Abstract

The use of advanced sensing devices for concrete and reinforced concrete structures (RCS) is considered a rational approach for the assessment of repair options and scheduling of inspection and maintenance strategies. The immediate benefits are cost reduction and a reliable prevention of unpredictable events. The use of optical fiber sensors (OFS) for such purposes has increased considerably in the last few years due to their intrinsic advantages. In most of the OFS, the chemical transducer consists of immobilized chemical reagents placed in the sensing region of the optical sensor by direct deposition or by encapsulation in a polymeric matrix. The choice of the support matrix impacts directly on the performance of the OFS. In the last two decades, the development of OFS functionalized with organic–inorganic hybrid (OIH) sol–gel membranes have been reported. Sol–gel route is considered a simple method that offers several advantages when compared to traditional synthesis processes, allowing to obtain versatile materials with unique chemical and physical properties, and is particularly valuable in the design of OIH materials. This review will provide an update of the current state-of-the-art of the OFS based on OIH sol-gel materials for concrete and RCS since 2016 until mid-2021. The main achievements in the synthesis of OIH membranes for deposition on OFS will be discussed. The challenges and future directions in this field will also be considered, as well as the main limitations of OFS for RCS monitoring.

1. Introduction

Concrete degradation is a complex process that results from physical and chemical reactions between concrete components and their surrounding environment. The corrosion of steel in reinforced concrete structures (RCS) has been widely studied and reported by several authors [1,2,3,4,5,6,7], since its premature degradation often results in expensive costs of repair, maintenance, and rehabilitation. To mitigate corrosion in RCS and improve their service life, different approaches—destructive and non-destructive methods—have been developed with the aim of monitoring both existing and new structures. Destructive methods provide information about the corrosion process [3,8]. Nevertheless, some constraints exist due to the heterogeneity of RCS and to the fact that the structures are limited to sampling [3]. On the other hand, the non-destructive methods (NDM) provide fast and real-time information about the entire structure. NDM enable the detection of the corrosion state of steel in concrete and the main causes of the reinforcement corrosion [3] as they allow to check active cracks, determine moisture ingress [9], the strength gain [10], as well as the chloride ions (Cl−) ingress [11].

The steel reinforcement in concrete is naturally protected by the high alkalinity of the concrete (pH > 12.5) that promotes the formation of a passive film on its surface during the curing process. This oxide layer can be influenced by the steel substrate, as well as the external environment [12]. In 2016, Alhozaimy et al. [13] studied the consequences of changing the oxygen concentrations on the quality of the passive films formed on the surface of steel rebars in RCS. It was shown that to develop a strong and stable passivation layer, which in turn would lead to low corrosion rates, a suitable amount of oxygen in the surrounding environment of the rebar and the concrete specimen must be present during the initial curing period. To prove that the authors left the specimens unsealed in the laboratory under ambient conditions, with free oxygen supply, completely sealed concrete specimens with no oxygen available were considered for comparison purposes and developed a weak passive layer, exhibiting higher corrosion rates [13].

Generally, in aggressive environments such as marine and industrial, a decrease in structural durability occurs. Concrete carbonation and aggressive species, such as Cl−, induce the corrosion process by destroying the passive layer on the steel surface [14]. The carbonation process results from the reactions between atmospheric CO2 and alkaline components of concrete. During concrete carbonation, the initial pH values may decrease to values between 6–9. The pH of concrete is influenced by the CO2 and depends on the humidity and the temperature that, in specific conditions, may accelerate the entire process. Cl− can penetrate the passive layer and when they exceed the chloride threshold value (CTV), the steel depassivation process begins, leading to the corrosion of reinforcing bars [4,14]. In 2007, Song et al. [14] determined this critical value to be equal to 1.2 kg m-3. Additionally, they also assumed that by the time the Cl− content reached 2.4 kg m−3, the passive film no longer existed.

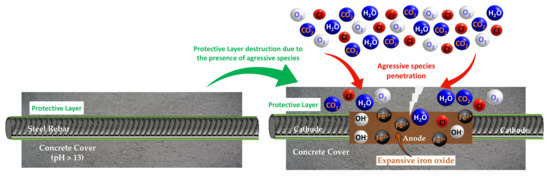

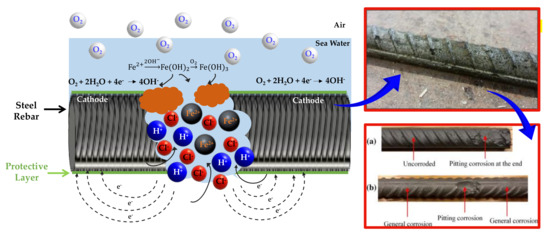

The products resulting from the corrosion of reinforcement in concrete—expansive oxides—occupy a higher volume than the initial uncorroded rebar, as shown in Figure 1. These oxides promote the formation of expansive forces in concrete and, as a consequence, induce cracking and with time to concrete detachment [3]. The evolution of the corrosion process associated with a decrease in strength and ductility of reinforcement, in extreme cases, may lead to the collapse of the structures.

Figure 1.

Electrochemical corrosion process on the concrete surface [7].

Concrete corrosion is an electrochemical process on the steel surface, based on two reactions—anodic (Equation (1)) and cathodic (Equation (2))—that take place in different locals of the rebar.

2Fe → 2Fe2+ + 4e− Anodic Reaction

O2 + 2H2O + 4e−→ 4OH− Cathodic Reaction

2Fe + 2H2O + O2 → 2Fe (OH)2 Global Reaction

To minimize or avoid corrosion of the concrete reinforcement, a suitable monitoring system is required. Optical fiber sensors (OFS) have proven to be an interesting and promising alternative in comparison with the conventional electrochemical ones. The main advantages of OFS are the robustness, small size, immunity to electromagnetic interference, high sensitivity, and resistivity to corrosion [15,16]. The development of functionalized OFS coupled to organic–inorganic hybrid materials (OIH) has shown promising and very interesting properties [17,18].

OIH are a new generation of multifunctional materials with a broad spectrum of useful properties and a diversity of applications [19]. They have several advantages, since they are chemically inert and resistant to thermal, photochemical, and biodegradation [20]. Moreover, OIH materials enable the incorporation of different components that introduce complementary functions to the material such as UV protection [21], anti-reflection [22], moisture resistance [23,24], corrosion inhibition [25], and adhesion protection [26]. Sol–gel is one of the most effective synthetic methods to produce OIH materials using organic solvents at mild temperatures [19,27]. It is also recognized as green, low-cost, and a versatile route [28]. Therefore, it is the main technology implemented for the synthesis of OIHs. The precursors and the synthesis conditions can be tuned, allowing to obtain a product with suitable physicochemical properties according to the required application. Additionally, sol-gel method is a versatile process that enables to adjust the porosity of the OIH matrix allowing the incorporation of sensitive species, such as chemosensors, into the OIH matrix [29]. The versatility of the sol-gel method [28,30,31] allows adjusting and controlling several parameters such as precursors, matrix porosity, curing time, and temperature of the OIH, making them a supporting membrane with suitable and interesting properties and the ability to host species for a given analyte [18,19,29].

Chemosensors are organic receptor molecules that selectively interact with a specific analyte, providing chemical information through the generation of detectable signals. Chemosensors use molecular recognition mechanism for recognition of an analyte, allowing the occurrence of the signal transduction. The signal produced may be based on the principles of fluorescence [32] or absorbance [33]. These types of molecules add to the OIH membrane’s extra optical and electrical properties. In this context, it is easy to comprehend that these new OIH materials show auspicious properties for application as supporting films in optical sensors area, such as fiber sensor devices. OFS based on OIH materials doped with chemosensors are a promising alternative due to the high selectivity of these molecules combined with the accuracy of the optical sensors [18]. These molecules may be introduced within the OIH matrices after polymerization, allowing obtaining OIH membranes with tuned functions.

This review is focused on the main achievements in the synthesis of OIH membranes for deposition on OFS. The OFS based on OIH sol-gel membranes for pH, Cl−, and moisture monitoring in concrete developed in the last years i.e., since 2016 until mid-2021, will be reviewed. The challenges and future directions in this field will also be debated, as well as the main limitations of OFS for RCS monitoring.

2. Optical Fiber Sensors (OFS)

2.1. Fundamentals

The first patents focused on the preparation and application of OFS appeared in the 1960s [1]. Since then, the developments in this particular area have been quite noteworthy [2,3,4,5,6]. The progress achieved is mainly related to the use of optical fibers by the telecommunications companies whose investigation and development made it possible to manufacture high quality fibers with a low production cost [1]. The widespread use of these type of sensors is also due their advantages, namely, the low installation costs, robustness, immunity to electromagnetic interferences, chemical inertia, thermal resistance, and wide bandwidth [1].

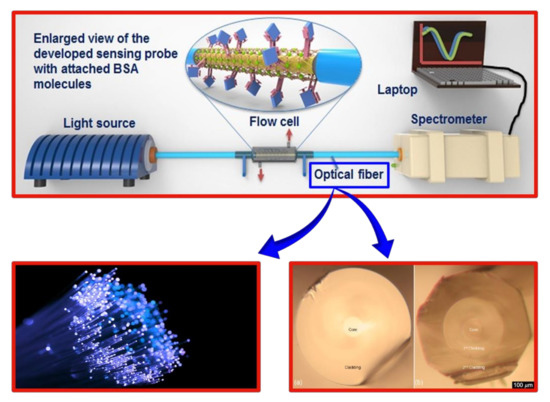

Generically, a device based on an OFS has a source, a modulator, a detector, and an electronic processing unit that makes the conversion of an optical signal in an electric one [7]. Figure 2 shows a schematic layout of an OFS.

Figure 2.

Layout of an OFS. Right side shows microscopic cross-section images of the double-coated optical fibers. (a) in the passive fiber the transition from the inner to the outer cladding occurs at a lower RI; (b) octagonal cross section of the second cladding of the active doped fiber [8,9].

