Tribological Behavior of NiTi Alloy Produced by Spark Plasma Sintering Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

3. Results and Discussion

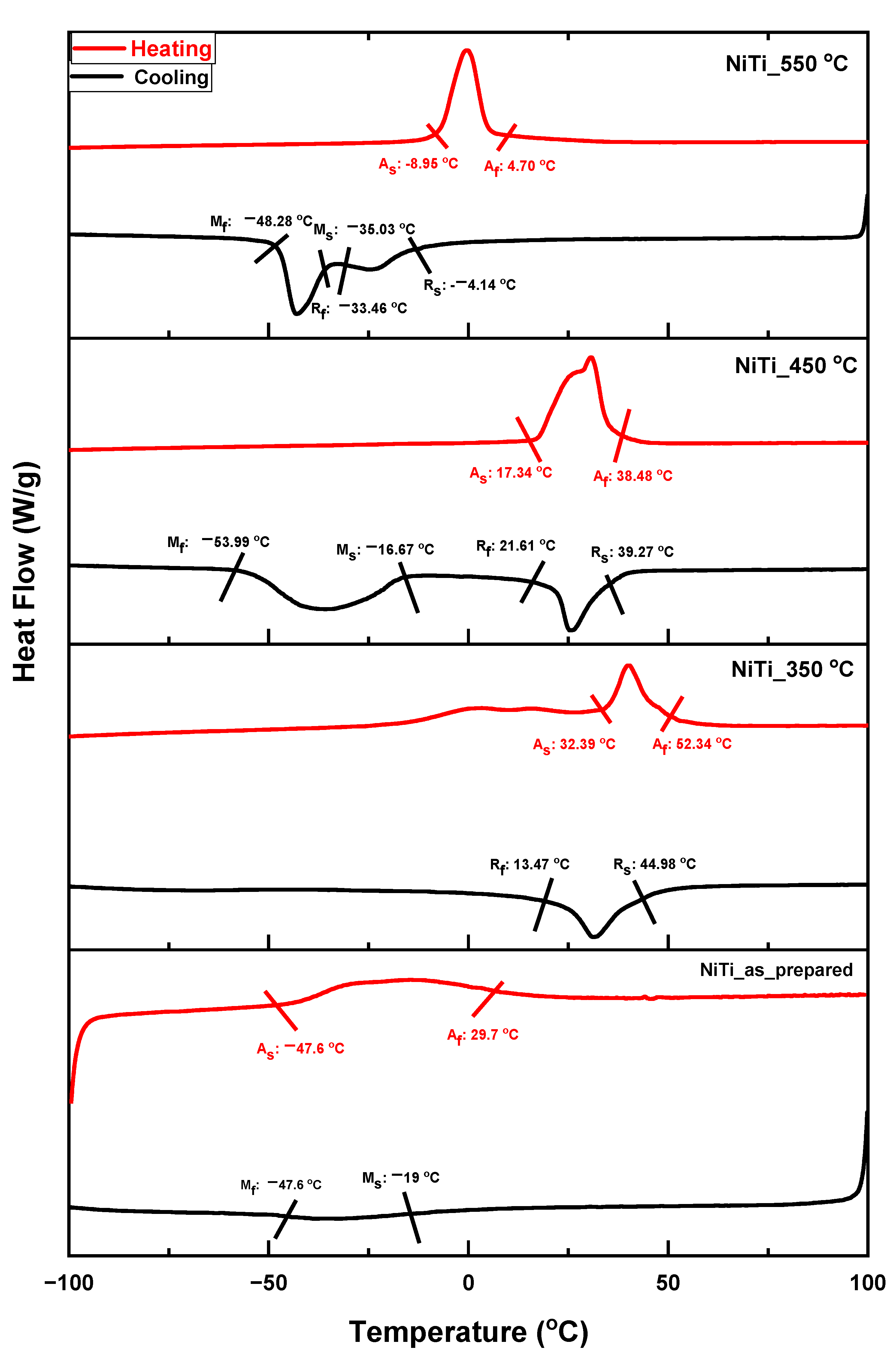

3.1. DSC Analysis of the NiTi Alloy and the Annealed NiTi Alloys

3.2. XRD Analysis of the NiTi Alloy and the Annealed NiTi Alloys

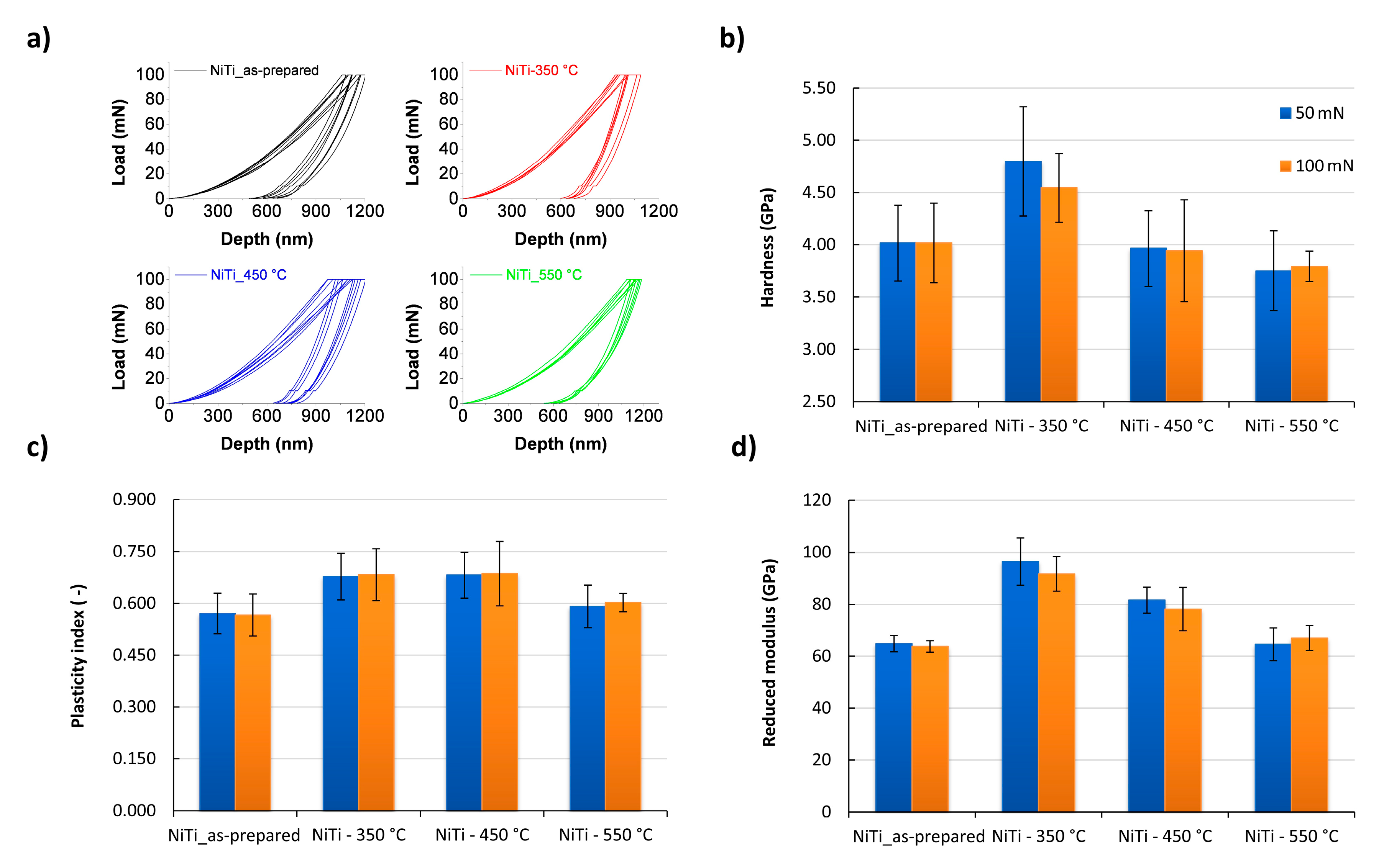

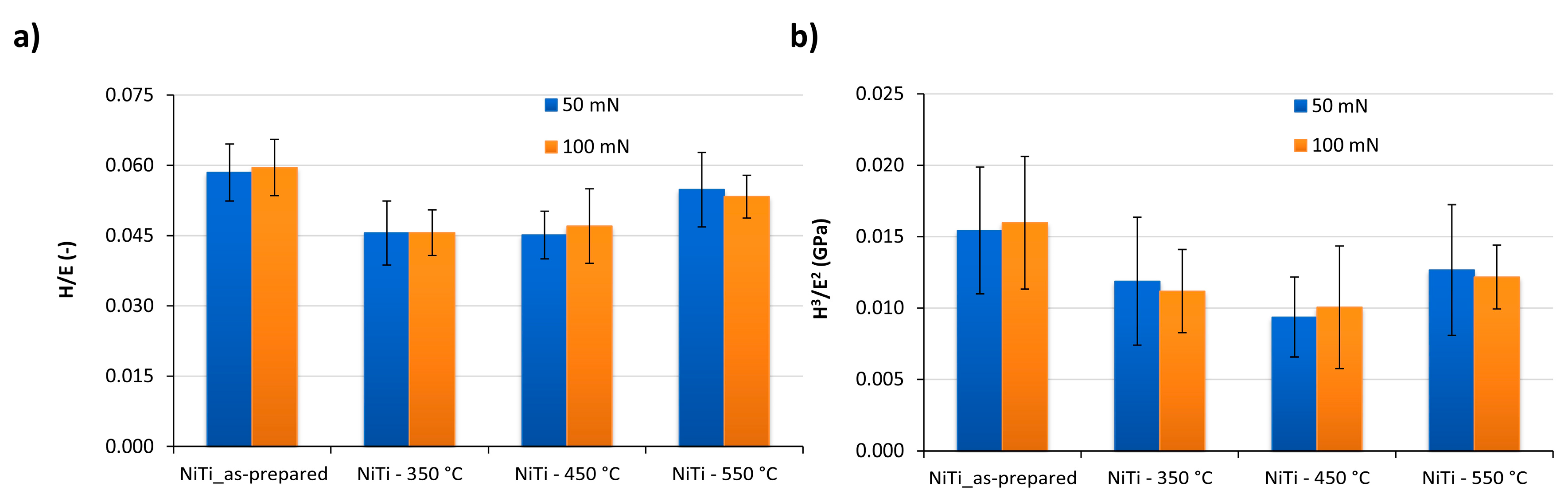

3.3. Nanoindentation of the NiTi Alloy and the Annealed NiTi Alloys

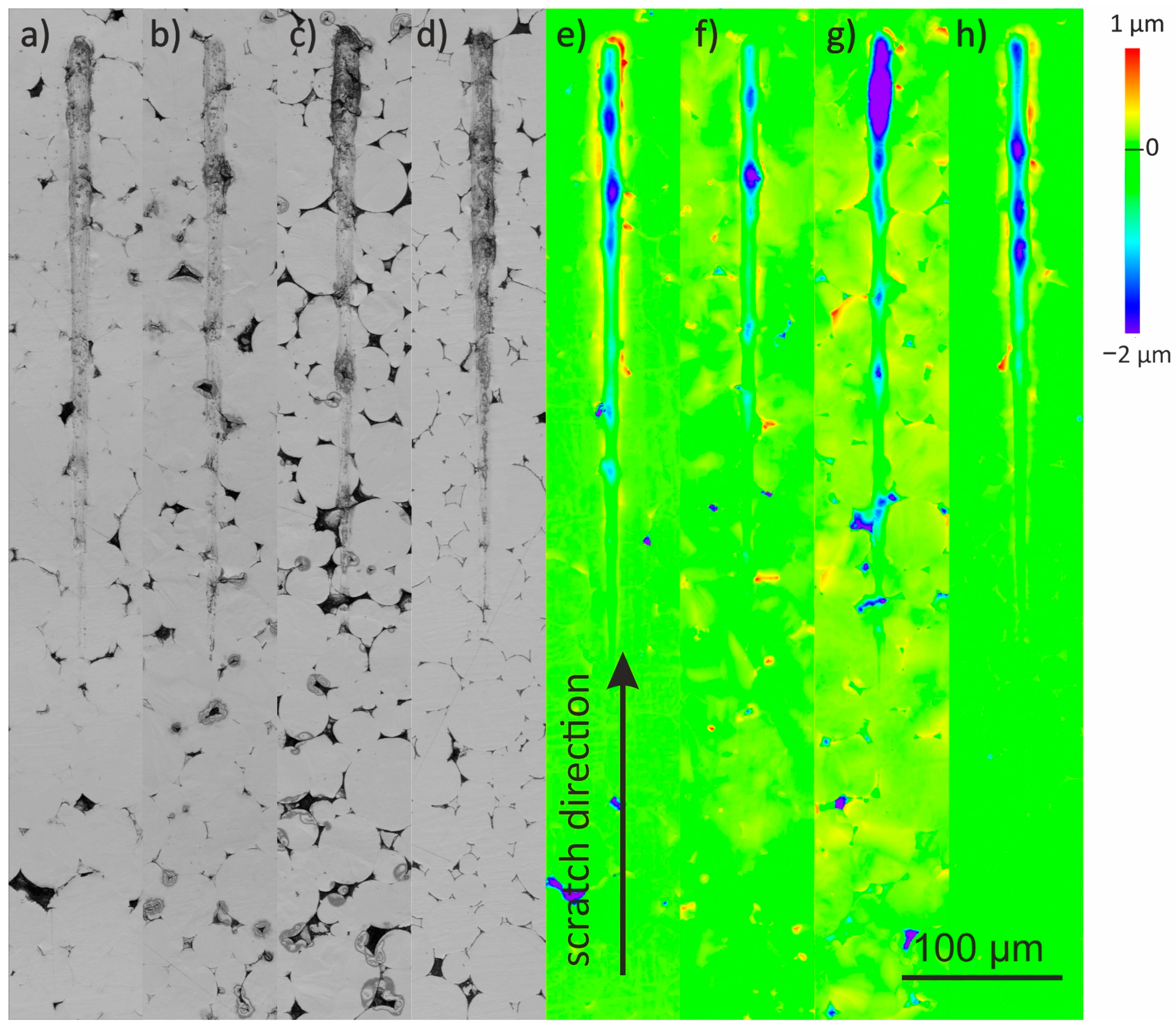

