3.1. Microstructure of Freeform Foam

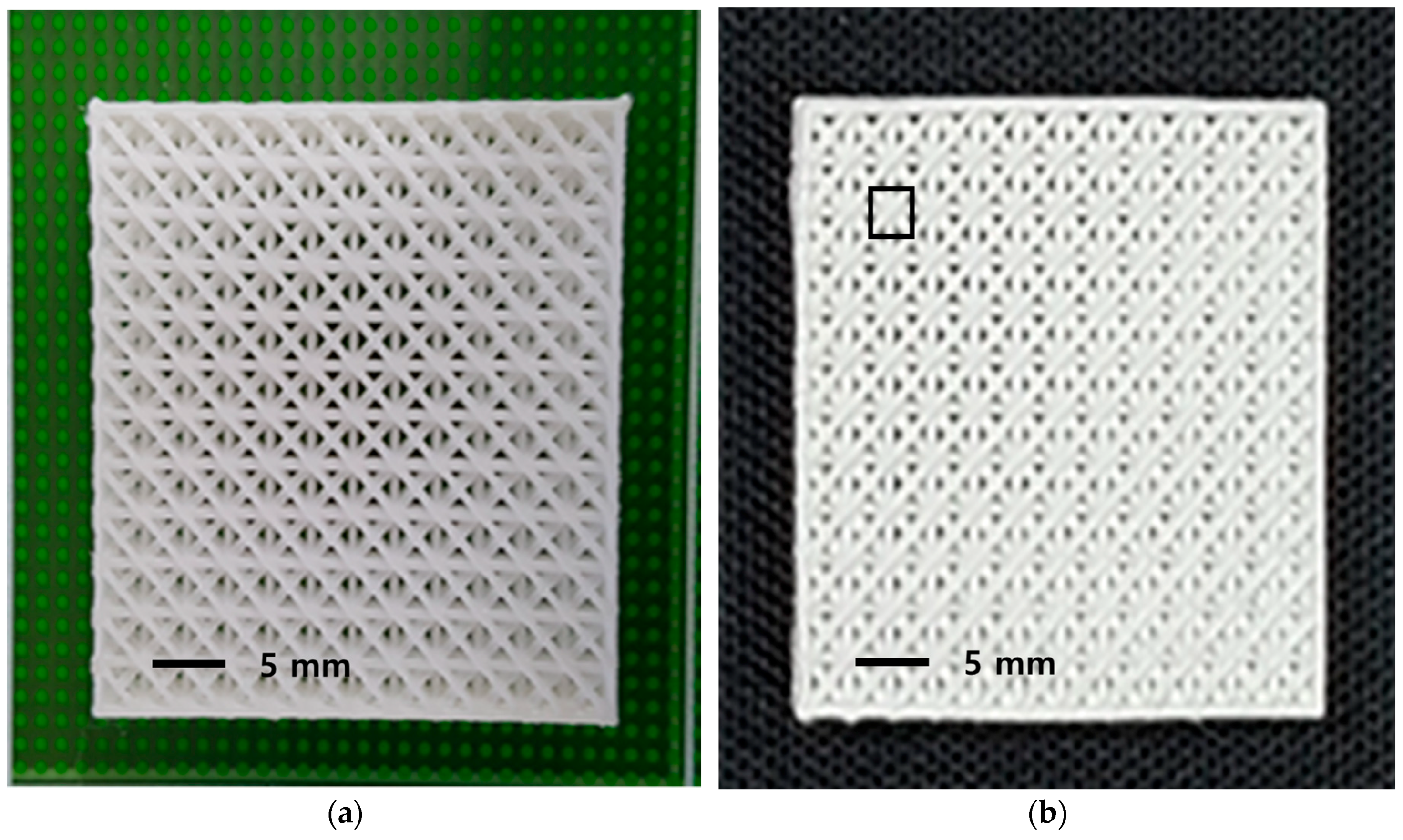

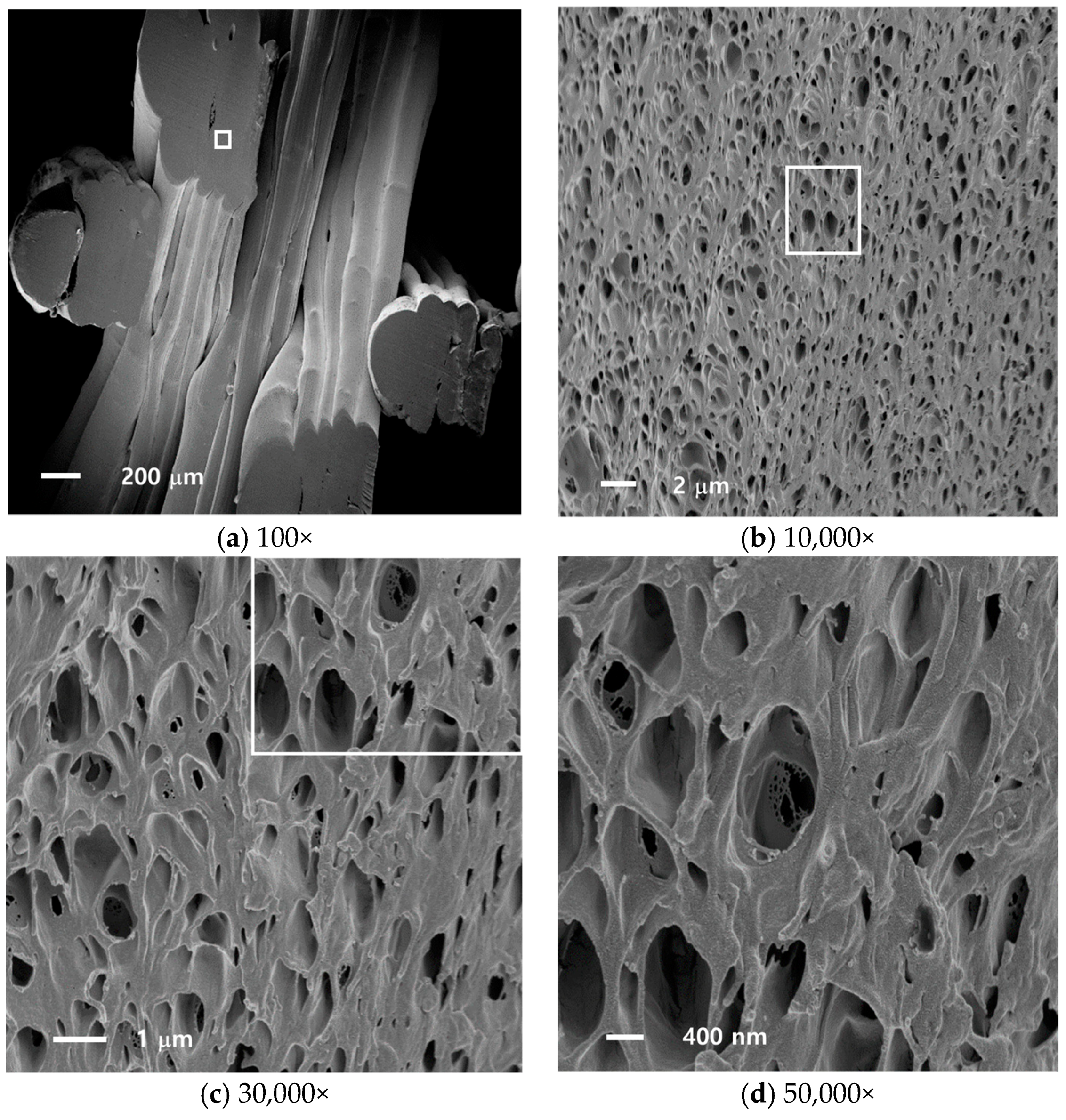

Figure 2 shows cross-sectional FE-SEM images of a fabricated 3D structure with nano-foams at the enlargement of 100×, 10,000×, 30,000× and 50,000×. It is observed that closed cells (pores) of various sizes are randomly distributed within the specimen, and a relatively small amount of polymer matrix is surrounding the hollow pores (cells), forming independent pores separated by robust interfaces. It is seen that carbon dioxide formed small pores in high density, and the pores can be grown to relatively larger sized pores through nucleation and cell growth processes. The structural flexibility of specimens is attributed to nanoscale pores, as visualized in

Figure 2b–d.

To obtain further information on the pore structure and pore density from the SEM images, the ImageJ and MorphoLibJ package (NIH, Bethesda, MD, USA) libraries were used. The measured cross-sectional areas were assumed to be circular, and the effective diameters were calculated using the calculation formula,