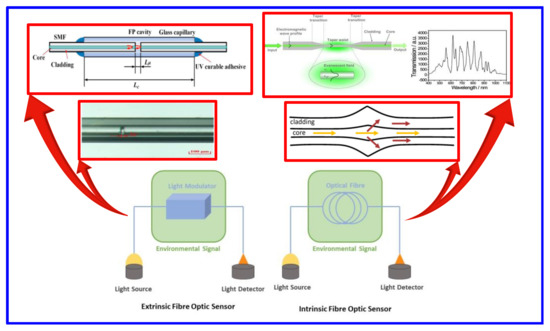

Generically, OFS may be classified in two main classes, namely the intrinsic and extrinsic ones. In an extrinsic sensor, the fiber itself is used as a mean of transportation of light from the source to the detector and the modulation of the signal occurs outside the fiber (Figure 3) [10]. In an intrinsic one, the light is also transported from the source to the detector through the fiber, however the modulation of the signal occurs inside the fiber (Figure 3) [10]. The conditions of the surrounding environment will cause changes in the physical properties of the fiber which will induce changes in the properties of the transmitted signal, such as reflection and refraction [11,12].

Figure 3.

Typical configurations of chemical OFS. Extrinsic sensors, in which fiber is used to direct light and intrinsic sensors, in which the sensor phase modifies the transmission characteristics of the fiber. The sensor membrane can be placed on the tip of the fiber or to the side; part of the coating can be removed and leave the fiber core exposed to the chemical interaction medium [13,14,15,16].

The development of OFS has expanded in recent years, favoring advances in different areas such as telecommunications [17,18], materials chemistry [19,20], microelectronics [21,22,23], and nanotechnology [24,25,26]. Focusing on the area of chemistry, most of the existing OFS are based on transduction principles such as fluorescence [27,28,29,30] or absorbance [31,32]. In the mentioned cases, the analytical response is achieved by changing the optical properties of a fixed recognition agent on a solid support due to the interaction with the species to be determined.

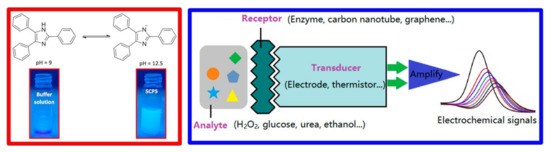

Chemical sensors are generically defined as devices that convert chemical information, in real time, into a measurable analytical signal [33,34]. They contain two basic functional units: a recognition element (receiver) and a transduction mechanism. The receptor can be based on three principles: physical, chemical, or biochemical. The transduction mechanism may be classified as optical, electrochemical, piezoelectric, and thermal [33]. Figure 4 schematizes examples of the aforementioned mechanisms.

Figure 4.

Chemical sensors and respective mechanisms. Right side show the fluorescence of the samples irradiated under 365 nm. Left side show the signal obtained [35,36].

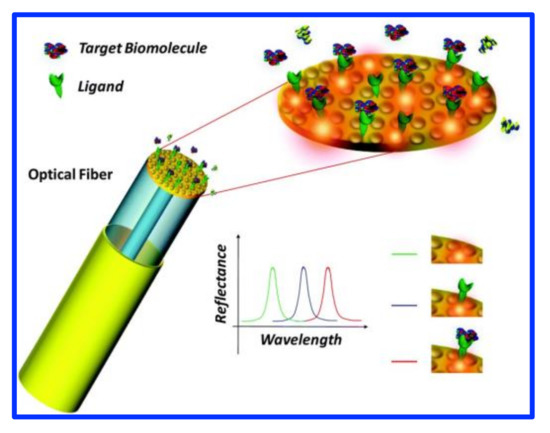

Optical sensors, or optrodes, are chemical sensors where electromagnetic radiation is used to generate analytical signals in the transducer element. They can be based on optical principles such as absorbance, reflectivity, luminosity, and fluorescence (Figure 4), covering different regions of the spectrum (ultraviolet (UV), visible, infrared (IR), near infrared (NIR)), not only to measure light intensity, but also other intensity-related properties such as RI, scattering, diffraction, and polarization. In this type of sensor, an optical fiber is usually incorporated to transmit the electromagnetic radiation to a sensitive area in direct contact with the sample, or directly from the sample [34]. Distal type sensors are the most common ones, where the indicator is fixed at the tip of a simple or forked optical fiber. Alternatively, the chemical sensor can be immobilized along a portion of the optical fiber core, creating an evanescent field sensor. Figure 5 shows the light-matter interaction on the surface of a biosensor. The biosensor consists of a metallic nanostructure supporting a plasmonic resonant mode integrated into the optical fiber [37]. The analyte–receptor molecule binding induces the shift of the maximum reflectance peak to longer wavelengths (right), with no change in intensity.

Figure 5.

Distal type sensors. Adapted with permission from [37] Copyright 2015 © Royal Society of Chemistry.

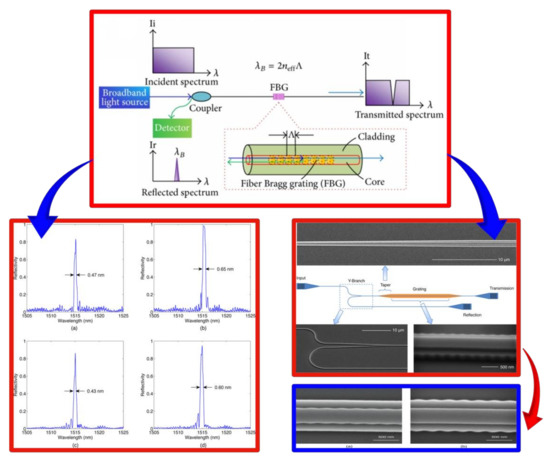

Bragg network sensors are characterized by the periodic modification of the RI of the optical fiber core due to exposure to an intensity pattern produced by ultraviolet (UV) radiation interference [38,39,40,41]. The incident radiation is transmitted and reflected. Fiber Bragg gratings (FBGs) selectively reflect radiation with a certain wavelength, determined by the Bragg condition (Equation (4)) [38,42,43,44,45]. All signals with different Bragg wavelengths are transmitted unchanged [40].

λB is the Bragg wavelength, is the effective refractive index of FBGs, and Λ is the grating period. The Bragg wavelength is sensitive to external disturbances such as temperature and voltage variations [39,46]. When the network is subjected to external disturbances, the period of the network changes and the Bragg wavelength changes linearly [38,39,45]. Therefore, monitoring the deviation of the Bragg allows the determination of parameters of interest such as voltage, temperature, and flux.

FBGs show highly promising alternatives for structural health monitoring (SHM) since it allows to combine intrinsic and OFS features. FBGs have small dimensions, immunity to electromagnetic interference, as well as high linearity, sensitivity, and multiplexing capacity, and may be incorporated into several types of structures including existing and new ones [38,42,47]. Figure 6 shows the layout of FBGs sensor.

Figure 6.

Layout of FBGs sensor. Left: Reflection spectra obtained using Bragg gratings on ridge waveguides (a) and (b) ridge grating, (c) and (d) slab grating.Adapted with permission from [39] Copyright 2015 © Royal Society of Chemistry. Right: The two configurations show similar performance but with a slight difference in bandwidth. SEM images of each of the FBG sensor components with emphasis on the top view ones of Bragg gratings (a) grating on ridge and (b) grating on slab [60].

Commonly, in an optical sensor, the chemical transducer consists of immobilizing chemical reagents placed in the optical sensor zone by direct deposition or encapsulation in a polymer or OIH sol-gel matrix. The choice of polymer support can influence sensor performance, i.e., its selectivity and response time (RT), and is controlled by parameters such as mechanical stability, analyte permeability, and reagent immobilization capacity [34].

Due to its simplicity and versatility, sol–gel technology is widely used in the development of OFS [19,48,49,50,51,52]. In this process, porous thin films doped with different chemical and biochemical species with sensory abilities, for a given analyte, are easily obtained at room temperature, allowing final structures with mechanical and thermal stability and suitable optical properties [34]. The use of OFS was reported in the measurement of several properties such as pressure [53], temperature [54], strain [55], chemical changes [56], humidity [57], pH [58], and others [59].

2.2. Applications

In the past 25 years [59], the development of OFS has been increasing due to the need to implement techniques that allow an evaluation and monitoring in real time several parameters. This need is interesting in a wide range of fields and construction is not an exception, aiming to ensure the integrity of RCS. The use of OFS has proved to be an remarkable alternative due to its intrinsic properties, high sensitivity, and resistance to corrosion [61].

The application of OIH materials in OFS is promising due to the high stability of the matrix, the wide flexibility in sensor specificity, and the control of porosity and surface properties (hydrophilic/hydrophobic balance). The development of OFS functionalized with OIH materials has already been reported for application in several fields, including biomedical [52], civil engineering [28,62,63,64], and environment [48,56,65].

Bhardwaj et al. [66] reported the development of an OFS for pH detection with different indicators, namely bromophenol blue, cresol red, and chlorophenol red, achieving a pH range between 2 and 13. A shift in resonance wavelength towards blue in alkaline solutions (−0.93 nm/pH) and a shift in resonance wavelength towards red in acidic solutions (1.02 nm/pH) were found. Pathak and Singh [67] reported another type of OFS for pH monitoring with three indicators, namely bromothymol blue, cresol red, and chlorophenol red. A pH range between 4 and 13 and a sensitivity of 0.49 dBm/pH was reported. In another field of application, Liu et al. [68], developed a fiber optic pH sensor aiming to detect ammonia in water. The sensor with the thicker silica coating showed higher sensitivity compared to the sensor with the thinner silica coating (0.131 nm/ppm and 0.069 nm/ppm, respectively). However, further refinement of the experimental results allowed the sensor to achieve a sensitivity of 2.47 nm/ppm. Kant et al. [69] reported the development of an OFS for the detection of caffeine integrating reduced graphene oxide nanohybrid membranes on chitosan modified silica membrane. The sensor features a detection limit of 1.994 nM and operates over a concentration range between 0 and 500 nM with a RT of 16 s. Despite the wide spectrum of applications and publications reported, the development of OFS functionalized with OIH materials is still at an early stage.

3. OFS for Durability Monitoring of Concrete and Reinforced Structures

The premature degradation of civil engineering structures such as bridges, tunnels, and dams, in contrast to the estimated lifetime and the high maintenance costs, has led to the need to develop and implement a set of methods to assess the current state of the structures in real time. SHM in concrete has been widely reported by several authors since allows monitoring several structural and environmental parameters by implementing a set of strategies for diagnosis, prevention and early identification of possible factors that induce concrete corrosion namely cracks, deformations, pH, temperature, moisture, and Cl− content [39,70,71,72,73]. Additionally, SHM enables optimizing decision-making to avoid catastrophic failures in civil structures [72].

