Sputter-Deposited Superconducting Thin Films for Use in SRF Cavities

Abstract

1. Introduction

2. Superconductivity and SRF Operation

2.1. Fundamentals

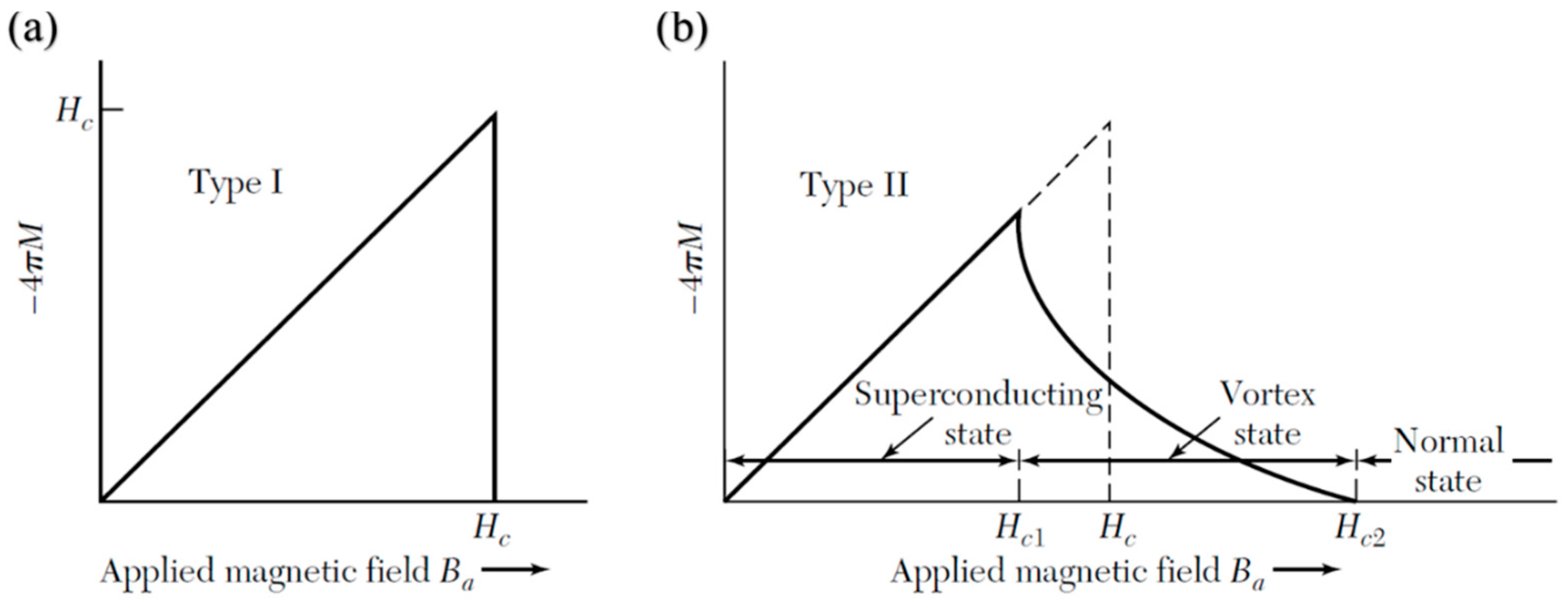

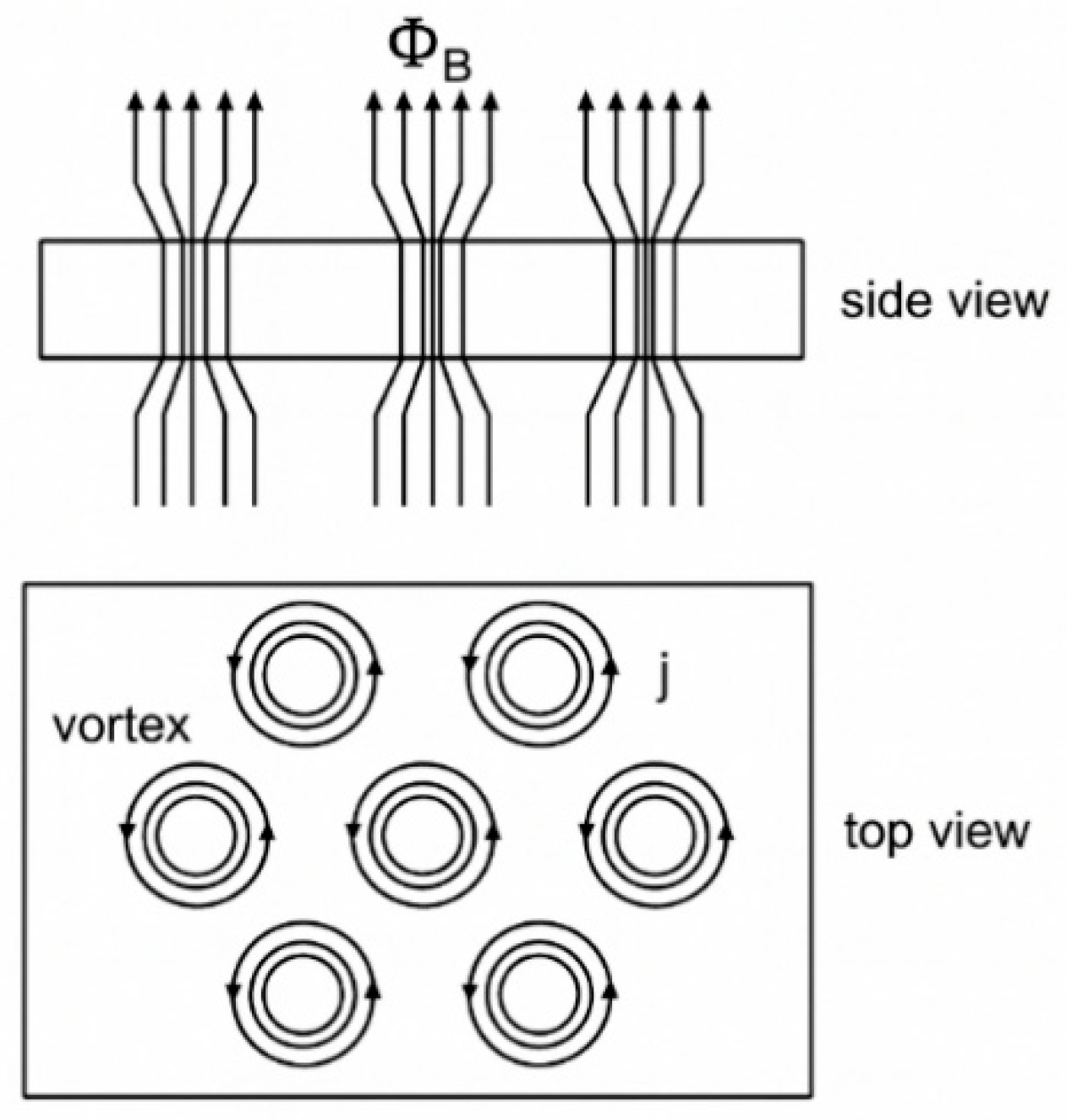

2.2. Superconductivity Theory

2.3. Surface Resistance in RF Fields

3. SRF Cavity Performance: Figures of Merit and Material Strategies

4. Sputtering Techniques for SRF Thin-Film Coatings

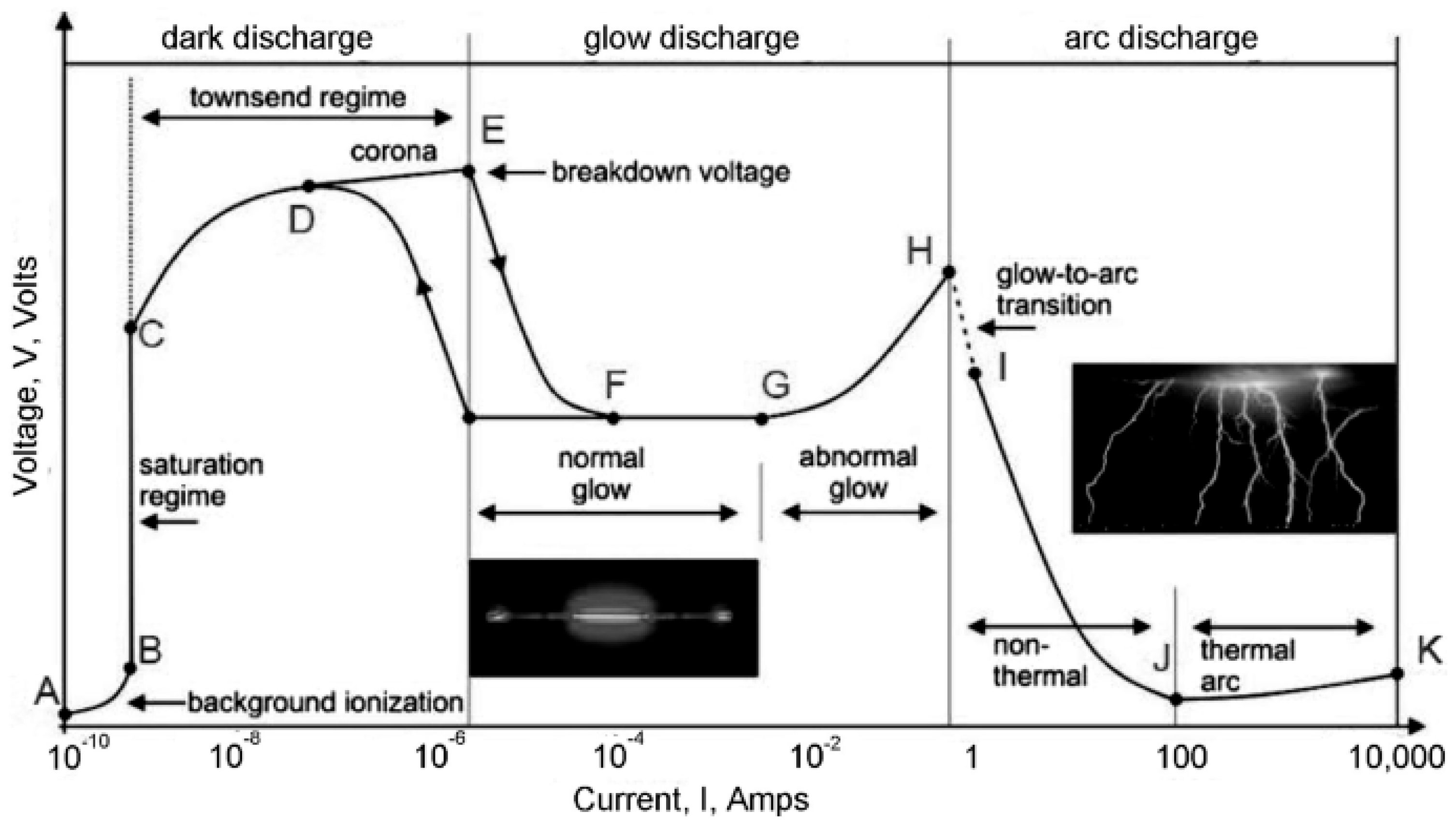

