Work Function Tuning of Zinc–Tin Oxide Thin Films Using High-Density O2 Plasma Treatment

Abstract

1. Introduction

2. Materials and Methods

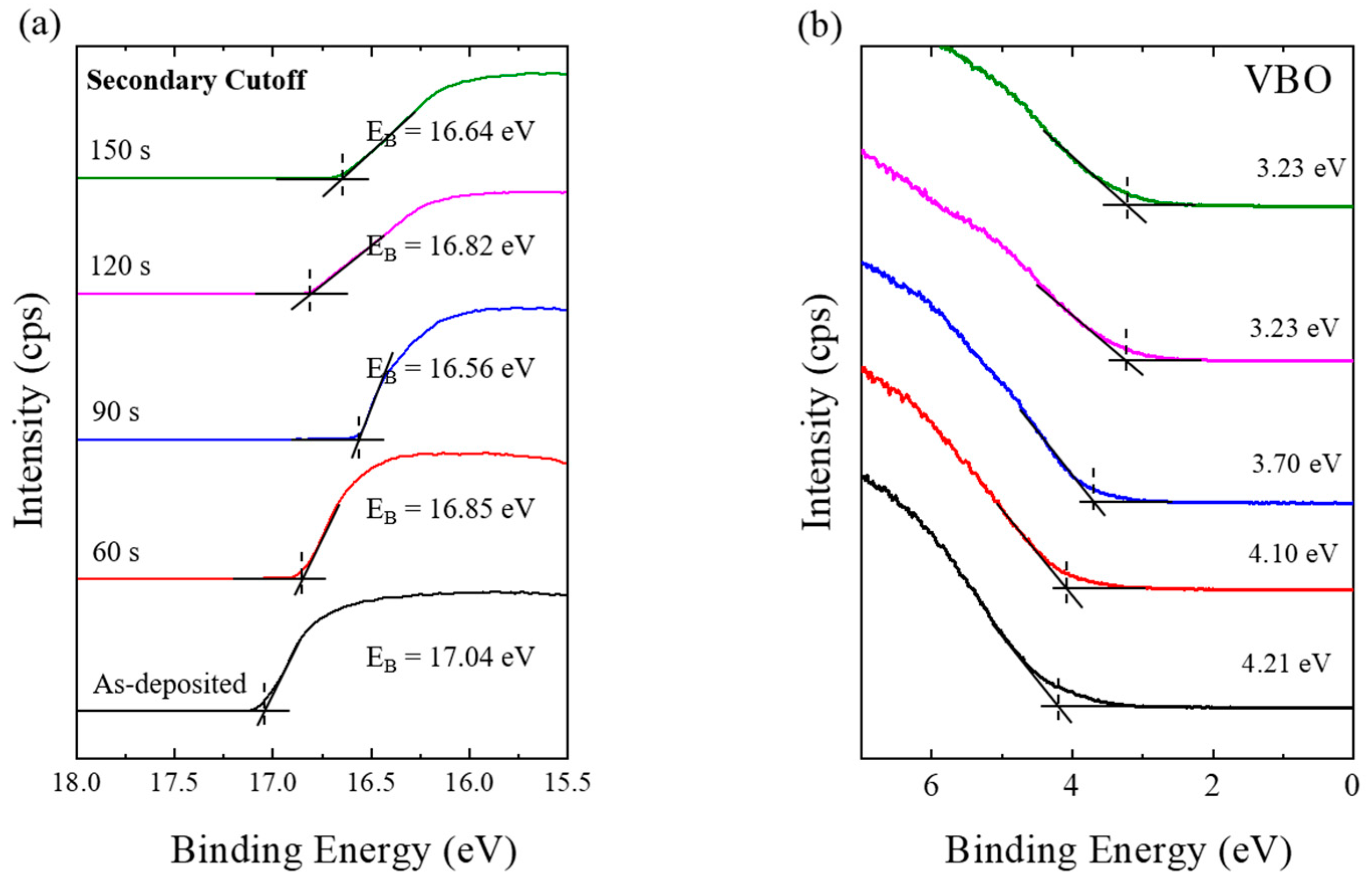

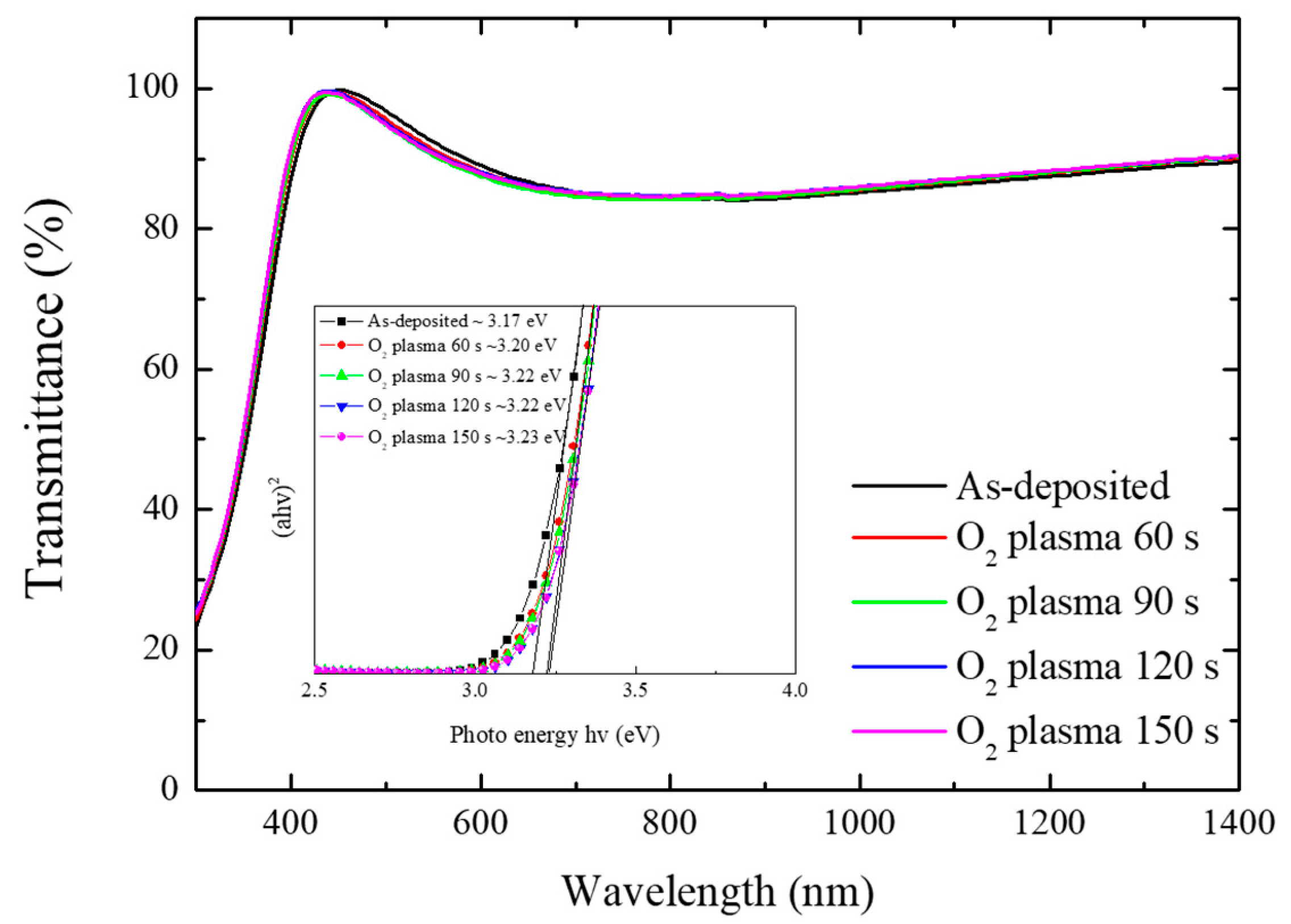

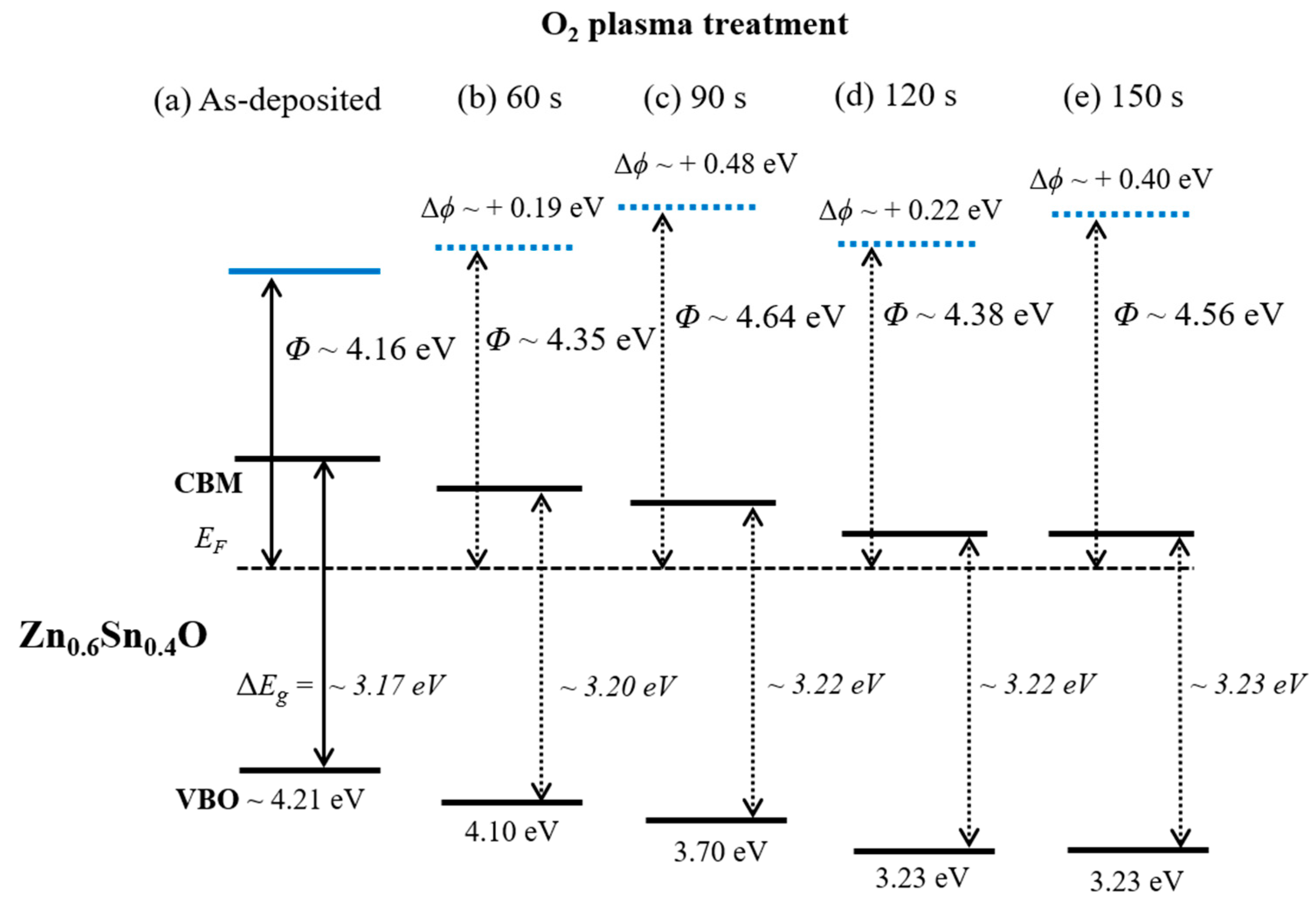

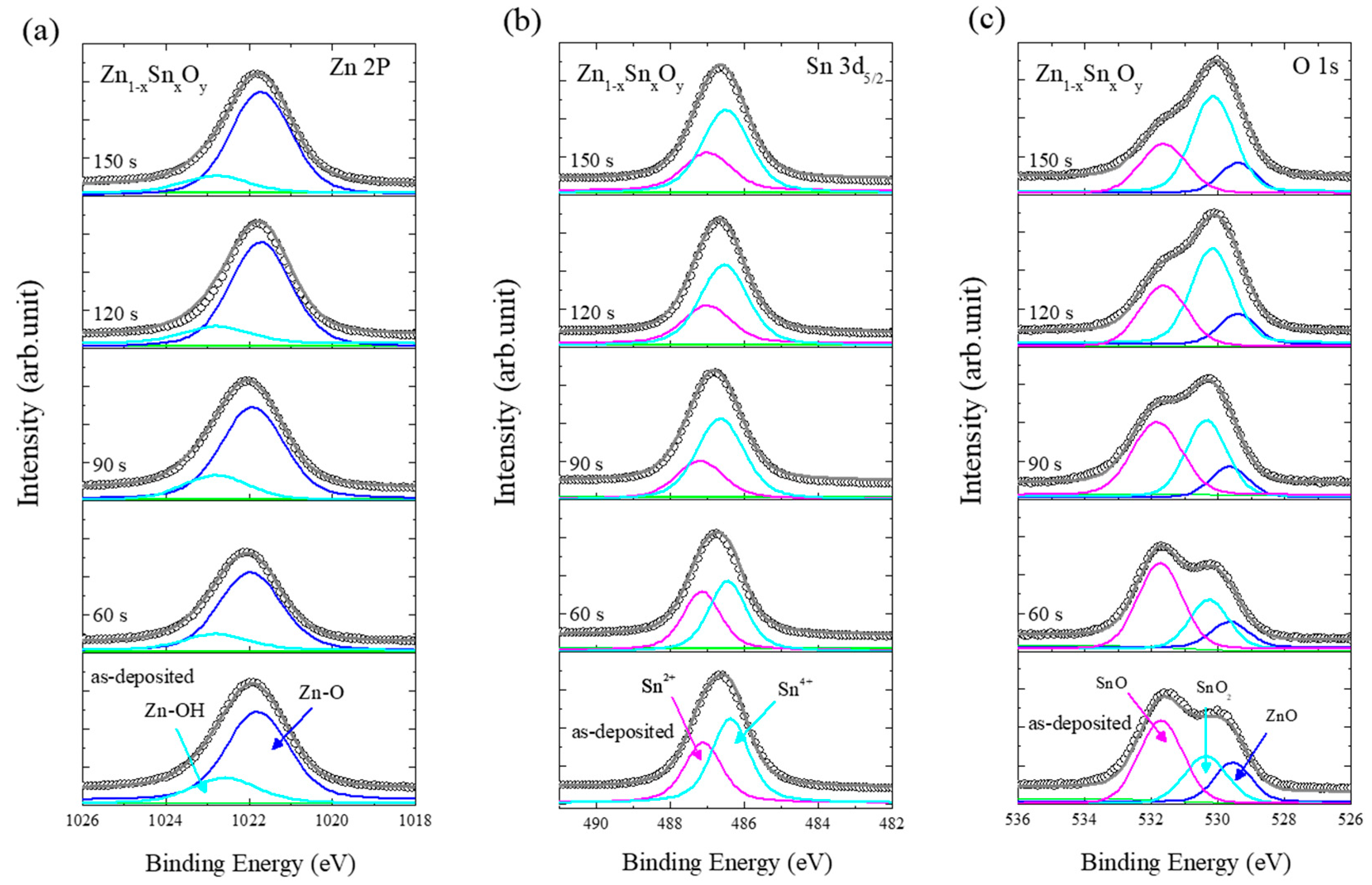

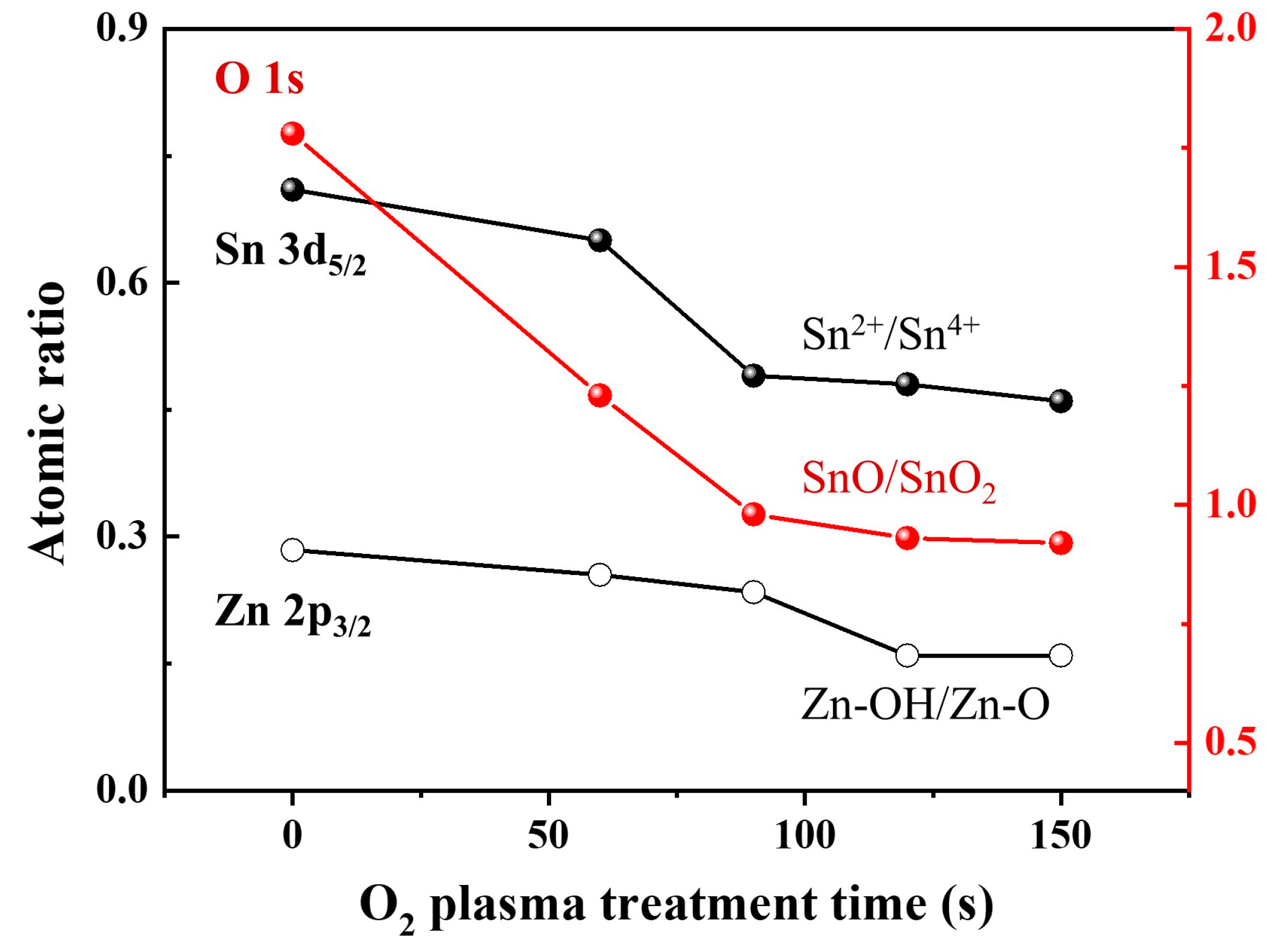

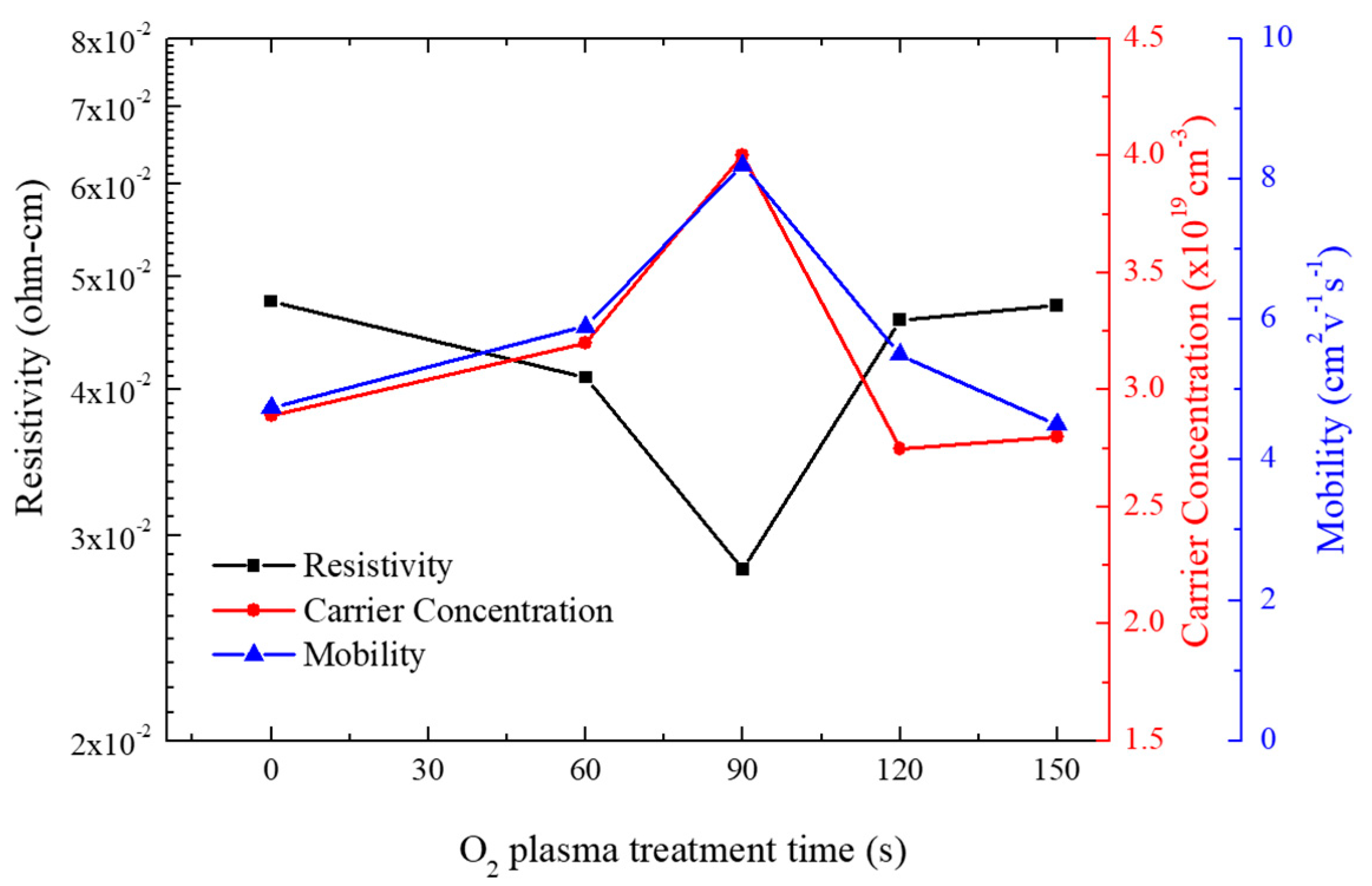

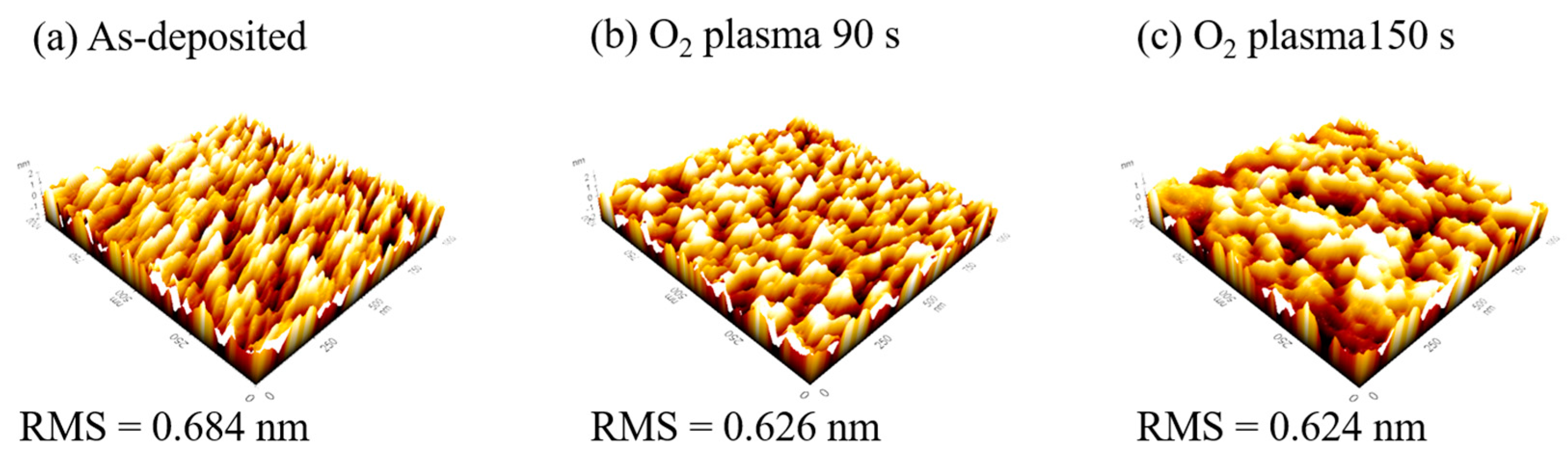