Monitoring of structures is mainly carried out by piezoelectric [74,75,76], strain [77,78], and OFS sensors [79,80,81,82]. The OFS are based on interferometric principles (Fabry-Perot and MZI) and optical (Bragg Fibers) or stimulated (Brillouin) dispersion principles [83,84].

OFS are promising in new, existing, or repaired concrete structures as they can detect a decrease in performance or the appearance of failures and pathologies [61]. However, they have not yet achieved all the desirable properties. The monitoring and identification of concrete pathologies are a complex process as structures are exposed to a variety of physical (temperature), chemical (pH and Cl− content), and mechanical (cracking and deformation) degradation processes. On the other hand, the heterogeneity of concrete structures makes it necessary to obtain essential information, i.e., the exact location of cracks [70,85,86]. Rossi and Le Maou [87] demonstrated how a crack can cause the breakage of an optical fiber and therefore total elimination of the transmitted signal. Moreover, the incorporation of OFS into concrete structures may result in small cracks (<1 µm), inducing the ingress of moisture or Cl− [72]. The cracks compromise the integrity, permeability, and corrosion resistance of concrete structures [72,88].

OFS have a dual sensitivity to temperature and strain, requiring the separation of the respective parameters. The coating polymer used in optical fibers also absorbs some strain, which may lead to inaccurate structural strain readings [89]. In recent decades, the development of OFS functionalized with OIH sol-gel membranes has proven to be a promising alternative for SHM as it allows the assessment of different parameters, i.e., pH, moisture, and Cl−. However, leaching of the doped species and resistance reduction was observed when applied to fresh concrete [34,50]. Therefore, this type of OFS requires suitable coatings with resistance to the adverse conditions and to the fresh concrete pH [72]. Moreover, the long-term stability of the OFS is conditional, since chemical and mechanical changes in concrete modify the properties of the optical fiber [86].

3.1. OFS for pH Monitoring of Concrete Structures

pH measurement is essential in fields of science, such as chemistry [90], environment [91,92,93], and biomedical [94,95,96,97,98]. The pH of a solution can be determined quickly by using indicator paper or glass electrodes. Both have advantages and disadvantages. The indicator paper only provides an approximate value on the Sorenson scale and not the exact numerical value, while glass electrodes have numerical and accurate values [99,100]. Despite this, glass electrodes may suffer from poor performance with low ionic strength solutions. Advances in modern electrochemical sensor technologies have reached high development in the field of environmental pollution control, and in biological and industrial applications. In such fields, conventional glass electrodes have been widely used, however there are still some limitations in specific applications. For example, it is difficult to use the configuration of glass sensors in the biomedical area in vivo, clinical, or food monitoring due to glass damage, size, and deformability limitations [94,101]. To overcome the disadvantages of the glass bar, other alternatives were explored, such as the incorporation of structures with metal oxide as an active component and promising materials for new pH sensors. A pH response was considered for certain types of electrically conductive and semiconductor oxides [102,103,104,105] i.e., platinum, iridium, ruthenium, osmium dioxide, titanium, palladium, tin, zirconium, lead, rhodium oxides [106,107,108,109,110,111]. Iridium, ruthenium, and titanium oxides have been widely used in several applications, particularly in pH detection due to their fast response, chemical stability, high durability, and conductivity. Moreover, they can be used at high temperatures and pressures, and in aggressive environments [112,113,114,115]. Nevertheless, besides their cost, iridium oxide have other disadvantages, such as the appearance of a different oxide states leading to deviations and hysteresis in measurements [101]. In comparison with other metal oxides, ruthenium oxide has unique properties such as including thermal stability, excellent corrosion resistance, high sensitivity, and low hysteresis and resistivity [116].

In order to advance the current state of the art, new OIH have been synthesized and doped with imidazole derivatives since they are a promising alternative for pH monitoring [35,117,118]. These compounds were widely disseminated about 20 decades ago, but the first synthesis was performed by Heinrich Debus in 1858 [119]. Imidazole is an organic, polar, and amphoteric compound with an aromatic heterocyclic structure. Thereby, they are grouped into a class of heterocyclic compounds since they have a similar ring structure with different substitutes and are the constituents of some substances, namely histamine, histidine, biotin, nuclei acid, and alkaloids [120,121,122]. Imidazole derivatives are promising probes for pH detection due to the amphoteric nature of their heterocyclic ring, since they can function as selective anions or cations, allowing for the recognition of several analytes [35,123]. Imidazole derivatives can be protonated or deprotonated depending on the pH [35].

Among the several types of sensor technologies available, the use of smart sensors and the industrialization of wireless sensor networks have attracted considerable attention in this research field [124,125,126]. Table 1 shows the most relevant optical sensors used for pH monitoring in different conditions and environments. It indicates the type of sensor, i.e., colorimetic or fluorimetric, the precursors and reagents used, the detection range, the sensitivity, and the RT. Table 1 includes the information reported in the last few years, i.e., from 2016 to mid-2021, focused on the study of OFS for pH monitoring based on sol–gel materials applied on concrete or highly alkaline environments (pH > 12). Knowing that the pH value of the healthy concrete pore solution is above 12.5 (and may fall down to values between 6 and 9 when carbonated) [50,127], it is possible to assess the application of the studies reported in Table 1.

Table 1.

pH sensors applied to concrete.

Table 1 shows that most of the sensors reported were fluorimetric. The one with the shortest RT—16 s—was an optical fluorimetric sensor reported by the authors Lu et al. in 2021, with a pH detection range between 8 and 12.5. A sensor for pH values above 12.5 was reported and was a ratiometric optical one.

As mentioned above, the pH value in considered healthy concrete structures is above 12.5. Analyzing the articles reported in Table 1, it can be highlighted that the detection limit is not reported, so it can only be predicted based on the detection interval. Thus, all methods used in pH monitoring, except for membrane sensors and fluorescent dyes for analytes, show a detection interval within the values of interest. Overall, any method mentioned in the Table 1 is suitable for pH monitoring in concrete structures. It should be noted that pH values below 9 in concrete and RCS are worrisome, and the cause of such variation should be investigated and mitigated to avoid further pathologies and deterioration.

3.2. OFS for Chloride Ions Detection

The detection and monitoring of chloride ion (Cl−) concentration plays an important role in several aspects, including human health [130,131,132], industrial process control [133], wasted water management [134], drinking water quality control [135,136], and corrosion forecasting of RCS [137,138,139]. There are several available methods for measuring Cl− concentration, including electrochemical sensors, OFS [28,140], and Bragg’s grating [141,142].

Cl− is one of the most important indicators for the deterioration of RCS [140,143,144,145,146]. In the presence of a critical amount of Cl−, also known as critical chloride content, reinforcement steel suffers quick localized corrosion, forming pits – pitting corrosion. Pitting corrosion is one of the most common corrosive process in RCS structures in the presence of Cl−. This corrosion process begins in places where the passivation layer is damaged due to the penetration of aggressive species, i.e., Cl− [147,148,149]. Although it does not have a direct and significant impact on the daily operation of a concrete structure, it can affect its structural performance in the medium-long term [150,151]. Corrosion drastically reduces the tensile strength of steel, compromising the load capacity of the structure [50,61,152]. During this process, the passivation layer, i.e., the passive iron oxide film, initially formed on the surface of the steel, is destroyed. In the case of chloride-induced corrosion, the passive film is broken locally. This process comes from the formation of oxides with Fe2O3 as the main component and results in the formation of bulky corrosion products, which leads to the early formation of cracks, causing volume expansion and tensile stress in the reinforcement which in turn leads to deformations [140,153,154].

Additionally, structures in the marine environment or exposed to ice/thaw salts are more prone to pitting corrosion. This is particularly true for the ones in the splash zone near the seawater, which is the area close to the air/water interface that suffers from accelerated deterioration due to atmospheric oxygen, water, and Cl− availability [155,156,157].

Figure 7 shows the corrosive process in concrete structures in marine environment. The air/water interface induces pitting corrosion by causing the local degradation of the passivation layer. At this site, a small area appears allowing the penetration of O2, H+ or of aggressive species i.e., Cl−. Throughout the corrosive process, iron oxides are formed. At an early stage, pitting corrosion is difficult to detect since it does not cause significant impacts on the concrete surface.

Figure 7.

Pitting corrosion [158,159,160].

Chloride ions threshold value (CTV) refers to chloride ions content that causes visible deterioration in RCS. This may be expressed as the total chloride content as a mass percentage of cement/concrete, or as the molar ratio between [Cl−] and [OH−]. The ratio [Cl−]/[OH−] reflects the aggressive ions rate for inhibitory ions that lead to the onset of corrosion. Given the risk of chloride pitting corrosion and the inhibitory effect of cement hydration products, this is the reason [Cl−]/[OH−] has the great advantage of being easy to measure [161].

Table 2 shows some most representative examples of sensors reported for detection of Cl−. It indicates the type of sensor, i.e., colorimetric, fluorescence, the transducer, the detection limit, the concentration range, and the sensitivity.

Table 2.

Some sensors for chloride ion monitoring reported since 2016.

Table 2 shows that most of the sensors reported were based on fluorescence. The sensor reported by Dhouib et al. showed higher concentration range between 0.045 M and 0.45 M using chloride-sensitive fluorophore immobilized in a calcium alginate sol-gel as a transducer. Xiao et al. reported the sensor, which showed smaller concentration range between 0.02 M and 0.06 M using lucigenin as a transducer.

3.3. OFS for Moisture Monitoring

Monitoring humidity is critical in several areas such as civil engineering [167], soils [168], and food packaging [169]. There is a variety of studied, developed, and commercialized electrochemical humidity sensors (HS) that are based on conductivity measures [170,171,172], humidity sensitive polymers in which the material properties change work as sensors [173,174] and OFS [62,175].

