Experimental Study on Axial Compressive Behavior of Gangue Aggregate Concrete Filled FRP and Thin-Walled Steel Double Tubular Columns

Abstract

:1. Introduction

2. Experimental Program

2.1. Material Properties

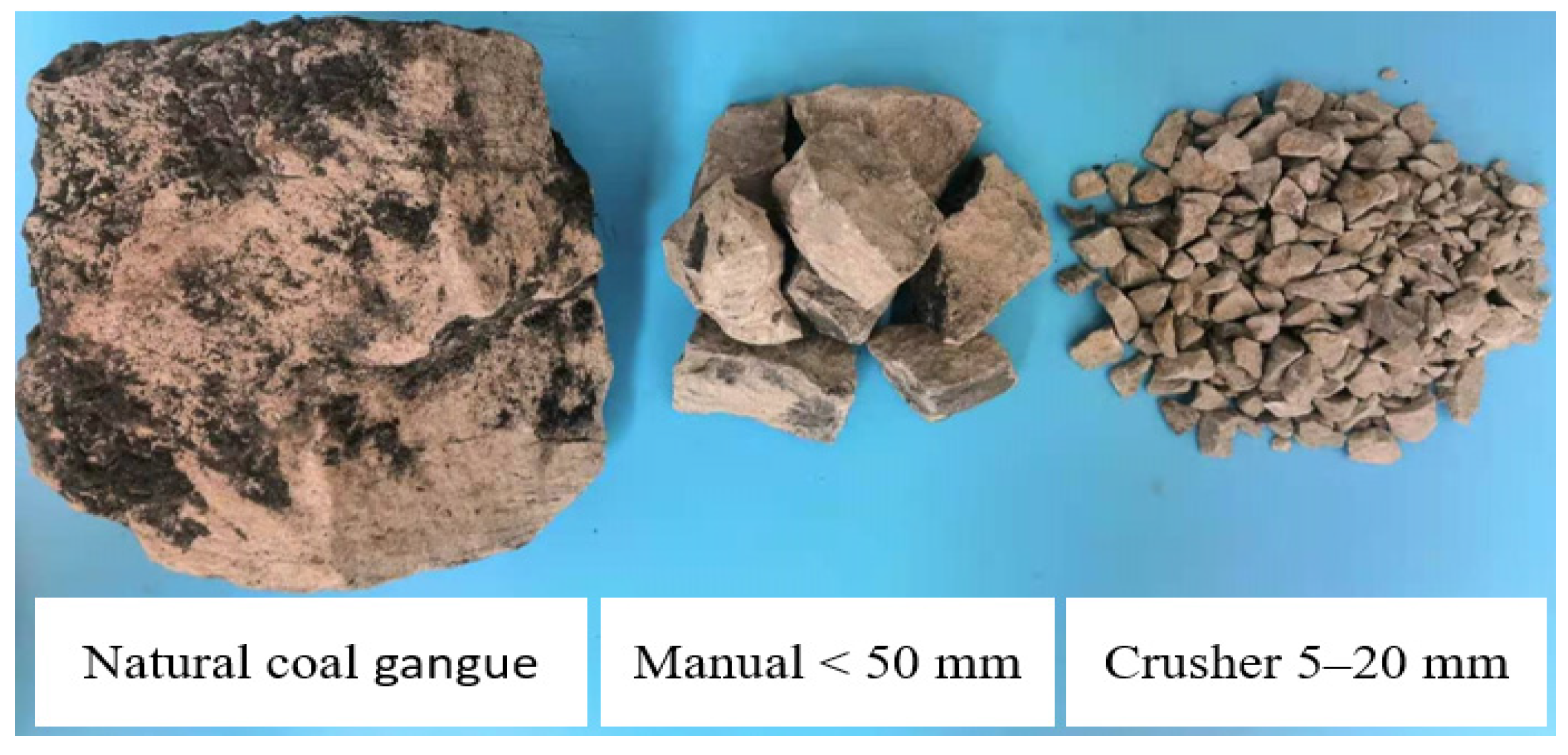

2.1.1. Gangue Aggregate Concrete

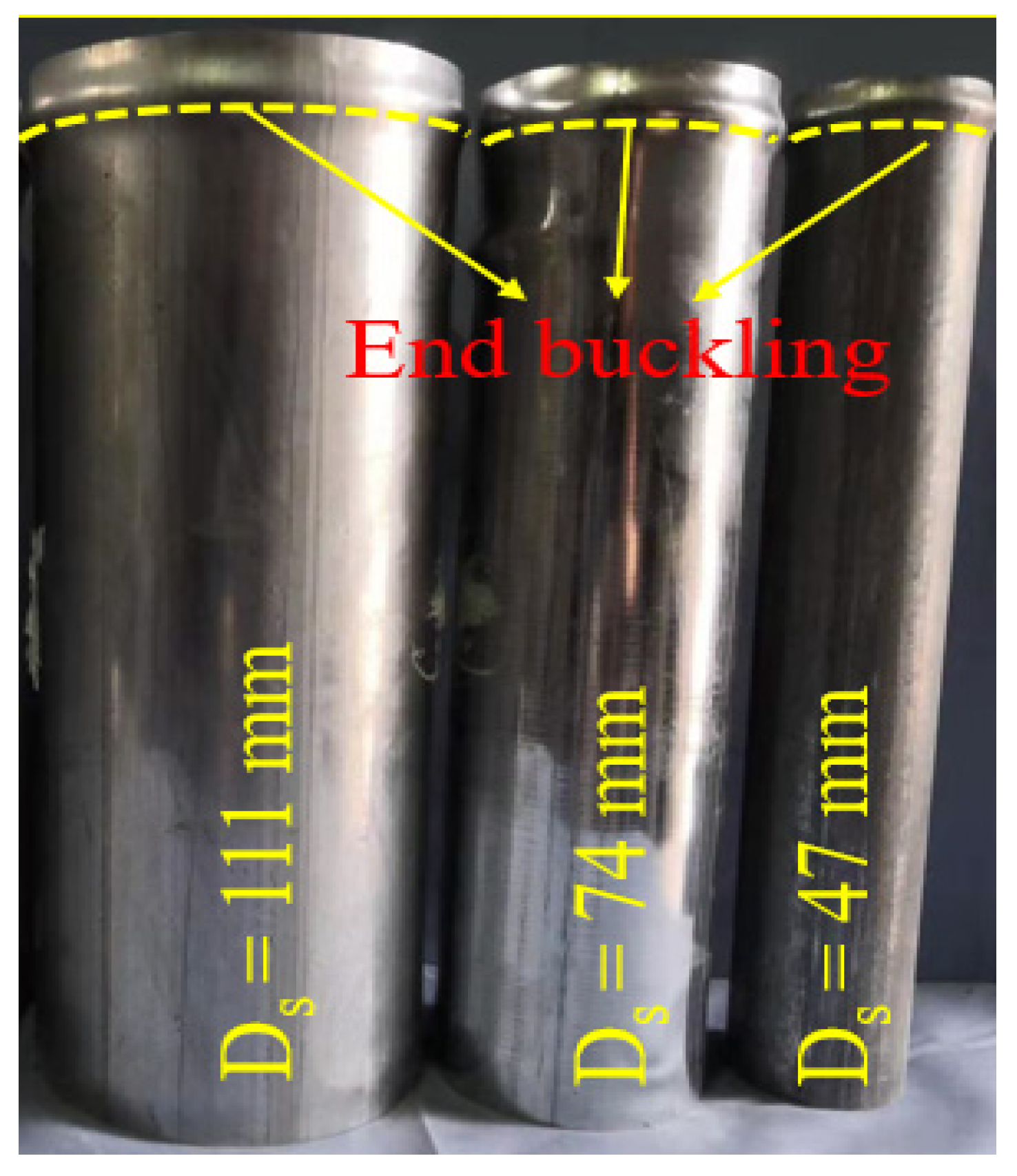

2.1.2. Steel Tube

2.1.3. CFRP Jacket

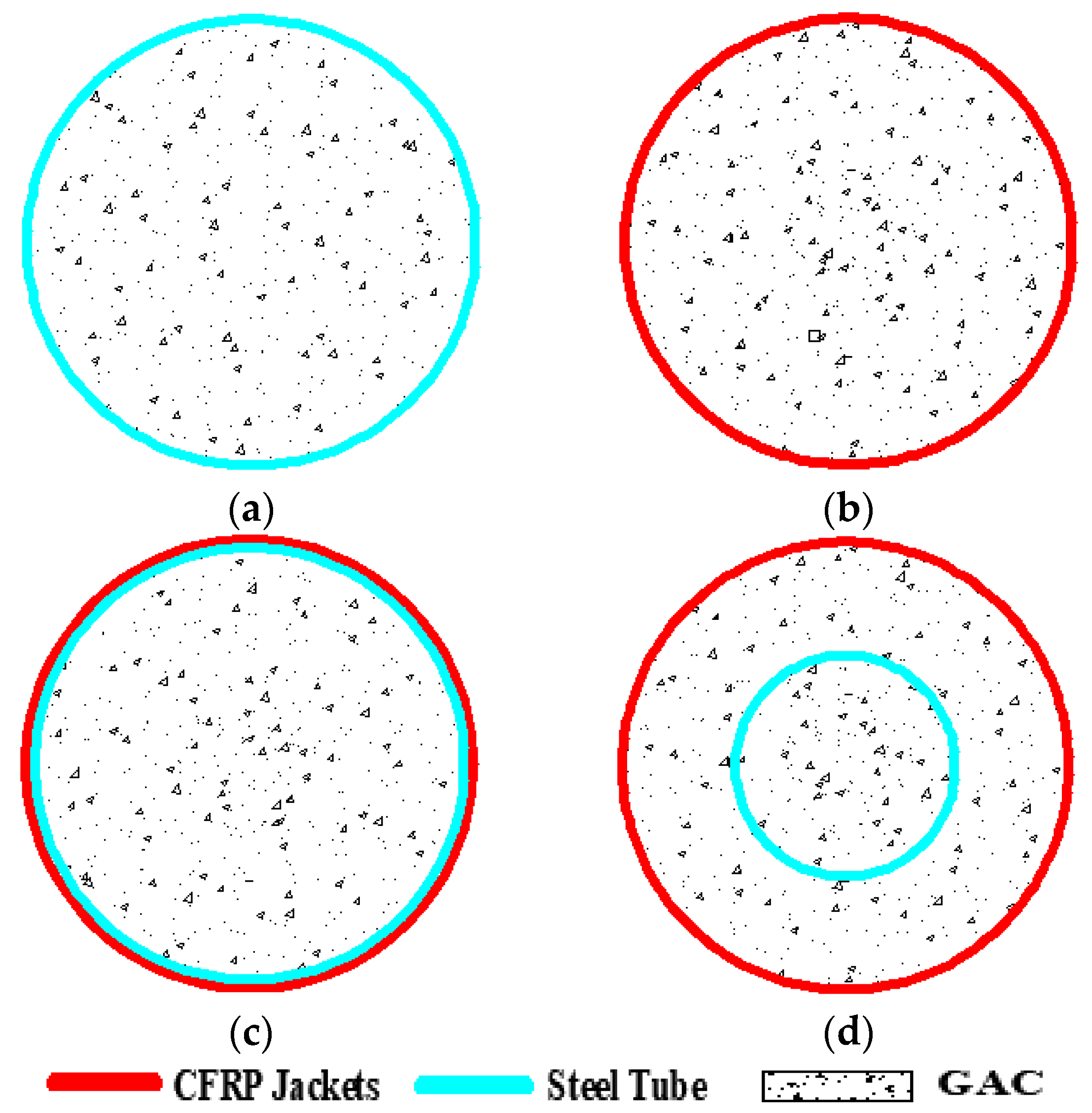

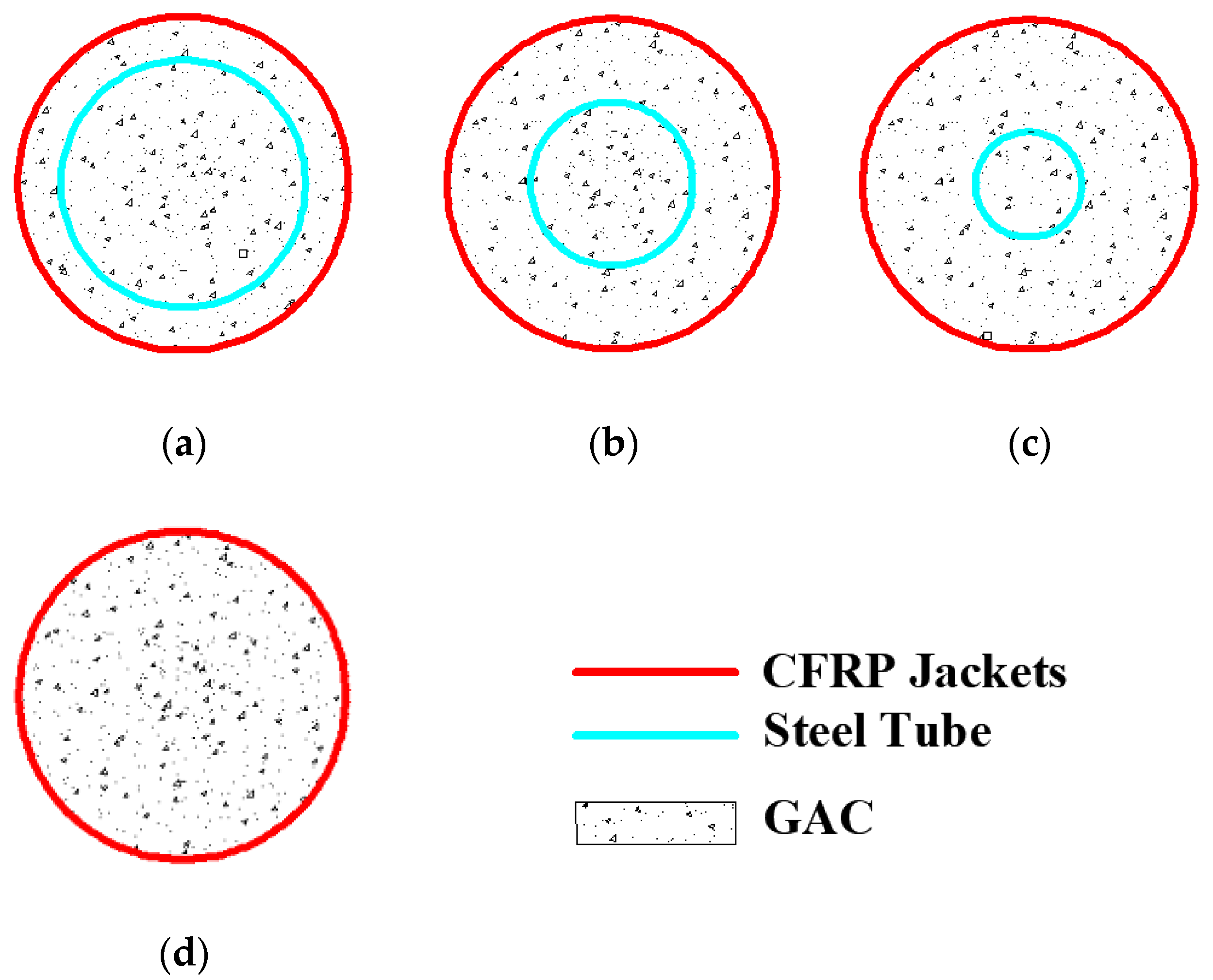

2.2. Specimens Design

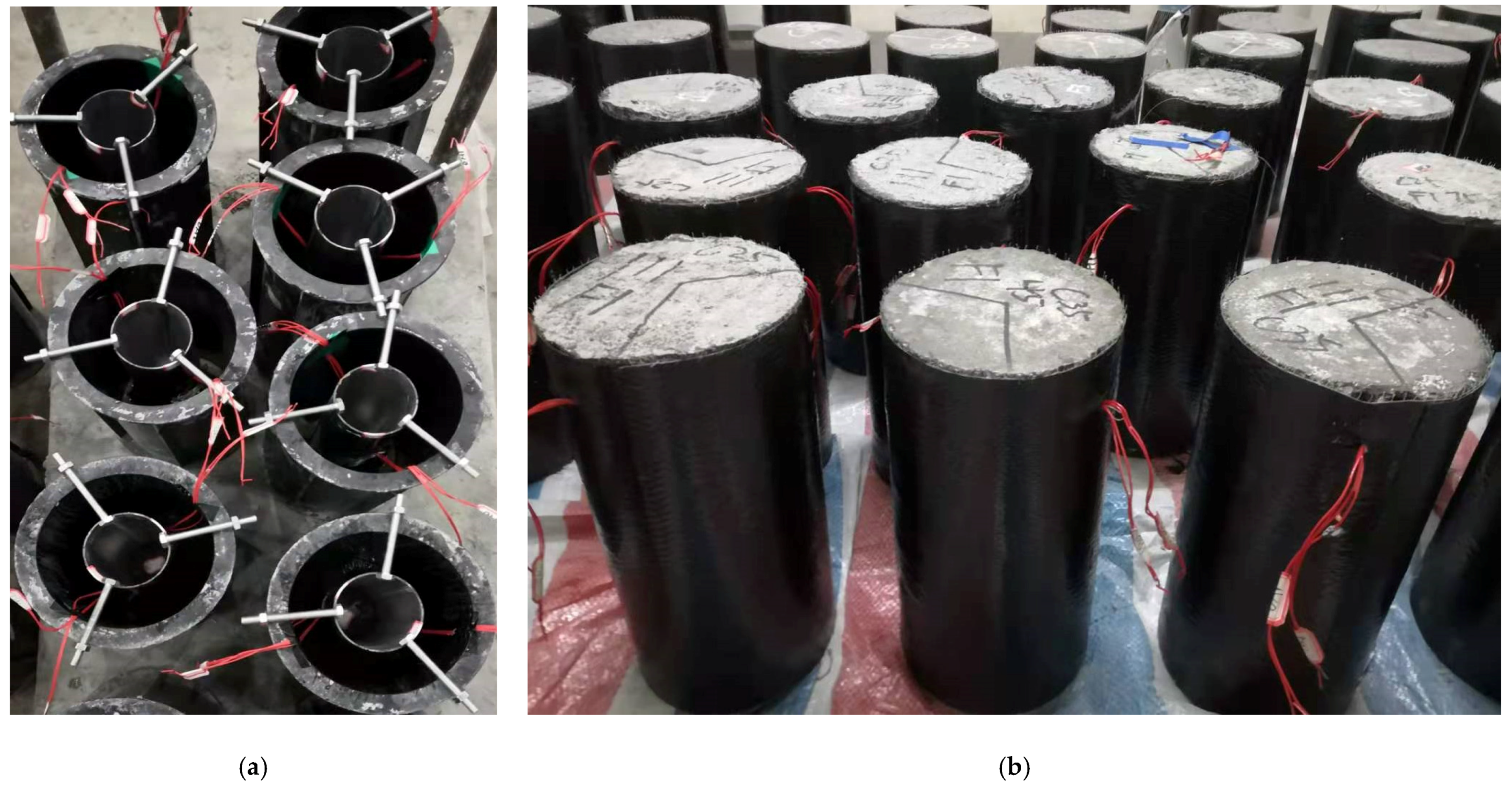

2.3. Preparation of Specimens

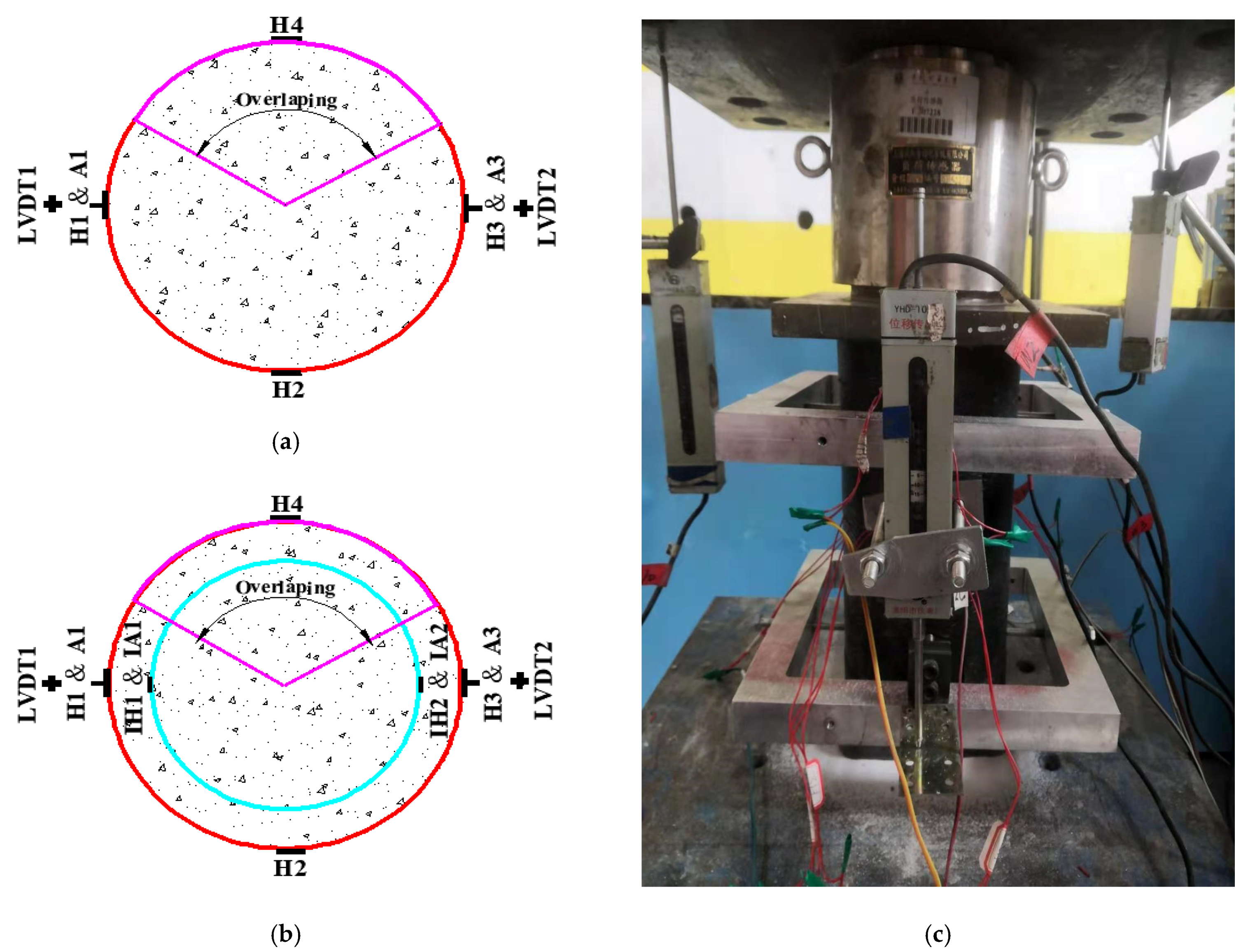

2.4. Test Setup and Instrumentation

3. Experimental Results

3.1. Failure Modes

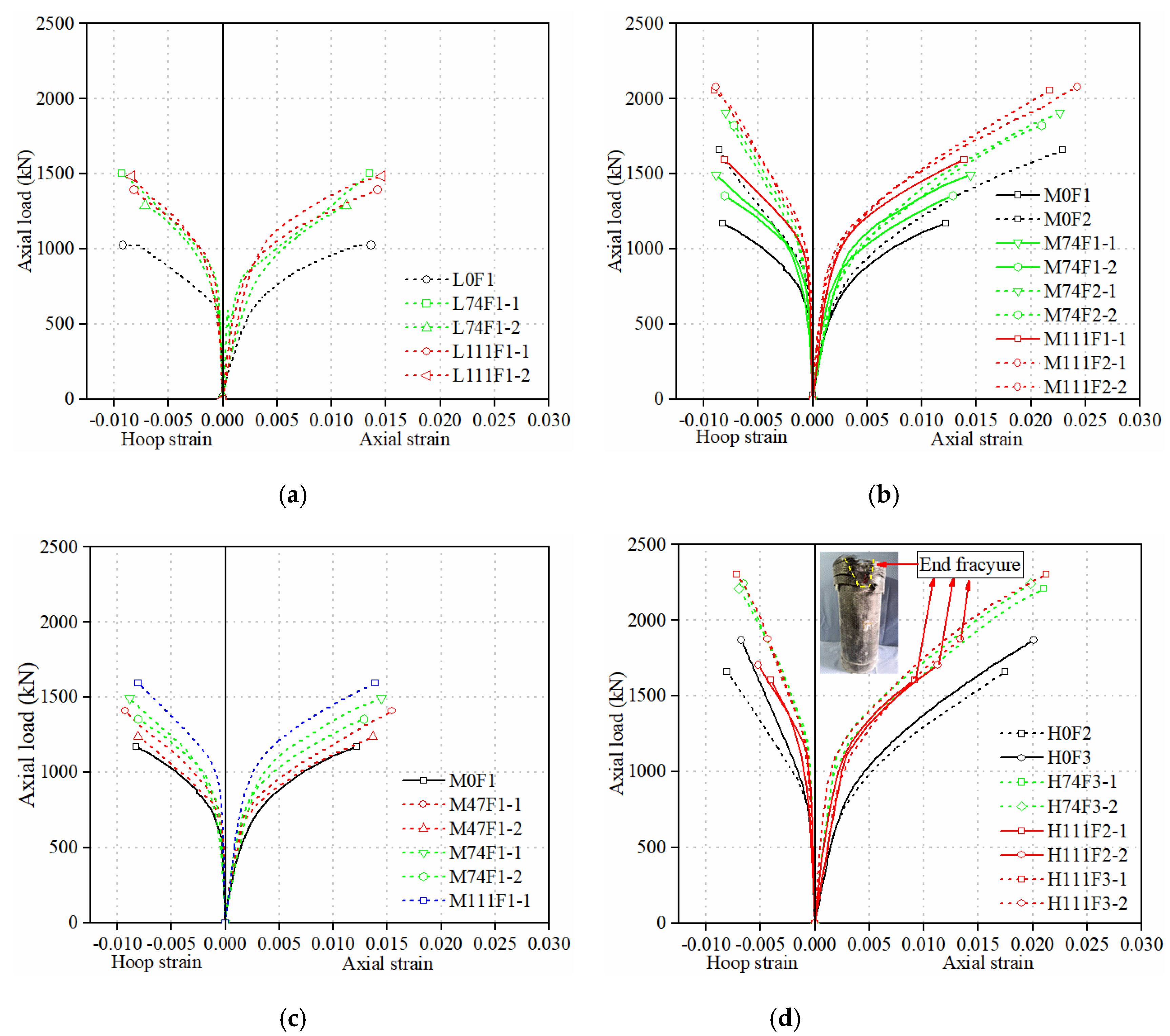

