Structural and Mechanical Properties of AlCoCrNi High Entropy Nitride Films: Influence of Process Pressure

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

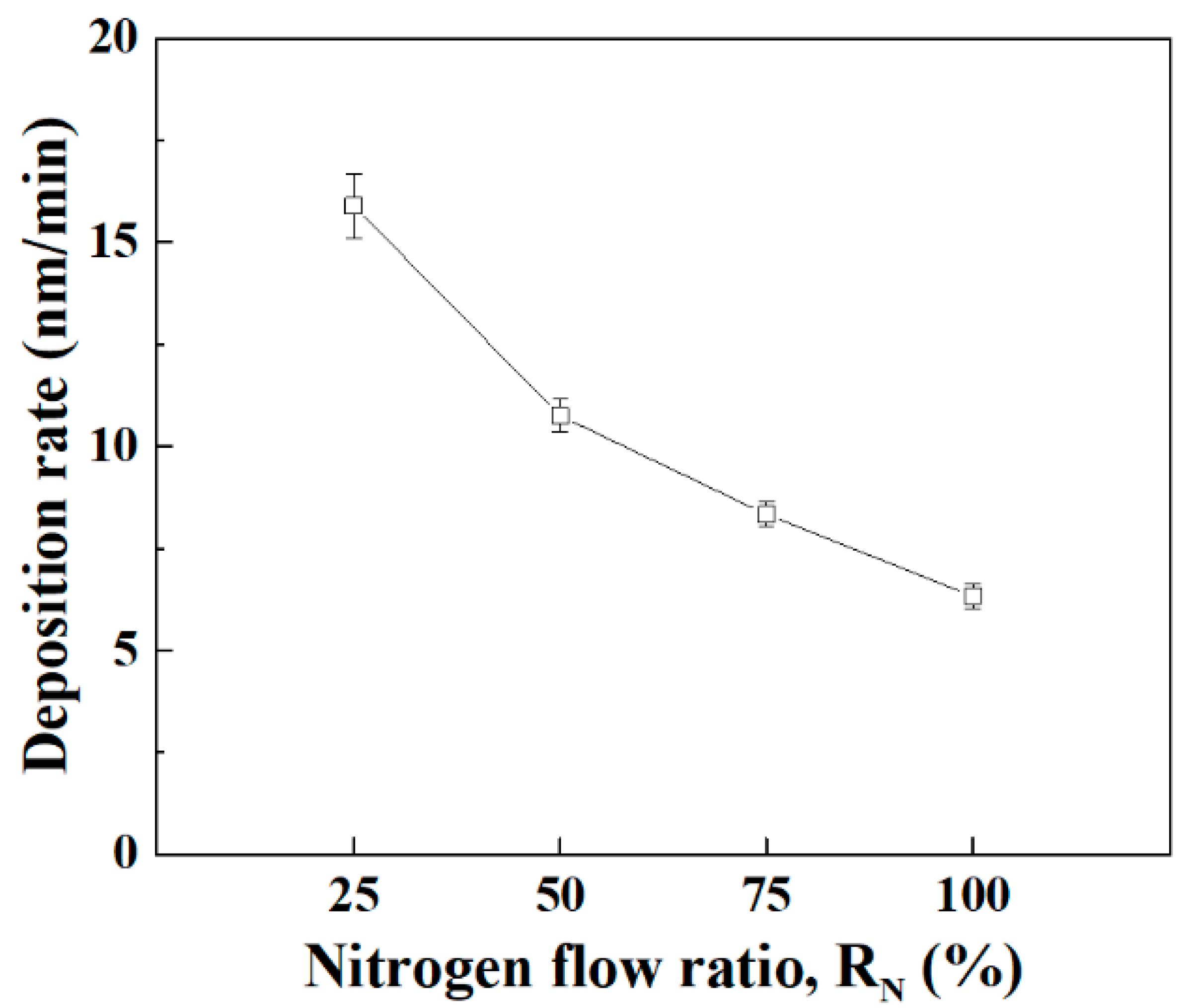

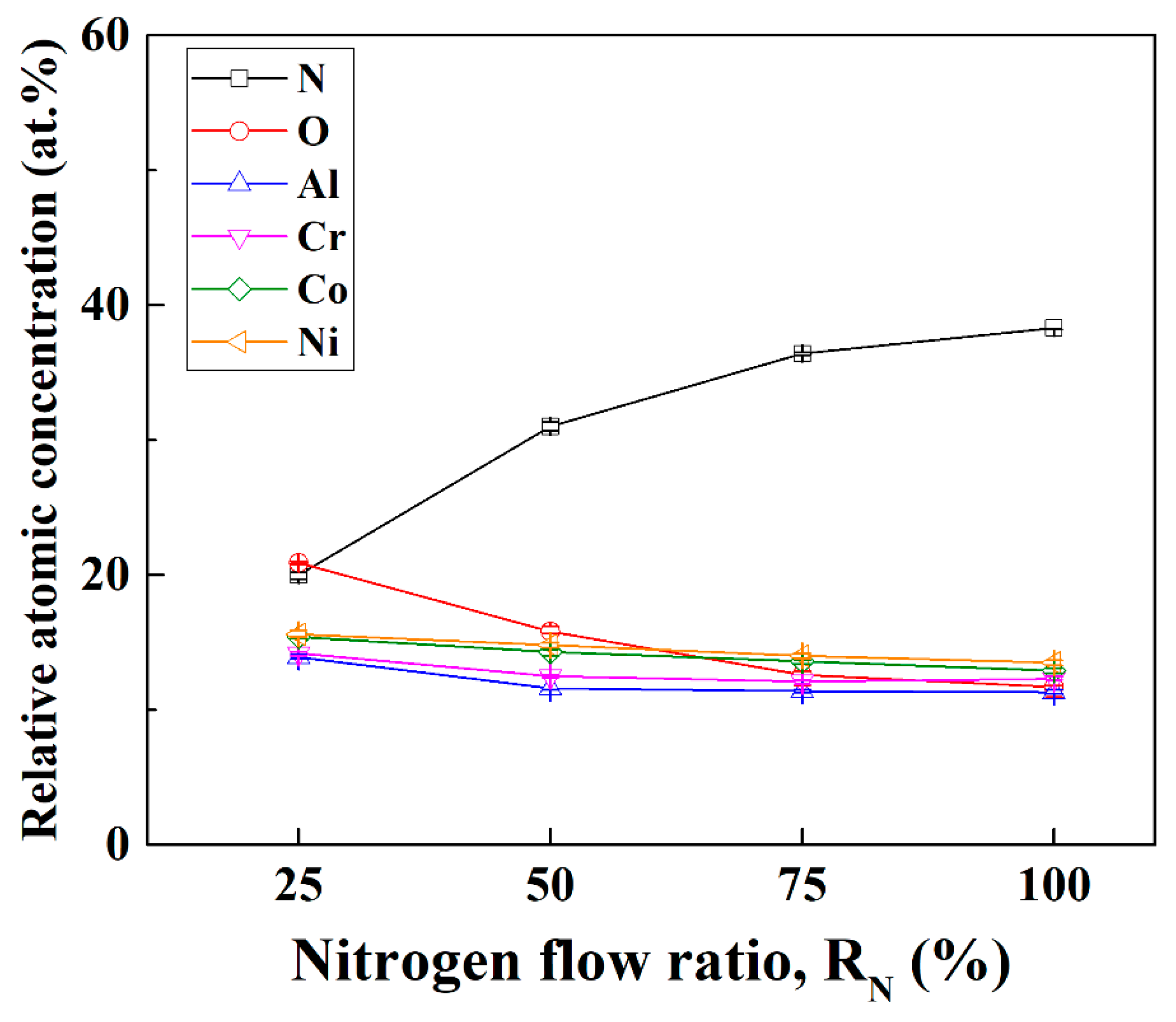

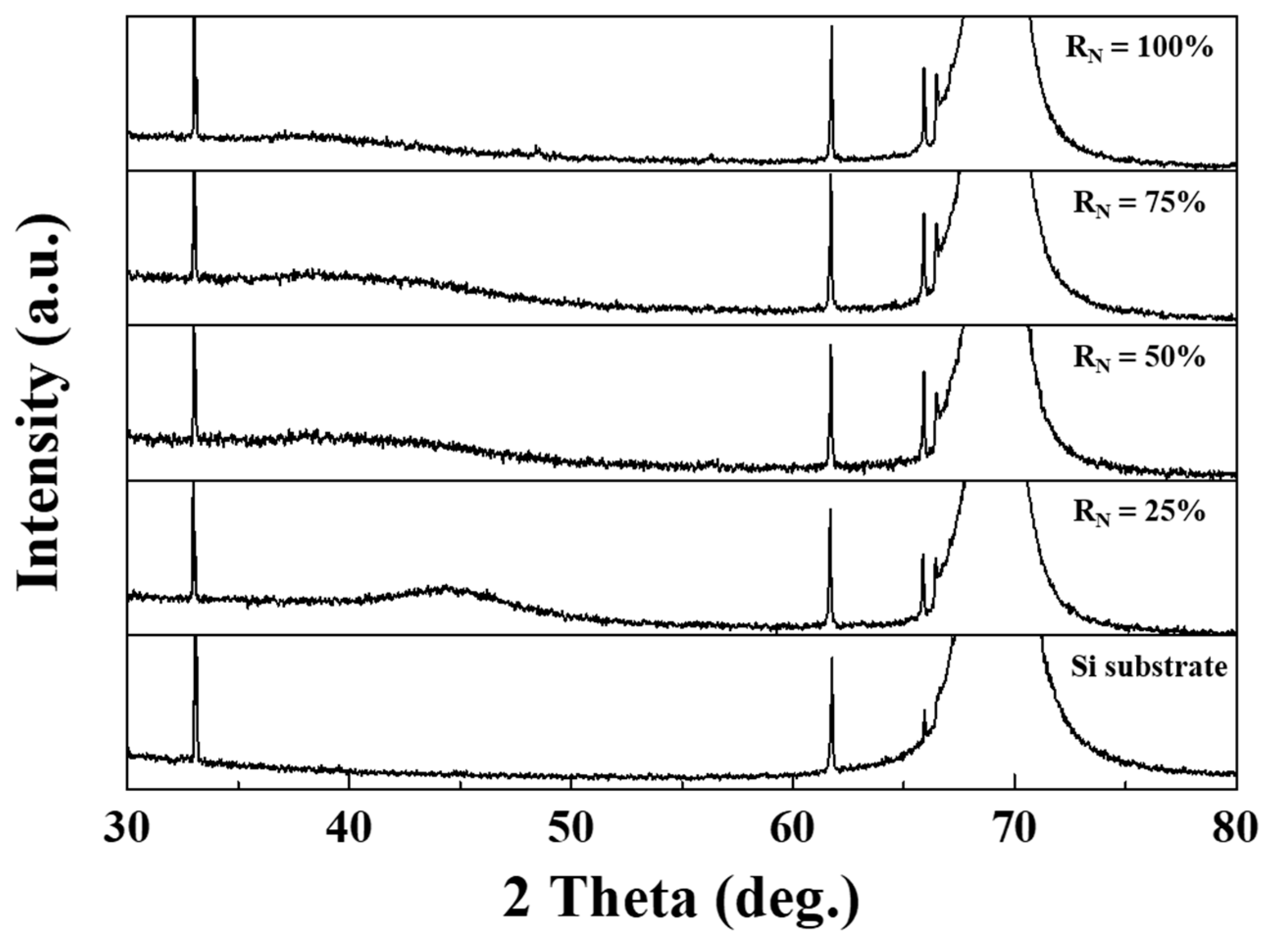

3.1. Effect of Nitrogen Flow Ratio

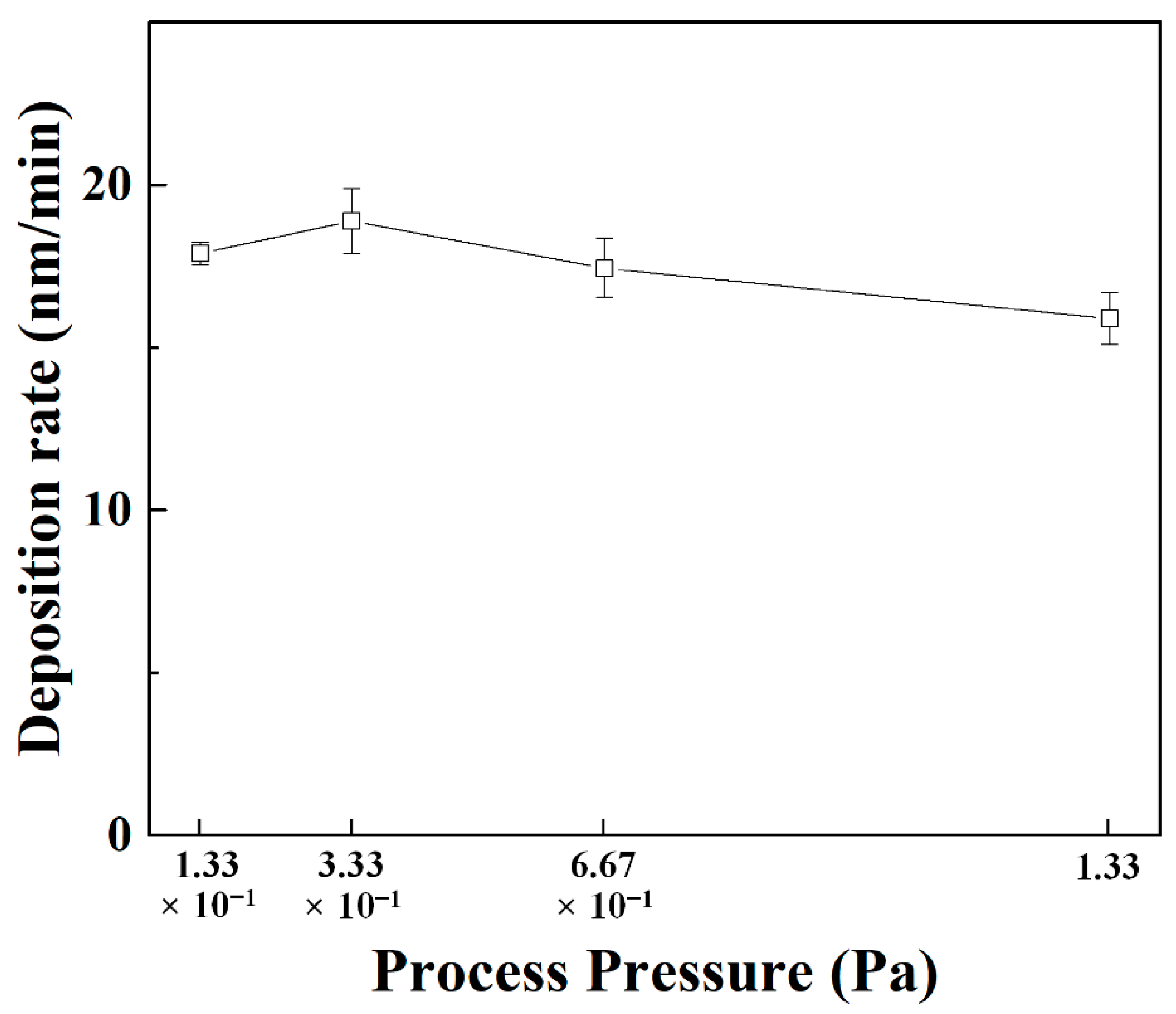

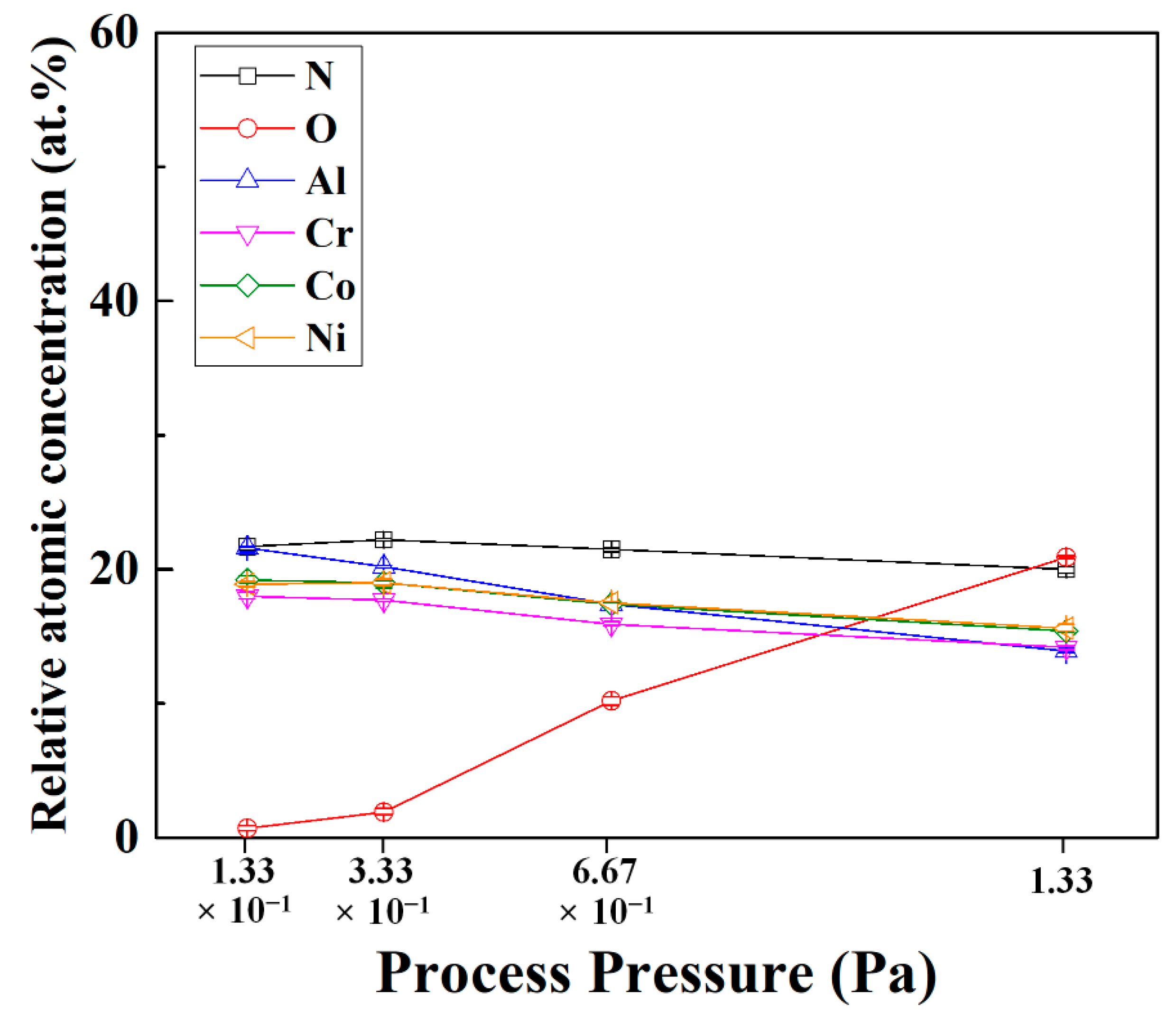

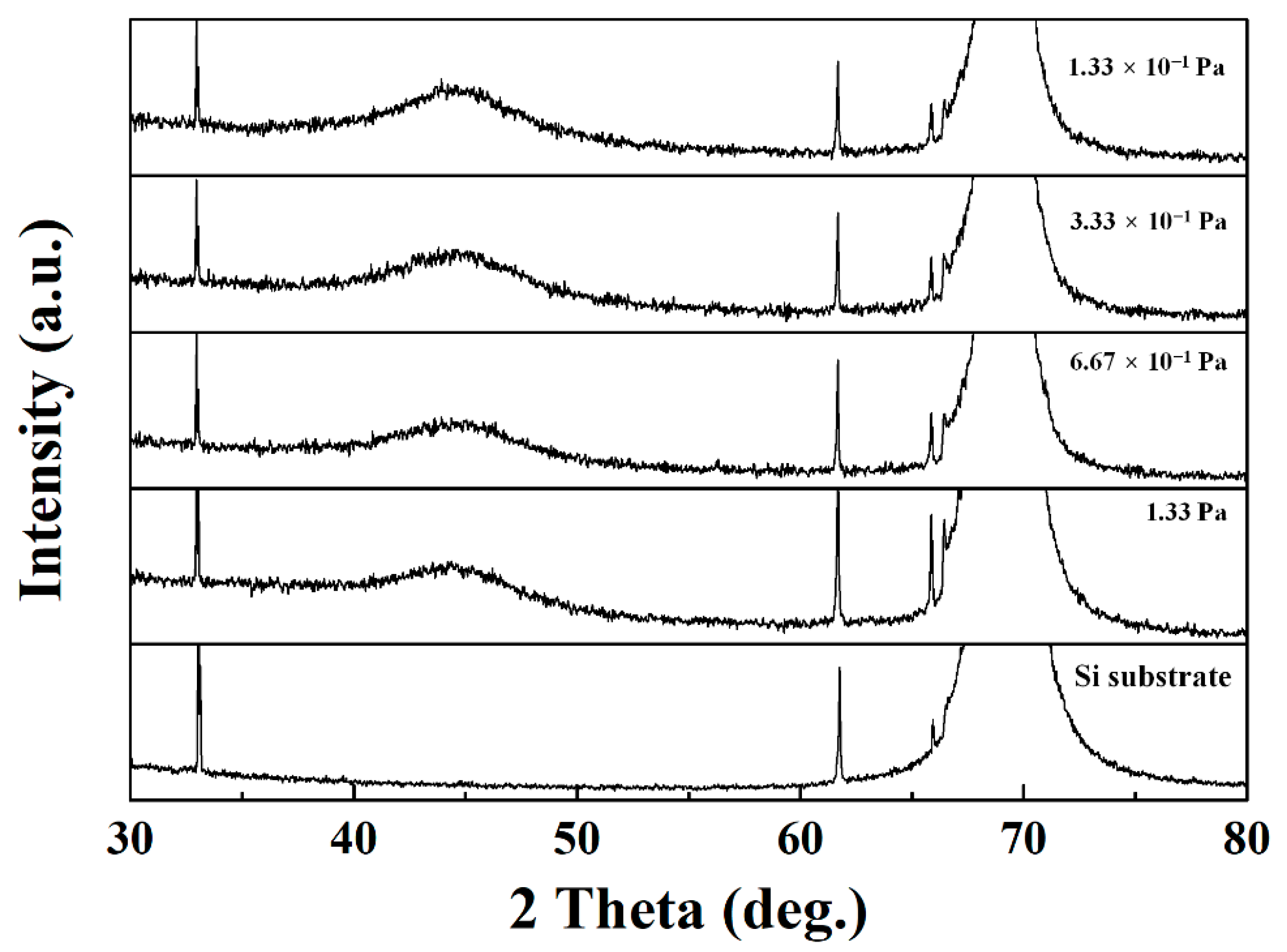

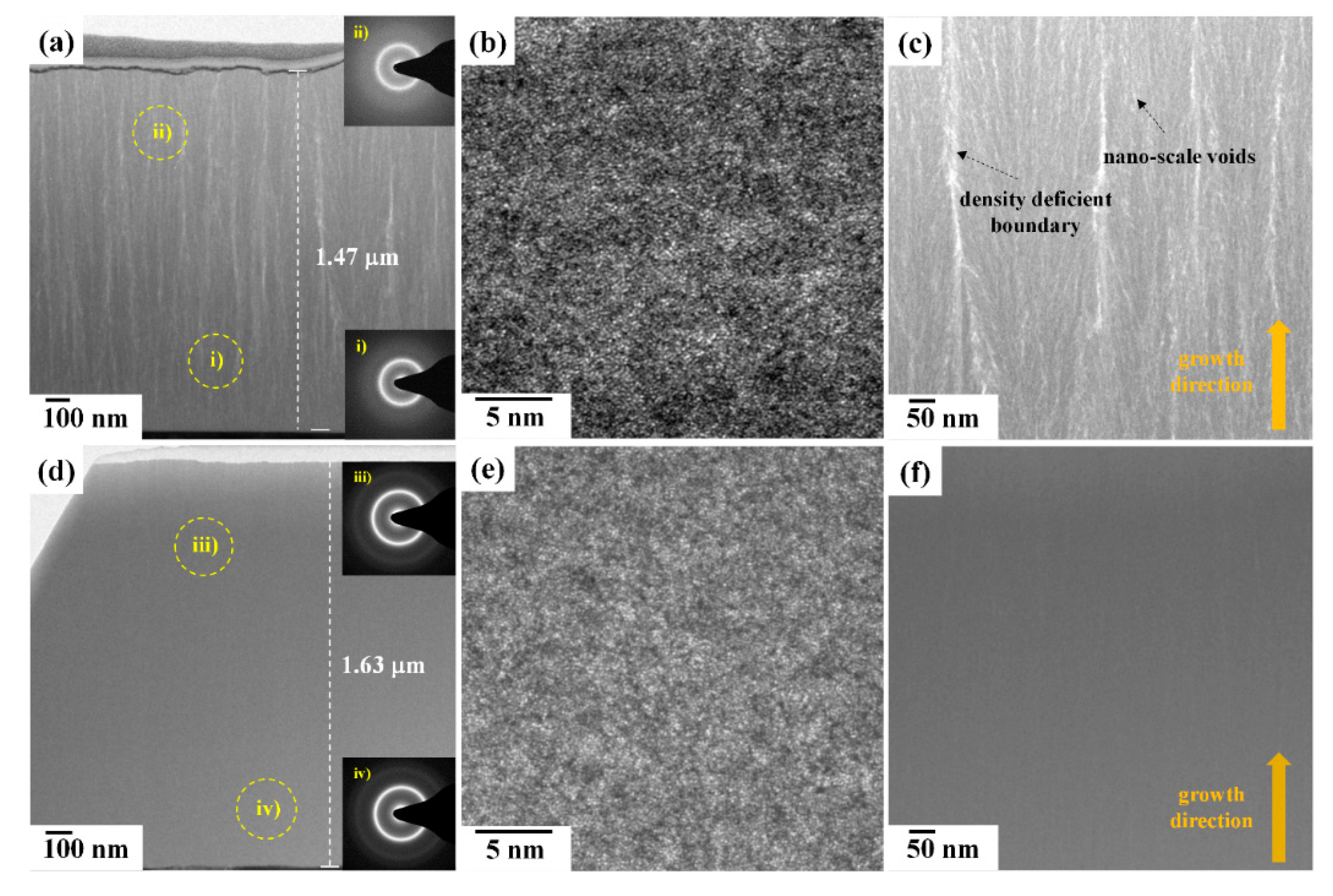