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ravi, S.K.; Sun, W.X.; Nandakumar, D.K.; Zhang, Y.X.; Tan, S.C. Optical manipulation of work function contrasts on metal thin films. Sci. Adv. 2018, 4, eaao6050. [Google Scholar] [CrossRef]

- Chuang, S.; Battaglia, C.; Azcatl, A.; McDonnell, S.; Kang, J.S.; Yin, X.T.; Tosun, M.; Kapadia, R.; Fang, H.; Wallace, R.M.; et al. MoS2 P-type transistors and diodes enabled by high work function MoOx contacts. Nano Lett. 2014, 14, 1337–1342. [Google Scholar] [CrossRef]

- Burgi, L.; Richards, T.J.; Friend, R.H.; Sirringhaus, H. Close look at charge carrier injection in polymer field-effect transistors. J. Appl. Phys. 2003, 94, 6129–6137. [Google Scholar] [CrossRef]

- Dominguez, M.A.; Alcantara, S.; Soto, S. Physically-based simulation of zinc oxide thin-film transistors: Contact resistance contribution on density of states. Solid-State Electron. 2016, 120, 41–46. [Google Scholar] [CrossRef]

- Liang, S.; Sheng, H.; Liu, Y.; Huo, Z.; Lu, Y.; Shen, H. ZnO Schottky ultraviolet photodetectors. J. Cryst. Growth 2001, 225, 110–113. [Google Scholar] [CrossRef]

- Goykhman, I.; Sassi, U.; Desiatov, B.; Mazurski, N.; Milana, S.; de Fazio, D.; Eiden, A.; Khurgin, J.; Shappir, J.; Levy, U.; et al. On-chip integrated, silicon–graphene plasmonic schottky photodetector with high responsivity and avalanche photogain. Nano Lett. 2016, 16, 3005–3013. [Google Scholar] [CrossRef]

- Alnuaimi, A.; Almansouri, I.; Saadat, I.; Nayfeh, A. High performance graphene-silicon Schottky junction solar cells with HfO2 interfacial layer grown by atomic layer deposition. Sol. Energy 2018, 164, 174–179. [Google Scholar] [CrossRef]

- Lee, K.H.; Jang, H.W.; Kim, K.B.; Tak, Y.H.; Lee, J.L. Mechanism for the increase of indium-tin-oxide work function by O2 inductively coupled plasma treatment. J. Appl. Phys. 2004, 95, 586–590. [Google Scholar] [CrossRef]

- Kang, J.H.; Cho, E.N.; Kim, C.E.; Lee, M.J.; Lee, S.J.; Myoung, J.M.; Yun, I. Mobility enhancement in amorphous InGaZnO thin-film transistors by Ar plasma treatment. Appl. Phys. Lett. 2013, 102, 222103. [Google Scholar] [CrossRef]

