Supercritical Antisolvent Processing of Nitrocellulose: Downscaling to Nanosize, Reducing Friction Sensitivity and Introducing Burning Rate Catalyst

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

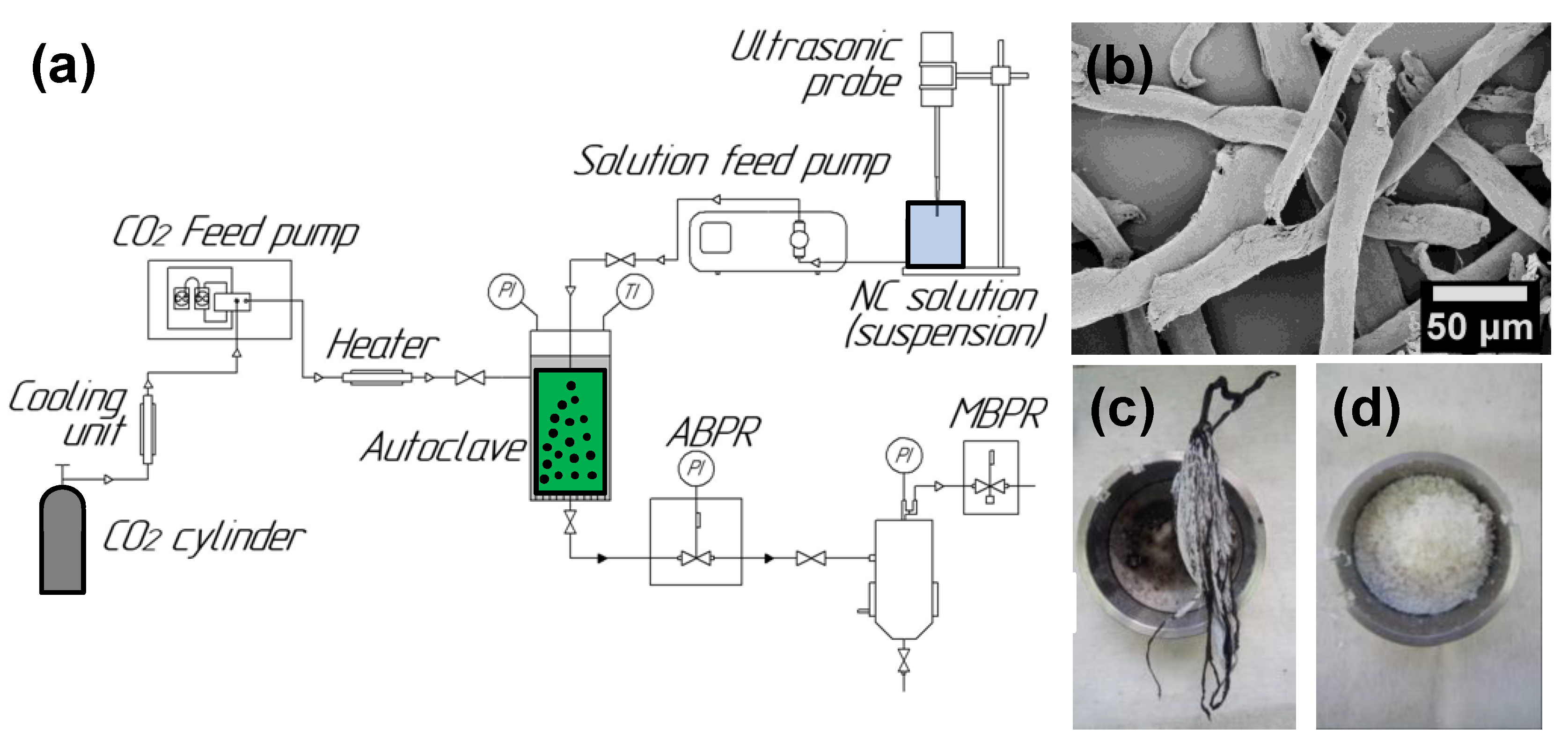

2.2. Fabrication of Composites

3. Results

3.1. Optimization of the Process Conditions

3.2. Nano-Nitrocellulose and Composites

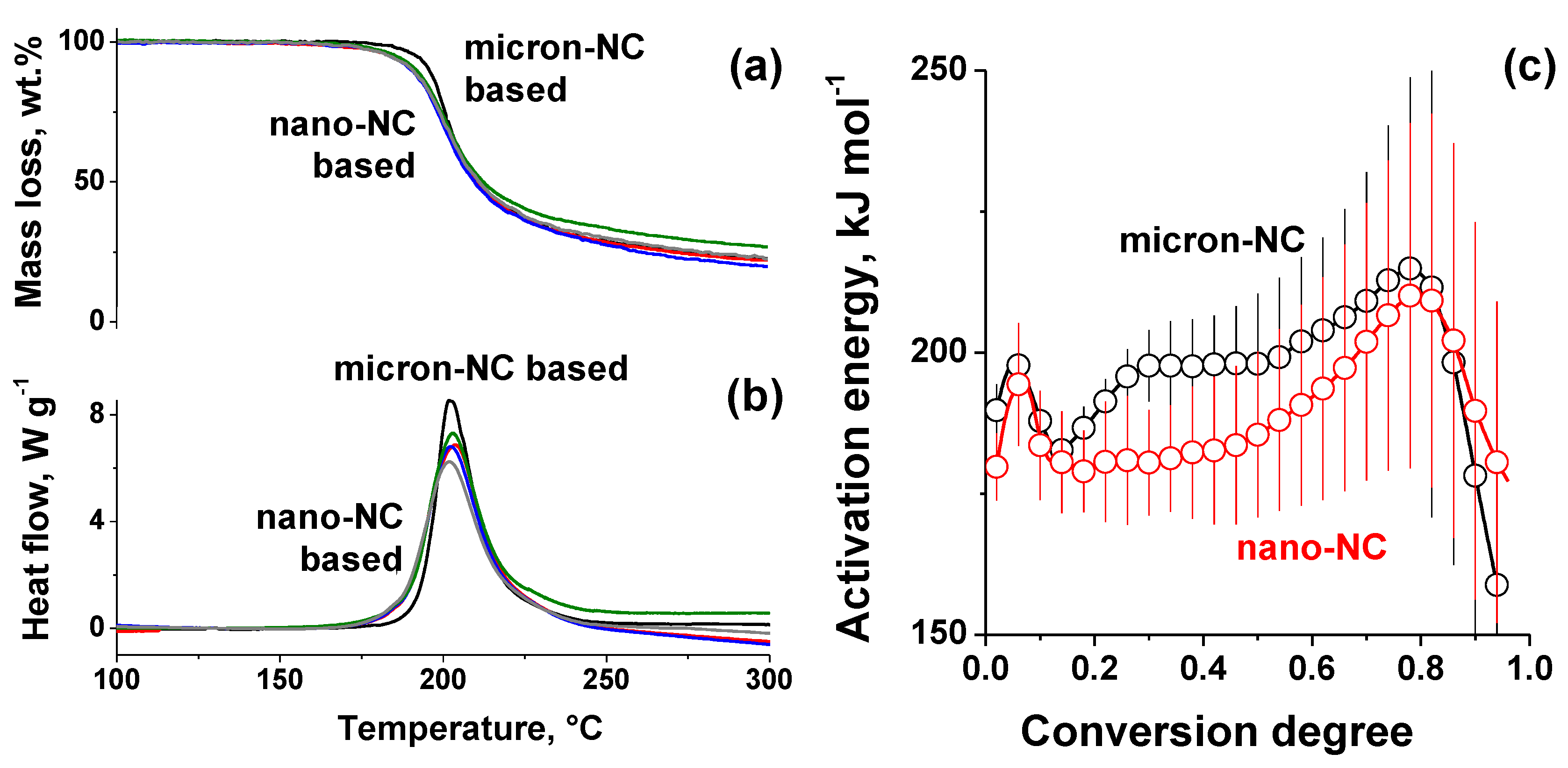

3.3. Thermal Behavior

3.4. Friction Sensitivity

3.5. Combustion Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Pre-exponential factor |

| ABPR | Automated back pressure regulator |

| B | Burn rate coefficient |

| CNTs | Carbon nanotubes |

| Ea | Apparent activation energy |

| EtOH | Ethanol |

| f | Feeding rate of NC-solution/suspension |

| F | Feeding rate of CO2 |

| MBPR | Manual back pressure regulator |

| MeOH | Methanol |

| micron-NC | Nitrocellulose microfibers (raw nitrocellulose) |

| n | Pressure exponent |

| nano-NC | Nitrocellulose nanoparticles |

| NC | Nitrocellulose |

| NC(sc) | Nitrocellulose particles obtained by SAS process |

| NC/CNT(sc) | Nitrocellulose composite with CNTs obtained by SAS process |

| NC/Fe2O3(sc) | Nitrocellulose with nano-Fe2O3 obtained by SAS process |

| NC/CNT/Fe2O3(sc) | Nitrocellulose with CNTs and nano-Fe2O3 obtained by SAS process |

