Effect of HfO2-Based Multi-Dielectrics on Electrical Properties of Amorphous In-Ga-Zn-O Thin Film Transistors

Abstract

:1. Introduction

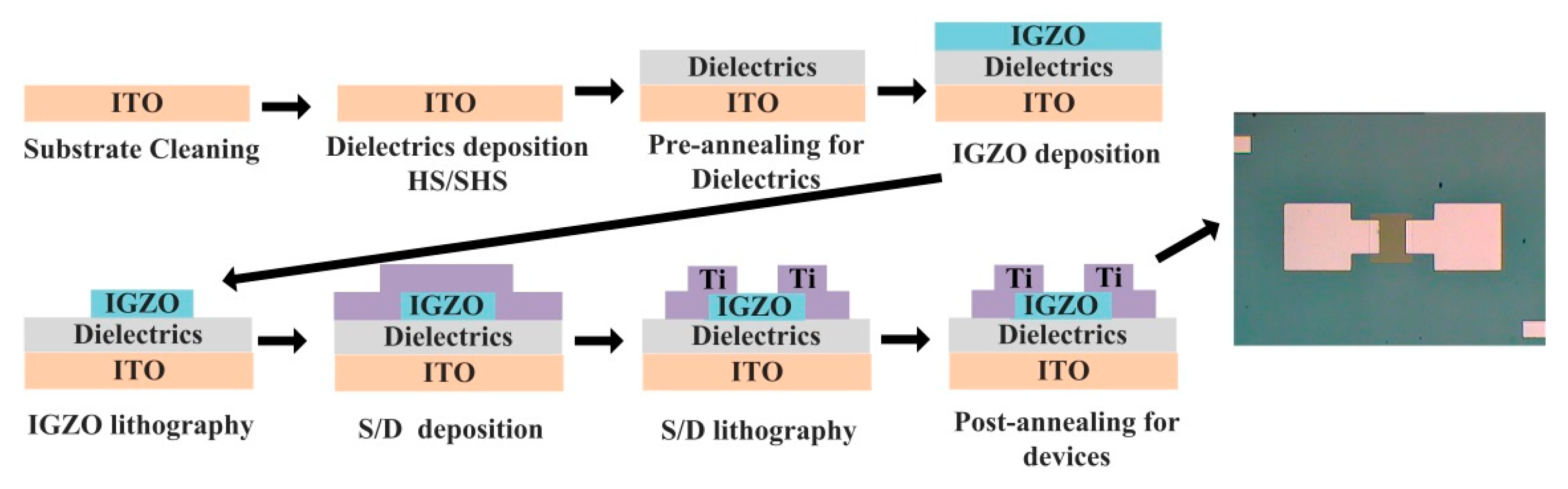

2. Materials and Methods

3. Results and Discussions

3.1. a-IGZO Fims

3.2. Dielectric Structures and Electrical Properties

3.3. Zr-Doped HfO2 Dieletrics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Park, J.S.; Kim, T.W.; Stryakhilev, D.; Lee, J.S.; An, S.G.; Pyo, Y.S.; Lee, D.B.; Mo, Y.G.; Jin, D.U.; Chung, H.K. Flexible full color organic light-emitting diode display on polyimide plastic substrate driven by amorphous indium gallium zinc oxide thin-film transistors. Appl. Phys. Lett. 2009, 95, 013503. [Google Scholar] [CrossRef]

- Lin, C.L.; Chang, W.Y.; Hung, C.C. Compensating pixel circuit driving AMOLED display with a-IGZO TFTs. IEEE Electron Device Lett. 2013, 34, 1166–1168. [Google Scholar] [CrossRef]

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Hosono, H. Ionic amorphous oxide semiconductors: Material design, carrier transport, and device application. J. Non-Cryst. Solids 2006, 352, 851–858. [Google Scholar] [CrossRef]

