Hierarchical 2D Cu-MOF@Graphene-Based Hybrids for Supercapacitor Electrodes

Abstract

1. Introduction

2. Experimental Methods

2.1. Synthesis of Materials

2.2. Structural Analysis

2.3. Electrochemical Characterization

3. Results and Discussion

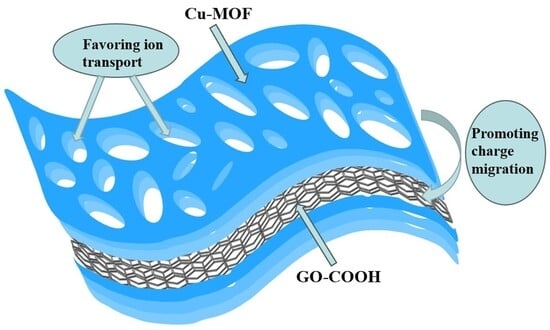

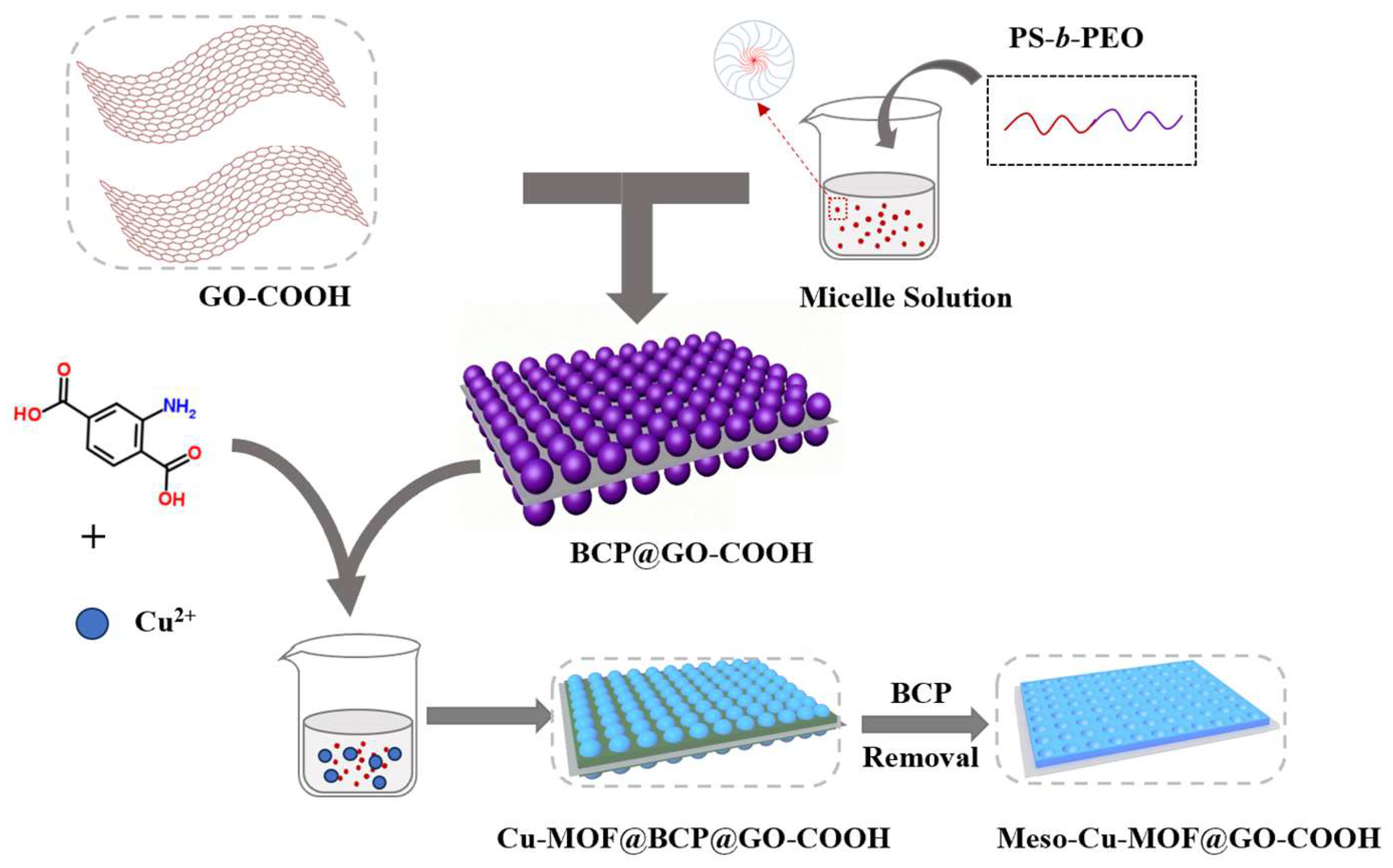

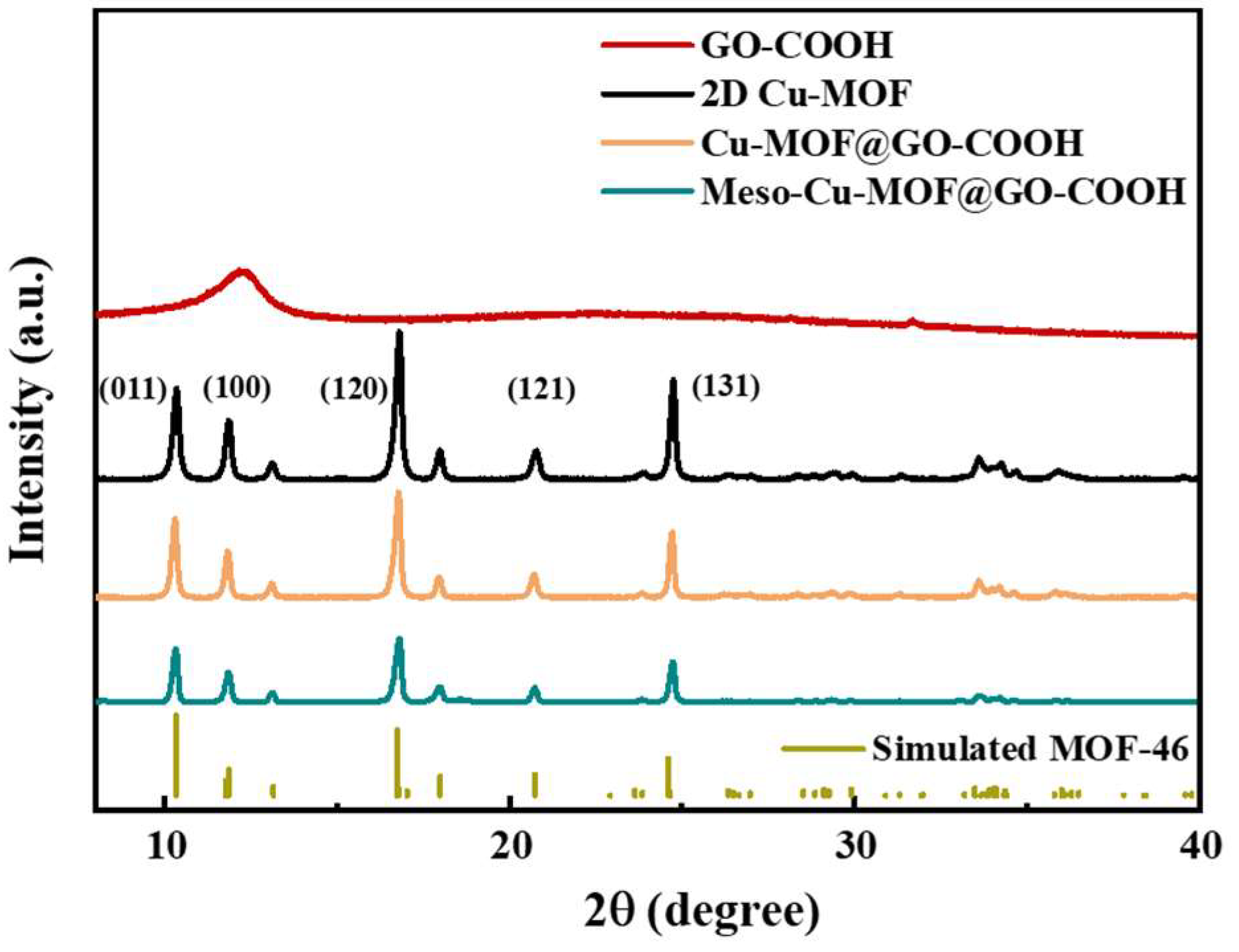

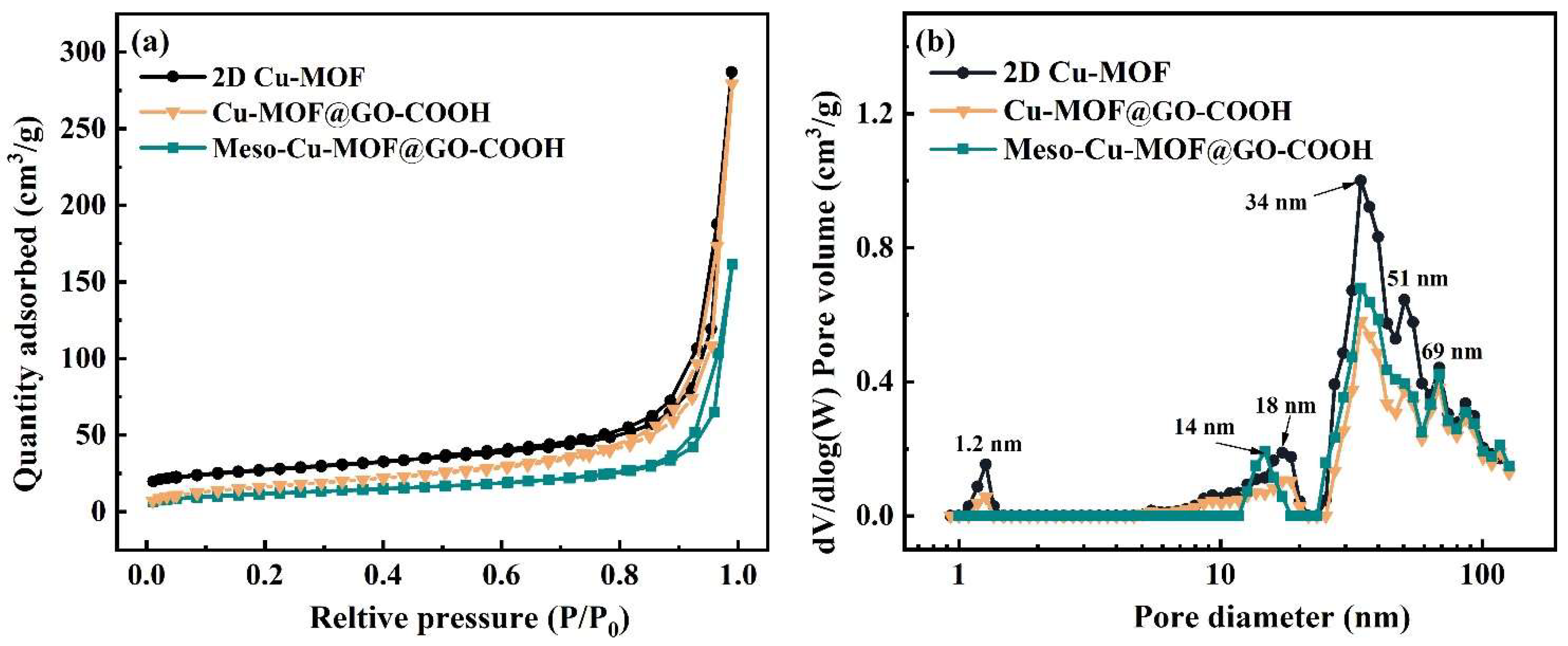

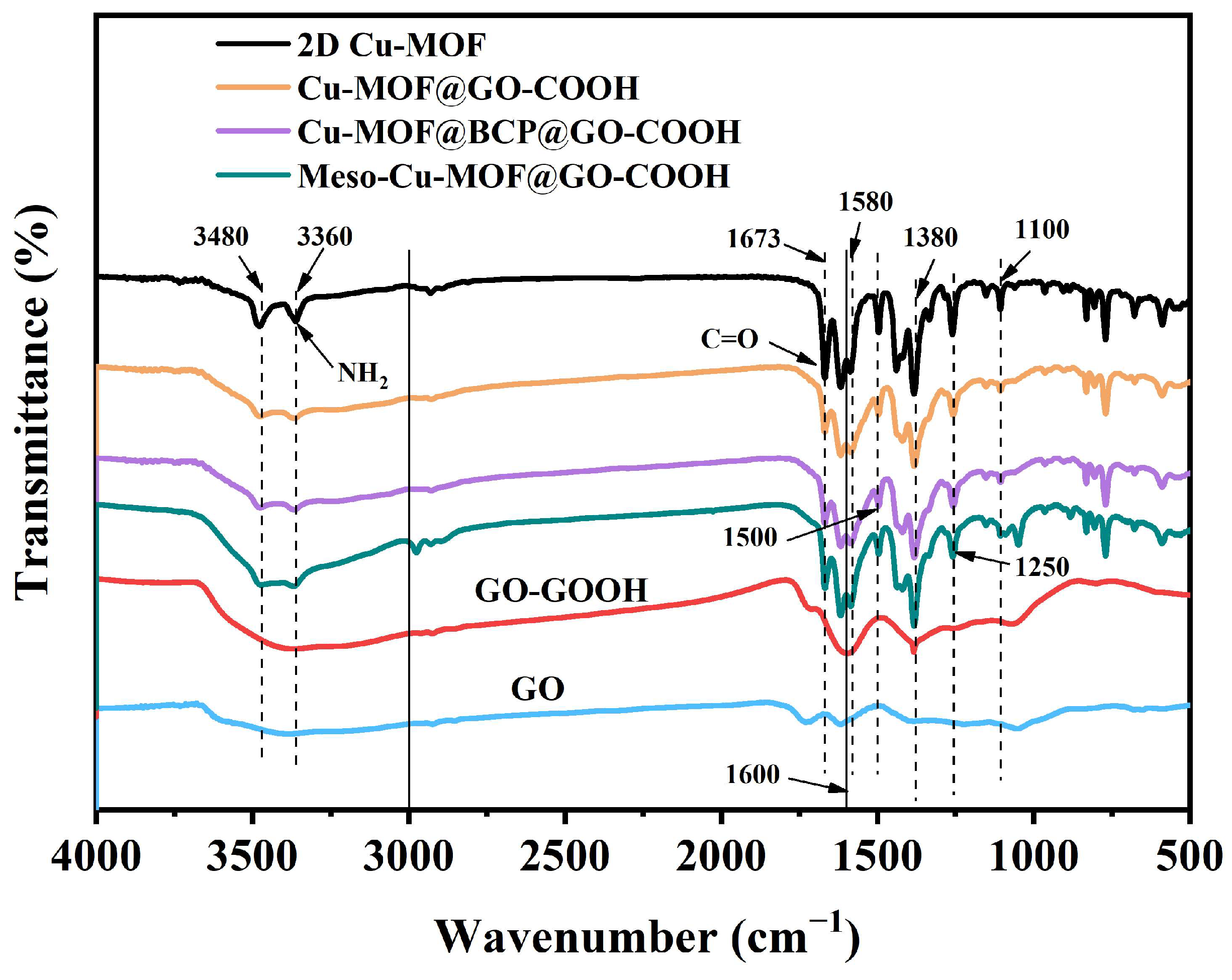

3.1. Structural Characteristics

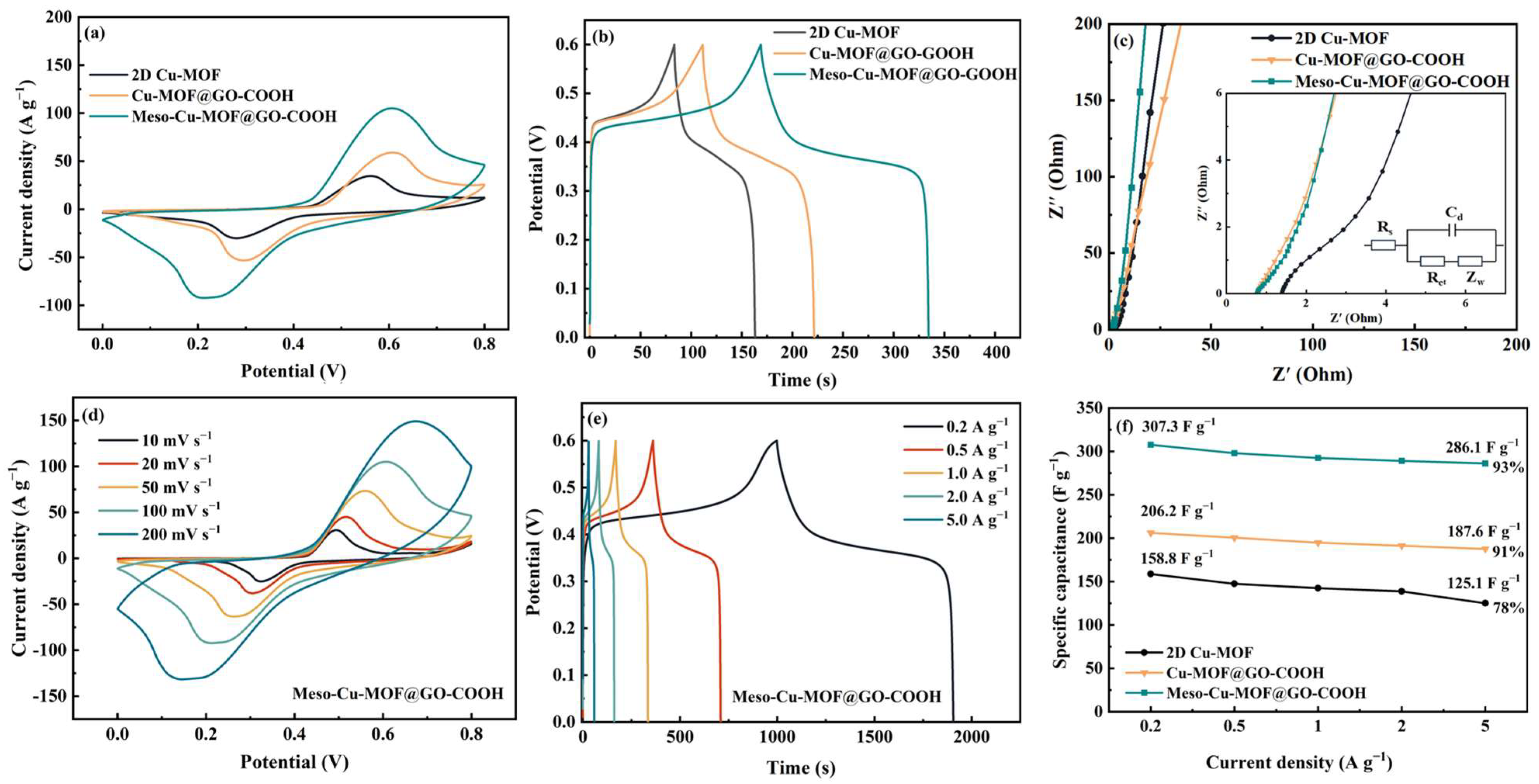

3.2. Electrochemical Performance of 2D MOF Hybrid Electrodes

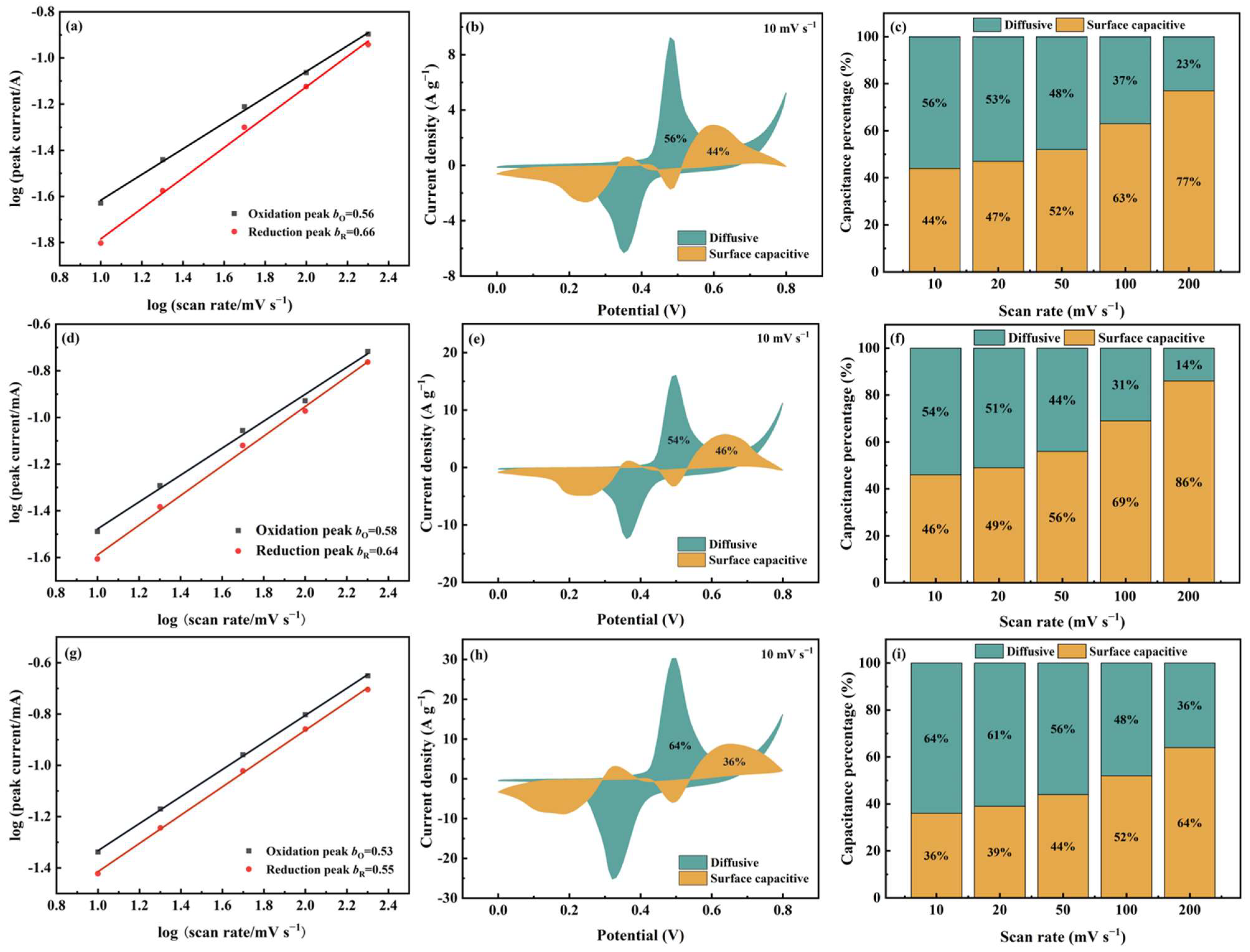

3.3. Energy Storage Mechanism