=

, where

A is the cross-sectional area, and

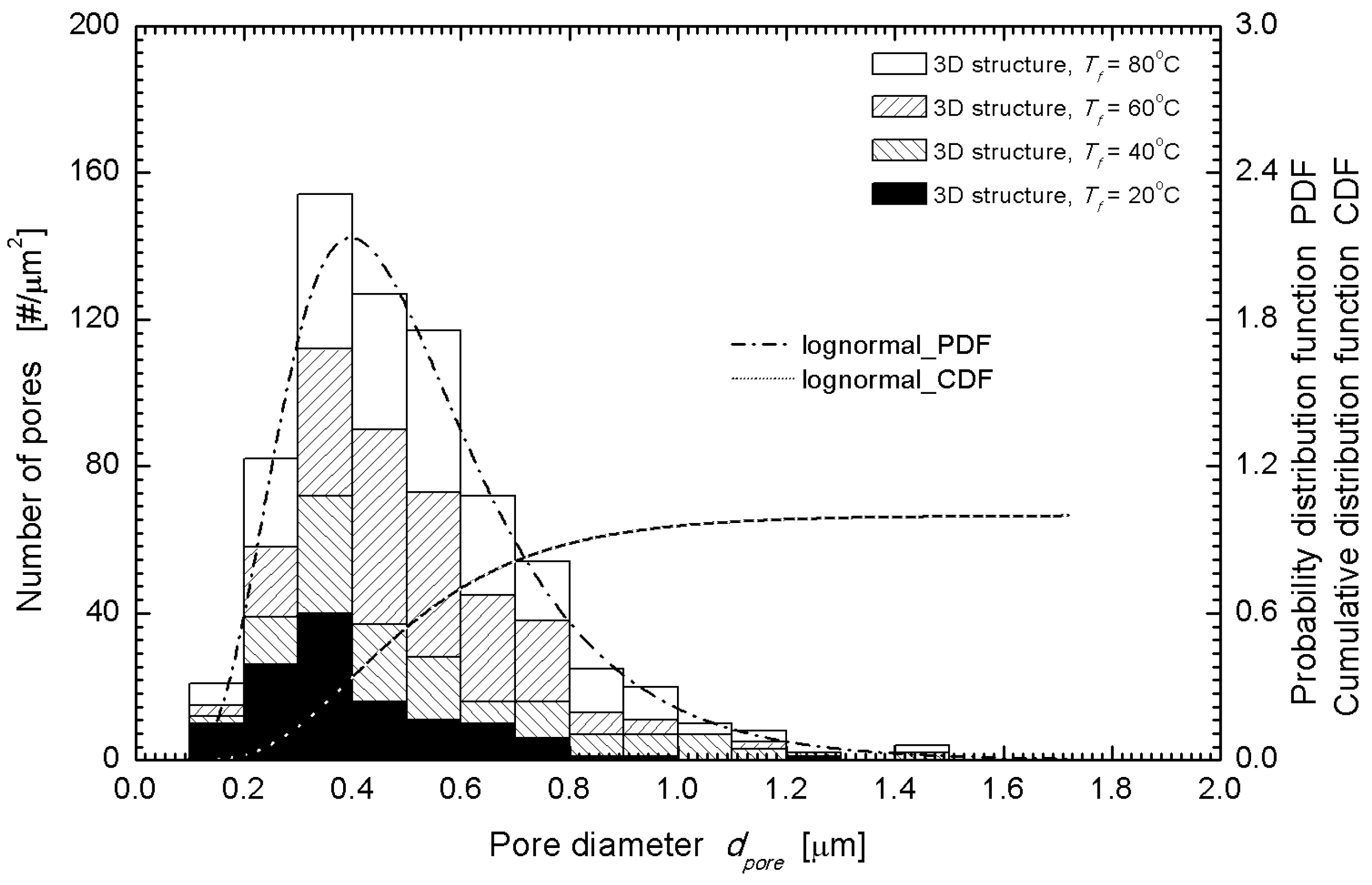

denotes the effective pore(cell) diameter. The pore size distribution obtained in this manner was fit to logarithmic normal distribution as many natural phenomena are well fit [

14], and the number average diameter was obtained. To estimate the number density of the pore formation (closed cell), the number of pores in a 100 μm

2 area was counted, by including at least 100 pores (interrogation areas were selected from various regions from center to edge to find representative characteristics). In the case of PLA, the size of the pore showed minor variations, similar to the case of ABS, but the probability density distribution function exhibited larger difference [

14]. The overall lognormal distribution fitting parameters were the mean diameter of 523.7 nm and variance of 0.05546 as shown in

Figure 3.

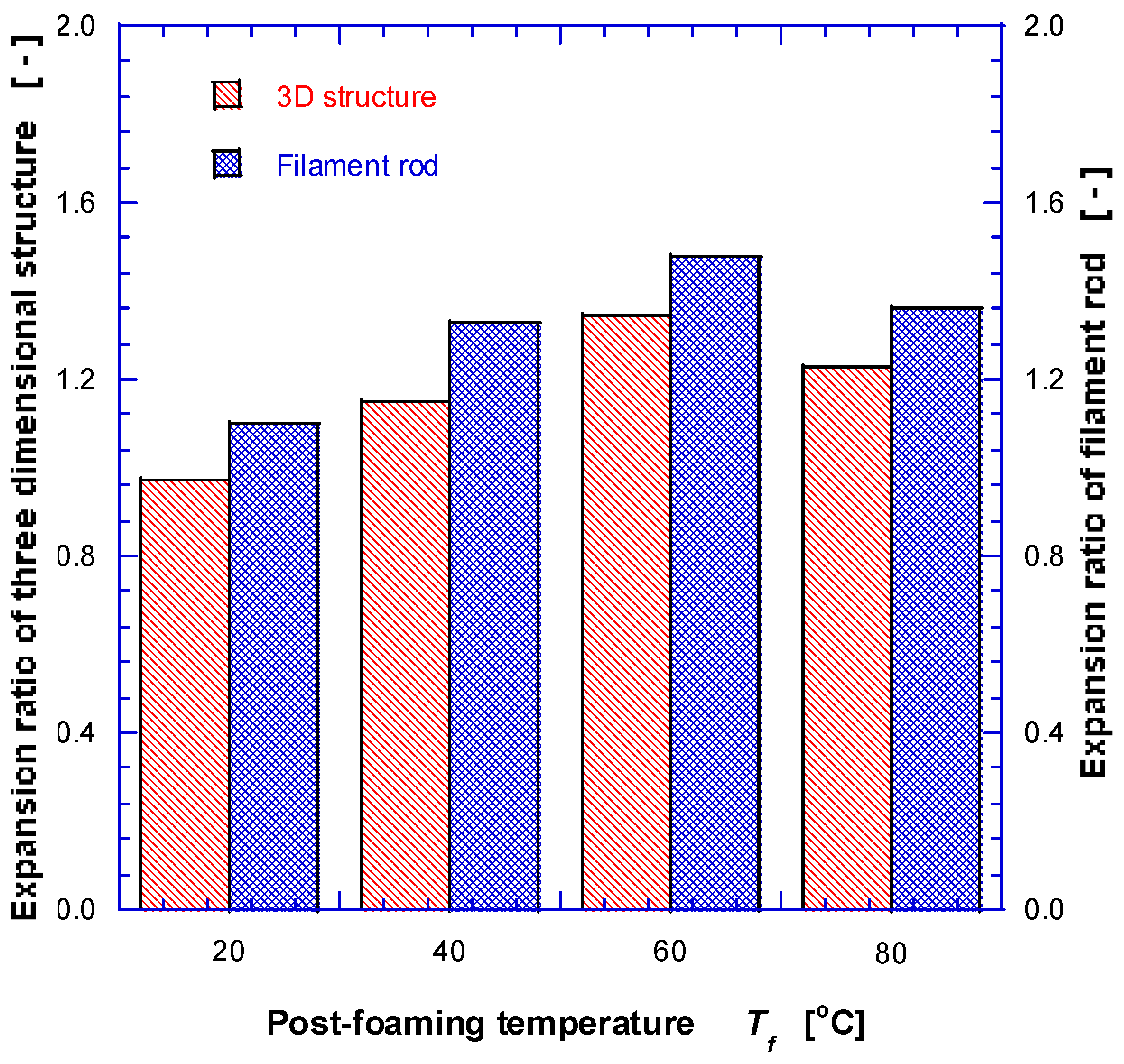

The sample was saturated at −20 °C and 10 MPa for 24 h, then suddenly depressurized (at the rate of ~50–100 MPa/s), and finally the foaming process was carried out for 3 min at 20 °C, 40 °C, 60 °C and 80 °C, respectively. Quenching in the thermostat-controlled bath at −20 °C was followed to suppress further foaming, and finally dried in a convection oven set at 50 °C. The resulting sizes of the three-dimensional structures and filaments were measured, and the calculated expansion ratios are plotted in

Figure 4. The volume expansion ratio

, based on the mass and apparent volume in the case of the 3D grid structure (and radial expansion ratio of the rod in the filament rod), has been calculated using the following formula.