- Nomura, K.; Ohta, H.; Ueda, K.; Kamiya, T.; Hirano, M.; Hosono, H. Thin-Film Transistor Fabricated in Single-Crystalline Transparent Oxide Semiconductor. Science 2010, 300, 1269–1272. [Google Scholar] [CrossRef]

- Kamiya, T.; Nomura, K.; Hosono, H. Present status of amorphous In-Ga-Zn-O thin-film transistors. Sci. Technol. Adv. Mater. 2010, 11, 044305. [Google Scholar] [CrossRef]

- Suresh, A.; Muth, J.F. Bias stress stability of indium gallium zinc oxide channel based transparent thin film transistors. Appl. Phys. Lett. 2008, 92, 033502. [Google Scholar] [CrossRef] [Green Version]

- Nomura, K.; Kamiya, T.; Hirano, M.; Hosono, H. Origins of threshold voltage shifts in room-temperature deposited and annealed a-In-Ga-Zn-O thin-film transistors. Appl. Phys. Lett. 2009, 95, 013502. [Google Scholar] [CrossRef]

- Yoon, S.M.; Seong, N.J.; Choi, K.; Seo, G.H.; Shin, W.C. Effects of Deposition Temperature on the Device Characteristics of Oxide Thin-Film Transistors Using In-Ga-Zn-O Active Channels Prepared by Atomic-Layer Deposition. ACS Appl. Mater. Interfaces 2017, 9, 22676–22684. [Google Scholar] [CrossRef]

- Wang, R.Z.; Wu, S.L.; Li, X.Y.; Zhang, J.T. The electrical performance and gate bias stability of an amorphous InGaZnO thin-film transistor with HfO2 high-k dielectrics. Solid-State Electron. 2017, 133, 6–9. [Google Scholar] [CrossRef]

- Liu, P.; Member, S.; Chou, Y.; Teng, L.; Li, F.; Fuh, C.-S.; Shieh, H.-P.D. Ambient Stability Enhancement of Thin-Film Transistor with InGaZnO Capped with InGaZnO:N Bilayer Stack Channel Layers. IEEE Electron Device Lett. 2011, 32, 1397–1399. [Google Scholar] [CrossRef]

- Shin, J.W.; Cho, W.J. Low thermal budget annealing technique for high performance amorphous In-Ga-ZnO thin film transistors. AIP Adv. 2017, 7, 7–13. [Google Scholar] [CrossRef] [Green Version]

- Cho, M.H.; Choi, C.H.; Seul, H.J.; Cho, H.C.; Jeong, J.K. Achieving a Low-Voltage, High-Mobility IGZO Transistor through an ALD-Derived Bilayer Channel and a Hafnia-Based Gate Dielectric Stack. ACS Appl. Mater. Interfaces 2021, 13, 16628–16640. [Google Scholar] [CrossRef]

- Chen, R.; Zhou, W.; Zhang, M.; Wong, M.; Kwok, H.S. Self-aligned top-gate InGaZnO thin fi lm transistors using SiO2/Al2O3 stack gate dielectric. Thin Solid Films 2013, 548, 572–575. [Google Scholar] [CrossRef]

- Yabuta, H.; Sano, M.; Abe, K.; Aiba, T.; Den, T.; Yabuta, H.; Sano, M.; Abe, K.; Aiba, T. High-mobility thin-film transistor with amorphous InGaZnO4 channel fabricated by room temperature rf-magnetron sputtering High-mobility thin-film transistor with amorphous InGaZnO 4 channel fabricated by room temperature rf-magnetron sputtering. Appl. Phys. Lett. 2006, 89, 112123. [Google Scholar] [CrossRef]

- Shimura, Y.; Nomura, K.; Yanagi, H.; Kamiya, T. Specific contact resistances between amorphous oxide semconductor In–Ga–Zn–O and metallic electrodes. Thin Solid Films 2008, 516, 5899–5902. [Google Scholar] [CrossRef]

