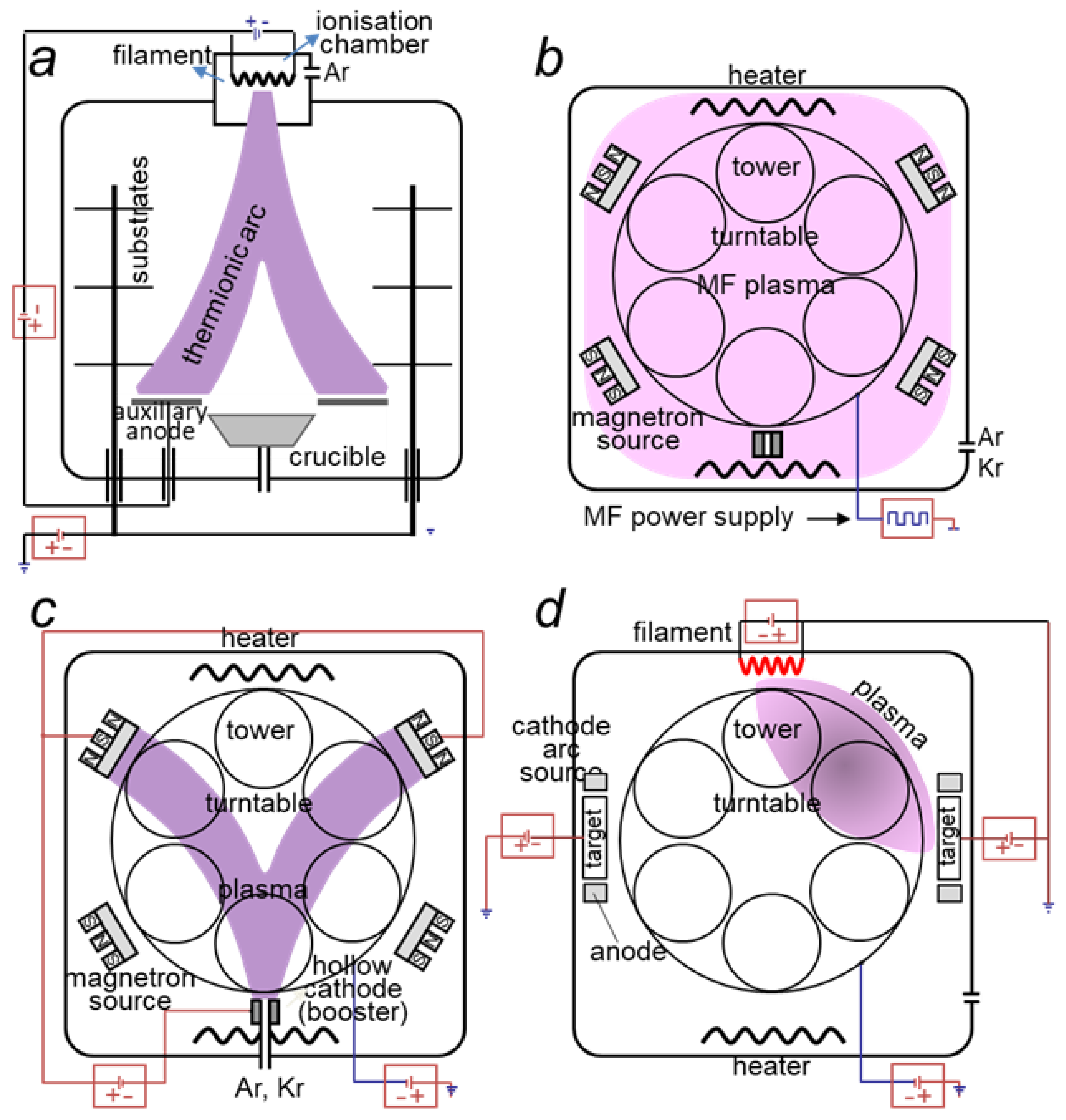

2.1. PVD Processes

2.2. Substrate Materials

2.3. Analytical Methods

3. Results and Discussion

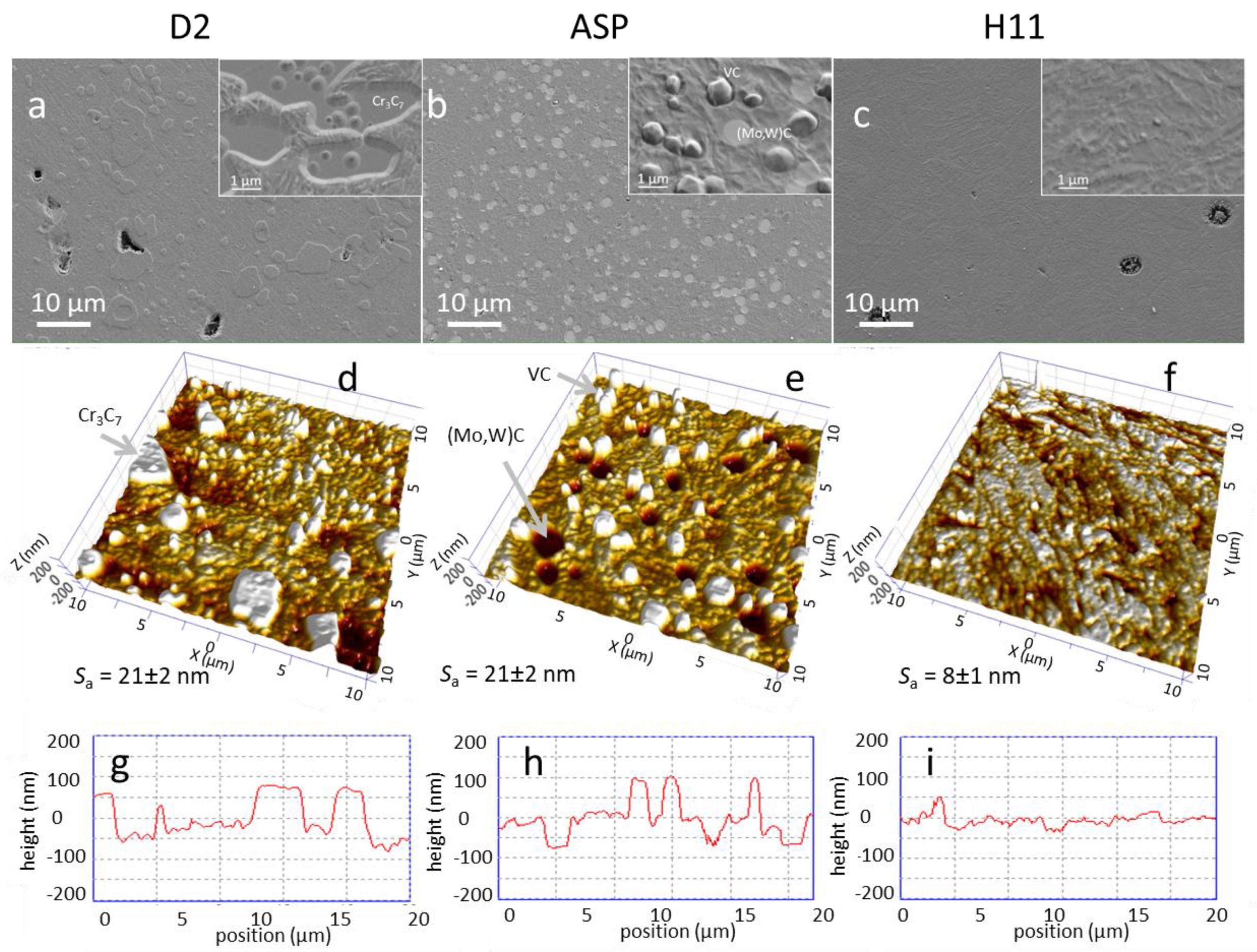

3.1. Topography of the Substrate Surface

3.1.1. Substrate Irregularities Induced by Mechanical Pretreatment

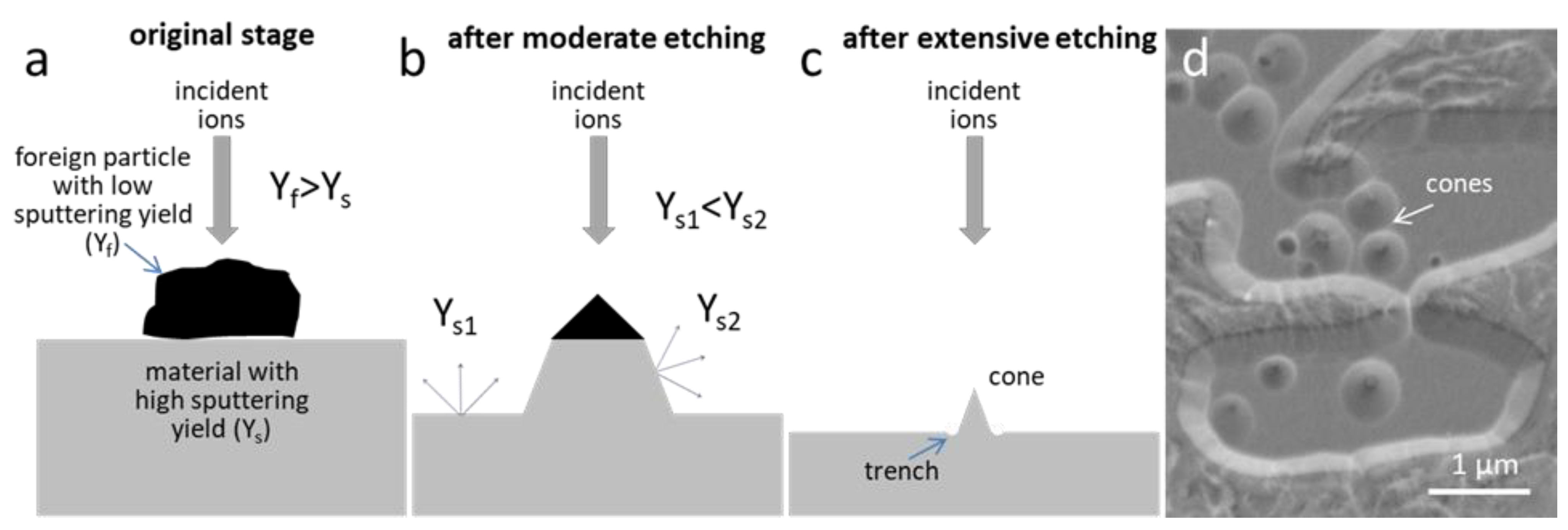

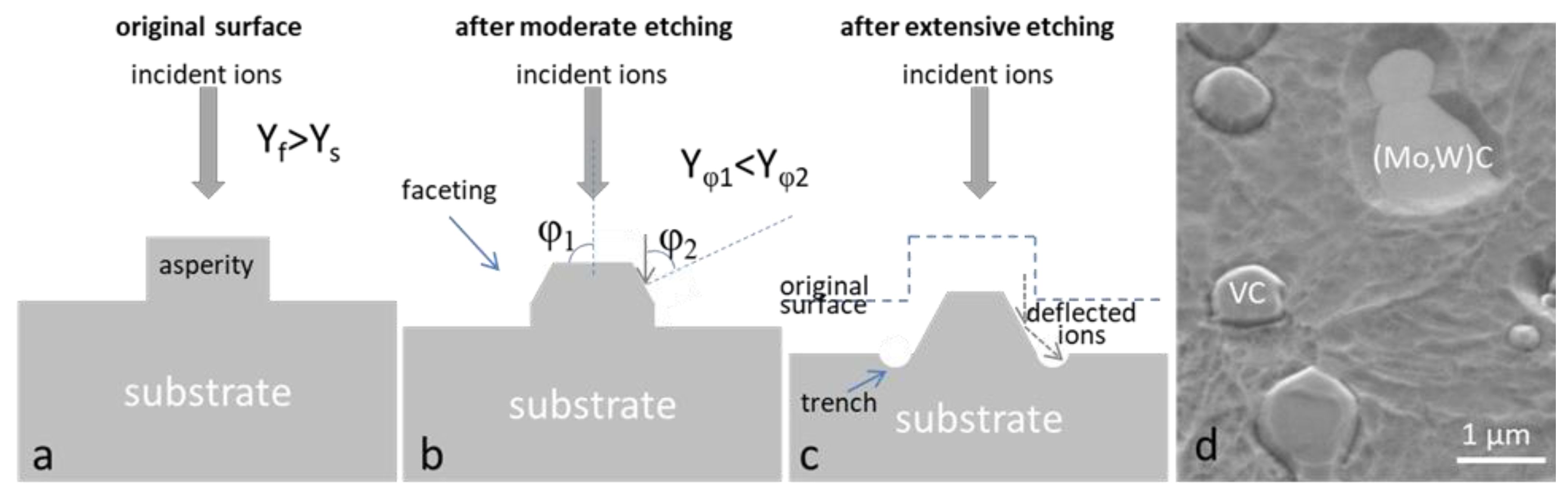

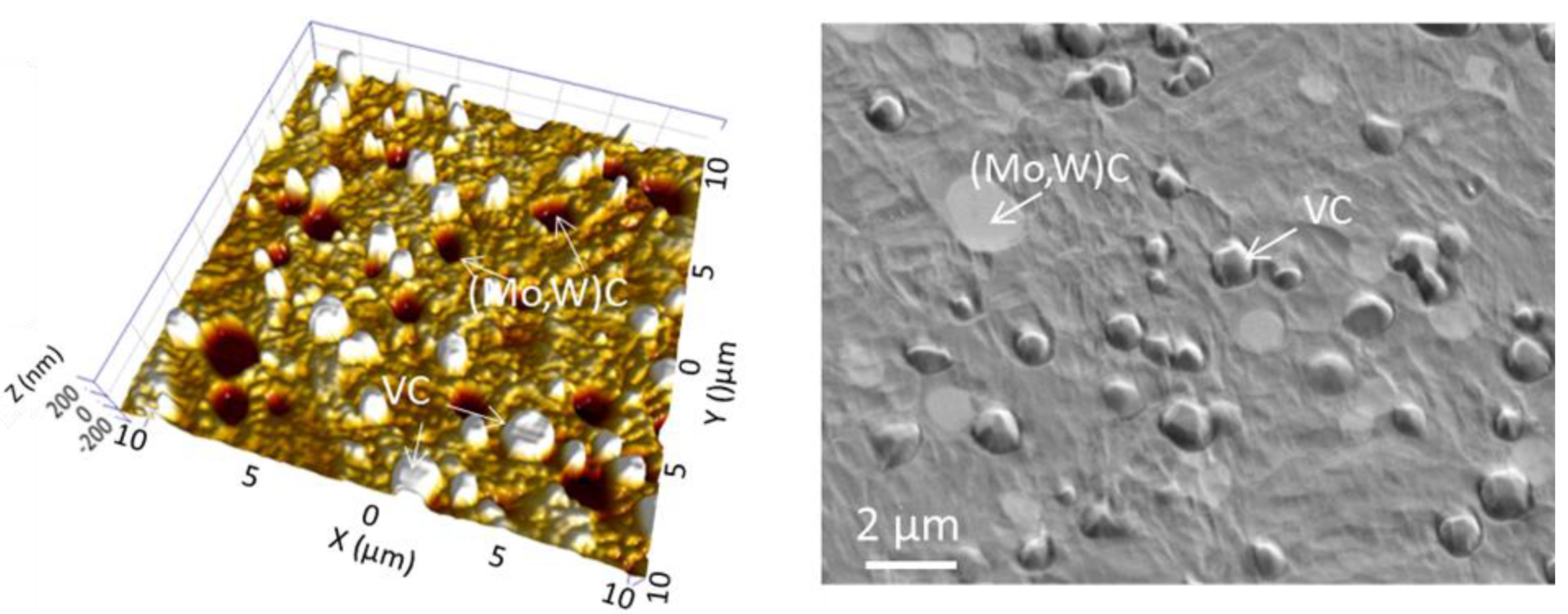

