Influence of NaCl Freeze–Thaw Cycles on the Mechanical Strength of Reactive Powder Concrete with the Assembly Unit of Sulphoaluminate Cement and Ordinary Portland Cement

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Raw Materials

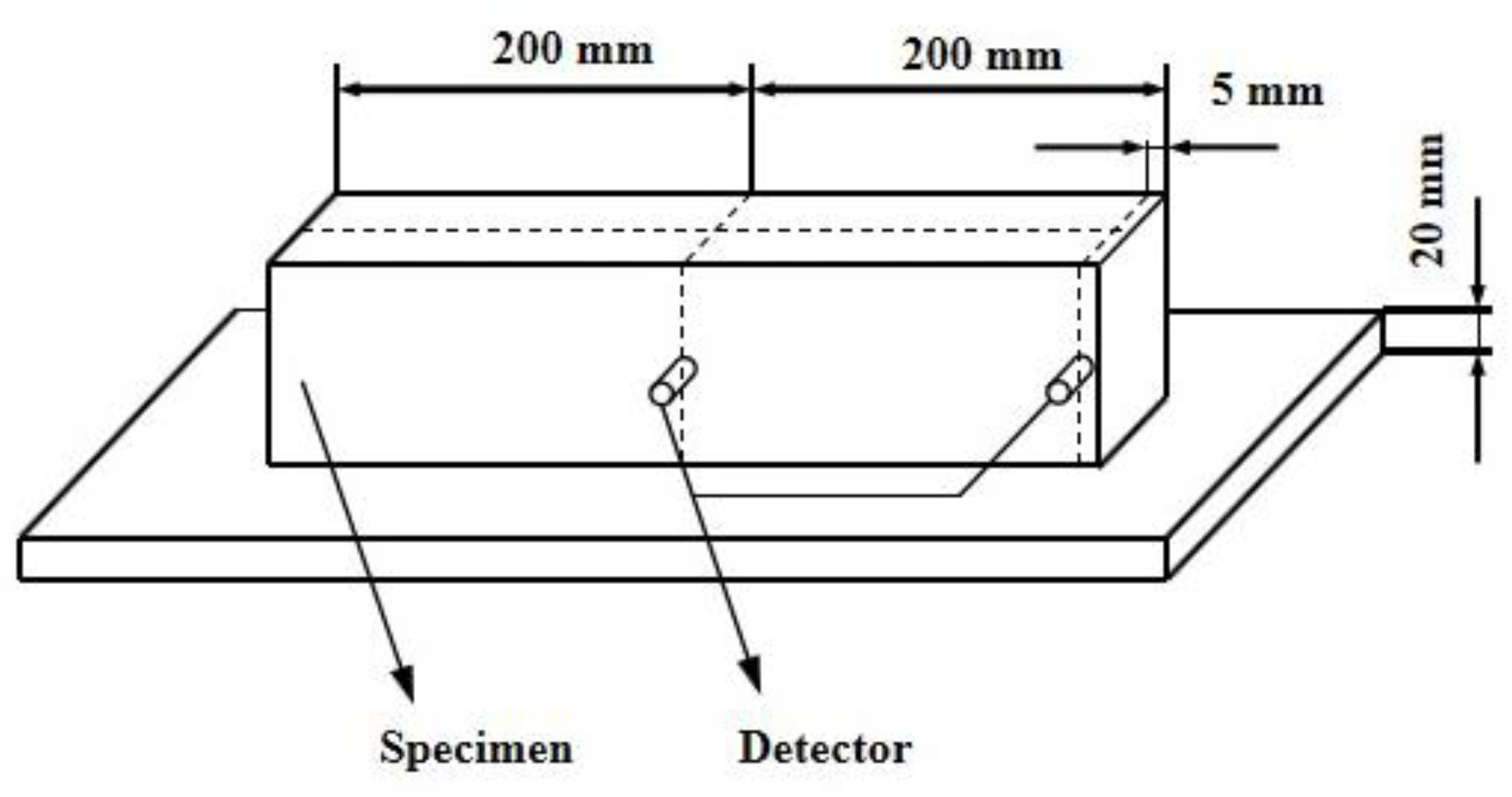

2.2. Measurement Methods

3. Results and Discussion

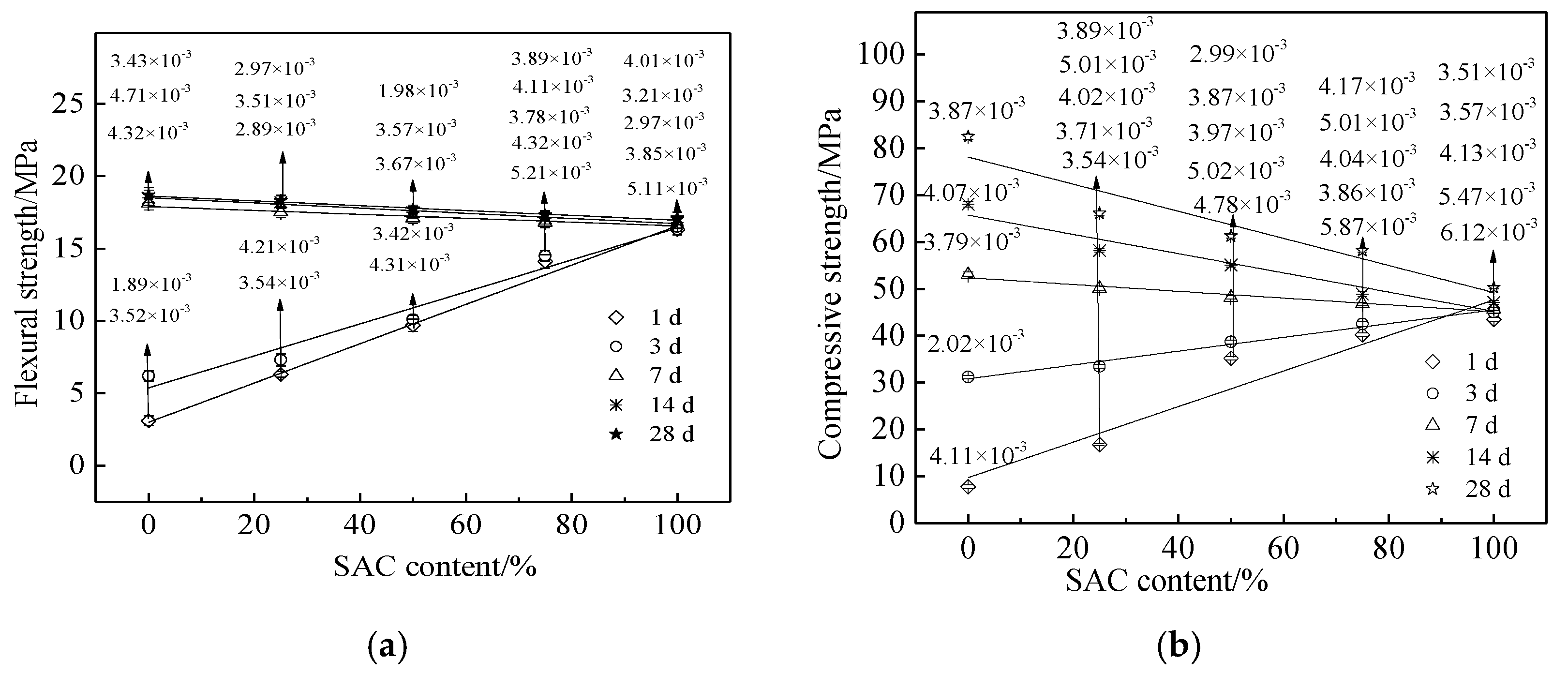

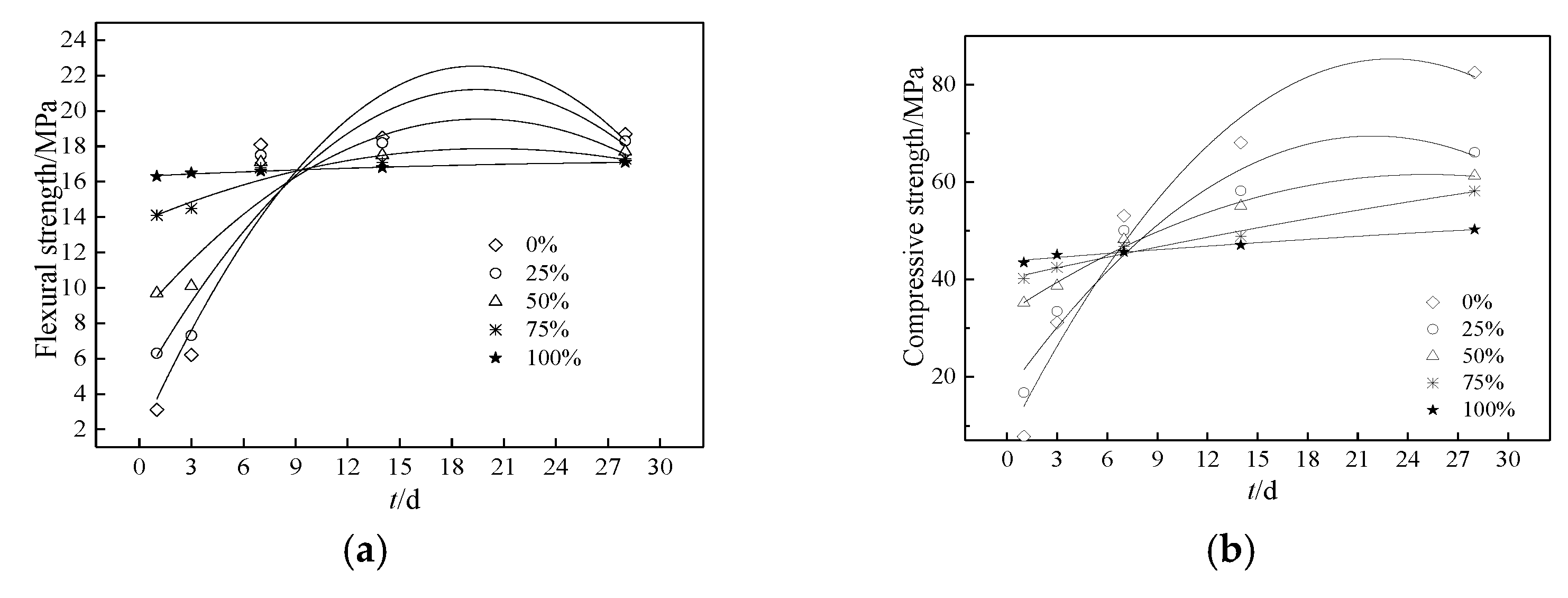

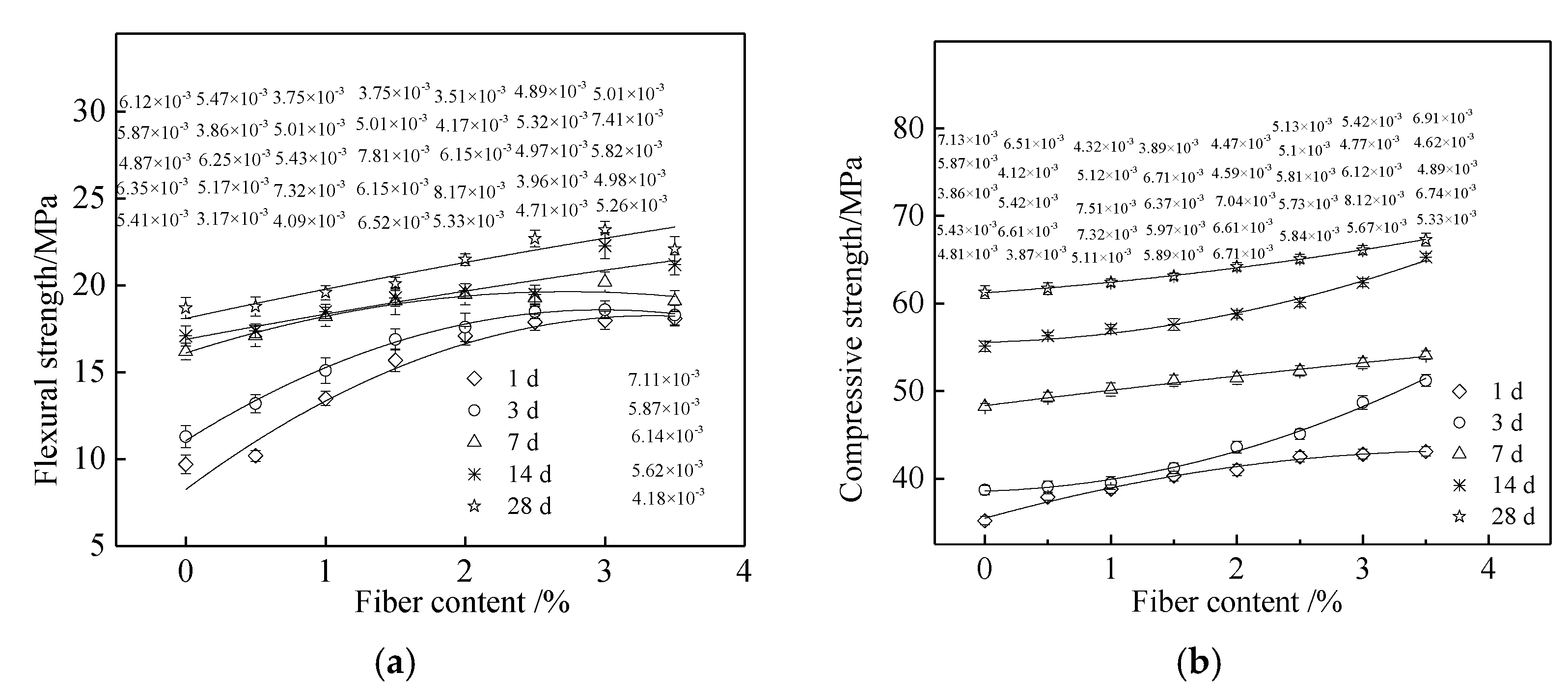

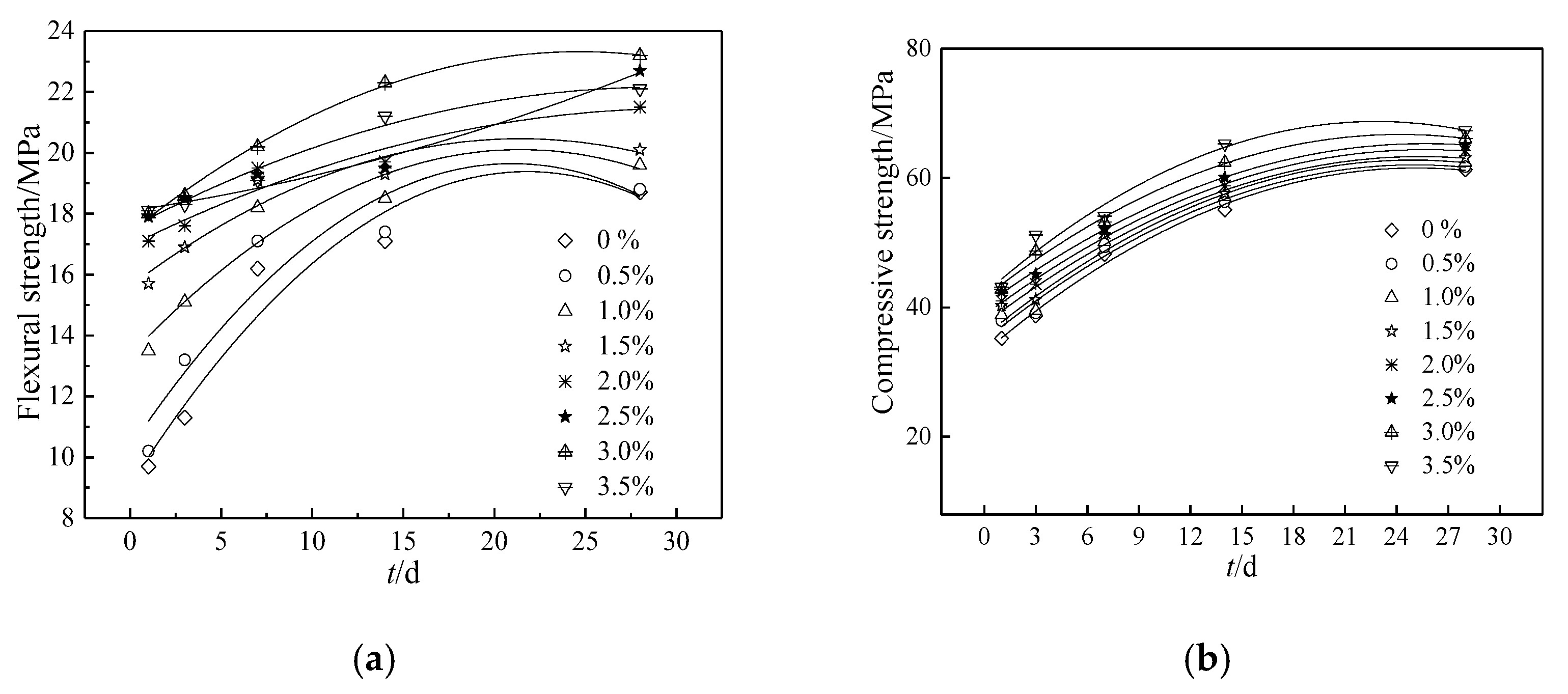