At the foaming temperature of 20 °C, the expansion ratio was very limited, but increased at higher temperature up to 60 °C. However, at 80 °C, it reduced vs. at 60 °C due to the glass transition at ~60 °C for the PLA; part of expanded pores was coalesced and/or ruptured, and part of open cell structures was shrunk and rearranged. It has been found that the swelling ratio of 3D structures totally constrained to each other is lower than that of the filament rod free from external stress. In addition, three-dimensional structures were expanded to the out-of-plane direction as well because of stacked flat shape of extruded polymer and internal residual stress. It has also been found that the swelling ratio of the cylindrical rod increases by ~7–14% compared with that of 3D structure, as shown in

Figure 4.

The cell (pore) density

, i.e., the number of cells (pores) per unit volume of the foam, and relative density (i.e.,

solid fraction = 1 −

void fraction), can be estimated from the following correlations:

where

n is the number of cells (pores) in the probe volume,

A is the probe area,

M is the magnification,

is the void fraction of foam,

is the polymer density,

is the foam density, and

is the relative density. Foam densities of rods were measured by weight displacement method [

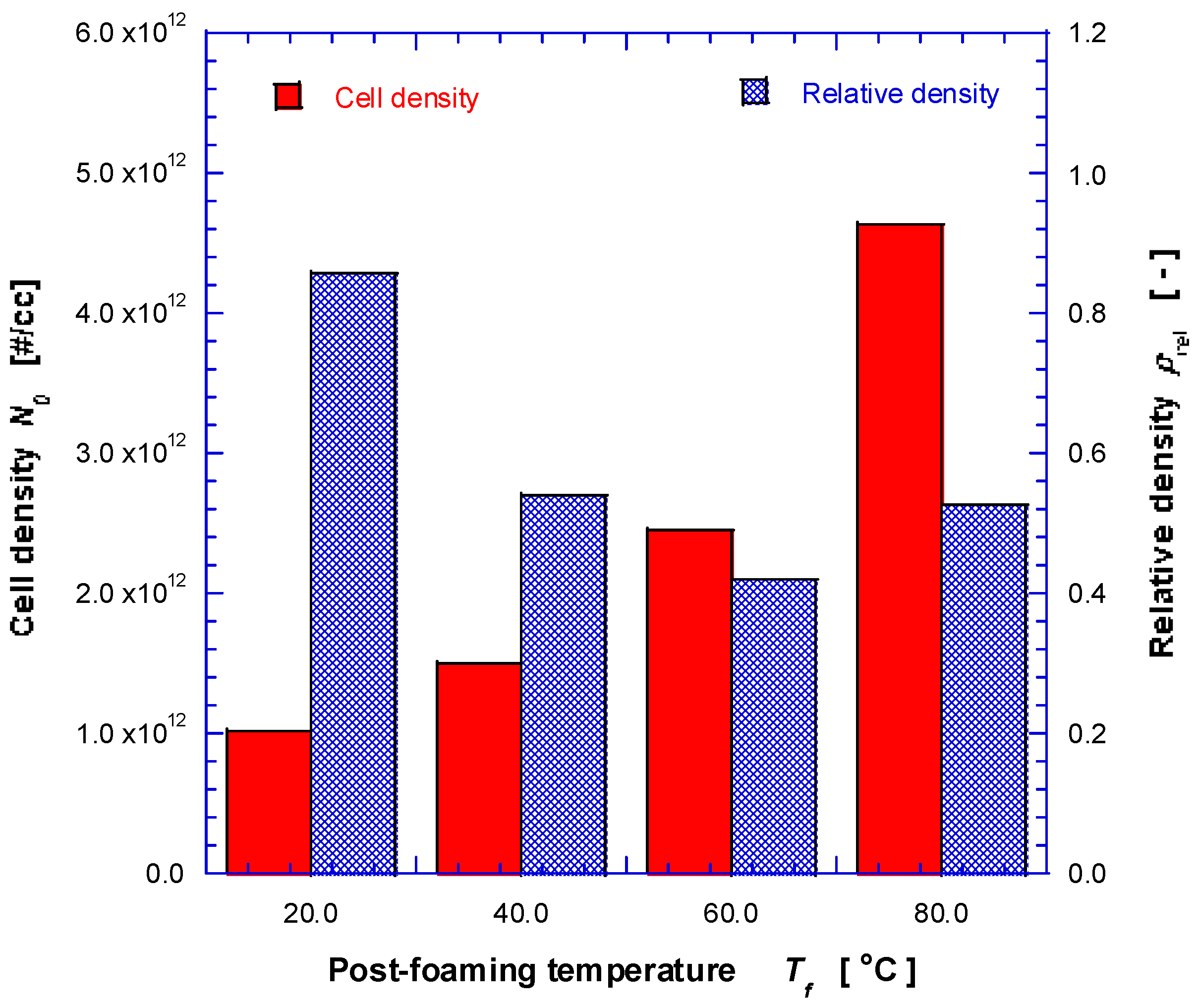

14]; the samples were weighed on an analytical scale and immersed in water, and then volume of water displaced by the sample was then measured. For 3D structures, it was calculated from mass and apparent volume. As shown in

Figure 5, the estimated cell (pore) density generally increases monotonically as

increases, and the relative density decreases monotonically except for the sample prepared by post-foaming temperature of 80 °C. The relative density of sample prepared by

= 80 °C is higher because fraction of pores has been coalesced, burst and shrunk considerably.