- Kamiya, T.; Nomura, K.; Hosono, H. Origins of High Mobility and Low Operation Voltage of Amorphous Oxide TFTs: Electronic Structure, Electron Transport, Defects and Doping. J. Disp. Technol. 2009, 5, 468–483. [Google Scholar] [CrossRef]

- Tanc, J.; Grigorovici, R.; Vancu, A. Optical Properties and Electronic Structure of Amorphous Germanium. Phys. Status Solidi (b) 1966, 15, 627–637. [Google Scholar]

- Triyoso, D.H.; Hegde, R.I.; Schaeffer, J.K.; Roan, D.; Tobin, P.J.; Samavedam, S.B.; White, B.E., Jr.; Gregory, R.; Wang, X. Impact of Zr addition on properties of atomic layer deposited HfO2 Impact of Zr addition on properties of atomic layer deposited HfO2. Appl. Phys. Lett. 2013, 88, 222901. [Google Scholar] [CrossRef]

- Senzaki, Y.; Park, S.; Chatham, H.; Bartholomew, L.; Nieveen, W.; Senzaki, Y.; Park, S.; Chatham, H.; Bartholomew, L.; Nieveen, W. Atomic layer deposition of hafnium oxide and hafnium silicate thin films using liquid precursors and ozone Atomic layer deposition of hafnium oxide and hafnium silicate thin films using liquid precursors and ozone. J. Vac. Sci. Technol. 2014, 22, 1175–1181. [Google Scholar] [CrossRef]

- Iii, J.J.G.; Triyoso, D.H.; Raymond, M. X-ray metrology for high- k atomic layer deposited HfxZr1ÀxO2 films. Microelectron. Eng. 2008, 85, 49–53. [Google Scholar]

- Liu, X.; Yang, C.; Kuo, Y.; Yuan, T. Memory Functions of Molybdenum Oxide Nanodots-Embedded ZrHfO High- k. Electrochem. Solid State Lett. 2012, 15, H192–H194. [Google Scholar] [CrossRef]

- Chiang, C.; Wu, C.; Liu, C.; Lin, J. Characterization of Hf1−xZrxO2 Gate Dielectrics with 0 ≤ x ≤ 1 Prepared by Atomic Layer Deposition for Metal Oxide Semiconductor Field Effect Transistor Applications. Jpn. J. Appl. Phys. 2012, 51, 011101. [Google Scholar] [CrossRef]

- Hung, C.H.; Wang, S.J.; Liu, P.Y.; Wu, C.H.; Wu, N.S.; Yan, H.P.; Lin, T.H. A room temperature process for the fabrication of amorphous indium gallium zinc oxide thin-film transistors with co-sputtered ZrxSi1−xO2 Gate dielectric and improved electrical and hysteresis performance. Jpn. J. Appl. Phys. 2017, 56, 04CG06. [Google Scholar] [CrossRef]

- Cai, W.; Brownless, J.; Zhang, J.; Li, H.; Tillotson, E.; Hopkinson, D.G.; Haigh, S.J.; Song, A. Solution-Processed HfOx for Half-Volt Operation of InGaZnO Thin-Film Transistors. ACS Appl. Electron. Mater. 2019, 1, 1581–1589. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Chen, X.; Li, C.; Ding, X. Low-voltage-drive and high output current InGaZnO thin-film transistors with novel SiO2/HfO2/SiO2 structure. Mol. Cryst. Liq. Cryst. 2017, 651, 228–234. [Google Scholar] [CrossRef]

- Lin, C.Y.; Chien, C.W.; Wu, C.H.; Hsieh, H.H.; Wu, C.C.; Yeh, Y.H.; Cheng, C.C.; Lai, C.M.; Yu, M.J. Top-gate staggered a-IGZO TFTs adopting the bilayer gate insulator for driving AMOLED. IEEE Trans. Electron Devices 2012, 59, 1701–1708. [Google Scholar] [CrossRef]