3.2. Load-Axial Strain Behavior

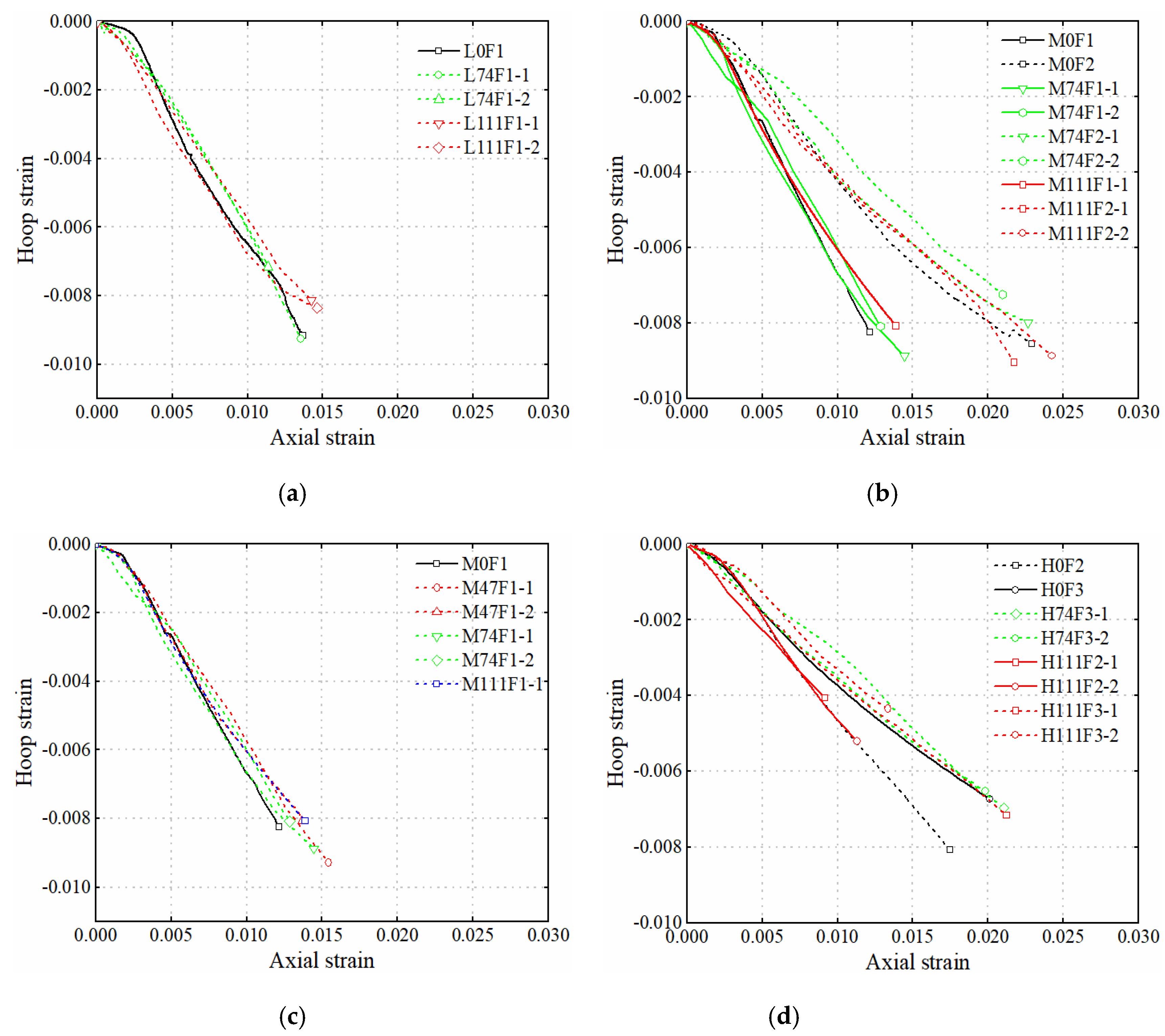

3.3. Axial Strain-Hoop Strain Behavior

4. Mechanical Behavior of Steel Tubes

4.1. Slip between Steel Tube and GAC

4.2. Bi-Directional Stress State of Steel Tube

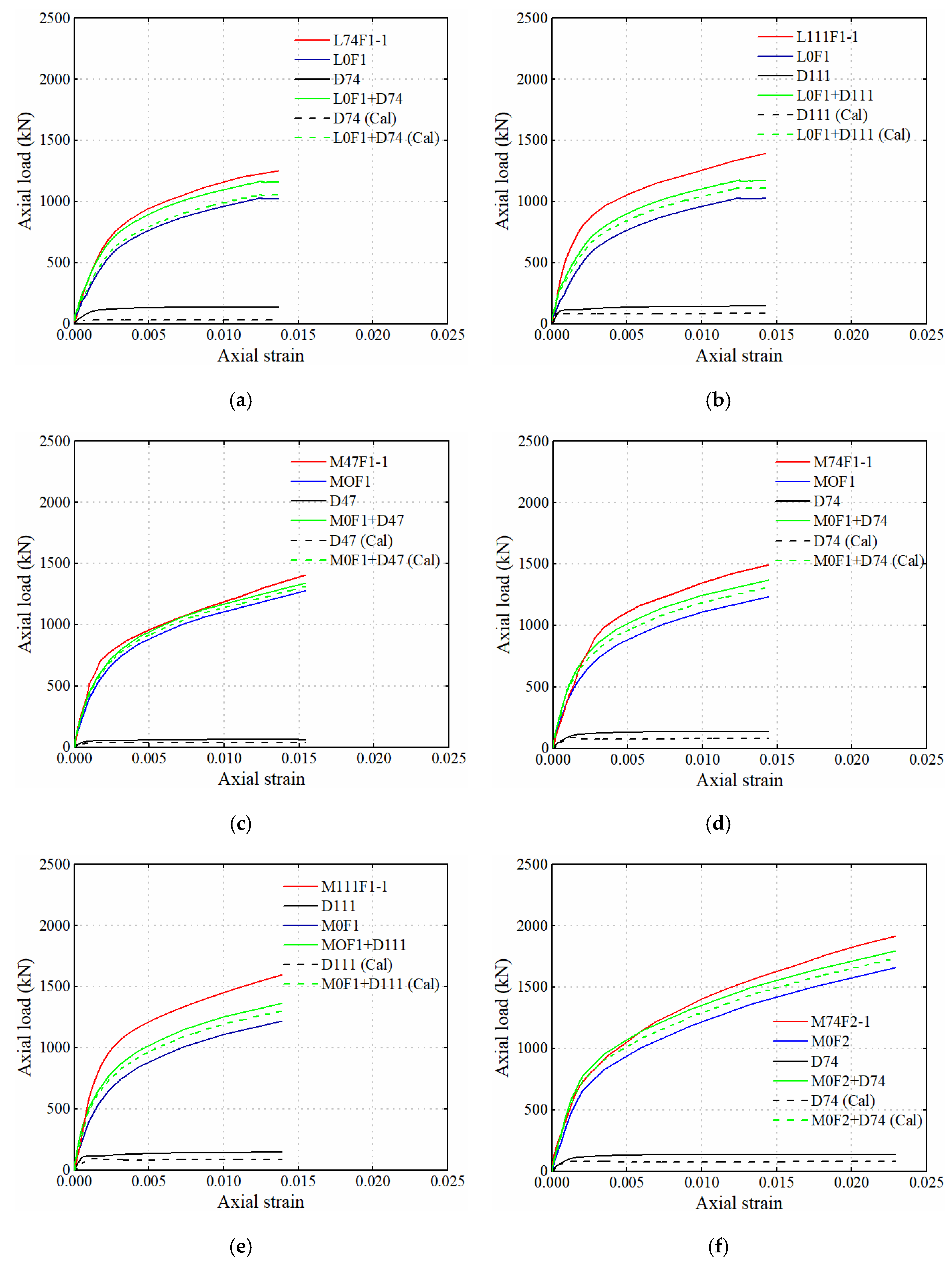

5. Combined Effects of Different Components

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Liu, Z. Recycling Utilization Patterns of Coal Mining Waste in China. Resour. Conserv. Recycl. 2010, 54, 1331–1340. [Google Scholar]

- Okagbue, C.O.; Ochulor, O.H. The Potential of Cement-Stabilized Coal-Reject as a Construction Material. Bull. Eng. Geol. Environ. 2007, 66, 143–151. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, G.; Guo, L.; Zhou, L.; Yuan, K. Utilization of Coal Gangue as Coarse Aggregates in Structural Concrete. Constr. Build. Mater. 2021, 268, 121212. [Google Scholar] [CrossRef]

- Zhao, H.; Ren, T.; Remennikov, A. Behaviour of Frp-Confined Coal Rejects Based Backfill Material under Compression. Constr. Build. Mater. 2021, 268, 121171. [Google Scholar] [CrossRef]

- Zhao, H.; Ren, T.; Remennikov, A. Standing Support Incorporating Frp and High Water-Content Material for Underground Space. Tunn. Undergr. Sp. Tech. 2021, 110, 103809. [Google Scholar] [CrossRef]

- Liu, G.L.; Wang, J.; Wang, H.B.; He, X.S.; Li, X.B. Application Research on Concrete Filled Steel Tube Supports Supporting Technology in Stress Concentration Roadway. Adv. Mater. Res. 2012, 594, 773–778. [Google Scholar] [CrossRef]

- Li, X.B.; Ma, Z.X.; Liu, G.L.; Chen, M.C.; Zhu, Q.M. Research on Steel Tube Confined Concrete Supports Support Technology for Soft Rock Roadway in Coal Bed Washout. Appl. Mech. Mater. 2011, 121, 3471–3476. [Google Scholar] [CrossRef]

- Li, Q.; Liu, L.; Li, J.K.; Li, Z. Research on D Section Steel Tube Filled with Concrete Used for High Stress Roadway Support in Deep Mines. In Proceedings of the 9th China-Russia Symposium “Coal in the 21st Century: Mining, Intelligent Equipment and Environment Protection”, Qingdao, China, 18–21 October 2018. [Google Scholar]