The reported true density of the polylactic acid mixed resin (Nature Works PLA) used for this study is ~1.24 g/cm

3. Based on the dimension of 36.0 × 36.0 × 5.4 mm

3 and a measured mass of 2.183 g for non-foamed freeform specimen, the bulk density is estimated at ~0.304 g/cm

3. Thus, solid fraction of the sample fabricated by 3D printing without foaming step was ~24.5%, i.e., 0.304 (g/cm

3)/1.24 (g/cm

3). One can obtain approximate values on the solid fraction of 3D structures after foaming by multiplying the solid fraction (~24.5%) to the relative density shown in

Figure 5 (solid fraction of foamed rib). Then, the void fraction, an important parameter for thermal and mechanical properties, can be estimated by subtracting from 100%.

3.2. Thermal and Pyrolysis Characteristics

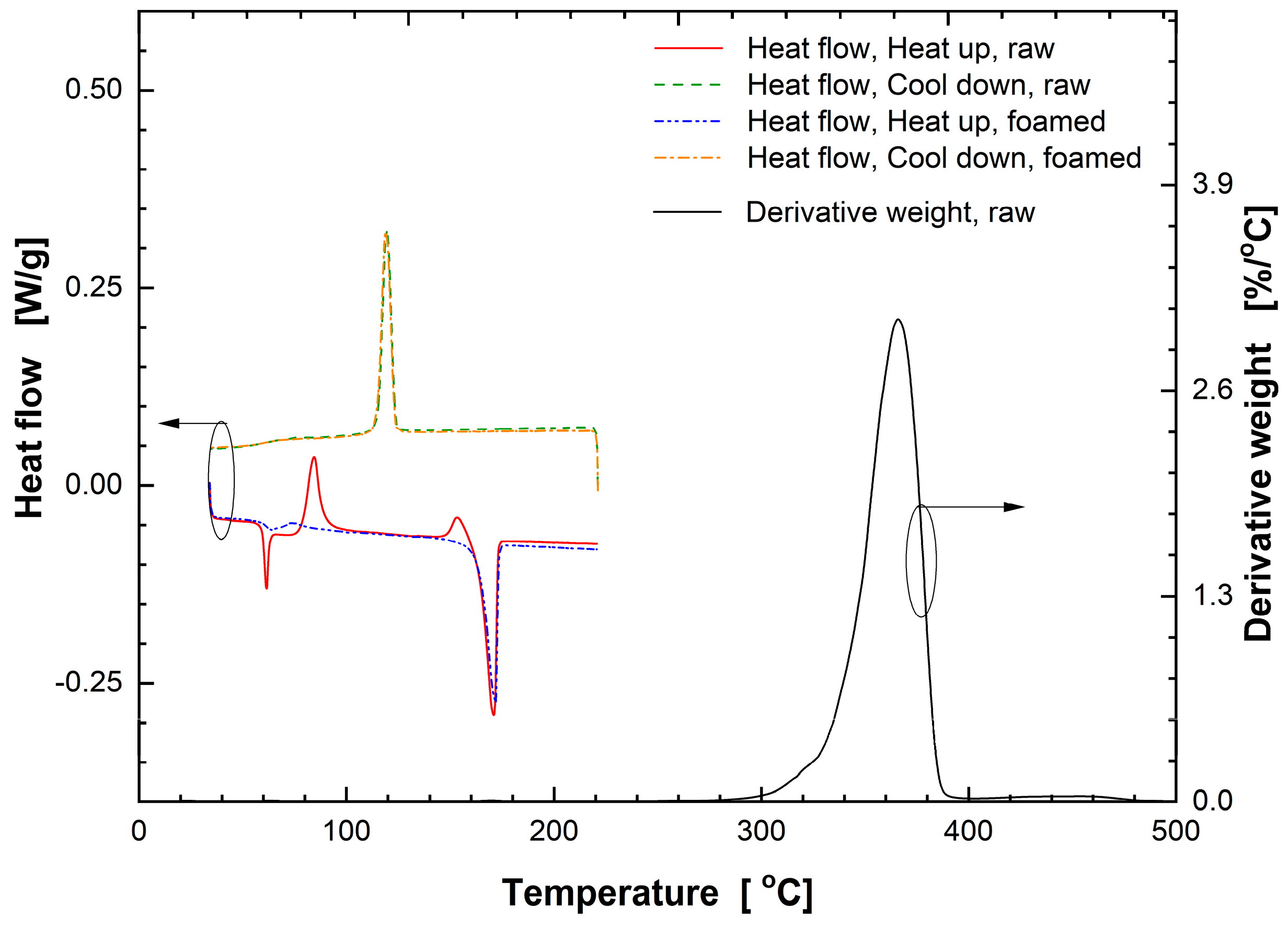

The thermal analysis was performed for the 3D printed samples and subsequently foamed samples as shown in the left part (lower temperature range up to 220 °C) of

Figure 6. One cycle test was conducted to investigate the precise state of PLA, i.e., for experimental measurement of glass transition temperatures before and after gas foaming process, using differential scanning calorimetry (Model Discovery, TA Instruments, New Castle, DE, USA). The analysis was carried out in an aluminum container in a nitrogen atmosphere based on the regulations in ASTM D 3417-83 and D 3418-82. The sample weight of 2–3 mg was used. Samples were heated from 34 °C up to 220 °C at the ramping rate of 2 °C/min, held at 220 °C for 5 min, and cooled down to 34 °C at the rate of 2 °C/min, completing one cycle.

During heating of the non-foamed specimen, as can be seen in

Figure 6, the initial phase transition takes place at 56.4 °C, which corresponds to the glass transition temperature in which the polymer transits to a highly elastic state. The endothermic peak at 170.9 °C indicates melting process. Observation of thermal transitions at temperature peaks of 84.4 °C and 153.7 °C are associated with cold crystallization. Cold crystallization is caused by the rearrangement of molecular chains in the crystalline PLA layer assisted by increased mobility during the manufacturing and heating processes. Since the polymer is in an amorphous state after the heating stage, this phase transition is present. During the cooling process, the phase transition occurs at 119.3 °C. It is presumed that the fabricated rigid freeform after extrusion from the nozzle and cooling is in amorphous and partially crystalline states. Moreover, the observed amorphous state is independent of the cooling rate because the heating and cooling speed of the DSC is as slow as 2 °C/min.