- Fang, M.; Zhang, C.M.; Chen, Q. Tuning the ITO work function by capacitively coupled plasma and its application in inverted organic solar cells. Appl. Surf. Sci. 2016, 385, 28–33. [Google Scholar] [CrossRef]

- Jain, V.K.; Kumar, P.; Kumar, M.; Jain, P.; Bhandari, D.; Vijay, Y.K. Study of post annealing influence on structural, chemical and electrical properties of ZTO thin films. J. Alloy. Compd. 2011, 509, 3541–3546. [Google Scholar] [CrossRef]

- Chandra, R.D.; Rao, M.; Zhang, K.K.; Prabhakar, R.R.; Shi, C.; Zhang, J.; Mhaisalkar, S.G.; Mathews, N. Tuning electrical properties in amorphous zinc tin oxide thin films for solution processed electronics. ACS Appl. Mater. Interfaces 2014, 6, 773–777. [Google Scholar] [CrossRef]

- Chiang, H.Q.; Wager, J.F.; Hoffman, R.L.; Jeong, J.; Keszler, D.A. High mobility transparent thin-film transistors with amorphous zinc tin oxide channel layer. Appl. Phys. Lett. 2005, 86, 013503. [Google Scholar] [CrossRef]

- Heineck, D.P.; McFarlane, B.R.; Wager, J.F. Zinc tin oxide thin-film-transistor enhancement/depletion inverter. IEEE Electron Device Lett. 2009, 30, 514–516. [Google Scholar] [CrossRef]

- Lindahl, J.; Watjen, J.T.; Hultqvist, A.; Ericson, T.; Edoff, M.; Torndahl, T. The effect of Zn1−xSnxOy buffer layer thickness in 18.0% efficient Cd-free Cu(In,Ga)Se2 solar cells. Prog. Photovolt. 2014, 21, 1588–1597. [Google Scholar] [CrossRef]

- Choi, K.H.; Koo, H.W.; Kim, T.W.; Kim, H.K. Antireflective ZnSnO/Ag bilayer-based transparent source and drain electrodes for transparent thin film transistors. Appl. Phys. Lett. 2012, 100, 263505. [Google Scholar] [CrossRef]

- Moriga, T.; Hayashi, Y.; Kondo, K.; Nishimura, Y.; Murai, K.; Nakabayashi, I.; Fukumoto, H.; Tominaga, K. Transparent conducting amorphous Zn–Sn–O films deposited by simultaneous dc sputtering. J. Vac. Sci. Technol. A 2004, 22, 1705–1710. [Google Scholar] [CrossRef]

- Huang, G.; Duan, L.; Dong, G.; Zhang, D.; Qiu, Y. High-mobility solution-processed tin oxide thin-film transistors with high-κ alumina dielectric working in enhancement mode. ACS Appl. Mater. Interfaces 2014, 6, 20786–20794. [Google Scholar] [CrossRef]

- Alshammari, F.H.; Hota, M.K.; Wang, Z.; Al-jawhari, H.; Alshareef, H.N. Atomic-Layer-Deposited SnO2 as Gate Electrode for Indium-Free Transparent Electronics. Adv. Electron. Mater. 2017, 3, 1700155. [Google Scholar] [CrossRef]

- Morales-Masis, M.; Dauzou, F.; Jeangros, Q.; Dabirian, A.; Lifka, H.; Gierth, R.; Ruske, M.; Moet, D.; Hessler-Wyser, A.; Ballif, C. An indium-free anode for large-area flexible OLEDs: Defect-free transparent conductive zinc tin oxide. Adv. Funct. Mater. 2016, 26, 384–392. [Google Scholar] [CrossRef]

- Um, D.S.; Woo, J.C.; Kim, C.I. Etching characteristics of TaN thin film using an inductively coupled plasma. Surf. Coat. Technol. 2010, 205, S333–S336. [Google Scholar] [CrossRef]

- Ratcliff, E.L.; Sigdel, A.K.; Macech, M.R.; Nebesny, K.; Lee, P.A.; Ginley, D.S.; Armstrong, N.R.; Berry, J.J. Surface composition, work function, and electrochemical characteristics of gallium-doped zinc oxide. Thin Solid Films 2012, 520, 5652–5663. [Google Scholar] [CrossRef]

- Sugiyama, K.; Ishii, H.; Ouchi, Y.; Seki, K. Dependence of indium–tin–oxide work function on surface cleaning method as studied by ultraviolet and x-ray photoemission spectroscopies. J. Appl. Phys. 2000, 87, 295–298. [Google Scholar] [CrossRef]

