Effects of Bias Voltages on the Structural, Mechanical and Oxidation Resistance Properties of Cr–Si–N Nanocomposite Coatings

Abstract

1. Introduction

2. Experimental Details

2.1. Coating Deposition

2.2. Characterization

3. Results and Discussion

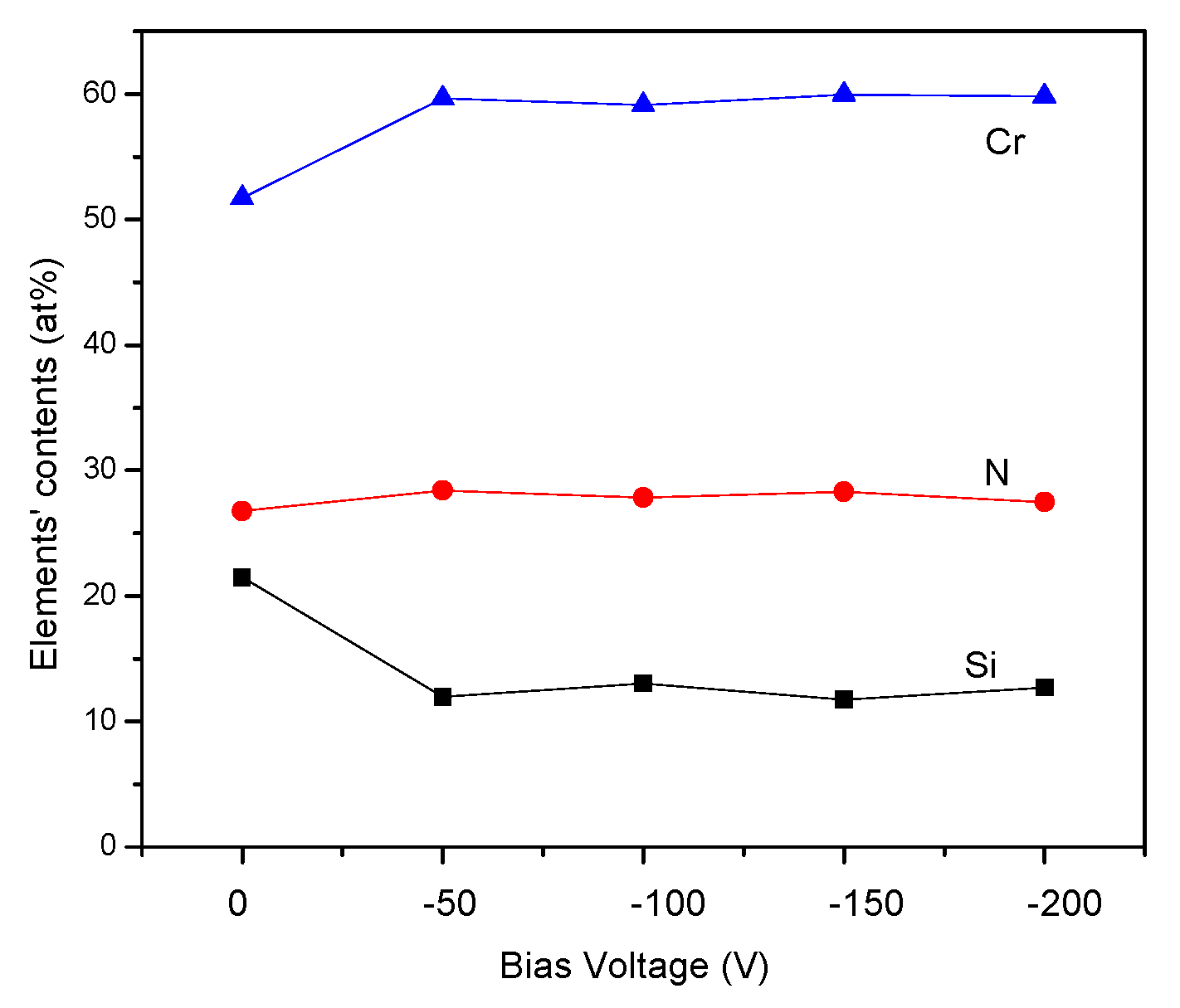

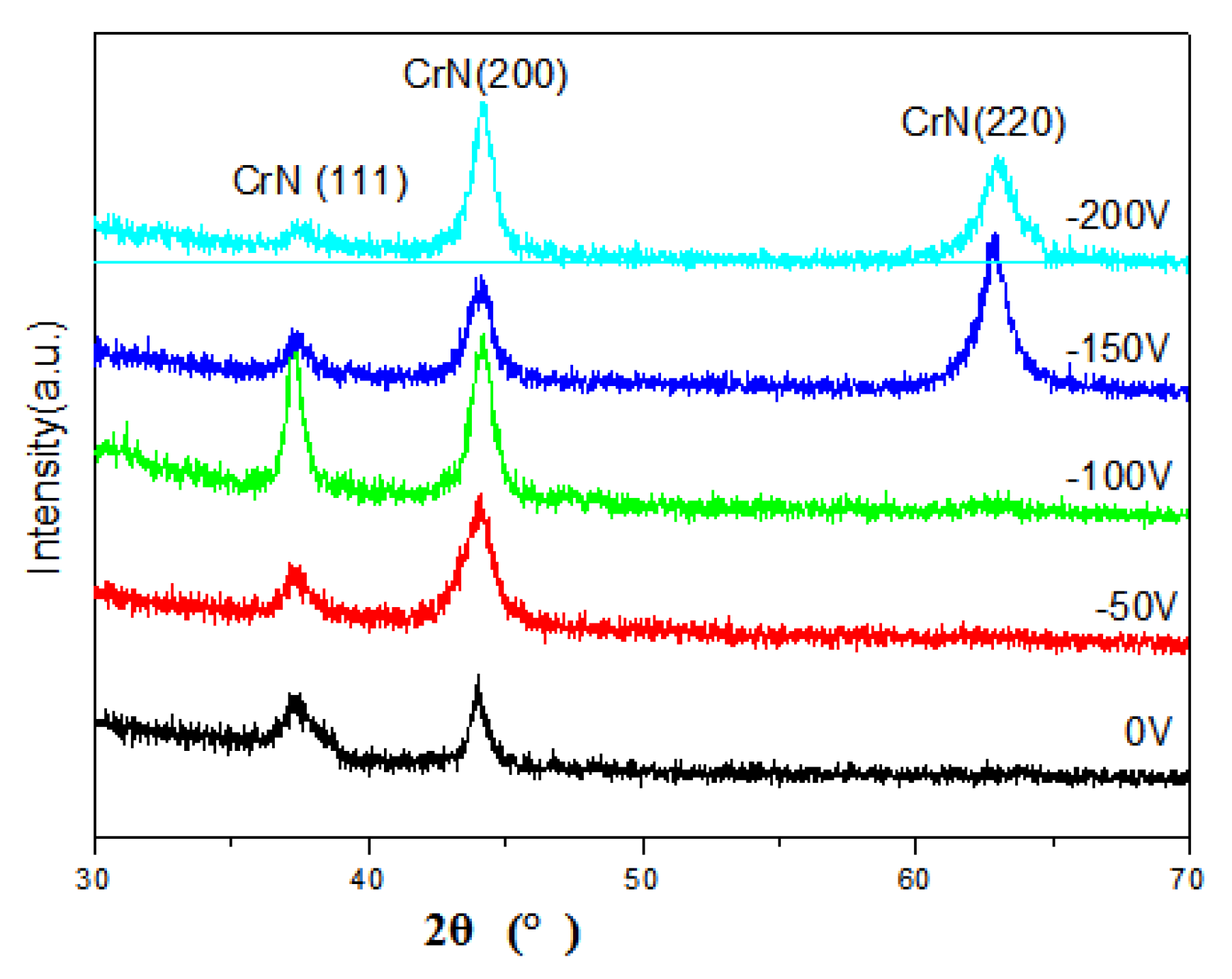

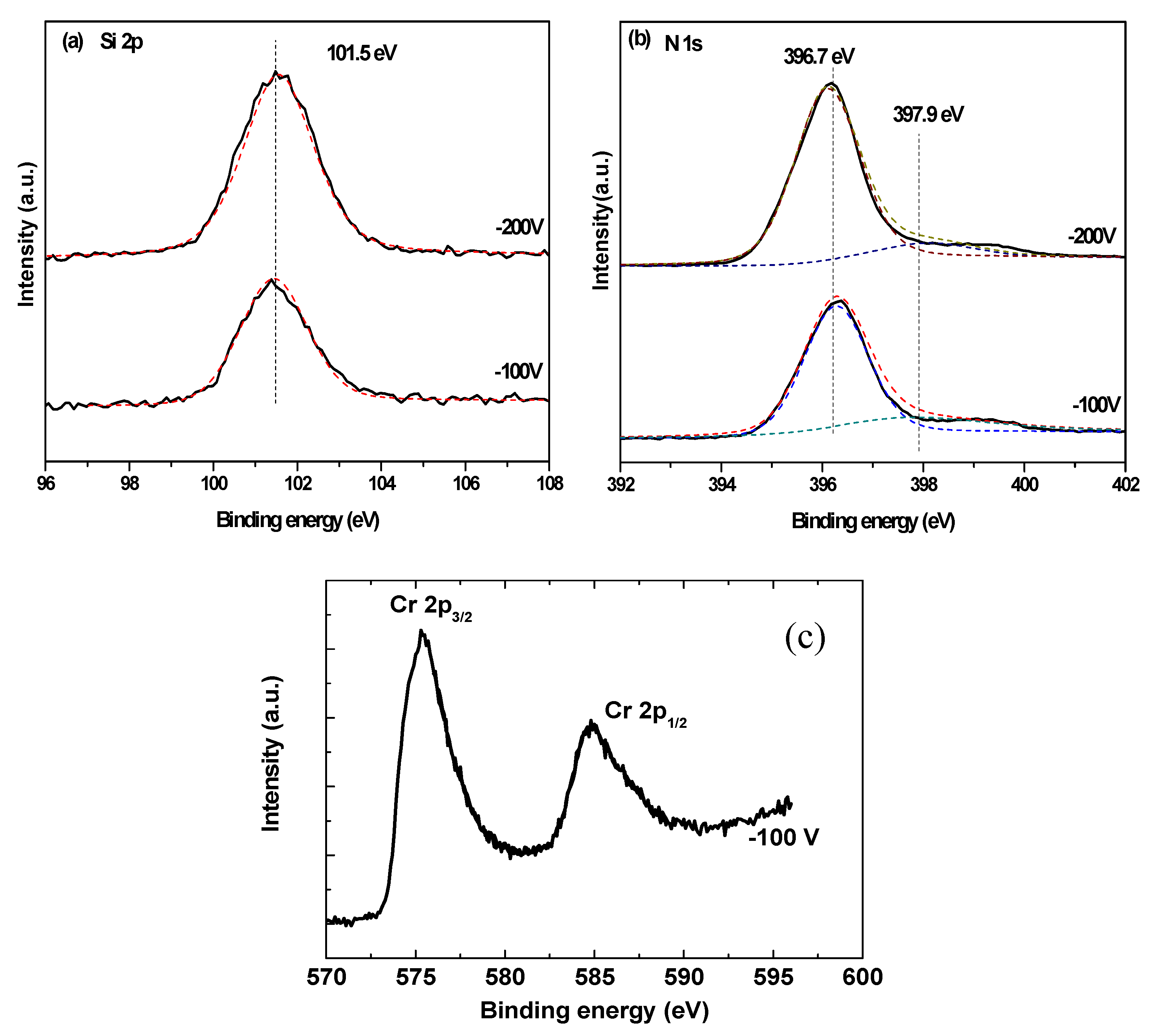

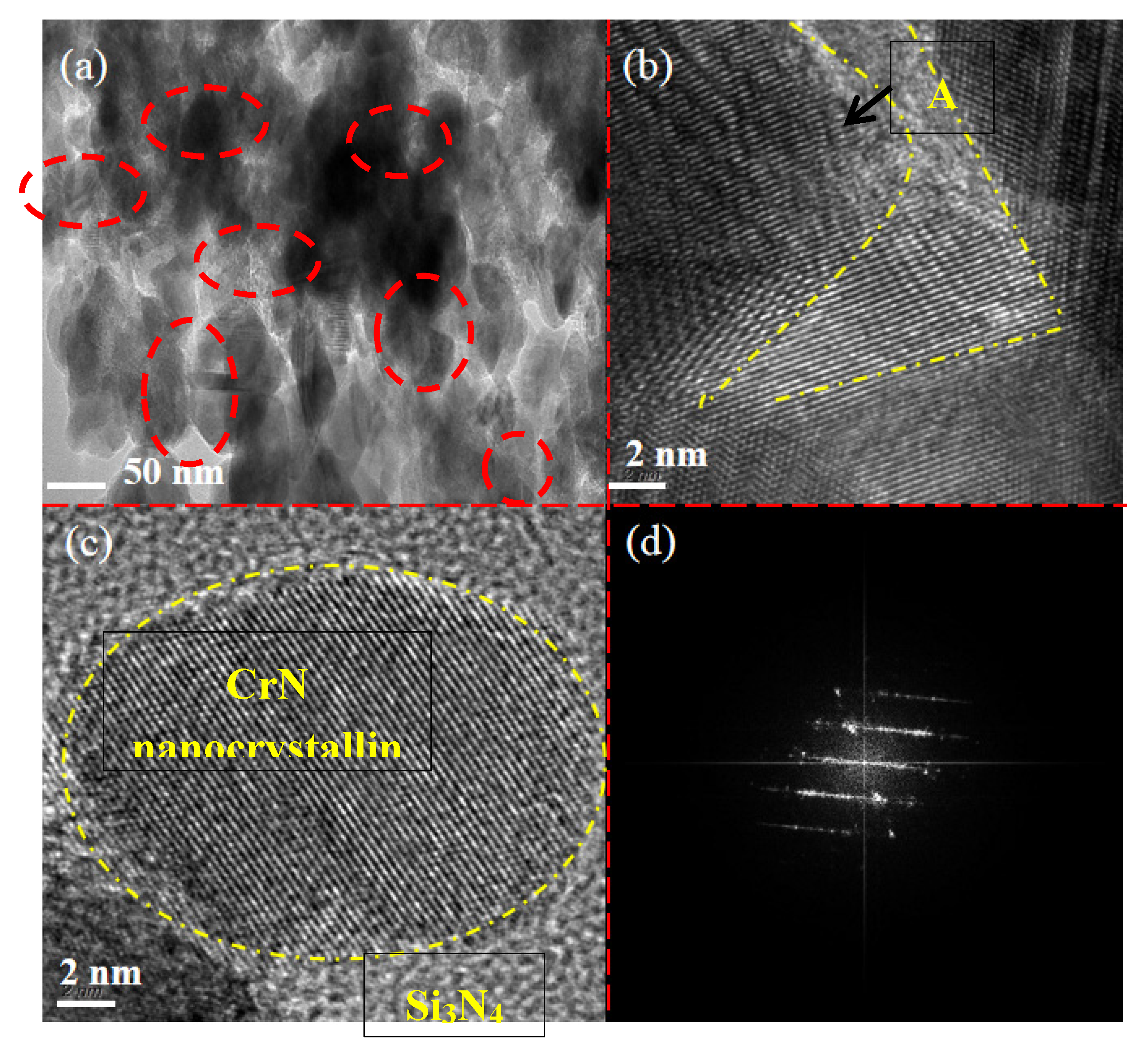

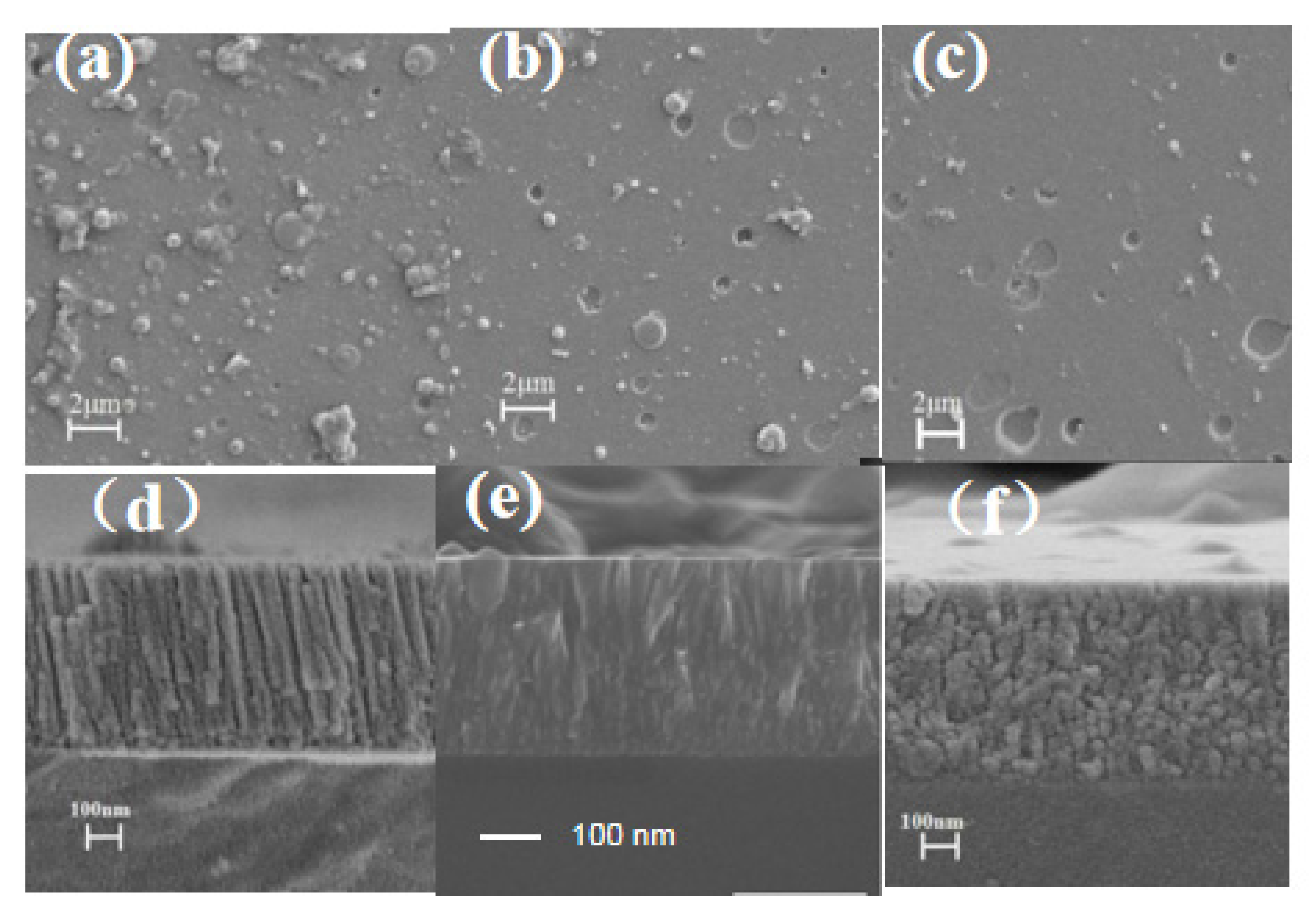

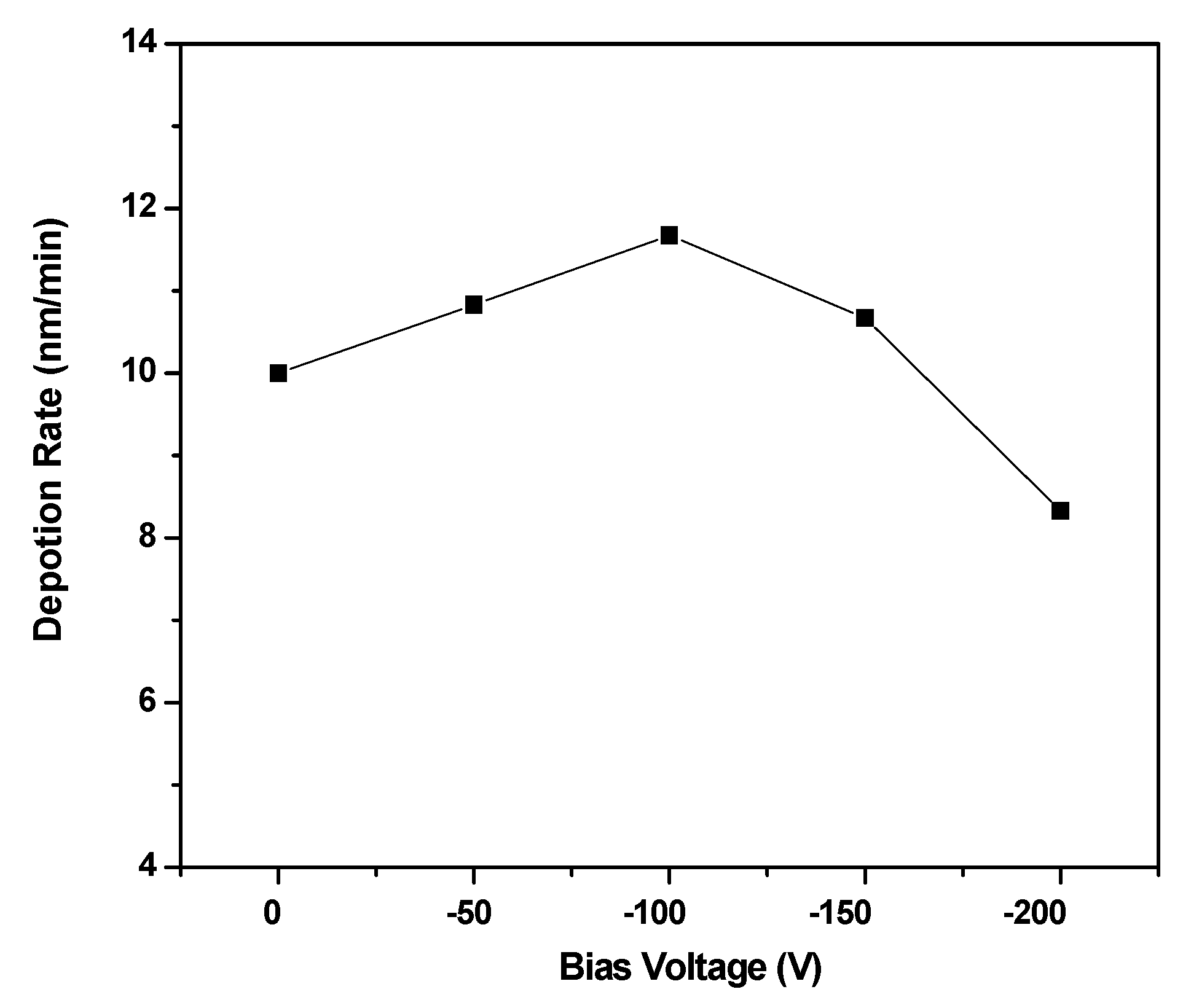

3.1. Characteristics of Coatings