On the other hand, the foamed specimens subjected to the saturation and post-forming processes show a clear difference in that carbon dioxide was contained or plasticization occurred during the post-foaming process so that no cold crystallization occurs due to rearrangement of molecular chains during the heating process.

Pyrolysis measurements were performed using a SDT (simultaneous DSC/TGA, TA Instruments, New Castle, DE, USA) analyzer, as also shown in

Figure 6. The maximum endothermic reaction occurring at 371.78 °C is assigned to the mixed components during evaporation and production of filament for 3D printing. As observed in the pyrolysis curve obtained by thermogravimetric analysis (TGA), the PLA, a constituent of freeform foam, starts to evaporate at ~297.3 °C (weight ratio of 99 wt.%), and weight loss rate is maximized at ~366 °C (~3.05 wt.%/°C), reaching almost full evaporation at ~431.5 °C (weight ratio of 1 wt.%) ultimately reaching negligible weight loss rate. Major pyrolysis event takes place between 338.6 and 376.5 °C, where ~80% of total mass is lost and most latent heat of evaporation is consumed. It is noted that, for temperature higher than 277.1 °C, thermal decomposition rate of filament material rapidly increases (>0.01 wt.%/°C), resulting in a large mass loss, thus setting the upper limit of working temperature for 3D printed features based on PLA.

On the other hand, morphology of PLA crystal is influenced by composition and thermal history. PLA crystals grown at different temperatures go through regime changes associated with nucleation and crystal growth rates [

15]. While the slow quiescent crystallization kinetics of PLA may limit its processing speed for some applications, utilizing stress-induced crystallization (SIC) with PLA has been success commercially because of naturally wide processing window. It is possible to achieve highly oriented PLA in the rubbery or molten state during 3D printing operations such as fiber extrusion, layer bonding, and/or shear scrubbing. Such fabrication routes take full advantage of the semi-crystalline nature of PLA to develop different properties. To estimate a degree of crystallinity, the following equation is used:

where

∆Hm is measured heat of fusion and

∆Hc is heat of crystallization. Most commonly, an enthalpy of fusion 93.1 J/g is used for a 100% crystalline poly-

l-lactide (PLLA) or poly-

d-lactide (PDLA) homo-polymers having infinite crystal thickness throughout the PLA literatures (i.e.,

∆Hm,max = 93.1 J/g was used here). From digital scanning calorimetry (DSC) scans, percent crystallinity of 26.88% is estimated for the fabricated freeform specimen.