| P | Pressure |

| Pc | Critical pressure of CO2 |

| RDX | 1,3,5-trinitro-1,3,5-triazinane |

| SAS | Supercritical Anti-Solvent process |

| sc-CO2 | Supercritical carbon dioxide |

| SEM | Scanning electron microscopy |

| Tc | Critical temperature of CO2 |

| TEM | Transmission electron microscopy |

| U | Burning rate |

References

- Selwitz, C. Cellulose Nitrate in Conservation; Research in Conservation; Getty Conservation Institute: Marina del Rey, CA, USA, 1988; ISBN 978-0-89236-098-7. [Google Scholar]

- Cretich, M.; Sedini, V.; Damin, F.; Pelliccia, M.; Sola, L.; Chiari, M. Coating of nitrocellulose for colorimetric DNA microarrays. Anal. Biochem. 2010, 397, 84–88. [Google Scholar] [CrossRef] [PubMed]

- Mujawar, L.H.; Moers, A.; Norde, W.; van Amerongen, A. Rapid mastitis detection assay on porous nitrocellulose membrane slides. Anal. Bioanal. Chem. 2013, 405, 7469–7476. [Google Scholar] [CrossRef] [PubMed]

- Holstein, C.A.; Chevalier, A.; Bennett, S.; Anderson, C.E.; Keniston, K.; Olsen, C.; Li, B.; Bales, B.; Moore, D.R.; Fu, E.; et al. Immobilizing affinity proteins to nitrocellulose: A toolbox for paper-based assay developers. Anal. Bioanal. Chem. 2016, 408, 1335–1346. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Y.; McConnell, G.C.; Ross, J.D.; DeWeerth, S.P.; Bellamkonda, R.V. A Novel Dexamethasone-releasing, Anti-inflammatory Coating for Neural Implants. In Proceedings of the 2nd International IEEE EMBS Conference on Neural Engineering, Arlington, VA, USA, 16–19 March 2005; IEEE: Piscataway, NJ, USA, 2005; pp. 522–525. [Google Scholar]

- Kubota, N. Propellants and Explosives; Wiley-VCH: Weinheim, Germany, 2006; ISBN 978-3-527-61010-5. [Google Scholar]

- Lengelle, G.; Duterque, J.; Trubert, J.-F. Physico-Chemical Mechanisms of Solid Propellant Combustion. In Solid Propellant Chemistry, Combustion, and Motor Interior Ballistics; Yang, V., Brill, T.B., Ren, W.Z., Eds.; Progress in Astronautics and Aeronautics; American Institute of Aeronautics and Astronautics, Inc.: Reston, VI, USA, 2000; pp. 287–334. ISBN 978-1-56347-442-2. [Google Scholar]

- de la Ossa, M.Á.F.; Torre, M.; García-Ruiz, C. Chapter 4. Nitrocellulose in propellants: Characteristics and thermal properties. In Advances in Materials Science Research; Wythers, M.C., Ed.; Nova Science Publishers, cop.: New York, NY, USA, 2012; Volume 7, pp. 201–220. ISBN 978-1-62100-045-7. [Google Scholar]

- Fu, G.; Wang, J.; Yan, M. Anatomy of Tianjin Port fire and explosion: Process and causes. Process Saf. Prog. 2016, 35, 216–220. [Google Scholar] [CrossRef]

- Saunders, C.W.; Taylor, L.T. A review of the synthesis, chemistry and analysis of nitrocellulose. J. Energy Mater. 1990, 8, 149–203. [Google Scholar] [CrossRef]

- Frolov, Y.V.; Pivkina, A.N.; Zav’yalov, S.A.; Murav’ev, N.V.; Skryleva, E.A.; Monogarov, K.A. Physicochemical characteristics of the components of energetic condensed systems. Russ. J. Phys. Chem. B 2010, 4, 916–922. [Google Scholar] [CrossRef]

- Yang, G.; Nie, F.; Li, J.; Guo, Q.; Qiao, Z. Preparation and Characterization of Nano-NTO Explosive. J. Energy Mater. 2007, 25, 35–47. [Google Scholar] [CrossRef]

