Effect of Interface Coating on High Temperature Mechanical Properties of SiC–SiC Composite Using Domestic Hi–Nicalon Type SiC Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of SiC–SiC Composites

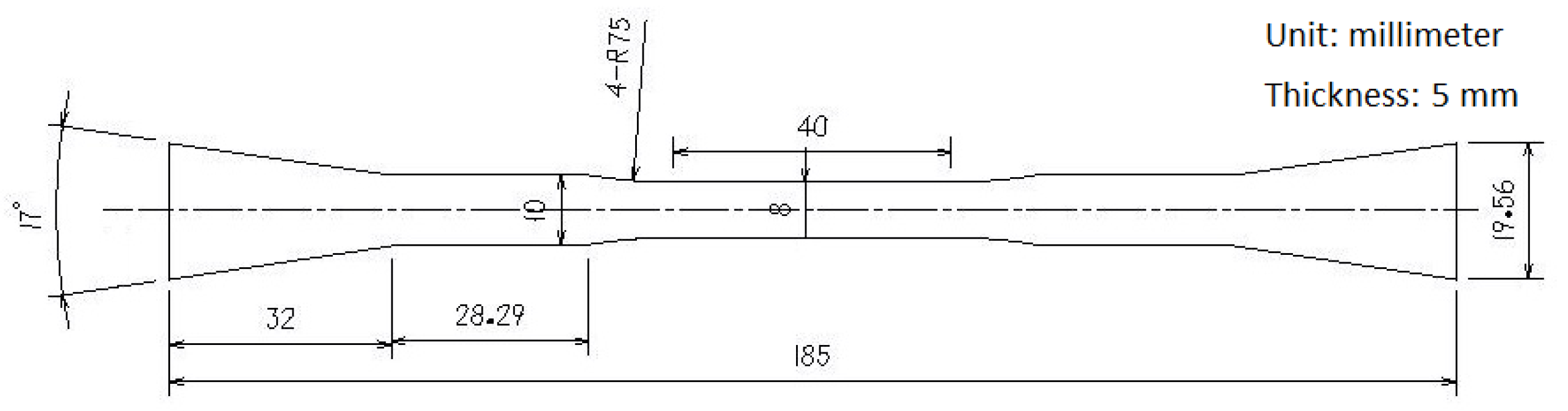

2.2. Tensile Test of SiC–SiC Composites at High Temperature in Air

3. Results and Discussion

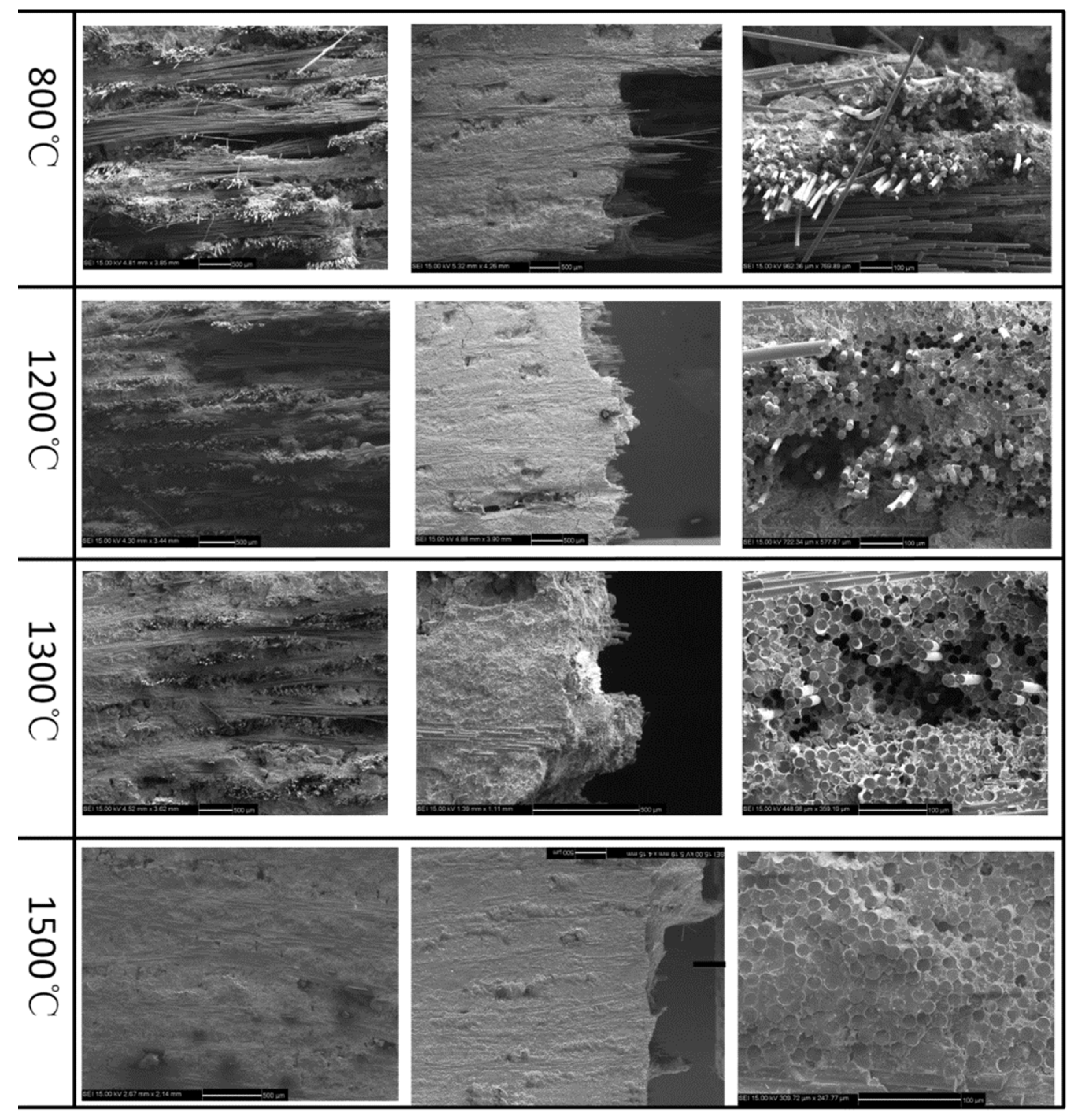

3.1. Tensile Strength of SiC–SiC Composites at High Temperature in Air

3.2. Tensile Strength of SiC Fiber at High Temperature

3.3. Influence of Fiber–Matrix Interface Coating on Tensile Properties of SiC–SiC Composites

4. Conclusions

- The tensile properties of SiC–SiC composites reinforced by domestic Hi–Nicalon type SiC fibers at 800, 1200, 1300, and 1500 °C were studied. The results show that when the temperature exceeded 1200 °C, the tensile strength of SiC–SiC composites decreased sharply and the composite failure mode converted from fiber-pull-out to fiber-break.

- Theoretical calculations showed that the toughening effect of fibers increases with interface strength when the composite failure mode is fiber-pull-out. Once the interface strength exceeds the critical value, the composite failure mode converts to fiber-break and the fracture toughness of SiC–SiC drops sharply. The finite element method simulations show