Comprehensive Enhancement of Mechanical, Water-Repellent and Antimicrobial Properties of Regenerated Seaweed and Plant-Based Paper with Chitosan Coating

Abstract

:1. Introduction

2. Materials and Methods

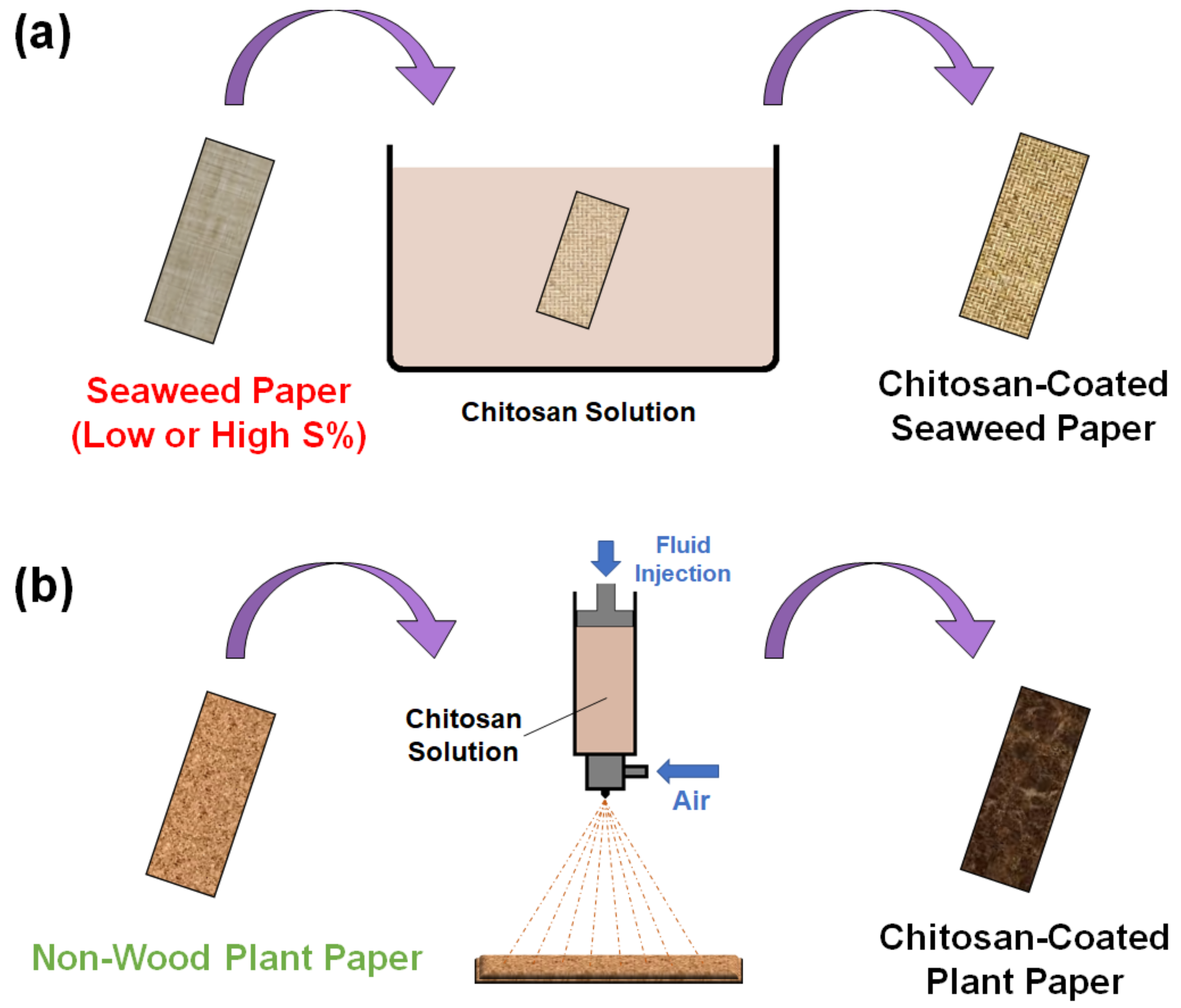

2.1. Chitosan Coating on Paper

2.2. Mechanical Characterization of Chitosan-Coated Paper

2.2.1. Water-Repellent Effect

2.2.2. Mechanical Properties

2.2.3. Contact Angle

2.3. Antimicrobial Characterizations of Chitosan-Coated Paper

3. Results and Discussion

3.1. Chitosan Coating on Seaweed and Plant Papers

