Effect of Size on Phase Mixing Patterns in Rapidly Solidified Au–Ge Nanoparticles

Abstract

1. Introduction

2. Materials and Methods

3. Results

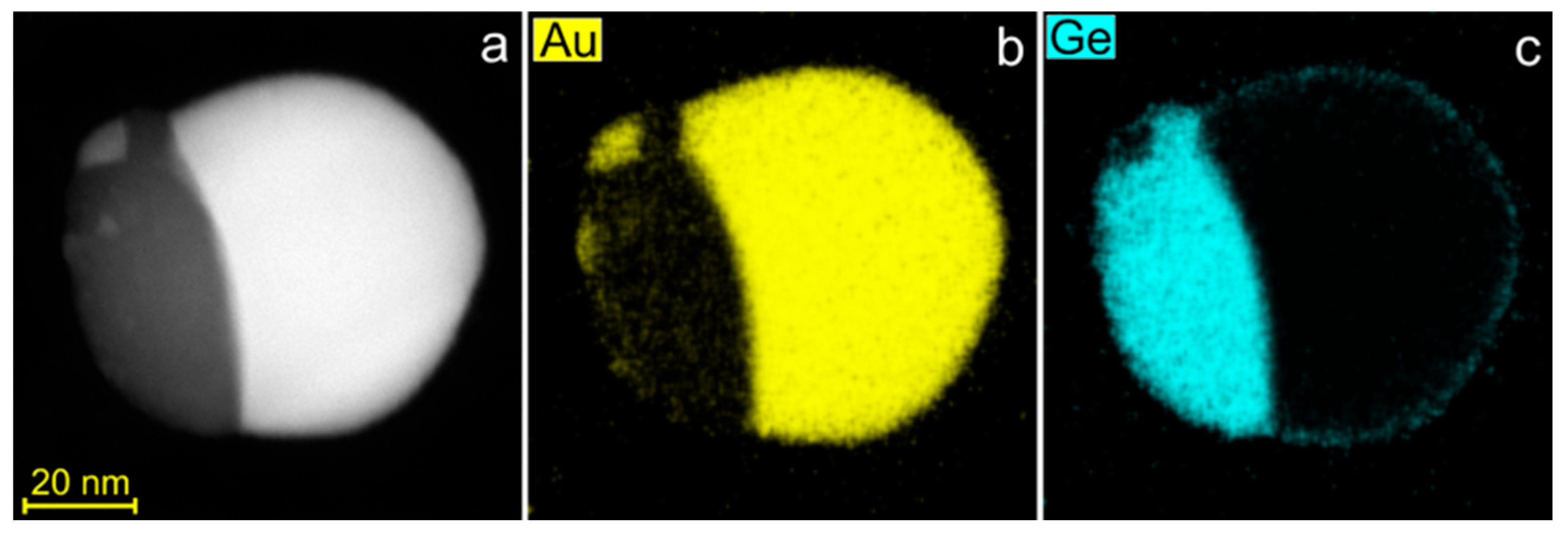

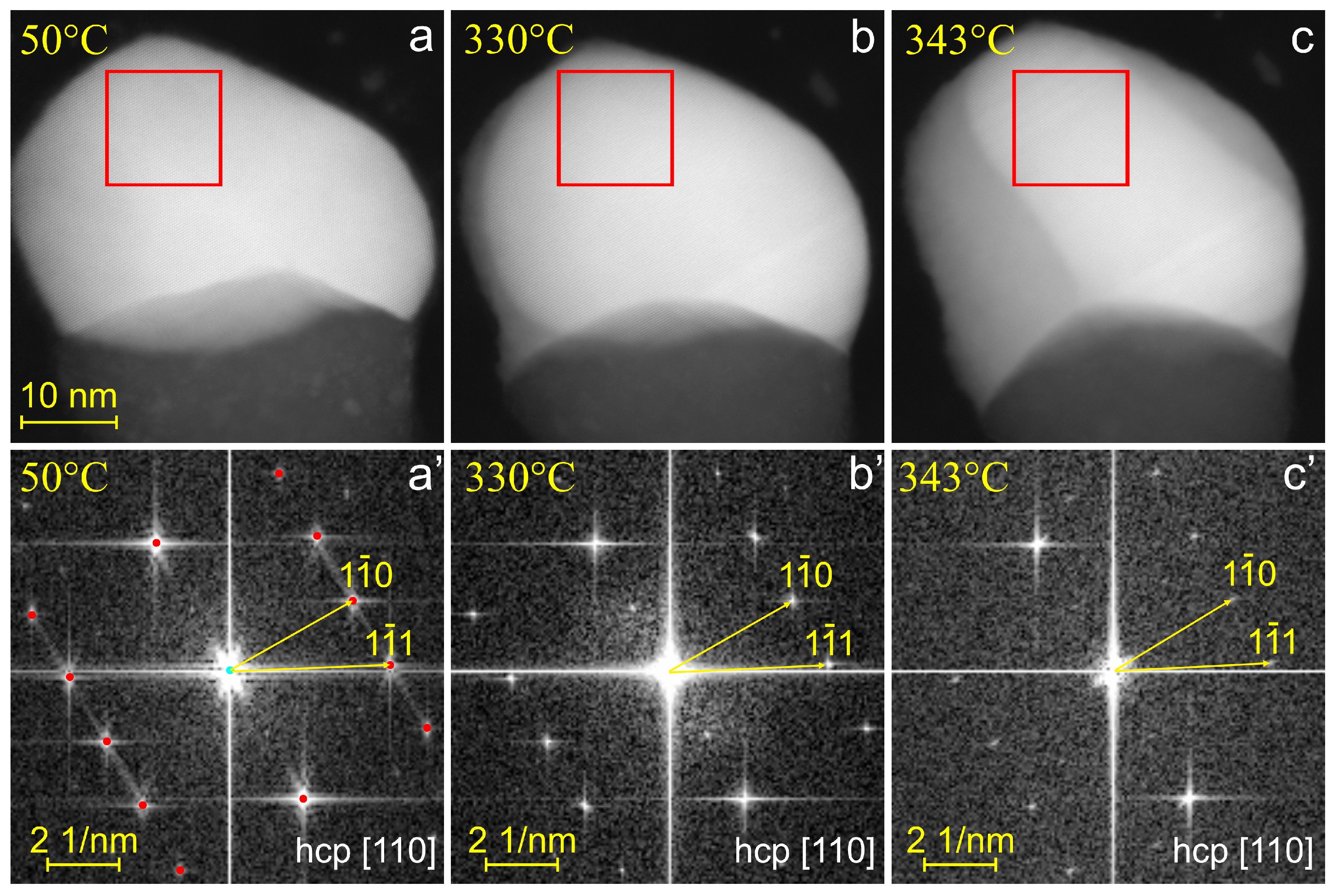

3.1. Solidification Patterns in 10–80 nm Au–Ge Nanoparticles

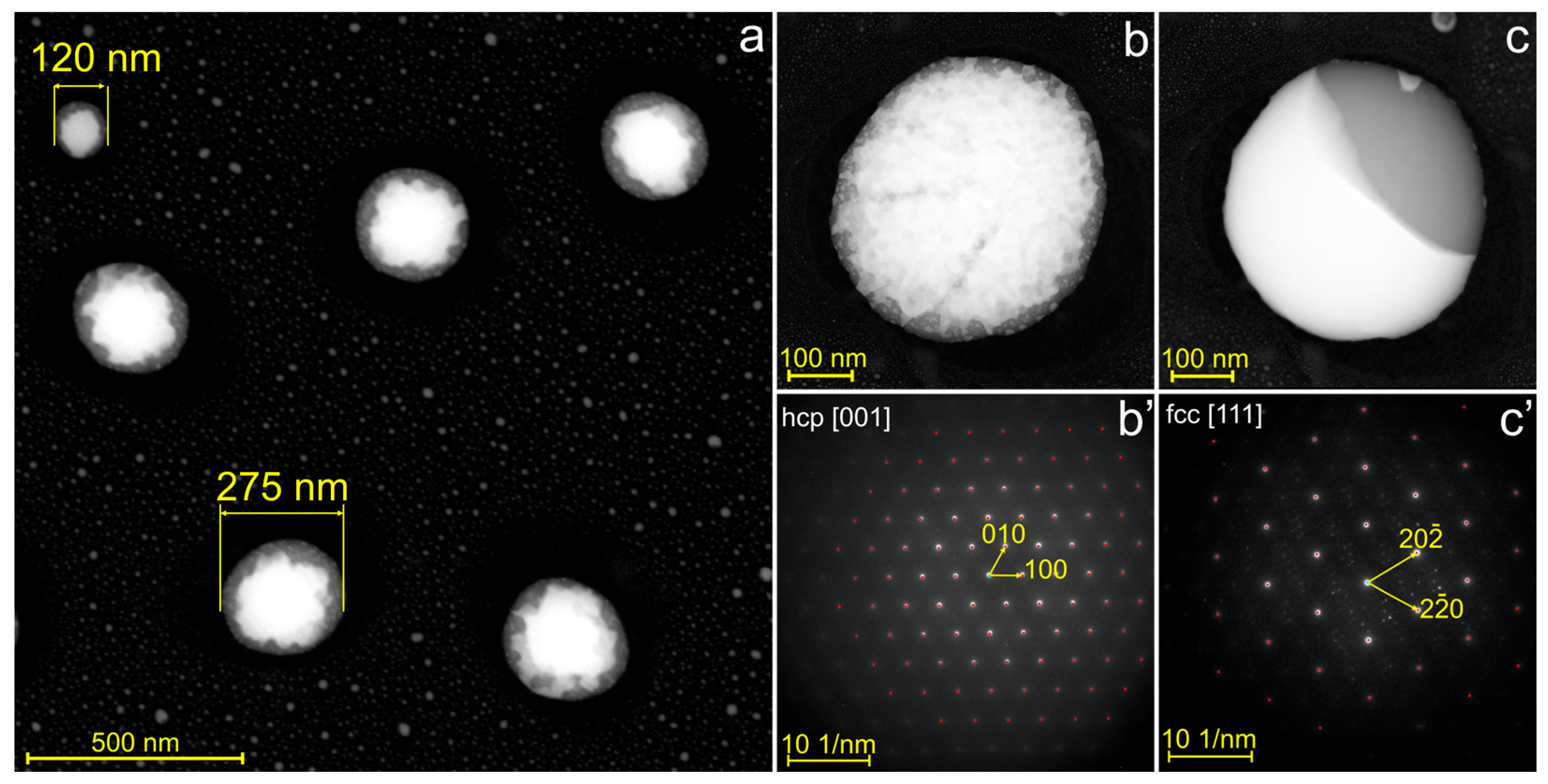

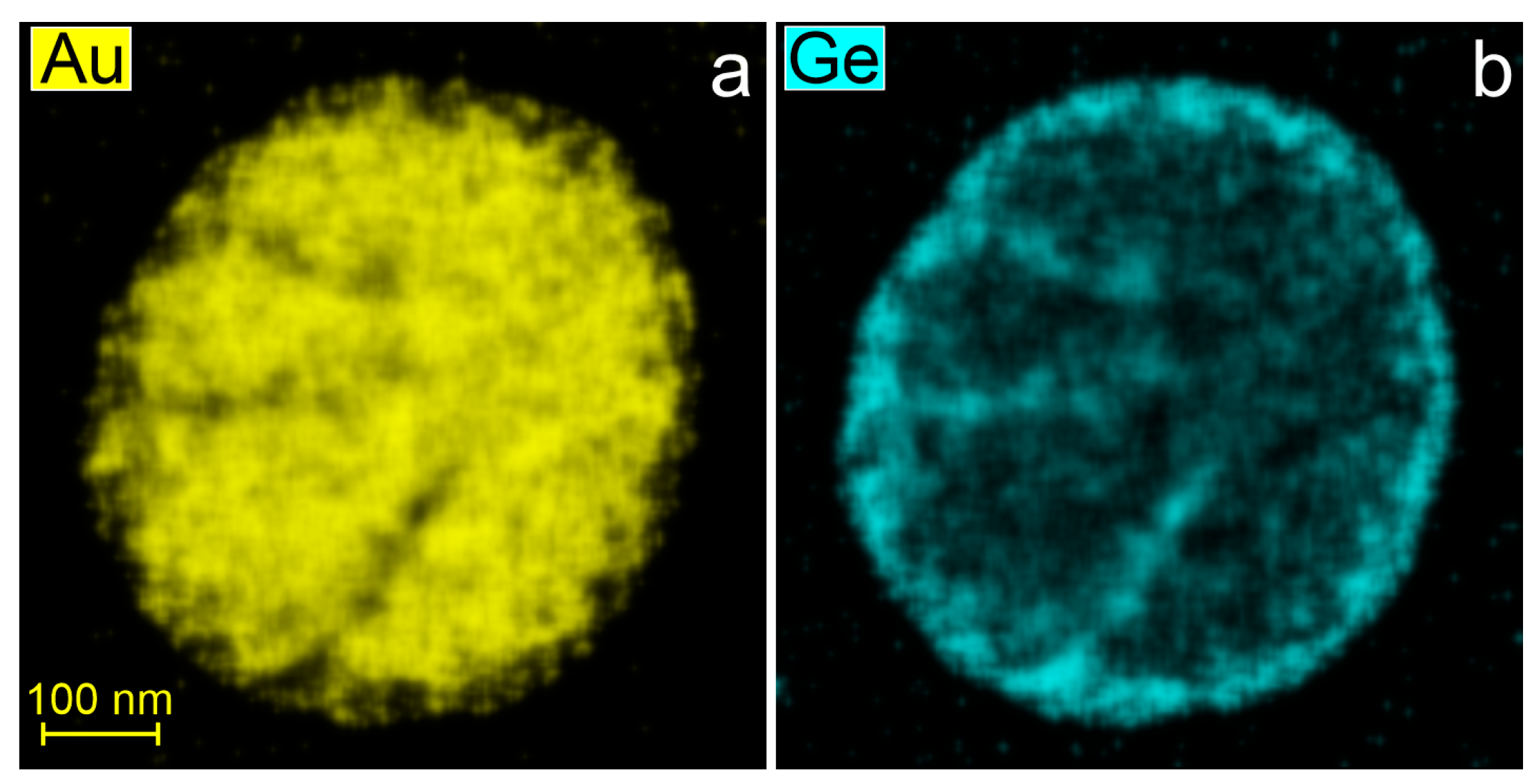

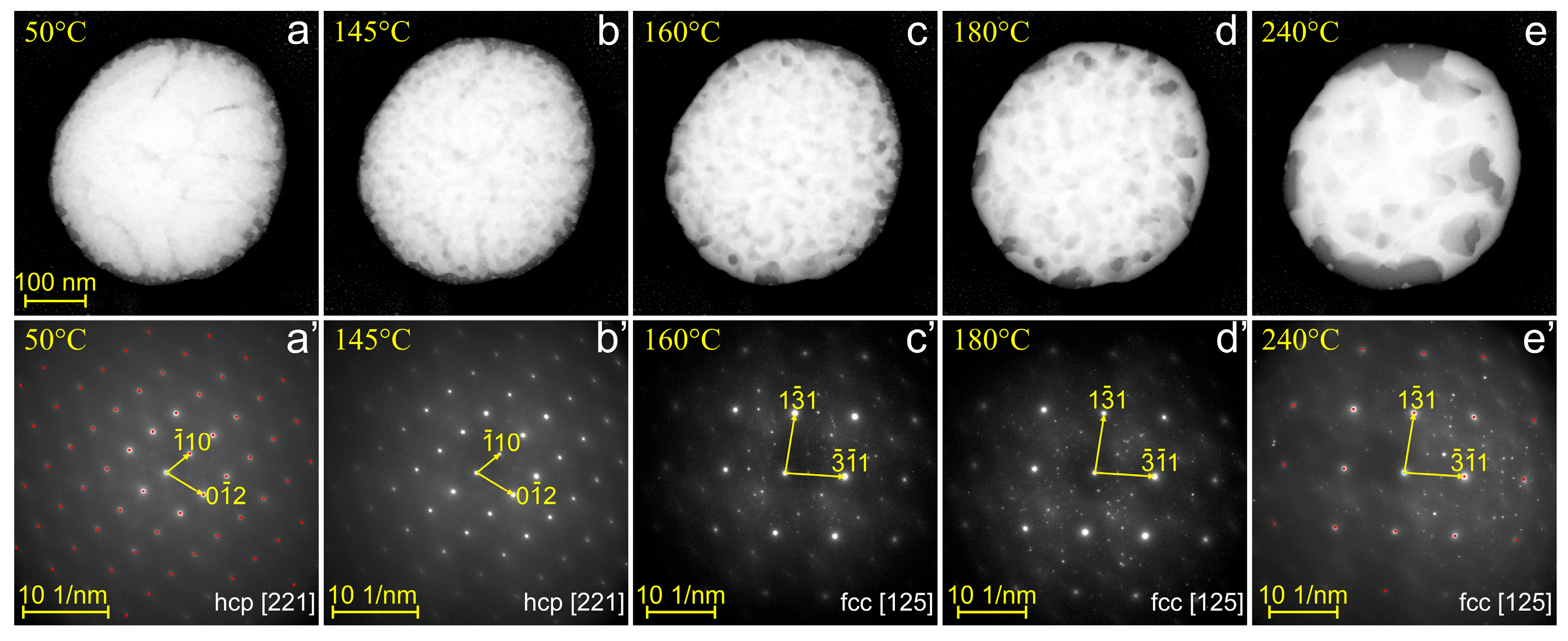

