Design Strategy and Application of Deep Eutectic Solvents for Green Synthesis of Nanomaterials

Abstract

1. Introduction

2. Fundamental of DES

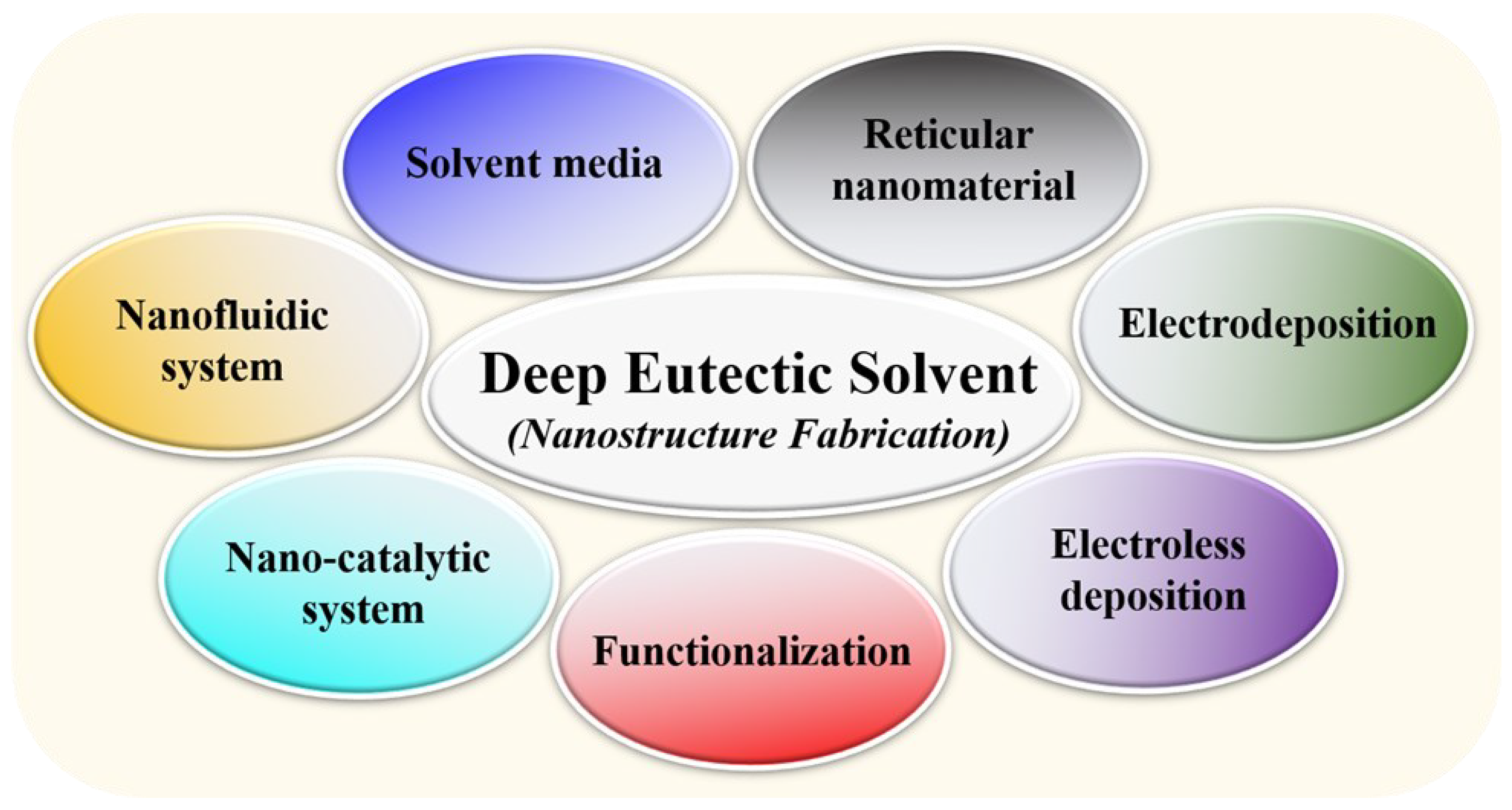

3. Design Strategy and Application of DES for Nanomaterial Fabrication

3.1. DES as a Solvent Medium for Wet-Chemical Approach

3.1.1. Preface

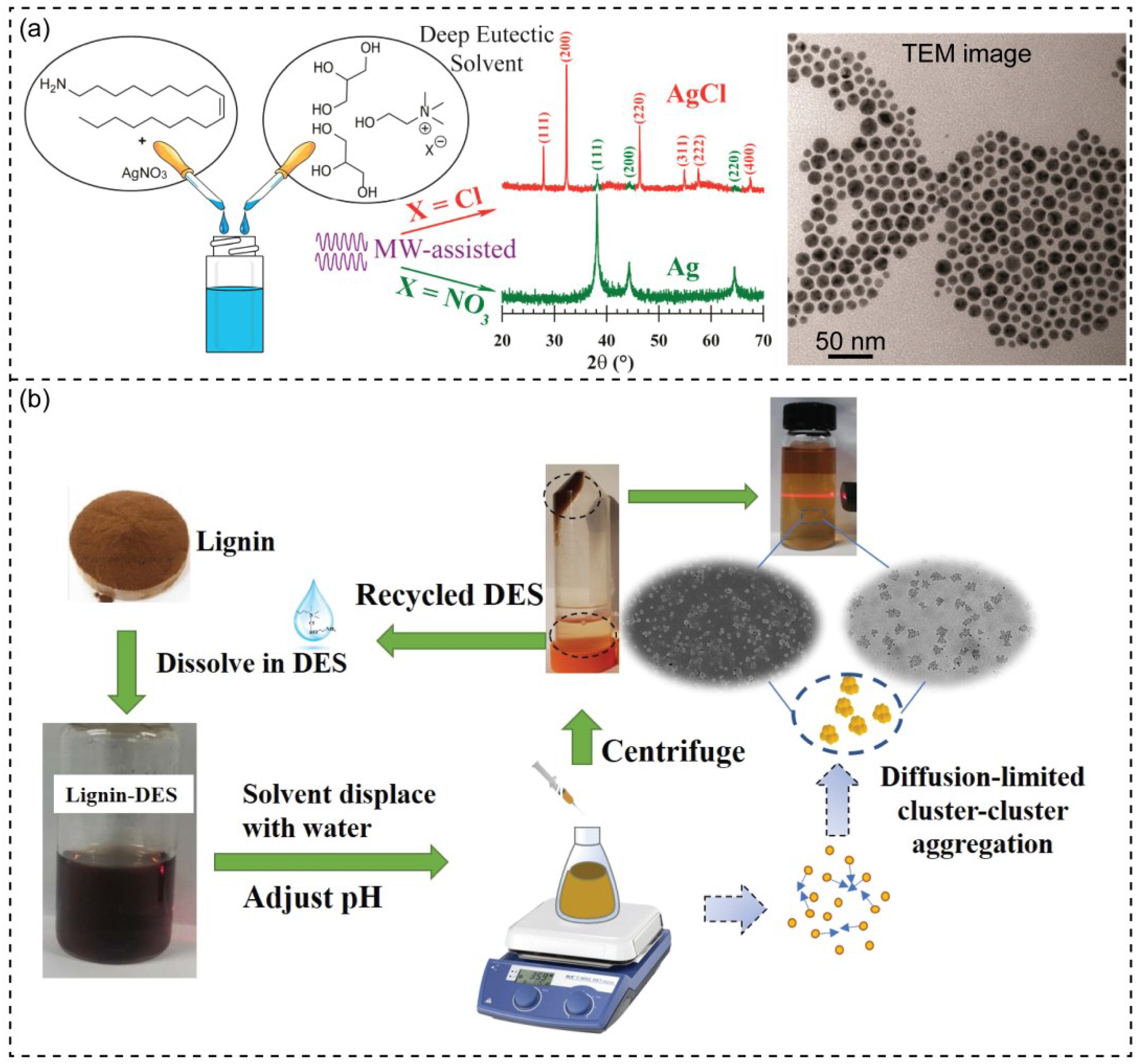

3.1.2. Nanostructure Fabrication in DES as a Reaction Medium

3.2. Nanosized Reticular Material Fabrication

3.2.1. MOF Fabrication

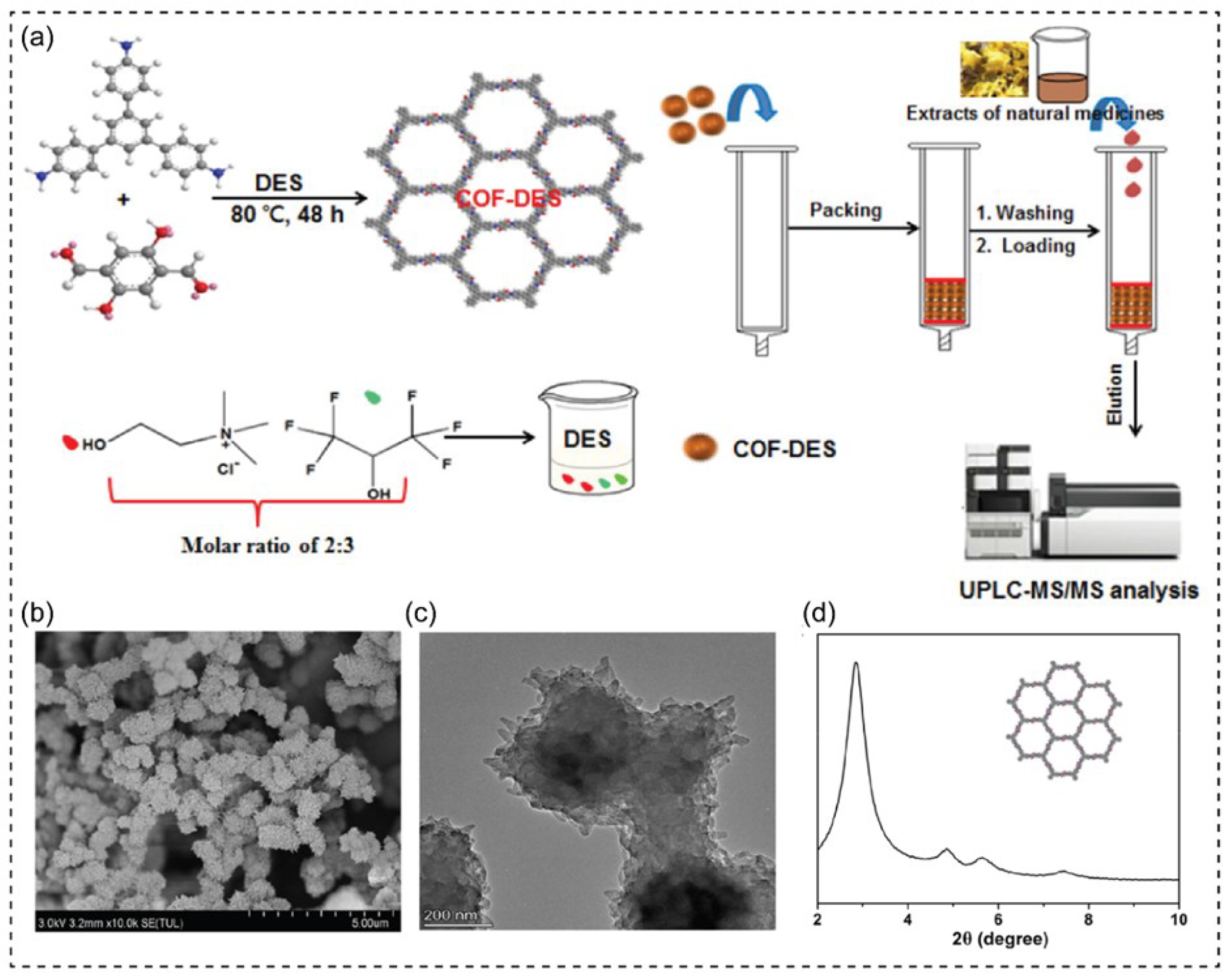

3.2.2. COF Fabrication

3.3. Electrodeposition/Electrochemical Synthesis