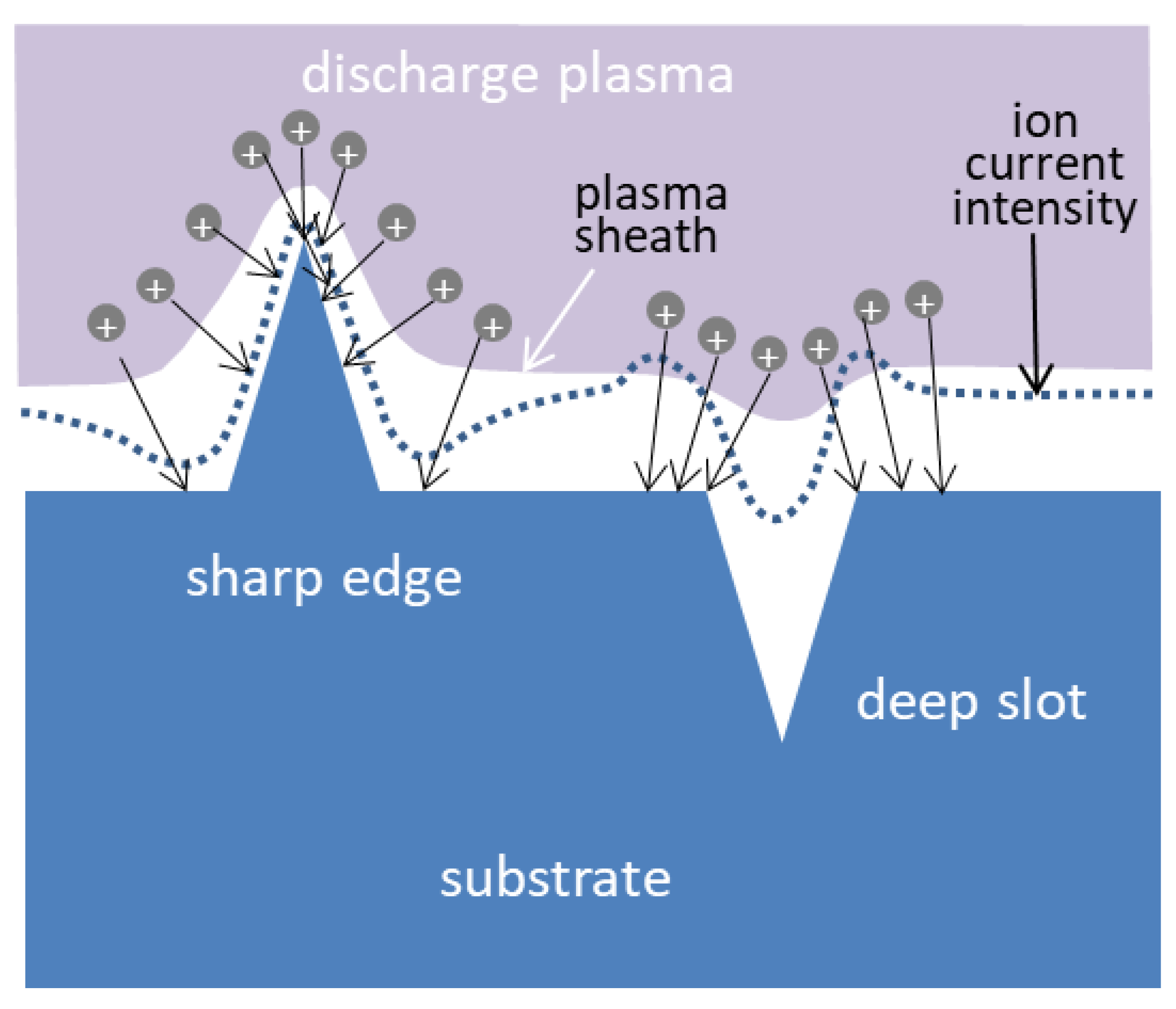

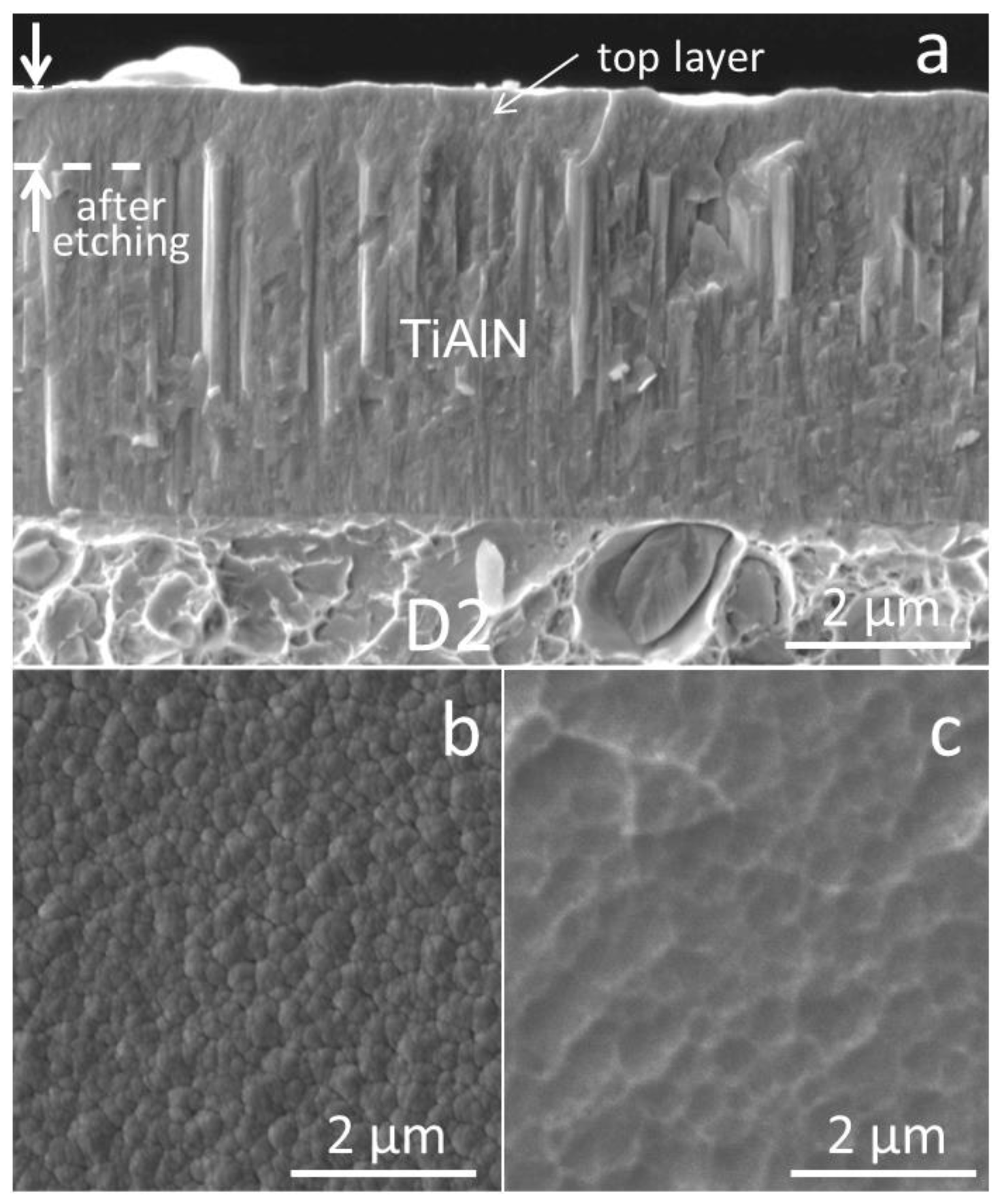

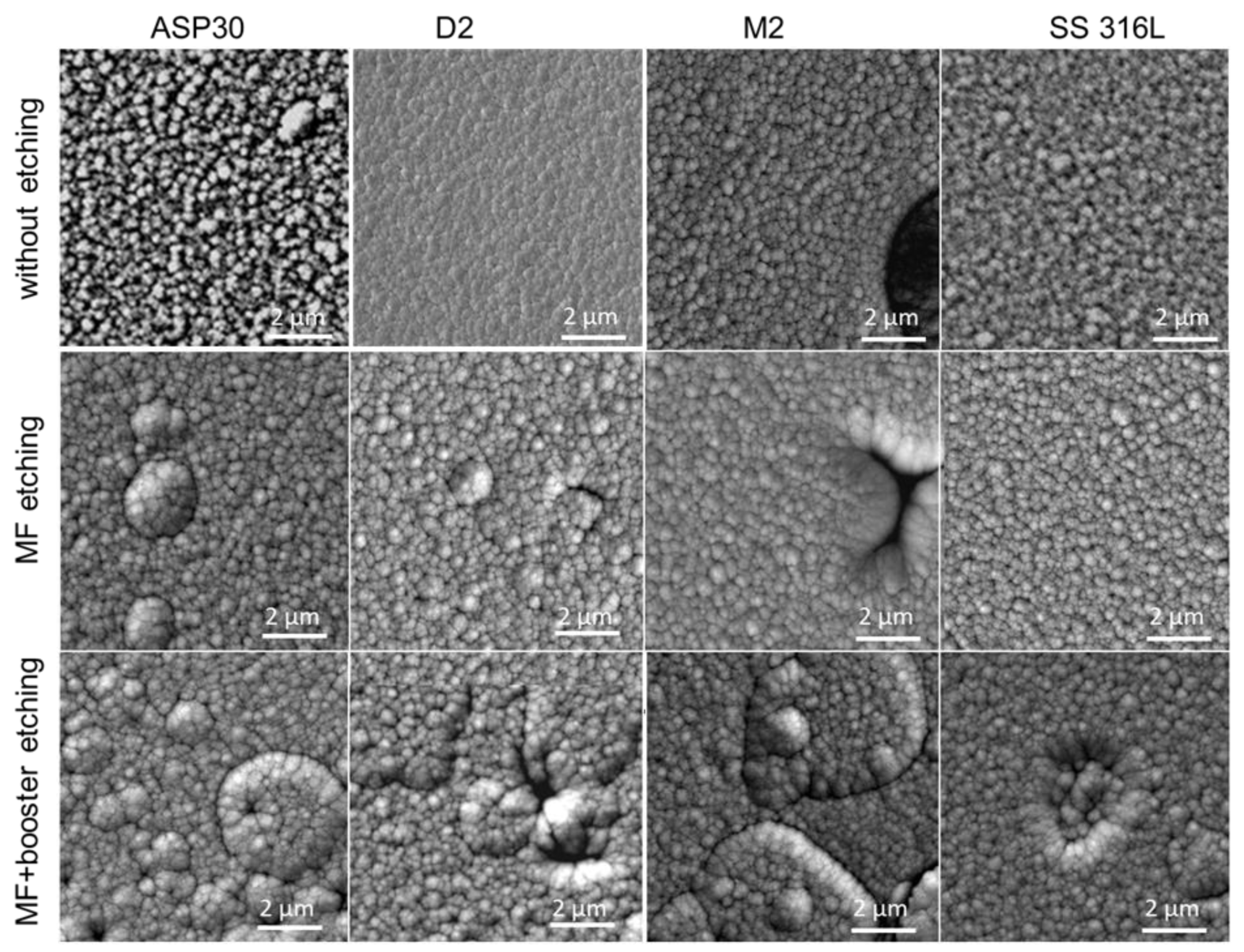

3.1.2. Substrate Irregularities Induced by Ion Etching

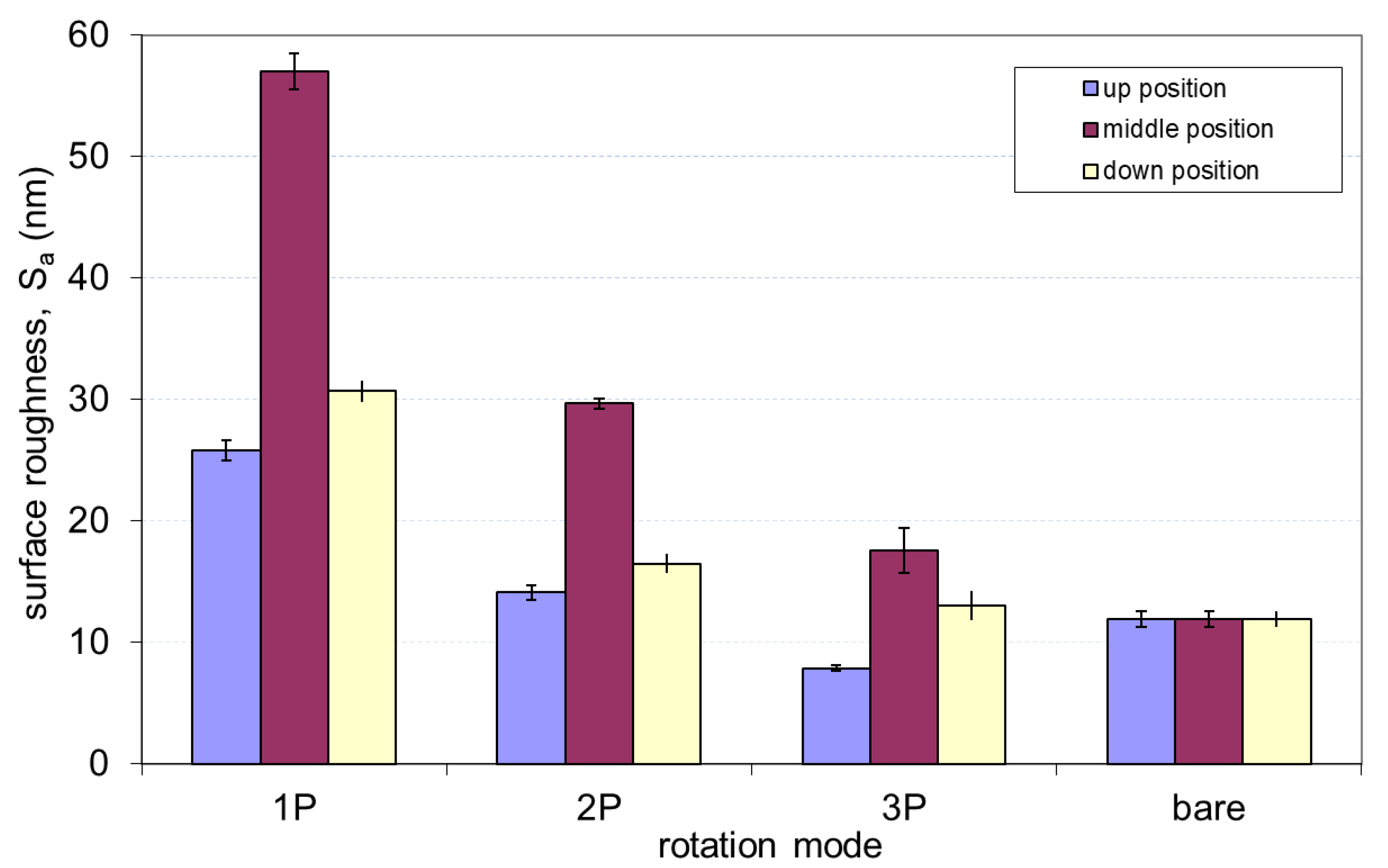

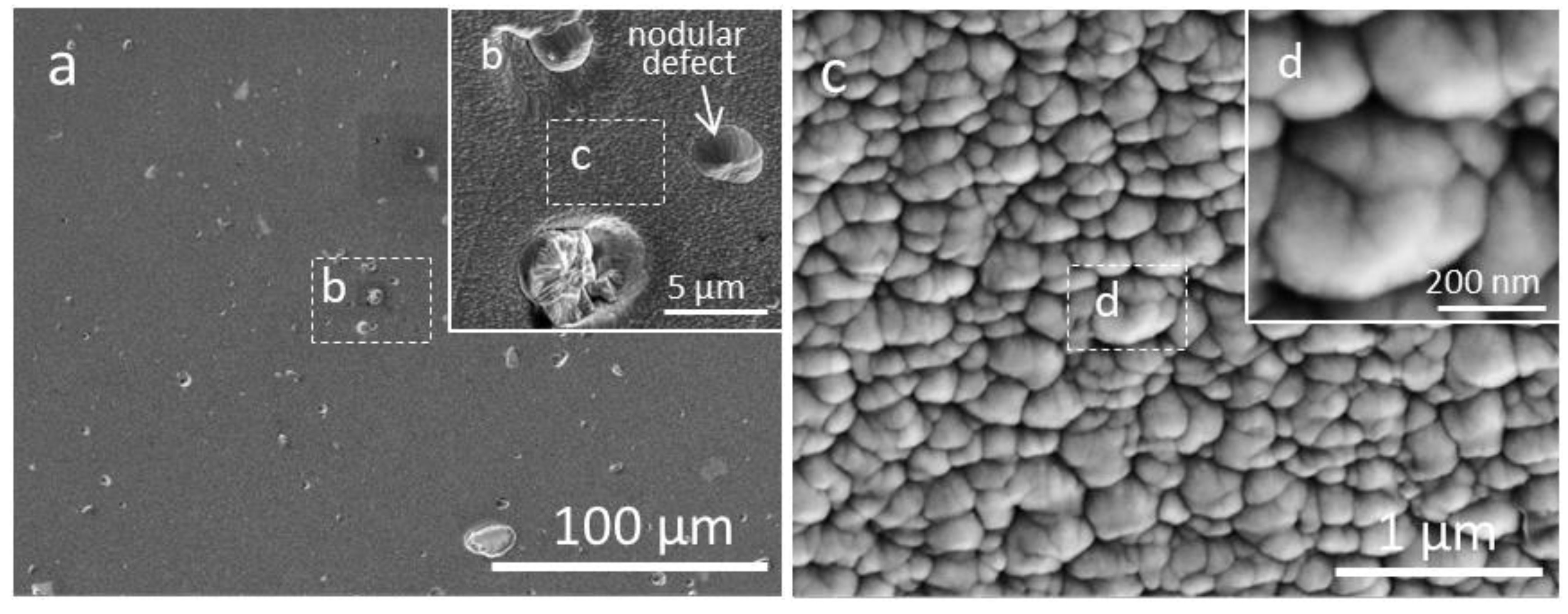

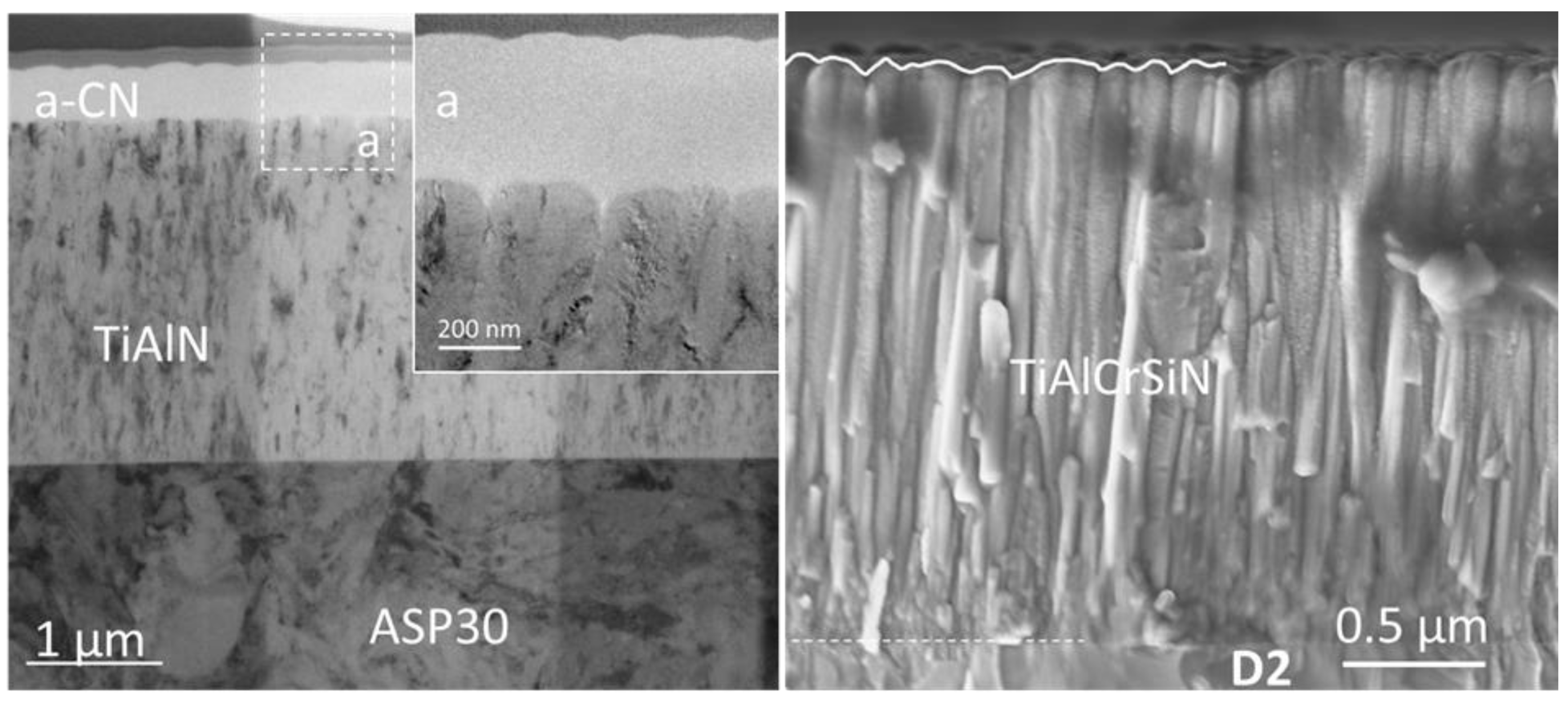

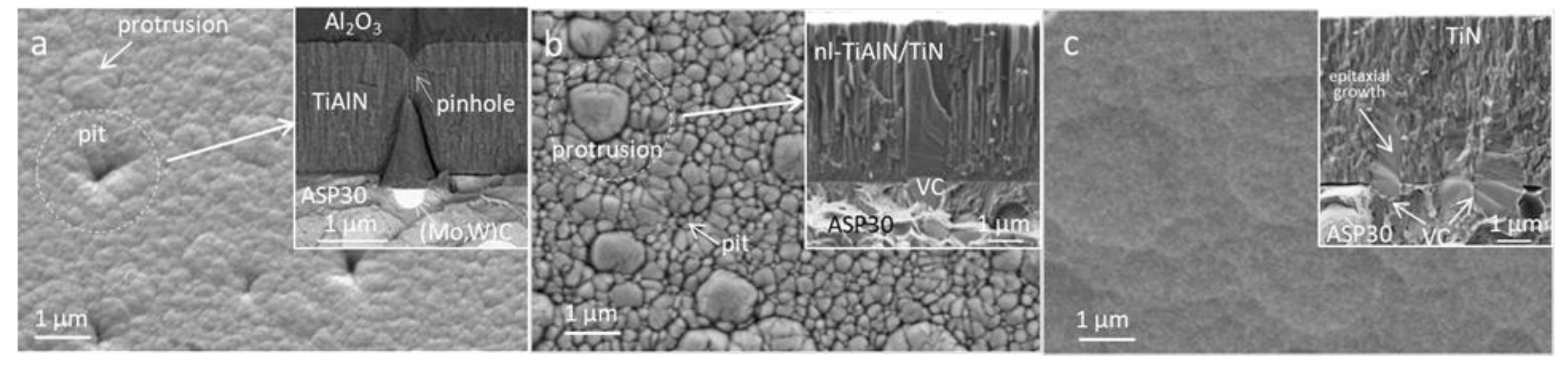

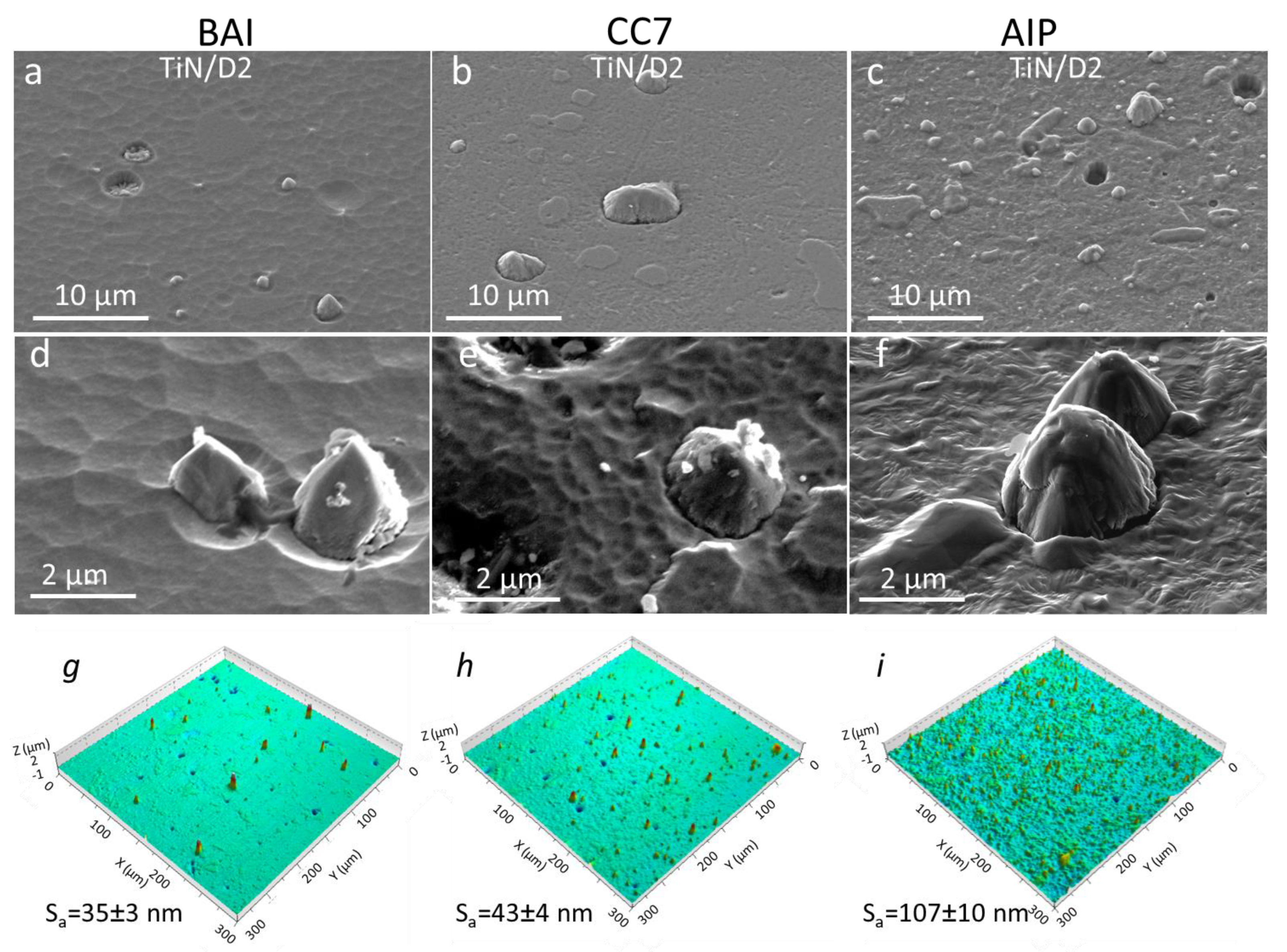