The strength and durability of concrete depends on several factors including temperature and dynamics of moisture transport [176,177]. The properties of concrete material change over time, and these properties (resistance, modulus of elasticity, creep, and shrinkage) are significantly influenced by the hydration heat and moisture content of concrete at an early age [178]. Self-drying due to the temperature of hydrated cement paste causes an additional decrease in moisture content, at an early age, which influences the properties of young concrete, as well as its medium-long-term behavior [179]. Temperature and high moisture content can also promote deterioration processes. The mechanisms of deterioration of concrete structures (bridges, dams, and buildings), as time goes by, are often related to the moisture and temperature properties of the structures. The moisture present in concrete resulting from seawater, rain, soil, snow, and floods leads to the transfer of high chloride concentrations, resulting in corrosion of reinforced steel bars (Figure 1). This moisture also promotes deterioration and damage resulting from chemical processes, such as carbonation and alkaline aggregate reactions [179]. For example, concrete damage due to ice/defrost is related to moisture transfer.

In these cases, volume changes occur, leading to cracks that may later lead to structural failures [180]. Recent studies have determined that extensive failures in concrete components are related to thermal and humidity variations [181]. These changes and degradation processes are initiated when the relative humidity (RH) level of concrete reaches critical values between 50% and 70% [182].

Therefore, a sensor for continuous monitoring of internal RH and temperature is extremely important during and after construction. When incorporated into concrete, the sensor system can provide key information about its curing process by monitoring indoor temperature and humidity. After being detected, this data can also be integrated into the maturity methods available to predict the resistivity of young concrete [183].

Knowing the strength of concrete at early ages brings great benefits, such as increasing productivity and accelerating construction process by reducing the curing period and consequently removing the formwork. When a concrete structure is put into use, continuous monitoring of internal temperature and humidity will provide information on the process of structural damage due to environmental effects such as ice/defrost cycles, chloride ion diffusion, alkalis–silica reaction, carbonation, and temperature changes.

Current methods for assessing temperature and relative internal humidity, which rely on destructive testing systems, are expensive and slow. In addition, these techniques require special equipment and hard work so that remotes sites gain access to them [182].

Humidity is generally associated with the presence of water in a gaseous state. Therefore, most HS are based on absorption and desorption processes. For OFS, changes in the evanescence field whose RI which are influenced by the absorption or desorption of water molecules are used to determine the RH [184].

Conventional HS (gravimetric, capacitive, and resistive) present some limitations in certain environments that may be in the presence of strong magnetic fields or high temperatures and in which humidity monitoring is vital [185]. When compared to traditional HS, OFS-based HS show several advantages that allow them to operate in harsher conditions.

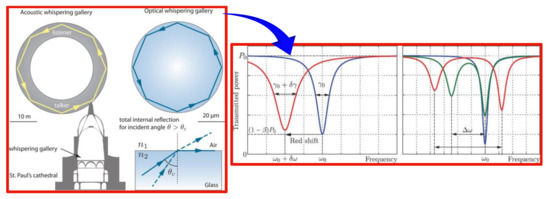

In the last few years, multiple HS based on optical fibers were reported, mainly FBG [186,187], Fabry-Perot interferometer [188,189,190] and whispering gallery modes (WGM) [191,192]. FBG based sensors are obtained by coating the surface of the optical fiber with a humidity sensitive material that can change the wavelength of the signal exposed to it. This type of sensor has two major disadvantages i.e., their low sensibility and the fact that its behavior is highly dependent on the temperature, which may lead to measurement mistakes. Regarding Fabry-Perot interferometers, the humidity sensitive coating must be used as an optical cavity. However, the production of this kind of sensors is very complex.

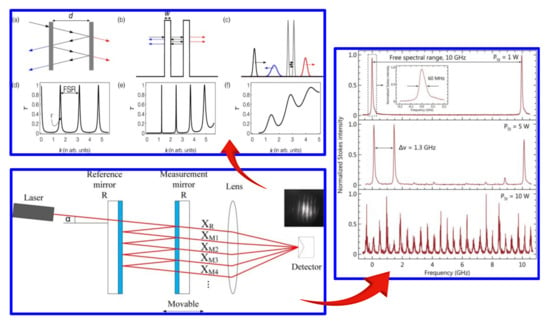

Figure 8 illustrates the typical structure of a Fabry-Perot interferometer which is based on the reflection of light through two reflecting mirrors—fixed and moving—arranged parallel to each other at a small distance. Part of the incident radiation is reflected, and the other part is transmitted into the lens. Interference occurs between the radiation reflected by the mirrors. The black, blue and red arrows (left side) correspond to incident, reflected and transmitted radiation, respectively [193]. Figure 8 right side show the spectra obtained from the scanning Fabry-Perot interferometer traces of the Raman laser emission [194].

Figure 8.

Fabry-Perot interferometers. (a) transmission and reflection of narrow-band light, (b) narrow-band matter-wave through a rectangular double barrier, (c) broad-band Gaussian wavepacket, (d), (e) and (f) correspond to the transmission resonance peaks [193,194,195].

Finally, whispering gallery modes-based sensors are very delicate regarding their structure, which means that their transportation and application must be performed very cautiously to prevent any damage.

Figure 9 shows the phenomenon of total internal reflection of radiation in WGM along the entire closed concave surface. In successive wave descriptions, radiation losses occur due to absorption and material scattering across the surface. The results illustrate that the blue (before) and red (after) lines represent the WGM transmission line of a resonance shift and associated broadening (left side). The transmission lines before (blue) and after the mode splitting induced by a single (green) or multiple (red) disturbing particles (right side) [196].

Figure 9.

Whispering gallery modes-based sensors. Adapted with permission from [196] Copyright 2015 © The Optical Society.

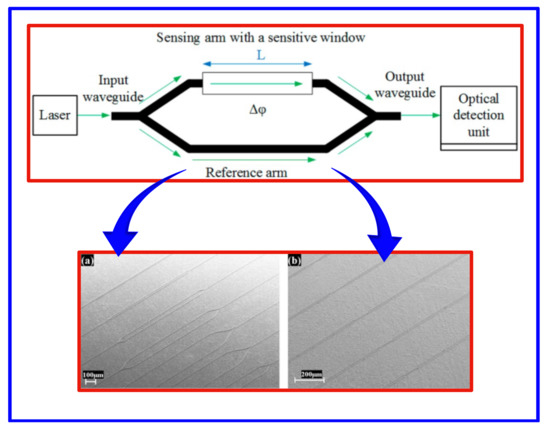

In 2006, Yeo et al. [197] developed an OFS to measure humidity in concrete. The sensor was developed using a FBG coated with a polyimide. To increase the adhesion between the coating layer and the silica surface, the FBG was treated with 3-aminopropyltriethoxysilane (3-APTS). The coating was achieved through multiple dipping of the FBG in the polyimide, resulting in a total deposition of 20 layers. The sensor was able to detect changes in the moisture content in different samples [197]. Recently, HS based on MZI (Mach-Zehnder interferometer) have also been developed (vide Figure 10).

Figure 10.

The typical configuration of the MZI structure consists of two waveguides (input and output), a beam splitter (the left Y-function), and a beam combiner (the right Y-function), as well as two straight waveguides between the two Y-functions as the sensor and the reference arms [198]. SEM images illustrate (a) a set of MZI ridge interferometer structures and (b) a set of ridge coupler structures. Adapted with permission from [199].Copyright 2014 © AIP Publishing.

For instance, Zhang et al. [200] in 2013 developed a sensor capable of measuring RH and temperature at the same time by cascading a photonic crystal fiber-based MZI and a FBG. The sensor was coated with a layer of polyvinyl alcohol that is moisture sensitive. The FBG sensor itself is not sensitive to humidity, however when coated with a sensitive material it becomes one. The coating may absorb the moisture present in the air and therefore dilatate, resulting in some tension on the FBG and the optical fiber that hosts it [201]. The influence of the humidity depends on the type and thickness of the coating and on how tough is the fiber [201]. The production process of the described system must be highly precise so that the simultaneous measurement of temperature and humidity is a reality. The sensor reported presented a range between 30% and 95% of RH [200]. In 2016, Wang et al. [202] developed a HS based on MZI coated with graphite oxide which operation principle is based on light polarization and respective changes in its RI. Graphite oxide was selected because of its RI, which changes accordingly to the RH of surrounding environment. The research team concluded that the sensor showed a maximum sensibility of 0.349 dB/%RH and a detection range between 60% and 77% and a good stability [202]. In 2020, Bian et al. [203] reported a HS composed of calcium alginate hydrogel and a MZI structure. The hydrogel was selected due to its response towards humidity. The authors combined a solution of sodium alginate and calcium chloride to obtain the calcium alginate hydrogel. The sensibility obtained was 0.48346 dB/%RH. The main advantages reported were the simple preparation, non-toxic, and low cost showing good repeatability, stability, and a fast response time [203]. In the last few years, there has been a significant growth in both the technology and uses of HS, since many different industries seek for this type of product [175]. There is a particular interest in sensors based on OF due to the advantages that they show when compared to electrochemical ones, namely their immunity to electromagnetic interferences and associated cost/benefit relation [204].

Table 3 compiles information from articles focused on the study of resistivity sensors applied to concrete.

Table 3.

Resistivity sensors reported since 2016.

The results obtained from the experiences of the articles mentioned in Table 3 are expressed in different units (Ω·m and %). For that reason, it is not possible to establish a reference value. Another reason for the lack of a reference value is the fact that there are several types of concrete, i.e., concrete with different constituents that, uniquely, influence resistivity. Table 3 also shows that the number of manuscripts focused on the development of resistivity sensors through the sol–gel method published since 2015 is significantly reduced.

Analyzing Table 3, the most suitable and promising method for resistivity sensor seems to be the screen-graphed sensor, since it is the only manuscript reported that presented a detection limit.

Table 4 shows some examples of optical sensors reported for moisture monitoring. It indicates the precursors and reagents, the RH, the sensitivity, and the response time (RT).

Table 4.

Some sensors for moisture monitoring reported in recent years.

Table 4 shows that most of the sensors reported were FBG and the one with the shortest RT was the FBG sensor with a RH between 25% and 95% and a sensitivity of 3.38–29.35 pm/%RH. Liehr et al. reported a POF sensor with the shortest RH range.