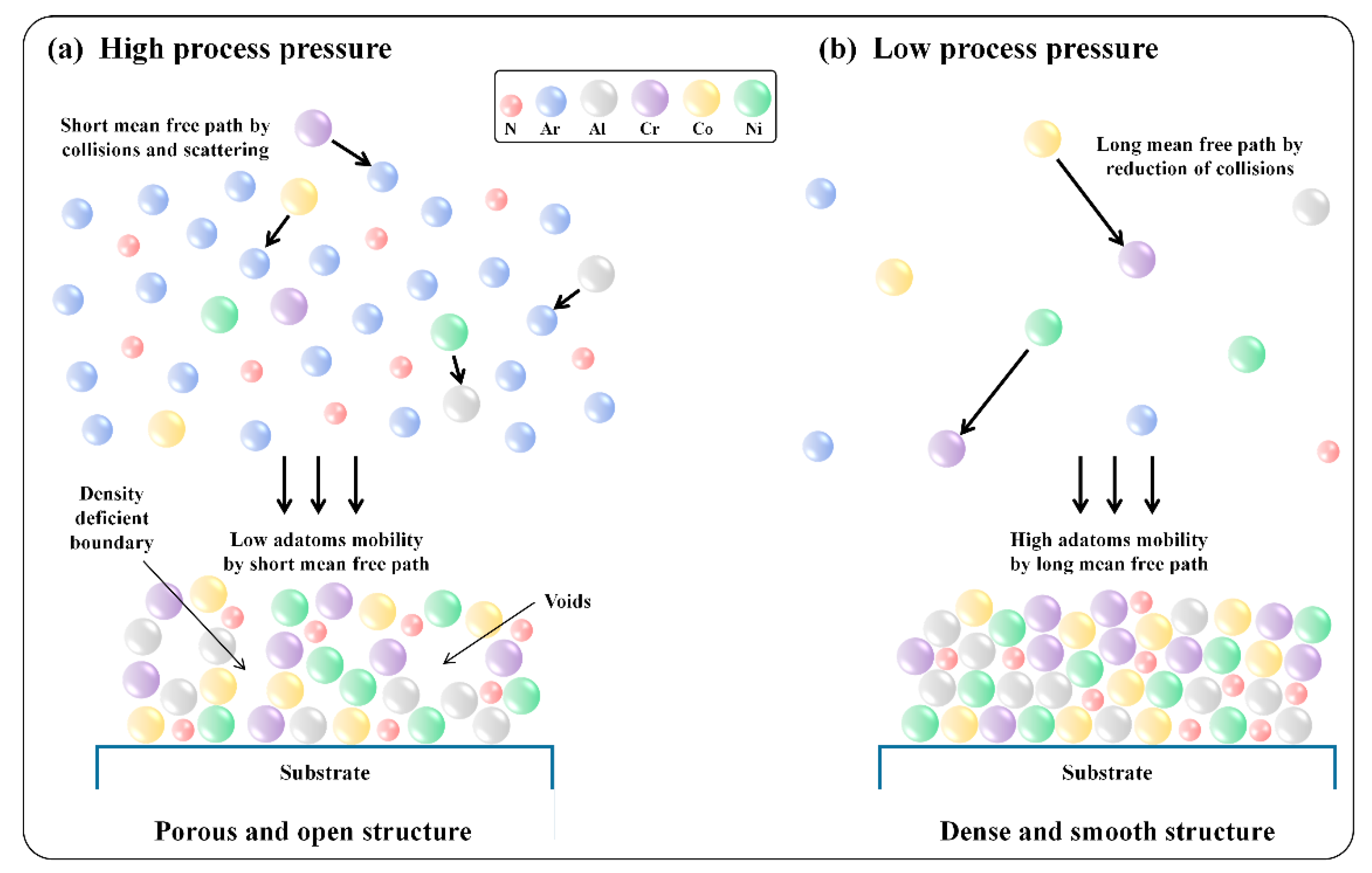

3.2. Effect of Process Pressure

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cantor, B.; Chang, I.; Knight, P.; Vincent, A. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Tong, C.J.; Chen, M.R.; Yeh, J.W.; Lin, S.J.; Chen, S.K.; Shun, T.T.; Chang, S.Y. Mechanical performance of the Al x CoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall. Mater. Trans. A 2005, 36, 1263–1271. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Kim, H.; Nam, S.; Roh, A.; Son, M.; Ham, M.H.; Kim, J.H.; Choi, H. Mechanical and electrical properties of NbMoTaW refractory high-entropy alloy thin films. Int. J. Refract. Met. Hard Mater. 2019, 80, 286–291. [Google Scholar] [CrossRef]

- Gorr, B.; Müller, F.; Azim, M.; Christ, H.J.; Müller, T.; Chen, H.; Kauffmann, A.; Heilmaier, M. High-temperature oxidation behavior of refractory high-entropy alloys: Effect of alloy composition. Oxid. Met. 2017, 88, 339–349. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Wang, Y.; Chen, G. Solid solution alloys of Al Co Cr Fe Ni Ti x with excellent room-temperature mechanical properties. Appl. Phys. Lett. 2007, 90, 181904. [Google Scholar] [CrossRef]

- Huang, Y.S.; Chen, L.; Lui, H.W.; Cai, M.H.; Yeh, J.W. Microstructure, hardness, resistivity and thermal stability of sputtered oxide films of AlCoCrCu0. 5NiFe high-entropy alloy. Mater. Sci. Eng. A 2007, 457, 77–83. [Google Scholar] [CrossRef]

- Wu, J.M.; Lin, S.J.; Yeh, J.W.; Chen, S.K.; Huang, Y.S.; Chen, H.C. Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear 2006, 261, 513–519. [Google Scholar] [CrossRef]

- Senkov, O.N.; Miracle, D.B.; Chaput, K.J.; Couzinie, J.P. Development and exploration of refractory high entropy alloys—A review. J. Mater. Res. 2018, 33, 3092–3128. [Google Scholar] [CrossRef]

- Tsai, M.H.; Wang, C.W.; Lai, C.H.; Yeh, J.W.; Gan, J.Y. Thermally stable amorphous (Al Mo Nb Si Ta Ti V Zr) 50 N 50 nitride film as diffusion barrier in copper metallization. Appl. Phys. Lett. 2008, 92, 052109. [Google Scholar] [CrossRef]

- Raju, M.; Ananth, M.; Vijayaraghavan, L. Influence of temperature on the electrochemical characteristics of MmNi3. 03Si0. 85Co0. 60Mn0. 31Al0. 08 hydrogen storage alloys. J. Power Sources 2008, 180, 830–835. [Google Scholar] [CrossRef]

- Ye, Q.; Feng, K.; Li, Z.; Lu, F.; Li, R.; Huang, J.; Wu, Y. Microstructure and corrosion properties of CrMnFeCoNi high entropy alloy coating. Appl. Surf. Sci. 2017, 396, 1420–1426. [Google Scholar] [CrossRef]