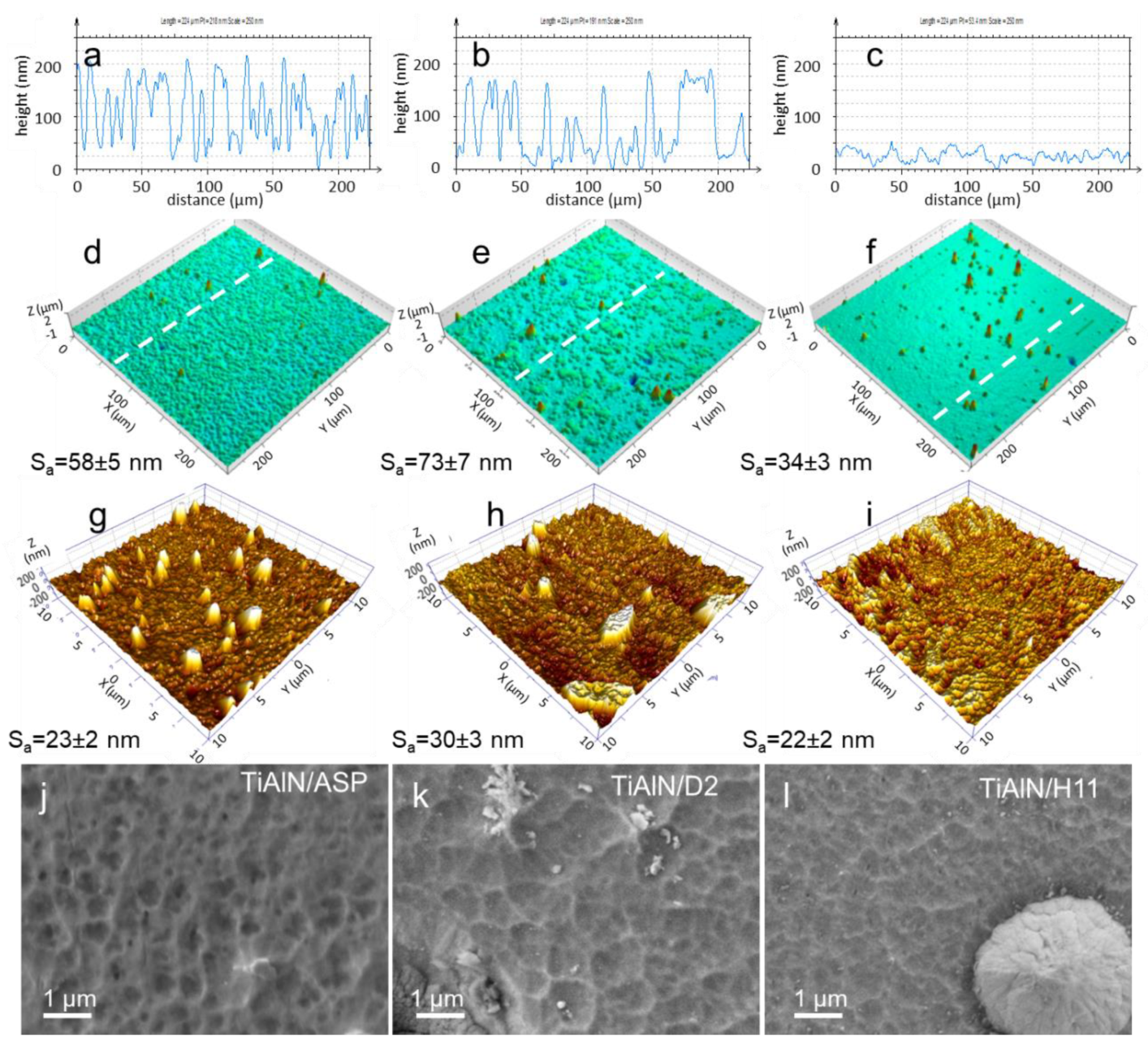

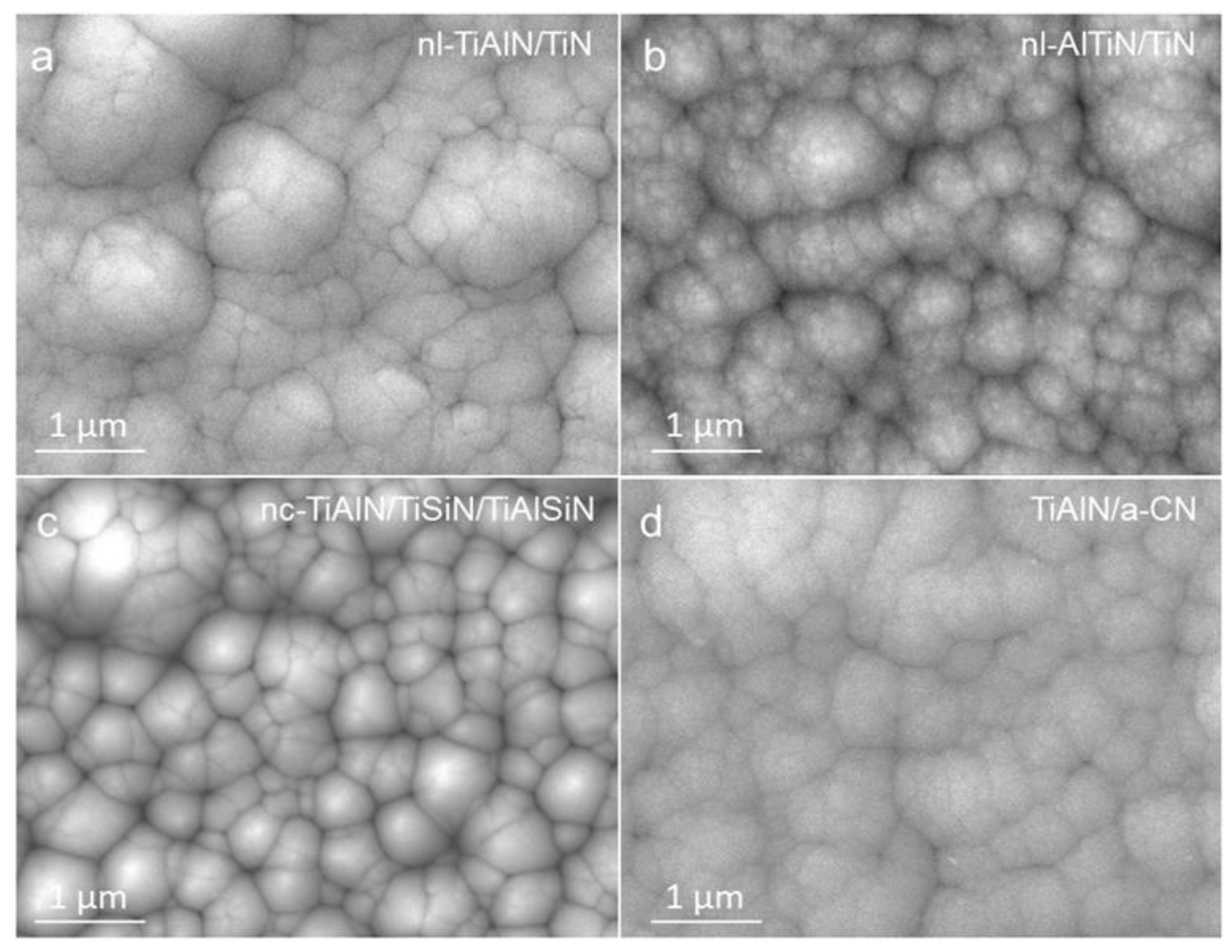

3.2. Micro Topography of Coating Surfaces

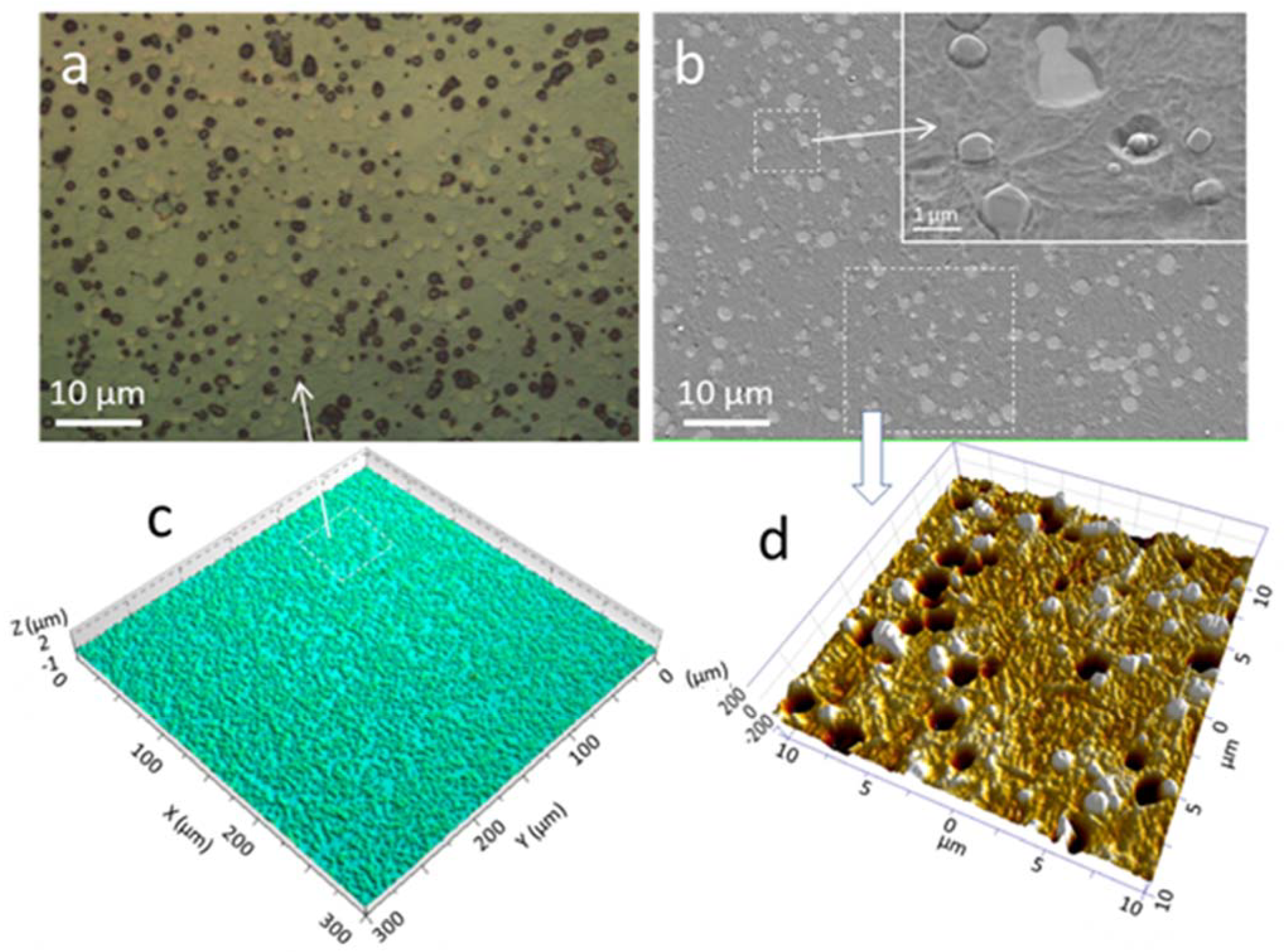

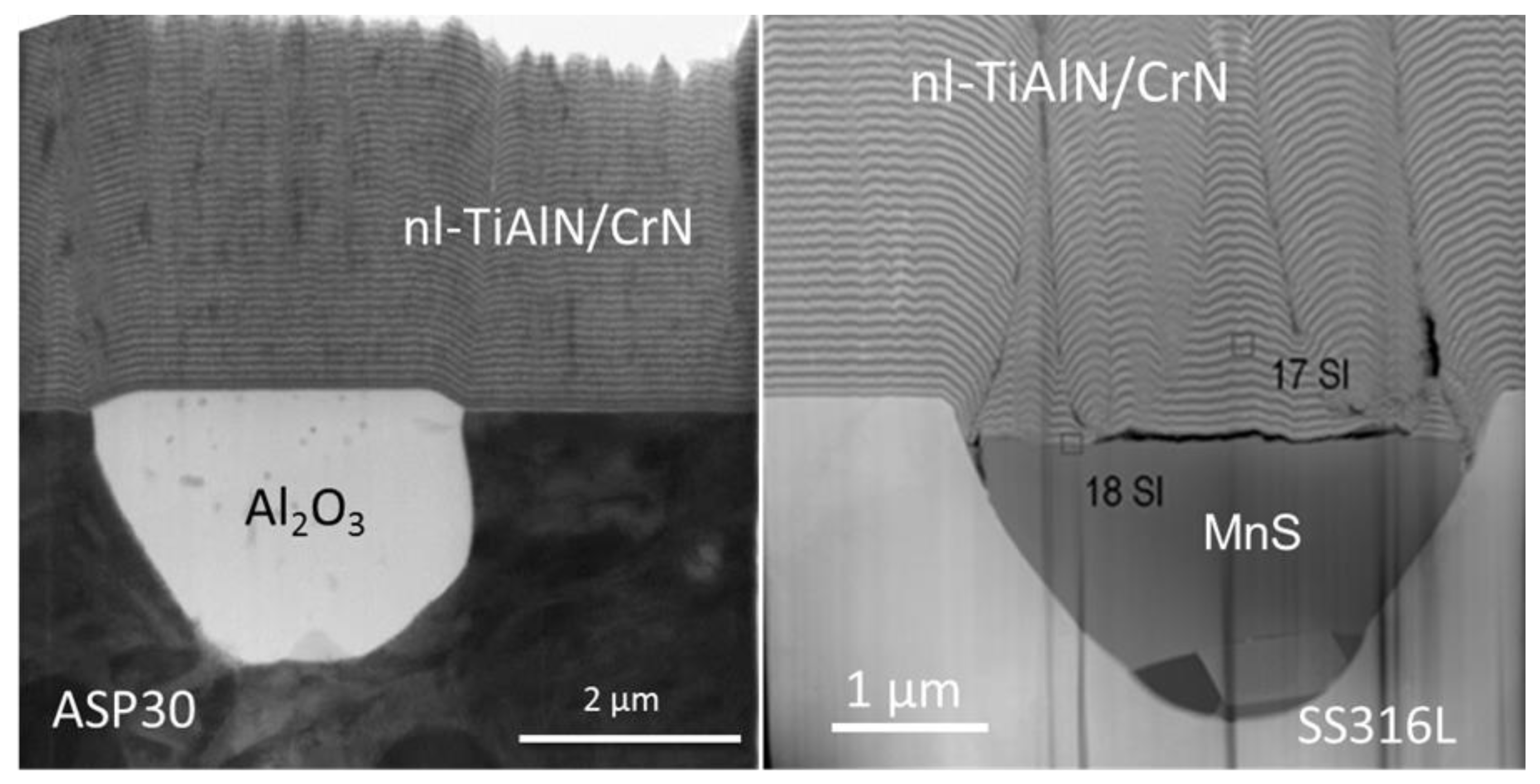

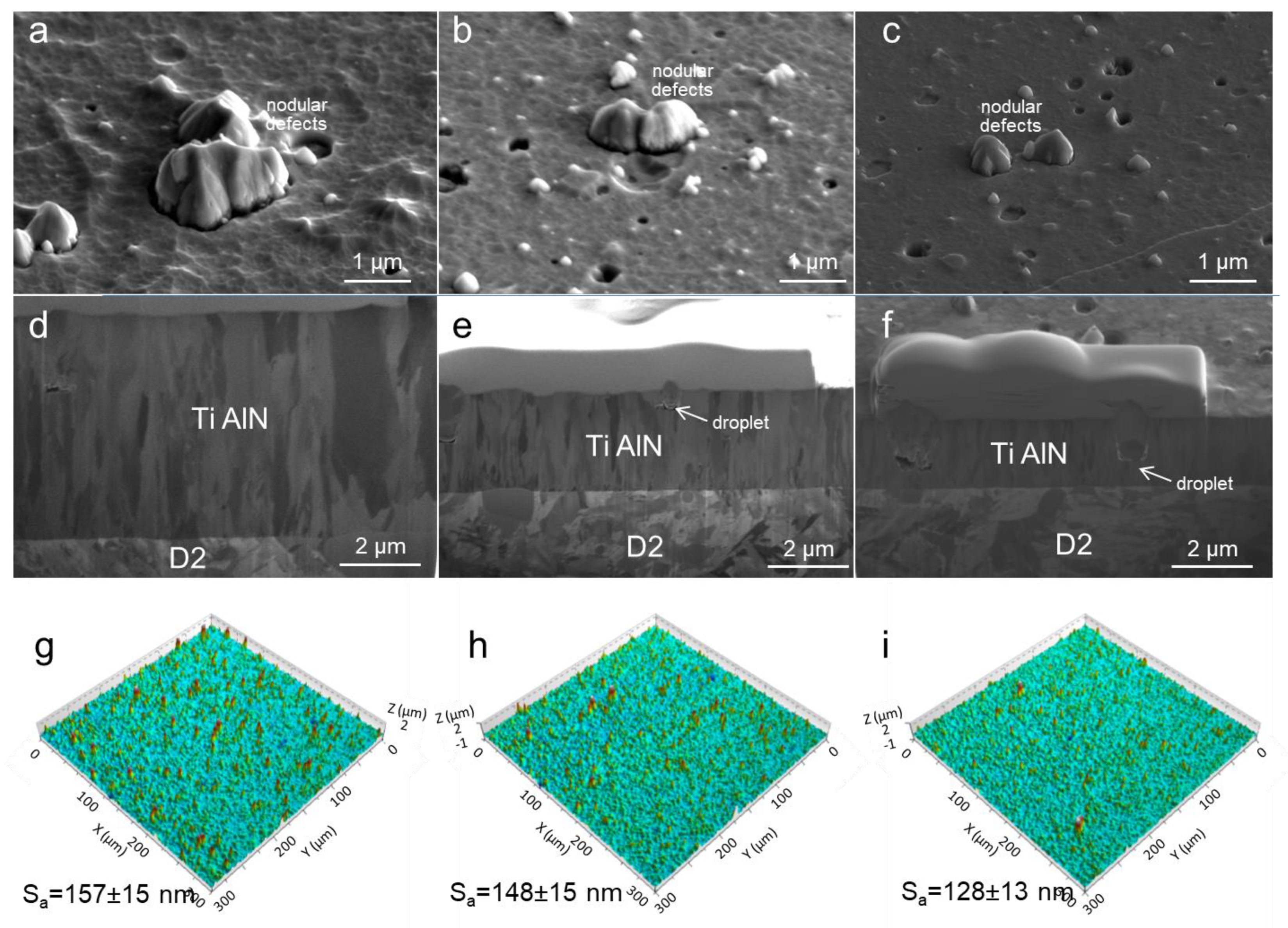

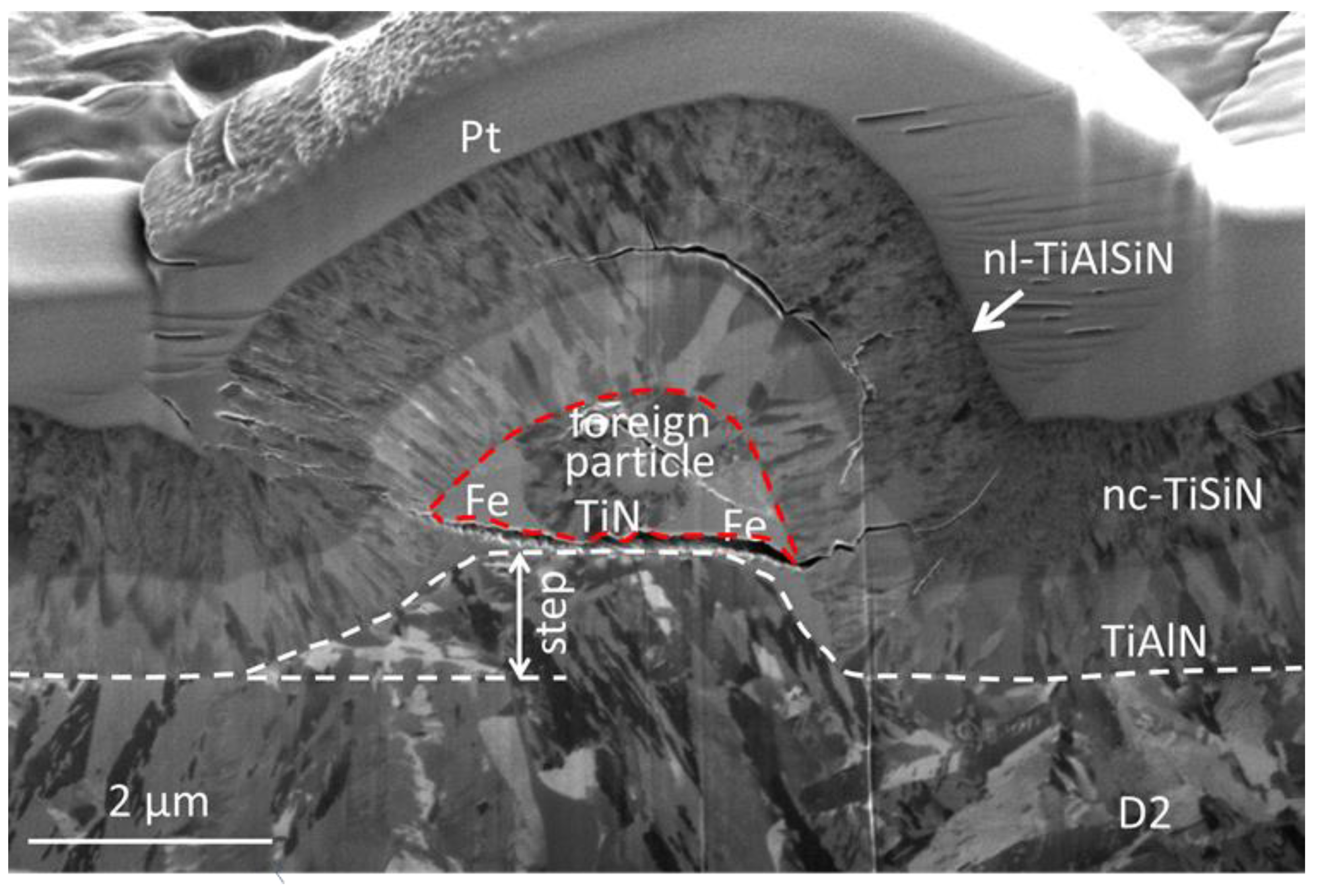

3.3. Influence of Growth Defects on Coating Topography

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Assender, A.; Bliznyuk, V.; Porfyrakis, K. How