Research on the Mechanism of Surfactant Warm Mix Asphalt Additive-Based on Molecular Dynamics Simulation

Abstract

1. Introduction

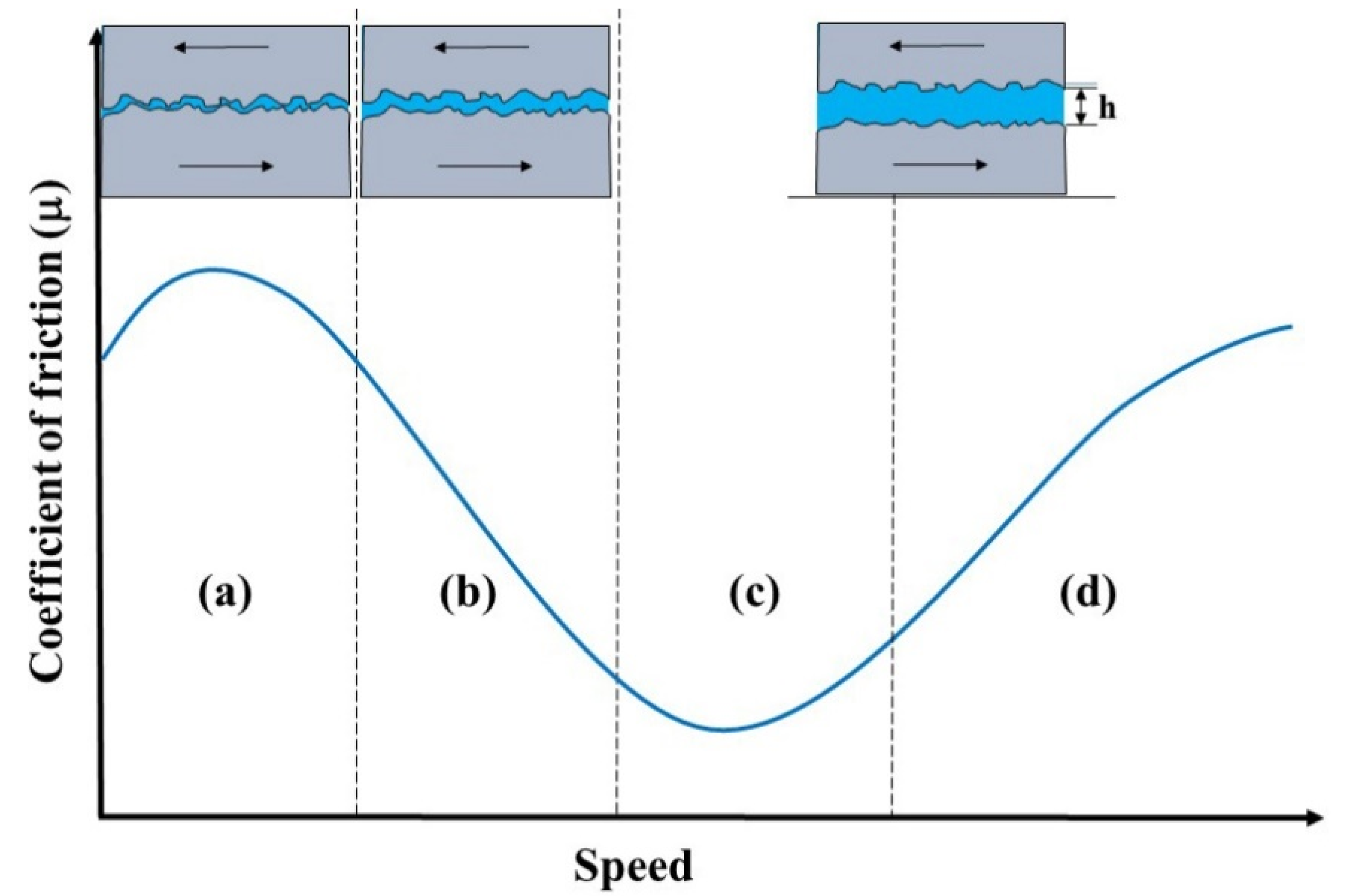

- In the mixed state (B), the lubricating oil forms fluid dynamic pressure as the velocity increases, which reduces direct contact between the two surfaces, thereby easing friction.

- In the elastohydrodynamic state (C), friction is minimized when the surfaces are no longer in contact.

- In the hydrodynamic region (D), friction depends primarily on the viscous resistance of the lubricant at high sliding speeds. Specifically, the friction of the whole system rises again as the internal friction of the lubricant increases.