that when the temperature exceeds the material preparation temperature, the residual radial stress at the interface increases and changes from tensile to compressive, causing transition of the failure mode and sudden reduction of tensile strength.

- Theoretical and experimental results showed that reducing the thickness of PyC interface coating improved the tensile strength of SiC–SiC composites at high temperatures.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, P.; Liu, F.; Wang, H.; Li, H.; Gou, Y. A review of third generation SiC fibers and SiCf/SiC composites. J. Mater. Sci. Technol. 2019, 35, 2743–2750. [Google Scholar] [CrossRef]

- Zhai, Z.; Wei, C.; Zhang, Y.; Cui, Y.; Zeng, Q. Investigations on the oxidation phenomenon of SiC/SiC fabricated by high repetition frequency femtosecond laser. Appl. Surf. Sci. 2020, 502, 144131. [Google Scholar] [CrossRef]

- Raj, S. Development and characterization of hot-pressed matrices for engineered ceramic matrix composites (E-CMCs). Ceram. Int. 2019, 45, 3608–3619. [Google Scholar] [CrossRef]

- Koyanagi, T.; Katoh, Y.; Nozawa, T.; Snead, L.; Kondo, S.; Henager, C.; Ferraris, M.; Hinoki, T.; Huang, Q. Recent progress in the development of SiC composites for nuclear fusion applications. J. Nucl. Mater. 2018, 511, 544–555. [Google Scholar] [CrossRef]