3.1. Mechanical Strengths

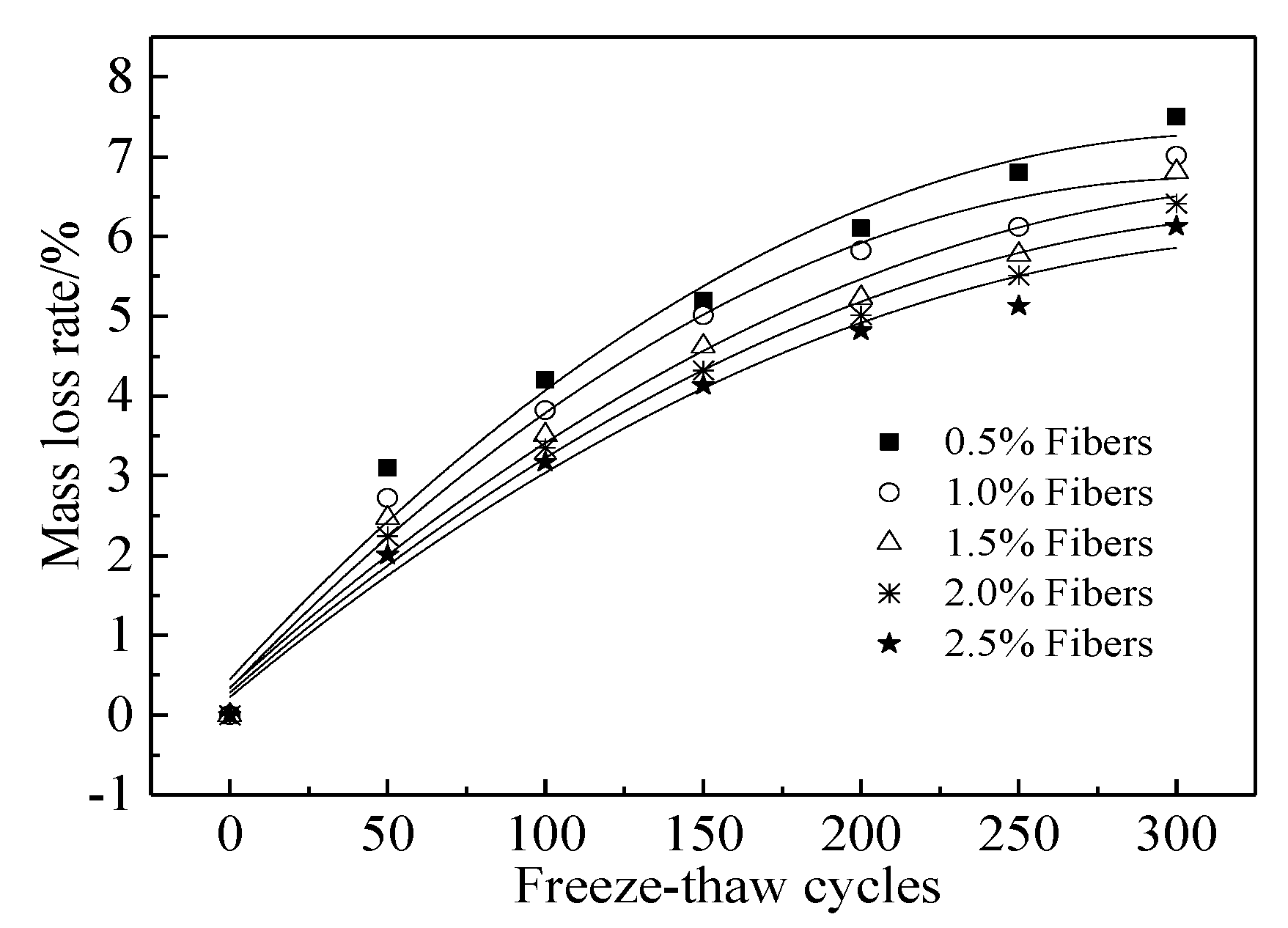

3.2. Mass Loss of RPC during NaCl Freeze-Thaw Cycles

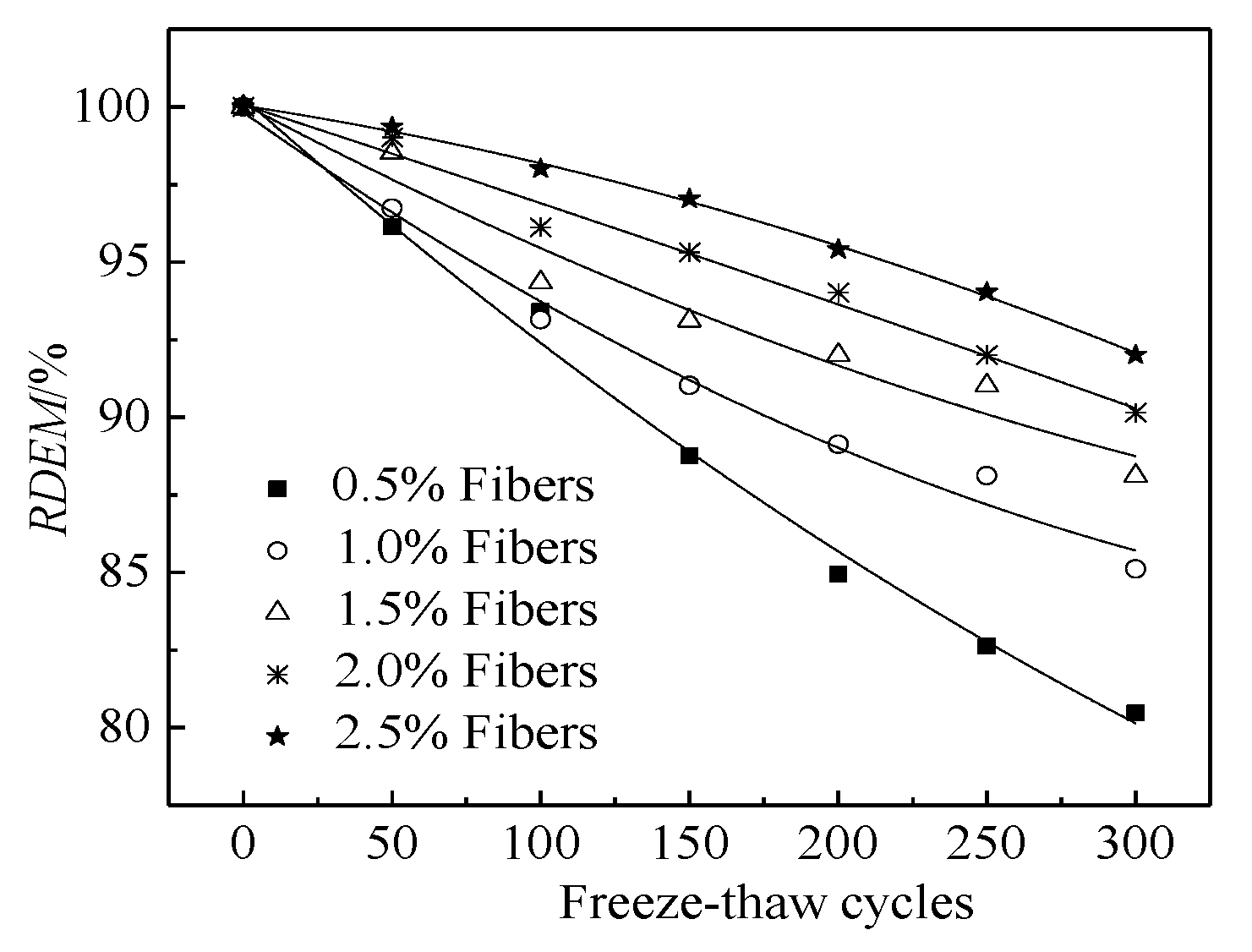

3.3. Mechanical Strengths Loss Rate of RPC during NaCl Freeze-Thaw Cycles

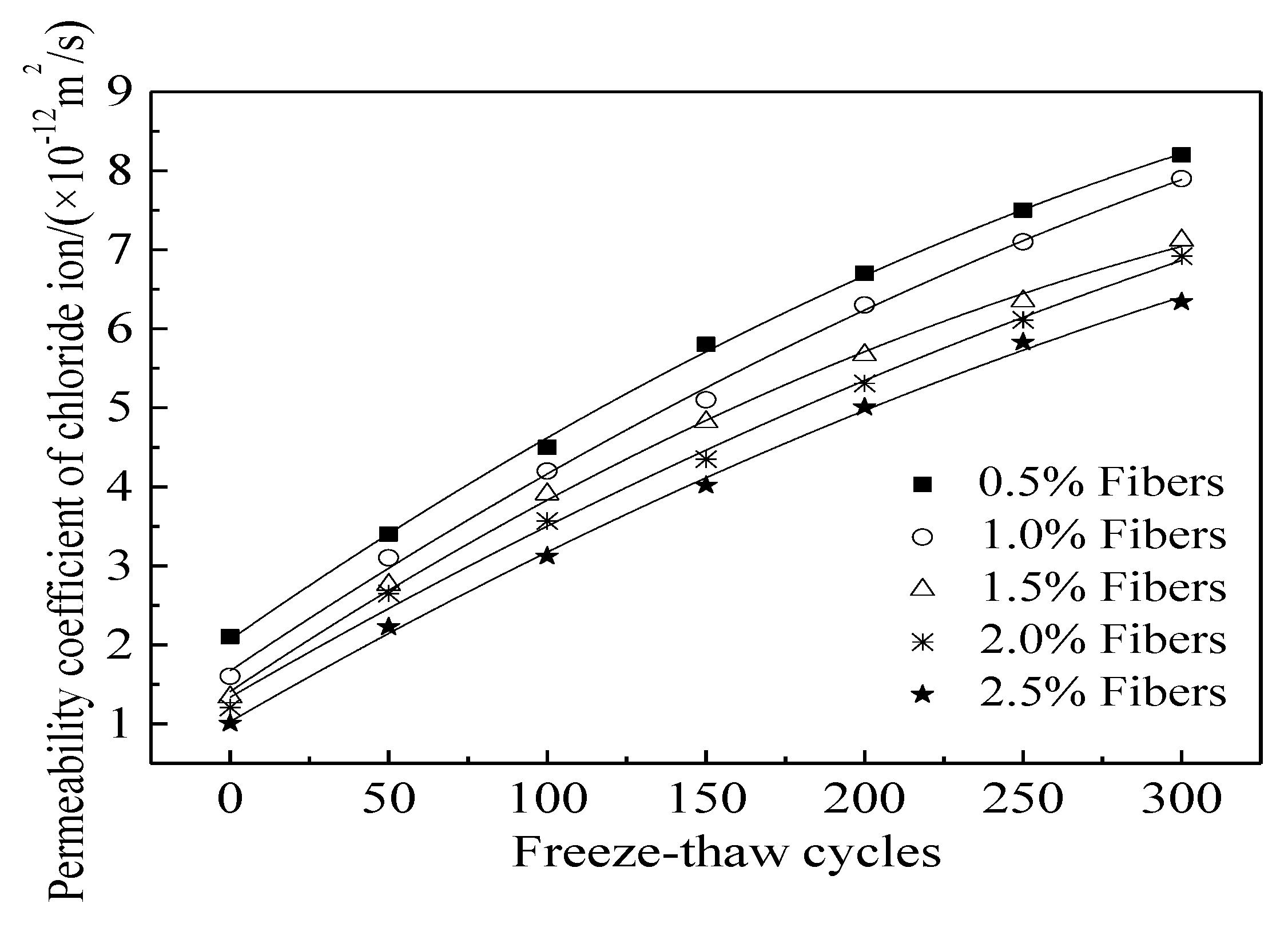

3.4. Chloride Migration Coefficient during Freeze–Thaw Cycles

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mo, Z.; Gao, X.; Su, A. Mechanical performances and microstructures of metakaolin contained UHPC matrix under steam curing conditions. Constr. Build. Mater. 