2. Calculation Method of MD Simulation

2.1. Calculation Parameters

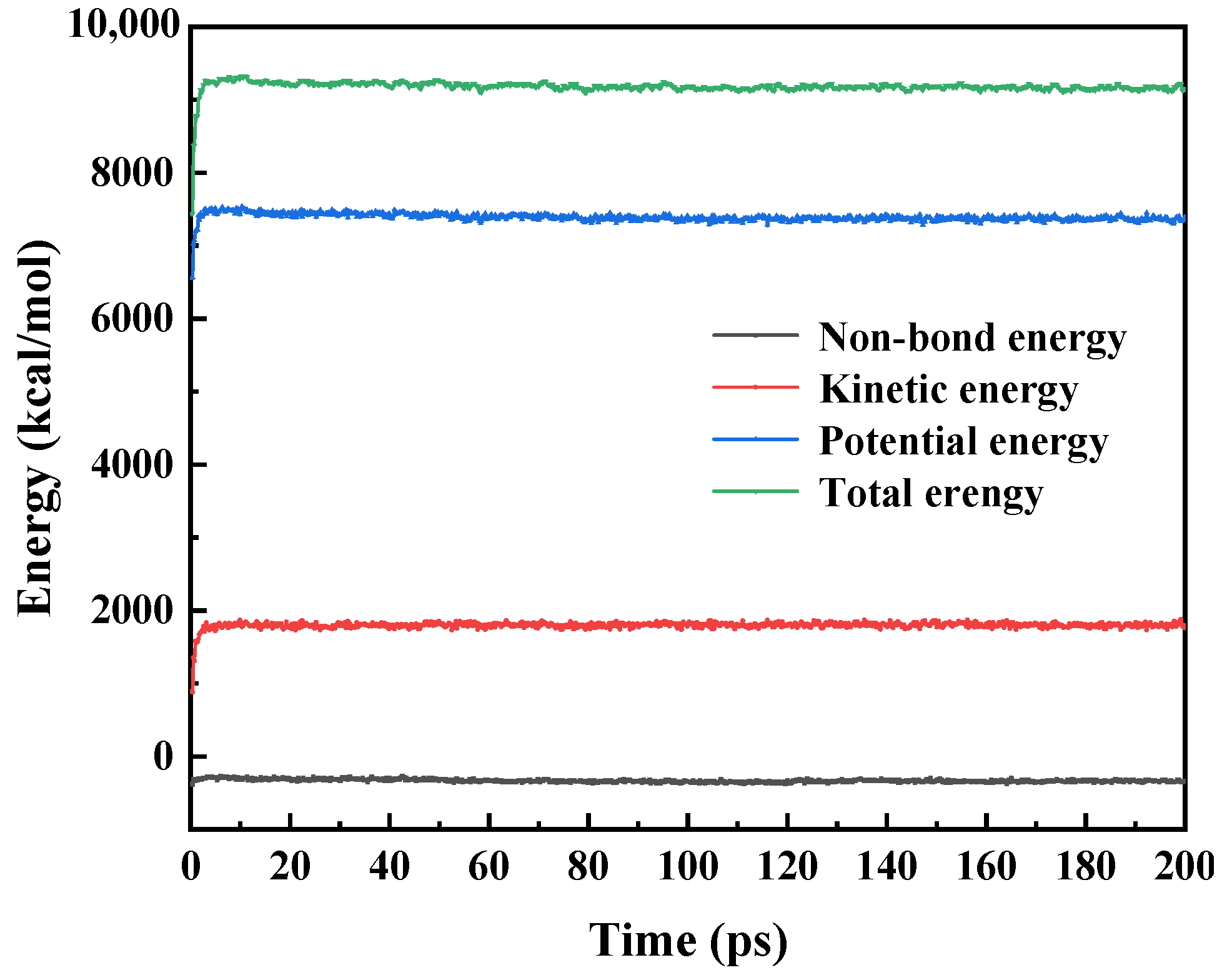

2.2. Details of MD Simulation

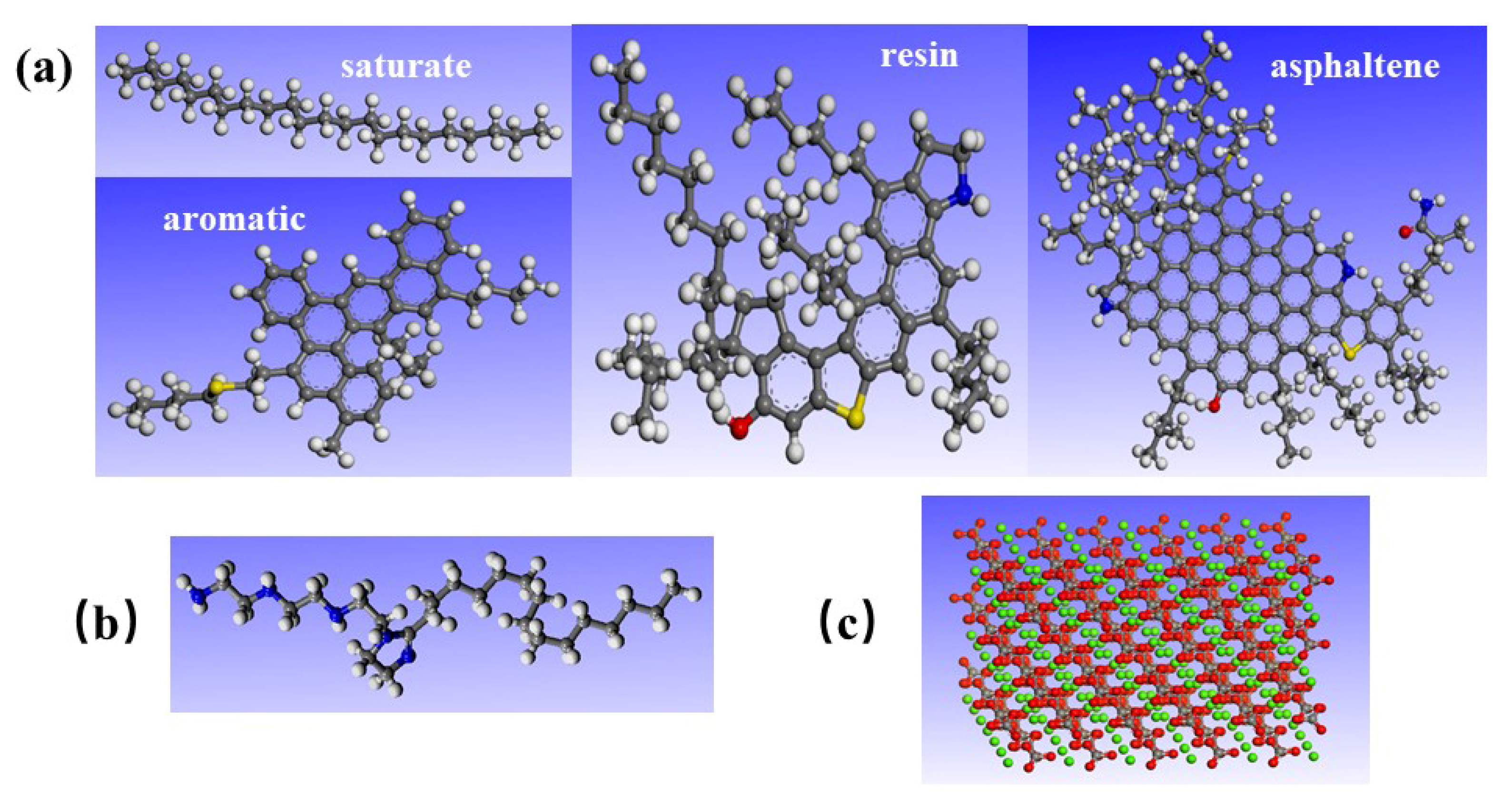

2.2.1. Construction of Asphalt Lubricating Film Cell

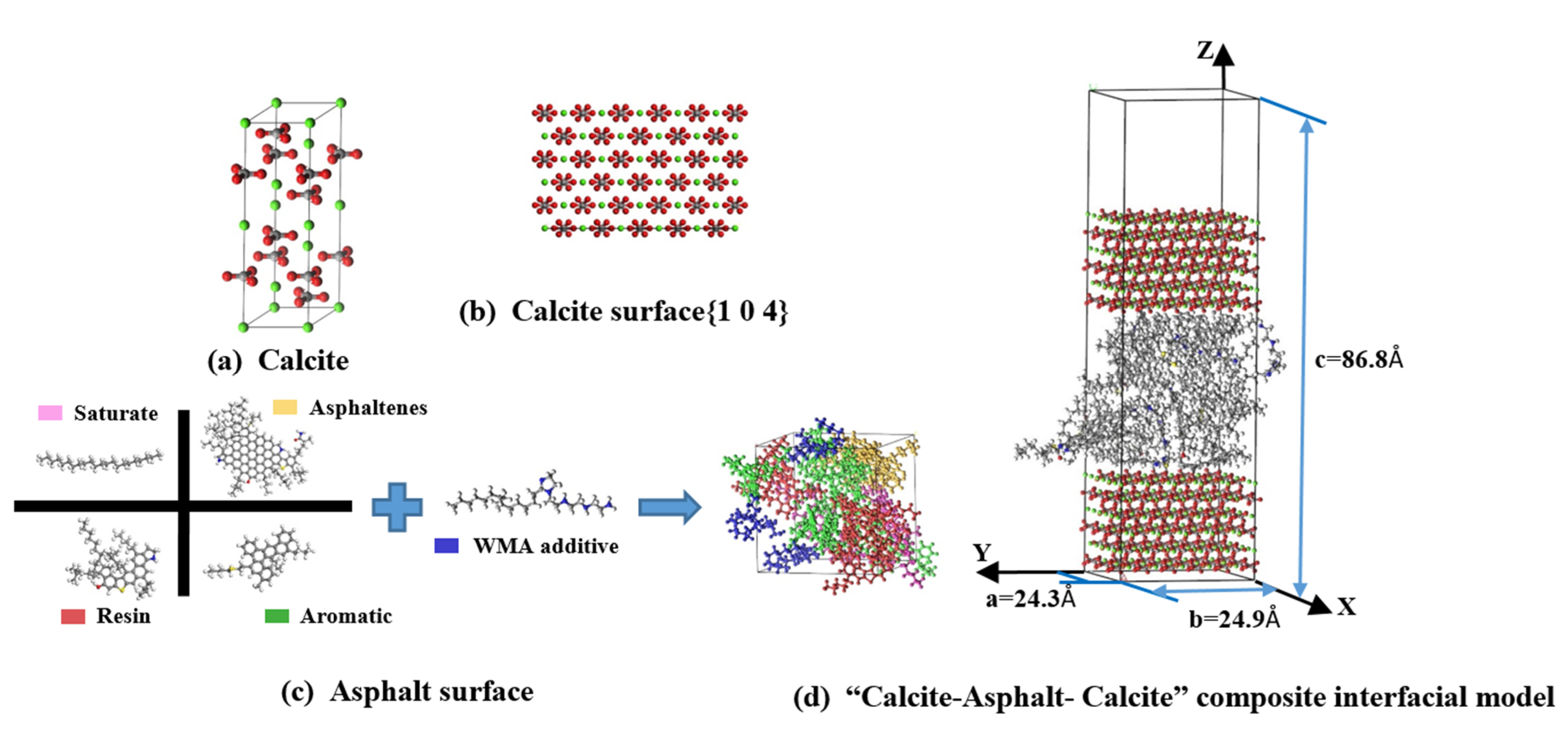

2.2.2. Construction of Calcite Cell

2.2.3. Construction of Shear Simulation Model of “Stone–Asphalt–Stone”

2.2.4. Simulation Process of Shear Molecular

3. Results and Discussion

3.1. Effect of Shear Rate

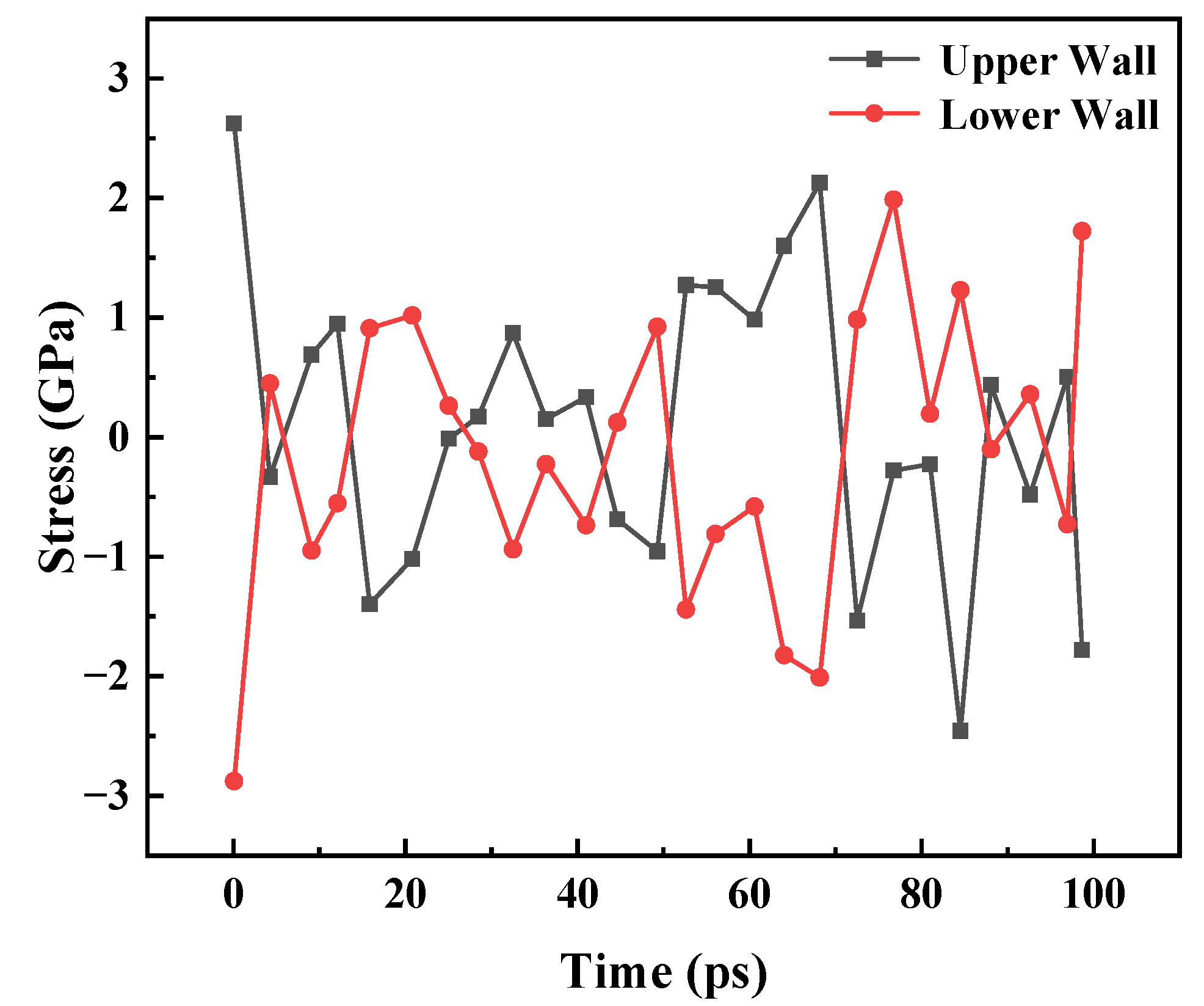