3.1.1. Dip Coating-Seaweed Paper

3.1.2. Spray Coating-Non-Wood Plant Paper

3.2. Water Repellent Properties of Chitosan-Coated Paper

3.3. Mechanical Properties of Chitosan-Coated Paper

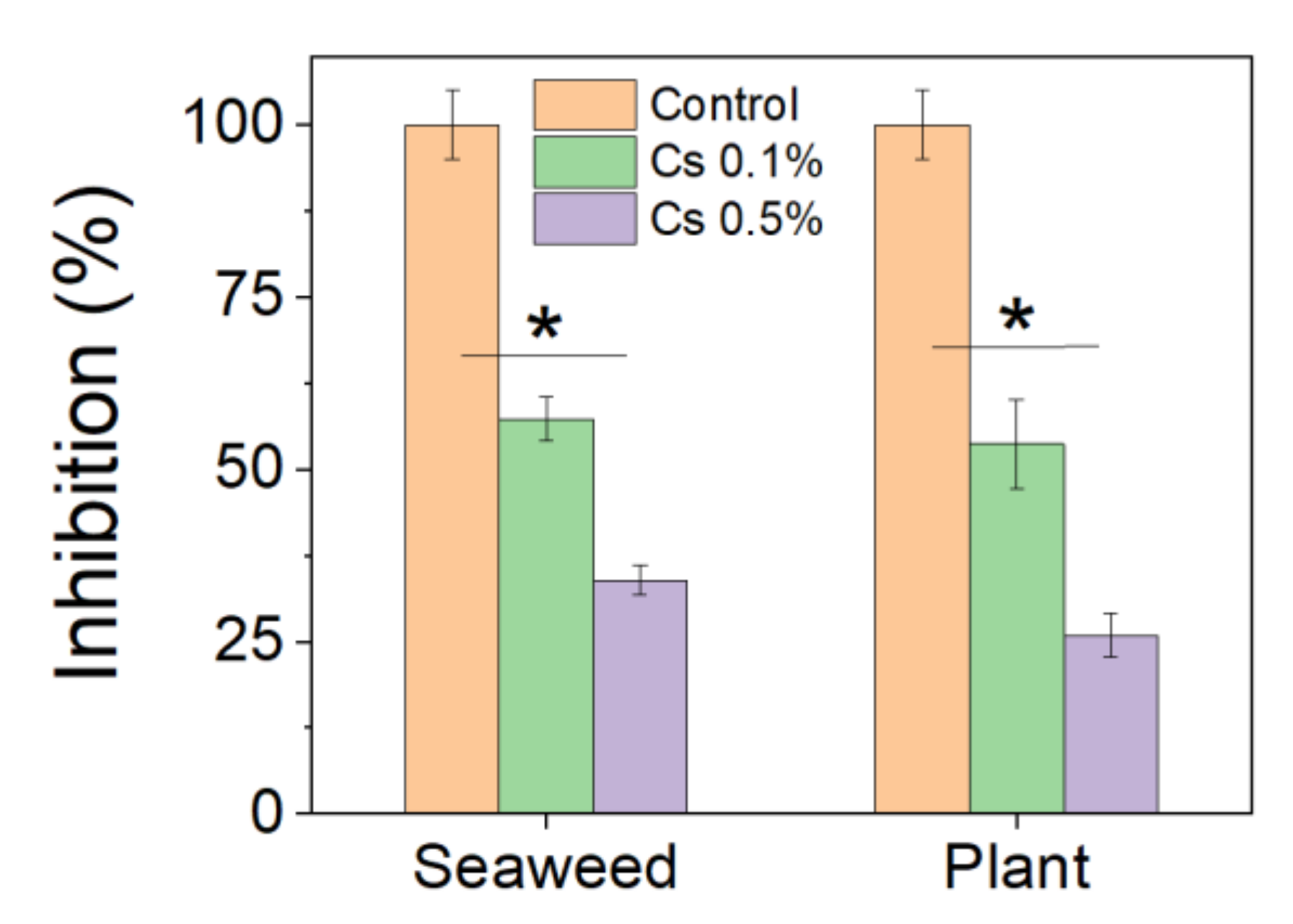

3.4. Antimicrobial Effect of Chitosan-Coated Paper

3.5. Surface Topography of Chitosan-Coated Paper

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Veldkamp, E.; Schmidt, M.; Powers, J.S.; Corre, M.D. Deforestation and reforestation impacts on soils in the tropics. Nat. Rev. Earth Environ. 2020, 1, 590–605. [Google Scholar] [CrossRef]