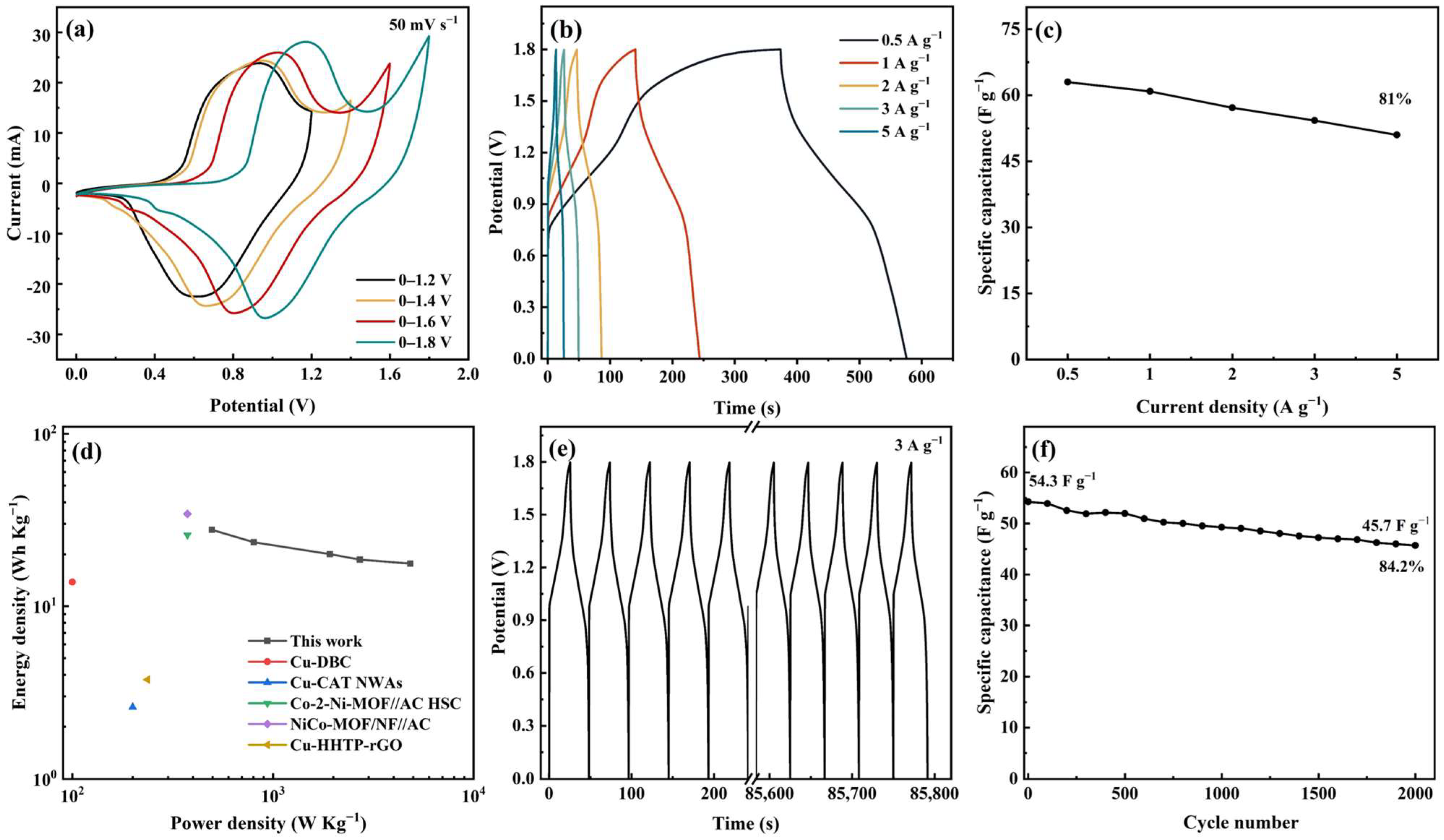

3.4. Electrochemical Performance of ASC Device

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhaduri, A.; Kim, C.; Ha, T. Recent Developments in Materials Design for Advanced Supercapacitors. Energy Environ. Mater. 2025, 8, e70070. [Google Scholar] [CrossRef]

- Tsyganov, A.; Vikulova, M.; Zotov, I.; Korotaev, E.; Plugin, I.; Sysoev, V.; Kirilenko, D.; Rabchinskii, M.; Asoyan, A.; Gorokhovsky, A.; et al. Application of W1.33CTz MXenes obtained by hydrothermal etching as an additive to enhance the electrochemical energy storage properties of binder-free Ti3C2Tx MXene films. Dalton Trans. 2025, 54, 8547–8558. [Google Scholar] [CrossRef]