4.1. Principles of Plasma Generation in Sputtering

4.2. DC Diode Sputtering

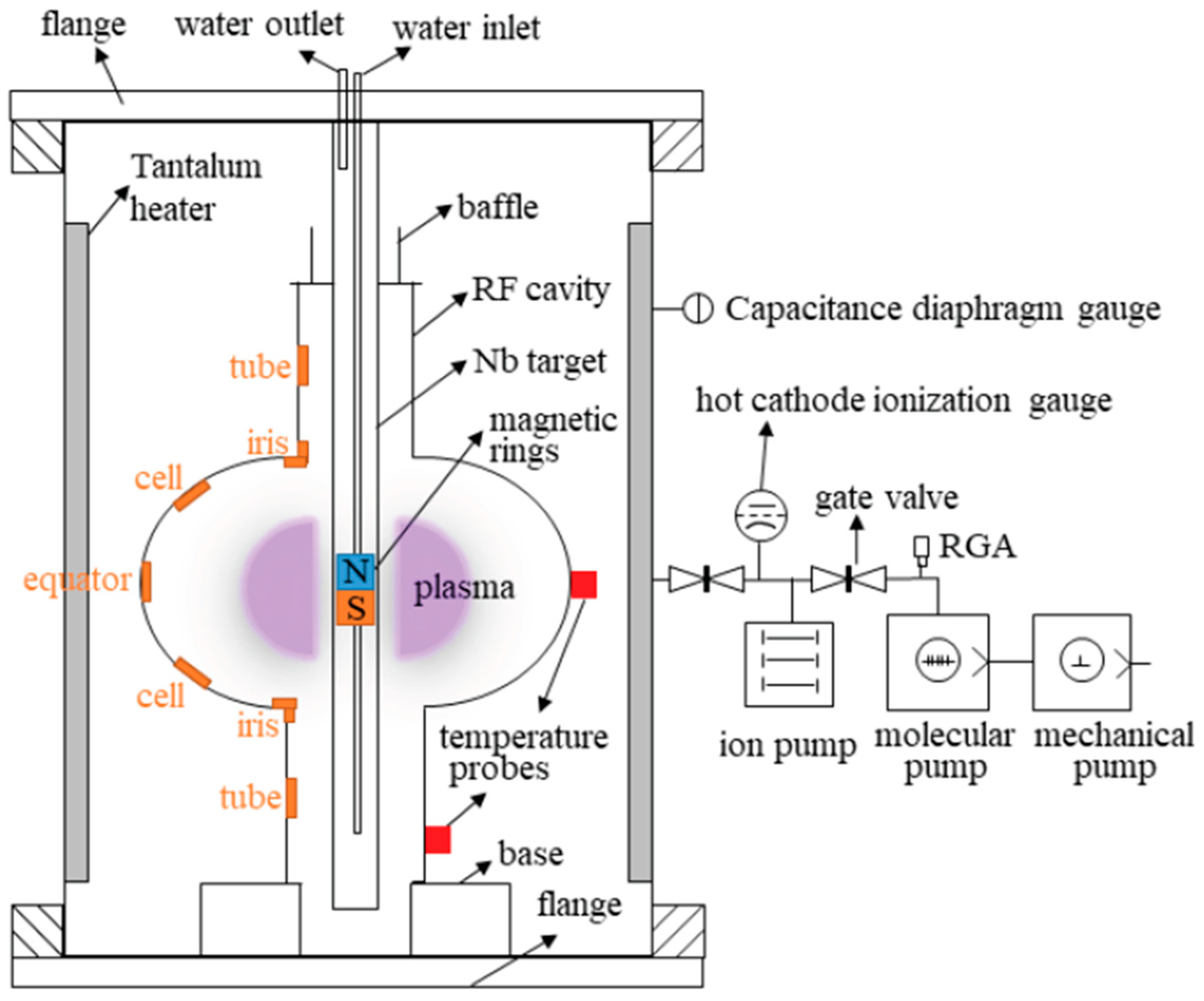

4.3. RF Diode Sputtering

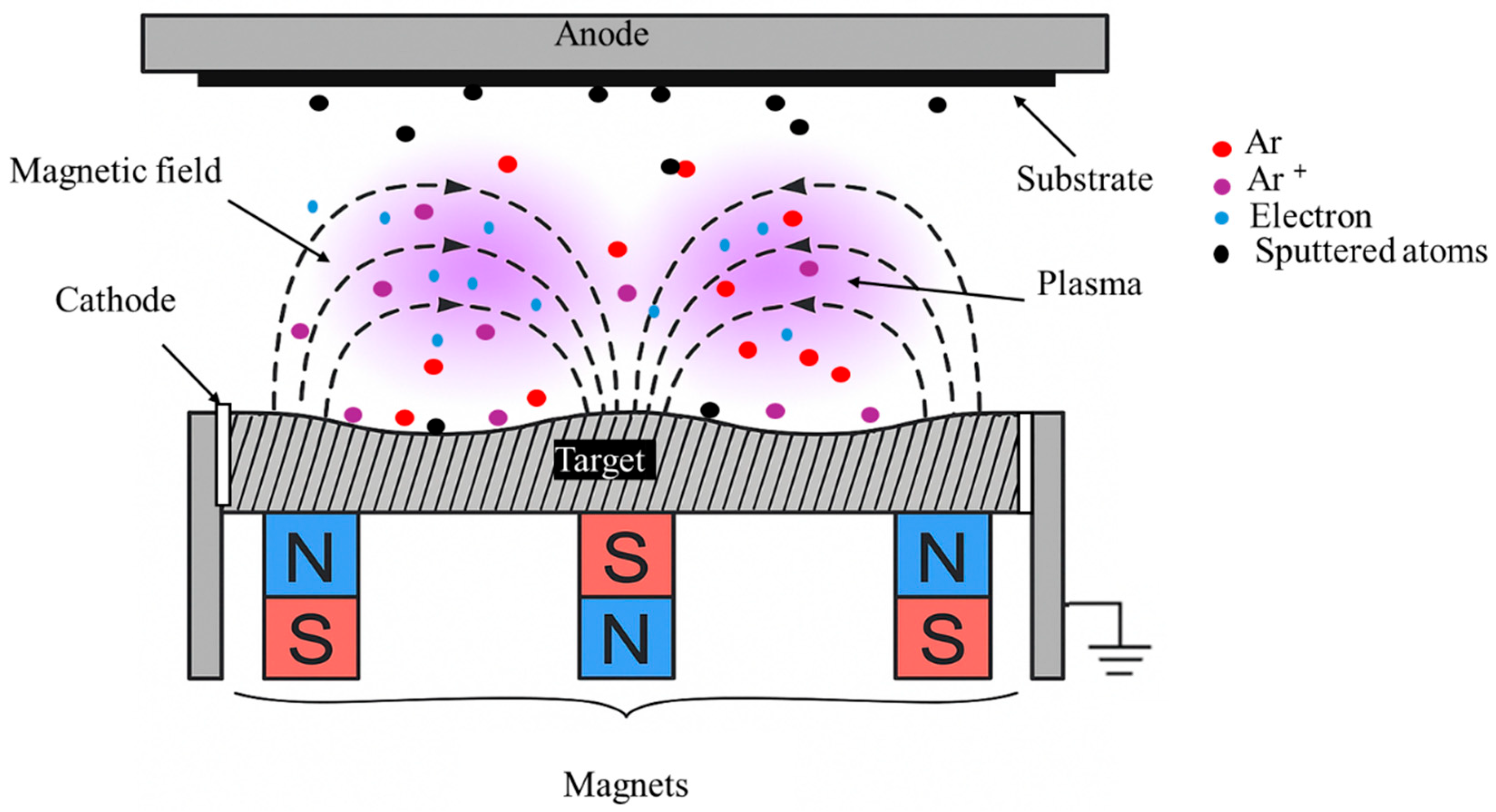

4.4. Magnetron Sputtering

4.5. Reactive Sputtering

4.6. Pulsed DC Magnetron Sputtering

4.7. High Power Impulse Magnetron Sputtering (HiPIMS)

5. Sputtered Superconducting Materials for SRF Cavities

5.1. Niobium (Nb)

5.2. Niobium Nitride (NbN)

5.3. Niobium Titanium Nitride (NbTiN)

5.4. Niobium Tin (Nb3Sn)