- Lawrence, D.; Vandecar, K. Effects of tropical deforestation on climate and agriculture. Nat. Clim. 2015, 5, 27–36. [Google Scholar] [CrossRef]

- Afelt, A.; Frutos, R.; Devaux, C. Bats, Coronaviruses, and Deforestation: Toward the Emergence of Novel Infectious Diseases? Front. Microbiol. 2018, 9, 702. [Google Scholar] [CrossRef] [Green Version]

- Pei, J.; Lin, A.; Zhang, F.; Zhu, D.; Li, J.; Wang, G. Using agar extraction waste of Gracilaria lemaneiformis in the papermaking industry. J. Appl. Phycol. 2013, 25, 1135–1141. [Google Scholar] [CrossRef]

- Seo, Y.-B.; Lee, Y.-W.; Lee, C.-H.; You, H.-C. Red algae and their use in papermaking. Bioresour. Technol. 2010, 101, 2549–2553. [Google Scholar] [CrossRef] [PubMed]

- Constante, A.; Pillay, S.; Ning, H.; Vaidya, U.K. Utilization of algae blooms as a source of natural fibers for biocomposite materials: Study of morphology and mechanical performance of Lyngbya fibers. Algal Res. 2015, 12, 412–420. [Google Scholar] [CrossRef]

- Mukherjee, P.; Keshri, J.P. Present status and development of algal pulp for hand-made paper making technology: A review. Adv. Plants Agric. Res. 2018, 8, 10–18. [Google Scholar]

- Wurtsbaugh, W.A.; Paerl, H.W.; Dodds, W.K. Nutrients, eutrophication and harmful algal blooms along the freshwater to marine continuum. WIREs Water 2019, 6, e1373. [Google Scholar] [CrossRef]

- Buschmann, A.H.; Camus, C.; Infante, J.; Neori, A.; Israel, Á.; Hernández-González, M.C.; Pereda, S.V.; Gomez-Pinchetti, J.L.; Golberg, A.; Tadmor-Shalev, N.; et al. Seaweed production: Overview of the global state of exploitation, farming and emerging research activity. Eur. J. Phycol. 2017, 52, 391–406. [Google Scholar] [CrossRef]

- Arumugam, N.; Chelliapan, S.; Kamyab, H.; Thirugnana, S.; Othman, N.; Nasri, N.S. Treatment of Wastewater Using Seaweed: A Review. Int. J. Environ. Res. Public Health 2018, 15, 2851. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reddy, N.; Yang, Y. Biofibers from agricultural byproducts for industrial applications. Trends Biotechnol. 2005, 23, 22–27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Z.; Wang, H.; Hui, L. Pulping and Papermaking of Non-Wood Fibers. In Pulp and Paper Processing; Kazi, S.N., Ed.; IntechOpen: London, UK, 2018; pp. 3–32. [Google Scholar]

- El-Sayed, E.S.A.; El-Sakhawy, M.; El-Sakhawy, M.A.-M. Non-wood fibers as raw material for pulp and paper industry. Nord. Pulp. Pap. Res. J. 2020, 35, 215–230. [Google Scholar] [CrossRef]

- Buxoo, S.; Jeetah, P. Feasibility of producing biodegradable disposable paper cup from pineapple peels, orange peels and Mauritian hemp leaves with beeswax coating. SN Appl. Sci. 2020, 2, 1359. [Google Scholar] [CrossRef]

- Tye, Y.Y.; Lee, K.T.; Wan Abdullah, W.N.; Leh, C.P. The world availability of non-wood lignocellulosic biomass for the production of cellulosic ethanol and potential pretreatments for the enhancement of enzymatic saccharification. Renew. Sust. Energ. Rev. 2016, 60, 155–172. [Google Scholar] [CrossRef]

