Effects of Nitrogen Flow Ratio on Structures, Bonding Characteristics, and Mechanical Properties of ZrNx Films

Abstract

1. Introduction

2. Materials and Methods

3. Results

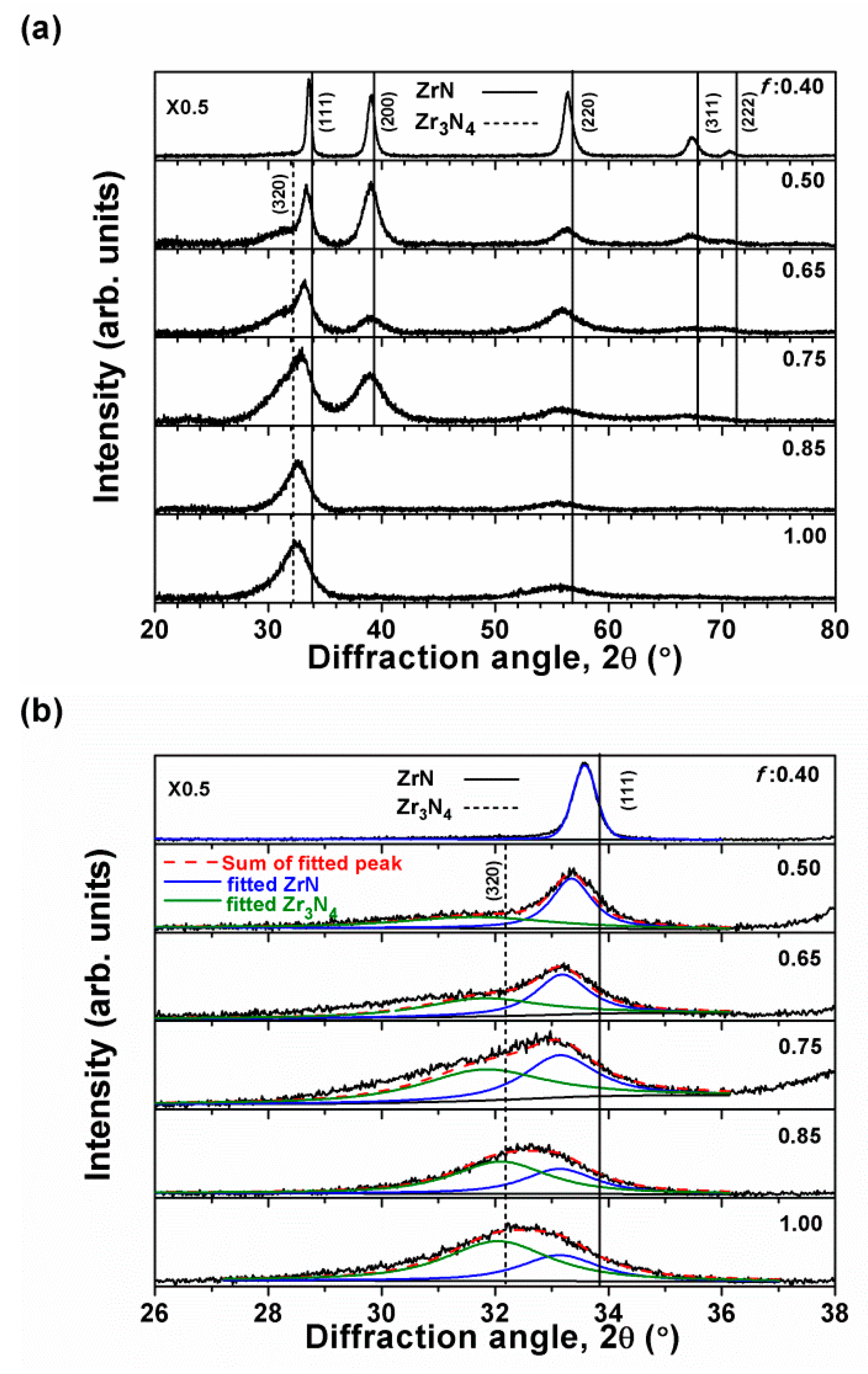

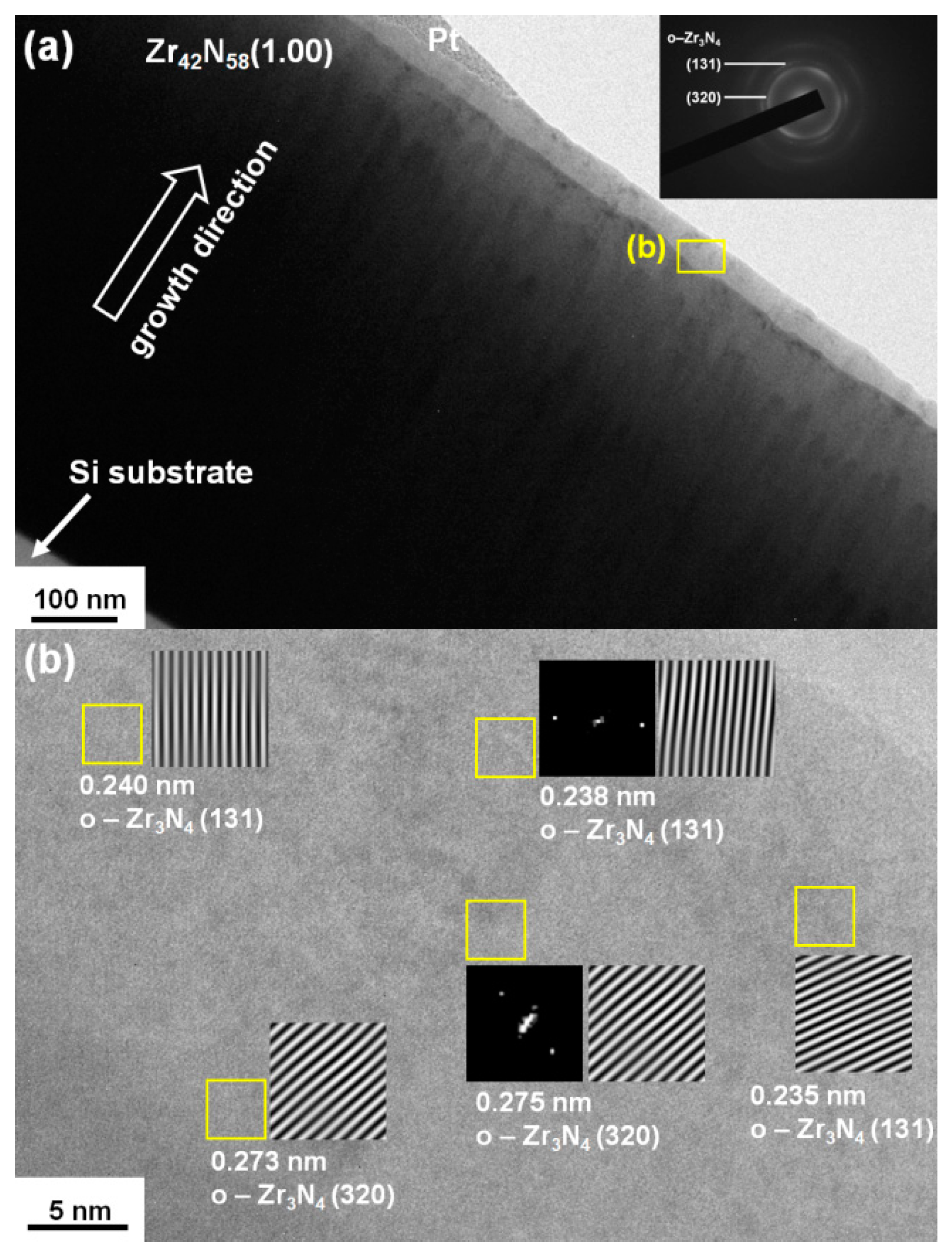

3.1. Chemical Compositions and Crystalline Phases