- Malinovskis, P.; Fritze, S.; Riekehr, L.; von Fieandt, L.; Cedervall, J.; Rehnlund, D.; Nyholm, L.; Lewin, E.; Jansson, U. Synthesis and characterization of multicomponent (CrNbTaTiW) C films for increased hardness and corrosion resistance. Mater. Des. 2018, 149, 51–62. [Google Scholar] [CrossRef]

- Hsieh, T.; Hsu, C.; Wu, C.; Kao, J.; Hsu, C. Effects of deposition parameters on the structure and mechanical properties of high-entropy alloy nitride films. Curr. Appl. Phys. 2018, 18, 512–518. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Kirnbauer, A.; Ertelthaler, P.; Koller, C.M. High-entropy ceramic thin films; A case study on transition metal diborides. Scr. Mater. 2018, 149, 93–97. [Google Scholar] [CrossRef]

- Li, Y.; Kostka, A.; Savan, A.; Ludwig, A. Atomic-scale investigation of fast oxidation kinetics of nanocrystalline CrMnFeCoNi thin films. J. Alloys Compd. 2018, 766, 1080–1085. [Google Scholar] [CrossRef]

- Dolique, V.; Thomann, A.L.; Brault, P.; Tessier, Y.; Gillon, P. Thermal stability of AlCoCrCuFeNi high entropy alloy thin films studied by in-situ XRD analysis. Surf. Coat. Technol. 2010, 204, 1989–1992. [Google Scholar] [CrossRef]

- Liang, S.C.; Tsai, D.C.; Chang, Z.C.; Sung, H.S.; Lin, Y.C.; Yeh, Y.J.; Deng, M.J.; Shieu, F.S. Structural and mechanical properties of multi-element (TiVCrZrHf) N coatings by reactive magnetron sputtering. Appl. Surf. Sci. 2011, 258, 399–403. [Google Scholar] [CrossRef]

- Feng, X.; Tang, G.; Sun, M.; Ma, X.; Wang, L. Chemical state and phase structure of (TaNbTiW) N films prepared by combined magnetron sputtering and PBII. Appl. Surf. Sci. 2013, 280, 388–393. [Google Scholar] [CrossRef]

- Huang, P.K.; Yeh, J.W. Inhibition of grain coarsening up to 1000 C in (AlCrNbSiTiV) N superhard coatings. Scr. Mater. 2010, 62, 105–108. [Google Scholar] [CrossRef]

- Cheng, K.H.; Lai, C.H.; Lin, S.J.; Yeh, J.W. Structural and mechanical properties of multi-element (AlCrMoTaTiZr) Nx coatings by reactive magnetron sputtering. Thin Solid Films 2011, 519, 3185–3190. [Google Scholar] [CrossRef]

- Lai, C.H.; Lin, S.J.; Yeh, J.W.; Chang, S.Y. Preparation and characterization of AlCrTaTiZr multi-element nitride coatings. Surf. Coat. Technol. 2006, 201, 3275–3280. [Google Scholar] [CrossRef]

- Ren, B.; Shen, Z.; Liu, Z. Structure and mechanical properties of multi-element (AlCrMnMoNiZr) Nx coatings by reactive magnetron sputtering. J. Alloys Compd. 2013, 560, 171–176. [Google Scholar] [CrossRef]

- Le, D.D.; Hong, S.K.; Ngo, T.S.; Lee, J.; Park, Y.C.; Hong, S.I.; Na, Y.S. Microstructural Investigation of CoCrFeMnNi High Entropy Alloy Oxynitride Films Prepared by Sputtering Using an Air Gas. Met. Mater. Int. 2018, 24, 1285–1292. [Google Scholar] [CrossRef]

- Sheng, W.; Yang, X.; Wang, C.; Zhang, Y. Nano-crystallization of high-entropy amorphous NbTiAlSiWxNy films prepared by magnetron sputtering. Entropy 2016, 18, 226. [Google Scholar] [CrossRef]

- Chen, T.; Shun, T.; Yeh, J.; Wong, M. Nanostructured nitride films of multi-element high-entropy alloys by reactive DC sputtering. Surf. Coat. Technol. 2004, 188, 193–200. [Google Scholar] [CrossRef]

- Ellmer, K. Magnetron sputtering of transparent conductive zinc oxide: Relation between the sputtering parameters and the electronic properties. J. Phys. D 2000, 33, R17. [Google Scholar] [CrossRef]

- Aissa, K.A.; Achour, A.; Camus, J.; Le Brizoual, L.; Jouan, P.Y.; Djouadi, M.A. Comparison of the structural properties and residual stress of AlN films deposited by dc magnetron sputtering and high power impulse magnetron sputtering at different working pressures. Thin Solid Films 2014, 550, 264–267. [Google Scholar] [CrossRef]

- Tsai, D.C.; Chang, Z.C.; Kuo, B.H.; Chen, B.C.; Chen, E.C.; Shieu, F.S. Wide variation in the structure and physical properties of reactively sputtered (TiZrHf) N coatings under different working pressures. J. Alloys Compd. 2018, 750, 350–359. [Google Scholar] [CrossRef]

- Jumaev, E.; Hong, S.H.; Kim, J.T.; Park, H.J.; Kim, Y.S.; Mun, S.C.; Park, J.Y.; Song, G.; Lee, J.K.; Min, B.H. Chemical evolution-induced strengthening on AlCoCrNi dual-phase high-entropy alloy with high specific strength. J. Alloys Compd. 2019, 777, 828–834. [Google Scholar] [CrossRef]

- Bull, S. Nanoindentation of coatings. J. Phys. D Appl. Phys. 2005, 38, R393. [Google Scholar] [CrossRef]