2021, 268, 121112. [Google Scholar] [CrossRef]

- Ormellese, M.; Berra, M.; Bolzoni, F.; Pastore, T. Corrosion inhibitors for chlorides induced corrosion in reinforced concrete structures. Cem. Concr. Res. 2006, 36, 536–547. [Google Scholar] [CrossRef]

- Cai, G.; Zhao, J. Application of sulphoaluminate cement to repair deteriorated concrete members in chloride ion rich environment-A basic experimental investigation of durability properties. KSCE J. Civil Eng. 2016, 20, 2832–2841. [Google Scholar] [CrossRef] [Green Version]

- Hong, X.; Wang, H.; Shi, F. Influence of NaCl freeze thaw cycles and cyclic loading on the mechanical performance and permeability of sulphoaluminate cement reactive powder concrete. Coatings 2020, 10, 1227. [Google Scholar] [CrossRef]

- Kuryatnyk, T.; Chabannet, M.; Ambroise, J.; Pera, J. Improvement of calcium sulphate water resistance by addition of calcium sulphoaluminate clinker. Mater. Lett. 2008, 62, 3713–3715. [Google Scholar] [CrossRef]

- Wang, H.; Gao, X.; Liu, J.; Ren, M.; Lu, A. Multi-functional properties of carbon nanofiber reinforced reactive powder concrete. Constr. Build. Mater. 2018, 187, 699–707. [Google Scholar] [CrossRef]

- Wang, H.; Shi, F.; Shen, J.; Zhang, A.; Zhang, L.; Huang, H.; Liu, J.; Jin, K.; Feng, L.; Tang, Z. Research on the self-sensing and mechanical properties of aligned stainless steel fiber reinforced reactive powder concrete. Cem. Concr. Compos. 2021, 119, 104001. [Google Scholar] [CrossRef]