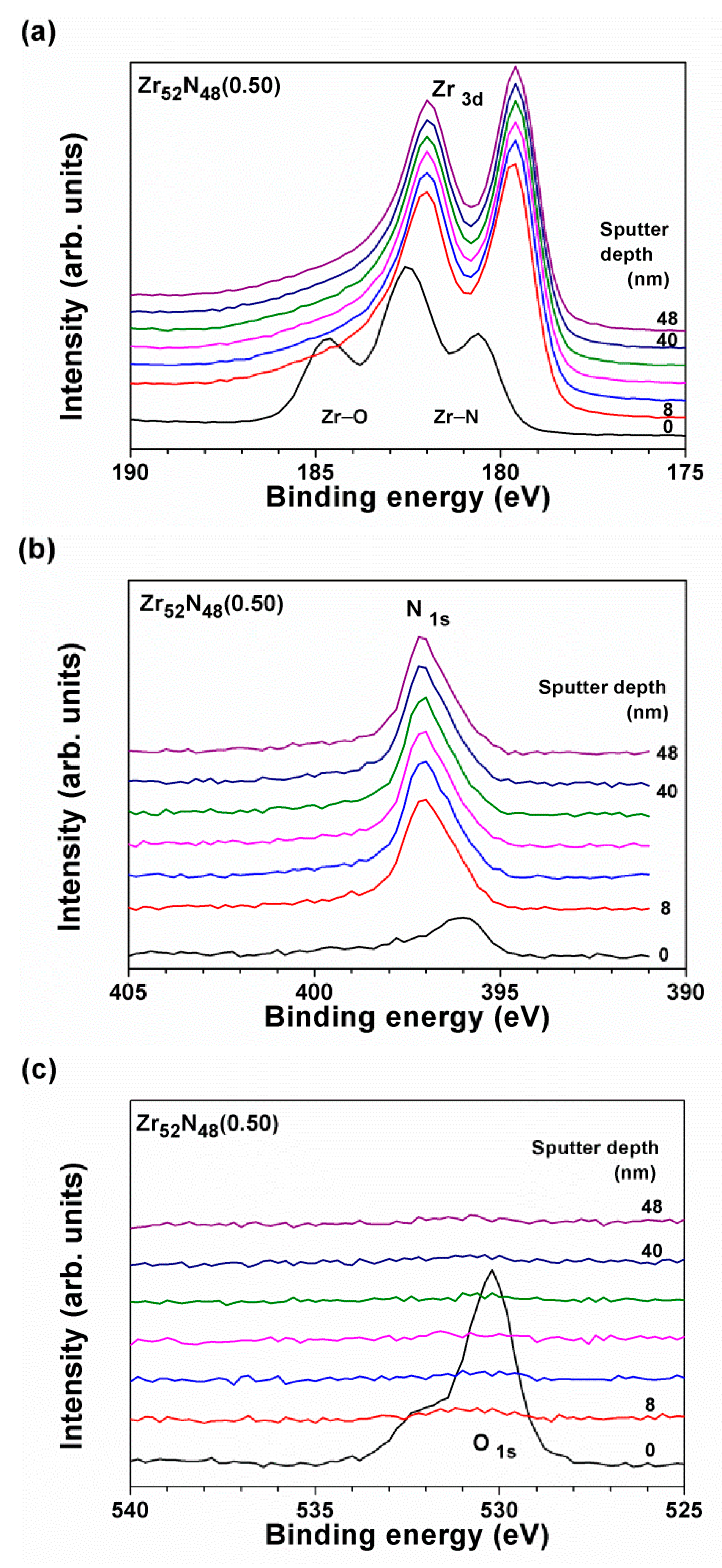

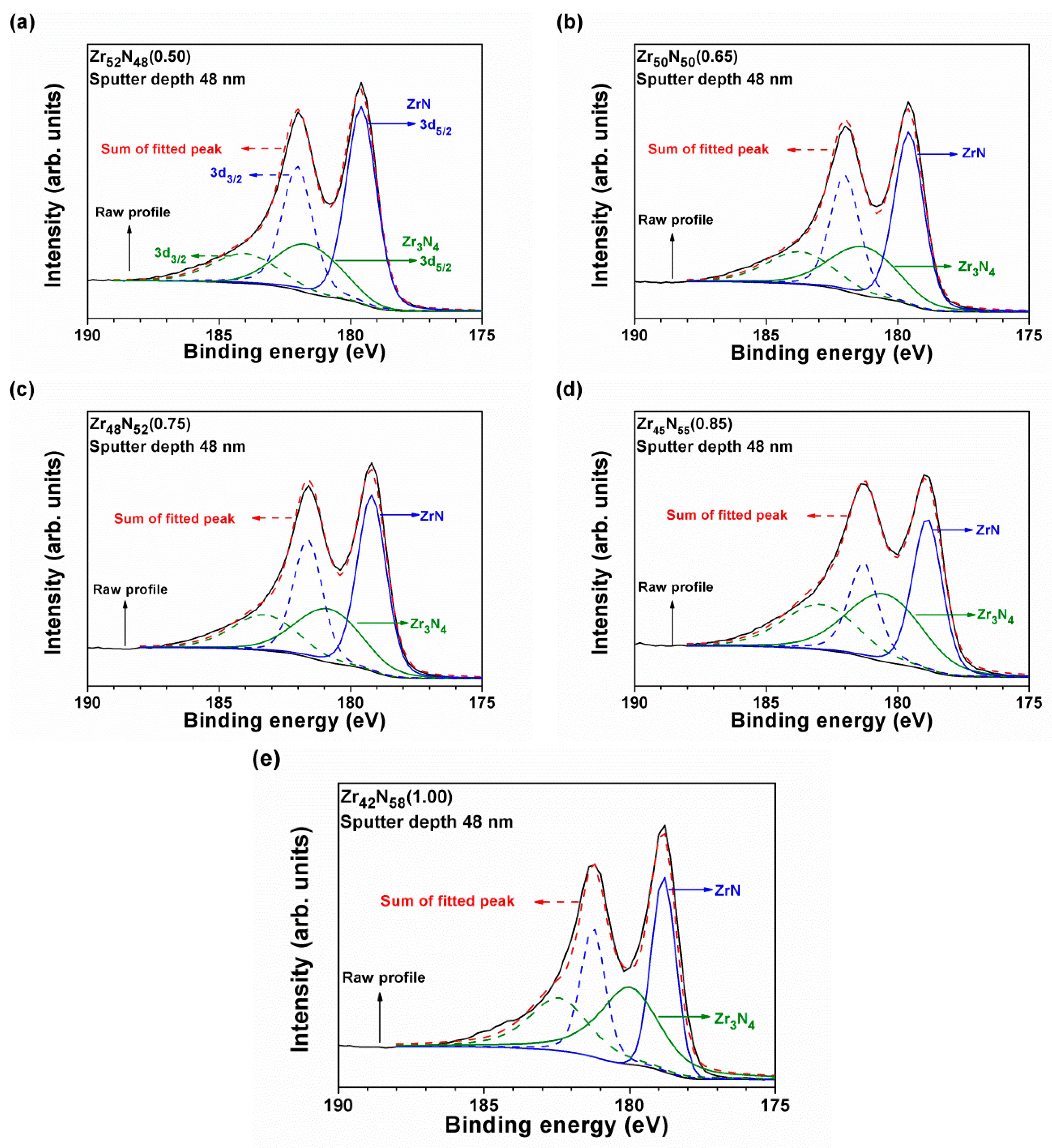

3.2. Bonding Characteristics

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Perry, A.J.; Georgson, M.; Sproul, W.D. Variations in the reflectance of TiN, ZrN and HfN. Thin Solid Films 1988, 157, 255–265. [Google Scholar] [CrossRef]

- Budke, E.; Krempel-Hesse, J.; Maidhof, H.; Schüssler, H. Decorative hard coatings with improved corrosion resistance. Surf. Coat. Technol. 1999, 112, 108–113. [Google Scholar] [CrossRef]

- Chou, W.J.; Yu, G.P.; Huang, J.H. Bias effect of ion-plated zirconium nitride film on Si(100). Thin Solid Films 2002, 405, 162–169. [Google Scholar] [CrossRef]

- Purandare, Y.P.; Ehiasarian, A.P.; Hovsepian, P.E. Structure and properties of ZrN coatings deposited by high power impulse magnetron sputtering technology. J. Vac. Sci. Technol. A 2011, 29, 011004. [Google Scholar] [CrossRef]