3.1.1. Variation Rule of Shear Stress

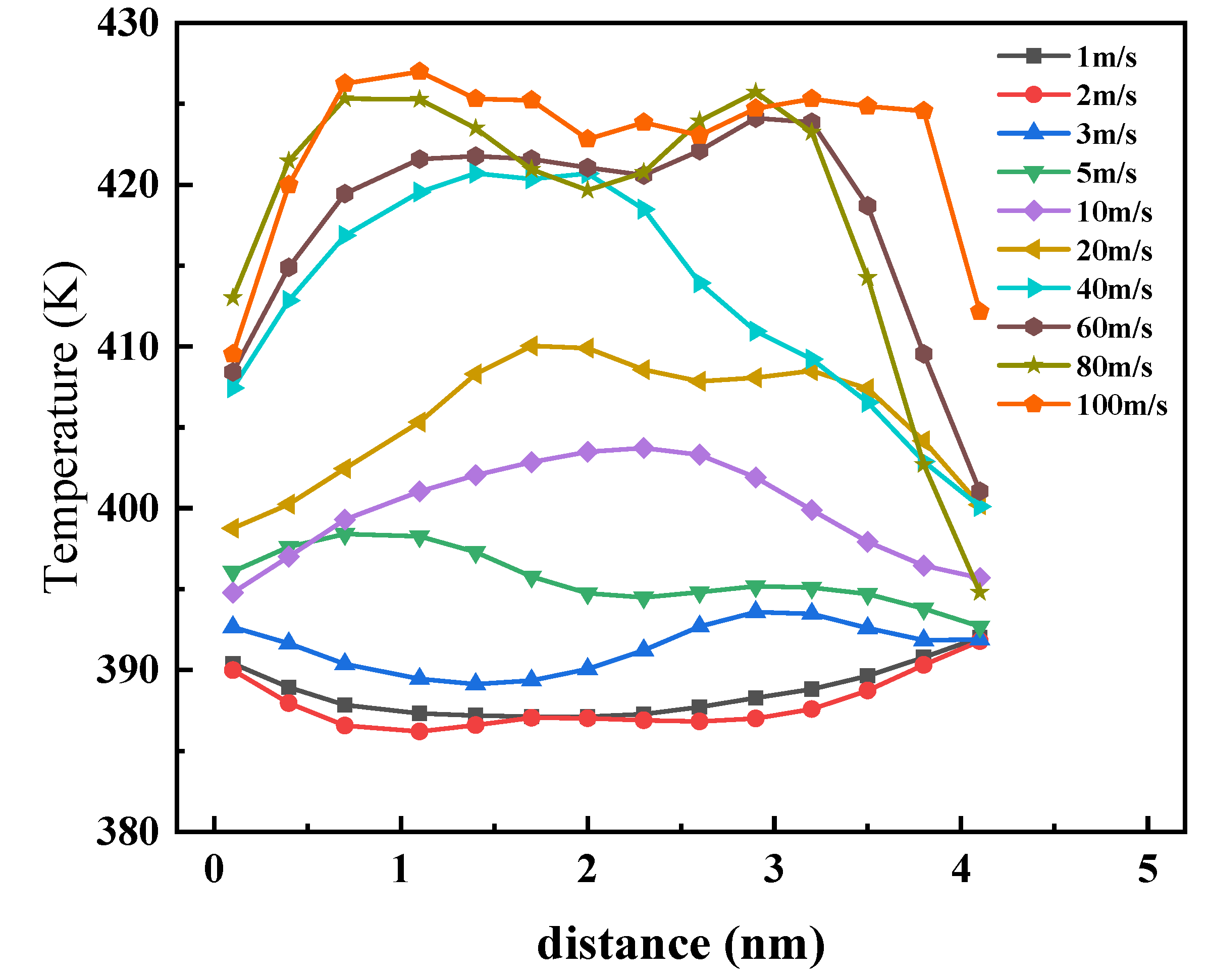

3.1.2. Influence of Shear Rate on Temperature Distribution in Asphalt Lubricating Film

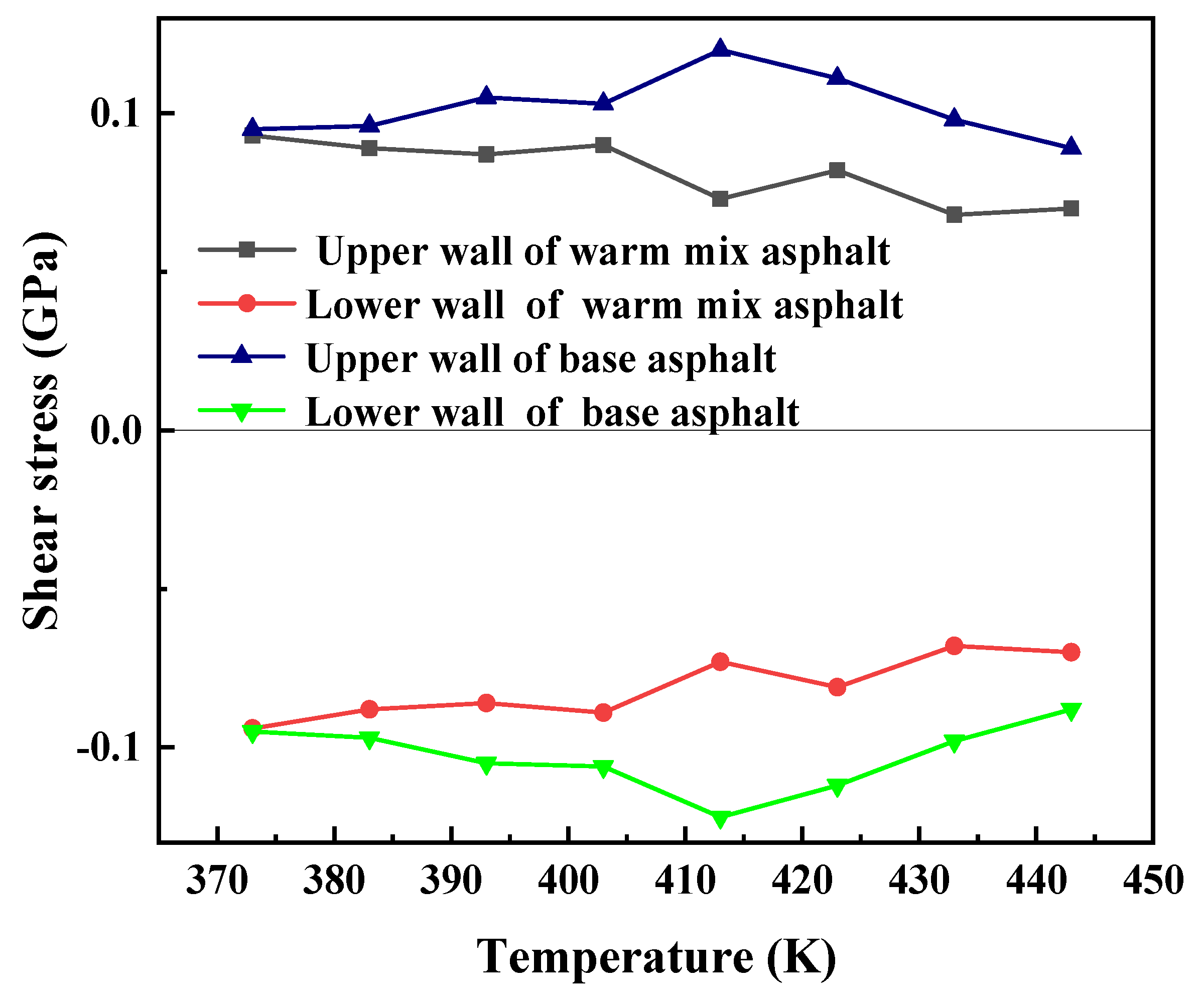

3.2. Effect of System Temperature on Shear Stress

3.3. Effects of WMA Additives

3.3.1. Effect of WMA Additive on Shear Stress of Friction System

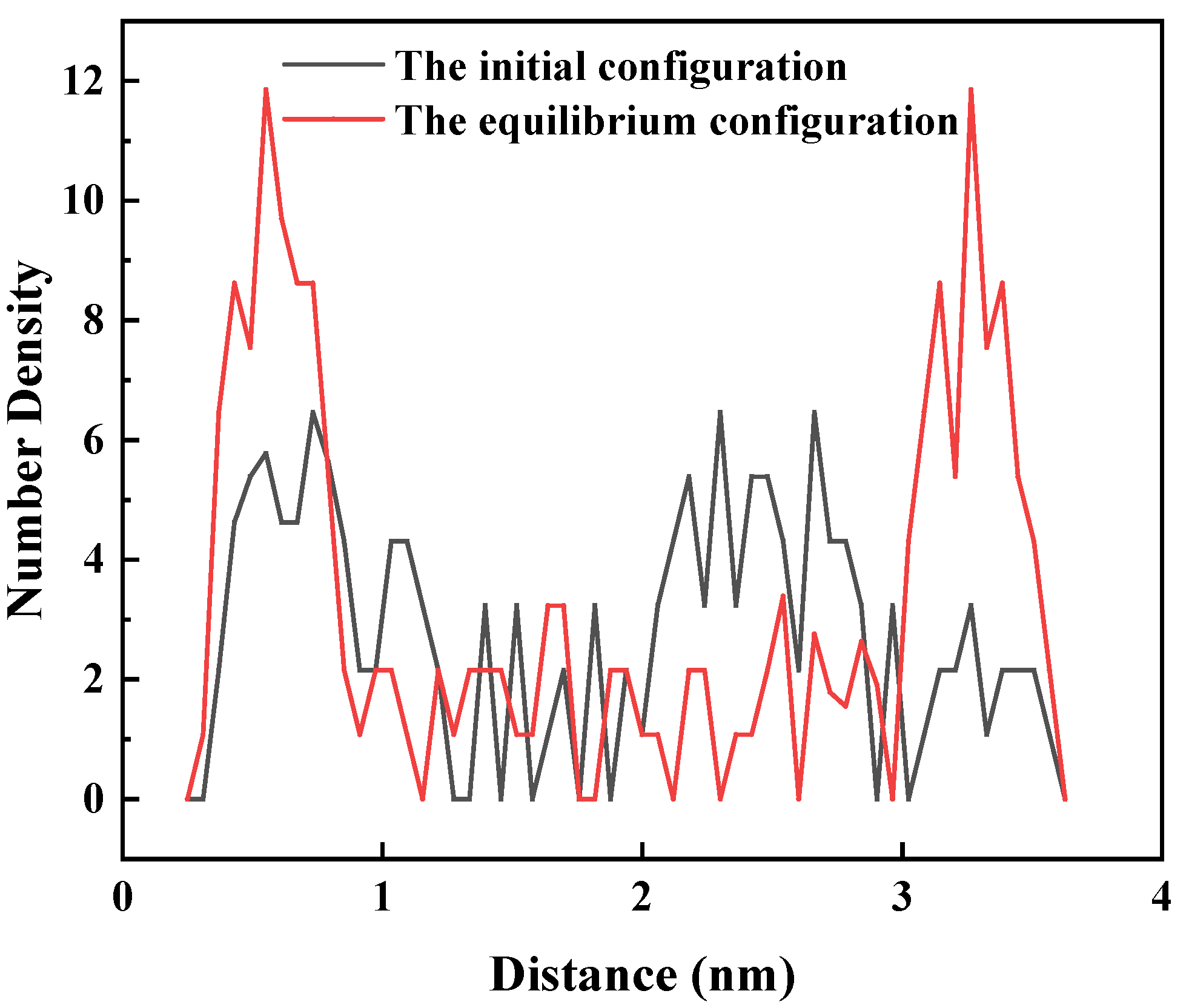

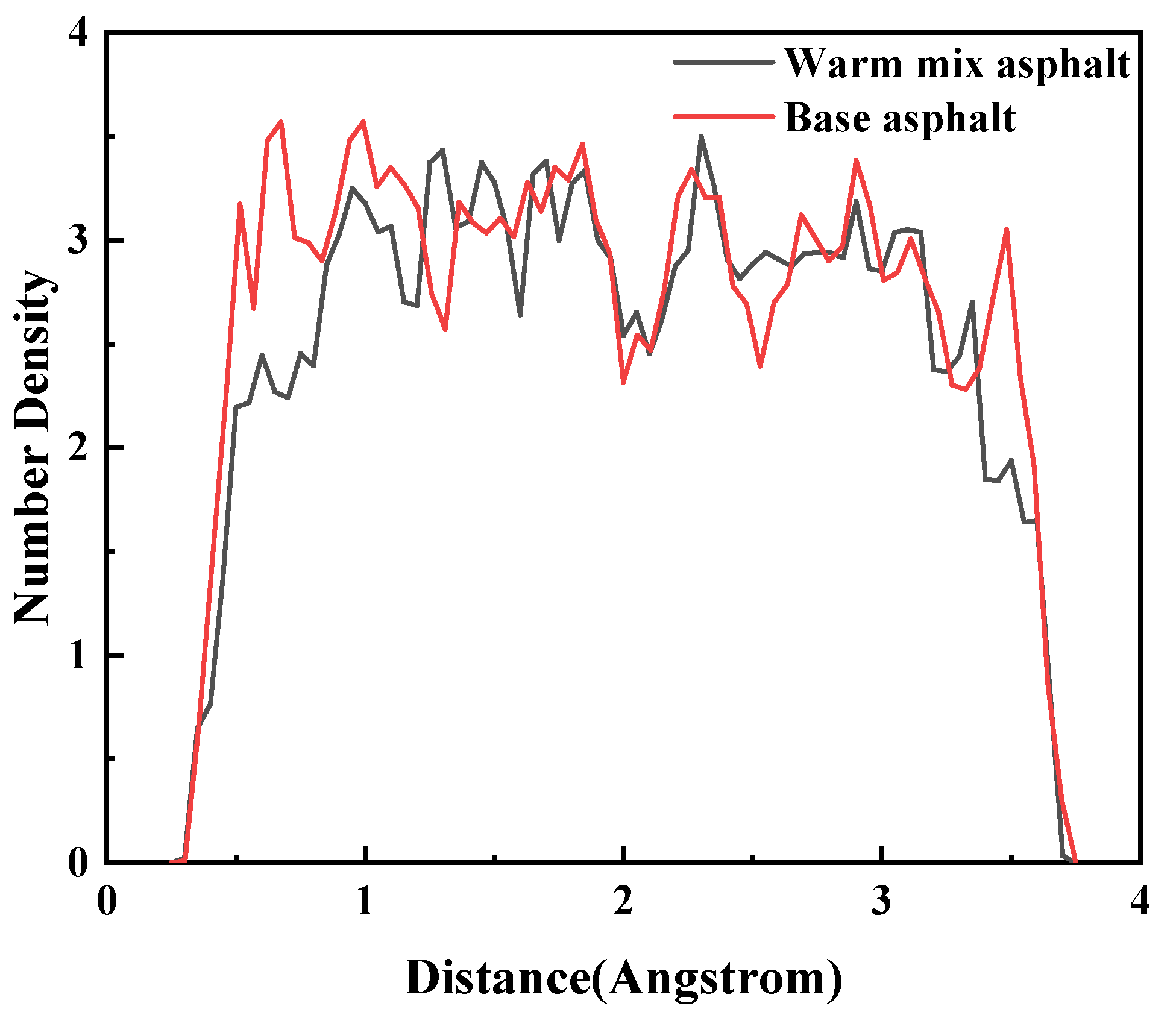

3.3.2. Density Distribution of IMDL WMA Additive Molecules between Frictional Surfaces