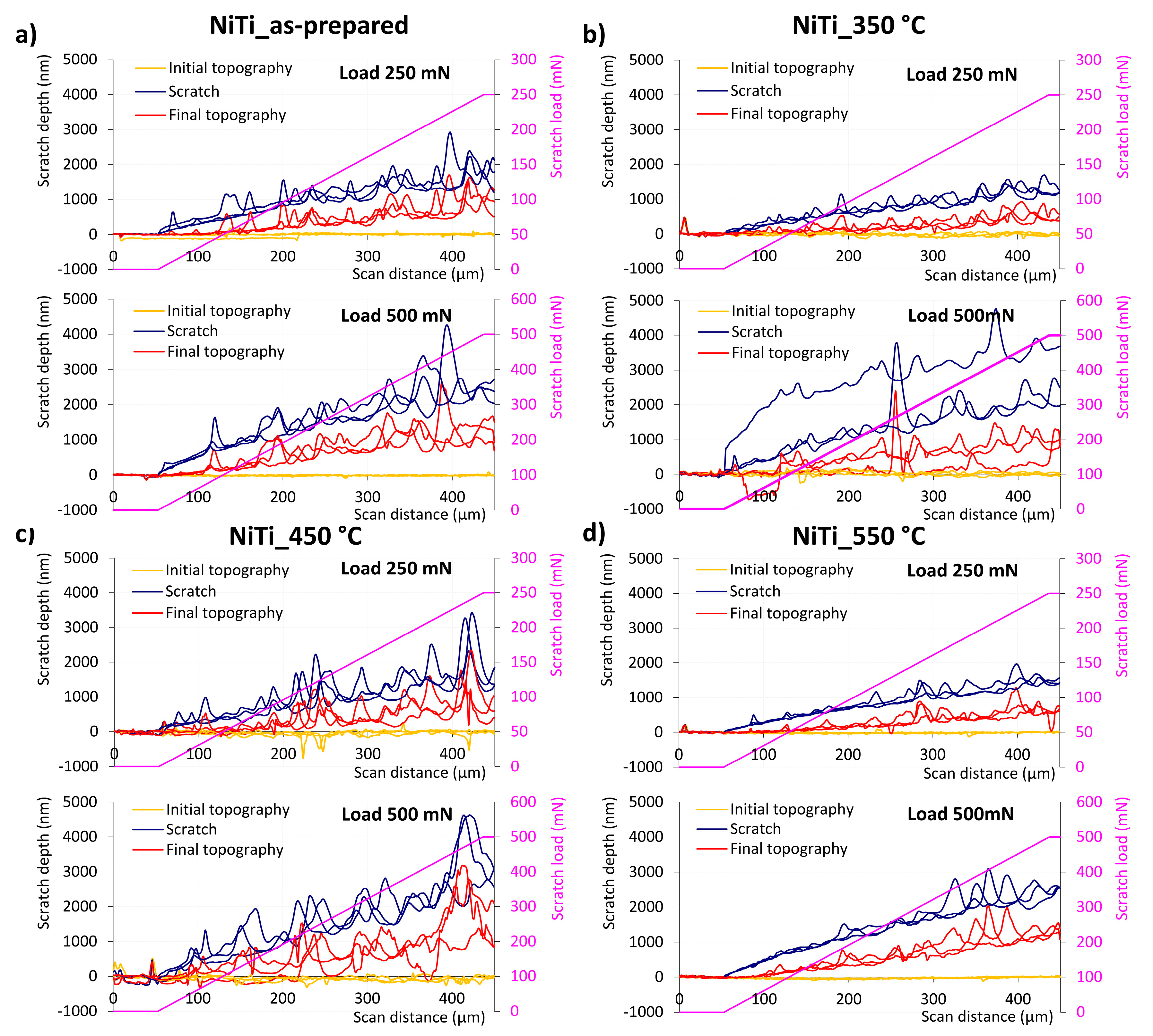

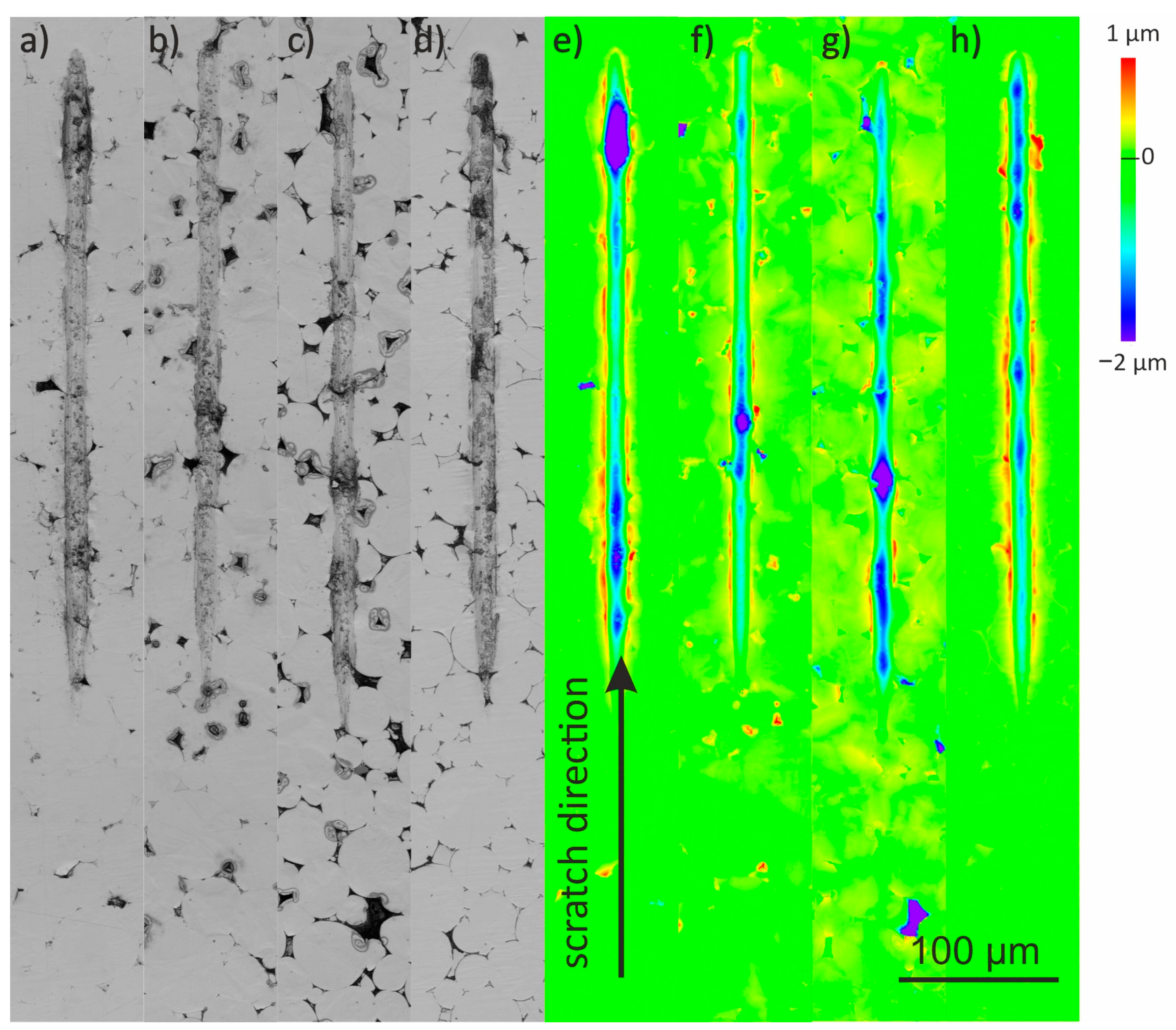

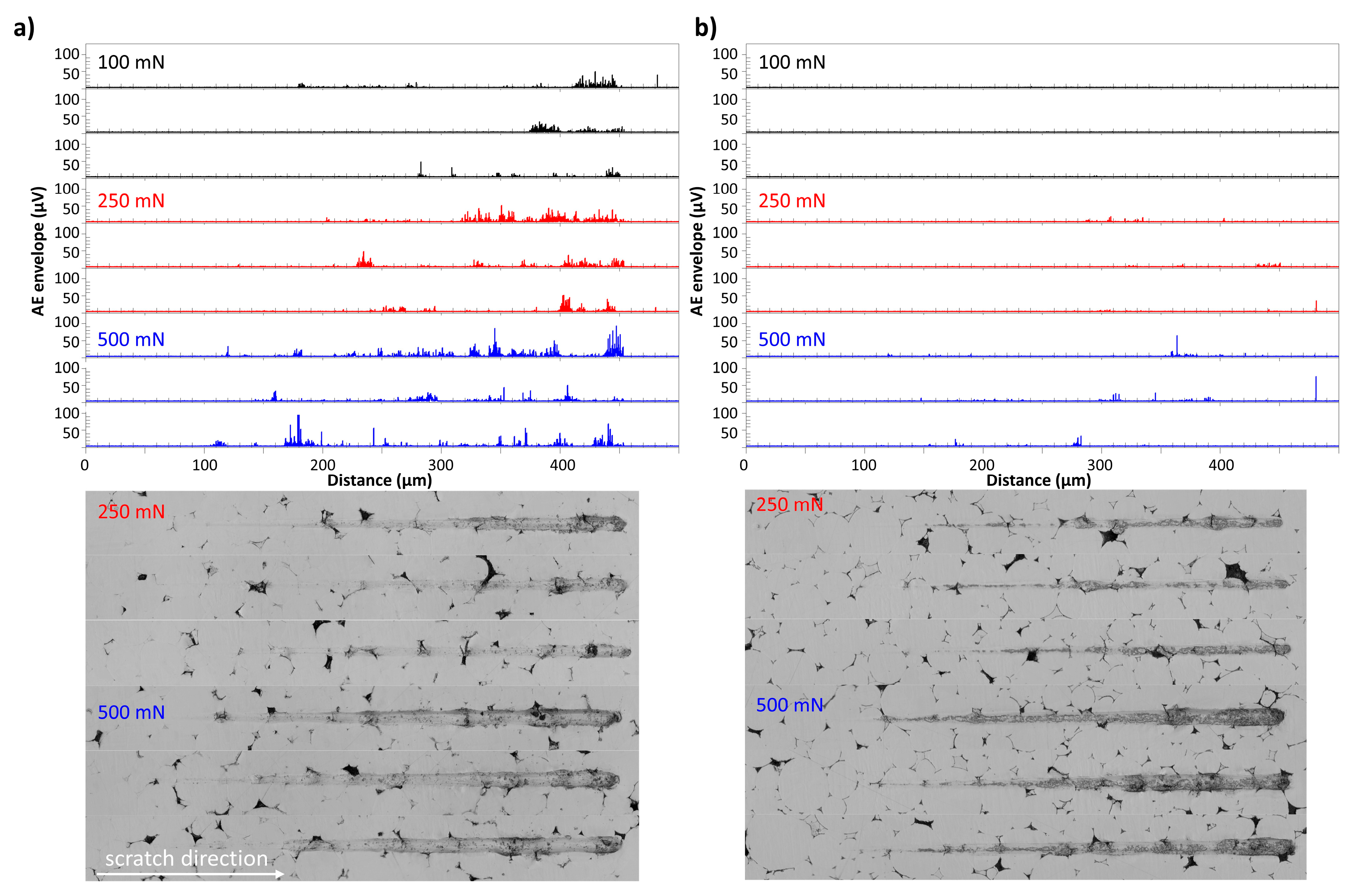

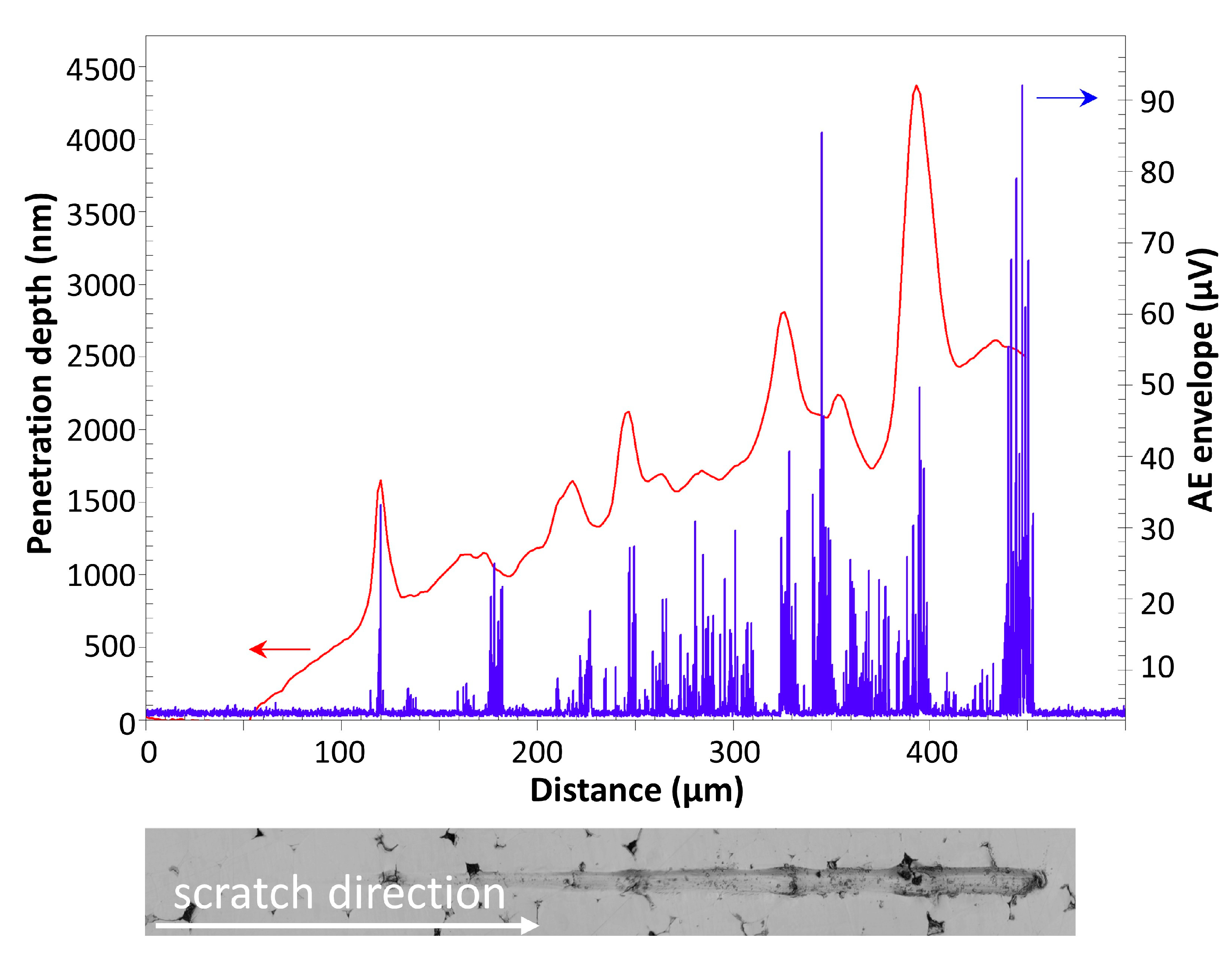

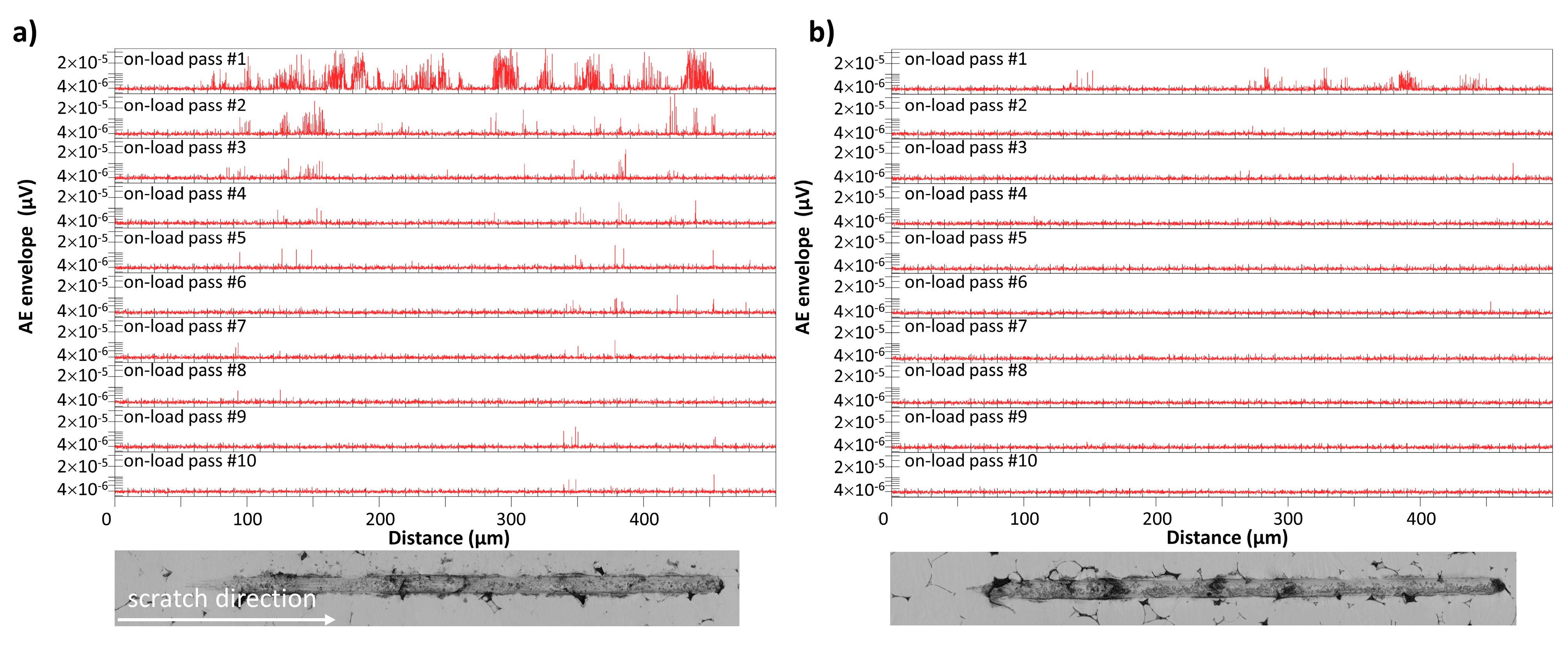

3.4. Scratch and Wear Tests for the NiTi Alloy and the Annealed NiTi Alloys

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Otsuka, K.; Ren, X. Physical metallurgy of Ti-Ni based shape memory alloys. Prog. Mater Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Shape Memory Alloys: A Material and a Technology. Adv. Eng. Mater. 2001, 3, 837–850. [Google Scholar] [CrossRef]