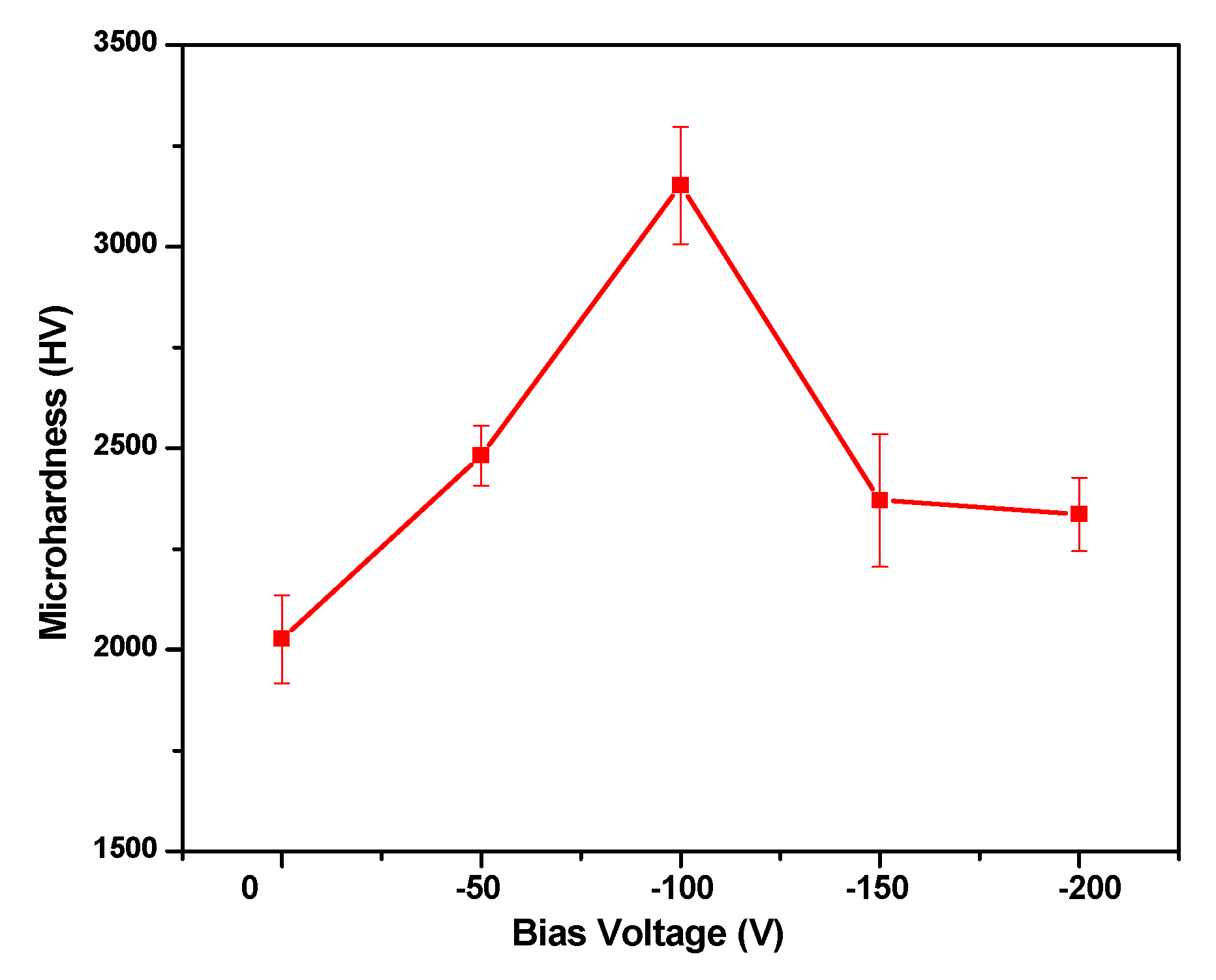

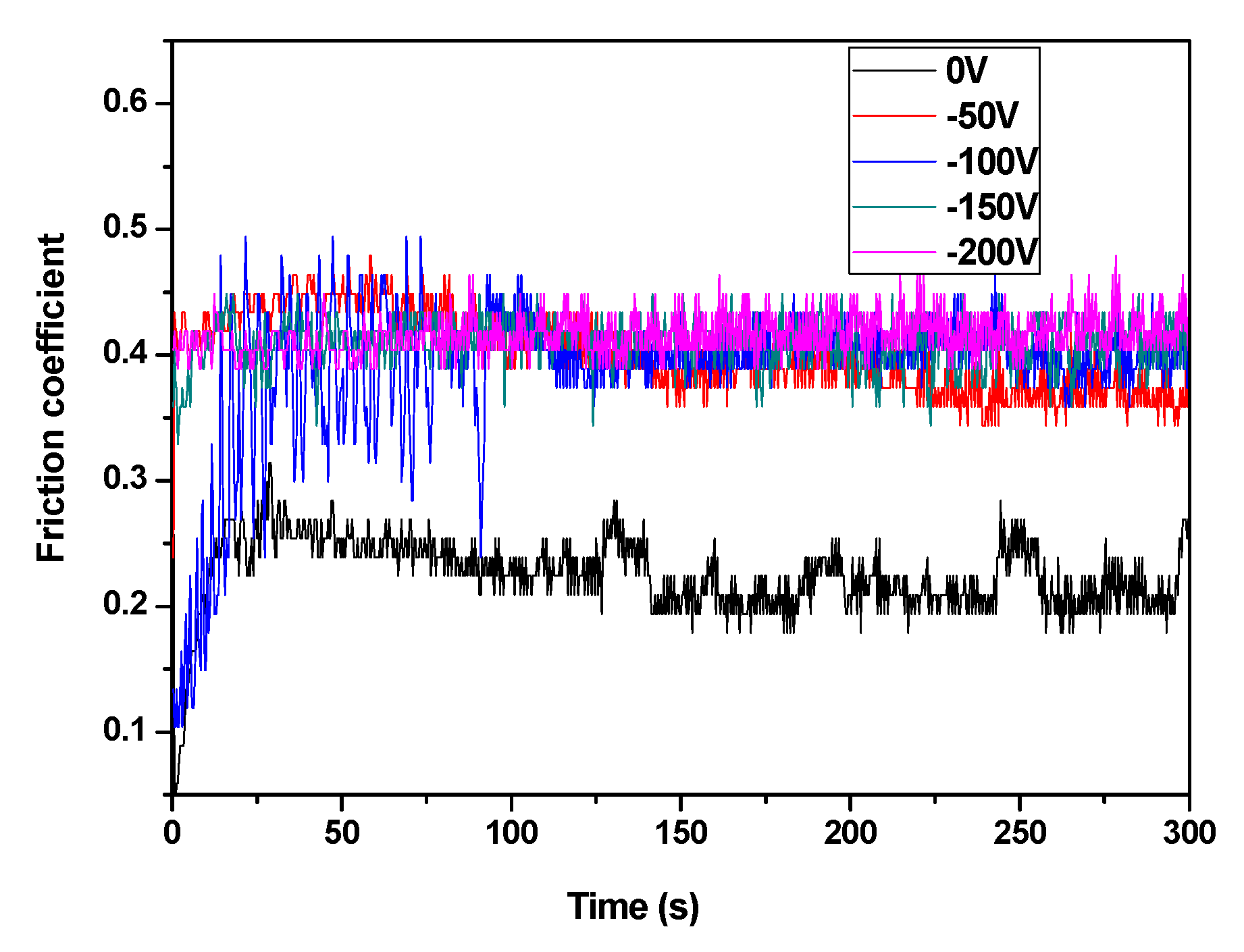

3.2. Mechanical Properties

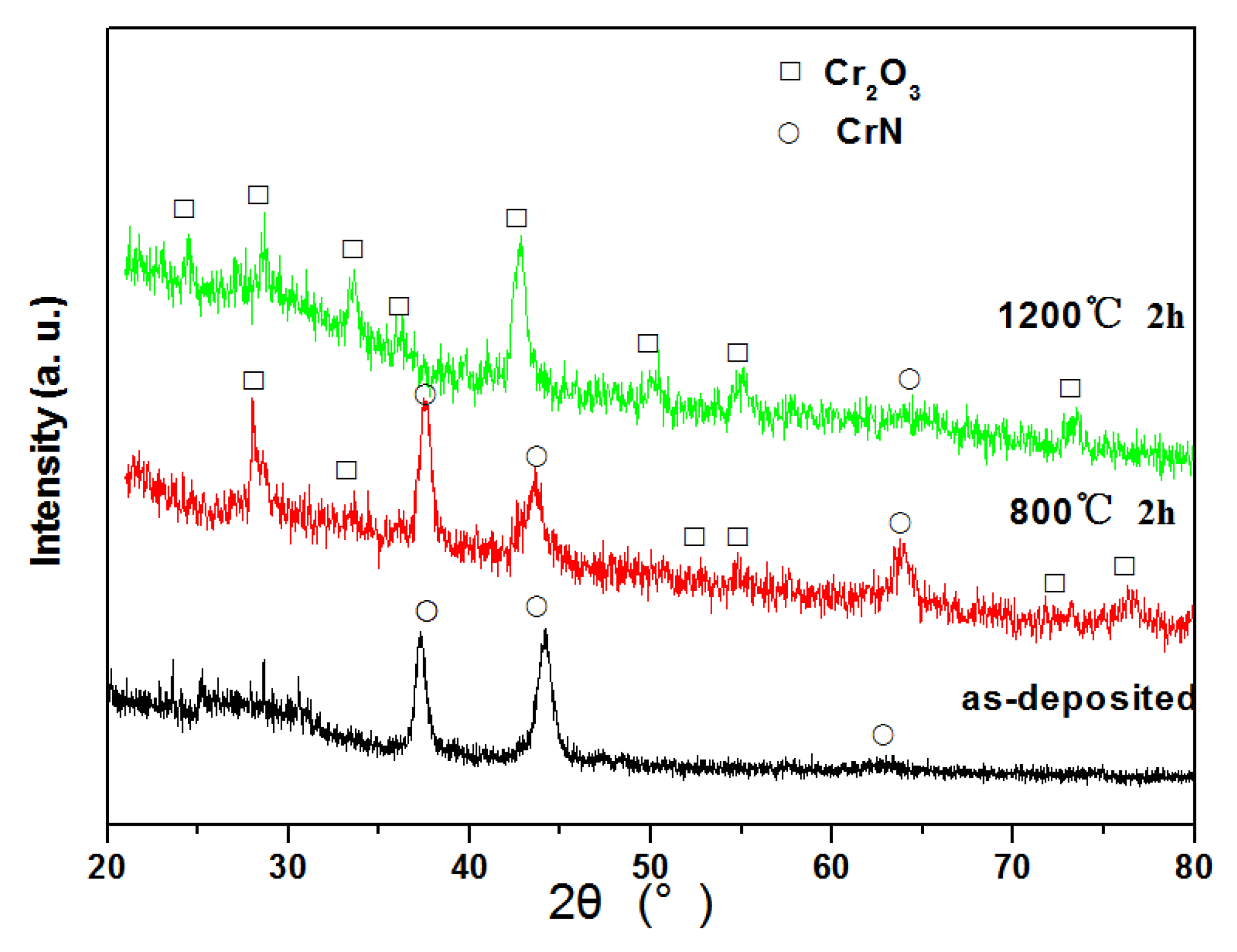

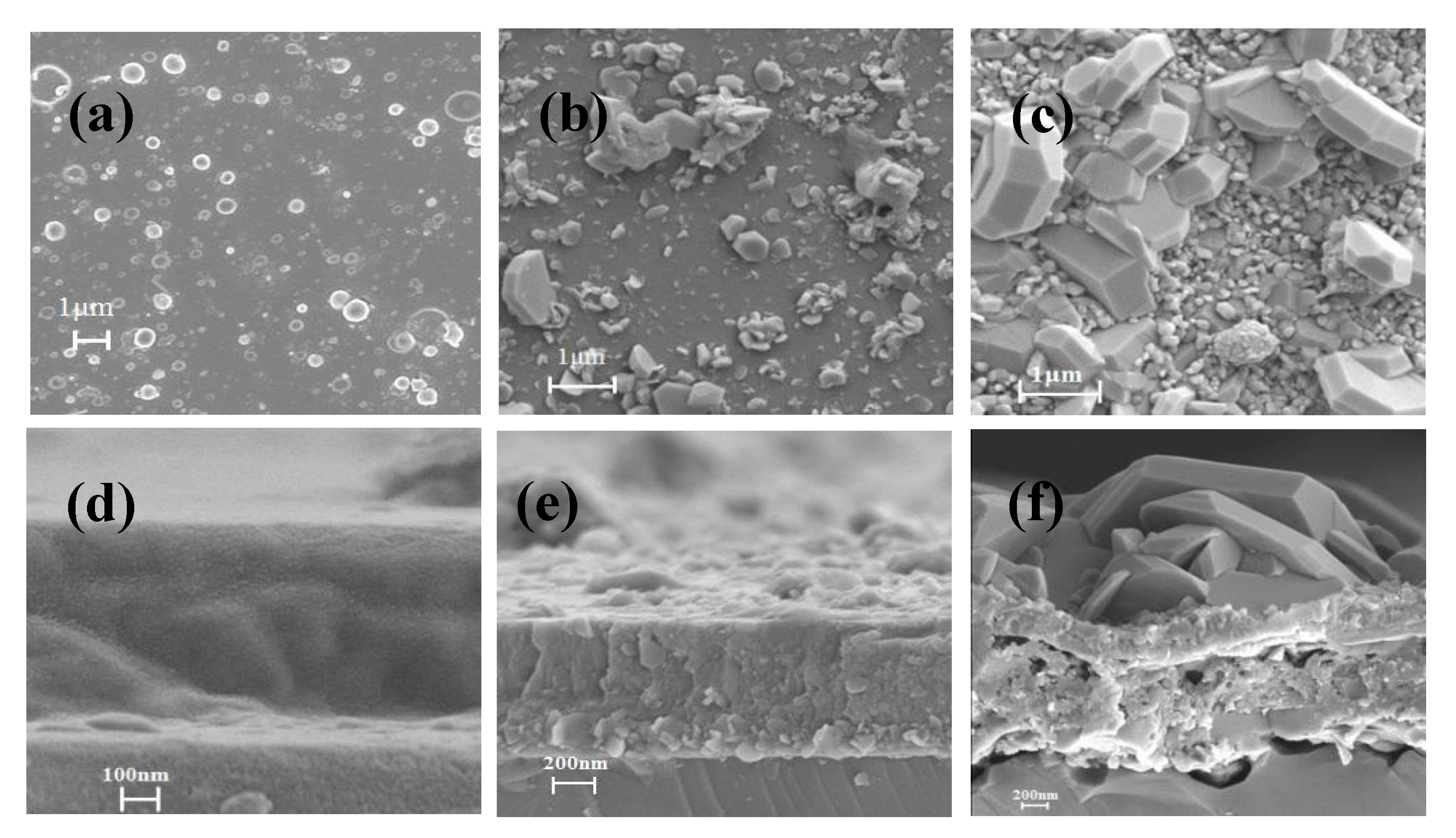

3.3. High-Temperature Oxidation Resistance Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, Q.; Lin, Y.; Zhou, F.; Kong, J. The influence of Ni concentration on the structure, mechanical and tribological properties of Ni–CrSiN coatings in seawater. J. Alloys Compd. 2020, 819, 152998. [Google Scholar] [CrossRef]