- Xia, W.; Mahmood, A.; Zou, R.; Xu, Q. Metal-organic frameworks and their derived nanostructures for electrochemical energy storage and conversion. Energy Environ. Sci. 2015, 8, 1837–1866. [Google Scholar] [CrossRef]

- Qiu, T.; Liang, Z.; Guo, W.; Tabassum, H.; Gao, S.; Zou, R. Metal–Organic Framework-Based Materials for Energy Conversion and Storage. ACS Energy Lett. 2020, 5, 520–532. [Google Scholar] [CrossRef]

- Mohamed, A.M.; Sayed, D.M.; Allam, N.K. Optimized Fabrication of Bimetallic ZnCo Metal-Organic Framework at NiCo-Layered Double Hydroxides for Multiple Storage and Capability Synergy All-Solid-State Supercapacitors. ACS Appl. Mater. Interfaces 2023, 15, 16755–16767. [Google Scholar] [CrossRef] [PubMed]

- Yue, L.; Chen, L.; Wang, X.; Lu, D.; Zhou, W.; Shen, D.; Yang, Q.; Xiao, S.; Li, Y. Ni/Co-MOF@aminated MXene hierarchical electrodes for high-stability supercapacitors. Chem. Eng. J. 2023, 451, 138687. [Google Scholar] [CrossRef]

- Li, S.; Wang, R.; Xie, M.; Xu, Y.; Chen, J.; Jiao, Y. Construction of trifunctional electrode material based on Pt-Coordinated Ce-Based metal organic framework. J. Colloid Interface Sci. 2022, 611, 378–389. [Google Scholar] [CrossRef]

- Wang, D.-G.; Liang, Z.; Gao, S.; Qu, C.; Zou, R. Metal-organic framework-based materials for hybrid supercapacitor application. Coord. Chem. Rev. 2020, 404, 213093. [Google Scholar] [CrossRef]

- Liang, N.; Shi, B.; Hu, X.; Li, W.; Huang, X.; Li, Z.; Zhang, X.; Zou, X.; Shi, J. A ternary heterostructure aptasensor based on metal-organic framework and polydopamine nanoparticles for fluorescent detection of sulfamethazine. Food Chem. 2024, 460, 140570. [Google Scholar] [CrossRef]

- Xu, S.; Shao, D.; Wang, J.; Zheng, X.; Yang, Z.; Wang, A.; Chen, Z.; Gao, Y. Pre-ligand-induced porous MOF as a peroxidase mimic for electrochemical analysis of deoxynivalenol (DON). Food Chem. 2025, 480, 143860. [Google Scholar] [CrossRef]

