The Impact of AlxGa1−xN Back Barrier in AlGaN/GaN High Electron Mobility Transistors (HEMTs) on Six-Inch MCZ Si Substrate

Abstract

1. Introduction

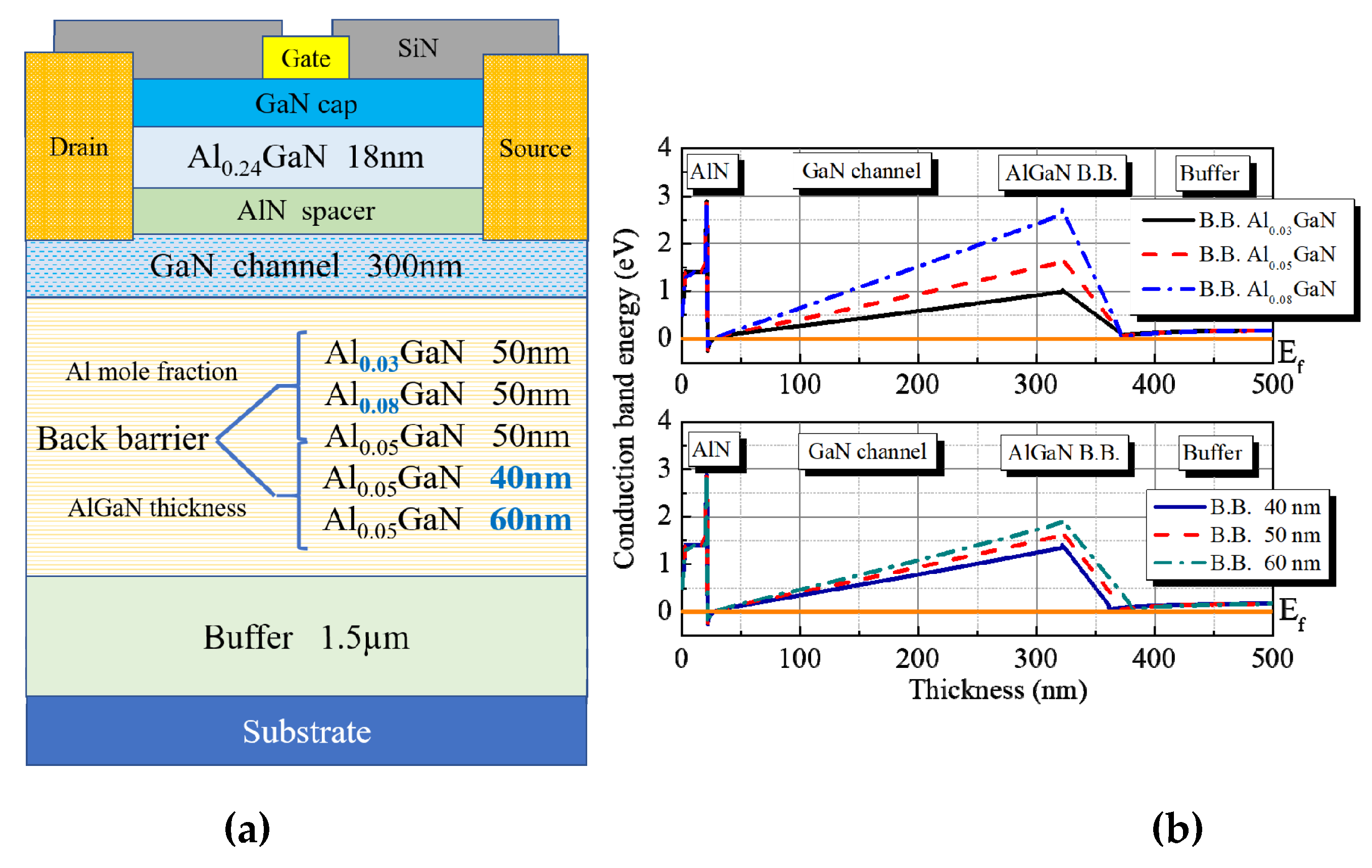

2. Device Fabrication

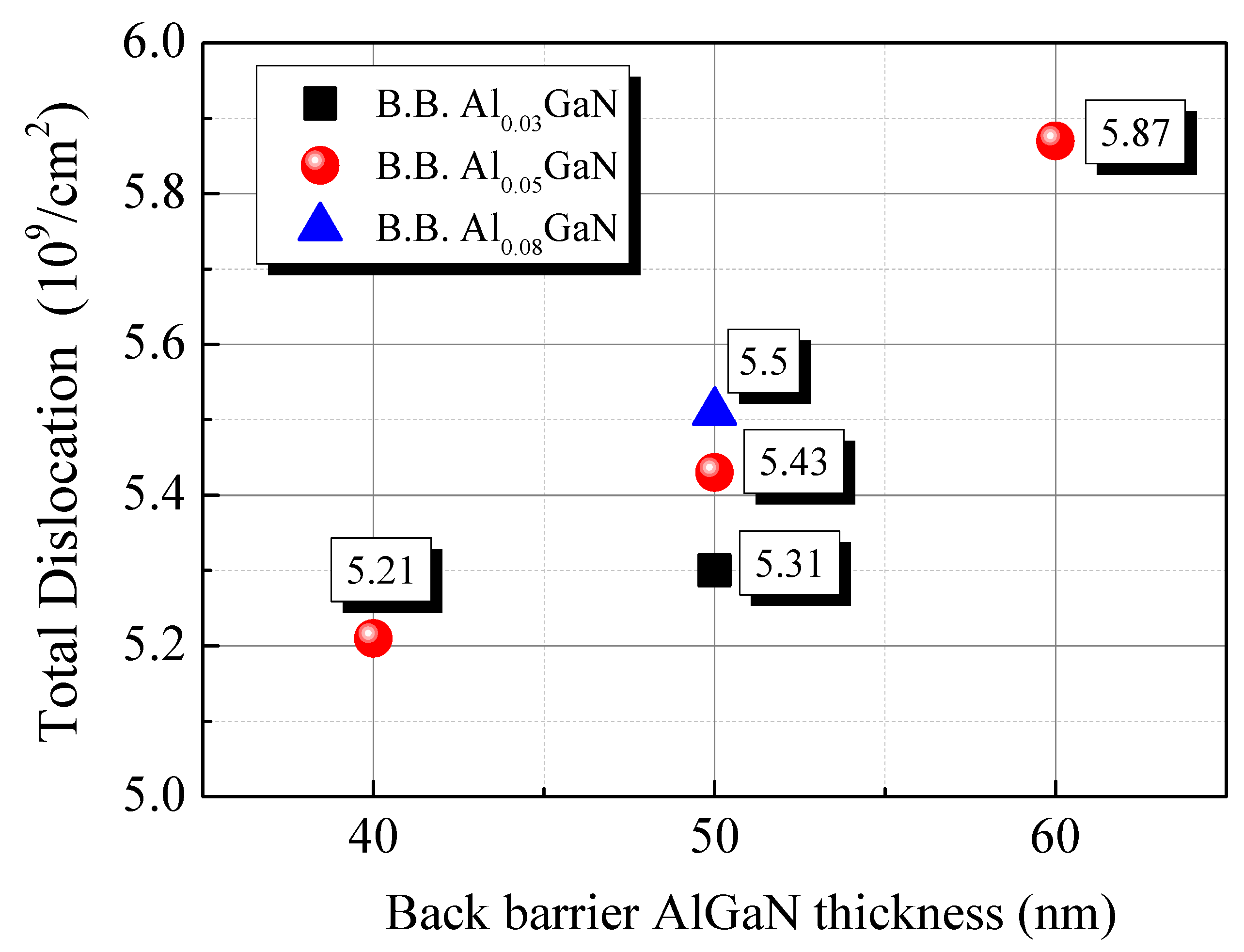