- Xu, S.; Li, X.; Zhao, Y.; Liu, C.; Mao, Q.; Cheng, L.; Zhang, L. Micromechanical properties and microstructural evolution of Amosic-3 SiC/SiC composites irradiated by silicon ions. J. Eur. Ceram. Soc. 2020, 40, 2811–2820. [Google Scholar] [CrossRef]

- Braun, J.; Sauder, C.; Lamon, J.; Balbaud-Célérier, F. Influence of an original manufacturing process on the properties and microstructure of SiC/SiC tubular composites. Compos. Part A 2019, 123, 170–179. [Google Scholar] [CrossRef]

- Wang, X.; Song, Z.; Cheng, Z.; Han, D.; Li, M.; Zhang, C. Tensile creep properties and damage mechanisms of 2D-SiCf/SiC composites reinforced with low-oxygen high-carbon type SiC fiber. J. Eur. Ceram. Soc. 2020, in press. [Google Scholar] [CrossRef]

- Buet, E.; Sauder, C.; Sornin, D.; Poissonnet, S.; Rouzaud, J.; Vix-Guterl, C. Influence of surface fibre properties and textural organization of a pyrocarbon interphase on the interfacial shear stress of SiC/SiC minicomposites reinforced with Hi-Nicalon S and Tyranno SA3 fibres. J. Eur. Ceram. Soc. 2014, 34, 179–188. [Google Scholar] [CrossRef]

- Buet, E.; Sauder, C.; Poissonnet, S.; Brender, P.; Gadiou, R.; Vix-Guterl, C. Influence of chemical and physical properties of the last generation of silicon carbide fibres on the mechanical behaviour of SiC/SiC composite. J. Eur. Ceram. Soc. 2012, 32, 547–557. [Google Scholar] [CrossRef]

- Fellah, C.; Brauna, J.; Sauder, C.; Sirotti, F.; Berger, M. Influence of the carbon interface on the mechanical behavior of SiC/SiC composites. Compos. Part A 2020, 133, 105867. [Google Scholar] [CrossRef]

- Hsu, C.-Y.; Zhang, Y.; Xie, Y.; Deng, F.; Karandikar, P.; Xiao, J.Q.; Ni, C.; Xie, Y.; Karandikar, P. In-situ measurement of SiC/Si interfacial tensile strength of reaction bonded SiC/Si composite. Compos. Part B 2019, 175, 107116. [Google Scholar] [CrossRef]

- Ding, D.; Zhou, W.; Luo, F.; Chen, M.; Zhu, D. Mechanical properties and oxidation resistance of SiCf/CVI-SiC composites with PIP-SiC interphase. Ceram. Int. 2012, 38, 3929–3934. [Google Scholar] [CrossRef]

- Wang, L.-Y.; Luo, R.-Y.; Cui, G.-Y.; Chen, Z.-F. Oxidation resistance of SiCf/SiC composites with a PyC/SiC multilayer interface at 500 °C to 1100 °C. Corros. Sci. 2020, 167, 108522. [Google Scholar] [CrossRef]

- Shimoda, K.; Hinoki, T.; Park, Y.-H. Development of non-brittle fracture in SiCf/SiC composites without a fiber/matrix interface due to the porous structure of the matrix. Compos. Part A 2018, 115, 397–404. [Google Scholar] [CrossRef]

- Kato, Y.; Ozawa, K.; Shih, C.; Nozawa, T.; Shinavski, R.J.; Hasegawa, A.; Snead, L.L. Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: Properties and irradiation effects. J. Nucl. Mater. 2014, 448, 448–476. [Google Scholar] [CrossRef]

- Lamon, J. Properties of Characteristics of SiC and SiC/SiC Composites. Comp. Nucl. Mater. 2012, 2, 323–338. [Google Scholar]

- Sha, J.; Hinoki, T.; Kohyama, A. Thermal and mechanical stabilities of Hi-Nicalon SiC fiber under annealing and creep in various oxygen partial pressures. Corros. Sci. 2008, 50, 3132–3138. [Google Scholar] [CrossRef]

- Chen, P.; Chen, S.; Peng, J.; Gao, F.; Liu, H. The interface behavior of a thin film bonded imperfectly to a finite thickness gradient substrate. Eng. Fract. Mech. 2019, 217, 106529. [Google Scholar] [CrossRef]