5.5. Niobium Aluminide (Nb3Al)

5.6. Vanadium Silicide (V3Si)

5.7. Mo-Re Alloys

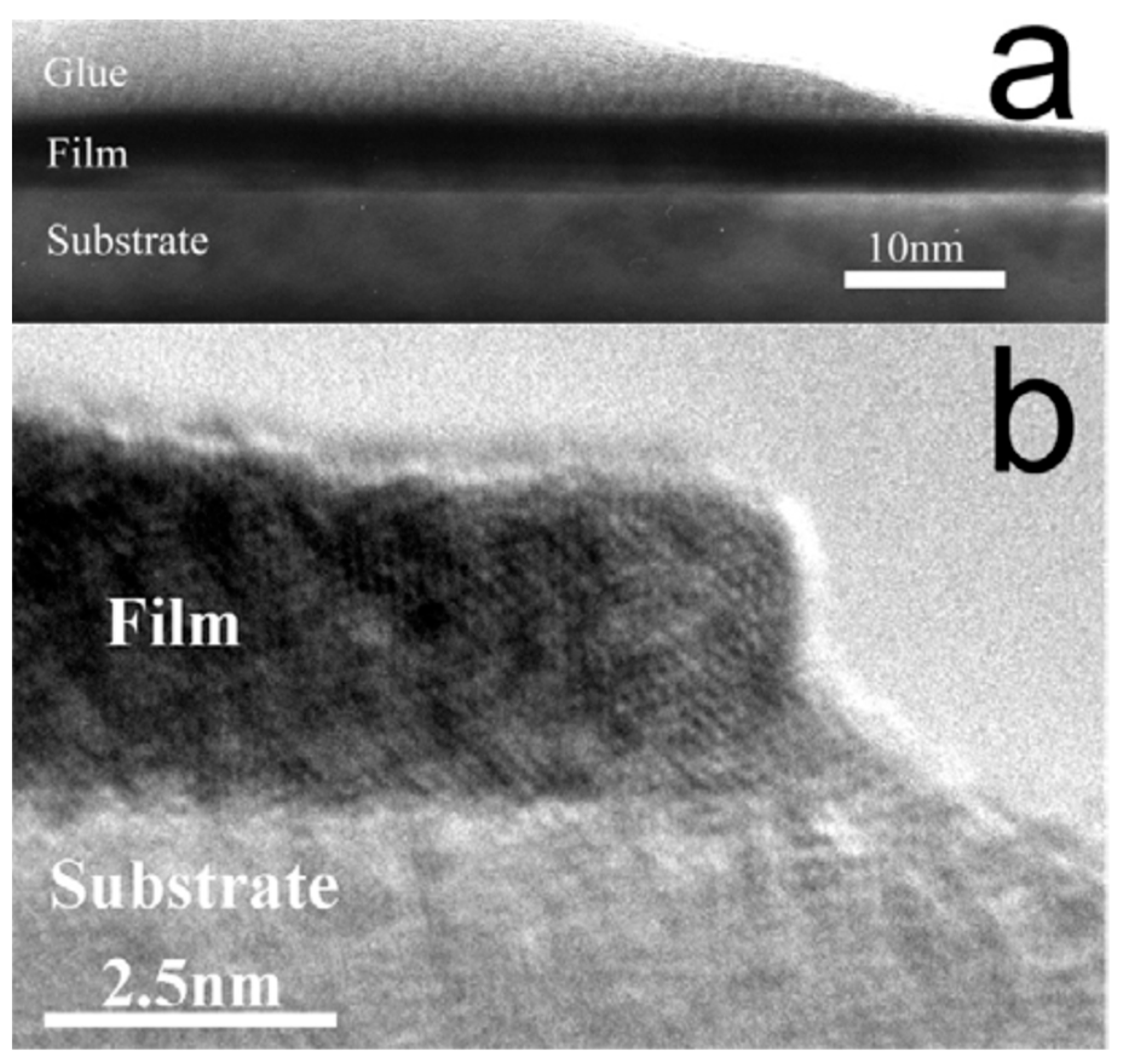

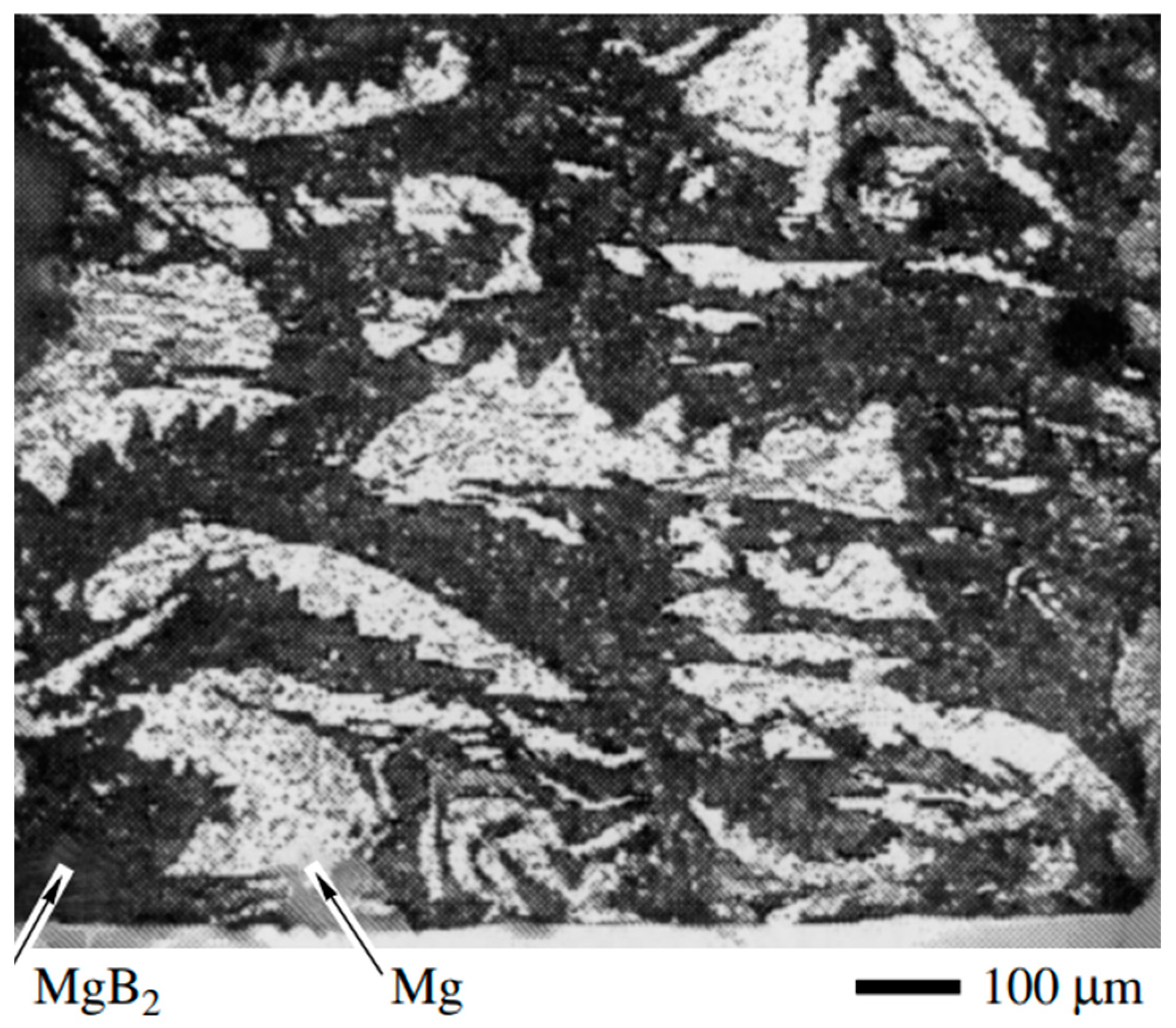

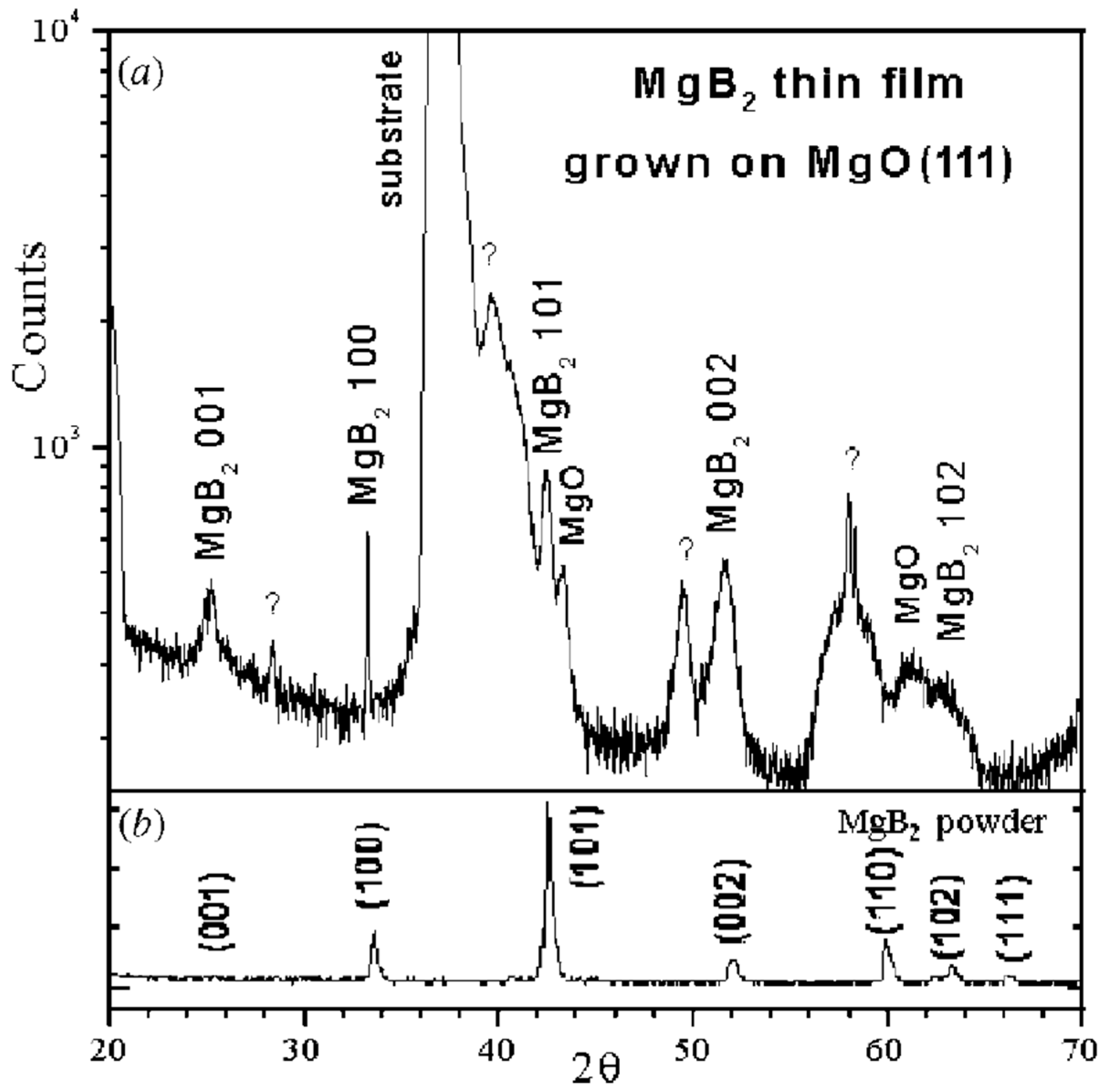

5.8. Magnesium Diboride (MgB2)

6. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Simon, N.; Drexler, E.; Reed, R. Properties of Copper and Copper Alloys at Cryogenic Temperatures. 1992. Available online: https://www.osti.gov/biblio/5340308 (accessed on 17 July 2025).