3.3. Mechanical Properties

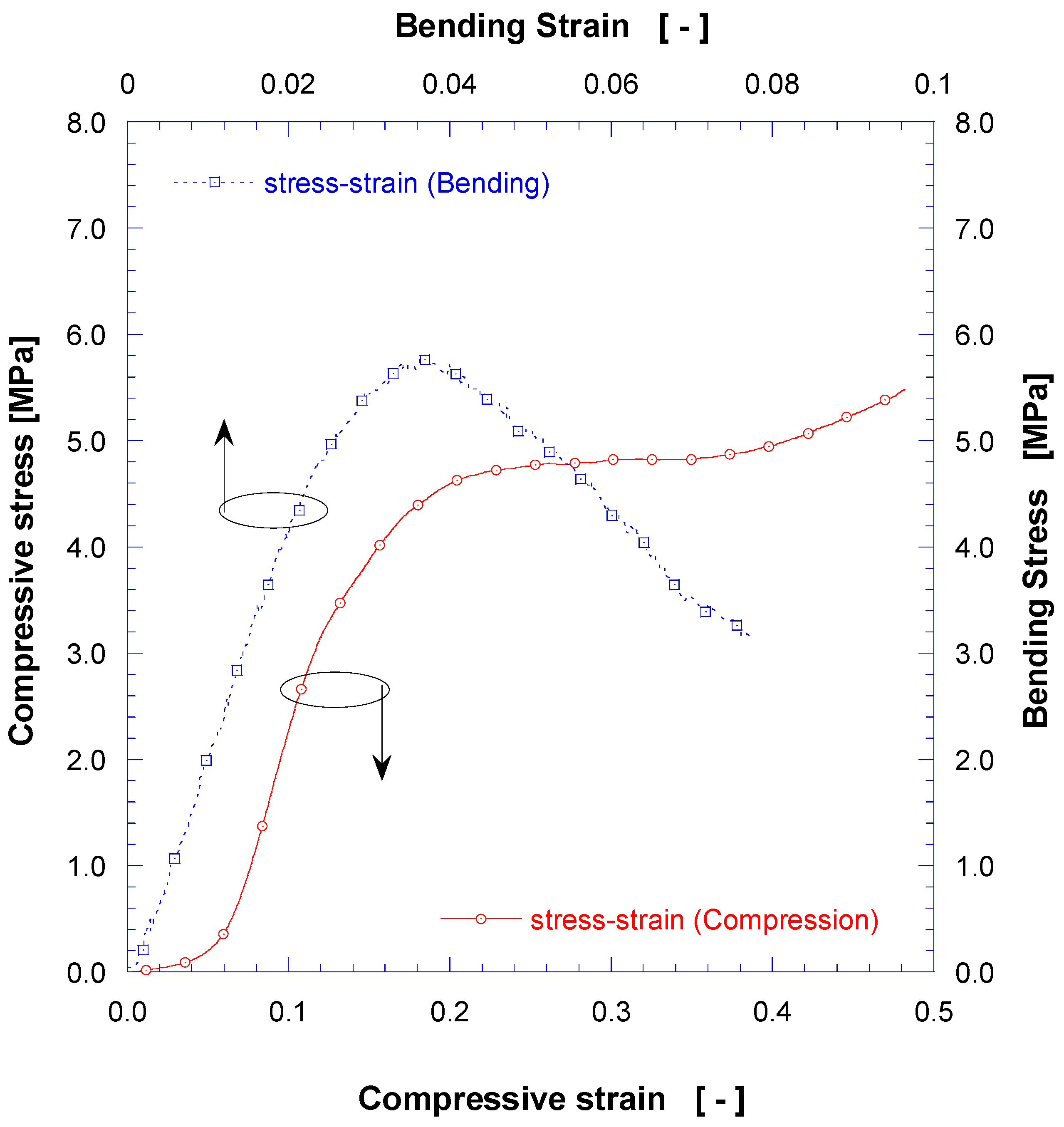

To understand the mechanical properties of 3D structures fabricated by 3D printing, representative compressive and bending test results are displayed in

Figure 7 (note difference in

x-axis scales). In the result of four-point bending test, the bending stress of freeform specimen showed an elastic behavior up to a bending strain of ~0.025 mm/mm with an initial tangential elastic modulus of 204.3 MPa. The maximum bending stress reached ~5.65 MPa at ~0.035 mm/mm, and then gradually decreased. The maximum bending strain at which fracture occurred was ~0.07 mm/mm. The main reasons for improved mechanical strength vs. typical insulating foams are: (i) the 3D printed structure of polylactic acid polymer has a relatively strong bonding force between molten layers; and (ii) the flexible freeform structure, as staggered grid studs, withstands a large strain. The dimension of specimen before compression test was 36.0 × 36.0 × 5.4 mm

3. The maximum compressive deflection was limited to ~4.2 mm, which was a machine limit for the protection of measuring equipment with overload protection during compression. In