Effects of Zr/(Zr+Ti) Molar Ratio on the Phase Structure and Hardness of TixZr1−xN Films

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

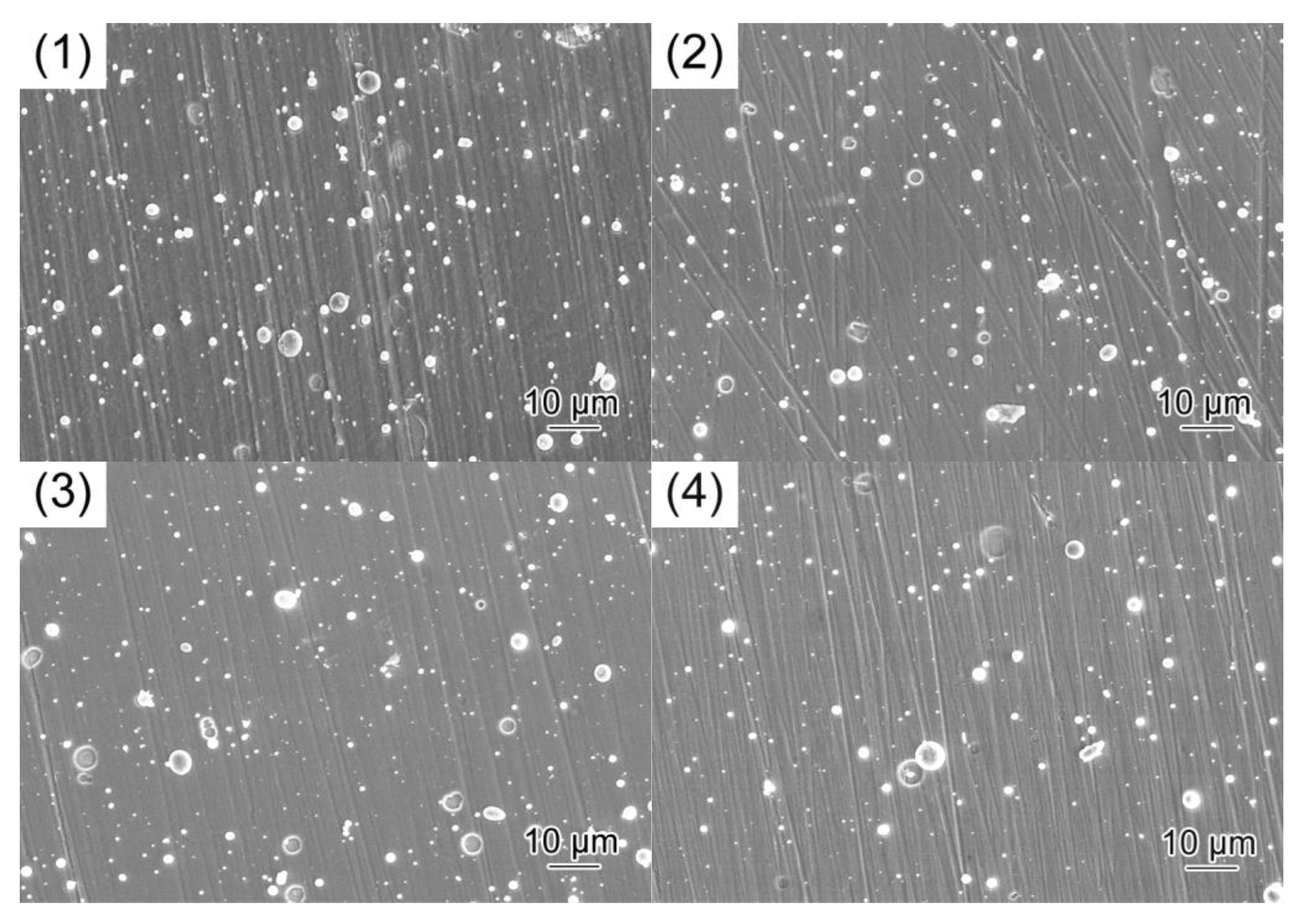