- Bayat, Y.; Zeynali, V. Preparation and Characterization of Nano-CL-20 Explosive. J. Energy Mater. 2011, 29, 281–291. [Google Scholar] [CrossRef]

- Lee, K.-Y.; Moore, D.S.; Asay, B.W.; Llobet, A. Submicron-Sized Gamma-HMX: 1. Preparation and Initial Characterization. J. Energy Mater. 2007, 25, 161–171. [Google Scholar] [CrossRef]

- Xia, M.; Yunjun, L.; Hua, Y.-L. Preparation and characterization of nitrocellulose nano-fibers. Chin. J. Energetic Mater. 2012, 20, 167–171. [Google Scholar]

- Sovizi, M.R.; Hajimirsadeghi, S.S.; Naderizadeh, B. Effect of particle size on thermal decomposition of nitrocellulose. J. Hazard. Mater. 2009, 168, 1134–1139. [Google Scholar] [CrossRef] [PubMed]

- Jin, M.; Luo, N.; Li, G.; Luo, Y. The thermal decomposition mechanism of nitrocellulose aerogel. J. Therm. Anal. Calorim. 2015, 121, 901–908. [Google Scholar] [CrossRef]

- Zhang, X.; Weeks, B.L. Preparation of sub-micron nitrocellulose particles for improved combustion behavior. J. Hazard. Mater. 2014, 268, 224–228. [Google Scholar] [CrossRef] [PubMed]

- Steinitz, M.; Tamir, S. An improved method to create nitrocellulose particles suitable for the immobilization of antigen and antibody. J. Immunol. Methods 1995, 187, 171–177. [Google Scholar] [CrossRef]

- Cox, C.D.; Liggett, T. Spherical Production of Small Particle Nitrocellulose. U.S. Patent 3671515A 1972. [Google Scholar]

- O’Neill, J.J., Jr. Nitrocellulose Particles. U.S. Patent 2885736A 1959. [Google Scholar]

- Plunguian, M. Process for Making Fine Particles of Nitrocellulose. U.S. Patent 3275250A 1966. [Google Scholar]

- Androsov, A.S.; Denisyuk, A.P.; Tokarev, N.P. Laws governing the effect of lead-copper catalysts on the combustion rate of a ballistic powder. Combust. Explos. Shock Waves 1976, 12, 698–700. [Google Scholar] [CrossRef]

- Denisyuk, A.P.; Demidova, L.A. Effect of Some Catalysts on Combustion of Double-Base Propellants. Combust. Explos. Shock Waves 2004, 40, 311–318. [Google Scholar] [CrossRef]

- Denisyuk, A.P.; Demidova, L.A.; Shepelev, Y.G.; Baloyan, B.M.; Telepchenkov, V.E. Highly efficient low-toxicity catalysts of combustion of double-base powders. Combust. Explos. Shock Waves 1997, 33, 688–694. [Google Scholar] [CrossRef]

- Zenin, A.A.; Finjakov, S.V.; Ibragimov, N.G.; Afiatullov, E.K. Mechanism of catalysis in combustion waves of modern ballistite propellants. Combust. Explos. Shock Waves 1999, 35, 532–542. [Google Scholar] [CrossRef]

- Merzhanov, A.G.; Dubovitskii, F.I. On the Theory of Steady State Monopropellant. Proc. USSR Acad. Sci. 1959, 129, 153–156. [Google Scholar]

- Kirchdoerfer, T.; Ortiz, M.; Stewart, D.S. Topology Optimization of Solid Rocket Fuel. AIAA J. 2019, 57, 1684–1690. [Google Scholar] [CrossRef]

- He, G.; Li, X.; Dai, Y.; Yang, Z.; Zeng, C.; Lin, C.; He, S. Constructing bioinspired hierarchical structure in polymer based energetic composites with superior thermal conductivity. Compos. Part B Eng. 2019, 162, 678–684. [Google Scholar] [CrossRef]

- Chen, S.; Tang, Y.; Yu, H.; Guan, X.; DeLuca, L.T.; Zhang, W.; Shen, R.; Ye, Y. Combustion enhancement of hydroxyl-terminated polybutadiene by doping multiwall carbon nanotubes. Carbon 2019, 144, 472–480. [Google Scholar] [CrossRef]

- Kim, J.H.; Cho, M.H.; Kim, K.J.; Kim, S.H. Laser ignition and controlled explosion of nanoenergetic materials: The role of multi-walled carbon nanotubes. Carbon 2017, 118, 268–277. [Google Scholar] [CrossRef]