- Wang, F.E.; Buehler, W.J.; Pickart, S.J. Crystal structure and a unique “martensitic“ transition of TiNi. J. Appl. Phys. 1965, 36, 3232. [Google Scholar] [CrossRef]

- Ball, A. On the importance of work hardening in the design of wear-resistant materials. Wear 1983, 91, 201. [Google Scholar] [CrossRef]

- El Feninat, F.; Laroche, G.; Fiset, M.; Mantovani, D. Shape memory materials for biomedical applications. Adv. Eng. Mater. 2002, 4, 91–104. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Liang, Y.N.; Li, S.Z.; Jin, Y.B.; Jin, W.; Li, S. Wear behavior of a TiNi alloy. Wear 1996, 198, 236–241. [Google Scholar] [CrossRef]

- Shearwood, C.; Fu, Y.Q.; Yu, L.; Khor, K.A. Spark plasma sintering of TiNi nano-powder. Scr. Mater. 2005, 52, 455–460. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, J.; Wang, Z.; Qiao, Y.; Xiong, T.; Zheng, Y. Cavitation Erosion and Jet Impingement Erosion Behavior of the NiTi Coating Produced by Air Plasma Spraying. Coatings 2018, 8, 346. [Google Scholar] [CrossRef] [Green Version]

- Feng, Y.; Du, Z.; Hu, Z. Effect of Ni Addition on the Corrosion Resistance of NiTi Alloy Coatings on AISI 316L Substrate Prepared by Laser Cladding. Coatings 2021, 11, 1139. [Google Scholar] [CrossRef]

- Salvetr, P.; Dlouhý, J.; Školáková, A.; Průša, F.; Novák, P.; Karlík, M.; Haušild, P. Influence of Heat Treatment on Microstructure and Properties of NiTi46 Alloy Consolidated by Spark Plasma Sintering. Materials 2019, 12, 4075. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Samal, S.; Tyc, O.; Cizek, J.; Klecka, J.; Lukáč, F.; Molnárová, O.; de Prado, E.; Weiss, Z.; Kopeček, J.; Heller, L.; et al. Fabrication of Thermal Plasma Sprayed NiTi Coatings Possessing Functional Properties. Coatings 2021, 11, 610. [Google Scholar] [CrossRef]

- Tomastik, J.; Ctvrtlik, R.; Drab, M.; Manak, J. On the Importance of Combined Scratch/Acoustic Emission Test Evaluation: SiC and SiCN Thin Films Case Study. Coatings 2018, 8, 196. [Google Scholar] [CrossRef] [Green Version]