- Dong, S.; Han, B.; Yu, X.; Ou, J. Constitutive model and reinforcing mechanisms of uniaxial compressive property for reactive powder concrete with super-fine stainless wire. Composites Part B 2019, 166, 298–309. [Google Scholar] [CrossRef]

- Dong, S.; Han, B.; Yu, X.; Ou, J. Dynamic impact behavior and constitutive model of super-fine stainless wire reinforced reactive powder concrete. Construct. Build. Mater. 2018, 184, 602–616. [Google Scholar] [CrossRef]

- Wang, H.; Jin, K.; Zhang, A.; Zhang, L.; Han, Y.; Liu, J.; Shi, F.; Feng, L. External erosion of sodium chloride on the degradation of self-sensing and mechanical properties of aligned stainless steel fiber reinforced reactive powder concrete. Constr. Build. Mater. 2021, 275, 06629. [Google Scholar]

- Wang, H.; Gao, X.; Liu, J. Effects of salt freeze-thaw cycles and cyclic loading on the piezoresistive properties of carbon nanofibers mortar. Constr. Build. Mater. 2018, 177, 192–201. [Google Scholar] [CrossRef]

- Materazzi, A.; Ubertini, F.; Alessandro, D. Carbon nanotube cement-based transducers for dynamic sensing of strain. Cement Concr. Compos. 2013, 37, 2–11. [Google Scholar] [CrossRef]

- Dong, S.; Han, B.; Ou, J.; Li, Z.; Han, L.; Yu, X.; Li, Z.; Han, L.; Yu, X. Electrically conductive behaviors and mechanisms of short-cut super-fine stainless wire reinforced reactive powder concrete. Cement Concr. Compos. 2016, 72, 48–65. [Google Scholar] [CrossRef] [Green Version]

- Gencel, O.; Ozel, C.; Brostow, W.; Martinez-Barrera, G. Mechanical properties of self-compacting concrete reinforced with polypropylene fibres. Mater. Res. Innov. 2011, 15, 216–225. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Soutsos, M.; Le, T.; Lampropoulos, A. Flexural performance of fibre reinforced concrete made with steel and synthetic fibres. Constr. Build. Mater. 2012, 36, 704–710. [Google Scholar] [CrossRef]

- Iyer, P.; Kenno, S.; Das, S. Mechanical properties of fiber-reinforced concrete made with basalt filament fibers. J. Mater. Civ. Eng. 2015, 27, 04015015. [Google Scholar] [CrossRef]

- Method of Testing Cements-Determination of Strength; The State Bureau of Quality and Technical Supervision: Beijing, China, 1999; GB/T 17671-1999.

- Standard for Test Method of Long-Term Performance and Durability of Ordinary Concrete; Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2009.

- Pelletier-Chaignat, L.; Winnefeld, F.; Lothenbach, B.; Müller, C.J. Beneficial use of limestone filler with calcium sulphoaluminate cement. Constr. Build. Mater. 2012, 26, 619–627. [Google Scholar] [CrossRef]

- Singh, M.; Kapur, P. Preparation of calcium sulphoaluminate cement using fertiliser plant wastes. J. Hazard. Mater. 2008, 157, 106–113. [Google Scholar] [CrossRef]

- Velazco, G.; Almanza, J.; Cortés, D.; Escobedo, J.; Escalante-Garcia, J. Effect of citric acid and the hemihydrate amount on the properties of a calcium sulphoaluminate cement. Mater. Constr. 2014, 64, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Tian, W.; Wang, M.; Qi, B.; Wang, W. Rapid strength formation of on-site carbon fiber reinforced high-performance concrete cured by ohmic heating. Constr. Build. Mater. 2020, 244, 118344. [Google Scholar] [CrossRef]

- Berger, S.; Céline Cau Dit Coumes, J.; Champenois, T.; Douillard, T.; Le Bescop, P.; Aouad, G.; Damidot, D. Stabilization of ZnCl2-containing wastes using calcium sulfoaluminate cement: Leaching behaviour of the solidified waste form, mechanisms of zinc retention. J. Hazard. Mater. 2011, 194, 268–276. [Google Scholar] [CrossRef] [PubMed]

- Aattache, A.; Soltani, R. Durability-related properties of early-age and long-termresistant laboratory elaborated polymer-based repair mortars. Constr. Build. Mater. 2020, 235, 117494. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, Q.; Pacheco-Torgal, F.; Zhang, Y. Hybrid effect of basalt fiber textile and macro polypropylene fiber on flexural load-bearing capacity and toughness of two-way concrete slabs. Constr. Build. Mater. 2020, 261, 119881. [Google Scholar] [CrossRef]

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Constr. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- Shen, D.; Liu, X.; Zeng, X.; Zhao, X.; Jiang, G. Effect of polypropylene plastic fibers length on cracking resistance of high performance concrete at early age. Constr. Build. Mater. 2020, 244, 117874. [Google Scholar] [CrossRef]

- Shi, F.; Pham, T.; Hao, H. Post-cracking behavior of basalt and macro polypropylene hybrid fibre reinforced concrete with different compressive strengths. Constr. Build. Mater. 2020, 262, 120108. [Google Scholar] [CrossRef]

- Du, H.X.; Qin, Y.X.; Zhang, W.; Zhang, N.; Hao, X.Y. Mechanics performance of high-performance concrete with polypropylene fibers. Appl. Mech. Mater. 2011, 99–100, 1233–1238. [Google Scholar] [CrossRef]

- Castoldi, R.; Souza, L.; Andrade Silva, F. Comparative study on the mechanical behavior and durability of polypropylene and sisal fiber reinforced concretes. Constr. Build. Mater. 2019, 211, 617–628. [Google Scholar] [CrossRef]

- Liu, Q.; Iqbal, M.; Yang, J.; Lu, X.-Y.; Zhang, P.; Rauf, M. Prediction of chloride diffusivity in concrete using artificial neural network: Modelling and performance evaluation. Constr. Build. Mater. 2021, 266, 12108. [Google Scholar]

- Ding, Y.; Huang, Y.; Zhang, Y.; Jalali, S.; Aguiar, J. Self-monitoring of freeze-thaw damage using triphasic electric conductive concrete. Constr. Build. Mater. 2015, 101, 440–446. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Zeng, Q.; Wang, L.; Yao, Y.; Li, K. Characterizing blended cement pastes under cyclic freeze-thaw actions by electrical resistivity. Constr. Build. Mater. 2013, 44, 477–486. [Google Scholar] [CrossRef]