3.4. Multifunctional OFS for SHM

The development of OFS in civil engineering has increased mainly due to the early degradation of structures such as bridges and dams [61,70,212,213,214,215], resulting in an expensive cost of repair and maintenance [49,216,217,218]. Therefore, OFS enable to monitor and evaluate structural integrity with more accuracy and selectivity, mitigating or preventing structural degradation [61,71,79]. Commonly, OFS are designed to individually monitor parameters such as temperature [64], strain [219,220], pH [66,128,129], moisture [63,197,221], and chloride ion content [28,140]. Variations of those parameters are then transmitted through changes in intensity, frequency, polarization, phase of light, or wavelength. Nevertheless, in recent years, multifunctional OFS have been developed to provide simultaneous information on a set of parameters, which is particularly advantageous to monitor civil structures, considering the number of parameters to be monitored due to the heterogeneity of concrete [200,222,223]. In this case, the application of Bragg gratings in multifunctional OFS is fruitful, mainly because they can monitor several parameters simultaneously, such as temperature, strain, and pH [38,42,47]. Thus, the determination of any change in the respective parameters leads to a change in the wavelength which consequently causes a change in the optical properties i.e., RI and mechanical properties of the materials [224]. Additionally, Bragg gratings provide an absolute, linear, and high-information transmission capacity [225].

The main aim of multifunctional OFS is to monitor, in situ, by a non-destructive method, the corrosion of reinforced concrete structures, the pH, the moisture, and the Cl− content [226,227]. It is emphasized that Cl− content and pH are the most important factors in the corrosion of reinforced concrete structures since, at the steel/concrete interface, they can determine the stability or degradation of the passivation film [228]. Besides that, OFS able to determine the Cl− content tend to be extrinsic [61,229]. To increase the service life of concrete structures, it is desirable to monitor several parameters simultaneously such as pH, humidity, and Cl− content. Therefore, the development of multifunctional OFS which enable continuous, in situ, and real-time monitoring of mentioned parameters is required.

4. Future and Research Challenges on OIH Sol-Gel Materials for OFS

Corrosion is one of the main problems of modern society that is always linked to high costs, and in extreme situations human lives losses. The development of multifunctional materials may be one interesting alternative and potentially the key to prevent and mitigate the corrosion processes in concrete and RCS. The sol-gel method allows obtaining OIH materials with distinctive properties, since they combine the different characteristics of the organic and inorganic components within the same matrix. Moreover, OIH membranes are innovative materials that allow the incorporation of complementary functions (i.e., UV protection, anti-corrosion, anti-reflection, and anti-fouling).

In the last few decades, the emergence of OFS has overcome most of the shortcomings existing in the conventional sensors due to their intrinsic properties such as small size, corrosion resistance, immunity to electromagnetic interference, and multiplexing capability. The OFS are designed to provide properties not achievable in existing equipment, allowing the acquisition of vital information in real time, ensuring the structural integrity of concrete and RCS.

Regarding all the literature reviewed and discussed through this manuscript, it was shown that the development of OFS functionalized with OIH sol-gel membranes has revealed to be a promising alternative to increase the service life of civil engineering structures. The OFS incorporated in structures, such as concrete exposed to extremely aggressive environments, allow to monitor accurately several physical parameters of the structure’s health. Other potential parameters that should be considered are pH, moisture, and Cl− content to mitigate and/or delay the initiation and development of the corrosion process of concrete and RCS.

The literature shows that the development of OFS functionalized with OIH materials for monitoring the concrete properties is still at an early stage, since most of the reported information is related to the monitoring of physical parameters such as torsion, temperature, displacement, and expansion. From this context emerges the need to develop new OIH sol-gel films/membranes for incorporation in optical fiber systems which can allow monitoring chemical parameters.

In a world that is globally connected, the future of monitoring civil engineering structures is intimately interconnected to smart and automatized systems. OFS are considered a convergence medium between different technologies enabling the production of automatized systems with alarms allowing interventions before real damage occurs. It is undeniable that the monitoring devices that are being developed and reach high projection will be created based on machine learning, artificial intelligence together with the internet of things (IoT). This will surely lead to the development of extremely smart systems and new concepts. The reflection of this is the well-known concepts of Lab-on-a-Chip and Lab-in-a-fiber [48].

A suitable automatic, multiplexed, and interesting device would be able to monitor important parameters simultaneously for concrete and RCS and at the same time have alarms in case of certain parameters reach threshold values, allowing intervention and repair of the structure to avoid accidents or catastrophes. This mitigates the risk of accidents, victims, as well as the costs involved.

5. Conclusions

The main reasons for early degradation of concrete and RCS are inadequate maintenance, incorrect construction, and failure in continuous monitoring. Exposure to extremely aggressive environments promotes ageing and premature degradation of concrete structures, resulting in high maintenance and repair costs. Preventive and mitigation actions are imperative since the continuous monitoring of structures allow the identification at an early stage of pathologies, favoring the ability to choose among the most suitable and economically feasible methods for each situation. Additionally, monitoring can ensure the projected lifetime, since early identification of the beginning of the corrosion process enables fast intervention, making the whole process more efficient and more cost-effective.

Sol-gel method is a simple, versatile, and environmentally friendly process as it allows obtaining multifunctional OIH materials with unique properties. The application of OIH films/membranes on OFS is promising due different properties such as high matrix stability, wide configuration flexibility in sensor specificity, control of porosity, and surface properties (hydrophilic/hydrophobic balance).

OFS based on OIH materials have a wide applicability in different fields, and civil engineering structures just as attractive as they allow monitoring the relevant parameters such as pH, moisture, and Cl− content. According to the literature reported through the manuscript, the development of resistivity OFS is still at a very early stage. Besides, pH sensors are the most developed ones as they have a wide field of applications since besides civil engineering field, they are vital in several physiological processes. The most representative pH sensor reported so far is colorimetric, with the smallest pH detection range (i.e., between 2 and 13) and a sensitivity of 1.02 and −0.93 nm/pH for acid and alkaline solutions, respectively. For Cl− monitoring, the most relevant optical sensors reported were based on fluorescence principle. The sensor that showed the smallest concentration ranged between 0.02 and 0.06 M used lucigenin as a transducer.

OIH materials coupled with optical fiber systems show promising and interesting properties to monitor different parameters in concrete and RCS such as cracks, deformations, strain, temperature, moisture, pH, and Cl− content. However, further studies are required to minimize and improve the limitations involved, such as the dual sensitivity to temperature and strain and absorption of some strain through the polymeric coating of the optical fiber. Moreover, essential information about the exact local of corrosion is required, as well as the development of suitable coatings to reduce the changes that occur in the properties of the optical fiber due to the aggressive environment.

Author Contributions

Conceptualization, R.B.F.; methodology, R.B.F.; investigation, B.R.G., R.A, T.S.; resources, R.B.F; writing—original draft preparation, B.R.G., R.A., T.S., R.B.F.; writing—review and editing, B.R.G. and R.B.F.; visualization, R.B.F.; supervision, R.B.F.; project administration, R.B.F.; funding acquisition, R.B.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the project “SolSensors—Development of Advanced Fiber Optic Sensors for Monitoring the Durability of Concrete Structures”, with reference POCI-01-0145-FEDER-031220 supported by the Program Budget COMPETE—Operational Program Competitiveness and Internationalization—COMPETE 2020 and the Lisbon Regional Operational Program in its FEDER component and by the budget of FCT Foundation for Science and Technology, I.P. The authors acknowledge the support of Centro de Química, CQUM, which is financed by national funds through the FCT Foundation for Science and Technology, I.P. under the project UID/QUI/00686/2020 and UID/QUI/00686/2021.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

Rita B. Figueira acknowledge her husband Hugo Gomes and his sons Francisco Gomes and Manuel Gomes for their support and patience.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| 3-APTS | 3-aminopropyltriethoxysilane |

| CTV | Chloride threshold value |

| DI | Deionized water |

| EtOH | Ethanol |

| FBGs | Fiber Bragg Gratings |

| HS | Humidity Sensors |

| IR | Infrared |

| LPG | Long Period Grating |

| MetOH | Methanol |

| MZI | Mach-Zehnder interferometer |

| NDM | Non-destructive methods |

| NIR | Near Infrared |

| OFS | Optical fiber sensors |

| OIH | Organic–inorganic hybrid |

| PCB | Printed Circuit Board |

| POF | Polymer Optical Fiber |

| RCS | Reinforced concrete structures |

| RH | Relative Humidity |

| RI | Refraction Index |

| RIU | Refractive Index Unit |

| RT | Response Time |

| SHM | Structural health monitoring |

| TEOS | Tetraethyl orthosilicate |

| UV | Ultraviolet |

| WGM | Whispering Gallery Modes |

References

- Jackson, R.G. Novel Sensors and Sensing; Taylor & Francis Limited: Oxfordshire, UK, 2019; ISBN 978-0-367-45431-9. [Google Scholar]

- Tabassum, R.; Kant, R. Recent Trends in Surface Plasmon Resonance Based fiber–optic Gas Sensors Utilizing Metal Oxides and Carbon Nanomaterials as Functional Entities. Sens. Actuators B Chem. 2020, 310, 127813. [Google Scholar] [CrossRef]

- Jiao, L.; Zhong, N.; Zhao, X.; Ma, S.; Fu, X.; Dong, D. Recent Advances in fiber-optic Evanescent Wave Sensors for Monitoring Organic and Inorganic Pollutants in Water. TrAC Trends Anal. Chem. 2020, 127, 115892. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhu, Z.-W.; Xiao, W.; Deng, Q.-X. Review of Fiber Optic Sensors in Geotechnical Health Monitoring. Opt. Fiber Technol. 2020, 54, 102127. [Google Scholar] [CrossRef]

- Du, C.; Dutta, S.; Kurup, P.; Yu, T.; Wang, X. A Review of Railway Infrastructure Monitoring Using Fiber Optic Sensors. Sens. Actuators A Phys. 2019, 303, 111728. [Google Scholar] [CrossRef]

- Liu, X. Evolution of Fiber-Optic Transmission and Networking toward the 5G Era. iScience 2019, 22, 489–506. [Google Scholar] [CrossRef] [PubMed]

- Figueira, R.B.; Almeida, J.M.; Ferreira, B.; Coelho, L.; Silva, C.J.R. Mater. Adv. in press. 2021. [CrossRef]

- Kaushik, S.; Tiwari, U.K.; Deep, A.; Sinha, R. Two-dimensional Transition Metal Dichalcogenides Assisted Biofunctionalized Optical Fiber SPR Biosensor for Efficient and Rapid Detection of Bovine Serum Albumin. Sci. Rep. 2019, 9, 1–11. [Google Scholar] [CrossRef]