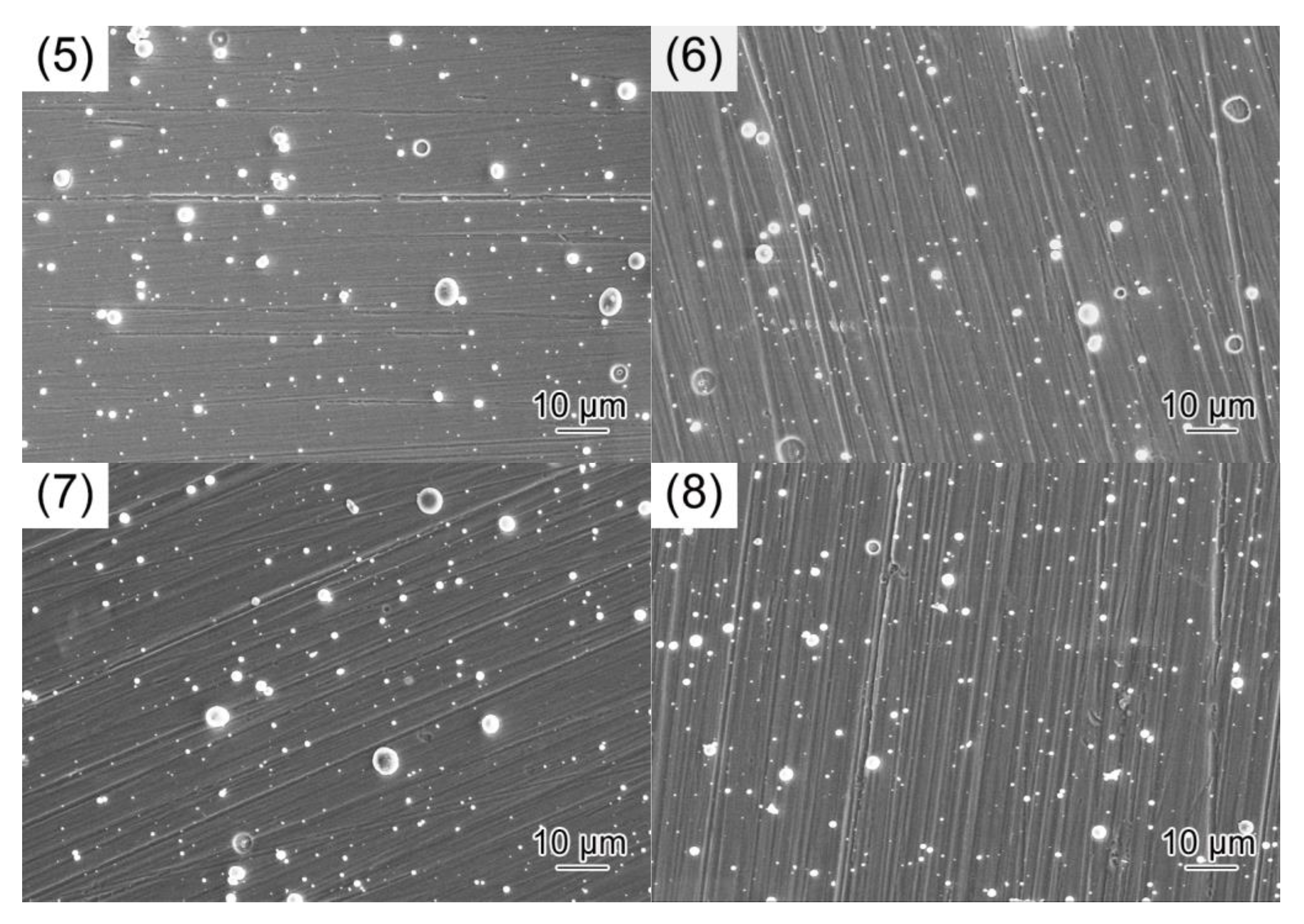

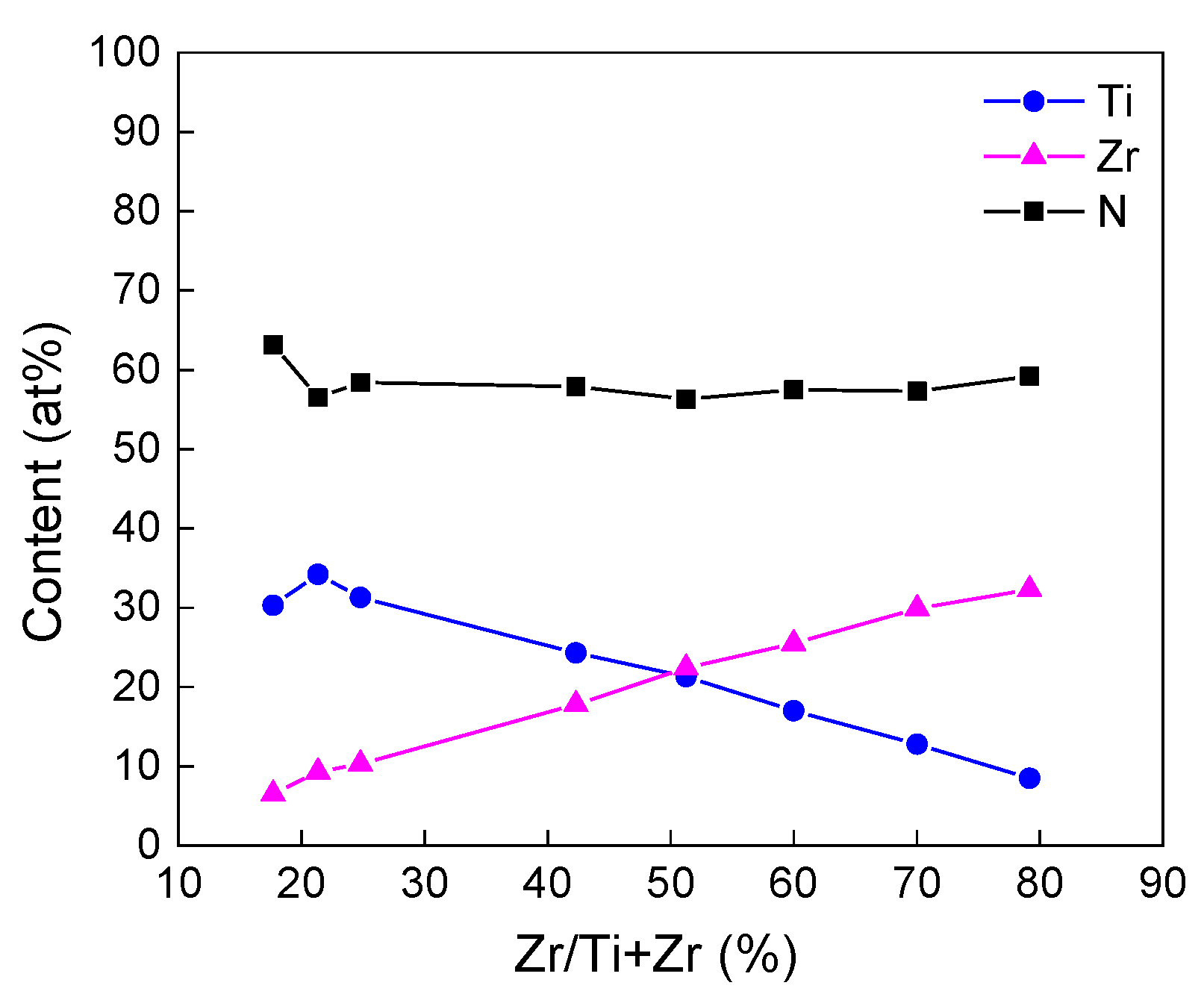

3.1. Surface Morphology and Surface Composition

3.2. Cross-Sectional Morphology and Elemental Distribution

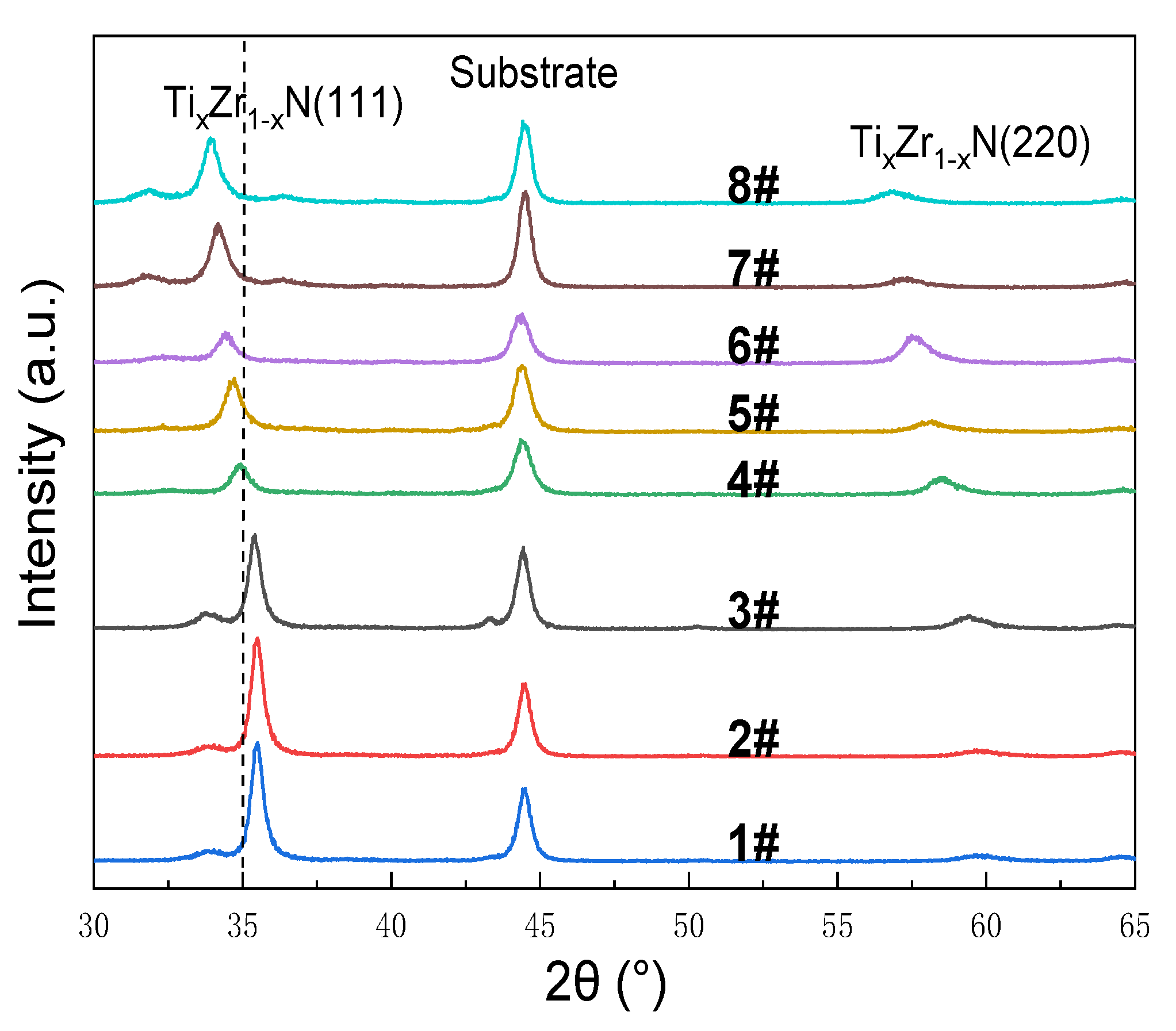

3.3. Phase Structure and Preferred Growth Orientation

3.4. Hardness

4. Conclusions

- The surface and cross-sectional morphologies and the deposition rate of TixZr1−xN films with varying Zr/Ti molar ratios were similar when the deposition conditions such as N2 gas flow and maintaining the total arc current at 110 A during evaporation of any two of the Ti, Zr, and TiZr targets were maintained.