compressive test, freeform specimens showed linear elastic behavior for the compressive strain range of ~0.07–0.12 mm/mm with an initial tangential elastic modulus of 52.67 MPa (coefficient of determination in linear modulus

R2 = 0.9986), and flat region for the strain range of 0.22–0.38 mm/mm with constant compressive stress value of ~4.81 MPa. The specific compressive strength and specific compressive modulus of elasticity were calculated as 15.82 MPa · cc/g and 169.67 MPa · cc/g respectively. In the compression test, the specimen did not rupture rapidly until strain reached about 25% because the space between inner grids in polymer matrix studs can accommodate and withstand high strains maintaining the connectivity.

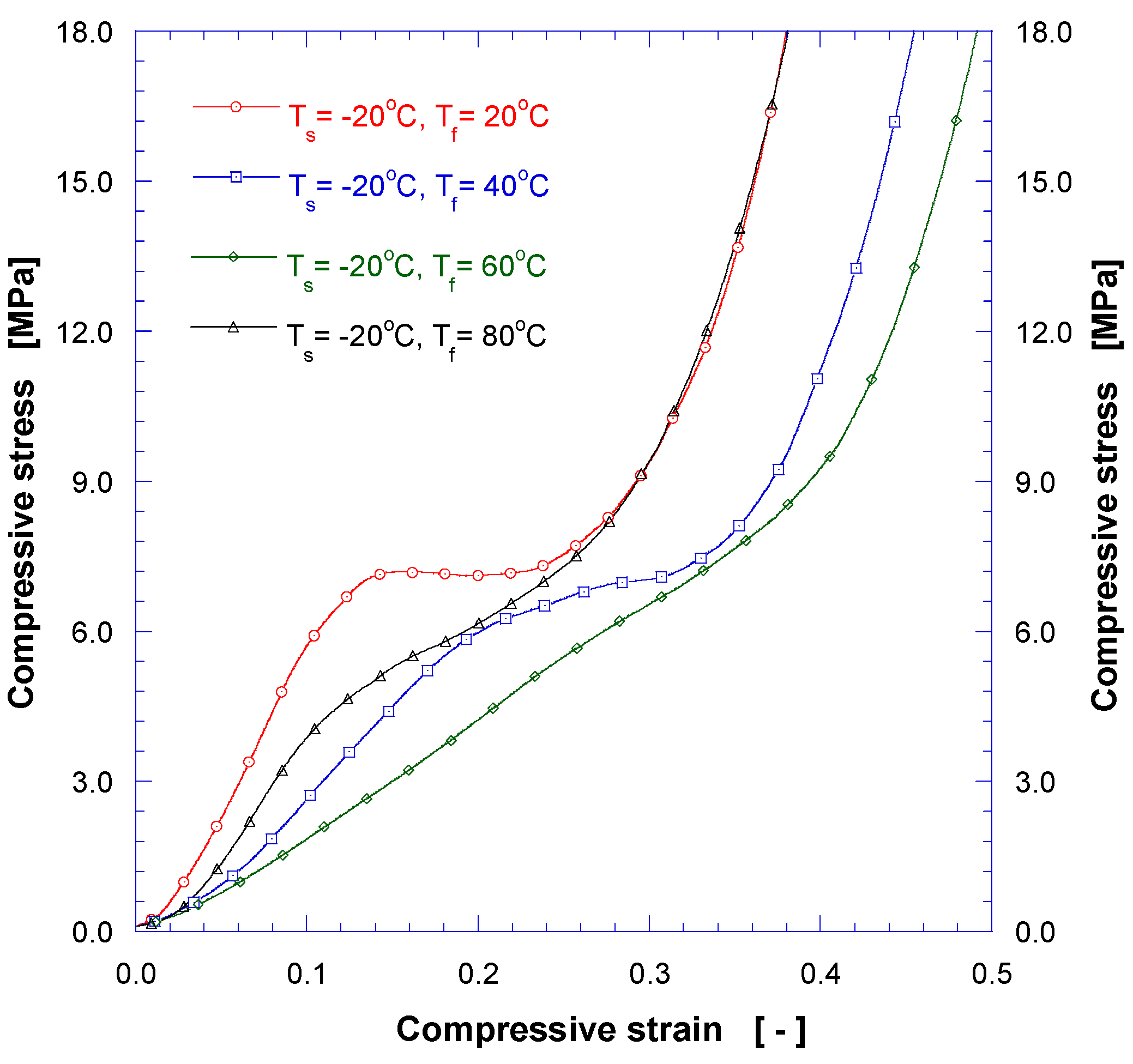

In post-foaming process, 3D printed structures may experience nonuniform deformations due to internal residual stress and/or nonuniform temperature distribution within the structure during the foaming process. We have used a jig of fine mesh and/or grill with a very flexible spring during the foaming process to partly resolve the deformation issues. The measured compressive strength of the PLA foam specimen is shown in