- Padamsee, H. Superconducting Radiofrequency Technology for Accelerators: State of Art and Emerging Trends; Wiley-VCH: Weinheim, Germany, 2023. [Google Scholar]

- Singer, W. Fabrication of elliptical SRF cavities. Supercond. Sci. Technol. 2017, 30, 33001. [Google Scholar] [CrossRef]

- Hryhorenko, O.; Antoine, C.Z.; Magnin, W.; Rajkumar, M.; Brisset, F.; Guilet, S.; Longuevergne, D. An Innovative Approach of Surface Polishing for SRF Cavity Applications. JMMP 2023, 7, 62. [Google Scholar] [CrossRef]

- Padamsee, H.; Seaman, A.K.; Shemelin, V.D. World Record Accelerating Gradient Achieved in a Superconducting Niobium RF Cavity. In Proceedings of the 2005 Particle Accelerator Conference, Knoxville, TN, USA, 16–20 May 2005. [Google Scholar]

- Nagata, T.; Masui, H.; Shinozawa, S.; Inoue, H.; Kako, E.; Yamanaka, M.; Murakami, M. Development of High Purity Niobium Components and Cavities for SRF Accelerator. In Proceedings of the 18th International Conference on RF Superconductivity (SRF′17), Lanzhou, China, 17–21 July 2017; JACoW: Geneva, Switzerland, 2018. [Google Scholar] [CrossRef]

- Vaglio, R. Alternative Superconducting Materials for RF Cavity Applications. In Proceedings of the 1997 Workshop on RF Superconductivity, Padova, Italy, 6–10 October 1997. [Google Scholar]

- Ge, G.M.; Eichhorn, R.G.; Elmore, B.; Furuta, F.; Gonnella, D.; Gruber, T.; Hoffstaetter, G.H.; Kaufman, J.J.; Liepe, M.; O’Connell, T.I.; et al. Performance of nitrogen-doped 9-cell srf cavities in vertical tests at Cornell University. In Proceedings of the SRF2015, Whistler, BC, Canada, 13–18 September 2015. [Google Scholar]

- Kelly, M.P.; Reid, T. Surface processing for bulk niobium superconducting radio frequency cavities. Supercond. Sci. Technol. 2017, 30, 43001. [Google Scholar] [CrossRef]

- Dhakal, P. Nitrogen doping and infusion in SRF cavities: A review. Phys. Open 2020, 5, 100034. [Google Scholar] [CrossRef]

- Terrazas, C.A.; Mireles, J.; Gaytan, S.M.; Morton, P.A.; Hinojos, A.; Frigola, P.; Wicker, R.B. Fabrication and characterization of high-purity niobium using electron beam melting additive manufacturing technology. Int. J. Adv. Manuf. Technol. 2015, 84, 1115–1126. [Google Scholar] [CrossRef]

- Lilje, L. State of the Art SRF Cavity Performance. In Proceedings of the LINAC 2004, Luebeck, Germany, 16–20 August 2004. [Google Scholar]

- Maxfield, B.W.; McLean, W.L. Superconducting Penetration Depth of Niobium. Phys. Rev. 1965, 139, A1515–A1522. [Google Scholar] [CrossRef]

- Kubo, S.; Asahi, M.; Hikita, M.; Igarashi, M. Magnetic penetration depths in superconducting NbN films prepared by reactive dc magnetron sputtering. Appl. Phys. Lett. 1984, 44, 258–260. [Google Scholar] [CrossRef]

- Tückmantel, J. The LEP2 Superconducting RF System CERN-SL-98-051-RF. 1998. Available online: https://cds.cern.ch/record/365878 (accessed on 15 July 2025).

- About HIE-ISOLDE|HIE-ISOLDE. Available online: https://hie-isolde-project.web.cern.ch/node/35217.html (accessed on 1 September 2025).

- CERN. The Large Hadron Collider. Available online: https://home.cern/science/accelerators/large-hadron-collider (accessed on 1 September 2025).

- Calatroni, S. 20 Years of experience with the Nb/Cu technology for superconducting cavities and perspectives for future developments. Phys. C Supercond. 2006, 441, 95–101. [Google Scholar] [CrossRef]

- Posen, S.; Liepe, M. SRF Cavities Beyond Niobium: Challenges and Potential. In Proceedings of the 2013 PAC, Pasadena, CA USA, 29 September–4 October 2013. [Google Scholar]

- Palmieri, V.; Vaglio, R. Thermal contact resistance at the Nb/Cu interface as a limiting factor for sputtered thin film RF superconducting cavities. Supercond. Sci. Technol. 2016, 29, 15004. [Google Scholar] [CrossRef]

- Ngampruetikorn, V.; Sauls, J.A. Effect of inhomogeneous surface disorder on the superheating field of superconducting RF cavities. Phys. Rev. Res. 2019, 1, 12015. [Google Scholar] [CrossRef]

- Gurevich, A.; Kubo, T.; Sauls, J.A. Challenges and opportunities of srf theory for next generation particle accelerators. arXiv 2022, arXiv:2203.08315. [Google Scholar] [CrossRef]

- Valente-Feliciano, A.-M. Superconducting RF materials other than bulk niobium: A review. Supercond. Sci. Technol. 2016, 29, 113002. [Google Scholar] [CrossRef]

- Gurevich, A. Enhancement of rf breakdown field of superconductors by multilayer coating. Appl. Phys. Lett. 2006, 88, 012511. [Google Scholar] [CrossRef]

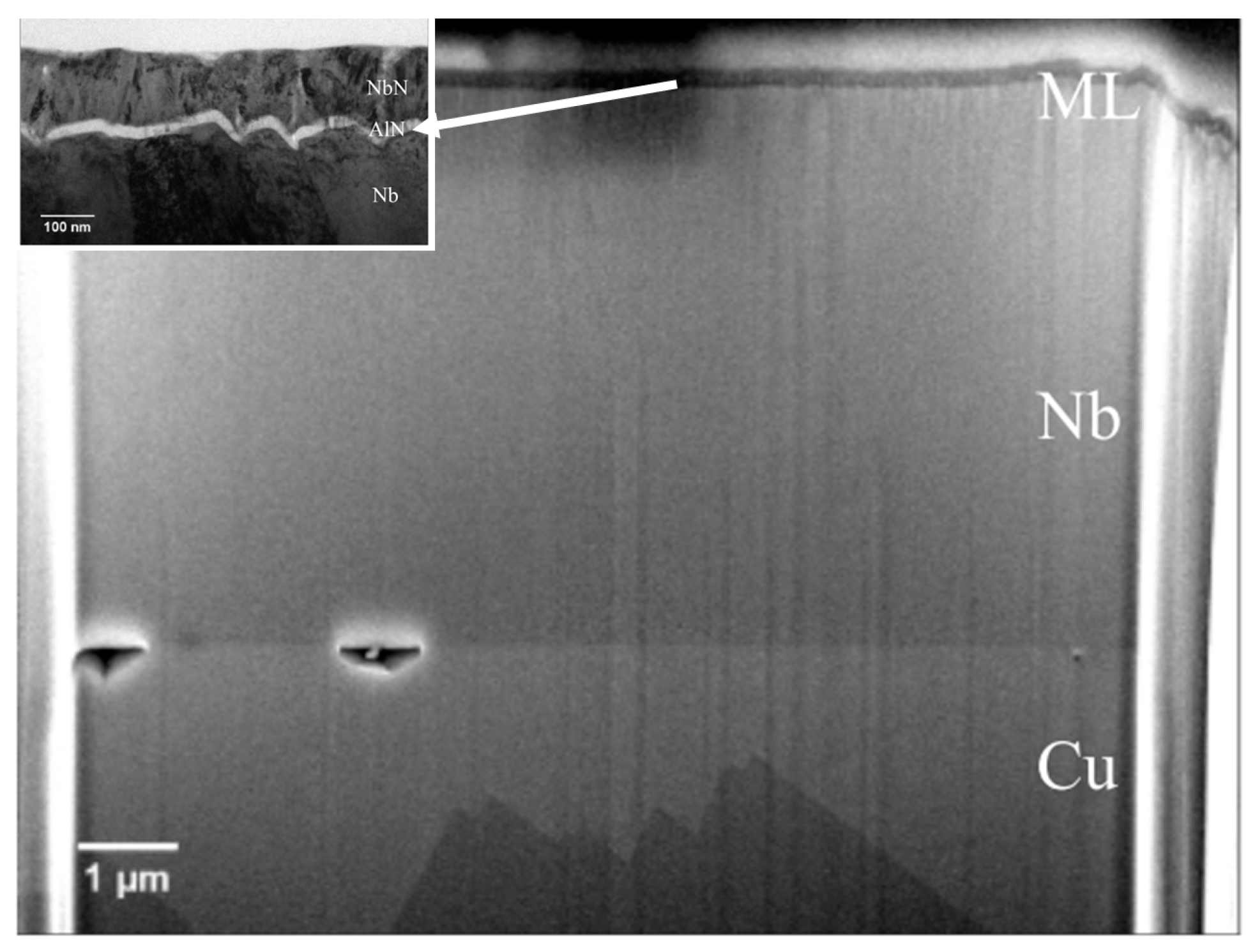

- Burton, M.C.; Beebe, M.; Lukaszew, R.A.; Riso, J.M. Superconducting NbN-Based Multilayer and NbTiN Thin Films for the Enhancement of SRF Accelerator Cavities. In Proceedings of the SRF2015, Whistler, BC, Canada, 13–18 September 2015. [Google Scholar]

- Katayama, R.; Hayano, H.; Kubo, T.; Saeki, T.; Ito, H.; Iwashita, Y.; Tongu, H.; Antoine, C.Z.; Ito, R.; Nagata, T. Evaluation of the superconducting characteristics of multi-layer thin-film structures of NbN and SiO2 on pure Nb substrate. arXiv 2019, arXiv:1907.03514. [Google Scholar] [CrossRef]

- Ito, H.; Hayano, H.; Kubo, T.; Saeki, T.; Katayama, R.; Iwashita, Y.; Tongu, H.; Ito, R.; Nagata, T.; Antoine, C.Z. Lower critical field measurement of NbN multilayer thin film superconductor at KEK. arXiv 2019, arXiv:1907.03410. [Google Scholar] [CrossRef]

- Valente, A.; Eremeev, G.; Phillips, H.; Reece, C.; Spradlin, J.; Yang, Q.; Lukaszew, R. NbTiN Based SIS Multilayer Structures for SRF Applications; JLAB-ACC-13-1716; DOE/OR/23177-2844; Thomas Jefferson National Accelerator Facility (TJNAF): Newport News, VA, USA, 2013. Available online: https://www.osti.gov/biblio/1164412 (accessed on 1 June 2025).

- Sharma, R.G. A Review of Theories of Superconductivity. Superconductivity 2021, 214, 123–160. [Google Scholar] [CrossRef]

- Hott, R.; Kleiner, R.; Wolf, T.; Zwicknagl, G. Review on Superconducting Materials. arXiv 2013, arXiv:1306.0429. [Google Scholar] [CrossRef]

- Fossheim, K.; Sudbø, A. Superconductivity; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- Onnes, H.K. Comm. Leiden Nr. 108. Proc. Roy. Acad. Amst. 1908, 108. Available online: https://dwc.knaw.nl/DL/publications/PU00013525.pdf (accessed on 1 September 2025).