| SiNx | HfO2 | ||

|---|---|---|---|

| Process Parameters | Values | Process Parameters | Values |

| Substrate temperature/°C | 300 | Substrate temperature/°C | RT |

| Power/W | 100 | Power/W | 150 |

| SiH4/NH3 ratio/sccm | 10:50 | Ar flow/sccm | 20 |

| Base vacuum/Pa | 2 × 10−3 | Base vacuum/Pa | 5 × 10−3 |

| Pressure/mTorr | 0.625 | Pressure/Pa | 1.8 × 10−1 |

| Deposition rate/nm·min−1 | 28.7 | Deposition rate/nm·min−1 | 2.2 |

| Elements | In | Ga | Zn | O | C |

|---|---|---|---|---|---|

| Atomic ratio/% | 12.74 | 13.31 | 5.52 | 46.15 | 22.28 |

| Binding energy/eV | 444.5 | 1117.8 | 1021.6 | 530.5 | 284.8 |

| Oxygen Flow /sccm | Mobility /cm2 V−1 s−1 | Carrier Concentration/cm−3 | Semiconductor Type |

|---|---|---|---|

| 0 | 9.1 | 1.38 × 1019 | n |

| 0.5 | 13.5 | 2.6 × 1018 | n |

| 1 | 10.8 | 8.57 × 1017 | n |

| 1.5 | 10.0 | 6.53 × 1017 | n |

| 2 | - | - | - |

| Gate Dielectrics | Vth /V | μsat /cm2 V−1 s−1 | Ion/Ioff | SS /V·dec−1 | NSS/cm−2 | ΔVth after PBS/V |

|---|---|---|---|---|---|---|

| This work | 1.4 | 19.5 | 108 | 0.21 | 4.8 × 1011 | 0.09 |

| HfO2 [25] | 0.21 | 7.5 | 5.2 × 105 | 0.071 | 1.2 × 1012 | 0.011 |

| Zr0.85Si0.15O2 [24] | 0.96 | 33.76 | 1.96 × 107 | 0.103 | 1.9 × 1012 | 0.3 |

| SiO2/HfO2/SiO2 [26] | 1.4 | 8.6 | 2.9 ×105 | 0.67 | 2.7 × 1012 | - |

| SiNx/SiO2 [27] | 2.6 | 13.8 | 3 × 108 | 0.49 | - | - |

| Al2O3/HfO2 [13] | 0.2 | 74.0 | 3 × 108 | 0.17 | 1.9 × 1011 | 0.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Wei, Q.; Li, J.; Fu, J.; Liu, Y.; Zhu, T.; Yu, C.; Niu, G.; Wu, S.; Wang, H. Effect of HfO2-Based Multi-Dielectrics on Electrical Properties of Amorphous In-Ga-Zn-O Thin Film Transistors. Coatings 2021, 11, 1381. https://doi.org/10.3390/coatings11111381

Wang R, Wei Q, Li J, Fu J, Liu Y, Zhu T, Yu C, Niu G, Wu S, Wang H. Effect of HfO2-Based Multi-Dielectrics on Electrical Properties of Amorphous In-Ga-Zn-O Thin Film Transistors. Coatings. 2021; 11(11):1381. https://doi.org/10.3390/coatings11111381

Chicago/Turabian StyleWang, Ruozheng, Qiang Wei, Jie Li, Jiao Fu, Yiwei Liu, Tianfei Zhu, Cui Yu, Gang Niu, Shengli Wu, and Hongxing Wang. 2021. "Effect of HfO2-Based Multi-Dielectrics on Electrical Properties of Amorphous In-Ga-Zn-O Thin Film Transistors" Coatings 11, no. 11: 1381. https://doi.org/10.3390/coatings11111381

APA StyleWang, R., Wei, Q., Li, J., Fu, J., Liu, Y., Zhu, T., Yu, C., Niu, G., Wu, S., & Wang, H. (2021). Effect of HfO2-Based Multi-Dielectrics on Electrical Properties of Amorphous In-Ga-Zn-O Thin Film Transistors. Coatings, 11(11), 1381. https://doi.org/10.3390/coatings11111381