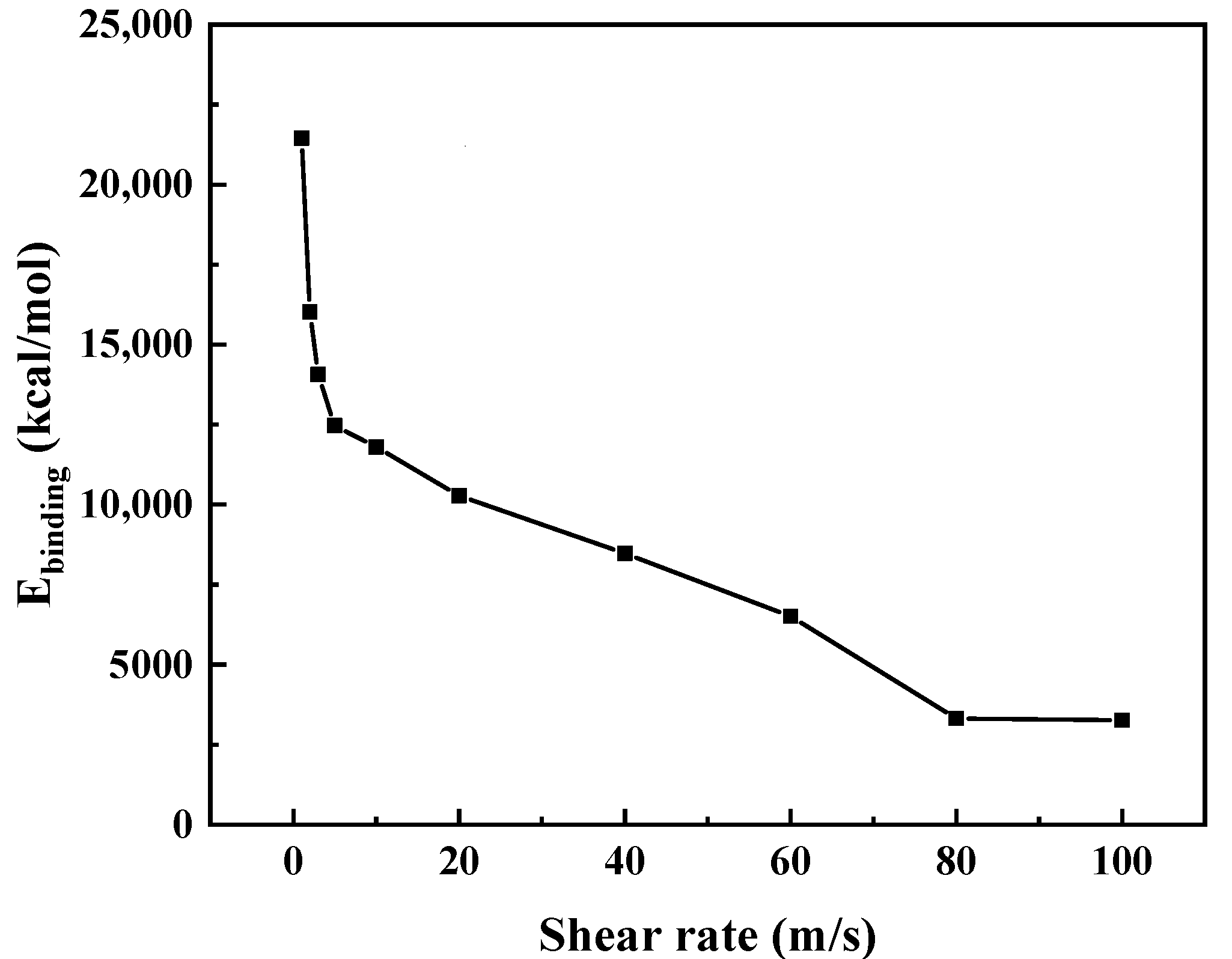

3.3.3. Adsorption Energy of Asphalt Lubrication Film on Friction Surface

4. Conclusions

- (1)

- In the friction system of warm mix asphalt and base asphalt, the shear stress changes differently with the increase of shear rate. The WMA lubricating film remains stable when the shear rate is in the range of 10–40 m/s, which means the shear stress of the warm mixed asphalt lubricating film is less affected by the shear rate and changes slowly. However, when the shear rate is higher than 40 m/s, the shear stress rises linearly with the increase of the shear rate. In the friction system of base asphalt lubricating film, the shear stress decreases first and then increases with the increment of shear rate. When the shear rate reaches 5 m/s, the lubricating film is in the most stable state with minimum friction force and shear stress.

- (2)

- The increment of shear rate leads to the increase of temperature in the lubricating film of WMA. When the shear rate is less than 5 m/s, the internal temperature of the lubricating film hardly changes without obvious regularity because of the small amount of friction force and the heat generated in the friction process. When the shear rate is in the range of 10–40 m/s, the temperature of the lubricating film increases gradually from the adsorption interface to the interior and reaches the maximum at the center of the film. When the shear rate is higher than 40 m/s, the temperature of the lubricating film rises sharply as a large amount of heat is generated during the friction process.