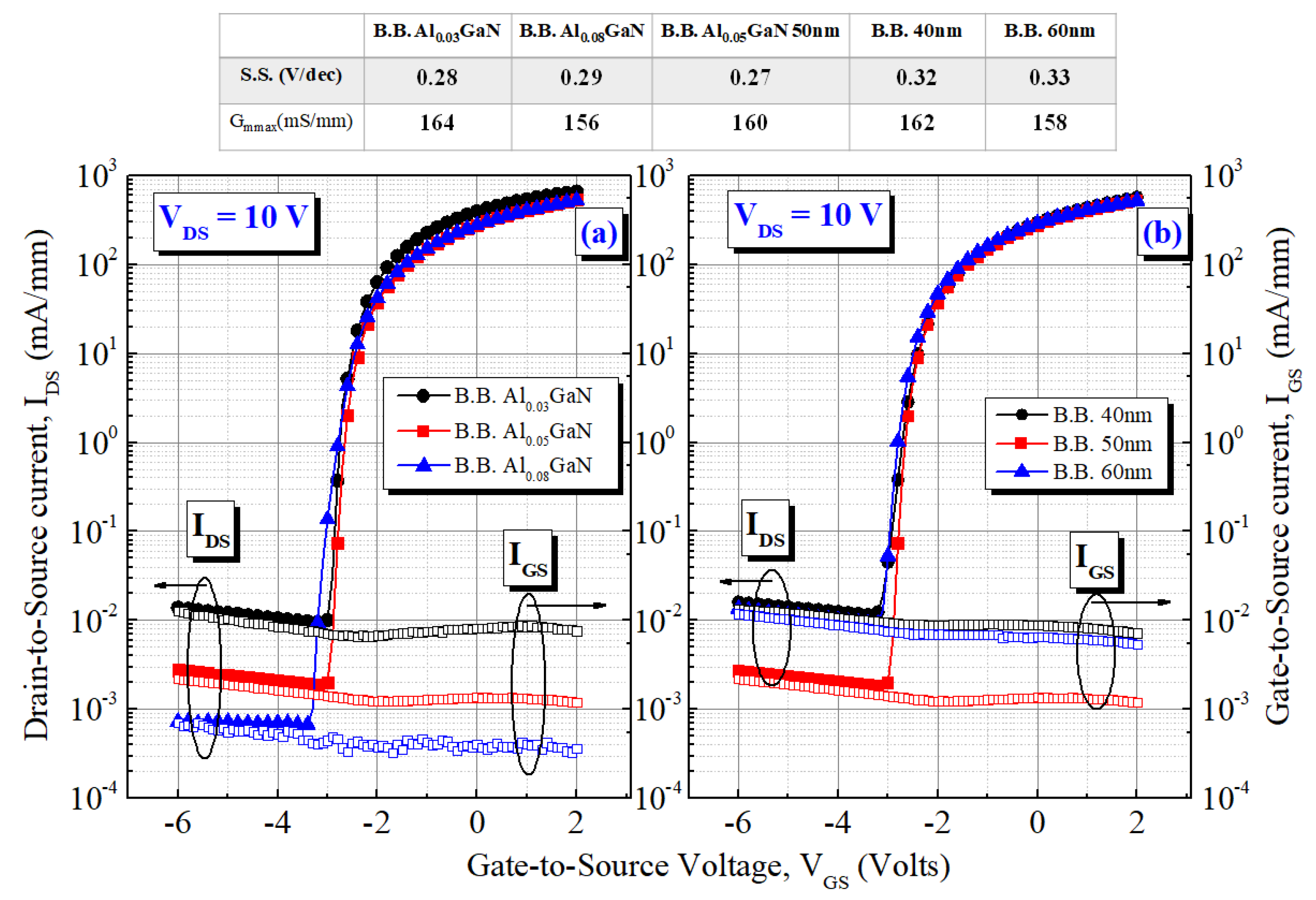

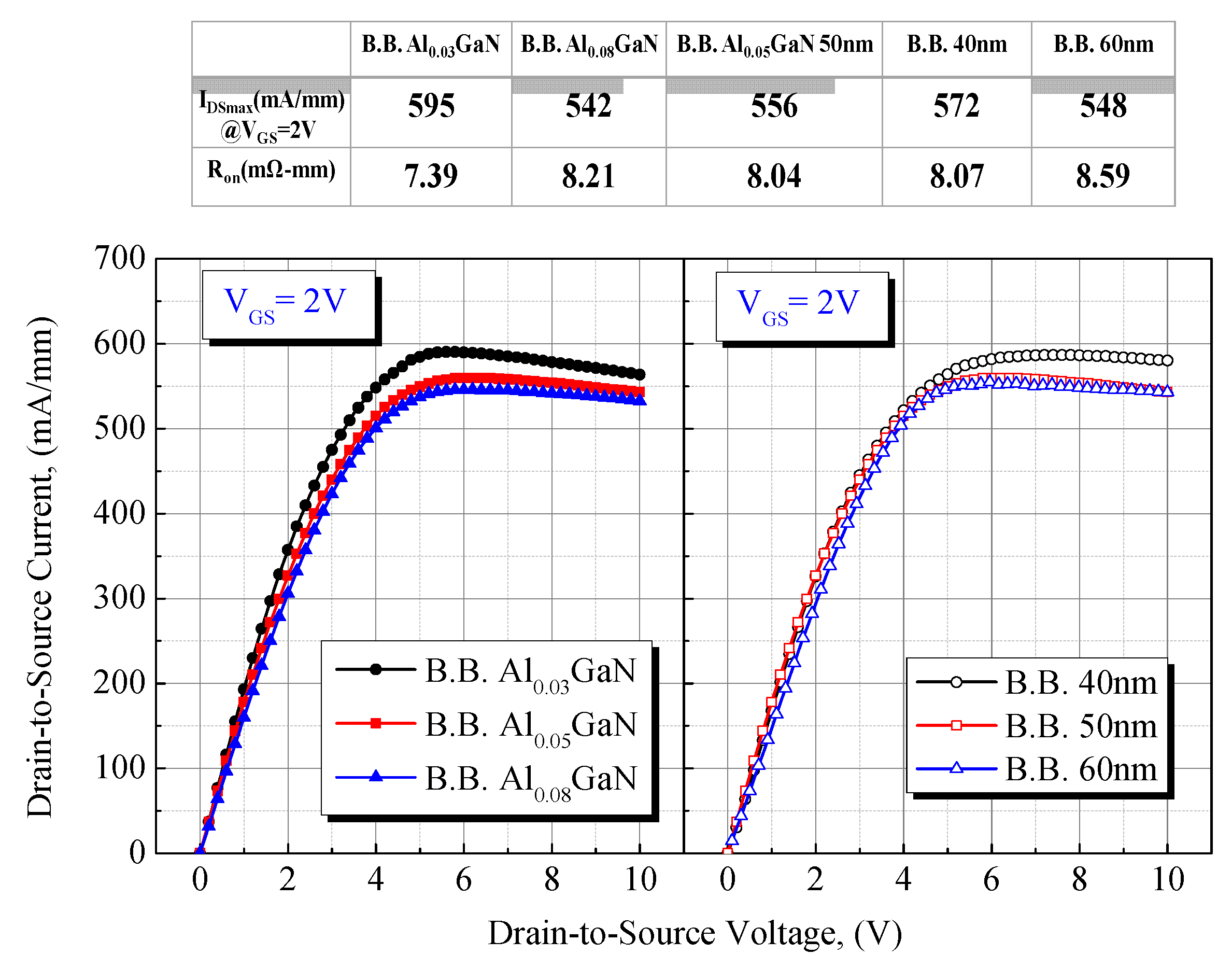