- Qi, Z.B.; Sun, P.; Zhu, F.P.; Wang, Z.C.; Peng, D.L.; Wu, C.H. The inverse Hall–Petch effect in nanocrystalline ZrN coatings. Surf. Coat. Technol. 2011, 205, 3692–3697. [Google Scholar] [CrossRef]

- Chang, L.C.; Chang, C.Y.; Chen, Y.I.; Kao, H.L. Mechanical properties and oxidation behavior of ZrNx thin films fabricated through high-power impulse magnetron sputtering deposition. J. Vac. Sci. Technol. A 2016, 34, 02D107. [Google Scholar] [CrossRef]

- Chou, W.J.; Yu, G.P.; Huang, J.H. Corrosion resistance of ZrN films on AISI 304 stainless steel substrate. Surf. Coat. Technol. 2003, 167, 59–67. [Google Scholar] [CrossRef]

- Xin, Y.; Liu, C.; Huo, K.; Tang, G.; Tian, X.; Chu, P.K. Corrosion behavior of ZrN/Zr coated biomedical AZ91 magnesium alloy. Surf. Coat. Technol. 2009, 203, 2554–2557. [Google Scholar] [CrossRef]

- Roman, D.; Bernardi, J.; Amorim, C.; Souza, F.; Spinelli, A.; Giacomelli, C.; Figueroa, C.A.; Baumvol, I.J.R.; Basso, R.L.O. Effect of deposition temperature on microstructure and corrosion resistance of ZrN thin films deposited by DC reactive magnetron sputtering. Mater. Chem. Phys. 2011, 130, 147–153. [Google Scholar] [CrossRef]

- Hu, C.; Guo, K.; Li, Y.; Gu, Z.; Quan, J.; Zhang, S.; Zheng, W. Optical coatings of durability based on transition metal nitrides. Thin Solid Films 2019, 688, 137339. [Google Scholar] [CrossRef]

- Huang, J.H.; Lau, K.W.; Yu, G.P. Effect of nitrogen flow rate on structure and properties of nanocrystalline TiN thin films produced by unbalanced magnetron sputtering. Surf. Coat. Technol. 2005, 191, 17–24. [Google Scholar] [CrossRef]

- Singh, A.; Kuppusami, P.; Khan, S.; Sudha, C.; Thirumurugesan, R.; Ramaseshan, R.; Divakar, R.; Mohandas, E.; Dash, S. Influence of nitrogen flow rate on microstructural and nanomechanical properties of Zr–N thin films prepared by pulsed DC magnetron sputtering. Appl. Surf. Sci. 2013, 280, 117–123. [Google Scholar] [CrossRef]

- Gu, Z.; Hu, C.; Huang, H.; Zhang, S.; Fan, X.; Wang, X.; Zheng, W. Identification and thermodynamic mechanism of the phase transition in hafnium nitride films. Acta Mater. 2015, 90, 59–68. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Khare, S.V.; Gall, D. Energetics of point defects in rocksalt structure transition metal nitrides: Thermodynamic reasons for deviations from stoichiometry. Acta Mater. 2018, 159, 77–88. [Google Scholar] [CrossRef]

- Kroll, P. Hafnium nitride with thorium phosphide structure: Physical properties and an assessment of the Hf-N, Zr-N, and Ti-N phase diagrams at high pressures and temperatures. Phys. Rev. Lett. 2003, 90, 125501. [Google Scholar] [CrossRef] [PubMed]

- Signore, M.A.; Valerini, D.; Tapfer, L.; Caretto, G.; Rizzo, A. Zirconium nitride films deposited in (Ar + N2 + H2) sputtering atmosphere: Optical, structural, and electrical properties. J. Vac. Sci. Technol. A 2011, 29, 061507. [Google Scholar] [CrossRef]

- Lerch, M.; Füglein, E.; Wrba, J. Synthesis, Crystal structure, and high temperature behavior of Zr3N4. Z. Anorg. Allg. Chem. 1996, 622, 367–372. [Google Scholar] [CrossRef]

- Takeyama, M.B.; Sato, M.; Noya, A. Thermally stable ZrN/Zr3N4 bilayered barrier system for through-Si-via process. Jpn. J. Appl. Phys. 2015, 54, 05EE02. [Google Scholar] [CrossRef]