- Dinu, M.; Gura, A.; Constantina, P.A.; Vladescu, A.; Petrik, L.; Braic, M. Enhancement of the corrosion resistance of 304 stainless steel by Cr–N and Cr(N,O) coatings. Coatings 2018, 8, 132. [Google Scholar] [CrossRef]

- Azizpour, A.; Hahn, R.; Klimashin, F.F.; Wojcik, T.; Poursaeidi, E.; Mayrhofer, P.H. Deformation and cracking mechanism in CrN/TiN multilayer coatings. Coatings 2019, 9, 363. [Google Scholar] [CrossRef]

- Yan, S.; Fu, T.; Wang, R.; Tian, C.; Wang, Z.; Huang, Z.; Yang, B.; Fu, D. Deposition of CrSiN/AlTiSiN nano-multilayer coatings by multi-arc ion plating using gas source silicon. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2013, 307, 143–146. [Google Scholar] [CrossRef]

- Iram, S.; Cai, F.; Wang, J.; Zhang, J.; Liang, J.; Ahmad, F.; Zhang, S. Effect of addition of Mo or V on the structure and cutting performance of AlCrN-based coatings. Coatings 2020, 10, 298. [Google Scholar] [CrossRef]

- Kazlauskas, D.; Jankauskas, V.; Tučkutė, S. Research on tribological characteristics of hard metal WC–Co tools with TiAlN and CrN PVD coatings for processing solid oak wood. Coatings 2020, 10, 632. [Google Scholar] [CrossRef]