- Meissner, W.; Ochsenfeld, R. Ein neuer Effekt bei Eintritt der Supraleitfhigkeit. Naturwissenschaften 1933, 21, 787–788. [Google Scholar] [CrossRef]

- Deaver, B.S.; Fairbank, W.M. Experimental Evidence for Quantized Flux in Superconducting Cylinders. Phys. Rev. Lett. 1961, 7, 43–46. [Google Scholar] [CrossRef]

- Kittel, C. Introduction to Solid State Physics, 8th ed.; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Beringer, D. T01-Thin Film Approaches to the Srf Cavity Problem: Fabrication and Characterization of Superconducting Thin Films. Ph.D. Thesis, The College of William and Mary, Williamsburg, VA, USA, 2016. [Google Scholar]

- Gorter, C.; Casimir, H. On supraconductivity I. Physica 1934, 1, 306–320. [Google Scholar] [CrossRef]

- London, F.; London, H. The electromagnetic equations of the supraconductor. Proc. R. Soc. Lond. A 1935, 149, 71–88. [Google Scholar] [CrossRef]

- Ginzburg, V.L.; Landau, L.D. On the Theory of Superconductivity. Zhurnal Eksperimental’noi I Teor. Fiz. 1950, 20, 1064–1082. [Google Scholar]

- Bardeen, J.; Cooper, L.N.; Schrieffer, J.R. Theory of Superconductivity. Phys. Rev. 1957, 108, 1175–1204. [Google Scholar] [CrossRef]

- Padamsee, H. RF Superconductivity: Science, Technology, and Applications; Wiley-VCH: Weinheim, Germany, 2009. [Google Scholar]

- Burton, M.C.; Palczewski, A.D.; Phillips, H.L.; Reece, C.E.; Valente-Feliciano, A.-M.; Lukaszew, R.A. RF Results of Nb Coated SRF Accelerator Cavities via HiPIMS. In Proceedings of the LINAC2018, Beijing, China, 16–21 September 2018; JACoW Publishing: Geneva, Switzerland, 2018. [Google Scholar] [CrossRef]

- Romanenko, A.; Grassellino, A.; Barkov, F.; Ozelis, J.P. Effect of mild baking on superconducting niobium cavities investigated by sequential nanoremoval. Phys. Rev. ST Accel. Beams 2013, 16, 12001. [Google Scholar] [CrossRef]

- Bayros, K.; Cyster, M.J.; Smith, J.S.; Cole, J.H. Influence of pinholes and weak-points in aluminum-oxide Josephson junctions. Phys. Rev. Mater. 2024, 8, 46202. [Google Scholar] [CrossRef]

- Senevirathne, I.H.; Beverstock, D.R.; Valente-Feliciano, A.-M.; Gurevich, A.V.; Delayen, J.R.; Beverstock, D.R. Investigation of the Multilayer Shielding Effect Through NbTiN-AIN Investigation of the Multilayer Shielding Effect Through NbTiN-AIN Coated Bulk Niobium Coated Bulk Niobium. In Proceedings of the 21st International Conference on RF Superconductivity, Grand Rapids, MI, USA, 25–30 June 2023. [Google Scholar]

- Subrahmanyam, A. Plasma Overview and the Basics of Cold Plasma. Material Synthesis. In Cold Plasma in Nano-Matter Synthesis; Springer: Cham, Switzerland, 2024; pp. 27–101. ISBN 978-3-031-64041-4. [Google Scholar]

- Wasa, K.; Kanno, I.; Kotera, H. Handbook of Sputter Deposition Technology: Fundamentals and Applications for Functional Thin Films, Nanomaterials and MEMS, 2nd ed.; William Andrew: Waltham, MA, USA, 2012. [Google Scholar]

- Ohring, M. Materials Science of Thin Films: Deposition and Structure, 2nd ed.; Academic Press: San Diego CA, USA, 2002. [Google Scholar]

- Lundin, D.; Minea, T.; Gudmundsson, J.T. High Power Impulse Magnetron Sputtering: Fundamentals, Technologies, Challenges and Applications; Elsevier Science: Amsterdam, The Netherlands, 2019; ISBN 9780128124543. [Google Scholar]

- Bandorf, R.; Sittinger, V.; Bräuer, G. High Power Impulse Magnetron Sputtering—HIPIMS. In Comprehensive Materials Processing; Hashmi, S., Batalha, G.F., van Tyne, C.J., Yilbas, B., Eds.; Elsevier: Oxford, UK, 2014; pp. 75–99. ISBN 978-0-08-096533-8. [Google Scholar]

- Borowski, P.; Myśliwiec, J. Recent Advances in Magnetron Sputtering: From Fundamentals to Industrial Applications. Coatings 2025, 15, 922. [Google Scholar] [CrossRef]

- Sublet, A.; Venturini Delsolaro, W.; Therasse, M.; Bartova, B.; Calatroni, S.; Jecklin, N.; Zhang, P.; Cantoni, M.; Aviles Santillana, I.; Mondino, I. Nb Coated HIE-ISOLDE QWR Superconducting Accelerating Cavities: From Process Development to Series Production. In Proceedings of the IPAC2014, Dresden, Germany, 15–20 June 2014. [Google Scholar]

- Junginger, T.; Calatroni, S.; Sublet, A.; Terenziani, G.; Prokscha, T.; Salman, Z.; Suter, A.; Proslier, T.; Zasadzinski, J. A low energy muon spin rotation and point contact tunneling study of niobium films prepared for superconducting cavities. Supercond. Sci. Technol. 2017, 30, 125013. [Google Scholar] [CrossRef]

- Baptista, A.; Silva, F.; Porteiro, J.; Míguez, J.; Pinto, G. Sputtering Physical Vapour Deposition (PVD) Coatings: A Critical Review on Process Improvement and Market Trend Demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef]

- Strenzke, V.; Weber, A.; Heydolph, P.; Moch, I.; González Díaz-Palacio, I.; Hillert, W.; Zierold, R.; Tiemann, L.; Blick, R.H. Challenges and solutions in RF sputtering of superconducting Nb for nanostructuring processes. J. Appl. Phys. 2024, 136, 205301. [Google Scholar] [CrossRef]

- Logan, J.S.R.F. diode sputtering. Thin Solid Film. 1990, 188, 307–321. [Google Scholar] [CrossRef]

- Kelly, P.; Arnell, R. Magnetron sputtering: A review of recent developments and applications. Vacuum 2000, 56, 159–172. [Google Scholar] [CrossRef]

- Keil, E. Status of LEP2 and LHC. AIP Conf. Proc. 1997, 397, 113–127. [Google Scholar] [CrossRef]

- Gudmundsson, J.T.; Lundin, D. Introduction to magnetron sputtering. In High Power Impulse Magnetron Sputtering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–48. [Google Scholar]

- Karthikeyan, S.; Hill, A.E.; Cowpe, J.S.; Pilkington, R.D. The influence of operating parameters on pulsed D.C. magnetron sputtering plasma. Vacuum 2010, 85, 634–638. [Google Scholar] [CrossRef]

- Musson, J.; Elsayed-Ali, H.E. Commissioning of a modulated pulse-power magnetron sputtering system for depositing niobium thin films. Vacuum 2024, 229, 113547. [Google Scholar] [CrossRef]

- Awais, A.; Lunt, A.; Sublet, A.; Rosaz, G.; Taborelli, M. Double Cathode Configuration for the Nb Coating of HIE-ISOLDE Cavities. In Proceedings of the SRF2017, Lanzhou, China, 17–21 July 2017; Joint Accelerator Conferences Website (JACoW): Geneva, Switzerland, 2018; pp. 854–858. [Google Scholar]

- Gudmundsson, J.T.; Brenning, N.; Lundin, D.; Helmersson, U. High power impulse magnetron sputtering discharge. J. Vac. Sci. Technol. A Vac. Surf. Film. 2012, 30, 030801. [Google Scholar] [CrossRef]

- Anders, A. Tutorial: Reactive high power impulse magnetron sputtering (R-HiPIMS). J. Appl. Phys. 2017, 121, 171101. [Google Scholar] [CrossRef]

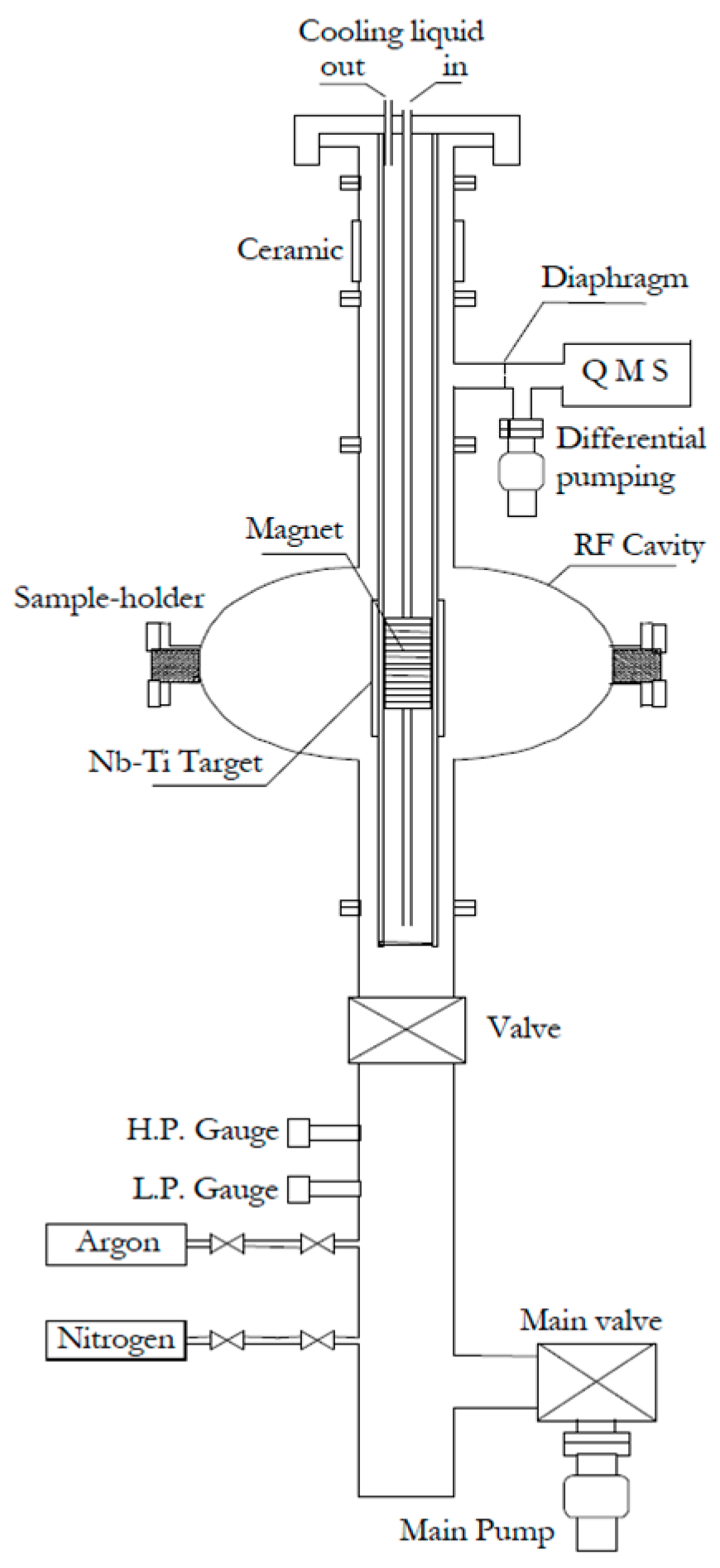

- Reddy, L.R.V.B.; Zubtsovskii, A.; Jiang, X. Effects of deposition parameters on superconducting NbTiN thin films for use in SRF multilayer structures. In Proceedings of the 11th International Workshop on Thin Films and New Ideas for Pushing the Limits of RF Superconductivity-TFSRF2024, Paris, France, 16–20 September 2024; NOVel Accelerator technology for efficient LIght Sources (NOVALIS): Darmstadt, Germany, 2023. [Google Scholar]