- Liang, N.; Shi, B.; Hu, X.; Shi, Y.; Wang, T.; Huang, X.; Li, Z.; Zhang, X.; Zou, X.; Shi, J. Simultaneous adsorption and fluorescent sensing of ampicillin based on a trimetallic metal-organic framework. Food Chem. 2025, 472, 142891. [Google Scholar] [CrossRef]

- Guan, H.; Chen, Y.; Wang, D.; Liu, Q.; Zhong, J.; Zhang, Z.; Lü, D. The novel nanozyme-based electrochemical-driven electrochromic visual biosensor based on PEDOT: PSS/RGO conductive film for rapid detection of nitrite in food samples. Food Chem. 2025, 481, 143971. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.; Wu, X.; Xue, S.; Yin, L.; Gao, S.; Zhang, Y.; Wang, C.; Wang, Y.; El-Seedi, H.R.; Zou, X.; et al. Magnetic metal-organic frameworks-based ratiometric SERS aptasensor for sensitive detection of patulin in apples. Food Chem. 2025, 466, 142200. [Google Scholar] [CrossRef]

- Shi, B.; Zhang, X.; Li, W.; Liang, N.; Hu, X.; Xiao, J.; Wang, D.; Zou, X.; Shi, J. An intrinsic dual-emitting fluorescence sensing toward tetracycline with self-calibration model based on luminescent lanthanide-functionalized metal-organic frameworks. Food Chem. 2023, 400, 133995. [Google Scholar] [CrossRef] [PubMed]

- Liang, N.; Hu, X.; Zhang, X.; Li, W.; Guo, Z.; Huang, X.; Li, Z.; Zhang, R.; Shen, T.; Zou, X.; et al. Ratiometric sensing for ultratrace tetracycline using electrochemically active metal–organic frameworks as response signals. J. Agric. Food Chem. 2023, 71, 7584–7592. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.; Li, Y.; Zhang, L.; Bi, N.; Gou, J.; Zhu, T.; Jia, L. A novel intelligently integrated MOF-based ratio fluorescence sensor for ultra-sensitive monitoring of TC in water and food samples. Food Chem. 2023, 405, 134899. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Jayan, H.; Gao, S.; Zhou, R.; Yosri, N.; Zou, X.; Guo, Z. Recent and emerging trends of metal-organic frameworks (MOFs)-based sensors for detecting food contaminants: A critical and comprehensive review. Food Chem. 2024, 448, 139051. [Google Scholar] [CrossRef]

- Marimuthu, M.; Arumugam, S.S.; Sabarinathan, D.; Li, H.; Chen, Q. Metal organic framework based fluorescence sensor for detection of antibiotics. Trends Food Sci. Technol. 2021, 116, 1002–1028. [Google Scholar] [CrossRef]

- Li, S.; Dai, Y.; Ye, P.; Liu, F.; Li, L.; Zhang, D.; Zhu, M. Hierarchical porous MOF/CTF hybrid frameworks used as protection against acidic harmful gases. Chem. Eng. J. 2024, 491, 152035. [Google Scholar] [CrossRef]

- Zhao, W.; Peng, J.; Wang, W.; Liu, S.; Zhao, Q.; Huang, W. Ultrathin two-dimensional metal-organic framework nanosheets for functional electronic devices. Coord. Chem. Rev. 2018, 377, 44–63. [Google Scholar] [CrossRef]

- Muzaffar, A.; Ahamed, M.B.; Deshmukh, K.; Thirumalai, J. A review on recent advances in hybrid supercapacitors: Design, fabrication and applications. Renew. Sustain. Energy Rev. 2019, 101, 123–145. [Google Scholar] [CrossRef]

- Liu, Q.; Guo, Z.; Wang, C.; Guo, S.; Xu, Z.; Hu, C.; Liu, Y.; Wang, Y.; He, J.; Wong, W. A Cobalt-Based Metal-Organic Framework Nanosheet as the Electrode for High-Performance Asymmetric Supercapacitor. Adv. Sci. 2023, 10, e2207545. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Yan, S.; Liu, Y.; Tian, Z.; Li, D.; Chen, Y.; Guo, L.; Wang, Y. Significantly enhanced electrochemical performance of 2D Ni-MOF by carbon quantum dot for high-performance supercapacitors. Electrochim. Acta 2022, 422, 140560. [Google Scholar] [CrossRef]

- Xu, X.; Lu, H.; Xu, D.; Zhou, P.; Ying, Y.; Li, L.; Liu, Y. Oxygen-rich vacancies CuCoLDH with 1D/2D nanoarray structure for high performance asymmetric supercapacitor. Appl. Surf. Sci. 2023, 614, 156174. [Google Scholar] [CrossRef]

- Jia, H.; Lu, S.; Shin, S.H.R.; Sushko, M.L.; Tao, X.; Hummel, M.; Thallapally, P.K.; Liu, J.; Gu, Z. In situ anodic electrodeposition of two-dimensional conductive metal-organic framework@nickel foam for high-performance flexible supercapacitor. J. Power Sources 2022, 526, 231163. [Google Scholar] [CrossRef]

- Bai, W.; Li, S.; Ma, J.; Cao, W.; Zheng, J. Ultrathin 2D metal–organic framework (nanosheets and nanofilms)-based xD–2D hybrid nanostructures as biomimetic enzymes and supercapacitors. J. Mater. Chem. A 2019, 7, 9086–9098. [Google Scholar] [CrossRef]

- Pomerantseva, E.; Gogotsi, Y. Two-dimensional heterostructures for energy storage. Nat. Energy 2017, 2, 17089. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, F.; Sun, Y.; Yu, K.; Guo, W.; Qu, F. A 2D/2D NiCo-MOF/Ti3C2 heterostructure for the simultaneous detection of acetaminophen, dopamine and uric acid by differential pulse voltammetry. Dalton Trans. 2021, 50, 16593–16600. [Google Scholar] [CrossRef]

- Ehrnst, Y.; Ahmed, H.; Komljenovic, R.; Massahud, E.; Shepelin, N.A.; Sherrell, P.C.; Ellis, A.V.; Rezk, A.R.; Yeo, L.Y. Acoustotemplating: Rapid Synthesis of Freestanding Quasi-2D MOF/Graphene Oxide Heterostructures for Supercapacitor Applications. J. Mater. Chem. A 2022, 10, 7058–7072. [Google Scholar] [CrossRef]