- (3)

- With the increase of temperature, the shear stress of the lubricating film of WMA shows a decreasing trend, while the shear stress of the lubricating film of base asphalt shows a trend of first increasing and then decreasing with maximum shear stress at 413 K, which indicates that the compactability of the mixture does not improve linearly with the increase of temperature. In addition, system temperature exerts little impact on shear stress, which is not the main factor affecting the adsorption lubrication of WMA.

- (4)

- The addition of IMDL WMA additive can effectively improve the lubricity of asphalt and stability of asphalt film by reducing the shear stress of asphalt lubricating film. After the friction system is balanced, the IMDL WMA additive molecules are mainly distributed at the friction interface and preferentially adsorbed on the stone surface to form a lubricating film. Besides, the adsorption energy of the WMA lubricating film on the stone surface decreases with the increase of the shear rate, which indicates that the higher the shear rate is, the more unfavorable it is for the WMA lubricating film to be wrapped on the stone surface, or even to rupture, such that the lubrication effect of the WMA lubricating film on the friction surface is weakened.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WMA | warm mix asphalt |

| MD | molecular dynamics |

| IMDL WMA | imidazoline type surfactant WMA |

| HMA | hot mix asphalt |

| RAP | recycled asphalt pavement |

| DSR | dynamic shear rheometer |

| ASTM | American Society for Testing and Materials |

| CSD | Cambridge Structural Database |

| LEED | low energy electron diffraction |

| XPS | X-ray photoelectron spectroscopy |

| SEM | scanning electron microscopy |

| XRD | X-ray diffraction |

| AFM | atomic force microscopy |

| NPT | isobaric-isothermal ensemble |

| NVT | canonical ensemble |

References

- Ingrassia, L.P.; Lu, X.H.; Canestrari, F.; Ferrotti, G. Tribological characterization of bituminous binders with Warm Mix Asphalt additives. Constr. Build. Mater. 2018, 172, 309–318. [Google Scholar] [CrossRef]

- Shi, J.T.; Fan, W.Y.; Wang, T.H.; Zhao, P.H.; Che, F. Evaluation of the physical performance and working mechanism of asphalt containing a surfactant warm mix additive. Adv. Mater. Sci. Eng. 2020, 2020, 8860466. [Google Scholar] [CrossRef]

- Shi, J.T.; Fan, W.Y.; Lin, Y.; Zhao, P.H.; Ouyang, J. Effects of surfactant warm-mix additives on the rheological properties of high-viscosity asphalt. Adv. Mater. Sci. Eng. 2020, 2020, 6506938. [Google Scholar] [CrossRef]

- Rodrigues, Y.O.; Costa, D.B.; de Figueirêdo Lopes Lucena, L.C.; Lopes, M.C. Performance of warm mix asphalt containing Moringa oleifera Lam seeds oil: Rheological and mechanical properties. Constr. Build. Mater. 2017, 154, 137–143. [Google Scholar] [CrossRef]

- Zelelew, H.; Paugh, C.; Corrigan, M.; Belagutti, S.; Ramakrishnareddy, J. Laboratory evaluation of the mechanical properties of plant-produced warm-mix asphalt mixtures. Road Mater. Pavement Des. 2013, 14, 49–70. [Google Scholar] [CrossRef]

- Li, X.S.; Xie, Z.X.; Fan, W.Z.; Wang, L.; Shen, J.N. Selecting warm mix asphalt additives by the properties of warm mix asphalt mixtures—China experience. Balt. J. Road Bridge Eng. 2015, 10, 79–88. [Google Scholar] [CrossRef]

- Liu, J.; Yan, K.; You, L.; Ge, D.; Wang, Z. Laboratory performance of warm mix asphalt binder containing polyphosphoric acid. Constr. Build. Mater. 2016, 106, 218–227. [Google Scholar] [CrossRef]

- Wang, H.P.; Liu, X.; Apostolidis, P.; Scarpas, T. Review of warm mix rubberized asphalt concrete: Towards a sustainable paving technology. J. Clean. Prod. 2018, 177, 302–314. [Google Scholar] [CrossRef]

- Zaumanis, M.; Olesen, E.; Haritonovs, V.; Brencis, G.; Smirnovs, J. Laboratory evaluation of organic and chemical warm mix asphalt technologies for SMA asphalt. Balt. J. Road Bridge Eng. 2012, 7, 191–197. [Google Scholar] [CrossRef]

- Mohd Hasan, M.R.; You, Z.; Yang, X.; Heiden, P.A. Quantification of physicochemical properties, activation energy, and temperature susceptibility of foamed asphalt binders. Constr. Build. Mater. 2017, 153, 557–568. [Google Scholar] [CrossRef]

- Jun Yoo, P.; Sik Eom, B.; Soo Park, K.; Hun Kim, D. Aggregate pre-coating approach using rubber- and silane-coupled thermoset polymer and emulsion for warm-mix asphalt mixtures. Constr. Build. Mater. 2017, 152, 708–714. [Google Scholar] [CrossRef]

- Zhang, Y.; Leng, Z.; Zou, F.L.; Wang, L.; Chen, S.S.; Tsang, D.C.W. Synthesis of zeolite A using sewage sludge ash for application in warm mix asphalt. J. Clean. Prod. 2018, 172, 686–695. [Google Scholar] [CrossRef]

- Tang, N.; Deng, Z.X.; Dai, J.G.; Yang, K.K.; Chen, C.Y.; Wang, Q. Geopolymer as an additive of warm mix asphalt: Preparation and properties. J. Clean. Prod. 2018, 192, 906–915. [Google Scholar] [CrossRef]

- Behnood, A. A review of the warm mix asphalt (WMA) technologies: Effects on thermo-mechanical and rheological properties. J. Clean. Prod. 2020, 259, 120817. [Google Scholar] [CrossRef]

- Guo, M.; Liu, H.Q.; Jiao, Y.B.; Mo, L.T.; Tan, Y.Q.; Wang, D.W.; Liang, M.C. Effect of WMA-RAP technology on pavement performance of asphalt mixture: A state-of-the-art review. J. Clean. Prod. 2020, 266, 121704. [Google Scholar] [CrossRef]

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm mix asphalt: An overview. J. Clean. Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Zhang, S.W.; Wang, D.Y.; Guo, F.; Deng, Y.H.; Feng, F.M.; Wu, Q.Y.; Chen, Z.J.; Li, Y.B. Properties investigation of the SBS modified asphalt with a compound warm mix asphalt (WMA) fashion using the chemical additive and foaming procedure. J. Clean. Prod. 2021, 319, 128789. [Google Scholar] [CrossRef]

- Hanz, A.J.; Faheem, A.; Mahmoud, E.; Bahia, H.U. Measuring effects of warm-mix additives: Use of newly developed asphalt binder lubricity test for the dynamic shear rheometer. Transp. Res. Rec. 2010, 2180, 85–92. [Google Scholar] [CrossRef]