- Zhou, Y.; Liu, X.; Xing, F.; Li, D.; Wang, Y.; Sui, L. Behavior and Modeling of Frp-Concrete-Steel Double-Skin Tubular Columns Made of Full Lightweight Aggregate Concrete. Constr. Build. Mater. 2017, 139, 52–63. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H. Compressive Behavior of Concrete Confined by Carbon Fiber Composite Jackets. J. Mater. Civ. Eng. 2000, 12, 139–146. [Google Scholar] [CrossRef]

- Jiang, T.; Teng, J.G. Analysis-Oriented Stress-Strain Models for Frp-Confined Concrete. Eng. Struct. 2007, 29, 2968–2986. [Google Scholar] [CrossRef] [Green Version]

- Teng, J.G.; Jiang, T.; Lam, L.; Luo, Y.Z. Refinement of a Design-Oriented Stress–Strain Model for Frp-Confined Concrete. J. Compos. Constr. 2009, 13, 269–278. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Zhao, X.; Singh Raman, R.K. Behaviour of Seawater and Sea Sand Concrete Filled Frp Square Hollow Sections. Thin Wall. Struct. 2020, 148, 106596. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Ultimate Condition of Fiber Reinforced Polymer-Confined Concrete. J. Compos. Constr. 2004, 8, 539–548. [Google Scholar] [CrossRef]

- Teng, J.G.; Huang, Y.L.; Lam, L.; Ye, L.P. Theoretical Model for Fiber-Reinforced Polymer-Confined Concrete. J. Compos. Constr. 2007, 11, 201–210. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, X.; Xing, F.; Cui, H.; Sui, L. Axial Compressive Behavior of Frp-Confined Lightweight Aggregate Concrete: An Experimental Study and Stress-Strain Relation Model. Constr. Build. Mater. 2016, 119, 1–15. [Google Scholar] [CrossRef]