- Rajak, R.; Saraf, M.; Mobin, S.M. Robust heterostructures of a bimetallic sodium–zinc metal–organic framework and reduced graphene oxide for high-performance supercapacitors. J. Mater. Chem. A 2019, 7, 1725–1736. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, S.; Lu, W.; Lei, D.; Tian, Y.; Guo, M.; Mi, P.; Qu, N.; Zhao, Y. MXenes induced formation of Ni-MOF microbelts for high-performance Supercapacitors. J. Colloid Interface Sci. 2021, 592, 95–102. [Google Scholar] [CrossRef]

- Shao, S.; Zhang, L.; Liu, W.; Zhang, Y.; Shen, X.; Nie, Y.; Yang, W.; Liu, H.; Li, S.; Li, S. Synthesis of Hierarchical Porous MOFs via Ligand Thermolysis for High-Performance Supercapacitor. J. Inorg. Organomet. Polym. Mater. 2022, 32, 4412–4421. [Google Scholar] [CrossRef]

- Li, S.; Yang, K.; Ye, P.; Ma, K.; Zhang, Z.; Huang, Q. Three-dimensional porous carbon/Co3O4 composites derived from graphene/Co-MOF for high performance supercapacitor electrodes. Appl. Surf. Sci. 2020, 503, 144090. [Google Scholar] [CrossRef]

- Li, S.; Yang, K.; Ye, P.; Jiang, H.; Zhang, Z.; Huang, Q.; Wang, L. Hierarchical interpenetrating rHGO-decorated NiCo2O4 nanowires architectures for high-performance supercapacitors. Appl. Surf. Sci. 2019, 473, 326–333. [Google Scholar] [CrossRef]

- Lan, K.; Wei, Q.; Wang, R.; Xia, Y.; Tan, S.; Wang, Y.; Elzatahry, A.; Feng, P.; Mai, L.; Zhao, D. Two-Dimensional Mesoporous Heterostructure Delivering Superior Pseudocapacitive Sodium Storage via Bottom-Up Monomicelle Assembly. J. Am. Chem. Soc. 2019, 141, 16755–16762. [Google Scholar] [CrossRef]

- Babu, R.S.; Vinodh, R.; de Barros, A.; Samyn, L.; Prasanna, K.; Maier, M.; Alves, C.; Kim, H.-J. Asymmetric supercapacitor based on carbon nanofibers as the anode and two-dimensional copper cobalt oxide nanosheets as the cathode. Chem. Eng. J. 2019, 366, 390–403. [Google Scholar] [CrossRef]

- Ma, Y.; Gao, G.; Su, H.; Rong, H.; Lai, L.; Liu, Q. A Cu4 cluster-based MOF as a supercapacitor electrode material with ultrahigh capacitance. Ionics 2021, 27, 1699–1707. [Google Scholar] [CrossRef]

- Liu, S.; Gordiichuk, P.; Wu, Z.-S.; Liu, Z.; Wei, W.; Wagner, M.; Mohamed-Noriega, N.; Wu, D.; Mai, Y.; Herrmann, A.; et al. Patterning two-dimensional free-standing surfaces with mesoporous conducting polymers. Nat. Commun. 2015, 6, 8817. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Zhou, X.; Ma, J.; Yang, X.; Deng, Y. Recent advances in amphiphilic block copolymer templated mesoporous metal-based materials: Assembly engineering and applications. Chem. Soc. Rev. 2020, 49, 1173–1208. [Google Scholar] [CrossRef]

- Hang, X.; Xue, Y.; Cheng, Y.; Du, M.; Du, L.; Pang, H. From Co-MOF to CoNi-MOF to Ni-MOF: A Facile Synthesis of 1D Micro-/Nanomaterials. Inorg. Chem. 2021, 60, 13168–13176. [Google Scholar] [CrossRef]

- Liu, F.; Ye, P.; Cheng, Q.; Zhang, D.; Nie, Y.; Shen, X.; Zhu, M.; Xu, H.; Li, S. By introducing multiple hydrogen bonds endows MOF electrodes with an enhanced structural stability. Inorg. Chem. 2024, 63, 14630–14640. [Google Scholar] [CrossRef]

- Nicks, J.; Zhang, J.; Foster, J.A. Tandem catalysis by ultrathin metal–organic nanosheets formed through post-synthetic functionalisation of a layered framework. Chem. Commun. 2019, 55, 8788–8791. [Google Scholar] [CrossRef] [PubMed]

- Rad, M.; Dehghanpour, S. ZnO as an efficient nucleating agent and morphology template for rapid, facile and scalable synthesis of MOF-46 and ZnO@MOF-46 with selective sensing properties and enhanced photocatalytic ability. RSC Adv. 2016, 6, 61784–61793. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, J.; Xiong, N.; Bai, Y.; Yilihamu, A.; Ma, Q.; Yang, S.; Wu, D.; Yang, S.-T. Carboxylation as an effective approach to improve the adsorption performance of graphene materials for Cu2+ removal. Sci. Total. Environ. 2019, 682, 591–600. [Google Scholar] [CrossRef]

- Cui, M.; Park, S.-J.; Kim, S. Carboxylated group effect of graphene oxide on capacitance performance of Zr-based metal organic framework electrodes. J. Inorg. Organomet. Polym. Mater. 2021, 31, 1939–1945. [Google Scholar] [CrossRef]

- Yuan, Y.; Gao, X.; Wei, Y.; Wang, X.; Wang, J.; Zhang, Y.; Gao, C. Enhanced desalination performance of carboxyl functionalized graphene oxide nanofiltration membranes. Desalination 2017, 405, 29–39. [Google Scholar] [CrossRef]

- Guo, S.; Raya, J.; Ji, D.; Nishina, Y.; Ménard-Moyon, C.; Bianco, A. Is carboxylation an efficient method for graphene oxide functionalization? Nanoscale Adv. 2020, 2, 4085–4092. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Ding, R.; Shi, W.; Xu, Q.; Liu, E. Ternary Ni-Co-F nanocrystal-based supercapacitors. Chem.-Eur. J. 2017, 23, 6896–6904. [Google Scholar] [CrossRef]