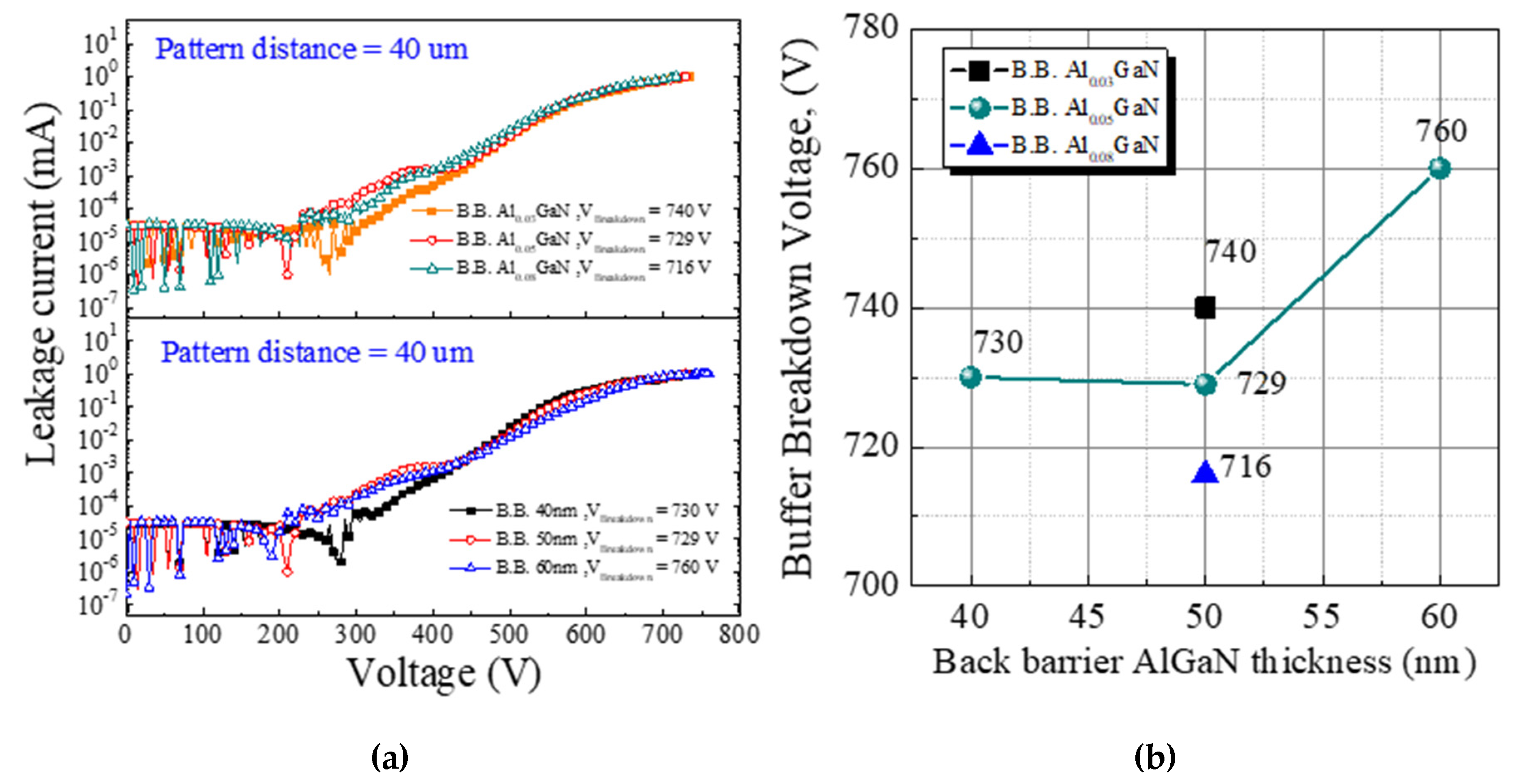

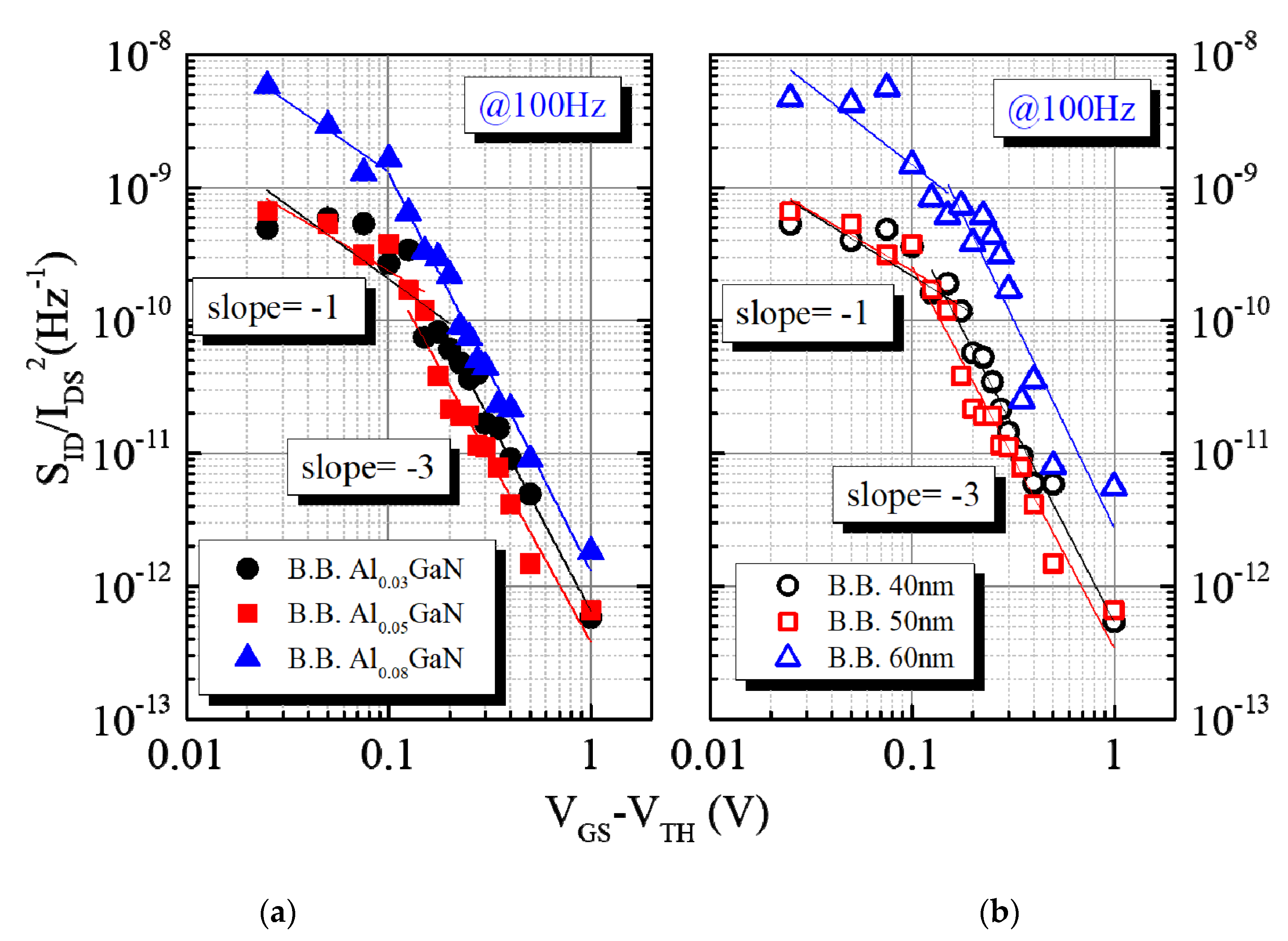

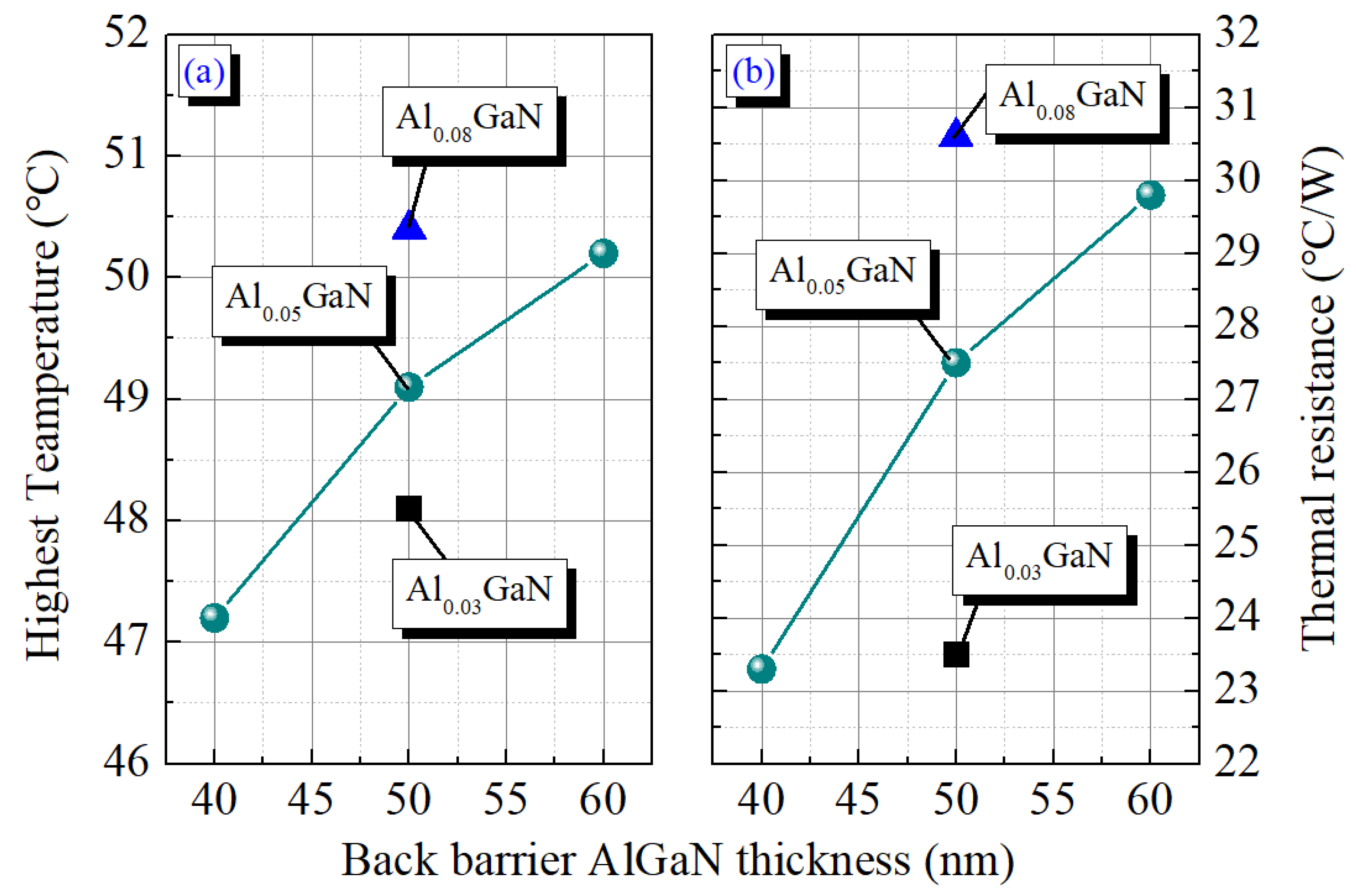