- Zerr, A.; Miehe, G.; Riedel, R. Synthesis of cubic zirconium and hafnium nitride having Th3P4 structure. Nat. Mater. 2003, 2, 185–189. [Google Scholar] [CrossRef]

- Dzivenko, D.A.; Zerr, A.; Boehler, R.; Riedel, R. Equation of state of cubic hafnium(IV) nitride having Th3P4-type structure. Solid State Commun. 2006, 139, 255–258. [Google Scholar] [CrossRef]

- Chihi, T.; Fatmi, M.; Ghebouli, B.; Guemmaz, M. Theoretical prediction of the structural, elastic, electronic and optical properties of Zr3N4 and Hf3N4 compounds. Solid State Sci. 2011, 13, 1414–1419. [Google Scholar] [CrossRef]

- Zhang, J.D.; Yang, K. Theoretical study of the thermodynamic properties of cubic Zr3N4 and Hf3N4 under high pressures. J. Alloy. Compd. 2014, 608, 90–94. [Google Scholar] [CrossRef]

- Mattesini, M.; Ahuja, R.; Johansson, B. Cubic Hf3N4 and Zr3N4: A class of hard materials. Phys. Rev. B 2003, 68, 184108. [Google Scholar] [CrossRef]

- Prieto, P.; Galán, L.; Sanz, J.M. Electronic structure of insulating zirconium nitride. Phys. Rev. B 1993, 47, 1613–1615. [Google Scholar] [CrossRef] [PubMed]

- Chhowalla, M.; Unalan, H.E. Thin films of hard cubic Zr3N4 stabilized by stress. Nat. Mater. 2005, 4, 317–322. [Google Scholar] [CrossRef] [PubMed]

- Sui, Y.; Liu, J.; Liu, B.; Wang, L.; Yao, B. Influence of flow ratio of N2 to (N2+Ar) mixture on the structure and properties of zirconium nitride films prepared by radio frequency magnetron sputtering. J. Mater. Res. 2009, 24, 3206–3212. [Google Scholar] [CrossRef]

- Meng, Q.N.; Wen, M.; Qu, C.Q.; Hu, C.Q.; Zheng, W.T. Preferred orientation, phase transition and hardness for sputtered zirconium nitride films grown at different substrate biases. Surf. Coat. Technol. 2011, 205, 2865–2870. [Google Scholar] [CrossRef]

- Norouzian, S.; Larijani, M.M.; Afzalzadeh, R. Effect of nitrogen flow ratio on structure and properties of zirconium nitride films on Si(100) prepared by ion beam sputtering. Bull. Mater. Sci. 2012, 35, 885–887. [Google Scholar] [CrossRef]

- Ke, Y.E.; Chen, Y.I. Mechanical properties, bonding characteristics, and thermal stability of magnetron-sputtered HfNx films. Surf. Coat. Technol. 2020, 388, 125575. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Janssen, G.C.A.M.; Abdalla, M.M.; van Keulen, F.; Pujada, B.R.; van Venrooy, B. Celebrating the 100th anniversary of the Stoney equation for film stress: Developments from polycrystalline steel strips to single crystal silicon wafers. Thin Solid Films 2009, 517, 1858–1867. [Google Scholar] [CrossRef]

- Chen, Y.I.; Chang, S.C.; Chang, L.C. Oxidation resistance and mechanical properties of Zr–Si–N coatings with cyclic gradient concentration. Surf. Coat. Technol. 2017, 320, 168–173. [Google Scholar] [CrossRef]

- Chang, L.C.; Zheng, Y.Z.; Chen, Y.I.; Chang, S.C.; Liu, B.W. Bonding characteristics and chemical inertness of Zr–Si–N coatings with a high Si content in glass molding. Coatings 2018, 8, 181. [Google Scholar] [CrossRef]

- Ruan, J.L.; Lii, D.F.; Lu, H.H.; Chen, J.S.; Huang, J.L. Microstructural and electrical characteristics of reactively sputtered ZrNx thin films. J. Alloy. Compd. 2009, 478, 671–675. [Google Scholar] [CrossRef]