- Roach, W.M.; Beringer, D.B.; Skuza, J.R.; Oliver, W.A.; Clavero, C.; Reece, C.E.; Lukaszew, R.A. Niobium thin film deposition studies on copper surfaces for superconducting radio frequency cavity applications. Phys. Rev. ST Accel. Beams 2012, 15, 062002. [Google Scholar] [CrossRef]

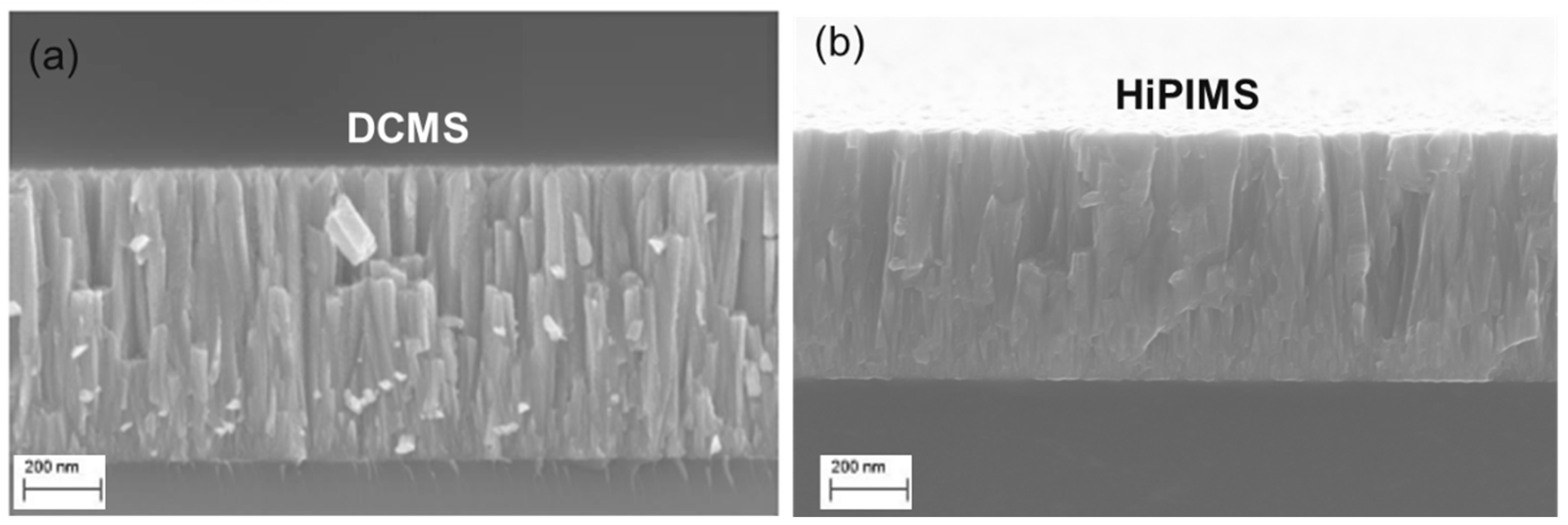

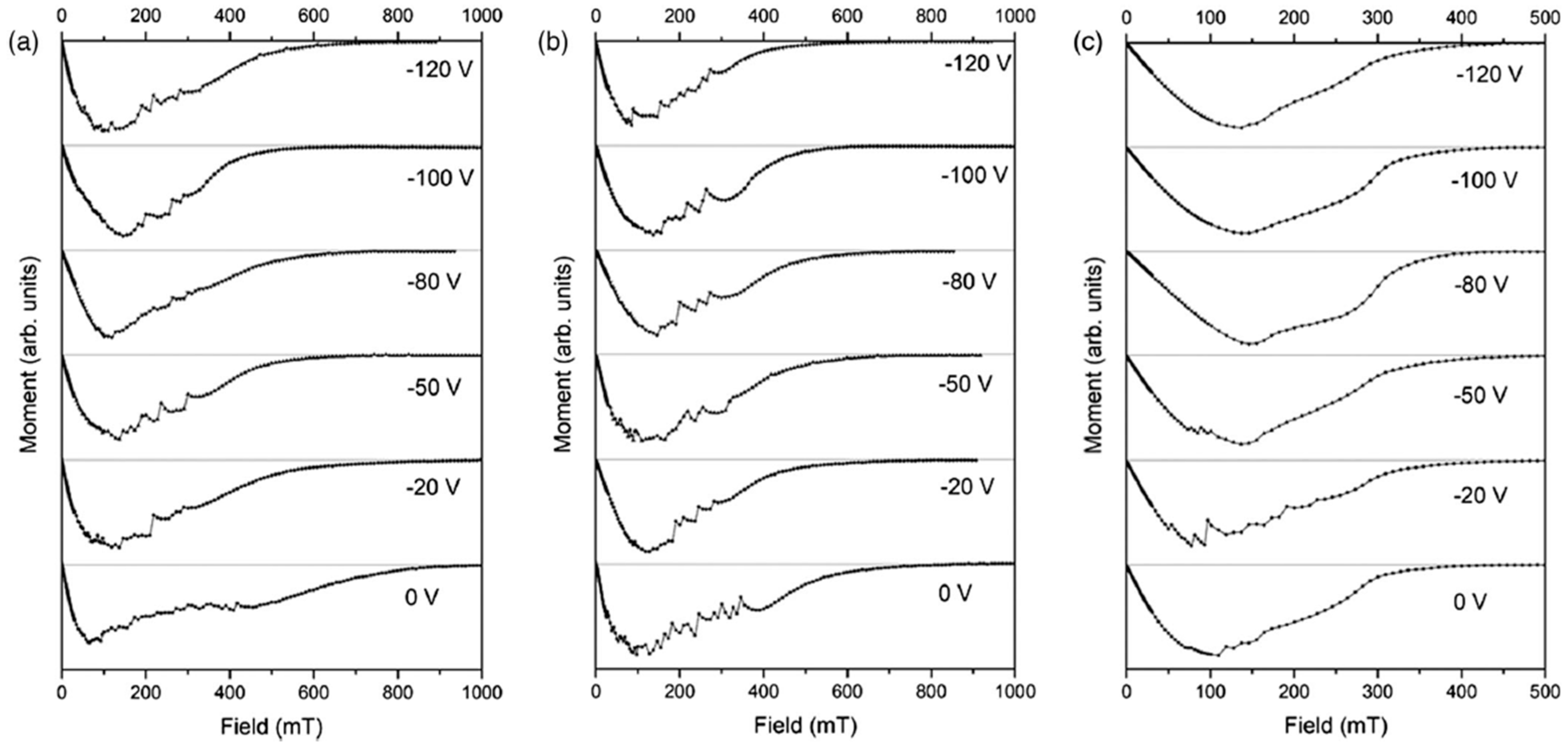

- Wilde, S.; Valizadeh, R.; Malyshev, O.B.; Stenning, G.B.G.; Sian, T.; Chesca, B. dc magnetometry of niobium thin film superconductors deposited using high power impulse magnetron sputtering. Phys. Rev. Accel. Beams 2018, 21, 073101. [Google Scholar] [CrossRef]

- Leith, S.; Qiao, J.; Vogel, M.; Seiler, E.; Ries, R.; Li, Y.; Wiktor, C.; Mueller, J.; Sakalli, Y.; Butz, B.; et al. HiPIMS deposition of superconducting Nb thin films onto Cu substrates. Vacuum 2023, 212, 112041. [Google Scholar] [CrossRef]

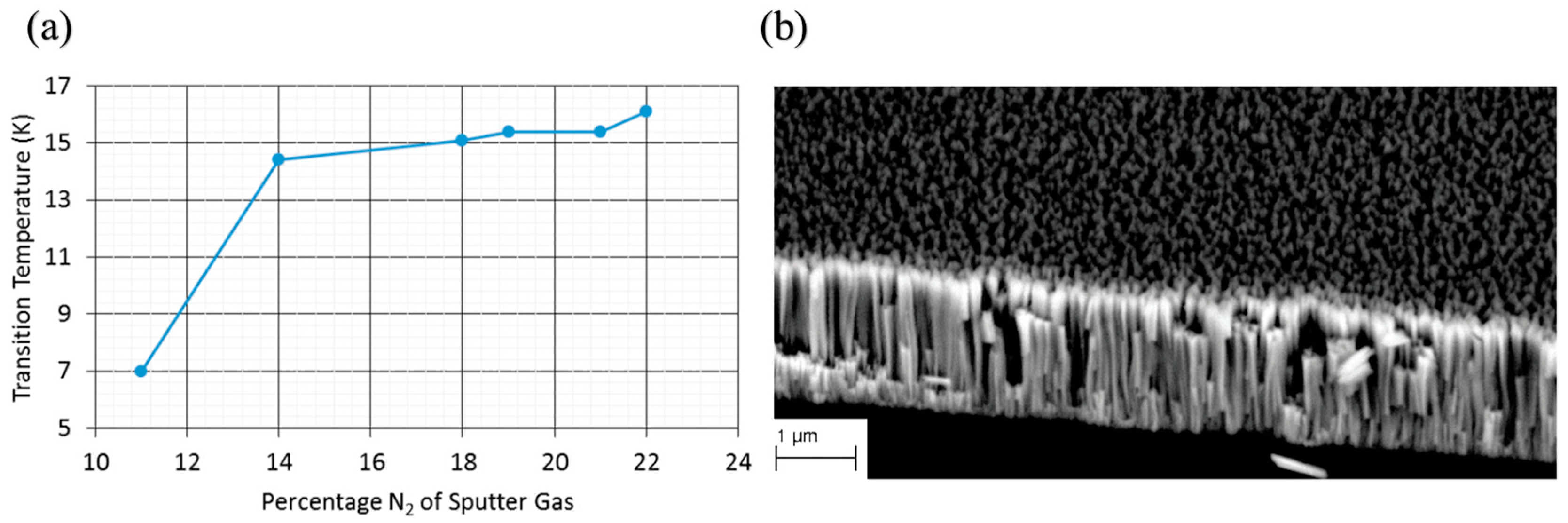

- Leith, S.; Vogel, M.; Fan, J.; Seiler, E.; Ries, R.; Jiang, X. Superconducting NbN thin films for use in superconducting radio frequency cavities. Supercond. Sci. Technol. 2021, 34, 25006. [Google Scholar] [CrossRef]