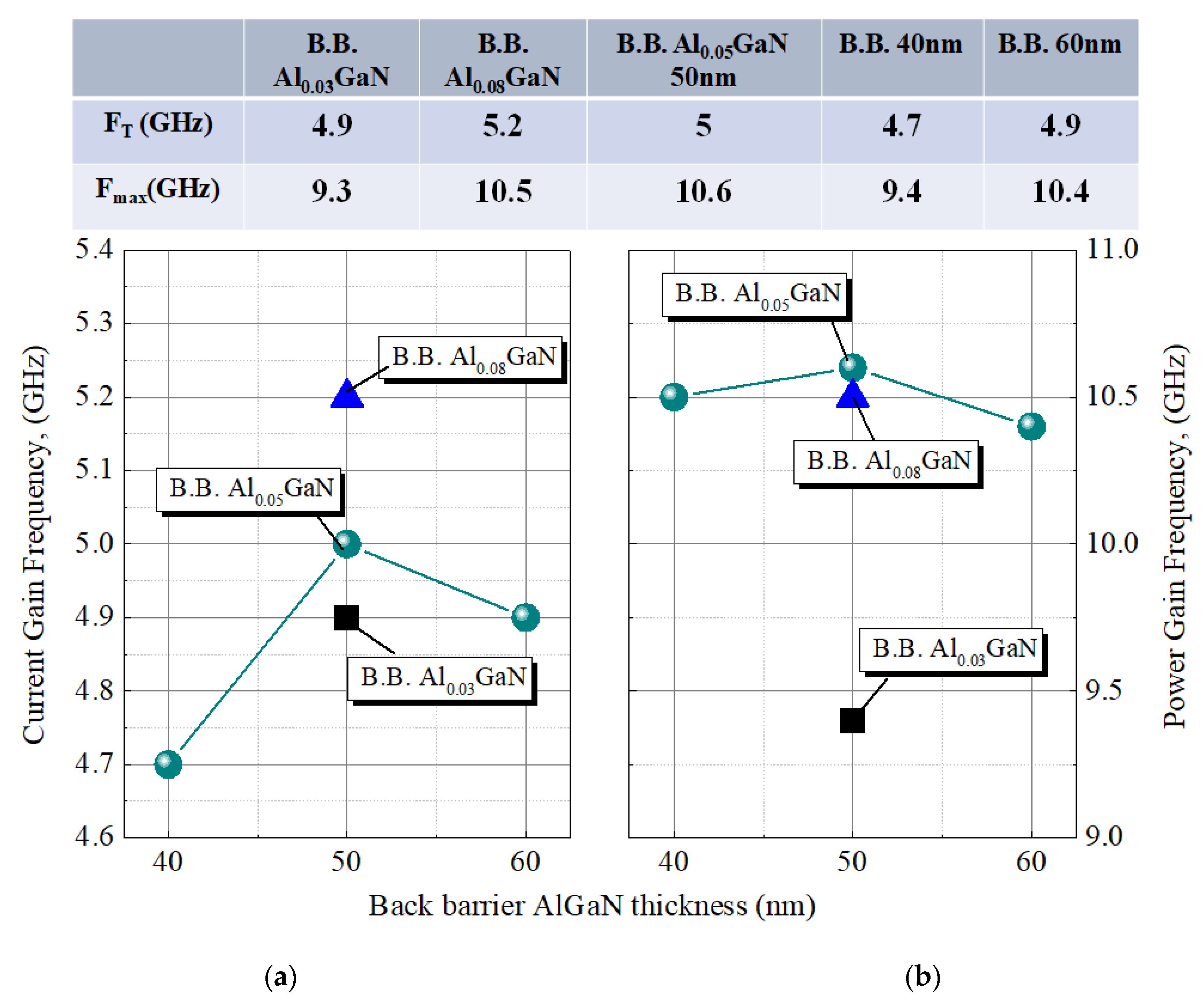

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Benjebbour, A.; Kitao, K.; Atarshi, H. IMT-2020 Radio interface standardization Trends in IYU-R. NTT DOCOMO Tech. J. 2018, 19, 55–63. [Google Scholar]