- Chaiyasarn, K.; Hussain, Q.; Joyklad, P.; Rodsin, K. New Hybrid Basalt/E-Glass Frp Jacketing for Enhanced Confinement of Recycled Aggregate Concrete with Clay Brick Aggregate. Case Stud. Constr. Mater. 2021, 14, e00507. [Google Scholar] [CrossRef]

- Dang, Z.; Feng, P.; Yang, J.; Zhang, Q. Axial Compressive Behavior of Engineered Cementitious Composite Confined by Fiber-Reinforced Polymer. Compos. Struct. 2020, 243, 112191. [Google Scholar] [CrossRef]

- Ye, Y.; Liang, S.; Feng, P.; Zeng, J. Recyclable Lrs Frp Composites for Engineering Structures: Current Status and Future Opportunities. Compos. Part B Eng. 2021, 212, 108689. [Google Scholar] [CrossRef]

- Xiong, M.X.; Lan, Z.H.; Chen, G.M.; Lu, Y.C.; Xu, Z. Behavior of Frp-Hsc-Steel Tubular Columns under Axial Compression: A Comparative Study. Compos. Struct. 2021, 261, 113566. [Google Scholar] [CrossRef]

- Dong, C.X.; Kwan, A.K.H.; Ho, J.C.M. Axial and Lateral Stress-Strain Model for Concrete-Filled Steel Tubes with Frp Jackets. Eng. Struct. 2016, 126, 365–378. [Google Scholar] [CrossRef]

- Liu, L.; Lu, Y. Axial Bearing Capacity of Short Frp Confined Concrete-Filled Steel Tubular Columns. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 454–458. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, G.; Wan, B.; Han, B.; Ran, J. Axial Compressive Behavior and Confinement Mechanism of Circular Frp-Steel Tubed Concrete Stub Columns. Compos. Struct. 2021, 256, 113082. [Google Scholar] [CrossRef]

- Lu, Y.; Li, N.; Li, S. Behavior of Frp-Confined Concrete-Filled Steel Tube Columns. Polymers 2014, 6, 1333–1349. [Google Scholar] [CrossRef]

- Park, J.W.; Hong, Y.K.; Hong, G.S.; Kim, J.H.; Choi, S.M. Design Formulas of Concrete Filled Circular Steel Tubes Reinforced by Carbon Fiber Reinforced Plastic Sheets. Procedia Eng. 2011, 14, 2916–2922. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Zhang, Y.; Chai, J.; Wu, G.; Dong, Z. Experimental Investigation of Rectangular Concrete-Filled Fiber Reinforced Polymer (Frp)-Steel Composite Tube Columns for Various Corner Radii. Compos. Struct. 2020, 244, 112311. [Google Scholar] [CrossRef]

- Hu, Y.M.; Yu, T.; Teng, J.G. Frp-Confined Circular Concrete-Filled Thin Steel Tubes under Axial Compression. J. Compos. Constr. 2011, 15, 850–860. [Google Scholar] [CrossRef]

- Teng, J.G.; Hu, Y.M.; Yu, T. Stress-Strain Model for Concrete in Frp-Confined Steel Tubular Columns. Eng. Struct. 2013, 49, 156–167. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, Y.; Bai, J.; Zhang, Y. Stress-Strain Model of an Frp-Confined Concrete Filled Steel Tube under Axial Compression. Thin Wall. Struct. 2019, 142, 149–159. [Google Scholar] [CrossRef]

- Deng, J.; Zheng, Y.; Wang, Y.; Liu, T.; Li, H. Study on Axial Compressive Capacity of Frp-Confined Concrete-Filled Steel Tubes and its Comparisons with Other Composite Structural Systems. Int. J. Polym. Sci. 2017, 2017, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Teng, J.G.; Wang, Z.; Yu, T.; Zhao, Y.; Li, L.J. Double-Tube Concrete Columns with a High-Strength Internal Steel Tube: Concept and Behaviour Under Axial Compression. Adv. Struct. Eng. 2018, 21, 1585–1594. [Google Scholar] [CrossRef]

- Zeng, J.; Lv, J.; Lin, G.; Guo, Y.; Li, L. Compressive Behavior of Double-Tube Concrete Columns with an Outer Square Frp Tube and an Inner Circular High-Strength Steel Tube. Constr. Build. Mater. 2018, 184, 668–680. [Google Scholar] [CrossRef]

- Wang, Z.; Tao, Z.; Yu, Q. Axial Compressive Behaviour of Concrete-Filled Double-Tube Stub Columns with Stiffeners. Thin Wall. Struct. 2017, 120, 91–104. [Google Scholar] [CrossRef]

- Louk Fanggi, B.A.; Ozbakkaloglu, T. Square Frp–Hsc–Steel Composite Columns: Behavior under Axial Compression. Eng. Struct. 2015, 92, 156–171. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Fanggi, B.L. Axial Compressive Behavior of Frp-Concrete-Steel Double-Skin Tubular Columns Made of Normal- and High-Strength Concrete. J. Compos. Constr. 2014, 18, 4013027. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, X. Hybrid Double Tube Sections Utilising Seawater and Sea Sand Concrete, Frp and Stainless Steel. Thin Wall. Struct. 2020, 149, 106643. [Google Scholar] [CrossRef]

- Zhao, H.; Ren, T.; Remennikov, A. Behaviour of Frp-Confined Coal Reject Concrete Columns under Axial Compression. Compos. Struct. 2021, 262, 113621. [Google Scholar] [CrossRef]

- ASTM. ASTM E8/E8M-21 Standard Test Method for Tension Testing of Metallic Materials; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM. ASTM D3039/D3039M-17 Standard Test Method for Tensile Properties of Polymer Matrix; ASTM: West Conshohocken, PA, USA, 2008. [Google Scholar]

| W/C | Water (kg/m3) | Cement (kg/m3) | Sand (kg/m3) | GA (kg/m3) | WRD (%) | |||

|---|---|---|---|---|---|---|---|---|

| 0.536 | 238.5 | 445 | 670 | 995 | 0 | 32.6 | 0.211 | 17.3 |

| 0.43 | 227.9 | 530 | 615 | 1000 | 0.2 | 37.5 | 0.203 | 20.2 |

| 0.349 | 212.9 | 610 | 565 | 1020 | 0.3 | 43.2 | 0.209 | 21 |

| Series | (mm) | (mm) | ||||

|---|---|---|---|---|---|---|

| D47 | 47 | 1.8 | 203 | 254 | 336 | 341 |

| D74 | 74 | 1.8 | 210 | 261 | 339 | 343 |

| D111 | 111 | 1.8 | 206 | 267 | 345 | 356 |

| Specimens | FRP Jacket | Steel Tube | (MPa) | Number of Specimens | |||

|---|---|---|---|---|---|---|---|

| Inner Diameter (mm) | Thickness (mm) | Outer Diameter (mm) | Thickness (mm) | ||||