- Rao, P.N.; Swami, M.K.; Ghosh, A.; Jangir, R.; Rai, S.K. Influence of deposition pressure on microstructure, mechanical and electrical properties of niobium thin films. Thin Solid Film. 2024, 805, 140503. [Google Scholar] [CrossRef]

- Rao, P.N.; Swami, M.K.; Ghosh, A.; Jangir, R.; Rai, S.K. Studies on magnetron sputtered niobium thin films: Influence of deposition angle of sputtered atoms. Appl. Phys. A 2025, 131, 168. [Google Scholar] [CrossRef]

- Carlos, C.P.; Leith, S.; Rosaz, G.; Pfeiffer, S.; Senatore, C. Planar deposition of Nb thin films by HiPIMS for superconducting radiofrequency applications. Vacuum 2024, 227, 113354. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, X.; Tan, W.; Xiao, L.; Zhu, L.; Xie, D. Study on laser annealing of niobium films deposited on copper for RF superconducting cavities. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2020, 964, 163803. [Google Scholar] [CrossRef]

- He, P.; Dai, J.; Duan, H.; Kan, J.; Ma, Y.; Xin, T.; Yang, Y.; Zhang, P. Preparation and Characterization of Nb Films Deposited in SRF Cavity via HiPIMS. In Effects of Deposition Parameters on Superconducting NbTiN Thin Films for Use in SRF Multilayer Structures. Proceedings of the 21th International Conference on RF Superconductivity (SRF’23), Grand Rapids, MI, USA, 25–30 June 2023; JACOW Publishing: Geneva, Switzerland, 2023; pp. 651–654. ISBN 2673-5504. [Google Scholar]

- Abdisatarov, B.; Eremeev, G.; Elsayed-Ali, H.E.; Bafia, D.; Murthy, A.; Sung, Z.; Netepenko, A.; Romanenko, A.; Carlos, C.P.A.; Rosaz, G.J.; et al. Optimizing superconducting Nb film cavities by mitigating medium-field Q -slope through annealing. Supercond. Sci. Technol. 2025, 38, 75006. [Google Scholar] [CrossRef]

- Bafia, D.; Grassellino, A.; Melnychuk, O.; Romanenko, A.; Sung, Z.-H.; Zasadzinski, J. Gradients of 50 MV/m in TESLA Shaped Cavities via Modified Low Temperature Bake. In Proceedings of the SRF2019, Dresden, Germany, 30 June–5 July 2019; JACoW Publishing: Geneva, Switzerland, 2019. [Google Scholar]

- Isagawa, S. rf superconducting properties of reactively sputtered NbN. J. Appl. Phys. 1981, 52, 921–927. [Google Scholar] [CrossRef]

- Ryohei, I.T. Development of NbN Film for next-generation superconducting acceleration cavities. In Proceedings of the 2019 Particle Accelerator Conference, Melbourne, Australia, 19–24 May 2019. [Google Scholar]

- Wilde, S.; Alves, E.; Barradas, N.; Chesca, B.; Hannah, A.; Malyshev, O.; Pattalwar, S.; Stenning, G.; Valizadeh, R. High Power Impulse Magnetron Sputtering of Thin Films for Superconducting RF Cavities. In Proceedings of the 17th International Conference on RF Superconductivity (SRF2015), Whistler, BC, Canada, 13–18 September 2015; JACoW: Geneva, Switzerland, 2015. [Google Scholar]

- Kalal, S.; Gupta, M.; Rawat, R. N concentration effects on structure and superconductivity of NbN thin films. J. Alloys Compd. 2021, 851, 155925. [Google Scholar] [CrossRef]

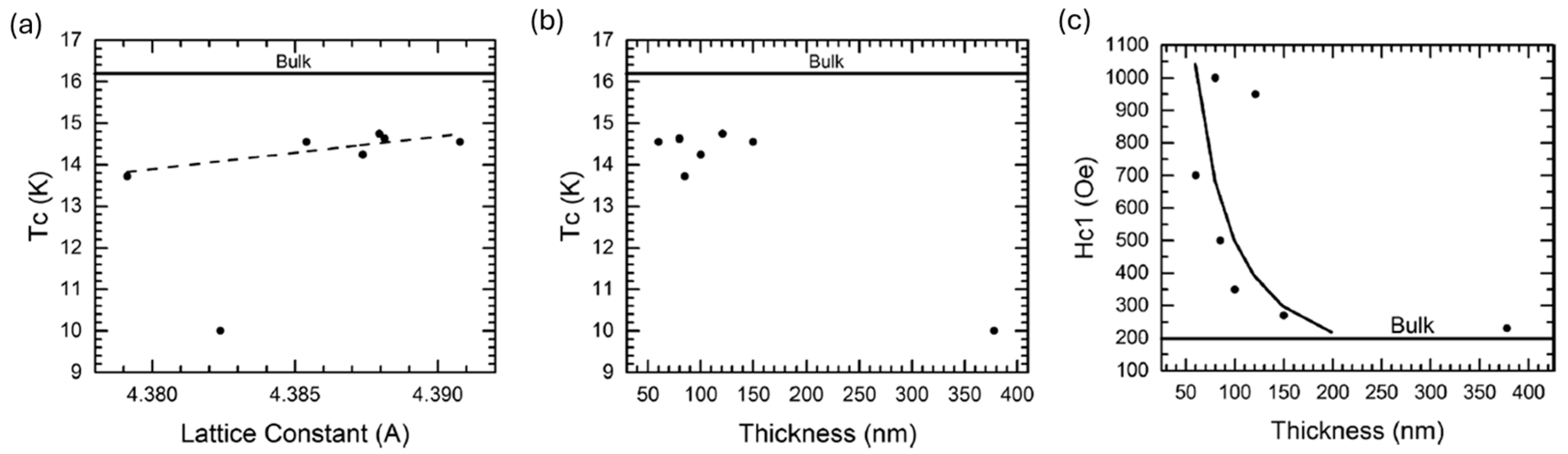

- Beebe, M.R.; Beringer, D.B.; Burton, M.C.; Yang, K.; Lukaszew, R.A. Stoichiometry and thickness dependence of superconducting properties of niobium nitride thin films. J. Vac. Sci. Technol. A Vac. Surf. Film. 2016, 34, 155925. [Google Scholar] [CrossRef]

- Di Leo, R. Niboium-titanium nitride thin films for superconducting rf accelerator cavities. J. Low Temp. Phys. 1989, 78, 41–50. [Google Scholar] [CrossRef]

- Bosland, P.; Cantacuzene, S.; Gobin, J.; Juillard, M.; Martignac, J. NbTiN Thin Films for RF Applications. In Proceedings of the Sixth Workshop on RF Superconductivity, CEBAF, Newport News, VA, USA, 4–8 October 1993. [Google Scholar]

- Marino, M. Study of NbTiN Coatings by Reactive Magnetron Sputtering for the Production of 1.5 GHz Superconducting Accelerating Cavities. In Proceedings of the Workshop on RF Superconductivity, Padua, Italy, 6–10 October 1997. [Google Scholar]

- Yu, L.; Singh, R.K.; Liu, H.; Wu, S.Y.; Hu, R.; Durand, D.; Bulman, J.; Rowell, J.M.; Newman, N. Fabrication of Niobium Titanium Nitride Thin Films with High Superconducting Transition Temperatures and Short Penetration Lengths. IEEE Trans. Appl. Supercond. 2005, 15, 44–48. [Google Scholar] [CrossRef]

- Valente-Feliciano, A.-M.; Eremeev, G.V.; Reece, C.E.; Spradlin, J.K. Growth and Characterization of Multi-Layer NbTiN Films. In Proceedings of the SRF2015, Whistler, BC, Canada, 13–18 September 2015. [Google Scholar]

- Burton, M.C.; Beebe, M.R.; Yang, K.; Lukaszew, R.A.; Valente-Feliciano, A.-M.; Reece, C. Superconducting NbTiN thin films for superconducting radio frequency accelerator cavity applications. J. Vac. Sci. Technol. 2016, 34, 021518. [Google Scholar] [CrossRef]

- Ge, H.; Jin, Y.-R.; Song, X.-H. High quality NbTiN films fabrication and rapid thermal annealing investigation. Chin. Phys. B 2019, 28, 77402. [Google Scholar] [CrossRef]

- Pratap, P.; Nanda, L.; Senapati, K.; Aloysius, R.P.; Achanta, V. Optimization of the superconducting properties of NbTiN thin films by variation of the N2 partial pressure during sputter deposition. Supercond. Sci. Technol. 2023, 36, 85017. [Google Scholar] [CrossRef]

- Sayeed, M.N.; Elsayed-Ali, H.; Eremeev, G.V.; Kelley, M.J.; Pudasaini, U.; Reece, C.E. Magnetron Sputtering of Nb3Sn for SRF Cavities. In Proceedings of the 9th International Particle Accelerator Conference, Vancouver, BC, Canada, 29 April–4 May 2018; JACoW Publishing: Geneva, Switzerland, 2018. [Google Scholar] [CrossRef]

- Sayeed, M.N.; Elsayed-Ali, H.; Burton, M.C.; Eremeev, G.V.; Reece, C.E.; Valente-Feliciano, A.-M.; Pudasaini, U. Deposition of Nb3Sn Films by Multilayer Sequential Sputtering for SRF Cavity Application. In Proceedings of the SRF2019, Dresden, Germany, 30 June–5 July 2019; JACoW Publishing: Geneva, Switzerland, 2019. [Google Scholar] [CrossRef]

- Sayeed, M.N.; Pudasaini, U.; Eremeev, G.V.; Elsayed-Ali, H.E. Fabrication of superconducting Nb3Sn film by Co-sputtering. Vacuum 2023, 212, 112019. [Google Scholar] [CrossRef]

- Howard, K.; Sun, Z.; Liepe, M.U. Thermal annealing of sputtered Nb3Sn and V3Si thin films for superconducting radio-frequency cavities. arXiv 2023, arXiv:2301.00756. [Google Scholar] [CrossRef]