- Ramana, J.V.; Kumar, S.; David, C.; Ray, A.K.; Raju, V.S. Characterisation of zirconium nitride coatings prepared by DC magnetron sputtering. Mater. Lett. 2000, 43, 73–76. [Google Scholar] [CrossRef]

- Berg, S.; Nyberg, T. Fundamental understanding and modeling of reactive sputtering processes. Thin Solid Films 2005, 476, 215–230. [Google Scholar] [CrossRef]

- Huang, J.H.; Ho, C.H.; Yu, G.P. Effect of nitrogen flow rate on the structure and mechanical properties of ZrN thin films on Si(1 0 0) and stainless steel substrates. Mater. Chem. Phys. 2007, 102, 31–38. [Google Scholar] [CrossRef]

- Sui, Y.R.; Xu, Y.; Yao, B.; Xiao, L.; Liu, B. Preparation, characterization and properties of N-rich Zr–N thin film with Th3P4 structure. Appl. Surf. Sci. 2009, 255, 6355–6358. [Google Scholar] [CrossRef]

- Höchst, H.; Bringans, R.D.; Steiner, P.; Wolf, T. Photoemission study of the electronic structure of stoichiometric and substoichiometric TiN and ZrN. Phys. Rev. B 1982, 25, 7183–7191. [Google Scholar] [CrossRef]

- Netterfield, R.P.; Martin, P.J.; McKenzie, D.R. Properties of ZrNx prepared by ion-assisted deposition. J. Mater. Sci. Lett. 1990, 9, 972–974. [Google Scholar] [CrossRef]

- Bertóti, I. Characterization of nitride coatings by XPS. Surf. Coat. Technol. 2002, 151–152, 194–203. [Google Scholar] [CrossRef]

- Carvalho, P.; Chappé, J.M.; Cunha, L.; Lanceros-Méndez, S.; Alpuim, P.; Vaz, F.; Alves, E.; Rousselot, C.; Espinós, J.P.; González-Elipe, A.R. Influence of the chemical and electronic structure on the electrical behavior of zirconium oxynitride films. J. Appl. Phys. 2008, 103, 104907. [Google Scholar] [CrossRef]

- Saha, R.; Nix, W.D. Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater. 2002, 50, 23–38. [Google Scholar] [CrossRef]

- Mae, T.; Nose, M.; Zhou, M.; Nagae, T.; Shimamura, K. The effects of Si addition on the structure and mechanical properties of ZrN thin films deposited by an r.f. reactive sputtering method. Surf. Coat. Technol. 2001, 142–144, 954–958. [Google Scholar] [CrossRef]

- Abadias, G.; Uglov, V.V.; Saladukhin, I.A.; Zlotski, S.V.; Tolmachova, G.; Dub, S.N.; Janse van Vuuren, A. Growth, structural and mechanical properties of magnetron-sputtered ZrN/SiNx nanolaminated coatings. Surf. Coat. Technol. 2016, 308, 158–167. [Google Scholar] [CrossRef]

- Ushakov, S.V.; Navrotsky, A.; Hong, Q.J.; van de Walle, A. Carbides and nitrides of zirconium and hafnium. Materials 2019, 12, 2728. [Google Scholar] [CrossRef]

- Qasmi, M.; Delobelle, P. Influence of the average roughness Rms on the precision of the Young’s modulus and hardness determination using nanoindentation technique with a Berkovich indenter. Surf. Coat. Technol. 2006, 201, 1191–1199. [Google Scholar] [CrossRef]

| Sample | fa | Chemical Composition (at.%) | xb | Thickness (nm) | D c (nm/min) | |||

|---|---|---|---|---|---|---|---|---|

| Zr | N | Si | O | |||||

| P1 d = 300 W, P2 e = 0 W | ||||||||

| Zr60N40 | 0.40 | 57.9 ± 0.8 | 38.8 ± 0.8 | - | 3.3 ± 0.1 | 0.67 | 820 | 13.7 |

| P1 = 150 W, P2 = 0 W | ||||||||

| Zr52N48 | 0.50 | 49.3 ± 0.8 | 46.4 ± 1.1 | 1.6 ± 0.0 | 2.5 ± 0.2 | 0.92 | 680 | 3.8 |