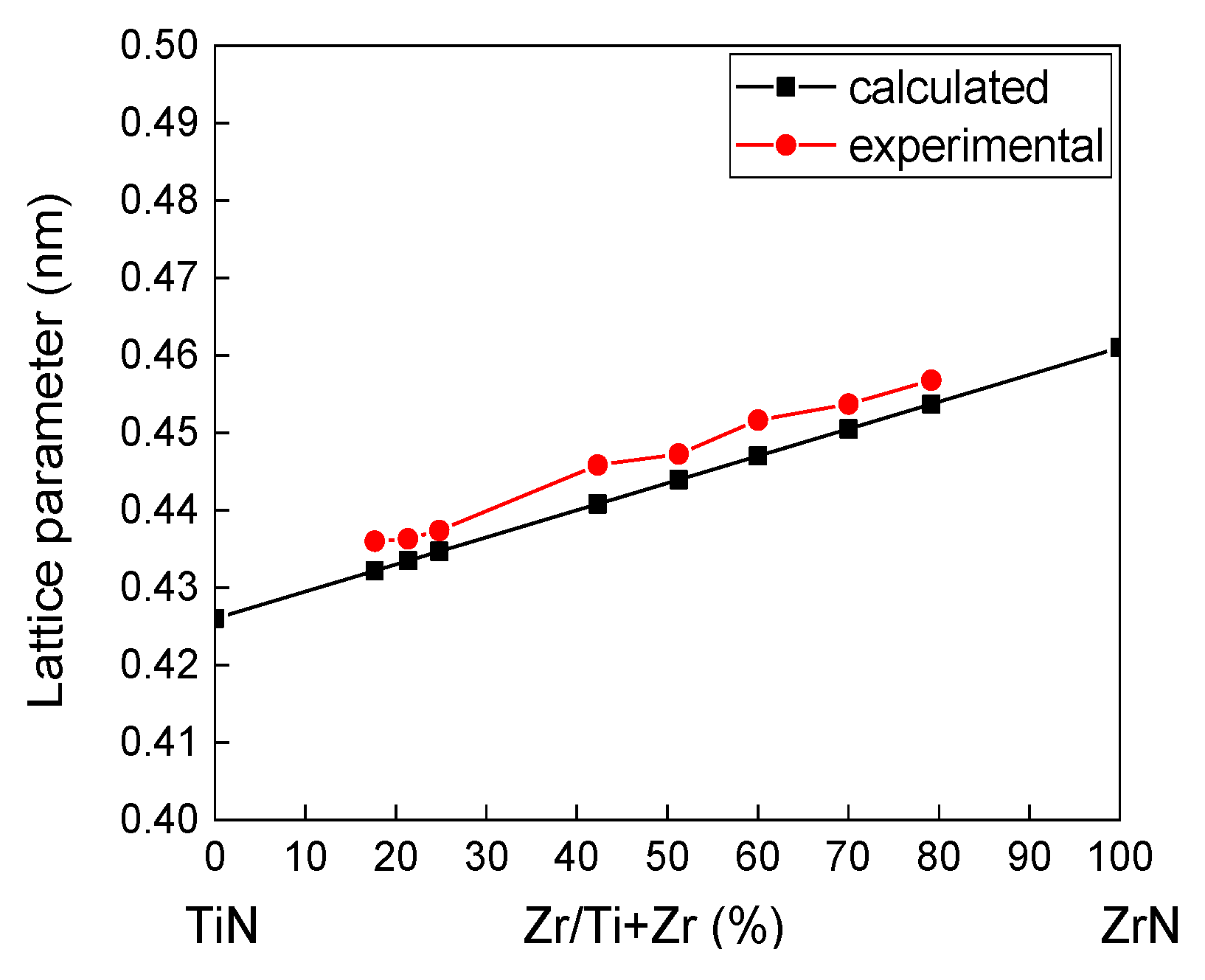

- The FCC structure of the films was retained while the lattice constant increased monotonically with increasing Zr/Ti molar ratio, consistent with Vegard’s law.

- The preferred growth orientations of the films were affected by their composition. When the Zr/Ti molar ratio was 40:60 or 60:40, the films showed preferred growth orientation in the (111) and (220) crystal planes; however, at other compositions, the films exhibited a preferred growth only in the (111) crystal plane. A symmetrical distribution in the preferred growth orientation relative to the Zr/Ti molar ratio 50:50 was displayed.