3.2. Solidification Patterns in Au–Ge Nanoparticles with Sizes from 80 to 500 nm

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guzman, J.; Boswell-Koller, C.N.; Beeman, J.W.; Bustillo, K.C.; Conry, T.; Dubón, O.D.; Hansen, W.L.; Levander, A.X.; Liao, C.Y.; Lieten, R.R.; et al. Reversible Phase Changes in Ge-Au Nanoparticles. Appl. Phys. Lett. 2011, 98, 193101. [Google Scholar] [CrossRef]

- Amirav, L.; Alivisatos, A.P. Photocatalytic Hydrogen Production with Tunable Nanorod Heterostructures. J. Phys. Chem. Lett. 2010, 1, 1051–1054. [Google Scholar] [CrossRef]

- O’Regan, C.; Biswas, S.; O’Kelly, C.; Jung, S.J.; Boland, J.J.; Petkov, N.; Holmes, J.D. Engineering the Growth of Germanium Nanowires by Tuning the Supersaturation of Au/Ge Binary Alloy Catalysts. Chem. Mater. 2013, 25, 3096–3104. [Google Scholar] [CrossRef]

- Idris, D.S.; Roy, A. Synthesis of Bimetallic Nanoparticles and Applications—An Updated Review. Crystals 2023, 13, 637. [Google Scholar] [CrossRef]

- Taranovskyy, A.; Tomán, J.J.; Gajdics, B.D.; Erdélyi, Z. 3D Phase Diagrams and the Thermal Stability of Two-Component Janus Nanoparticles: Effects of Size, Average Composition and Temperature. Phys. Chem. Chem. Phys. 2021, 23, 6116–6127. [Google Scholar] [CrossRef]

- Calvo, F. Thermodynamics of Nanoalloys. Phys. Chem. Chem. Phys. 2015, 17, 27922–27939. [Google Scholar] [CrossRef]

- Malviya, K.D.; Chattopadhyay, K. Temperature- and Size-Dependent Compositionally Tuned Microstructural Landscape for Ag-46 Atom % Cu Nanoalloy Prepared by Laser Ablation in Liquid. J. Phys. Chem. C 2016, 120, 27699–27706. [Google Scholar] [CrossRef]