| Zr50N50 | 0.65 | 48.0 ± 2.0 | 47.3 ± 2.2 | 1.8 ± 0.0 | 2.8 ± 0.3 | 1.00 | 616 | 3.4 |

| Zr48N52 | 0.75 | 44.1 ± 0.4 | 47.8 ± 0.3 | 4.8 ± 0.1 | 3.2 ± 0.1 | 1.08 | 556 | 3.1 |

| Zr45N55 | 0.85 | 39.5 ± 1.6 | 47.5 ± 2.2 | 10.8 ± 0.4 | 2.2 ± 0.2 | 1.22 | 348 | 1.9 |

| P1 = 150 W, P2 = 150 W | ||||||||

| Zr42N58 | 1.00 | 40.5 ± 0.0 | 56.0 ± 0.2 | 1.5 ± 0.2 | 2.0 ± 0.1 | 1.38 | 694 | 3.9 |

| Sample | Zr 3d5/2 (eV) Zr–N(ZrN) | Zr–N(Zr3N4) | Intensity Ratio (XPS) ZrN:Zr3N4 | Intensity Ratio (XRD) ZrN(111):Zr3N4(320) |

|---|---|---|---|---|

| Zr60N40(0.40) | 179.55 ± 0.06 | 181.39 ± 0.05 | 80:20 | 100:0 |

| Zr52N48(0.50) | 179.62 ± 0.04 | 181.59 ± 0.03 | 67:33 | 54:46 |

| Zr50N50(0.65) | 179.59 ± 0.04 | 181.29 ± 0.04 | 59:41 | 49:51 |

| Zr48N52(0.75) | 179.14 ± 0.03 | 180.74 ± 0.05 | 56:44 | 44:56 |

| Zr45N55(0.85) | 178.84 ± 0.06 | 180.42 ± 0.04 | 48:52 | 37:63 |

| Zr42N58(1.00) | 178.82 ± 0.02 | 180.06 ± 0.04 | 44:56 | 33:67 |

| Sample | Hardness (GPa) | Young’s Modulus (GPa) | Stress (GPa) | Roughness (nm) |

|---|---|---|---|---|

| Zr60N40(0.40) | 21.0 ± 0.3 | 248 ± 6 | −0.9 ± 0.2 | 1.0 ± 0.0 |

| Zr52N48(0.50) | 18.9 ± 1.0 | 228 ± 10 | −0.6 ± 0.1 | 1.2 ± 0.0 |

| Zr50N50(0.65) | 19.0 ± 0.5 | 234 ± 6 | −0.2 ± 0.2 | 1.0 ± 0.1 |

| Zr48N52(0.75) | 18.8 ± 0.9 | 228 ± 5 | −0.5 ± 0.1 | 0.7 ± 0.0 |

| Zr45N55(0.85) | 17.3 ± 0.4 | 211 ± 3 | −0.7 ± 0.2 | 0.8 ± 0.1 |

| Zr42N58(1.00) | 18.3 ± 0.9 | 210 ± 5 | −1.2 ± 0.1 | 1.0 ± 0.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ke, Y.-E.; Chen, Y.-I. Effects of Nitrogen Flow Ratio on Structures, Bonding Characteristics, and Mechanical Properties of ZrNx Films. Coatings 2020, 10, 476. https://doi.org/10.3390/coatings10050476

Ke Y-E, Chen Y-I. Effects of Nitrogen Flow Ratio on Structures, Bonding Characteristics, and Mechanical Properties of ZrNx Films. Coatings. 2020; 10(5):476. https://doi.org/10.3390/coatings10050476

Chicago/Turabian StyleKe, Yi-En, and Yung-I Chen. 2020. "Effects of Nitrogen Flow Ratio on Structures, Bonding Characteristics, and Mechanical Properties of ZrNx Films" Coatings 10, no. 5: 476. https://doi.org/10.3390/coatings10050476

APA StyleKe, Y.-E., & Chen, Y.-I. (2020). Effects of Nitrogen Flow Ratio on Structures, Bonding Characteristics, and Mechanical Properties of ZrNx Films. Coatings, 10(5), 476. https://doi.org/10.3390/coatings10050476