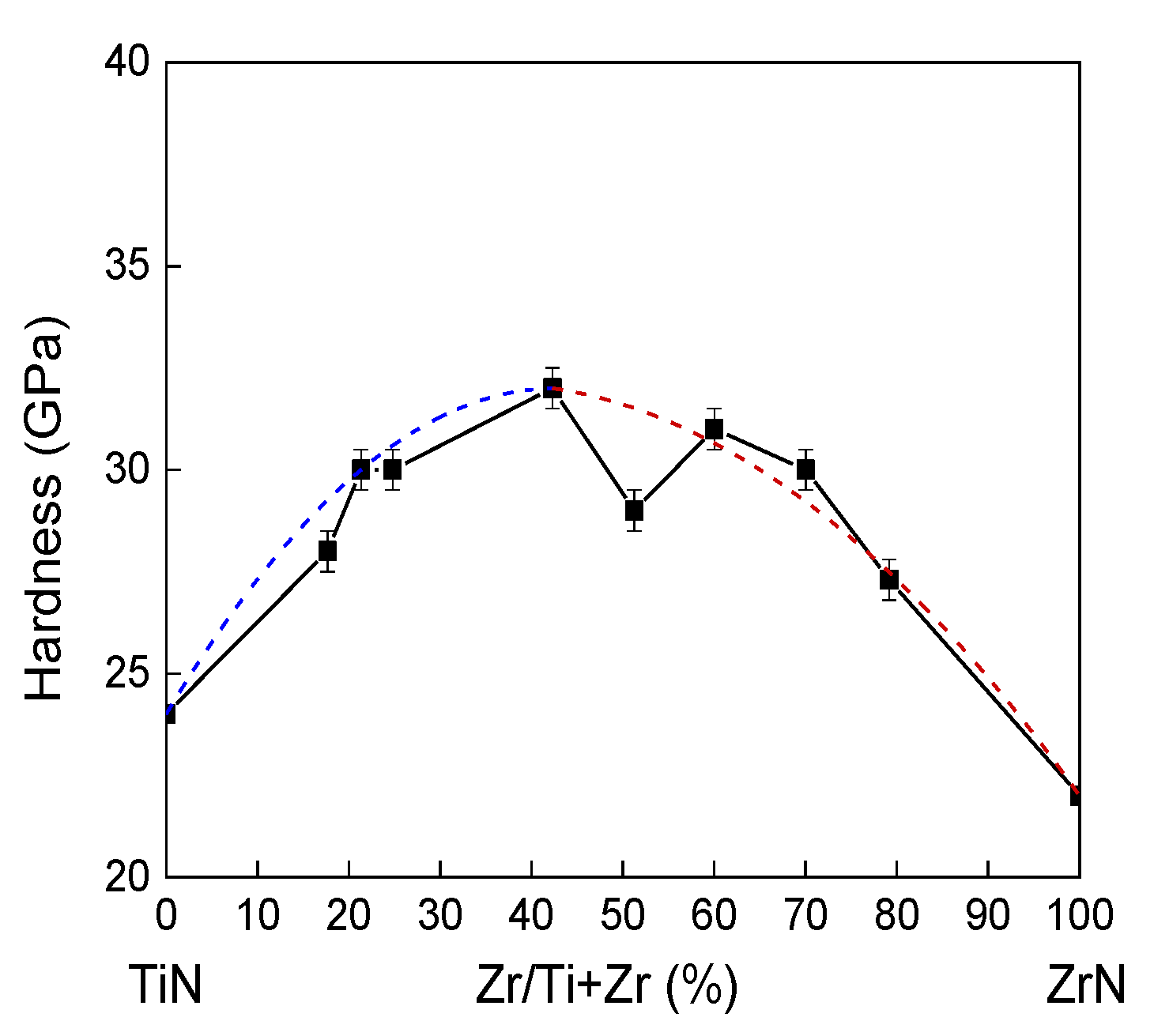

- The films exhibited a quasi-parabolic hardness distribution. The maximum hardness was observed at a Zr/Ti ratio of 40:60. An inflection point with a small reduction in hardness occurred at a Zr/Ti ratio of 50:50, after which the hardness increased as Zr/Ti ratio increased from 40:60 to 60:40.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Donohue, L.A.; Cawley, J.; Brooks, J.S. Deposition and characterisation of arc-bond sputter TixZryN coatings from pure metallic and segmented targets. Surf. Coat. Technol. 1995, 72, 128–138. [Google Scholar] [CrossRef]

- Grimberg, I.; Zhitomirsky, V.M.; Boxman, R.L.; Goldsmith, S.; Weiss, B.Z. Multicomponent Ti-Zr-N and Ti-Nb-N coatings deposited by vacuum arc. Surf. Coat. Technol. 1998, 108, 154–159. [Google Scholar] [CrossRef]

- Uglov, V.V.; Anishchik, V.M.; Khodasevich, V.V.; Prikhodko, Z.L.; Zlotski, S.V.; Abadias, G.; Dub, S.N. Structural characterization and mechanical properties of Ti-Zr-N coatings, deposited by vacuum arc. Surf. Coat. Technol. 2004, 180, 519–525. [Google Scholar] [CrossRef]

- Uglov, V.V.; Anishchik, V.M.; Zlotski, S.V.; Abadias, G. The phase composition and stress development in ternary Ti-Zr-N coatings grown by vacuum arc with combining of plasma flows. Surf. Coat. Technol. 2006, 200, 6389–6394. [Google Scholar] [CrossRef]

- Rother, B.; Donohue, L.A.; Kappl, H. Quantification of the interface strength between (Ti,Zr)N coatings and high speed steel. Surf. Coat. Technol. 1996, 82, 214–217. [Google Scholar] [CrossRef]