- Arnaoutakis, G. Novel Up-Conversion Concentrating Photovoltaic Concepts. Ph.D. Thesis, Heriot-Watt University, Edinburgh, Scotland, 2015. [Google Scholar]

- Yin, S.; Ruffin, P.B.; Yu, F.T.S. Fiber Optic Sensors; CRC Press: Boca Raton, FL, USA, 2017; ISBN 978-1-4200-5366-1. [Google Scholar]

- Dislich, H.; Hinz, P. History and Principles of the sol-gel Process, and Some New Multicomponent Oxide Coatings. J. Non Cryst. Solids 1982, 48, 11–16. [Google Scholar] [CrossRef]

- Elsalamawy, M.; Mohamed, A.R.; Kamal, E.M. The Role of Relative Humidity and Cement Type on Carbonation Resistance of Concrete. Alex. Eng. J. 2019, 58, 1257–1264. [Google Scholar] [CrossRef]

- Alhozaimy, A.; Hussain, R.R.; Al-Negheimish, A. Significance of Oxygen Concentration on the Quality of Passive Film Formation for Steel Reinforced Concrete Structures during the Initial Curing of Concrete. Cem. Concr. Compos. 2016, 65, 171–176. [Google Scholar] [CrossRef]

- Song, H.-W.; Kim, H.-J.; Velu, S.; Kim, T.-H. A Micro-Mechanics Based Corrosion Model for Predicting the Service Life of Reinforced Concrete Structures. Int. J. Electrochem. Sci. 2007, 2, 341–354. [Google Scholar]

- Korposh, S.; James, S.W.; Lee, S.-W.; Tatam, R.P. Tapered Optical Fibre Sensors: Current Trends and Future Perspectives. Sensors 2019, 19, 2294. [Google Scholar] [CrossRef] [PubMed]

- Correia, R.; James, S.W.; Lee, S.-W.; Morgan, S.P.; Korposh, S. Biomedical Application of Optical Fibre Sensors. J. Opt. 2018, 20, 073003. [Google Scholar] [CrossRef]

- Weng, Y.; Ip, E.; Pan, Z.; Wang, T. Advanced Spatial-Division Multiplexed Measurement Systems Propositions—From Telecommunication to Sensing Applications: A review. Sensors 2016, 16, 1387. [Google Scholar] [CrossRef] [PubMed]

- Alwis, L.; Sun, T.; Grattan, K. Developments in Optical Fibre Sensors for Industrial Applications. Opt. Laser Technol. 2015, 78, 62–66. [Google Scholar] [CrossRef]

- Gomes, B.; Figueira, R.; Costa, S.; Raposo, M.; Silva, C. Synthesis, Optical and Electrical Characterization of Amino-alcohol Based sol-gel Hybrid Materials. Polymers 2020, 12, 2671. [Google Scholar] [CrossRef] [PubMed]

- Sousa, R.P.C.L.; Ferreira, B.; Azenha, M.; Costa, S.P.G.; Silva, C.J.R.; Figueira, R. PDMS Based Hybrid sol-gel Materials for Sensing Applications in Alkaline Environments: Synthesis and Characterization. Polymers 2020, 12, 371. [Google Scholar] [CrossRef]

- Volkov, P.; Semikov, D.; Goryunov, A.; Luk’yanov, A.; Tertyshnik, A.; Vopilkin, E.; Krayev, S. Miniature fiber-optic Sensor Based on Si Microresonator for Absolute Temperature Measurements. Sens. Actuators A Phys. 2020, 316, 112385. [Google Scholar] [CrossRef]

- Pissadakis, S. Lab-in-a-fiber sensors: A review. Microelectron. Eng. 2019, 217. [Google Scholar] [CrossRef]

- Wang, W.; Liu, T.; Yi, D. Detection of Mercury Ion Based on Quantum Dots Using Miniaturised Optical Fibre Sensor. J. Eng. 2019, 2019, 8595–8598. [Google Scholar] [CrossRef]

- Islam, S.; Bidin, N.; Riaz, S.; Krishnan, G.; Naseem, S. Sol–gel Based Fiber Optic pH Nanosensor: Structural and Sensing Properties. Sens. Actuators A Phys. 2015, 238, 8–18. [Google Scholar] [CrossRef]

- Ricciardi, A.; Consales, M.; Pisco, M.; Cusano, A. Application of Nanotechnology to Optical Fibre Sensors: Recent Advancements and New Trends. Opt. Fibre Sens. Fundam. Dev. Optim. Devices 2020, 289–329. [Google Scholar] [CrossRef]

- Elosua, C.; Arregui, F.J.; Del Villar, I.; Ruiz-Zamarreño, C.; Corres, J.M.; Bariain, C.; Goicoechea, J.; Hernaez, M.; Rivero, P.J.; Socorro, A.B.; et al. Micro and Nanostructured Materials for the Development of Optical Fibre Sensors. Sensors 2017, 17, 2312. [Google Scholar] [CrossRef]

- Lu, F.; Wright, R.; Lu, P.; Cvetic, P.C.; Ohodnicki, P.R. Distributed Fiber Optic pH Sensors Using sol-gel Silica Based Sensitive Materials. Sens. Actuators B Chem. 2021, 340, 129853. [Google Scholar] [CrossRef]

- Figueira, R.B. Hybrid Sol–Gel Coatings for Corrosion Mitigation: A Critical Review. Polymers 2020, 12, 689. [Google Scholar] [CrossRef]

- Chu, C.-S.; Chuang, C.-Y. Optical Fiber Sensor for Dual Sensing of Dissolved Oxygen and Cu2+ Ions Based on PdTFPP/CdSe Embedded in sol–gel Matrix. Sens. Actuators B Chem. 2015, 209, 94–99. [Google Scholar] [CrossRef]

- Ruan, S.; Ebendorff-Heidepriem, H.; Ruan, Y. Optical Fibre turn-on Sensor for the Detection of Mercury Based on Immobilized Fluorophore. Measurement 2018, 121, 122–126. [Google Scholar] [CrossRef]

- Wang, H.; Liu, B.; Ding, Z.; Wang, X. Determination of Water PH Using Absorption-based Optical Sensors: Evaluation of Different Calculation Methods. In Proceedings of the International Conference on Optical and Photonics Engineering (icOPEN 2016), Chengdu, China, 26–30 September 2016; 10250, p. 102502D. [Google Scholar]

- Inserra, B.; Hayashi, K.; Marchisio, A.; Tulliani, J.-M. Sol–gel-entrapped pH Indicator for Monitoring pH Variations in Cementitious Materials. J. Appl. Biomater. Funct. Mater. 2020, 18, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.-D.; Wolfbeis, O.S. Fiber-Optic Chemical Sensors and Biosensors (2015–2019). Anal. Chem. 2019, 92, 397–430. [Google Scholar] [CrossRef] [PubMed]

- Jerónimo, P.C.; Araújo, A.N.; Montenegro, M. Optical Sensors and Biosensors Based on sol–gel Films. Talanta 2007, 72, 13–27. [Google Scholar] [CrossRef]

- Sousa, R.P.C.L.; Figueira, R.B.; Gomes, B.R.; Costa, S.P.G.; Azenha, M.; Pereira, R.F.P.; Raposo, M.M. Organic–Inorganic Hybrid sol–gel Materials Doped with a Fluorescent Triarylimidazole Derivative. RSC Adv. 2021, 11, 24613–24623. [Google Scholar] [CrossRef]

- Chen, K.; Chou, W.; Liu, L.; Cui, Y.; Xue, P.; Jia, M. Electrochemical Sensors Fabricated by Electrospinning Technology: An Overview. Sensors 2019, 19, 3676. [Google Scholar] [CrossRef] [PubMed]

- Ricciardi, A.; Crescitelli, A.; Vaiano, P.; Quero, G.; Consales, M.; Pisco, M.; Esposito, E.; Cusano, A. Lab-on-fiber Technology: A New Vision for Chemical and Biological Sensing. Analyst 2015, 140, 8068–8079. [Google Scholar] [CrossRef]

- Álvarez-Botero, G.; Barón, F.; Cano, C.C.; Sosa, O.; Varon, M. Optical Sensing Using Fiber Bragg Gratings: Fundamentals and Applications. IEEE Instrum. Meas. Mag. 2017, 20, 33–38. [Google Scholar] [CrossRef]

- Ye, X.W.; Su, Y.H.; Han, J.P. Structural Health Monitoring of Civil Infrastructure Using Optical Fiber Sensing Technology: A Comprehensive Review. Sci. World J. 2014, 2014, 1–11. [Google Scholar] [CrossRef]

- Kousiatza, C.; Tzetzis, D.; Karalekas, D. In-situ Characterization of 3D Printed Continuous Fiber Reinforced Composites: A Methodological Study Using Fiber Bragg Grating Sensors. Compos. Sci. Technol. 2019, 174, 134–141. [Google Scholar] [CrossRef]

- Webb, D.J. Fibre Bragg Grating Sensors in Polymer Optical Fibres. Meas. Sci. Technol. 2015, 26, 092004. [Google Scholar] [CrossRef]

- Majumder, M.; Gangopadhyay, T.K.; Chakraborty, A.K.; Dasgupta, K.; Bhattacharya, D. Fibre Bragg Gratings in Structural Health Monitoring—Present Status and Applications. Sens. Actuators A Phys. 2008, 147, 150–164. [Google Scholar] [CrossRef]

- Maaskant, R.; Alavie, T.; Measures, R.; Tadros, G.; Rizkalla, S.; Guha-Thakurta, A. Fiber-optic Bragg Grating Sensors for Bridge Monitoring. Cem. Concr. Compos. 1997, 19, 21–33. [Google Scholar] [CrossRef]

- Mihailov, S.J. Fiber Bragg Grating Sensors for Harsh Environments. Sensors 2012, 12, 1898–1918. [Google Scholar] [CrossRef]

- Li, W.; Ho, S.C.M.; Song, G. Corrosion Detection of Steel Reinforced Concrete Using Combined Carbon Fiber and Fiber Bragg Grating Active Thermal Probe. Smart Mater. Struct. 2016, 25, 045017. [Google Scholar] [CrossRef]