- Lyu, F.; Li, X.; Chen, C.; Liu, C.; Li, C.; Jiang, M.; Hu, X. High adhesion diamond films deposited on stainless steel by using nanocomposite films with mosaic interface as an interlayer. Appl. Surf. Sci. 2020, 528, 146916. [Google Scholar] [CrossRef]

- Li, B.-S.; Wang, T.-G.; Ding, J.; Cai, Y.; Shi, J.; Zhang, X. Influence of N2/Ar flow ratio on microstructure and properties of the AlCrSiN coatings deposited by high-power impulse magnetron sputtering. Coatings 2018, 8, 3. [Google Scholar] [CrossRef]

- Ding, J.; Zhang, T.; Yun, J.M.; Kang, M.C.; Wang, Q.; Kim, K.H. Microstructure, mechanical, oxidation and corrosion properties of the Cr–Al–Si–N coatings deposited by a hybrid sputtering system. Coatings 2017, 7, 119. [Google Scholar] [CrossRef]

- Fu, Y.; Zhou, F.; Zhang, M.; Wang, Q.; Zhou, Z. Structural, mechanical and tribocorrosion performances of CrMoSiN coatings with various Mo contents in artificial seawater. Appl. Surf. Sci. 2020, 525. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, L.; Wang, S.; Yan, P.; Xue, Q. Structure and mechanical properties of reactive sputtering CrSiN films. Appl. Surf. Sci. 2009, 255, 4425–4429. [Google Scholar] [CrossRef]

- Xu, M.; Kang, S.; Luc, J.; Yan, X.; Chen, T.; Wang, Z. Properties of a plasma-nitrided coating and a CrNx coating on the stainless steel bipolar plate of PEMFC. Coatings 2020, 10, 183. [Google Scholar] [CrossRef]

- Wan, Q.; Yang, B.; Chen, Y.; Cai, Y.; Liu, Y.; Meng, L.; Gao, D. Effect of bilayer period on microstructure and mechanical properties of TiSiN/TiN coatings. Materialia 2018, 3, 260–264. [Google Scholar] [CrossRef]