- Shi, X.; Fay, L.; Peterson, M. Freeze-thaw damage and chemical change of a portland cement concrete in the presence of diluted deicers. Mater. Struct. 2010, 43, 933–946. [Google Scholar] [CrossRef]

- Jiang, W.; Shen, X.; Xia, J.; Mao, L.; Yang, J.; Liu, Q. A numerical study on chloride diffusion in freeze-thaw affected concrete. Constr. Build. Mater. 2018, 179, 553–565. [Google Scholar] [CrossRef]

- Sun, L.; Jiang, K.; Zhu, X.; Xu, L. An alternating experimental study on the combined effect of freeze-thaw and chloride penetration in concrete. Constr. Build. Mater. 2020, 252, 119025. [Google Scholar] [CrossRef]

- Wang, H.; Gao, X.; Liu, J. Coupling effect of salt freeze-thaw cycles and cyclic loading on performance degradation of carbon nanofiber mortar. Cold Reg. Sci. Technol. 2018, 154, 95–102. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Z.; Fu, K. Experimental studies on the chloride ionpermeability of concrete considering the effect of freeze–thaw damage. Constr. Build. Mater. 2020, 236, 117556. [Google Scholar] [CrossRef]

| Types | Particle Size/μm | ||||||

|---|---|---|---|---|---|---|---|

| 0.3 | 0.6 | 1 | 4 | 8 | 64 | 360 | |

| SAC | 0 | 0.35 | 1.92 | 16.35 | 30.12 | 95.15 | 100 |

| P·O cement | 0 | 0.33 | 2.66 | 15.01 | 28.77 | 93.59 | 100 |

| Slag power | 0.025 | 0.1 | 3.51 | 19.63 | 35.01 | 97.9 | 100 |

| Silica fume | 31.2 | 58.3 | 82.3 | 100 | 100 | 100 | 100 |

| Types | SiO2 | Al2O3 | Fe2O3 | MgO | CaO | SO3 | Ti2O |

|---|---|---|---|---|---|---|---|

| SAC | 13.95 | 22.46 | 2.67 | 2.92 | 39.39 | 14.34 | 1.66 |

| P·O cement | 20.86 | 5.47 | 3.94 | 1.73 | 62.23 | 2.66 | / |

| Slag power | 34.06 | 14.74 | 0.23 | 9.73 | 35.93 | 0.23 | 3.51 |

| Silica fume | 90 | 0.2 | 0.6 | 0.2 | 0.4 | 0 | 7.4 |

| Water | OPC | SAC | SF | GGBS | Quartz Sand | Water-Reducer | PPFs | Li2SO4 | Tartaric Acid | Calcium Formate |

|---|---|---|---|---|---|---|---|---|---|---|

| 244.4 | 740.7 | 0 | 370.3 | 111.1 | 977.9 | 16.3 | 0 | 0 | 0 | 5.2 |

| 244.4 | 555.5 | 185.2 | 370.3 | 111.1 | 977.9 | 16.3 | 0 | 1.3 | 0.3 | 3.9 |

| 244.4 | 370.4 | 370.4 | 370.3 | 111.1 | 977.9 | 16.3 | 0 | 2.6 | 0.6 | 2.6 |

| 244.4 | 185.2 | 555.5 | 370.3 | 111.1 | 977.9 | 16.3 | 0 | 3.9 | 0.8 | 1.3 |

| 244.4 | 0 | 740.7 | 370.3 | 111.1 | 977.9 | 16.3 | 0 | 5.2 | 1.1 | 0 |

| 244.4 | 370.4 | 370.4 | 370.3 | 111.1 | 977.9 | 16.3 | 0 | 2.6 | 0.6 | 2.6 |

| 244.4 | 370.4 | 370.4 | 370.3 | 111.1 | 977.9 | 16.3 | 0.46 | 2.6 | 0.6 | 2.6 |

| 244.4 | 370.4 | 370.4 | 370.3 | 111.1 | 977.9 | 16.3 | 0.91 | 2.6 | 0.6 | 2.6 |

| 244.4 | 370.4 | 370.4 | 370.3 | 111.1 | 977.9 | 16.3 | 1.37 | 2.6 | 0.6 | 2.6 |

| 244.4 | 370.4 | 370.4 | 370.3 | 111.1 | 977.9 | 16.3 | 1.82 | 2.6 | 0.6 | 2.6 |

| 244.4 | 370.4 | 370.4 | 370.3 | 111.1 | 977.9 | 16.3 | 2.28 | 2.6 | 0.6 | 2.6 |

| 244.4 | 370.4 | 370.4 | 370.3 | 111.1 | 977.9 | 16.3 | 2.73 | 2.6 | 0.6 | 2.6 |

| 244.4 | 370.4 | 370.4 | 370.3 | 111.1 | 977.9 | 16.3 | 3.19 | 2.6 | 0.6 | 2.6 |