- Du, G.Y.; Ba, D.C.; Tan, Z.; Sun, W.; Liu, K.; Han, Q.K. Vibration damping performance of ZrTiN coating deposited by arc ion plating on TC4 Titanium alloy. Surf. Coat. Technol. 2013, 229, 172–175. [Google Scholar] [CrossRef]

- Jeona, S.; Haa, J.; Choi, Y.; Joc, I.; Leea, H. Interfacial stability and diffusion barrier ability of Ti1−xZrxN coatings by pulsed laser thermal shock. Appl. Surf. Sci. 2014, 320, 602–608. [Google Scholar] [CrossRef]

- Huang, J.H.; Chen, Y.F.; Yu, G.P. Evaluation of the fracture toughness of Ti1−xZrxN hard coatings: Effect of compositions. Surf. Coat. Technol. 2019, 358, 487–496. [Google Scholar] [CrossRef]

- Sakamoto, I.; Maruno, S.; Jim, P. Preparation and microstructure of reactively sputtered Ti1−xZrxN films. Thin Solid Film. 1993, 228, 169–172. [Google Scholar] [CrossRef]

- Hasegawa, H.; Suzuki, T. Effects of second metal contents on microstructure and micro-hardness of ternary nitride films synthesized by cathodic arc method. Surf. Coat. Technol. 2004, 188, 234–240. [Google Scholar] [CrossRef]

- Niu, E.W.; Li, L.; Lv, G.H.; Chen, H.; Li, X.Z.; Yang, X.Z.; Yang, S.Z. Characterization of Ti-Zr-N films deposited by cathodic vacuum arc with different substrate bias. Appl. Surf. Sci. 2008, 254, 3909–3914. [Google Scholar] [CrossRef]

- Harris, S.G.; Doyle, E.D.; Wong, Y.C.; Munroe, P.R.; Cairney, J.M.; Long, J.M. Reducing the macroparticle content of cathodic arc evaporated TiN coatings. Surf. Coat. Technol. 2003, 183, 283–294. [Google Scholar] [CrossRef]

- Wan, X.; Zhao, S.; Yang, Y.; Gong, J.; Sun, C. Effects of nitrogen pressure and pulse bias voltage on the properties of Cr-N coatings deposited by arc ion plating. Surf. Coat. Technol. 2009, 204, 1800–1810. [Google Scholar] [CrossRef]

- Tang, J.F.; Li, C.Y.; Yang, F.C.; Chang, C.L. Influence of nitrogen content and bias voltage on residual stress and the tribological and mechanical properties of CrAlN films. Coatings 2020, 10, 546. [Google Scholar] [CrossRef]

- Lin, Y.W.; Huang, J.H.; Yu, G.P. Effect of nitrogen flow rate on properties of nanostructured TiZrN thin films produced by radio frequency magnetron sputtering. Thin Solid Film. 2010, 518, 7308–7311. [Google Scholar] [CrossRef]

- Tay, B.K.; Shi, X.; Yang, H.S.; Tan, H.; Chua, D.; Teo, S. The effect of deposition conditions on the properties of TiN thin films prepared by filtered cathodic vacuum-arc technique. Surf. Coat. Technol. 1999, 111, 229–233. [Google Scholar] [CrossRef]

- Huang, J.H.; Lau, K.W.; Yu, G.P. Effect of nitrogen flow rate on structure and properties of nanocrystalline TiN thin films produced by unbalanced magnetron sputtering. Surf. Coat. Technol. 2005, 191, 17–24. [Google Scholar] [CrossRef]

- Zhang, J.; Yin, L.Y. Microstructure and mechanical properties of (Ti,Al,Nb)N hard films with N-gradient distributions. Thin Solid Film. 2015, 584, 141–145. [Google Scholar] [CrossRef]

- Chen, L.; Wang, S.Q.; Du, Y.; Li, J. Microstructure and mechanical properties of gradient Ti(C, N) and TiN/Ti(C, N) multilayer PVD coatings. Mater. Sci. Eng. A 2007, 478, 336–339. [Google Scholar] [CrossRef]