- Green, B.; Moore, K.; Hill, D.; CdeBaca, M.; Schultz, J. GaN RF device technology and applications, present and future. In Proceedings of the IEEE Bipolar/BiCMOS Circuits and Technology Meeting (BCTM), Bordeaux, France, 30 September–3 October 2013; pp. 101–106. [Google Scholar]

- Inoue, K.; Sano, S.; Tateno, Y.; Yamaki, F.; Ebihara, K.; Ui, N.; Deguchi, H. Development of Gallium Nitride High Electron Mobility Transistors for Cellular Base Stations. GaN 2010, 1, 3. [Google Scholar]

- Hsu, S.S.H.; Tsou, C.; Lian, Y.; Lin, Y. GaN-on-silicon devices and technologies for RF and microwave applications. In Proceedings of the IEEE International Symposium on Radio-Frequency Integration Technology (RFIT), Taipei, Taiwan, 24–26 August 2016; pp. 1–3. [Google Scholar]

- Dogmus, E. RF GaN Market: Applications, Players, Devices, and Technologies; Market & Technology Report for Yole Developpement: Lyon, France, May 2019. [Google Scholar]

- Kumar, V.; Lu, W.; Schwindt, R.; Kuliev, A.; Simin, G.; Yang, J.; Khan, M.A.; Adesida, I. AlGaN/GaN HEMTs on SiC with fT of over 120 GHz. IEEE Electron Device Lett. 2002, 23, 455–457. [Google Scholar] [CrossRef]

- Ping, A.T.; Chen, Q.; Yang, J.W.; Khan, M.A.; Adesida, I. DC and microwave performance of high-current AlGaN/GaN heterostructure field effect transistors grown on p-type SiC substrates. IEEE Electron Device Lett. 1998, 19, 54–56. [Google Scholar] [CrossRef]

- Chandrasekar, H. Substrate Effects in GaN-on-Silicon RF Device Technology. Int. J. High Speed Electron. Syst. 2019, 28, 1940001. [Google Scholar] [CrossRef]

- Driad, S.B.; Maher, H.; Defrance, N.; Hoel, V.; De Jaeger, J.C.; Renvoise, M.; Frijlink, P. AlGaN/GaN HEMTs on silicon substrate with 206-GHz FMAX. IEEE Electron Device Lett. 2013, 34, 36–38. [Google Scholar] [CrossRef]

- Medjdoub, F.; Zegaoui, M.; Grimbert, B.; Ducatteau, D.; Rolland, N.; Rolland, P.A. First demonstration of high-power GaN-on-silicon transistors at 40 GHz. IEEE Electron Device Lett. 2012, 33, 1168–1170. [Google Scholar] [CrossRef]

- Ciftja, A. Refining and Recycling of Silicon: A Review; Technology Report for Norwegian University of Science and Technology: Trondheim, Norway, 2008. [Google Scholar]

- Wang, Y.H.; Liang, Y.C.; Samudra, G.S.; Chu, P.J.; Liao, Y.C.; Huang, C.F.; Kuo, W.H.; Lo, G.Q. High-temperature studies of multiple fluorinated traps within an Al2O3 gate dielectric for E-Mode AlGaN/GaN power MISHEMTs. Semicond. Sci. Technol. 2016, 31, 025004. [Google Scholar] [CrossRef]

- Wang, W.; Li, L.; He, L.; Yang, F.; Chen, Z.; Zheng, Y.; He, L.; Wu, Z.; Zhang, B.; Liu, Y. Influence of AlGaN back barrier layer thickness on the dynamic RON characteristics of AlGaN/GaN HEMTs. In Proceedings of the China International Forum on Solid State Lighting: International Forum on Wide Bandgap Semiconductors China (SSLChina: IFWS), Beijing, China, 13–15 November 2016; pp. 15–17. [Google Scholar]

- Lee, H.Y. 3000-V 4.3-mΩ cm2 InAlN/GaN MOSHEMTS with AlGaN back barrier. IEEE Electron Device Lett. 2012, 33, 982–984. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, Y. A review of GaN-based optoelectronic devices on silicon substrate. Chin. Sci. Bull. 2014, 59, 1251–1275. [Google Scholar] [CrossRef]

- Palacios, T.; Chakraborty, A.; Heikman, S.; Keller, S.; DenBaars, S.P.; Mishra, U.K. AlGaN/GaN high electron mobility transistors with InGaN back-bardecemberriers. IEEE Electron Device Lett. 2006, 27, 13–15. [Google Scholar] [CrossRef]

- Safriuk, N.V.; Stanchu, G.V.; Kuchuk, A.V.; Kladko, V.P.; Belyaev, A.E.; Machulin, V.F. X-ray diffraction investigation of GaN layers on Si(111) and Al2O3 (0001) substrates. Semicond. Phys. Quantum Electron. Optoelectron. 2013, 16, 265–272. [Google Scholar] [CrossRef]

- Booker, I.D.; Khoshroo, L.; Woitok, J.F.; Kaganer, V.; Mauder, C.; Behmenburg, H.; Gruis, J.; Heuken, M.; Kalisch, H.; Jansen, R. Dislocation density assessment by X-ray GaN rocking curve scans. Phys. Status Solidi C 2010, 7–8, 1787–1789. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Y.; Zhu, J.; Lau, K.M.; Chen, K.J. AlGaN/GaN/InGaN/GaN DH-HEMTs with an InGaN notch for enhanced carrier confinement. IEEE Electron Device Lett. 2006, 27, 10–12. [Google Scholar]