- Sewak, R.; Dey, C.C. Martenitic phase transformation in NiTi. Sci. Rep. 2019, 9, 13500. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Bao, L.; Liu, A.; Jin, X.; Tong, Y.; Luo, J.; Zhong, Z.; Zheng, Y. Microstructure, mechanical properties and superelasticity of biomedical porous NiTi alloy prepared by microwave sintering. Mater. Sci. Eng. C 2015, 46, 387–393. [Google Scholar] [CrossRef]

- Velmurugan, C.; Senthilkumar, V.; Biswas, K.; Yadav, S. Densification and microstructural evolution of spark plasma sintered NiTi shape memory alloy. Adv. Powder Technol. 2018, 29, 2456–2462. [Google Scholar] [CrossRef]

- Yadav, K.C.; Verma, M. Review of tribology (friction, wear and lubrication) study on titanium and its alloy surfaces. Int. J. Rec. Adv. Eng. Technol. 2016, 2347, 58–63. [Google Scholar]

- Yang, R.; Ma, W.; Duan, C.; Yang, Z.; Zhang, Y.; Wang, T.; Wang, Q. Tribologically induced amorphization in the subsurface of aged Ni-rich TiNi alloy during dry sliding. Intermetallics 2019, 113, 106574. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, R.; Hu, S.; Tu, F.; Jin, W. Research combining experiment and FEM analysis on sliding wear behaviors and mechanisms of TiNi alloy. Wear 2017, 386–387, 218–222. [Google Scholar] [CrossRef]

- Rominiyi, A.L.; Shongwe, M.B.; Ogunmuyiwa, E.N.; Babalola, B.J.; Lepele, P.F.; Olubambi, P.A. Effect of nickel addition on densification, microstructure and wear behaviour of spark plasma sintered CP-titanium. Mater. Chem. Phys. 2020, 240, 122130. [Google Scholar]

- Samal, S.; Molnárová, O.; Průša, F.; Kopeček, J.; Heller, L.; Šittner, P.; Škodová, M.; Abate, L.; Blanco, I. Net-Shape NiTi Shape Memory Alloy by Spark Plasma Sintering Method. Appl. Sci. 2021, 11, 1802. [Google Scholar] [CrossRef]

- Ctvrtlik, R.; Tomastik, J.; Vaclavek, L.; Beake, B.D.; Harris, A.J.; Martin, A.S.; Hanak, M.; Abrham, P. High-Resolution Acoustic Emission Monitoring in Nanomechanics. JOM 2019, 71, 3358–3367. [Google Scholar] [CrossRef]

- Lukás, P.; Sittner, P.; Neov, D.; Novák, V.; Lugovoy, D.; Tovar, M. R-Phase Phenomena in Neutron Diffraction Investigations of Thermomechanically Loaded NiTi Polycrystals. Mater. Sci. Forum Vol. 2002, 404–407, 835–840. [Google Scholar] [CrossRef]

- Ling, H.C.; Roy, K. Stress-Induced Shape Changes and Shape Memory in the R and Martensite Transformations in Equiatomic NiTi. Metall Mater. Trans. A 1981, 12, 2101–2111. [Google Scholar] [CrossRef]

- Salvetr, P.; Kubatík, T.F.; Pignol, D.; Novák, P. Fabrication of Ni-Ti Alloy by Self-Propagating High-Temperature Synthesis and Spark Plasma Sintering Technique. Metall. Mater. Trans. B. 2017, 48, 772–778. [Google Scholar] [CrossRef]

- Ni, W.; Cheng, Y.T.; Lukitsch, M.J.; Weiner, A.M.; Lev, L.C.; Grummon, D.S. Effects of the ratio of hardness to Young’s modulus on the friction and wear behavior of bilayer coatings. Appl. Phys. Lett. 2004, 85, 4028–4030. [Google Scholar] [CrossRef]

- Pintaude, G. Introduction of the Ratio of the Hardness to the Reduced Elastic Modulus for Abrasion. In Tribology-Fundamentals and Advancements; Gegner, J., Ed.; IntechOpen: London, UK, 2013. [Google Scholar]

- Nishida, M.; Wayman, C.M.; Honma, T. Precipitation processes in near-equiatomic TiNi shape memory alloys. Metall. Trans. A 1986, 17, 1505–1515. [Google Scholar] [CrossRef]

- Adharapurapu, R.R.; Jiang, F.; Vecchio, K.S. Aging effects on hardness and dynamic compressive behavior of Ti–55Ni (at.%) alloy. Mater. Sci. Eng. A 2010, 527, 1665–1676. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Samal, S. Thermal plasma technology: The prospective future in material processing. J. Clean. Prod. 2017, 142, 3131–3150. [Google Scholar] [CrossRef]

- Tomastik, J.; Ctvrtlik, R.; Ingr, T.; Manak, J.; Opletalova, A. Effect of Nitrogen Doping and Temperature on Mechanical Durability of Silicon Carbide Thin Films. Sci. Rep. 2018, 8, 10428. [Google Scholar] [CrossRef] [PubMed]

- Saedi, S.; Turabi, A.S.; Taheri Andani, M.; Haberland, C.; Karaca, H.; Elahinia, M. The influence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting. J. Alloys Compd. 2016, 677, 204–210. [Google Scholar] [CrossRef]

- Hu, Z.-Y.; Zhang, Z.-H.; Cheng, X.-W.; Wang, F.-C.; Zhang, Y.-F.; Li, S.-L. A review of multi-physical fields induced phenomena and effects in spark plasma sintering: Fundamentals and applications. Mater. Des. 2020, 191, 108662. [Google Scholar] [CrossRef]

- Cai, W.; Men, X.L.; Zhao, L.C. Recent development of TiNi-based shape memory alloys. Solid State Mater. Sci. 2005, 9, 296–302. [Google Scholar] [CrossRef]

- de Araújo, C.J.; da Silva, N.J.; da Silva, M.M.; Gonzalez, C.H. A comparative study of Ni–Ti and Ni–Ti–Cu shape memory alloy processed by plasma melting and injection molding. Mater. Des. 2011, 32, 4925–4930. [Google Scholar] [CrossRef]

- Gonzalez, C.H.; Oliveira, C.A.N.; Pina, E.A.C.; Filho, S.L.U.; Filho, O.O.A.; de Araújo, C.J. Heat treatments and thermomechanical cycling influences on the R-phase in Ti–Ni shape memory alloys. Mater. Res. 2010, 13, 325–331. [Google Scholar] [CrossRef] [Green Version]