- Ververis, C.; Georghiou, K.; Christodoulakis, N.; Santas, P.; Santas, R. Fiber dimensions, lignin and cellulose content of various plant materials and their suitability for paper production. Ind. Crops Prod. 2004, 19, 245–254. [Google Scholar] [CrossRef]

- Nakagaito, A.N.; Yano, H. The effect of morphological changes from pulp fiber towards nano-scale fibrillated cellulose on the mechanical properties of high-strength plant fiber based composites. Appl. Phys. A 2004, 78, 547–552. [Google Scholar] [CrossRef]

- Lourenço, A.; Pereira, H. Compositional Variability of Lignin in Biomass. In Lignin-Trends and Applications; Poletto, M., Ed.; IntechOpen: London, UK, 2018; pp. 65–98. [Google Scholar]

- McCandless, E.L.; Craigie, J.S. Sulfated Polysaccharides in Red and Brown Algae. Annu. Rev. Plant Physiol. 1979, 30, 41–53. [Google Scholar] [CrossRef]

- Xu, S.-Y.; Huang, X.; Cheong, K.-L. Recent Advances in Marine Algae Polysaccharides: Isolation, Structure, and Activities. Mar. Drugs 2017, 15, 388. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Sahoo, D. A comprehensive analysis of alginate content and biochemical composition of leftover pulp from brown seaweed Sargassum wightii. Algal Res. 2017, 23, 233–239. [Google Scholar] [CrossRef]

- Holdt, S.L.; Kraan, S. Bioactive compounds in seaweed: Functional food applications and legislation. J. Appl. Phycol. 2011, 23, 543–597. [Google Scholar] [CrossRef]

- Voragen, A.G.J.; Coenen, G.-J.; Verhoef, R.P.; Schols, H.A. Pectin, a versatile polysaccharide present in plant cell walls. Struct. Chem. 2009, 20, 263. [Google Scholar] [CrossRef] [Green Version]

- Ravi Kumar, M.N.V. A review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27. [Google Scholar] [CrossRef]

- Xiong Chang, X.; Mujawar Mubarak, N.; Ali Mazari, S.; Sattar Jatoi, A.; Ahmad, A.; Khalid, M.; Walvekar, R.; Abdullah, E.C.; Karri, R.R.; Siddiqui, M.T.H.; et al. A review on the properties and applications of chitosan, cellulose and deep eutectic solvent in green chemistry. J. Ind. Eng. Chem 2021, 104, 362–380. [Google Scholar] [CrossRef]

- Yu, Y.; Ren, Y. Effect of chitosan coating on preserving character of post-harvest fruit and vegetable: A review. J. Food Process. Technol. 2013, 4, 1000254. [Google Scholar]

- Frank, L.A.; Onzi, G.R.; Morawski, A.S.; Pohlmann, A.R.; Guterres, S.S.; Contri, R.V. Chitosan as a coating material for nanoparticles intended for biomedical applications. React. Funct. Polym. 2020, 147, 104459. [Google Scholar] [CrossRef]

- Kumar, N.; Petkoska, A.T.; AL-Hilifi, S.A.; Fawole, O.A. Effect of Chitosan–Pullulan Composite Edible Coating Functionalized with Pomegranate Peel Extract on the Shelf Life of Mango (Mangifera indica). Coatings 2021, 11, 764. [Google Scholar] [CrossRef]

- Nechita, P.; Roman, M. Review on Polysaccharides Used in Coatings for Food Packaging Papers. Coatings 2020, 10, 566. [Google Scholar] [CrossRef]

- Divsalar, E.; Tajik, H.; Moradi, M.; Forough, M.; Lotfi, M.; Kuswandi, B. Characterization of cellulosic paper coated with chitosan-zinc oxide nanocomposite containing nisin and its application in packaging of UF cheese. Int. J. Biol. Macromol. 2018, 109, 1311–1318. [Google Scholar] [CrossRef] [PubMed]

- Raghavendra, G.M.; Jung, J.; Kim, D.; Seo, J. Effect of chitosan silver nanoparticle coating on functional properties of Korean traditional paper. Prog. Org. Coat. 2017, 110, 16–23. [Google Scholar] [CrossRef]