Surface Topography Relates to Materials’ Properties. Science 2002, 297, 973–976. [Google Scholar] [CrossRef] [PubMed]

- Harlin, P.; Carlsson, P.; Bexell, U.; MOlsson, M. Influence of surface roughness of PVD coatings on tribological performance in sliding contacts. Surf. Coat. Technol. 2006, 201, 4253. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovšek, A.; Kovač, J. Tribological aspects related to the morphology of PVD hard coatings. Surf. Coat. Technol. 2018, 343, 138–147. [Google Scholar] [CrossRef]

- Olofsson, J.; Gerth, J.; Nyberg, H.; Wiklund, U.; Jacobson, S. On the influence from micro topography of PVD coatings on friction behaviour, material transfer and tribofilm formation. Wear 2011, 271, 2046–2057. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 249. [Google Scholar] [CrossRef]

- Vilhena, L.M.; Sedlaček, M.; Podgornik, B.; Vižintin, J.; Babnik, A.; Možina, J. Surface texturing by pulsed Nd:YAG laser. Tribol. Int. 2009, 42, 1496–1504. [Google Scholar] [CrossRef]

- Kearns, V.R.; McMurray, R.J.; Dalby, M.J. Biomaterial surface topography to control cellular response: Technologies, cell behaviour and biomedical applications. In Surface Modification of Biomaterials; Williams, R., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2011; pp. 169–201. [Google Scholar]

- Curtis, A.; Wilkinson, C. Topographical control of cells. Biomaterials 1997, 18, 1573. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, B.; Liu, Y.; Suo, X.; Li, H. Influence of surface topography on bacterial adhesion. Biointerphases 2018, 13, 060801. [Google Scholar] [CrossRef]