- Yasuhara, A.; Homma, M.; Sannomiya, T. In Situ Observation of Structural and Optical Changes of Phase-Separated Ag-Cu Nanoparticles during a Dewetting Process via Transmission Electron Microscopy. ACS Appl. Mater. Interfaces 2022, 14, 35020–35026. [Google Scholar] [CrossRef]

- Bogatyrenko, S.I.; Kryshtal, A.P.; Kruk, A. Effect of Size on the Formation of Solid Solutions in Ag-Cu Nanoparticles. J. Phys. Chem. C 2023, 127, 2569–2580. [Google Scholar] [CrossRef]

- Ternero, P.; Preger, C.; Eriksson, A.C.; Rissler, J.; Hübner, J.M.; Messing, M.E. In-Flight Tuning of Au-Sn Nanoparticle Properties. Langmuir 2024, 40, 16393–16399. [Google Scholar] [CrossRef]

- Guisbiers, G.; Khanal, S.; Ruiz-Zepeda, F.; Roque De La Puente, J.; José-Yacaman, M. Cu-Ni Nano-Alloy: Mixed, Core-Shell or Janus Nano-Particle? Nanoscale 2014, 6, 14630–14635. [Google Scholar] [CrossRef] [PubMed]

- Okamoto, H.; Massalski, T.B. The Au-Ge (Gold-Germanium) System. Bull. Alloy Phase Diagr. 1984, 5, 601–610. [Google Scholar] [CrossRef]

- Read, C.G.; Biacchi, A.J.; Schaak, R.E. Au-Ge and Ag-Ge Heterodimers with Tunable Domain Sizes: A Supersaturation-Precipitation Route to Colloidal Hybrid Nanoparticles. Chem. Mater. 2013, 25, 4304–4311. [Google Scholar] [CrossRef]

- Kim, B.J.; Wen, C.Y.; Tersoff, J.; Reuter, M.C.; Stach, E.A.; Ross, F.M. Growth Pathways in Ultralow Temperature Ge Nucleation from Au. Nano Lett. 2012, 12, 5867–5872. [Google Scholar] [CrossRef]

- Rath, A.; Dash, J.K.; Juluri, R.R.; Schowalter, M.; Mueller, K.; Rosenauer, A.; Satyam, P.V. Nano Scale Phase Separation in Au-Ge System on Ultra Clean Si(100) Surfaces. J. Appl. Phys. 2012, 111, 104319. [Google Scholar] [CrossRef]

- Jany, B.R.; Gauquelin, N.; Willhammar, T.; Nikiel, M.; Van Den Bos, K.H.W.; Janas, A.; Szajna, K.; Verbeeck, J.; Van Aert, S.; Van Tendeloo, G.; et al. Controlled Growth of Hexagonal Gold Nanostructures during Thermally Induced Self-Assembling on Ge(001) Surface. Sci. Rep. 2017, 7, srep42420. [Google Scholar] [CrossRef]

- Khshanovska, O.; Salamon, W.; Kryshtal, A. Formation and Coexistence of Metastable Phases during Solidification of Single AuGe Nanoparticles: An In Situ TEM Study. J. Phys. Chem. C 2024, 128, 21739–21750. [Google Scholar] [CrossRef]

- Marshall, A.F.; Goldthorpe, I.A.; Adhikari, H.; Koto, M.; Wang, Y.C.; Fu, L.; Olsson, E.; McIntyre, P.C. Hexagonal Close-Packed Structure of Au Nanocatalysts Solidified after Ge Nanowire Vapor-Liquid-Solid Growth. Nano Lett. 2010, 10, 3302–3306. [Google Scholar] [CrossRef]

- Marshall, A.F.; Thombare, S.V.; McIntyre, P.C. Crystallization Pathway for Metastable Hexagonal Close-Packed Gold in Germanium Nanowire Catalysts. Cryst. Growth Des. 2015, 15, 3734–3739. [Google Scholar] [CrossRef]