- Kim, M.; Cha, C. Graft Architecture Guided Simultaneous Control of Degradation and Mechanical Properties of In Situ Forming and Fast Dissolving Polyaspartamide Hydrogels. Biomacromolecules 2020, 21, 3693–3703. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Ahn, Y.; Lee, K.; Jung, W.; Cha, C. In situ facile-forming chitosan hydrogels with tunable physicomechanical and tissue adhesive properties by polymer graft architecture. Carbohydr. Polym. 2020, 229, 115538. [Google Scholar] [CrossRef]

- Kamal, T.; Anwar, Y.; Khan, S.B.; Chani, M.T.S.; Asiri, A.M. Dye adsorption and bactericidal properties of TiO2/chitosan coating layer. Carbohydr. Polym. 2016, 148, 153–160. [Google Scholar] [CrossRef] [PubMed]

- Cha, C.; Antoniadou, E.; Lee, M.; Jeong, J.H.; Ahmed, W.W.; Saif, T.A.; Boppart, S.A.; Kong, H. Tailoring Hydrogel Adhesion to Polydimethylsiloxane Substrates Using Polysaccharide Glue. Angew. Chem. Int. Ed. 2013, 52, 6949–6952. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.; Hong, J.; Roh, H.J.; Kim, S.H.; Lee, H.; Lee, S.K.; Cha, C. Dual ionic crosslinked interpenetrating network of alginate-cellulose beads with enhanced mechanical properties for biocompatible encapsulation. Cellulose 2017, 24, 4963–4979. [Google Scholar] [CrossRef]

- Lee, K.; Choi, S.; Kim, C.; Kang, W.S.; Son, W.; Bae, S.C.; Oh, J.-W.; Lee, S.K.; Cha, C. Implementation of Combinatorial Genetic and Microenvironmental Engineering to Microbial-Based Field-Deployable Microbead Biosensors for Highly Sensitive and Remote Chemical Detection. ACS Sensors 2019, 4, 2716–2723. [Google Scholar] [CrossRef]

- García-Ríos, V.; Ríos-Leal, E.; Robledo, D.; Freile-Pelegrin, Y. Polysaccharides composition from tropical brown seaweeds. Phycol. Res. 2012, 60, 305–315. [Google Scholar] [CrossRef]

- Liu, K. Effects of sample size, dry ashing temperature and duration on determination of ash content in algae and other biomass. Algal Res. 2019, 40, 101486. [Google Scholar] [CrossRef]

- Devlieghere, F.; Vermeulen, A.; Debevere, J. Chitosan: Antimicrobial activity, interactions with food components and applicability as a coating on fruit and vegetables. Food Microbiol. 2004, 21, 703–714. [Google Scholar] [CrossRef]

- Prykäri, T.; Czajkowski, J.; Alarousu, E.; Myllylä, R. Optical coherence tomography as an accurate inspection and quality evaluation technique in paper industry. Opt. Rev. 2010, 17, 218–222. [Google Scholar] [CrossRef]

- Akbari, A.; Derikvandi, Z.; Mojallali Rostami, S.M. Influence of chitosan coating on the separation performance, morphology and anti-fouling properties of the polyamide nanofiltration membranes. J. Ind. Eng. Chem 2015, 28, 268–276. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saleh, R.I.; Kim, M.; Cha, C. Comprehensive Enhancement of Mechanical, Water-Repellent and Antimicrobial Properties of Regenerated Seaweed and Plant-Based Paper with Chitosan Coating. Coatings 2021, 11, 1384. https://doi.org/10.3390/coatings11111384

Saleh RI, Kim M, Cha C. Comprehensive Enhancement of Mechanical, Water-Repellent and Antimicrobial Properties of Regenerated Seaweed and Plant-Based Paper with Chitosan Coating. Coatings. 2021; 11(11):1384. https://doi.org/10.3390/coatings11111384

Chicago/Turabian StyleSaleh, Rabi Ibrahim, Mirae Kim, and Chaenyung Cha. 2021. "Comprehensive Enhancement of Mechanical, Water-Repellent and Antimicrobial Properties of Regenerated Seaweed and Plant-Based Paper with Chitosan Coating" Coatings 11, no. 11: 1384. https://doi.org/10.3390/coatings11111384

APA StyleSaleh, R. I., Kim, M., & Cha, C. (2021). Comprehensive Enhancement of Mechanical, Water-Repellent and Antimicrobial Properties of Regenerated Seaweed and Plant-Based Paper with Chitosan Coating. Coatings, 11(11), 1384. https://doi.org/10.3390/coatings11111384