| Equation | Curing Time/d | a | b | R2 |

|---|---|---|---|---|

| 1 | 0.136 | 2.99 | 0.994 | |

| 3 | 0.111 | 5.37 | 0.957 | |

| 7 | −0.0135 | 17.90 | 0.950 | |

| 14 | −0.0179 | 18.51 | 0.967 | |

| 28 | −0.0168 | 18.63 | 0.953 | |

| 1 | 0.379 | 9.74 | 0.900 | |

| 3 | 0.147 | 30.84 | 0.980 | |

| 7 | −0.0724 | 52.4 | 0.946 | |

| 14 | −0.205 | 65.74 | 0.918 | |

| 28 | −0.289 | 78.14 | 0.879 |

| Equation | SAC Content/% | a | b | c | R2 |

|---|---|---|---|---|---|

| 0 | −0.056 | 2.165 | 1.606 | 0.785 | |

| 25 | −0.0440 | 1.717 | 4.46 | 0.780 | |

| 50 | −0.0289 | 1.135 | 8.387 | 0.762 | |

| 75 | −0.0103 | 0.413 | 13.71 | 0.836 | |

| 100 | −0.000612 | 0.0453 | 16.307 | 0.962 | |

| 0 | −0.147 | 6.772 | 7.332 | 0.931 | |

| 25 | −0.110 | 4.809 | 16.780 | 0.901 | |

| 50 | −0.0451 | 2.267 | 33.035 | 0.985 | |

| 75 | −0.00453 | 0.765 | 40.149 | 0.959 | |

| 100 | −0.00176 | 0.283 | 43.702 | 0.953 |

| Equation | Curing Age/d | a | b | c | R2 |

|---|---|---|---|---|---|

| 1 | −0.895 | 5.984 | 8.265 | 0.952 | |

| 3 | −0.846 | 5.047 | 11.076 | 0.996 | |

| 7 | −0.472 | 2.582 | 16.119 | 0.940 | |

| 14 | −0.0616 | 1.513 | 16.904 | 0.854 | |

| 28 | −0.0714 | 1.753 | 0.847 | 0.847 | |

| 1 | 3.981 | 3.981 | 35.483 | 0.983 | |

| 3 | 0.408 | 0.4081 | 38.579 | 0.992 | |

| 7 | 1.805 | 1.805 | 48.342 | 0.988 | |

| 14 | 0.344 | 0.3441 | 55.579 | 0.981 | |

| 28 | 0.993 | 0.993 | 61.225 | 0.998 |

| Equation | PPFs Content/% | a | b | c | R2 |

|---|---|---|---|---|---|

| 0 | −0.0216 | 0.943 | 9.095 | 0.879 | |

| 0.5 | −0.0212 | 0.890 | 10.317 | 0.793 | |

| 1 | −0.0147 | 0.630 | 13.357 | 0.833 | |

| 1.5 | −0.0106 | 0.452 | 15.621 | 0.827 | |

| 2 | −0.00484 | 0.295 | 16.955 | 0.877 | |

| 2.5 | 0.00264 | 0.0885 | 18.093 | 0.938 | |

| 3 | −0.00973 | 0.481 | 17.387 | 0.995 | |

| 3.5 | −0.00542 | 0.317 | 17.528 | 0.950 | |

| 0 | −0.0451 | 2.267 | 33.035 | 0.985 | |

| 0.5 | −0.0432 | 2.166 | 34.876 | 0.970 | |

| 1 | −0.0438 | 2.182 | 35.559 | 0.961 | |

| 1.5 | −0.0402 | 2.041 | 37.392 | 0.964 | |

| 2 | −0.0389 | 1.997 | 38.729 | 0.994 | |

| 2.5 | −0.0381 | 1.955 | 40.205 | 0.997 | |

| 3 | −0.0431 | 2.085 | 41.489 | 0.984 | |

| 3.5 | −0.0512 | 2.337 | 42.073 | 0.942 |

| Equation | PPFs Content/% | a | b | c | R2 |

|---|---|---|---|---|---|

| 0.5 | −6.76 × 10−5 | 0.043 | 0.448 | 0.968 | |

| 1.0 | −6.62 × 10−5 | 0.0412 | 0.333 | 0.975 | |

| 1.5 | −5.07 × 10−5 | 0.0358 | 0.344 | 0.971 | |

| 2.0 | −4.91 × 10−5 | 0.0343 | 0.282 | 0.979 | |

| 2.5 | −4.69 × 10−5 | 0.0328 | 0.226 | 0.979 |

| Equation | PPFs Content/% | a | b | c | R2 |

|---|---|---|---|---|---|

| 0 | 1.56 × 10−4 | 0.00942 | 0.640 | 0.954 | |

| 1 | 1.37 × 10−4 | 0.00912 | 0.313 | 0.967 | |

| 2 | 1.02 × 10−4 | 0.0115 | 0.133 | 0.957 | |

| 3 | 1.12 × 10−4 | 0.00479 | 0.206 | 0.953 | |

| 4 | 7.90 × 10−5 | 0.00941 | 0.0974 | 0.935 | |

| 0 | 0.0395 | −0.806 | / | 0.983 | |

| 1 | 0.0356 | −0.695 | / | 0.992 | |

| 2 | 0.0340 | −0.698 | / | 0.988 | |

| 3 | 0.0329 | −0.759 | / | 0.981 | |

| 4 | 0.0301 | −0.600 | / | 0.998 |

| Equation | PPFs Content/% | a | b | c | R2 |

|---|---|---|---|---|---|

| 0 | 5.90 × 10−5 | −0.08485 | 100.287 | 0.992 | |

| 1 | 6.98 × 10−5 | −0.06801 | 99.827 | 0.984 | |

| 2 | 4.30 × 10−5 | −0.05075 | 100.093 | 0.951 | |

| 3 | −4.33 × 10−5 | −0.03131 | 100.070 | 0.979 | |

| 4 | −3.97 × 10−5 | −0.01466 | 100.040 | 0.997 |

| Equation | PPFs Content/% | a | b | c | R2 |

|---|---|---|---|---|---|

| 0 | −2.52 × 10−5 | 0.0281 | 2.067 | 0.999 | |

| 1 | −2.10 × 10−5 | 0.0270 | 1.674 | 0.997 | |

| 2 | −2.72 × 10−5 | 0.0269 | 1.411 | 0.998 | |

| 3 | −1.61 × 10−5 | 0.0233 | 1.338 | 0.995 | |

| 4 | −1.77 × 10−5 | 0.0232 | 1.029 | 0.998 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Z.; Wang, H. Influence of NaCl Freeze–Thaw Cycles on the Mechanical Strength of Reactive Powder Concrete with the Assembly Unit of Sulphoaluminate Cement and Ordinary Portland Cement. Coatings 2021, 11, 1238. https://doi.org/10.3390/coatings11101238

Cai Z, Wang H. Influence of NaCl Freeze–Thaw Cycles on the Mechanical Strength of Reactive Powder Concrete with the Assembly Unit of Sulphoaluminate Cement and Ordinary Portland Cement. Coatings. 2021; 11(10):1238. https://doi.org/10.3390/coatings11101238

Chicago/Turabian StyleCai, Zhangjie, and Hui Wang. 2021. "Influence of NaCl Freeze–Thaw Cycles on the Mechanical Strength of Reactive Powder Concrete with the Assembly Unit of Sulphoaluminate Cement and Ordinary Portland Cement" Coatings 11, no. 10: 1238. https://doi.org/10.3390/coatings11101238

APA StyleCai, Z., & Wang, H. (2021). Influence of NaCl Freeze–Thaw Cycles on the Mechanical Strength of Reactive Powder Concrete with the Assembly Unit of Sulphoaluminate Cement and Ordinary Portland Cement. Coatings, 11(10), 1238. https://doi.org/10.3390/coatings11101238