- Chen, P.; Chen, S.; Peng, J. Interface behavior of a thin-film bonded to a graded layer coated elastic half-plane. Int. J. Mech. Sci. 2016, 115, 489–500. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, B.; He, X.; Huang, Y.; Hwang, K. Failure analysis and the optimal composites design of carbon nanotube-composites. Compos. Sci. Tech. 2010, 70, 1360–1367. [Google Scholar] [CrossRef]

- Drissi-Habti, M.; Nakano, K.; Kagawa, Y. Modelling of the interfacial behaviour in the Hi-Nicalon fibre-reinforced α-Si3N4 ceramic matrix composites using microindentation tests. Mat. Sci. Eng. A 1998, 250, 178–185. [Google Scholar] [CrossRef]

- Mueller, W.; Moosburg-Will, J.; Sause, M.; Horn, S. The Microscopic analysis of single—fiber push—out tests on ceramic matrix composites performed with Berkovich and flat-end indenter and evaluation of interfacial fracture toughness. J. Eur. Ceram. Soc. 2013, 33, 441–451. [Google Scholar] [CrossRef]

- Li, J.; Lv, Z.; Ren, C.; Chen, G.; Dong, J. Finite element simulation of interface shear strength of c/sic composites with thermal residual stress. J. Mat. Sci. Eng. 2017, 35, 801–805. (In Chinese) [Google Scholar]

- Wang, S.F.; Feng, J.L.; Yang, Z.J. Two active plane finite element model in Mohr-Coulomb elastoplasticity. Finite Elem. Anal. Des. 1999, 32, 213–219. [Google Scholar] [CrossRef]

- Chai, Y.; Zhou, X.; Zhang, H. Effect of oxidation treatment on KD-II SiC fiber–reinforced SiC composites. Ceram. Int. 2017, 43, 9934–9940. [Google Scholar] [CrossRef]

| Si Content Wt % | C Content Wt % | O Content Wt % | C/Si Mole Ratio |

|---|---|---|---|

| 61.5 | 37.9 | 0.6 | 1.44 |

| Room Temperature | 1300 °C in Air | Strength Retention Rate (%) | ||

|---|---|---|---|---|

| Strength (GPa) | Cv Value (%) | Strength (GPa) | Cv Value (%) | |

| 2.8 | 11.9 | 2.21 | 23.6 | 78.9 |

| d | Ef | Em | vm | σf | δb |

|---|---|---|---|---|---|

| μm | GPa | GPa | - | GPa | μm |

| 14 | 270 | 270 | 0.15 | 3 | 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, E.; Sun, W.; Liu, H.; Wu, K.; Ma, D.; Sun, X.; Feng, Z.; Li, J.; Yuan, Z. Effect of Interface Coating on High Temperature Mechanical Properties of SiC–SiC Composite Using Domestic Hi–Nicalon Type SiC Fibers. Coatings 2020, 10, 477. https://doi.org/10.3390/coatings10050477

Jin E, Sun W, Liu H, Wu K, Ma D, Sun X, Feng Z, Li J, Yuan Z. Effect of Interface Coating on High Temperature Mechanical Properties of SiC–SiC Composite Using Domestic Hi–Nicalon Type SiC Fibers. Coatings. 2020; 10(5):477. https://doi.org/10.3390/coatings10050477

Chicago/Turabian StyleJin, Enze, Wenting Sun, Hongrui Liu, Kun Wu, Denghao Ma, Xin Sun, Zhihai Feng, Junping Li, and Zeshuai Yuan. 2020. "Effect of Interface Coating on High Temperature Mechanical Properties of SiC–SiC Composite Using Domestic Hi–Nicalon Type SiC Fibers" Coatings 10, no. 5: 477. https://doi.org/10.3390/coatings10050477

APA StyleJin, E., Sun, W., Liu, H., Wu, K., Ma, D., Sun, X., Feng, Z., Li, J., & Yuan, Z. (2020). Effect of Interface Coating on High Temperature Mechanical Properties of SiC–SiC Composite Using Domestic Hi–Nicalon Type SiC Fibers. Coatings, 10(5), 477. https://doi.org/10.3390/coatings10050477