- Zhao, P.H.; Ren, R.B.; Zhou, H.; Ouyang, J.; Li, Z.G.; Sun, D.C. Preparation and properties of imidazoline surfactant as additive for warm mix asphalt. Constr. Build. Mater. 2021, 273, 121692. [Google Scholar] [CrossRef]

- Hanz, A.J.; Bahia, H.U. Asphalt binder contribution to mixture workability and application of asphalt lubricity test to estimate compactability temperatures for warm-mix asphalt. Transp. Res. Rec. 2013, 2371, 87–95. [Google Scholar] [CrossRef]

- Canestrari, F.; Ingrassia, L.P.; Ferrotti, G.; Lu, X.H. State of the art of tribological tests for bituminous binders. Constr. Build. Mater. 2017, 157, 718–728. [Google Scholar] [CrossRef]

- Bairgi, B.K.; Mannan, U.A.; Tarefder, R.A. Influence of foaming on tribological and rheological characteristics of foamed asphalt. Constr. Build. Mater. 2019, 205, 186–195. [Google Scholar] [CrossRef]

- Gallego, R.; Cidade, T.; Sanchez, R.; Valencia, C.; Franco, J.M. Tribological behaviour of novel chemically modified biopolymer-thickened lubricating greases investigated in a steel-steel rotating ball-on-three plates tribology cell. Tribol. Int. 2016, 94, 652–660. [Google Scholar] [CrossRef]

- Mannan, U.A.; Tarefder, R.A. Tribological and rheological characterisation of asphalt binders at different temperatures. Road Mater. Pavement Des. 2018, 19, 445–452. [Google Scholar] [CrossRef]

- Maru, M.M.; Trommer, R.M.; Almeida, F.A.; Silva, R.F.; Achete, C.A. Assessment of the lubricant behaviour of biodiesel fuels using Stribeck curves. Fuel Process. Technol 2013, 116, 130–134. [Google Scholar] [CrossRef]

- Puchalski, S. Investigation of Warm Mix Asphalt Additives Using the Science of Tribology to Explain Improvements in Mixture Compaction; A dissertation submitted in partial fulfillment of the requirement for the degree of Master of Science; College of Engineering, University of Wisconsin-Madison: Madison, WI, USA, 2012. [Google Scholar]

- Luo, H.; Fan, W.Y.; Li, Y.; Zhao, P.H.; Nan, G.Z. Effects of fatty acids on low-sulfur diesel lubricity: Experimental investigation, DFT calculation and MD simulation. China Pet. Process. Petrochem. Technol. 2013, 15, 74–81. [Google Scholar] [CrossRef]

- Chen, T.T.; Mei, D.Q.; Ren, W.Y.; Wang, H.Q.; Yuan, Y.N.; Guo, R. Adsorption of esters contained fuel on the Fe surface: A molecular dynamics study. Acta Pet. Sin. (Pet. Process. Sec.) 2019, 35, 714–720. [Google Scholar] [CrossRef]

- Chen, C.S.; Cian, H.J.; Yu, C.H.; Huang, C.W. Friction coefficient calculation and mechanism analysis for MoS2 nanoparticle from molecular dynamics simulation. Procedia Eng. 2014, 79, 617–621. [Google Scholar] [CrossRef][Green Version]

- Godlevskii, V.A.; Fomichev, D.S.; Shilov, M.A.; Berezina, E.V.; Kuznetsov, S.A. Use of a computer molecular simulation to describe lubricating layer structure. J. Frict. Wear. 2009, 30, 7–11. [Google Scholar] [CrossRef]

- Gao, Y.M.; Zhang, Y.Q.; Yang, Y.; Zhang, J.H.; Gu, F. Molecular dynamics investigation of interfacial adhesion between oxidised bitumen and mineral surfaces. Appl. Surf. Sci. 2019, 479, 449–462. [Google Scholar] [CrossRef]

- Xu, G.X.; Wang, H. Study of cohesion and adhesion properties of asphalt concrete with molecular dynamics simulation. Comp. Mater. Sci. 2016, 112, 161–169. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, H.L.; Gao, Y.; Wang, L. Study of diffusion characteristics of asphalt–aggregate interface with molecular dynamics simulation. Int. J. Pavement Eng. 2021, 22, 319–330. [Google Scholar] [CrossRef]

- Chu, L.; Luo, L.; Fwa, T.F. Effects of aggregate mineral surface anisotropy on asphalt-aggregate interfacial bonding using molecular dynamics (MD) simulation. Constr. Build. Mater. 2019, 225, 1–12. [Google Scholar] [CrossRef]

- Guo, M.; Tan, Y.Q.; Bhasin, A.; Wei, J.M.; Hou, Y. Using molecular dynamics to investigate interfacial adhesion between asphalt binder and mineral aggregate. In Proceedings of the The 4th Chinese–European Workshop on Functional Pavement Design (CEW 2016), Guangzhou, China, 24 June 2016. [Google Scholar]

- Cooper, T.G.; De Leeuw, N.H. A Computer modeling study of the competitive adsorption of water and organic surfactants at surfaces of the mineral scheelite. Langmuir 2004, 20, 3984. [Google Scholar] [CrossRef] [PubMed]

- De Leeuw, N.H.; Parker, S.C. Surface structure and morphology of calcium carbonate polymorphs calcite, aragonite, and vaterite: An atomistic approach. J. Phys. Chem. B 1998, 102, 2914–2922. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, P.; Dong, M.; Yang, Y.; Shi, J.; Wang, J.; Wu, W.; Zhao, X.; Zhou, X.; Wang, C. Research on the Mechanism of Surfactant Warm Mix Asphalt Additive-Based on Molecular Dynamics Simulation. Coatings 2021, 11, 1303. https://doi.org/10.3390/coatings11111303

Zhao P, Dong M, Yang Y, Shi J, Wang J, Wu W, Zhao X, Zhou X, Wang C. Research on the Mechanism of Surfactant Warm Mix Asphalt Additive-Based on Molecular Dynamics Simulation. Coatings. 2021; 11(11):1303. https://doi.org/10.3390/coatings11111303

Chicago/Turabian StyleZhao, Pinhui, Mingliang Dong, Yansheng Yang, Jingtao Shi, Junjie Wang, Wenxin Wu, Xingchi Zhao, Xu Zhou, and Chenlong Wang. 2021. "Research on the Mechanism of Surfactant Warm Mix Asphalt Additive-Based on Molecular Dynamics Simulation" Coatings 11, no. 11: 1303. https://doi.org/10.3390/coatings11111303

APA StyleZhao, P., Dong, M., Yang, Y., Shi, J., Wang, J., Wu, W., Zhao, X., Zhou, X., & Wang, C. (2021). Research on the Mechanism of Surfactant Warm Mix Asphalt Additive-Based on Molecular Dynamics Simulation. Coatings, 11(11), 1303. https://doi.org/10.3390/coatings11111303