- Pharr, G.M.; Oliver, W.C.; Cook, R.F.; Kirchner, P.D.; Kroll, M.C.; Dinger, T.R.; Clarke, D.R. Electrical resistance of metallic contacts on silicon and germanium during indentation. J. Mater. Res. 1992, 7, 961–972. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Chung, Y.W.; Cutiongco, E.C.; Bhatia, C.S.; White, R.L.; Rhoades, R.L.; Gorbatkin, S.M. Nanoindentation and nano scratching of hard coating materials for magnetic disks. Mater. Sci. Eng. 1995, 356, 767–772. [Google Scholar]

- Beake, B.D.; Isern, L.; Bhattacharyya, D.; Endrino, J.L.; Lawson, K.; Walker, T. Nano- and micro-scale impact testing of zirconia, alumina and zirconia-alumina duplex optical coatings on glass. Wear 2020, 462–463, 203499. [Google Scholar] [CrossRef]

- Arciniegas, A.; Casals, J.; Manero Pena, J.; Gil, F.J. Study of hardness and wear behaviour of NiTi shape memory alloys. J. Alloy. Compo. 2008, 460, 213–219. [Google Scholar] [CrossRef]

- Burnett, P.J.; Rickerby, D.S. The relationship between hardness and scratch adhesion. Thin Solid Films 1987, 154, 403–416. [Google Scholar] [CrossRef]

- Li, D.Y.; Liu, R. The mechanism responsible for high wear resistance of pseudo-elastic TiNi alloy-a novel tribo-material. Wear 1999, 225–229, 777–783. [Google Scholar] [CrossRef]

- Neupane, R.; Farhat, Z. Wear and Dent Resistance of Superelastic TiNi Alloy. Wear 2013, 301, 682–687. [Google Scholar] [CrossRef]

| Sample | As (°C) | Af (°C) | Rs (°C) | Rf (°C) | Ms (°C) | Mf (°C) |

|---|---|---|---|---|---|---|

| NiTi_as-prepared | –47.6 | 29.7 | - | - | –19 | –47.6 |

| NiTi powder | 32 | 62 | 40 | –2 | –19 | –47.6 |

| NiTi_350 °C | 32.39 | 52.34 | 44.98 | 13.47 | - | |

| NiTi_450 °C | 17.34 | 38.48 | 39.27 | 21.61 | –16.67 | –53.99 |

| NiTi_550 °C | –8.95 | 4.70 | –14.14 | –33.46 | –35.03 | –48.28 |

| Sample | Phase/Lattice | Space Group | Content (% m/m) | RBragg | Crystallite Size (nm) | Strain (%) | Rprofile | D-stat |

|---|---|---|---|---|---|---|---|---|

| NiTi particles | NiTi cubic | Pm-3m | 78.5 | 6.22 | 74.8 | 0.03 | 0.63 | 1.72 |

| NiTi monoclinic | P21/m | 21.5 | 7.84 | 25.2 | 0.10 | 1.88 | 0.73 | |

| NiTi_as-prepared | NiTi cubic | Pm-3m | 77.7 | 1.43 | 30.2 | 0.00 | 1.69 | 0.21 |

| NiTi monoclinic | P21/m | 22.3 | 1.22 | 6.3 | 1.00 | 1.69 | 0.21 | |

| NiTi_350 °C | NiTi trigonal | P-3 | 71.7 | 2.48 | 33.1 | 0.10 | 1.27 | 0.43 |

| NiTi monoclinic | P21/m | 16.2 | 3.49 | 7.7 | 1.00 | 1.37 | 0.31 | |

| Ni4Ti3 rhomboedric | R-3 | 12.1 | 3.97 | NC | NC | NC | NC | |

| NiTi_450 °C | NiTi trigonal | P-3 | 61.8 | 0.12 | 28 | 0.20 | 1.11 | 0.63 |

| NiTi monoclinic | P21/m | 25.5 | 0.28 | 15.5 | 1.00 | 1.08 | 0.70 | |

| Ni4Ti3 rhomboedric | R-3 | 12.7 | 0.27 | NC | NC | NC | NC | |

| NiTi_550 °C | NiTi cubic | Pm-3m | 88.5 | 3.88 | 25 | 0.00 | 1.90 | 0.12 |

| NiTi monoclinic | P21/m | 4.4 | 1.19 | 7.5 | 0.00 | 1.88 | 0.12 | |

| Ni4Ti3 rhomboedric | R-3 | 6.5 | 2.22 | NC | NC | NC | NC | |

| TiO2 tetragonal | P42/mmm | 0.6 | 0.98 | NC | NC | NC | NC |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samal, S.; Cibulková, J.; Čtvrtlík, R.; Tomáštík, J.; Václavek, L.; Kopeček, J.; Šittner, P. Tribological Behavior of NiTi Alloy Produced by Spark Plasma Sintering Method. Coatings 2021, 11, 1246. https://doi.org/10.3390/coatings11101246

Samal S, Cibulková J, Čtvrtlík R, Tomáštík J, Václavek L, Kopeček J, Šittner P. Tribological Behavior of NiTi Alloy Produced by Spark Plasma Sintering Method. Coatings. 2021; 11(10):1246. https://doi.org/10.3390/coatings11101246

Chicago/Turabian StyleSamal, Sneha, Jana Cibulková, Radim Čtvrtlík, Jan Tomáštík, Lukáš Václavek, Jaromír Kopeček, and Petr Šittner. 2021. "Tribological Behavior of NiTi Alloy Produced by Spark Plasma Sintering Method" Coatings 11, no. 10: 1246. https://doi.org/10.3390/coatings11101246

APA StyleSamal, S., Cibulková, J., Čtvrtlík, R., Tomáštík, J., Václavek, L., Kopeček, J., & Šittner, P. (2021). Tribological Behavior of NiTi Alloy Produced by Spark Plasma Sintering Method. Coatings, 11(10), 1246. https://doi.org/10.3390/coatings11101246