| L0F1 | 150 | 0.167 | / | / | / | 32.6 | 1 |

| M0F1 | 150 | 0.167 | / | / | / | 37.5 | 1 |

| M0F2 | 150 | 0.334 | / | / | / | 37.5 | 1 |

| H0F2 | 150 | 0.334 | / | / | / | 43.2 | 1 |

| H0F3 | 150 | 0.501 | / | / | / | 43.2 | 1 |

| L74F1-1,2 | 150 | 0.167 | 74 | 1.8 | 41.1 | 32.6 | 2 |

| L111F1-1,2 | 150 | 0.167 | 111 | 1.8 | 61.7 | 32.6 | 2 |

| M47F1-1,2 | 150 | 0.167 | 47 | 1.8 | 26.1 | 37.5 | 2 |

| M74F1-1,2 | 150 | 0.167 | 74 | 1.8 | 41.1 | 37.5 | 2 |

| M74F2-1,2 | 150 | 0.334 | 74 | 1.8 | 41.1 | 37.5 | 2 |

| M111F1-1,2 | 150 | 0.167 | 111 | 1.8 | 61.7 | 37.5 | 2 |

| M111F2-1,2 | 150 | 0.334 | 111 | 1.8 | 61.7 | 37.5 | 2 |

| H74F3-1,2 | 150 | 0.501 | 74 | 1.8 | 41.1 | 43.2 | 2 |

| H111F2-1,2 | 150 | 0.334 | 111 | 1.8 | 61.7 | 43.2 | 2 |

| H111F3-1,2 | 150 | 0.501 | 111 | 1.8 | 61.7 | 43.2 | 2 |

| Specimens | (kN) | (kN) | (kN) | (%) | (%) | (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| L0F1 | 576 | 1031 | / | 1.79 | / | 0.211 | 1.367 | / | 6.48 | / |

| M0F1 | 662 | 1170 | / | 1.77 | / | 0.203 | 1.217 | / | 6.00 | / |

| M0F2 | 662 | 1659 | / | 2.51 | / | 0.203 | 2.29 | / | 11.28 | / |

| H0F2 | 763 | 1661 | / | 2.18 | / | 0.209 | 1.748 | / | 8.36 | / |

| H0F3 | 763 | 1871 | / | 2.45 | / | 0.209 | 2.012 | / | 9.63 | / |

| L74F1-1 | 576 | / | 1503 | / | 1.46 | 0.211 | / | 1.353 | / | 0.99 |

| L74F1-2 | 576 | / | 1293 | / | 1.25 | 0.211 | / | 1.136 | / | 0.83 |

| L111F1-1 | 576 | / | 1393 | / | 1.35 | 0.211 | / | 1.424 | / | 1.04 |

| L111F1-2 | 576 | / | 1486 | / | 1.44 | 0.211 | / | 1.461 | / | 1.07 |

| M47F1-1 | 662 | / | 1409 | / | 1.20 | 0.203 | / | 1.543 | / | 1.27 |

| M47F1-2 | 662 | / | 1240 | / | 1.06 | 0.203 | / | 1.366 | / | 1.12 |

| M74F1-1 | 662 | / | 1493 | / | 1.28 | 0.203 | / | 1.445 | / | 1.19 |

| M74F1-2 | 662 | / | 1356 | / | 1.16 | 0.203 | / | 1.284 | / | 1.06 |

| M74F2-1 | 662 | / | 1908 | / | 1.15 | 0.203 | / | 2.266 | / | 0.99 |

| M74F2-2 | 662 | / | 1823 | / | 1.10 | 0.203 | / | 2.096 | / | 0.92 |

| M111F1-1 | 662 | / | 1597 | / | 1.36 | 0.203 | / | 1.389 | / | 1.14 |

| M111F1-2 b | 662 | / | / | / | / | 0.203 | / | / | / | / |

| M111F2-1 | 662 | / | 2057 | / | 1.24 | 0.203 | / | 2.173 | / | 0.95 |

| M111F2-2 | 662 | / | 2079 | / | 1.25 | 0.203 | / | 2.425 | / | 1.06 |

| H74F3-1 | 763 | / | 2212 | / | 1.18 | 0.209 | / | 2.104 | / | 1.05 |

| H74F3-2 | 763 | / | 2244 | / | 1.20 | 0.209 | / | 1.983 | / | 0.99 |

| H111F2-1 | 763 | / | 1605 a | / | 0.97 | 0.209 | / | 0.917 | / | 0.52 |

| H111F2-2 | 763 | / | 1705 a | / | 1.03 | 0.209 | / | 1.129 | / | 0.65 |

| H111F3-1 | 763 | / | 2304 | / | 1.23 | 0.209 | / | 2.214 | / | 1.10 |

| H111F3-2 | 763 | / | 1877 a | / | 1.00 | 0.209 | / | 1.336 | / | 0.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Xia, J.; Chang, H.; Han, Y.; Yu, L.; Jiang, L. Experimental Study on Axial Compressive Behavior of Gangue Aggregate Concrete Filled FRP and Thin-Walled Steel Double Tubular Columns. Coatings 2021, 11, 1404. https://doi.org/10.3390/coatings11111404

Wang J, Xia J, Chang H, Han Y, Yu L, Jiang L. Experimental Study on Axial Compressive Behavior of Gangue Aggregate Concrete Filled FRP and Thin-Walled Steel Double Tubular Columns. Coatings. 2021; 11(11):1404. https://doi.org/10.3390/coatings11111404

Chicago/Turabian StyleWang, Jian, Junwu Xia, Hongfei Chang, Youmin Han, Linli Yu, and Li Jiang. 2021. "Experimental Study on Axial Compressive Behavior of Gangue Aggregate Concrete Filled FRP and Thin-Walled Steel Double Tubular Columns" Coatings 11, no. 11: 1404. https://doi.org/10.3390/coatings11111404

APA StyleWang, J., Xia, J., Chang, H., Han, Y., Yu, L., & Jiang, L. (2021). Experimental Study on Axial Compressive Behavior of Gangue Aggregate Concrete Filled FRP and Thin-Walled Steel Double Tubular Columns. Coatings, 11(11), 1404. https://doi.org/10.3390/coatings11111404