- Damiati, L.; Eales, M.G.; Nobbs, A.H.; Su, B.; Tsimbouri, P.M.; Salmeron-Sanchez, M.; Dalby, M.J. Impact of surface topography and coating on osteogenesis and bacterial attachment on titanium implants. J. Tissue Eng. 2018, 9, 1–16. [Google Scholar] [CrossRef]

- Oshida, Y.; Guven, Y. Biocompatible coatings for metallic biomaterials. In Surface Coating and Modification of Metallic Biomaterials; Wen, C., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 287–343. [Google Scholar]

- Liu, X.; Li, D.; Zhao, Y.; Li, X.; Shao, J. Characteristics of nodular defect in HfO2/SiO2 multilayer optical coatings. Appl. Surf. Sci. 2010, 256, 3783–3788. [Google Scholar] [CrossRef]

- Piegari, A.; Flory, F. Optical Thin Films and Coatings: From Materials to Applications; Woodhead Publishing Limited: Cambridge, UK, 2018. [Google Scholar]

- Rebeggiani, S.; Rosen, B.G.; Sandberg, A. A quantitative method to estimate high gloss polished tool steel surfaces. J. Phys. Conf. Ser. 2011, 311, 012004. [Google Scholar] [CrossRef]

- Gassner, M.; Schalk, N.; Sartory, B.; Pohler, M.; Czettl, C.; Mitterer, C. Influence of Ar ion etching on the surface topography of cemented carbide cutting inserts. Int. J. Refract. Metals Hard. Mater. 2017, 69, 234–239. [Google Scholar] [CrossRef]

- Moll, E.; Daxinger, H. Method and Apparatus for Evaporating Materials in a Vacuum Coating Plant. U.S. Patent 4,197,175, 8 April 1980. [Google Scholar]

- Panjan, P.; Drnovšek, A.; Gselman, P.; Čekada, M.; Panjan, M. Review of Growth Defects in Thin Films Prepared by PVD Techniques. Coatings 2020, 10, 447. [Google Scholar] [CrossRef]

- Erkens, G. New approaches to plasma enhanced sputtering of advanced hard coatings. Surf. Coat. Technol. 2007, 201, 4806–4812. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Sato, T.; Takahar, K.; Hanaguri, K. Properties of (Ti,Cr,Al)N coatings with high Al content deposited by new plasma enhanced arc-cathode. Surf. Coat. Technol. 2003, 174–175, 620–626. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Silva, F.J.G.; Lopes, H.; Casais, R.C.B.; Baptista, A.; Pinto, G.; Alexandre, R. Wear behavior and machining performance of TiAlSiN-coate tools obtained by dc MS and HiPIMS: A comparative study. Materials 2021, 14, 5122. [Google Scholar] [CrossRef]

- Saketi, S.; Östby, J.; Olsson, M. Influence of tool surface topography on the material transfer tendency and tool wear in the turning of 316L stainless s steel. Wear 2016, 368–369, 239–252. [Google Scholar] [CrossRef]

- Klocke, F.; Dambon, O.; Behrens, B. Analysis of defect mechanisms in polishing of tool steels. Prod. Eng. 2011, 5, 475–483. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Ehiasarian, A.P. Six strategies to produce application tailored nanoscale multilayer structured PVD coatings by conventional and High Power Impulse Magnetron Sputtering (HIPIMS). Thin Solid Films 2019, 688, 137409. [Google Scholar] [CrossRef]

- Taglauer, E. Surface Cleaning Using Sputtering. Appl. Phys. A 1990, 51, 238–251. [Google Scholar] [CrossRef]

- Ghose, D.; Karmohapatro, B. Topography of Solid Surfaces Modified by Fast Ion Bombardment. Adv. Electron. Electron Phys. 1990, 79, 73–154. [Google Scholar]

- Navinšek, B. Sputtering—surface changes induced by ion bombardment. Prog. Surf. Sci. 1976, 7, 49–70. [Google Scholar] [CrossRef]

- Wehner, G.K.; Hajicek, D.J. Cone Formation on Metal Targets during Sputtering. J. Appl. Phys. 1971, 42, 1145. [Google Scholar] [CrossRef]

- Ziegler, J.; Biersack, J.P.; Ziegler, M.D. SRIM-The Stopping and Ranges of Ions in Solids; SRIM Co.: Chester, UK, 2008. [Google Scholar]

- Vossen, J.L. The preparation of substrates for film deposition using glow discharge techniques. J. Phys. E Sci. Instrum. 1979, 12, 159. [Google Scholar] [CrossRef]

- Nordin, M.; Ericson, F. Growth characteristics of multilayered physical vapour deposited TiN/TaNx on high speed steel substrate. Thin Solid Films 2001, 385, 174–181. [Google Scholar] [CrossRef]

- Baptista, A.; Silva, F.; Porteiro, J.; Miguez, J.; Pinto, G. Sputtering Physical Vapour Deposition (PVD) Coatings: A Critical Review on Process Improvement andMarket Trend Demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef]

- Terek, V.; Miletić, A.; Kovačević, L.; Kukuruzović, D.; Škorić, B.; Panjan, P.; Terek, P. Surface Topography and Grain Morphology of Nanolayer TiAlN/TiSiN Coating Governed by Substrate Material and Rotation during Deposition. Mater. Proc. 2020, 2, 32. [Google Scholar]

- Grigoriev, S.; Metel, A. Plasma- and beam-assisted deposition methods. In Nanostructured Thin Films and Nanodispersion Strengthened Coatings; Voevodin, A.A., Shtansky, D.V., Levashov, E.A., Moore, J.J., Eds.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2004; pp. 147–154. [Google Scholar]

- Mattox, D.M. Particle bombardment effects on thin film deposition: A review. J. Vac. Sci. Technol. A 1989, 7, 1105. [Google Scholar] [CrossRef]

- Macak, E.B.; Munz, W.D.; Rodenburg, J.M. Electron microscopy studies of hard coatings deposited on sharp edges by combined cathodic arc unbalanced magnetron PVD. Surf. Coat. Technol. 2002, 151–152, 349–354. [Google Scholar] [CrossRef]

- Mattox, D.M. Atomistic Film Growth and Resulting Film Properties. SVC Bull. Spring 2009, 30–31. [Google Scholar]

- Petrov, I.; Barna, P.B.; Hultman, L.; Green, J.E. Microstructural evolution during film growth. J. Vac. Sci. Technol. A 2003, 21, S117–S128. [Google Scholar] [CrossRef]

- Mirkarimi, B.; Baker, S.L.; Stearns, D.G. Planarization of Substrate Pits and Scratches. U.S. Patent 2005/0118533 A1, 2 June 2005. [Google Scholar]

- Johansson, B.O.; Sundgren, J.E.; Hentzell, H.T.G.; Karlsson, S.E. Influence of substrate shape on TiN films prepaared by reactive sputtering. Thin Solid Films 1984, 111, 313–322. [Google Scholar] [CrossRef]

- Čekada, M.; Panjan, P.; Drnovšek, A.; Drobnič, M. Increase of coating thickness on sharp edges, deposited by cathodic arc evaporation. Surf. Coat. Technol. 2021, 405, 126691. [Google Scholar] [CrossRef]

- Panjan, M.; Čekada, M.; Panjan, P.; Zupanič, F.; Kölker, W. Dependence of microstructure and hardness of TiAlN/VN hard coatings on the type of substrate rotation. Vacuum 2012, 86, 699–702. [Google Scholar] [CrossRef]

| Deposition System | BAI 730 | CC800/7 | CC800/9 sinOx ML | AIPocket | |

|---|---|---|---|---|---|

| preheating | heating method | Electron bombardment | Infrared heating | infrared heating | infrared heating |

| preheating temperature (°C) | 450 | 450 | 450 | 450 | |

| etching | etching mode | DC | RF | MF/booster | pulsed DC |

| type of ions | Ar | Ar + Kr | Ar + Kr | Ar | |

| negative substrate etching voltage (V) | 200 | 200 | 650/200 | 300/400 | |

| etching time (min) | 15 | 85 + 55 ** | 15/60 | 45 | |

| deposition | deposition method | low-voltage electron beam evaporation | Magnetron sputtering | magnetron sputtering | cathodic arc evaporation |

| temperature (°C) | 450 | 450 | 450 | 450 | |

| working gas | Ar + N2 | Ar + Kr + N2 | Ar + Kr + N2 | N2 | |

| pressure of working gas (Pa) | 0.2 | 0.75 | 0.66 | 4 | |

| deposition time (min) | 80 | 165 | 200 | 45 | |

| negative substrate bias voltage (V) | 125 | 95 | 90 | 70 | |

| average deposition rate * (nm/min) | 50 | 20 | 20 | 85 | |

| average substrate current density (mA/cm2) | 3–5 | ~2 | ~2.5 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panjan, P.; Drnovšek, A.; Mahne, N.; Čekada, M.; Panjan, M. Surface Topography of PVD Hard Coatings. Coatings 2021, 11, 1387. https://doi.org/10.3390/coatings11111387

Panjan P, Drnovšek A, Mahne N, Čekada M, Panjan M. Surface Topography of PVD Hard Coatings. Coatings. 2021; 11(11):1387. https://doi.org/10.3390/coatings11111387

Chicago/Turabian StylePanjan, Peter, Aljaž Drnovšek, Nastja Mahne, Miha Čekada, and Matjaž Panjan. 2021. "Surface Topography of PVD Hard Coatings" Coatings 11, no. 11: 1387. https://doi.org/10.3390/coatings11111387

APA StylePanjan, P., Drnovšek, A., Mahne, N., Čekada, M., & Panjan, M. (2021). Surface Topography of PVD Hard Coatings. Coatings, 11(11), 1387. https://doi.org/10.3390/coatings11111387