- Shin, H.; Kim, C.; Bae, C.; Lee, J.S.; Lee, J.; Kim, S. Effects of ion damage on the surface of ITO films during plasma treatment. Appl. Surf. Sci. 2007, 253, 8928–8932. [Google Scholar] [CrossRef]

- Masterton, W.L.; Slowinski, E.J.; Stanitski, C.L. Chemical Principles: Alternative Edition with a Qualitative Analysis Supplement; Saunders College Pub: Philadelphia, PA, USA, 1983. [Google Scholar]

- D’Agostino, D.; Giorgio, C.D.; Bobba, F.; Trolio, A.D.; Alippi, P.; Cucolo, A.M.; Bonapasta, A.A. Effects of cobalt substitution on ZnO surface reactivity and electronic structure. J. Mater. Chem. C 2019, 7, 8364–8373. [Google Scholar] [CrossRef]

- Gutmann, S.; Conrad, M.; Wolak, M.A.; Beerbom, M.M.; Schlaf, R. Work function measurements on nano-crystalline zinc oxide surfaces. J. Appl. Phys. 2012, 111, 123710. [Google Scholar] [CrossRef]

- Zhang, X.; Qin, J.; Xue, Y.; Yu, P.; Zhang, B.; Wang, L.; Liu, R. Effect of aspect ratio and surface defects on the photocatalytic activity of ZnO nanorods. Sci. Rep. 2014, 4, 4596. [Google Scholar] [CrossRef]

- Hu, X.; Masuda, Y.; Ohji, T.; Kato, K. Fabrication of Zn(OH)2/ZnO nanosheet-ZnO nanoarray hybrid structured films by a dissolution-recrystallization route. J. Am. Ceram. Soc. 2010, 93, 881–886. [Google Scholar] [CrossRef]

- Hwang, S.; Kim, Y.Y.; Lee, J.H.; Seo, D.K.; Lee, J.Y.; Cho, H.K. Irregular electrical conduction types in tin oxide thin films induced by nanoscale phase separation. J. Am. Ceram. Soc. 2012, 95, 324–327. [Google Scholar] [CrossRef]

- Kover, L.; Kovacs, Z.; Sanjines, R.; Moretti, G.; Cserny, I.; Margaritondo, G.; Palinkas, J.; Adachi, H. Electronic structure of tin oxides: High-resolution study of XPS and Auger spectra. Surf. Interface Anal. 1995, 23, 461–466. [Google Scholar] [CrossRef]

- Gamsjäger, H.; Gajda, T.; Sangster, J.; Saxena, S.K.; Voigt, W.; Perrone, J. Chemical Thermodynamics of TIN; OECD Publishing: Paris, France, 2012; Volume 12. [Google Scholar]

- Reisman, A.; Berkenblit, M.; Ghez, R.; Chan, S.A. The equilibrium constant for the reaction of ZnO + H2 and the chemical vapor transport of ZnO via the Zn + H2O reaction. J. Electron. Mater. 1972, 1, 395–419. [Google Scholar] [CrossRef]

- Liang, Z.; Zhang, Q.; Wiranwetchayan, O.; Xi, J.; Yang, Z.; Park, K.; Li, C.; Cao, G. Effects of the morphology of a ZnO buffer layer on the photovoltaic performance of inverted polymer solar cells. Adv. Funct. Mater. 2012, 22, 2194–2201. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joo, Y.-H.; Wi, J.-H.; Lee, W.-J.; Chung, Y.-D.; Cho, D.-H.; Kang, S.; Um, D.-S.; Kim, C.-I. Work Function Tuning of Zinc–Tin Oxide Thin Films Using High-Density O2 Plasma Treatment. Coatings 2020, 10, 1026. https://doi.org/10.3390/coatings10111026

Joo Y-H, Wi J-H, Lee W-J, Chung Y-D, Cho D-H, Kang S, Um D-S, Kim C-I. Work Function Tuning of Zinc–Tin Oxide Thin Films Using High-Density O2 Plasma Treatment. Coatings. 2020; 10(11):1026. https://doi.org/10.3390/coatings10111026

Chicago/Turabian StyleJoo, Young-Hee, Jae-Hyung Wi, Woo-Jung Lee, Yong-Duck Chung, Dae-Hyung Cho, Saewon Kang, Doo-Seung Um, and Chang-Il Kim. 2020. "Work Function Tuning of Zinc–Tin Oxide Thin Films Using High-Density O2 Plasma Treatment" Coatings 10, no. 11: 1026. https://doi.org/10.3390/coatings10111026

APA StyleJoo, Y.-H., Wi, J.-H., Lee, W.-J., Chung, Y.-D., Cho, D.-H., Kang, S., Um, D.-S., & Kim, C.-I. (2020). Work Function Tuning of Zinc–Tin Oxide Thin Films Using High-Density O2 Plasma Treatment. Coatings, 10(11), 1026. https://doi.org/10.3390/coatings10111026