- Rojas, J.R.; Restrepo-Parra, E.; Prieto-Ortiz, F.; Olaya-Florez, J. On the application of digital image processing to surfaces of different nitride coatings. Superlattices Microstruct. 2008, 43, 564–569. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.; Chen, Z.; Li, J.; Li, M. Influence of deposition parameters on hard Cr–Al–N coatings deposited by multi-arc ion plating. Appl. Surf. Sci. 2012, 258, 3629–3636. [Google Scholar] [CrossRef]

- Lee, J.-W.; Tien, S.-K.; Kuo, Y.-C. The effects of pulse frequency and substrate bias to the mechanical properties of CrN coatings deposited by pulsed DC magnetron sputtering. Thin Solid Films 2006, 494, 161–167. [Google Scholar] [CrossRef]

- Chang, L.-C.; Liu, Y.-H.; Chen, Y.-I. Mechanical properties and oxidation behavior of Cr–Si–N coatings. Coatings 2019, 9, 528. [Google Scholar] [CrossRef]

- Tang, J.-F.; Lin, C.-Y.; Yang, F.-C.; Chang, C.-L. Influence of nitrogen content and bias voltage on residual stress and the tribological and mechanical properties of CrAlN films. Coatings 2020, 10, 546. [Google Scholar] [CrossRef]

- Wang, Q.; Kim, K.H. Microstructural control of Cr–Si–N films by a hybrid arc ion plating and magnetron sputtering process. Acta Mater. 2009, 57, 4974–4987. [Google Scholar] [CrossRef]

- Carvalho, S.; Ribeiro, E.; Rebouta, L.; Pacaud, J.; Goudeau, P.; Renault, P.O.; Riviere, J.; Tavares, C.J. PVD grown (Ti,Si,Al)N nanocomposite coatings and (Ti,Al)N/(Ti,Si)N multilayers: Structural and mechanical properties. Surf. Coat. Technol. 2003, 172, 109–116. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Grundmeier, G.; Arcos, T.D.L.; Wiesing, M.; Kruppe, N.C. (Cr,Al)N/(Cr,Al)ON oxy-nitride coatings deposited by hybrid dcMS/HPPMS for plastics processing applications. Surf. Coat. Technol. 2016, 308, 394–403. [Google Scholar] [CrossRef]

- Tan, S.; Zhang, X.; Wu, X.; Fang, F.; Jiang, J. Effect of substrate bias and temperature on magnetron sputtered CrSiN fifilms. Appl. Surf. Sci. 2011, 257, 1850–1853. [Google Scholar] [CrossRef]

- Biswas, B.; Purandare, Y.; Khan, I.; Hovsepian, P.E. Effect of substrate bias voltage on defect generation and their inflfluence on corrosion and tribological properties of HIPIMS deposited CrN/NbN coatings. Surf. Coat. Technol. 2018, 344, 383–393. [Google Scholar] [CrossRef]

- Lomello, F.; Sanchette, F.; Schuster, F.; Tabarant, M.; Billard, A. Influence of bias voltage on properties of AlCrN coatings prepared by cathodic arc deposition. Surf. Coat. Technol. 2013, 224, 77–81. [Google Scholar] [CrossRef]

- Takadoum, J.; Houmid-Bennani, H.; Mairey, D. The wear characteristics of silicon nitride. J. Eur. Ceram. Soc. 1998, 18, 553–556. [Google Scholar] [CrossRef]

- Lou, B.-S.; Chang, Y.-C.; Lee, J.-W. High temperature oxidation behaviors of CrNx and Cr–Si–N thin films at 1000 °C. Coatings 2019, 9, 540. [Google Scholar] [CrossRef]

- Mikula, M.; Grancic, B.; Drienovský, M.; Satrapinskyy, L.; Roch, T.; Hájovská, Z.; Gregor, M.; Plecenik, T.; Čička, R.; Plecenik, A.; et al. Thermal stability and high-temperature oxidation behavior of Si–Cr–N coatings with high content of silicon. Surf. Coat. Technol. 2013, 232, 349–356. [Google Scholar] [CrossRef]

- Lin, J.; Mishra, B.; Moore, J.J.; Sproul, W. A study of the oxidation behavior of CrN and CrAlN thin films in air using DSC and TGA analyses. Surf. Coat. Technol. 2008, 202, 3272–3283. [Google Scholar] [CrossRef]

- Kim, J.W.; Kim, K.H.; Lee, D.; Moore, J. Study on high-temperature oxidation behaviors of Cr–Si–N films. Surf. Coat. Technol. 2006, 200, 6702–6705. [Google Scholar] [CrossRef]

- Wang, T.-G.; Liu, Y.; Sina, H.; Shi, C.; Iyengar, S.; Melin, S.; Kim, K.H. High-temperature thermal stability of nanocrystalline Cr2O3 films deposited on silicon wafers by arc ion plating. Surf. Coat. Technol. 2013, 228, 140–147. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, Y.; Huang, L.; Zou, C. Effects of Bias Voltages on the Structural, Mechanical and Oxidation Resistance Properties of Cr–Si–N Nanocomposite Coatings. Coatings 2020, 10, 796. https://doi.org/10.3390/coatings10080796

Xiang Y, Huang L, Zou C. Effects of Bias Voltages on the Structural, Mechanical and Oxidation Resistance Properties of Cr–Si–N Nanocomposite Coatings. Coatings. 2020; 10(8):796. https://doi.org/10.3390/coatings10080796

Chicago/Turabian StyleXiang, Yanxiong, Lingling Huang, and Changwei Zou. 2020. "Effects of Bias Voltages on the Structural, Mechanical and Oxidation Resistance Properties of Cr–Si–N Nanocomposite Coatings" Coatings 10, no. 8: 796. https://doi.org/10.3390/coatings10080796

APA StyleXiang, Y., Huang, L., & Zou, C. (2020). Effects of Bias Voltages on the Structural, Mechanical and Oxidation Resistance Properties of Cr–Si–N Nanocomposite Coatings. Coatings, 10(8), 796. https://doi.org/10.3390/coatings10080796