- Yan, Q.-L.; Zhao, F.-Q.; Kuo, K.K.; Zhang, X.-H.; Zeman, S.; DeLuca, L.T. Catalytic effects of nano additives on decomposition and combustion of RDX-, HMX-, and AP-based energetic compositions. Prog. Energy Combust. Sci. 2016, 57, 75–136. [Google Scholar] [CrossRef]

- Pivkina, A.N.; Muravyev, N.V.; Monogarov, K.A.; Fomenkov, I.V.; Schoonman, J. Catalysis of HMX Decomposition and Combustion: Defect Chemistry Approach. In Energetic Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 193–230. ISBN 978-0-12-802710-3. [Google Scholar]

- Muravyev, N.V.; Pivkina, A.N.; Schoonman, J.; Monogarov, K.A. Catalytic influence of nanosized titanium dioxide on the thermal decomposition and combustion of HMX. Int. J. Energy Mater. Chem. Propuls. 2014, 13, 211–228. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, N.; Li, J.; Gong, H.; An, T.; Zhao, F.; Ma, H. Thermal behavior of nitrocellulose-based superthermites: Effects of nano-Fe2O3 with three morphologies. RSC Adv. 2017, 7, 23583–23590. [Google Scholar] [CrossRef]

- Corr, S. 1,1,1,2-Tetrafluoroethane; from refrigerant and propellant to solvent. J. Fluor. Chem. 2002, 118, 55–67. [Google Scholar] [CrossRef]

- Carbon Dioxide Recovery and Utilization; Aresta, M. (Ed.) Springer: Dordrecht, The Netherlands, 2003; ISBN 978-90-481-6335-9. [Google Scholar]

- Lemmon, E.W.; McLinden, M.O.; Friend, D.G. Thermophysical Properties of Fluid Systems. In NIST Chemistry WebBook; NIST Standard Reference Database Number 69; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1997. [Google Scholar]

- Darr, J.A.; Poliakoff, M. New Directions in Inorganic and Metal-Organic Coordination Chemistry in Supercritical Fluids. Chem. Rev. 1999, 99, 495–542. [Google Scholar] [CrossRef] [PubMed]

- Sihvonen, M. Advances in supercritical carbon dioxide technologies. Trends Food Sci. Technol. 1999, 10, 217–222. [Google Scholar] [CrossRef]

- Jung, J.; Perrut, M. Particle design using supercritical fluids: Literature and patent survey. J. Supercrit. Fluids 2001, 20, 179–219. [Google Scholar] [CrossRef]

- Pourmortazavi, S.M.; Hajimirsadeghi, S.S. Application of Supercritical Carbon Dioxide in Energetic Materials Processes: A Review. Ind. Eng. Chem. Res. 2005, 44, 6523–6533. [Google Scholar] [CrossRef]

- Seo, B.; Kim, T.; Park, H.J.; Kim, J.-Y.; Lee, K.D.; Lee, J.M.; Lee, Y.-W. Extension of the Hansen solubility parameter concept to the micronization of cyclotrimethylenetrinitramine crystals by supercritical anti-solvent process. J. Supercrit. Fluids 2016, 111, 112–120. [Google Scholar] [CrossRef]

- Lee, B.-M.; Jeong, J.-S.; Lee, Y.-H.; Lee, B.-C.; Kim, H.-S.; Kim, H.; Lee, Y.-W. Supercritical Antisolvent Micronization of Cyclotrimethylenetrinitramin: Influence of the Organic Solvent. Ind. Eng. Chem. Res. 2009, 48, 11162–11167. [Google Scholar] [CrossRef]

- CNTs “Taunit” and Synthesis Thereof; NanoTechCenter Ltd.: Tambov, Russia, 2019.

- Eisenreich, N.; Pfeil, A. Non-linear least-squares fit of non-isothermal thermoanalytical curves. reinvestigation of the kinetics of the autocatalytic decomposition of nitrated cellulose. Thermochim. Acta 1983, 61, 13–21. [Google Scholar] [CrossRef]

- Binke, N.; Rong, L.; Xianqi, C.; Yuan, W.; Rongzu, H.; Qingsen, Y. Study on the Melting Process of Nitrocellulose by Thermal Analysis Method. J. Therm. Anal. Calorim. 1999, 58, 249–256. [Google Scholar] [CrossRef]

- Šesták, J.; Berggren, G. Study of the kinetics of the mechanism of solid-state reactions at increasing temperatures. Thermochim. Acta 1971, 3, 1–12. [Google Scholar] [CrossRef]