- Liu, Q.; Zou, R.; Wu, J.; Xu, K.; Lu, A.; Bando, Y.; Golberg, D.; Hu, J. Molten Au/Ge Alloy Migration in Ge Nanowires. Nano Lett. 2015, 15, 2809–2816. [Google Scholar] [CrossRef]

- Peng, S.; Meng, A.C.; Braun, M.R.; Marshall, A.F.; McIntyre, P.C. Plasmons and Inter-Band Transitions of Hexagonal Close Packed Gold Nanoparticles. Appl. Phys. Lett. 2019, 115, 051107. [Google Scholar] [CrossRef]

- Ahuja, R.; Rekhi, S.; Johansson, B. Theoretical Prediction of a Phase Transition in Gold. Phys. Rev. B Condens. Matter Mater. Phys. 2001, 63, 212101. [Google Scholar] [CrossRef]

- de la Peña, F.; Prestat, E.; Fauske, V.T.; Burdet, P.; Jokubauskas, P.; Nord, M.; Ostasevicius, T.; MacArthur, K.E.; Sarahan, M.; Johnstone, D.N.; et al. Hyperspy/Hyperspy: HyperSpy, v1.5.2; Zenodo: Geneva, Switzerland, 2019. [Google Scholar]

- Stadelmann, P.A. EMS—A Software Package for Electron Diffraction Analysis and HREM Image Simulation in Materials Science. Ultramicroscopy 1987, 21, 131–145. [Google Scholar] [CrossRef]

- Liao, Y. Practical Electron Microscopy and Database—An Online Book; GlobalSino: Columbia, SC, USA, 2006. [Google Scholar]

- Bogatyrenko, S.I.; Gladkikh, N.T.; Kryshtal’, A.P.; Samsonik, A.L.; Sukhov, V.N. Diffusion in Nanodisperse Layered Film Systems. Phys. Met. Metallogr. 2010, 109, 255–260. [Google Scholar] [CrossRef]

- Yuan, C.W.; Shin, S.J.; Liao, C.Y.; Guzman, J.; Stone, P.R.; Watanabe, M.; Ager, J.W.; Haller, E.E.; Chrzan, D.C. Structure Map for Embedded Binary Alloy Nanocrystals. Appl. Phys. Lett. 2008, 93, 193114. [Google Scholar] [CrossRef]

- Morokhow, I.D.; Chizhik, N.T.; Gladkich, N.T.; Grigoreva, L.V. Phase Size Effect in Highly Dispersed Systems. Sov. Phys.-Dokl. 1978, 243, 917–920. [Google Scholar]

- Rivlin, V.G.; Waghorne, R.M.; Williams, G.I. The Structure of Gold Alloys in the Liquid State. Gold Bull. 1976, 9, 84–87. [Google Scholar] [CrossRef]

- Buffat, P.; Borel, J.-P. Size Effect on the Melting Temperature of Gold Particles. Phys. Rev. A 1976, 13, 2287–2298. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khshanovska, O.; Ovsynskyi, V.; Kryshtal, A. Effect of Size on Phase Mixing Patterns in Rapidly Solidified Au–Ge Nanoparticles. Nanomaterials 2025, 15, 924. https://doi.org/10.3390/nano15120924

Khshanovska O, Ovsynskyi V, Kryshtal A. Effect of Size on Phase Mixing Patterns in Rapidly Solidified Au–Ge Nanoparticles. Nanomaterials. 2025; 15(12):924. https://doi.org/10.3390/nano15120924

Chicago/Turabian StyleKhshanovska, Olha, Vladyslav Ovsynskyi, and Aleksandr Kryshtal. 2025. "Effect of Size on Phase Mixing Patterns in Rapidly Solidified Au–Ge Nanoparticles" Nanomaterials 15, no. 12: 924. https://doi.org/10.3390/nano15120924

APA StyleKhshanovska, O., Ovsynskyi, V., & Kryshtal, A. (2025). Effect of Size on Phase Mixing Patterns in Rapidly Solidified Au–Ge Nanoparticles. Nanomaterials, 15(12), 924. https://doi.org/10.3390/nano15120924