- Antunes, P.; Lima, H.; Alberto, N.; Bilro, L.; Pinto, P.; Costa, A.; Rodrigues, H.; Pinto, J.L.; Nogueira, R.; Varum, H.; et al. Optical Sensors Based on Fiber Bragg Gratings for Structural Health Monitoring. In New Developments in Sensing Technology for Structural Health Monitoring; Lecture Notes in Electrical Engineering; Mukhopadhyay, S.C., Ed.; Springer: Heidelberg/Berlin, Germany, 2011; pp. 253–295. ISBN 978-3-642-21099-0. [Google Scholar]

- Bremer, K.; Wollweber, M.; Weigand, F.; Rahlves, M.; Kuhne, M.; Helbig, R.; Roth, B. Fibre Optic Sensors for the Structural Health Monitoring of Building Structures. Procedia Technol. 2016, 26, 524–529. [Google Scholar] [CrossRef]

- Sousa, R.P.C.L.; Figueira, R.B.; Costa, S.P.G.; Raposo, M.M.M. Optical Fiber Sensors for Biocide Monitoring: Examples, Transduction Materials, and Prospects. ACS Sens. 2020, 5, 3678–3709. [Google Scholar] [CrossRef] [PubMed]

- Figueira, R.B. Electrochemical Sensors for Monitoring the Corrosion Conditions of Reinforced Concrete Structures: A Review. Appl. Sci. 2017, 7, 1157. [Google Scholar] [CrossRef]

- Figueira, R.B.; Silva, C.J.R. Organic-Inorganic Hybrid Sol-Gel Materials for Optical Fiber Sensing Application. Meet. Abstr. 2020, MA2020-02, 3369. [Google Scholar] [CrossRef]

- Barczak, M.; McDonagh, C.; Wencel, D. Micro- and Nanostructured Sol-Gel-Based Materials for Optical Chemical Sensing (2005–2015). Microchim. Acta 2016, 183, 2085–2109. [Google Scholar] [CrossRef]

- Tang, Z.; Gomez, D.; He, C.; Korposh, S.; Morgan, S.P.; Correia, R.; Hayes-Gill, B.; Setchfield, K.; Liu, L. A U-Shape Fibre-Optic pH Sensor Based on Hydrogen Bonding of Ethyl cellulose with a Sol-Gel matrix. J. Lightwave Technol. 2020, 39, 1557–1564. [Google Scholar] [CrossRef]

- Yang, D.; Liu, Y.; Wang, Y.; Zhang, T.; Shao, M.; Yu, D.; Fu, H.; Jia, Z. Integrated Optic-Fiber Sensor Based on Enclosed EFPI and Structural Phase-Shift for Discriminating Measurement of Temperature, Pressure and RI. Opt. Laser Technol. 2020, 126, 106112. [Google Scholar] [CrossRef]

- Yang, Y.; Averardi, A.; Gupta, N. An Intensity Modulation Based Fiber-Optic Loop Sensor for High Sensitivity Temperature Measurement. Sens. Actuators A Phys. 2019, 297. [Google Scholar] [CrossRef]

- Kaya, M.; Esentürk, O. Study of Strain Measurement by Fiber Optic Sensors with a Sensitive Fiber Loop Ringdown Spectrometer. Opt. Fiber Technol. 2019, 54, 102070. [Google Scholar] [CrossRef]

- Mahendran, R.; Wang, L.; Machavaram, V.; Pandita, S.; Chen, R.; Kukureka, S.; Fernando, G. Fiber-Optic Sensor Design for Chemical Process and Environmental Monitoring. Opt. Lasers Eng. 2009, 47, 1069–1076. [Google Scholar] [CrossRef]

- Kim, H.J.; Shin, H.Y.; Pyeon, C.H.; Kim, S.; Lee, B. Fiber-Optic Humidity Sensor System for the Monitoring and Detection of Coolant Leakage in Nuclear Power Plants. Nucl. Eng. Technol. 2020, 52, 1689–1696. [Google Scholar] [CrossRef]

- Chauhan, M.; Singh, V.K. Fiber Optic pH Sensor Using TiO2-SiO2 Composite Layer with a Temperature Cross-sensitivity Feature. Optik 2020, 212, 164709. [Google Scholar] [CrossRef]

- Sabri, N.; Aljunid, S.A.; Salim, M.S.; Fouad, S. Fiber Optic Sensors: Short Review and Applications. In Recent Trends in Physics of Material Science and Technology; Gaol, F.L., Shrivastava, K., Akhtar, J., Eds.; Springer Series in Materials Science Springer: Singapore, 2015; pp. 299–311. ISBN 978-981-287-128-2. [Google Scholar]

- Wang, X.; Shi, W.; Yun, H.; Grist, S.; Jaeger, N.A.F.; Chrostowski, L. Narrow-band Waveguide Bragg Gratings on SOI Wafers with CMOS-compatible Fabrication Process. Opt. Express 2012, 20, 15547–15558. [Google Scholar] [CrossRef]

- Merzbacher, C.I.; Kersey, A.D.; Friebele, E.J. Fiber Optic Sensors in Concrete Structures: A Review. Smart Mater. Struct. 1996, 5, 196–208. [Google Scholar] [CrossRef]

- Yeo, T.; Sun, T.; Grattan, K. Fibre-Optic Sensor Technologies for Humidity and Moisture Measurement. Sens. Actuators A Phys. 2008, 144, 280–295. [Google Scholar] [CrossRef]

- Grahn, W.; Makedonski, P.; Wichern, J.; Kowalsky, W.; Wiese, S. Fiber Optic Sensors for an In-Situ Monitoring of Moisture and PH Value in Reinforced Concrete. In Proceedings of the Imaging Spectrometry VII; International Society for Optics and Photonics: Washington, DC, USA, 2002; Volume 4480, pp. 395–404. [Google Scholar]

- Górriz, B.T.; Payá-Zaforteza, I.; García, P.C.; Maicas, S.S. New Fiber Optic Sensor for Monitoring Temperatures in Concrete Structures during Fires. Sens. Actuators A Phys. 2017, 254, 116–125. [Google Scholar] [CrossRef]

- Zolkapli, M.; Saharudin, S.; Herman, S.H.; Abdullah, W.F.H. Quasi-distributed Sol-Gel Coated Fiber Optic Oxygen Sensing Probe. Opt. Fiber Technol. 2018, 41, 109–117. [Google Scholar] [CrossRef]

- Bhardwaj, V.; Pathak, A.K.; Singh, V.K. No-core Fiber-based Highly Sensitive Optical Fiber pH Sensor. J. Biomed. Opt. 2017, 22, 057001. [Google Scholar] [CrossRef]

- Pathak, A.K.; Singh, V.K. Fabrication and Characterization of Down-tapered Optical Fiber pH Sensor Using Sol-Gel Method. Optik 2017, 149, 288–294. [Google Scholar] [CrossRef]

- Liu, D.; Han, W.; Mallik, A.K.; Yuan, J.; Yu, C.; Farrell, G.; Semenova, Y.; Wu, Q. High Sensitivity Sol-Gel Silica Coated Optical Fiber Sensor for Detection of Ammonia in Water. Opt. Express 2016, 24, 24179. [Google Scholar] [CrossRef]

- Kant, R.; Tabassum, R.; Gupta, B.D. Integrating Nanohybrid Membranes of Reduced Graphene Oxide: Chitosan: Silica Sol Gel with Fiber Optic SPR for Caffeine Detection. Nanotechnology 2017, 28, 195502. [Google Scholar] [CrossRef] [PubMed]

- Villalba, S.; Casas, J. Application of Optical Fiber Distributed Sensing to Health Monitoring of Concrete Structures. Mech. Syst. Signal Process. 2012, 39, 441–451. [Google Scholar] [CrossRef]

- Bado, M.; Casas, J. A review of Recent Distributed Optical Fiber Sensors Applications for Civil Engineering Structural Health Monitoring. Sensors 2021, 21, 1818. [Google Scholar] [CrossRef] [PubMed]

- Taheri, S. A Review on Five Key Sensors for Monitoring of Concrete Structures. Constr. Build. Mater. 2019, 204, 492–509. [Google Scholar] [CrossRef]

- Wu, T.; Liu, G.; Fu, S.; Xing, F. Recent Progress of Fiber-Optic Sensors for the Structural Health Monitoring of civil Infrastructure. Sensors 2020, 20, 4517. [Google Scholar] [CrossRef] [PubMed]

- Qing, X.P.; Chan, H.-L.; Beard, S.J.; Ooi, T.K.; Marotta, S.A. Effect of Adhesive on the Performance of Piezoelectric Elements used to Monitor Structural Health. Int. J. Adhes. Adhes. 2006, 26, 622–628. [Google Scholar] [CrossRef]

- Liu, W.; Giurgiutiu, V. Finite Element Simulation of Piezoelectric Wafer Active Sensors for Structural Health Monitoring with Coupled-filed Elements. Proc. SPIE 2007, 6529, 65293. [Google Scholar] [CrossRef]

- Li, X.; Cui, H.; Zhang, B.; Yuan, C. Experimental Study of a Structural Health Monitoring Method Based on Piezoelectric Element Array. In Proceedings of the 2017 IEEE 3rd Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 3–5 October 2017; pp. 27–31. [Google Scholar]

- Nie, M.; Xia, Y.-H.; Yang, H.-S. A Flexible and Highly Sensitive Graphene-Based Strain Sensor for Structural Health Monitoring. Clust. Comput. 2018, 22, 8217–8224. [Google Scholar] [CrossRef]

- Li, X.D.; Li, S.L.; Zhong, S.L.; Ge, S. Comparison Analysis of Fiber Bragg Brating and Resistance Strain Gauge Used in Quayside Container Crane Structural Health Monitoring. Appl. Mech. Mater. 2013, 330, 485–493. [Google Scholar] [CrossRef]

- Leung, C.K.Y.; Wan, K.T.; Inaudi, D.; Bao, X.; Habel, W.; Zhou, Z.; Ou, J.; Ghandehari, M.; Wu, H.C.; Imai, M. Review: Optical Fiber Sensors for Civil Engineering Applications. Mater. Struct. 2013, 48, 871–906. [Google Scholar] [CrossRef]

- Rajeev, P.; Kodikara, J.; Chiu, W.K.; Kuen, T. Distributed Optical Fibre Sensors and Their Applications in Pipeline Monitoring. Key Eng. Mater. 2013, 558, 424–434. [Google Scholar] [CrossRef]