- Burnham, A.K. Application of the Šesták-Berggren Equation to Organic and Inorganic Materials of Practical Interest. J. Therm. Anal. Calorim. 2000, 60, 895–908. [Google Scholar] [CrossRef]

- Brill, T.B.; Gongwer, P.E. Thermal Decomposition of Energetic Materials 69. Analysis of the kinetics of nitrocellulose at 50–500 °C. Propellants Explos. Pyrotech. 1997, 22, 38–44. [Google Scholar] [CrossRef]

- STANAG 4487. Explosives, Friction Sensitivity Tests; NATO: Brussels, Belgium, 2002; p. 1. [Google Scholar]

- Shin, J.; Lee, K.Y.; Yeo, T.; Choi, W. Facile One-pot Transformation of Iron Oxides from Fe2O3 Nanoparticles to Nanostructured Fe3O4@C Core-Shell Composites via Combustion Waves. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef] [PubMed]

- Zeldovich, Y.B. Theory of combustion of propellants and explosives Zh. Eksperimentalnoy i Teor. Fiz. 1942, 12, 498–524. [Google Scholar]

- Sinditskii, V.P.; Egorshev, V.Y.; Berezin, M.V.; Serushkin, V.V. Mechanism of HMX combustion in a wide range of pressures. Combust. Explos. Shock Waves 2009, 45, 461–477. [Google Scholar] [CrossRef]

| Sample | Decomposition onset 1, °C | Heat Effect 1, J·g−1 | Friction Sensitivity, N | Burning Rate 2, mm·s−1 |

|---|---|---|---|---|

| NC | 193 | 1880 ± 90 | 234 ± 21 | 13.8 ± 0.5 |

| NC(sc) | 189 | 1970 ± 30 | 342 ± 18 | 13.1 ± 0.5 |

| NC/CNT(sc) | 188 | 1920 ± 150 | >360 (10%) | 13.2 ± 0.5 |

| NC/Fe2O3(sc) | 186 | 1790 ± 150 | 229 ± 18 | 13.1 ± 0.5 |

| NC/CNT/Fe2O3(sc) | 189 | 1890 ± 150 | >360 (40%) | 15.8 ± 0.6 |

| NC/CNT/Fe2O3 | 193 | 1590 ± 150 | 222 ± 31 | 14.6 ± 0.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobrynin, O.S.; Zharkov, M.N.; Kuchurov, I.V.; Fomenkov, I.V.; Zlotin, S.G.; Monogarov, K.A.; Meerov, D.B.; Pivkina, A.N.; Muravyev, N.V. Supercritical Antisolvent Processing of Nitrocellulose: Downscaling to Nanosize, Reducing Friction Sensitivity and Introducing Burning Rate Catalyst. Nanomaterials 2019, 9, 1386. https://doi.org/10.3390/nano9101386

Dobrynin OS, Zharkov MN, Kuchurov IV, Fomenkov IV, Zlotin SG, Monogarov KA, Meerov DB, Pivkina AN, Muravyev NV. Supercritical Antisolvent Processing of Nitrocellulose: Downscaling to Nanosize, Reducing Friction Sensitivity and Introducing Burning Rate Catalyst. Nanomaterials. 2019; 9(10):1386. https://doi.org/10.3390/nano9101386

Chicago/Turabian StyleDobrynin, Oleg S., Mikhail N. Zharkov, Ilya V. Kuchurov, Igor V. Fomenkov, Sergey G. Zlotin, Konstantin A. Monogarov, Dmitry B. Meerov, Alla N. Pivkina, and Nikita V. Muravyev. 2019. "Supercritical Antisolvent Processing of Nitrocellulose: Downscaling to Nanosize, Reducing Friction Sensitivity and Introducing Burning Rate Catalyst" Nanomaterials 9, no. 10: 1386. https://doi.org/10.3390/nano9101386

APA StyleDobrynin, O. S., Zharkov, M. N., Kuchurov, I. V., Fomenkov, I. V., Zlotin, S. G., Monogarov, K. A., Meerov, D. B., Pivkina, A. N., & Muravyev, N. V. (2019). Supercritical Antisolvent Processing of Nitrocellulose: Downscaling to Nanosize, Reducing Friction Sensitivity and Introducing Burning Rate Catalyst. Nanomaterials, 9(10), 1386. https://doi.org/10.3390/nano9101386