- Then, H. Experimental observation and physics of “negative” capacitance and steeper than 40mV/decade subthreshold swing in Al0.83In0.17N/AlN/GaN MOS-HEMT on SiC substrate. In Proceedings of the Technical Digest International Electron Devices Meeting, Washington, DC, USA, 9–11 December 2013; pp. 28.3.1–28.3.4. [Google Scholar]

- Jana, R. On the possibility of sub 60 mV/decade subthreshold switching in piezoelectric gate barrier transistors. Phys. Status Solidi. 2013, 10, 1469–1472. [Google Scholar] [CrossRef]

- Jana, R. Sub-Boltzmann transistors with piezoelectric gate barriers. Energy Effic. Electron. Syst. P 2013, 1, 1–2. [Google Scholar]

- Chen, Y.Q.; Zhang, Y.C.; Liu, Y.; Liao, X.Y.; En, Y.F.; Fang, W.X.; Huang, Y. Effect of Hydrogen on Defects of AlGaN/GaN HEMTs Characterized by Low-Frequency Noise. IEEE Trans. Electron Devices. 2018, 65, 1321–1326. [Google Scholar] [CrossRef]

- Silvestri, M.; Uren, M.J.; Killat, N.; Marcon, D.; Kuball, M. Localization of off-stress-induced damage in AlGaN/GaN high electron mobility transistors by means of low frequency 1/f noise measurements. Appl. Phys. Lett. 2013, 103, 043506. [Google Scholar] [CrossRef]

- Ghibaudo, G.; Roux, O.; Nguyen-Duc, C.; Balestra, F.; Brini, J. Improved analysis of low frequency noise in field-effect MOS transistors. Phys. Status Solidi A 1991, 124, 571–581. [Google Scholar] [CrossRef]

- Vertiatchikh, A.V.; Eastman, L.F. Effect of the surface and barrier defects on the AlGaN/GaN HEMT low-frequency noise performance. IEEE Electron Device Lett. 2003, 24, 535–537. [Google Scholar] [CrossRef]

- He, L.; Li, L.; Zheng, Y.; Yang, F.; Shen, Z.; Che, Z.; Wang, W.; Zhang, J.; Zhang, X.; He, L.; et al. The influence of Al composition in AlGaN back barrier layer on leakage current and dynamic RON characteristics of AlGaN/GaN HEMTs. Phys. Status Solidi A 2017, 214, 1600824. [Google Scholar] [CrossRef]

- Wang, M.; Yan, D.; Zhang, C.; Xie, B.; Wen, C.P.; Wang, J.; Hao, Y.; Wu, W.; Shen, B. Investigation of Surface-and Buffer-Induced Current Collapse in GaN High-Electron Mobility Transistors Using a Soft Switched Pulsed I-V Measurement. IEEE Electron Device Lett. 2014, 35, 1094. [Google Scholar] [CrossRef]

- Huang, S.; Jiang, Q.; Yang, S.; Zhou, C.; Chen, K.J. Effective passivation of AlGaN/GaN HEMTs by ALD-grown AlN thin film. IEEE Electron Device Lett. 2012, 33, 516. [Google Scholar] [CrossRef]

- Tang, Z.; Huang, S.; Jiang, Q.; Liu, S.; Liu, C.; Chen, K.J. High-voltage (600-V) low-leakage low-current-collapse AlGaN/GaN HEMTs with AlN/SiNx passivation. IEEE Electron Device Lett. 2013, 34, 366. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.Y.; Chiu, H.C.; Hsu, W.C.; Liu, C.M.; Chuang, C.Y.; Liu, J.Z.; Huang, Y.L. The Impact of AlxGa1−xN Back Barrier in AlGaN/GaN High Electron Mobility Transistors (HEMTs) on Six-Inch MCZ Si Substrate. Coatings 2020, 10, 570. https://doi.org/10.3390/coatings10060570

Wang HY, Chiu HC, Hsu WC, Liu CM, Chuang CY, Liu JZ, Huang YL. The Impact of AlxGa1−xN Back Barrier in AlGaN/GaN High Electron Mobility Transistors (HEMTs) on Six-Inch MCZ Si Substrate. Coatings. 2020; 10(6):570. https://doi.org/10.3390/coatings10060570

Chicago/Turabian StyleWang, H.Y., H.C. Chiu, W.C. Hsu, C.M. Liu, C.Y. Chuang, J.Z. Liu, and Y.L. Huang. 2020. "The Impact of AlxGa1−xN Back Barrier in AlGaN/GaN High Electron Mobility Transistors (HEMTs) on Six-Inch MCZ Si Substrate" Coatings 10, no. 6: 570. https://doi.org/10.3390/coatings10060570

APA StyleWang, H. Y., Chiu, H. C., Hsu, W. C., Liu, C. M., Chuang, C. Y., Liu, J. Z., & Huang, Y. L. (2020). The Impact of AlxGa1−xN Back Barrier in AlGaN/GaN High Electron Mobility Transistors (HEMTs) on Six-Inch MCZ Si Substrate. Coatings, 10(6), 570. https://doi.org/10.3390/coatings10060570