Figure 8. It is observed that the modulus of elasticity decreases as the post-foaming temperature increases up to 60 °C, and increases at

= 80 °C. The highest mechanical strength of CO

2 saturated grid sample is greater than that of pristine one presumably because crystals are rearranged due to the plasticization effects by CO

2 impregnation. The maximum compressive stress increased by about 50%, from 4.8 MPa to 7.2 MPa. As previously described, when the post-foaming temperature exceeds glass transition temperature (

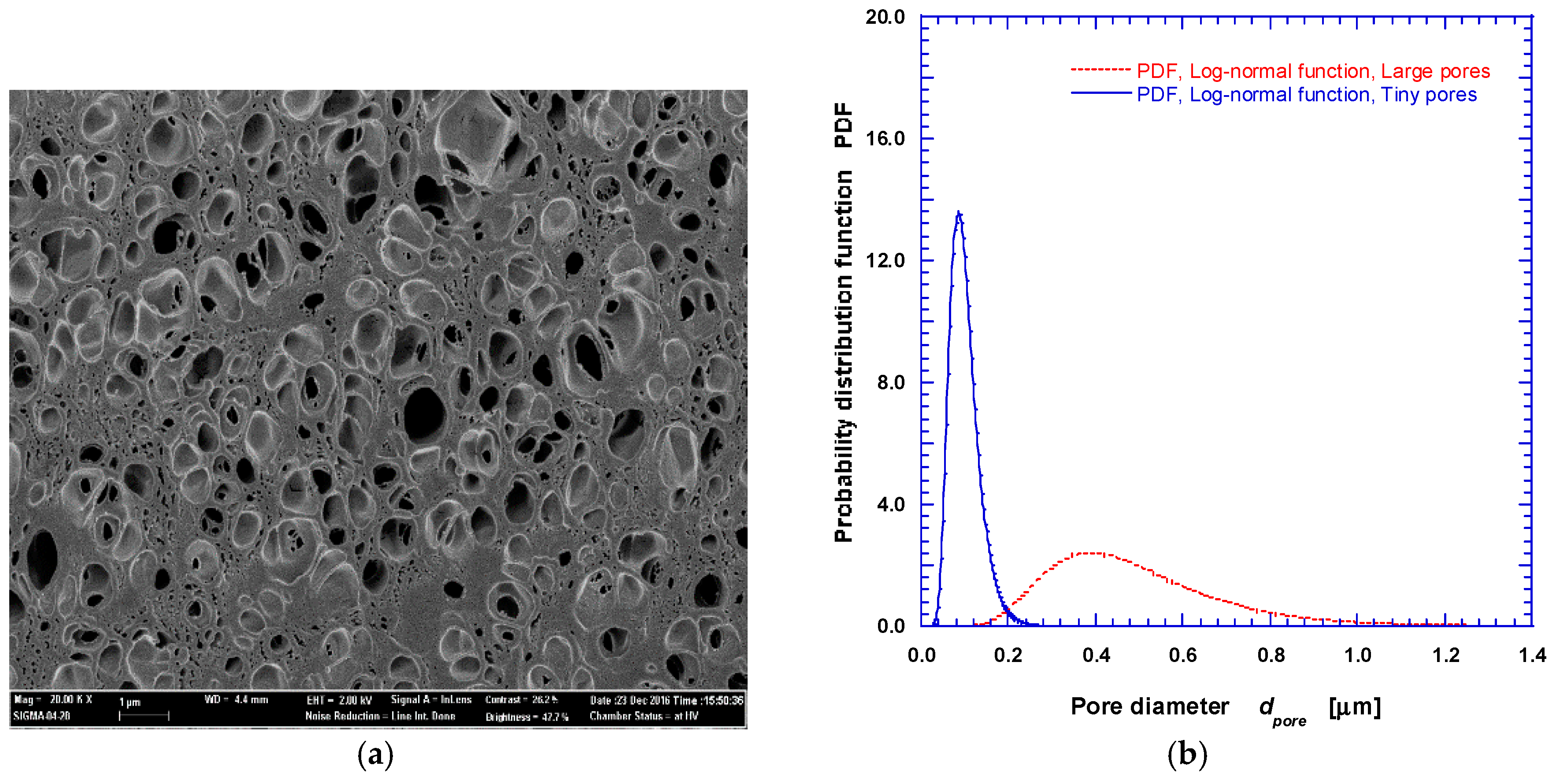

) of PLA, the cell (pore) is partially expanded and ruptured leading to reduced foam size. As shown in an SEM image (

Figure 9a) for the post-foaming temperature of 80 °C, large pores were formed in an irregular fashion, and some of them were burst, forming open cells. The SEM image in

Figure 9a was analyzed to obtain the pore size distribution shown in

Figure 9b. It forms dual diameter distributions with mean diameters of 490.8 nm and 100.5 nm, confirming the formation of multi-scale structure and the possibility of controlling physical properties by suitable tuning of foaming conditions. Further research on the controlling mechanisms of the cell size and closed/open cell ratios is under way.