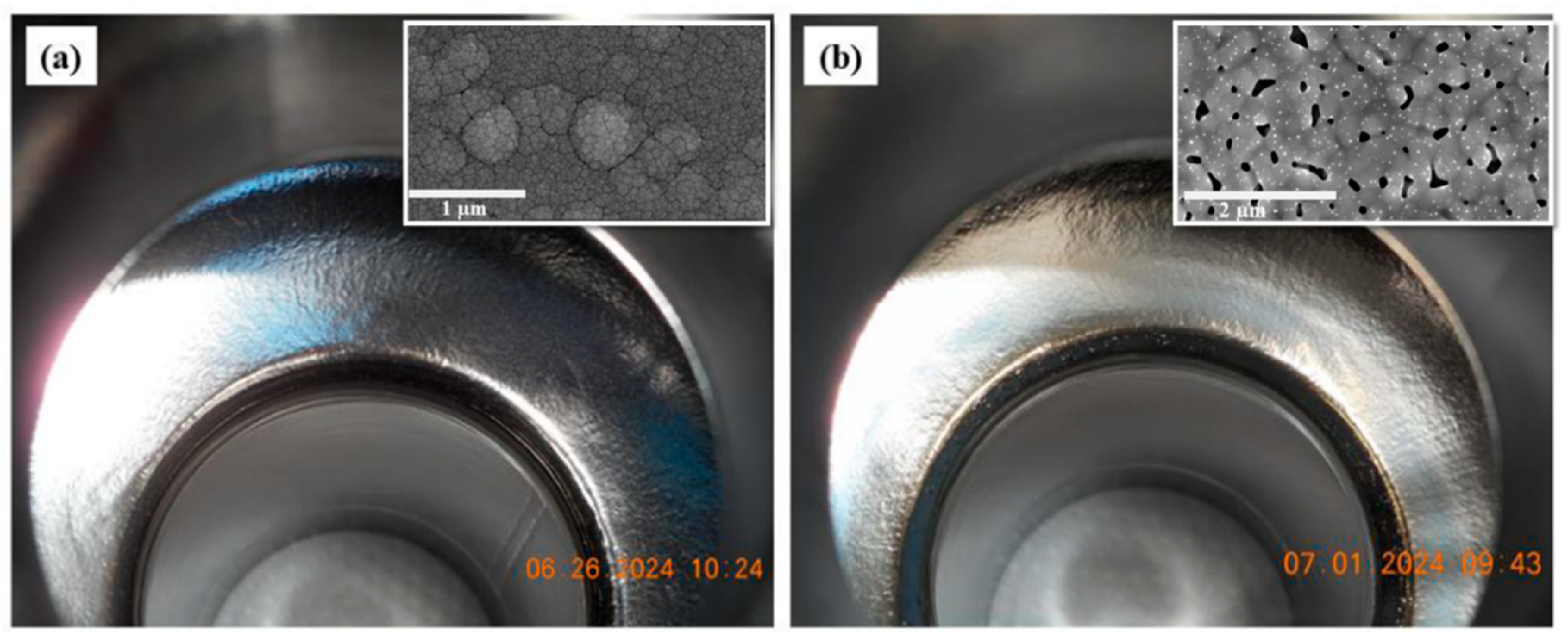

- Shakel, M.S. [5]-2025-Nb3Sn coating of SRF cavity by co-sputtering from a composite target. arXiv 2025, arXiv:2508.02894. [Google Scholar] [CrossRef]

- Ilyina, E.A.; Rosaz, G.; Descarrega, J.B.; Vollenberg, W.; Lunt, A.J.G.; Leaux, F.; Calatroni, S.; Venturini-Delsolaro, W.; Taborelli, M. Development of sputtered Nb3Sn films on copper substrates for superconducting radiofrequency applications. Supercond. Sci. Technol. 2019, 32, 35002. [Google Scholar] [CrossRef]

- Keiichi, T.; Osamu, M. Synthesis of Nb3Al Thin Films by Magnetron Sputtering. Jpn. J. Appl. Phys. 1981, 20. [Google Scholar] [CrossRef]

- Agatsuma, K.; Tateishi, H.; Arai, K.; Umeda, M.; Saitoh, T.; Gotoh, K. Nb3Al thin films made by single RF magnetron sputtering target. Phys. C Supercond. 2002, 372–376, 1378–1381. [Google Scholar] [CrossRef]

- Dochev, D.; Pavolotsky, A.B.; Belitsky, V.; Olofsson, H. Nb3Al thin film deposition for low-noise terahertz electronics. J. Phys. Conf. Ser. 2008, 97, 12072. [Google Scholar] [CrossRef]

- Cadieu, F.J.; Johnson, G.R.; Douglass, D.H. Superconducting properties of V3Si produced by reactive diffusion. J. Low. Temp. Phys. 1972, 6, 529–531. [Google Scholar] [CrossRef]

- Gavaler, J.R.; Greggi, J. Reactively Sputtered V/sub 3/Si and Nb/sub 3/Ge Films; Westinghouse RandD Center: Pittsburgh, PA, USA, 1985; p. MAG 21:2. [Google Scholar]

- Stewart, G.R. Superconductivity in the A15 structure. Phys. C Supercond. Its Appl. 2015, 514, 28–35. [Google Scholar] [CrossRef]

- Christopher, B.; Daniel, S.; Gavin, S. V3Si: An alternative thin film material for superconducting RF cavities. In Proceedings of the 15th International Particle Accelerator Conference, Nashville, TN, USA, 19–24 May 2024. [Google Scholar]

- Gavaler, J.R.; Janocko, M.A.; Jones, C.K. A-15 structure Mo–Re superconductor. Appl. Phys. Lett. 1972, 21, 179–180. [Google Scholar] [CrossRef]

- Andreone, A.; Barone, A.; Di Chiara, A.; Fontana, F.; Mascolo, G.; Palmieri, V.; Peluso, G.; Pepe, G.; Di Uccio, U.S. Characterization of superconducting thin films by Mo75Re25 target for rf cavity applications. J. Supercond. 1989, 2, 493–500. [Google Scholar] [CrossRef][Green Version]

- Deambrosis, S.M.; Keppel, G.; Ramazzo, V.; Roncolato, C.; Sharma, R.G.; Palmieri, V. A15 superconductors: An alternative to niobium for RF cavities. Phys. C Supercond. 2006, 441, 108–113. [Google Scholar] [CrossRef]

- Seleznev, V.A.; Tarkhov, M.A.; Voronov, B.M.; Milostnaya, I.I.; Lyakhno, V.Y.; Garbuz, A.S.; Mikhailov, M.Y.; Zhigalina, O.M.; Gol’tsman, G.N. Deposition and characterization of few-nanometers-thick superconducting Mo–Re films. Supercond. Sci. Technol. 2008, 21, 115006. [Google Scholar] [CrossRef]

- Ermolov, S.N.; Indenbom, M.V.; Rossolenko, A.N.; Bdikin, I.K.; Uspenskaya, L.S.; Stepakov, N.S.; Glebovskii, V.G. Superconducting MgB2 films obtained by magnetron sputtering. Jetp Lett. 2001, 73, 557–561. [Google Scholar] [CrossRef]

- Jin, B.B.; Dahm, T.; Gubin, A.I.; Choi, E.-M.; Kim, H.J.; Lee, S.-I.; Kang, W.N.; Klein, N. Anomalous coherence peak in the microwave conductivity of c-axis oriented MgB2 thin films. Phys. Rev. Lett. 2003, 91, 127006. [Google Scholar] [CrossRef]

- Sene, F.C.d.C. Review on the state-of-the-art and challenges in the MgB2 component manufacturing for superconducting applications. Superconductivity 2024, 9, 100083. [Google Scholar] [CrossRef]

- Misra, N.; Hannah, A.N.; Valizadeh, R. Facile deposition of superconducting MgB2 thin films on substrates: A comparative investigation of electrochemical deposition and magnetron sputtering techniques. In Proceedings of the IPAC2019, Melbourne, VIC, Australia, 19–24 May 2019; JACoW Publishing: Geneva, Switzerland, 2019. [Google Scholar] [CrossRef]

- Mičunek, R.; Plecenik, A.; Kúš, P.; Zahoran, M.; Tomášek, M.; Plecenik, T.; Gregor, M.; Štefečka, M.; Jacko, V.; Greguš, J.; et al. Preparation of MgB2 superconducting thin films by magnetron sputtering. Phys. C Supercond. Its Appl. 2006, 435, 78–81. [Google Scholar] [CrossRef]

| Material | Tc (K) | ρn (μΩcm) | Hc (0) (T) | Hc1 (0) (T) | Hc2 (0) (T) | λ (nm) | Δ (meV) | ξ (nm) |

|---|---|---|---|---|---|---|---|---|

| Nb | 9.23 | 2 | 0.2 | 0.18 | 0.28 | 40 | 1.5 | 35 |

| NbN | 16.2 | 70 | 0.23 | 0.02 | 15 | 200–350 | 2.6 | 3–5 |

| NbTiN | 17.3 | 35 | 0.23 | 0.03 | 15 | 150–200 | 2.8 | 5 |

| Nb3Sn | 18 | 8–20 | 0.54 | 0.05 | 28 | 80–100 | 3.1 | 4 |

| V3Si | 17 | 4 | 0.72 | 0.072 | 24.5 | 179 | 2.5 | 3.5 |

| Nb3Al | 18.7 | 54 | 33 | 210 | 3 | |||

| MgB2 | 40 | 0.1–10 | 0.43 | 0.03 | 3.5–60 | 140 | 2.3/7.2 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lakki Reddy Venkata, B.R.; Zubtsovskii, A.; Jiang, X. Sputter-Deposited Superconducting Thin Films for Use in SRF Cavities. Nanomaterials 2025, 15, 1522. https://doi.org/10.3390/nano15191522

Lakki Reddy Venkata BR, Zubtsovskii A, Jiang X. Sputter-Deposited Superconducting Thin Films for Use in SRF Cavities. Nanomaterials. 2025; 15(19):1522. https://doi.org/10.3390/nano15191522

Chicago/Turabian StyleLakki Reddy Venkata, Bharath Reddy, Aleksandr Zubtsovskii, and Xin Jiang. 2025. "Sputter-Deposited Superconducting Thin Films for Use in SRF Cavities" Nanomaterials 15, no. 19: 1522. https://doi.org/10.3390/nano15191522

APA StyleLakki Reddy Venkata, B. R., Zubtsovskii, A., & Jiang, X. (2025). Sputter-Deposited Superconducting Thin Films for Use in SRF Cavities. Nanomaterials, 15(19), 1522. https://doi.org/10.3390/nano15191522