- Kong, M.; Wang, Z.; Wang, W.; Ma, M.; Liu, D.; Hao, S.; Kong, R.; Du, G.; Asiri, A.M.; Yao, Y.; et al. NiCoP nanoarray: A superior pseudocapacitor electrode with high areal capacitance. Chem.-Eur. J. 2017, 23, 4435–4441. [Google Scholar] [CrossRef]

- Cheng, H.; Xiao, R.; Bian, H.; Li, Z.; Zhan, Y.; Tsang, C.K.; Chung, C.; Lu, Z.; Li, Y.Y. Periodic porous silicon thin films with interconnected channels as durable anode materials for lithium ion batteries. Mater. Chem. Phys. 2014, 144, 25–30. [Google Scholar] [CrossRef]

- Wang, J.; Zhong, Q.; Xiong, Y.; Cheng, D.; Zeng, Y.; Bu, Y. Fabrication of 3D Co-doped Ni-based MOF hierarchical micro-flowers as a high-performance electrode material for supercapacitors. Appl. Surf. Sci. 2019, 483, 1158–1165. [Google Scholar] [CrossRef]

- Gittins, J.W.; Balhatchet, C.J.; Chen, Y.; Liu, C.; Madden, D.G.; Britto, S.; Golomb, M.J.; Walsh, A.; Fairen-Jimenez, D.; Dutton, S.E.; et al. Insights into the electric double-layer capacitance of two-dimensional electrically conductive metal–organic frameworks. J. Mater. Chem. A 2021, 9, 16006–16015. [Google Scholar] [CrossRef]

- Ramachandran, R.; Zhao, C.; Luo, D.; Wang, K.; Wang, F. Synthesis of copper benzene-1, 3, 5-tricarboxylate metal organic frameworks with mixed phases as the electrode material for supercapacitor applications. Appl. Surf. Sci. 2018, 460, 33–39. [Google Scholar] [CrossRef]

- Rajak, R.; Saraf, M.; Kumar, P.; Natarajan, K.; Mobin, S.M. Construction of a Cu-based metal–organic framework by employing a mixed-ligand strategy and its facile conversion into nanofibrous CuO for electrochemical energy storage applications. Inorg. Chem. 2021, 60, 16986–16995. [Google Scholar] [CrossRef]

- Zou, J.; Xie, D.; Xu, J.; Song, X.; Zeng, X.; Wang, H.; Zhao, F. Rational design of honeycomb Ni-Co LDH/graphene composite for remarkable supercapacitor via ultrafast microwave synthesis. Appl. Surf. Sci. 2022, 571, 151322. [Google Scholar] [CrossRef]

- Wang, J.; Polleux, J.; Lim, J.; Dunn, B. Pseudocapacitive contributions to electrochemical energy storage in TiO2 (anatase) nanoparticles. J. Phys. Chem. C 2007, 111, 14925–14931. [Google Scholar] [CrossRef]

- Deng, Y.; Wang, X.; Wang, Z.; Wang, X.; Li, Z.; Wang, L.; Zhou, C.; Chen, D.; Luo, Y. Yolk–shell structured nickel cobalt sulfide and carbon nanotube composite for high-performance hybrid supercapacitors. Energy Fuels 2021, 35, 5342–5351. [Google Scholar] [CrossRef]

- Mao, F.; Li, Y.; Zou, Z.; Huang, B.; Yang, J.; Yao, J. Zn2+ storage performance and structural change of orthorhombic V2O5 nanowires as the cathode material for rechargeable aqueous zinc-ion batteries. Electrochim. Acta 2021, 397, 139255. [Google Scholar] [CrossRef]

- Ninawe, P.; Gupta, K.; Ballav, N. Chemically integrating a 2D metal–organic framework with 2D functionalized graphene. Inorg. Chem. 2021, 60, 19079–19085. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Ding, K.; Tian, H.; Yao, M.; Nath, B.; Deng, W.; Wang, Y.; Xu, G. Conductive metal–organic framework nanowire array electrodes for high-performance solid-state supercapacitors. Adv. Funct. Mater. 2017, 27, 1702067. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Y.; Xie, Z.; Li, Y.; Liu, Y.; Sun, J.; Ma, Y.; Terasaki, O.; Chen, L. Inside cover: Conjugated copper–catecholate framework electrodes for efficient energy storage. Angew. Chem. Int. Ed. 2020, 59, 962. [Google Scholar] [CrossRef]

- Wang, J.; Zhong, Q.; Zeng, Y.; Cheng, D.; Xiong, Y.; Bu, Y. Rational construction of triangle-like nickel-cobalt bimetallic metal-organic framework nanosheets arrays as battery-type electrodes for hybrid supercapacitors. J. Colloid Interface Sci. 2019, 555, 42–52. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.; Zhang, Y.; Li, W.; Ye, P.; Nie, Y.; Zhu, M.; Li, S. Hierarchical 2D Cu-MOF@Graphene-Based Hybrids for Supercapacitor Electrodes. Nanomaterials 2025, 15, 1628. https://doi.org/10.3390/nano15211628

Yang M, Zhang Y, Li W, Ye P, Nie Y, Zhu M, Li S. Hierarchical 2D Cu-MOF@Graphene-Based Hybrids for Supercapacitor Electrodes. Nanomaterials. 2025; 15(21):1628. https://doi.org/10.3390/nano15211628

Chicago/Turabian StyleYang, Mengkun, Yongqiang Zhang, Wenjie Li, Pingwei Ye, Yijing Nie, Maiyong Zhu, and Sumin Li. 2025. "Hierarchical 2D Cu-MOF@Graphene-Based Hybrids for Supercapacitor Electrodes" Nanomaterials 15, no. 21: 1628. https://doi.org/10.3390/nano15211628

APA StyleYang, M., Zhang, Y., Li, W., Ye, P., Nie, Y., Zhu, M., & Li, S. (2025). Hierarchical 2D Cu-MOF@Graphene-Based Hybrids for Supercapacitor Electrodes. Nanomaterials, 15(21), 1628. https://doi.org/10.3390/nano15211628