- Pharr, G.; Oliver, W. Measurement of thin film mechanical properties using nanoindentation. Mrs Bull. 1992, 17, 28–33. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Jehn, H.A.; Hofmann, S.; Rückborn, V.E.; Münz, W.D. Morphology and properties of sputtered (Ti, Al) N layers on high speed steel substrates as a function of deposition temperature and sputtering atmosphere. J. Vac. Sci. Technol. A 1986, 4, 2701–2705. [Google Scholar] [CrossRef]

- Mason, R.S.; Pichilingi, M. Sputtering in a glow discharge ion source-pressure dependence: Theory and experiment. J. Phys. D Appl. Phys. 1994, 27, 2363. [Google Scholar] [CrossRef]

- An, Z.; Jia, H.; Wu, Y.; Rack, P.D.; Patchen, A.D.; Liu, Y.; Ren, Y.; Li, N.; Liaw, P.K. Solid-solution CrCoCuFeNi high-entropy alloy thin films synthesized by sputter deposition. Mater. Res. Lett. 2015, 3, 203–209. [Google Scholar] [CrossRef]

- Ghidelli, M.; Gravier, S.; Blandin, J.J.; Pardoen, T.; Raskin, J.P.; Mompiou, F. Compositional-induced structural change in ZrxNi100− x thin film metallic glasses. J. Alloys Compd. 2014, 615, S348–S351. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, J.; Hou, C.; Li, J.; Jiang, Q. Dense and smooth amorphous films of multicomponent FeCoNiCuVZrAl high-entropy alloy deposited by direct current magnetron sputtering. Mater. Des. 2013, 46, 675–679. [Google Scholar] [CrossRef]

- Depla, D.; Leroy, W. Magnetron sputter deposition as visualized by Monte Carlo modeling. Thin Solid Films 2012, 520, 6337–6354. [Google Scholar] [CrossRef]

- Thornton, J.A. The microstructure of sputter-deposited coatings. J. Vac. Sci. Technol. A. 1986, 4, 3059–3065. [Google Scholar] [CrossRef]

- French, B.; Bilello, J. In situ observations of the real-time stress-evolution and delamination of thin Ta films on Si (100). Thin Solid Films 2004, 446, 91–98. [Google Scholar] [CrossRef]

- Kim, Y.S.; Park, H.J.; Mun, S.C.; Jumaev, E.; Hong, S.H.; Song, G.; Kim, J.T.; Park, Y.K.; Kim, K.S.; Jeong, S.I. Investigation of structure and mechanical properties of TiZrHfNiCuCo high entropy alloy thin films synthesized by magnetron sputtering. J. Alloys Compd. 2019, 797, 834–841. [Google Scholar] [CrossRef]

| Parameters | Conditions of Nitrogen Flow Ratio | Conditions of Process Pressure |

|---|---|---|

| Nitrogen flow ratio, RN (%) | 25, 50, 75, and 100 | 25 |

| Process pressure (Pa) | 10 | 1.33 × 10−1, 3.33 × 10−1, 6.67 × 10−1, and 1.33 |

| Total gas flow (SCCM) | 20 | |

| Base pressure (Pa) | <3.33 × 10−4 | |

| Sputtering power (W) | D.C. 300 | |

| Rotation speed (rpm) | 10 | |

| Deposition temperature | Room temperature | |

| Process Pressure (Pa) | Nitrogen Flow Ratio, RN (%) | Mechanical Properties | ||

|---|---|---|---|---|

| HIT (GPa) | EIT (GPa) | H/E | ||

| 1.33 | 25 | 8.2 ± 0.9 | 142 ± 11 | 0.0577 ± 0.0018 |

| 50 | 7.7 ± 1.6 | 146 ± 20 | 0.0527 ± 0.0036 | |

| 75 | 7.7 ± 0.5 | 146 ± 18 | 0.0527 ± 0.0028 | |

| 100 | - | - | - | |

| Process Pressure (Pa) | Nitrogen Flow Ratio, RN (%) | Mechanical Properties | ||

|---|---|---|---|---|

| HIT (GPa) | EIT (GPa) | H/E | ||

| 1.33 | 25 | 8.2 ± 0.9 | 142 ± 11 | 0.0577 ± 0.0018 |

| 6.67 × 10−1 | 11.9 ± 0.8 | 176 ± 21 | 0.0669 ± 0.0027 | |

| 3.33 × 10−1 | 13.1 ± 2.7 | 193 ± 19 | 0.0681 ± 0.0072 | |

| 1.33 × 10−1 | 16.8 ± 0.5 | 243 ± 39 | 0.0692 ± 0.0076 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.S.; Park, H.J.; Lim, K.S.; Hong, S.H.; Kim, K.B. Structural and Mechanical Properties of AlCoCrNi High Entropy Nitride Films: Influence of Process Pressure. Coatings 2020, 10, 10. https://doi.org/10.3390/coatings10010010

Kim YS, Park HJ, Lim KS, Hong SH, Kim KB. Structural and Mechanical Properties of AlCoCrNi High Entropy Nitride Films: Influence of Process Pressure. Coatings. 2020; 10(1):10. https://doi.org/10.3390/coatings10010010

Chicago/Turabian StyleKim, Young Seok, Hae Jin Park, Ki Seong Lim, Sung Hwan Hong, and Ki Buem Kim. 2020. "Structural and Mechanical Properties of AlCoCrNi High Entropy Nitride Films: Influence of Process Pressure" Coatings 10, no. 1: 10. https://doi.org/10.3390/coatings10010010

APA StyleKim, Y. S., Park, H. J., Lim, K. S., Hong, S. H., & Kim, K. B. (2020). Structural and Mechanical Properties of AlCoCrNi High Entropy Nitride Films: Influence of Process Pressure. Coatings, 10(1), 10. https://doi.org/10.3390/coatings10010010