- Takeda, S.-I.; Aoki, Y.; Nagao, Y. Damage Monitoring of CFRP Stiffened Panels Under Compressive Load Using FBG Sensors. Compos. Struct. 2012, 94, 813–819. [Google Scholar] [CrossRef]

- Tan, C.; Shee, Y.G.; Yap, B.; Adikan, F.M. Fiber Bragg Grating Based Sensing System: Early Corrosion Detection for Structural Health Monitoring. Sens. Actuators A Phys. 2016, 246, 123–128. [Google Scholar] [CrossRef]

- Yehia, S.; Landolsi, T.; Hassan, M.; Hallal, M. Monitoring of Strain Induced by Heat of Hydration, Cyclic and Dynamic Loads in Concrete Structures Using Fiber-Optics Sensors. Measurement 2014, 52, 33–46. [Google Scholar] [CrossRef]

- Royon, M.; Jamon, D.; Blanchet, T.; Royer, F.; Vocanson, F.; Marin, E.; Morana, A.; Boukenter, A.; Ouerdane, Y.; Jourlin, Y.; et al. Sol–Gel Waveguide-Based Sensor for Structural Health Monitoring on Large Surfaces in Aerospace Domain. Aerospace 2021, 8, 109. [Google Scholar] [CrossRef]

- Silva, R.N.F.; Tsuruta, K.M.; Rabelo, D.S.; Neto, R.M.F.; Cavalini, A.A.; Steffen, V. Impedance-Based Structural Health Monitoring Applied to Steel Fiber-Reinforced Concrete Structures. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–15. [Google Scholar] [CrossRef]

- Sakiyama, F.I.H.; Lehmann, F.; Garrecht, H. Structural Health Monitoring of Concrete Structures Using Fibre-Optic-Based Sensors: A Review. Mag. Concr. Res. 2021, 73, 174–194. [Google Scholar] [CrossRef]

- Rossi, P.; Le Maou, F. New Method for Detecting Cracks in Concrete Using Fibre Optics. Mater. Struct. 1989, 22, 437–442. [Google Scholar] [CrossRef]

- Bao, T.; Wang, J.; Yao, Y. A Fiber Optic Sensor for Detecting and Monitoring Cracks in Concrete Structures. Sci. China Ser. E Technol. Sci. 2010, 53, 3045–3050. [Google Scholar] [CrossRef]

- Deng, L.; Cai, C. Applications of Fiber Optic Sensors in Civil Engineering. Struct. Eng. Mech. 2007, 25, 577–596. [Google Scholar] [CrossRef]

- Gerlach, G.; Guenther, M.; Suchaneck, G.; Sorber, J.; Arndt, K.-F.; Richter, A. Application of Sensitive Hydrogels in Chemical and pH Sensors. Macromol. Symp. 2004, 210, 403–410. [Google Scholar] [CrossRef]

- Manjakkal, L.; Cvejin, K.; Kulawik, J.; Zaraska, K.; Szwagierczak, D.; Stojanovic, G. Sensing Mechanism of RuO2–SnO2 Thick Film pH Sensors Studied by Potentiometric Method and Electrochemical Impedance Spectroscopy. J. Electroanal. Chem. 2015, 759, 82–90. [Google Scholar] [CrossRef]

- Ke, X. Micro-fabricated Electrochemical Chloride Ion Sensors: From the Present to the Future. Talanta 2020, 211, 120734. [Google Scholar] [CrossRef] [PubMed]

- Manjakkal, L.; Szwagierczak, D.; Dahiya, R. Metal Oxides Based Electrochemical pH Sensors: Current Progress and Future Perspectives. Prog. Mater. Sci. 2019, 109, 100635. [Google Scholar] [CrossRef]

- Huang, W.-D.; Cao, H.; Deb, S.; Chiao, M.; Chiao, J. A Flexible pH Sensor Based on the Iridium Oxide Sensing Film. Sens. Actuators A Phys. 2011, 169, 1–11. [Google Scholar] [CrossRef]

- Grant, S.A.; Bettencourt, K.; Krulevitch, P.; Hamilton, J.; Glass, R. In Vitro and in Vivo Measurements of Fiber Optic and Electrochemical Sensors to Monitor Brain Tissue pH. Sens. Actuators B Chem. 2001, 72, 174–179. [Google Scholar] [CrossRef]

- O’Hare, D.; Parker, K.H.; Winlove, C.P. Metal–Metal Oxide pH Sensors for Physiological Application. Med. Eng. Phys. 2006, 28, 982–988. [Google Scholar] [CrossRef]

- Alam, A.U.; Qin, Y.; Nambiar, S.; Yeow, J.T.; Howlader, M.M.; Hu, N.-X.; Deen, J. Polymers and Organic Materials-based pH Sensors for Healthcare Applications. Prog. Mater. Sci. 2018, 96, 174–216. [Google Scholar] [CrossRef]

- Nguyen, C.M.; Rao, S.; Yang, X.; Dubey, S.; Mays, J.; Cao, H.; Chiao, J.-C. Sol-gel Deposition of Iridium Oxide for Biomedical Micro-devices. Sensors 2015, 15, 4212–4228. [Google Scholar] [CrossRef]

- Vasylevska, A.S.; Karasyov, A.A.; Borisov, S.; Krause, C. Novel Coumarin-based Fluorescent pH Indicators, Probes and Membranes Covering a Broad pH Range. Anal. Bioanal. Chem. 2007, 387, 2131–2141. [Google Scholar] [CrossRef] [PubMed]

- Wolfbeis, O.S. Fiber-Optic Chemical Sensors and Biosensors. Anal. Chem. 2008, 80, 4269–4283. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.Y.; Yang, S. Fabrication method and characterization of electrodeposited and heat-treated iridium oxide films for pH sensing. Sens. Actuators B Chem. 2014, 196, 31–38. [Google Scholar] [CrossRef]

- Mihell, J.; Atkinson, J. Planar Thick-film pH Electrodes Based on Ruthenium Dioxide Hydrate. Sens. Actuators B Chem. 1998, 48, 505–511. [Google Scholar] [CrossRef]

- Ryynänen, T.; Nurminen, K.; Hämäläinen, J.; Leskela, M.; Lekkala, J. pH Electrode Based on ALD Deposited Iridium Oxide. Procedia Eng. 2010, 5, 548–551. [Google Scholar] [CrossRef][Green Version]

- Manjakkal, L.; Cvejin, K.; Kulawik, J.; Zaraska, K.; Szwagierczak, D.; Socha, R.P. Fabrication of Thick Film Sensitive RuO2-TiO2 and Ag/AgCl/KCl Reference Electrodes and Their Application for pH Measurements. Sens. Actuators B Chem. 2014, 204, 57–67. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, J. A Ruthenium Oxide and Iridium Oxide Coated Titanium Electrode for pH Measurement. RSC Adv. 2020, 10, 25952–25957. [Google Scholar] [CrossRef]

- Da Silva, G.; Lemos, S.; Pocrifka, L.; Marreto, P.; Rosario, A.; Pereira, E. Development of Low-cost Metal Oxide pH Electrodes Based on the Polymeric Precursor Method. Anal. Chim. Acta 2008, 616, 36–41. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, J.; Pan, D.; Wei, H.; Wang, C.; Pan, F.; Xia, J.; Ma, S. pH Electrodes Based on Iridium Oxide Films for Marine Monitoring. Trends Environ. Anal. Chem. 2020, 25, e00083. [Google Scholar] [CrossRef]

- El-Giar, E.E.-D.M.; Wipf, D. Microparticle-based Iridium Oxide Ultramicroelectrodes for pH Sensing and Imaging. J. Electroanal. Chem. 2007, 609, 147–154. [Google Scholar] [CrossRef]

- Sardarinejad, A.; Maurya, D.K.; Alameh, K. The pH Sensing Properties of RF Sputtered RuO2 Thin-film Prepared Using Different Ar/O2 Flow Ratio. Materials 2015, 8, 3352–3363. [Google Scholar] [CrossRef]

- Shylendra, S.P.; Lonsdale, W.; Wajrak, M.; Nur-E-Alam, M.; Alameh, K. Titanium Nitride Thin Film Based Low-Redox-Interference Potentiometric pH Sensing Electrodes. Sensors 2020, 21, 42. [Google Scholar] [CrossRef] [PubMed]

- Deibert, B.J.; Li, J. A Distinct Reversible Colorimetric and Fluorescent Low pH Response on a Water-Stable Zirconium–Porphyrin Metal–Organic Framework. Chem. Commun. 2014, 50, 9636–9639. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.-R.; Ren, Q.-Q.; Yuan, X.-J.; Wen, W.; Chen, W.; Zhan, D.-P. Iridium Oxide Based Coaxial pH Ultramicroelectrode. Electrochem. Commun. 2014, 40, 35–37. [Google Scholar] [CrossRef]

- Koncki, R.; Mascini, M. Screen-Printed Ruthenium Dioxide Electrodes for pH Measurements. Anal. Chim. Acta 1997, 351, 143–149. [Google Scholar] [CrossRef]

- Bause, S.; Decker, M.; Gerlach, F.; Nather, J.; Köster, F.; Neubauer, P.; Vonau, W. Development of an Iridium-based pH Sensor for Bioanalytical Applications. J. Solid State Electrochem. 2017, 22, 51–60. [Google Scholar] [CrossRef]

- Zimer, A.M.; Lemos, S.; Pocrifka, L.; Mascaro, L.; Pereira, E. Needle-like IrO/Ag Combined pH Microelectrode. Electrochem. Commun. 2010, 12, 1703–1705. [Google Scholar] [CrossRef]

- Sardarinejad, A.; Maurya, D.; Alameh, K. The Effects of Sensing Electrode Thickness on Ruthenium Oxide Thin-Film pH Sensor. Sens. Actuators A Phys. 2014, 214, 15–19. [Google Scholar] [CrossRef]

- Ferreira, R.C.M.; Costa, S.P.G.; Gonçalves, H.; Belsley, M.; Raposo, M.M.M. Fluorescent Phenanthroimidazoles Functionalized with Heterocyclic Spacers: Synthesis, optical chemosensory ability and two-photon absorption (TPA) properties. New J. Chem. 2017, 41, 12866–12878. [Google Scholar] [CrossRef]