- Chang, C.L.; Yang, F.C. Effect of target composition on the microstructural mechanical, and corrosion properties of TiAlN thin films deposited by high-power impulse magnetron sputtering. Surf. Coat. Technol. 2018, 352, 330–337. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, L.; Tang, W.; Ruan, Q.; Li, X.; Wu, Z.; Qasim, A.M.; Cui, S.; Li, T.; Tian, X.; et al. Study of TiAlN coatings deposited by continuous high power magnetron sputtering (C-HPMS). Surf. Coat. Technol. 2020, 402, 126315–126323. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, S.S.; Deng, X.; Liu, J.Y.; Wang, Z.P.; Qu, Z. Cutting performance and wear behavior of AlTiN- and TiAlSiN-coated carbide tools during dry milling of Ti-6Al-4V. Acta Metall. Sin. (Engl. Lett.) 2020, 33, 459–470. [Google Scholar] [CrossRef] [Green Version]

- Sabitzer, C.; Paulitsch, J.; Kolozsvári, S.; Rachbauer, R.; Mayrhofer, P.H. Influence of bias potential and layer arrangement on structure and mechanical properties of arc evaporated Al-Cr-N coatings. Vacuum 2014, 106, 49–52. [Google Scholar] [CrossRef]

- Fan, Q.X.; Zhang, J.J.; Wu, Z.H.; Liu, Y.M.; Zhang, T.; Yan, B.; Wang, T.G. Influence of Al content on the microstructure and properties of the CrAlN coatings deposited by arc ion plating. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 1221–1230. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Zhou, F.; Yan, J.W. Evaluating mechanical properties and crack resistance of CrN, CrTiN, CrAlN and CrTiAlN coatings by nanoindentation and scratch tests. Surf. Coat. Technol. 2016, 285, 203–213. [Google Scholar] [CrossRef]

- Sundgren, J.E. Structure and properties of TiN coatings. Thin Solid Film. 1985, 128, 21–44. [Google Scholar] [CrossRef]

- Molarius, J.M.; Korhonen, A.S.; Ristolainen, E.O. Ti-N phases formed by reactive ion plating. Vac. Sci. Technol. 1985, 3, 2419–2425. [Google Scholar] [CrossRef]

- Larijani, M.; Tabrizi, N.; Norouzian, S.; Jafari, A.; Lahouti, S.; Hosseini, H.H.; Afshari, N. Structural and mechanical properties of ZrN films prepared by ion beam sputtering with varying N2/Ar ratio and substrate temperature. Vacuum 2006, 81, 550–555. [Google Scholar] [CrossRef]

- Hoerling, A.; Sjölén, J.; Willmann, H.; Larsson, T.; Odén, M.; Hultman, L. Thermal stability, microstructure and mechanical properties of Ti1−xZrxN thin films. Thin Solid Film. 2008, 516, 6421–6431. [Google Scholar] [CrossRef]

| Sample No. | Cathodic Arc Current (A) | ||

|---|---|---|---|

| Ti Target | Zr Target | Ti-Zr Alloy Target | |

| 1 | 62 | – | 48 |

| 2 | 55 | – | 55 |

| 3 | 48 | – | 62 |

| 4 | 62 | 48 | – |

| 5 | 54 | 56 | – |

| 6 | 48 | 62 | – |

| 7 | – | 48 | 62 |

| 8 | – | 62 | 48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Peng, L.; Wang, X.; Liu, D.; Wang, N. Effects of Zr/(Zr+Ti) Molar Ratio on the Phase Structure and Hardness of TixZr1−xN Films. Coatings 2021, 11, 1342. https://doi.org/10.3390/coatings11111342

Zhang J, Peng L, Wang X, Liu D, Wang N. Effects of Zr/(Zr+Ti) Molar Ratio on the Phase Structure and Hardness of TixZr1−xN Films. Coatings. 2021; 11(11):1342. https://doi.org/10.3390/coatings11111342

Chicago/Turabian StyleZhang, Jun, Lijing Peng, Xiaoyang Wang, Dongling Liu, and Nan Wang. 2021. "Effects of Zr/(Zr+Ti) Molar Ratio on the Phase Structure and Hardness of TixZr1−xN Films" Coatings 11, no. 11: 1342. https://doi.org/10.3390/coatings11111342

APA StyleZhang, J., Peng, L., Wang, X., Liu, D., & Wang, N. (2021). Effects of Zr/(Zr+Ti) Molar Ratio on the Phase Structure and Hardness of TixZr1−xN Films. Coatings, 11(11), 1342. https://doi.org/10.3390/coatings11111342