3.3.1. Principles and Characterization

3.3.2. Electropolymerization

3.3.3. Electrodeposition of Metal-Based Materials

| Metal or Alloy | Type | DES Component | Molar Ratio | References |

|---|---|---|---|---|

| Ni | Nanoparticle | ChCl-EG | 1:3 | [134] |

| Ni | Nanosheet | ChCl-EG | 1:2 | [135] |

| Ni | Nanostructure and nanofilm | ChCl-U ChCl-EG | 1:2 1:2 | [136,138,140] |

| Te | Nanoparticle | ChCl-U ChCl-EG | 1:2 1:2 | [141] |

| Pd | Nanoparticle | ChCl-U | 1:2 | [142] |

| Pd | Nanocrystal | ChCl-U | 1:2 | [143,144] |

| Fe | Nanoparticle | ChCl-U | 1:2 | [154] |

| Cu | Nanoparticle | ChCl-U | 1:2 | [147] |

| Au-Ag | Nanoparticle | ChCl-EG | 1:2 | [152] |

| Mn | Nanofilm | ChCl-U | 1:2 | [153] |

| Fe-Cr | Nanocrystal | ChCl-EG | 1:3 | [155,156] |

| Cu-Au | Bimetallic nanostructure | ChCl-U | 1:2 | [157] |

| Ni-Mo | Nanocrystal | ChCl-PG | 1:2 | [158] |

| Au-Pt | Nanoflower | ChCl-EG | 1:2 | [159] |

| Ni-Co | Nanofilm | ChCl-EG | 1:2 | [160] |

| Pd-Co | Nanoparticle | ChCl-U | 1:2 | [161] |

| Co-Pt | Nanocrystal | ChCl-U | 1:2 | [162] |

| Ni-Co-Sn | Nanocrystal | ChCl-EG | 1:2 | [163] |

3.3.4. Electrodeposition of Alloys

3.4. Electroless Decomposition

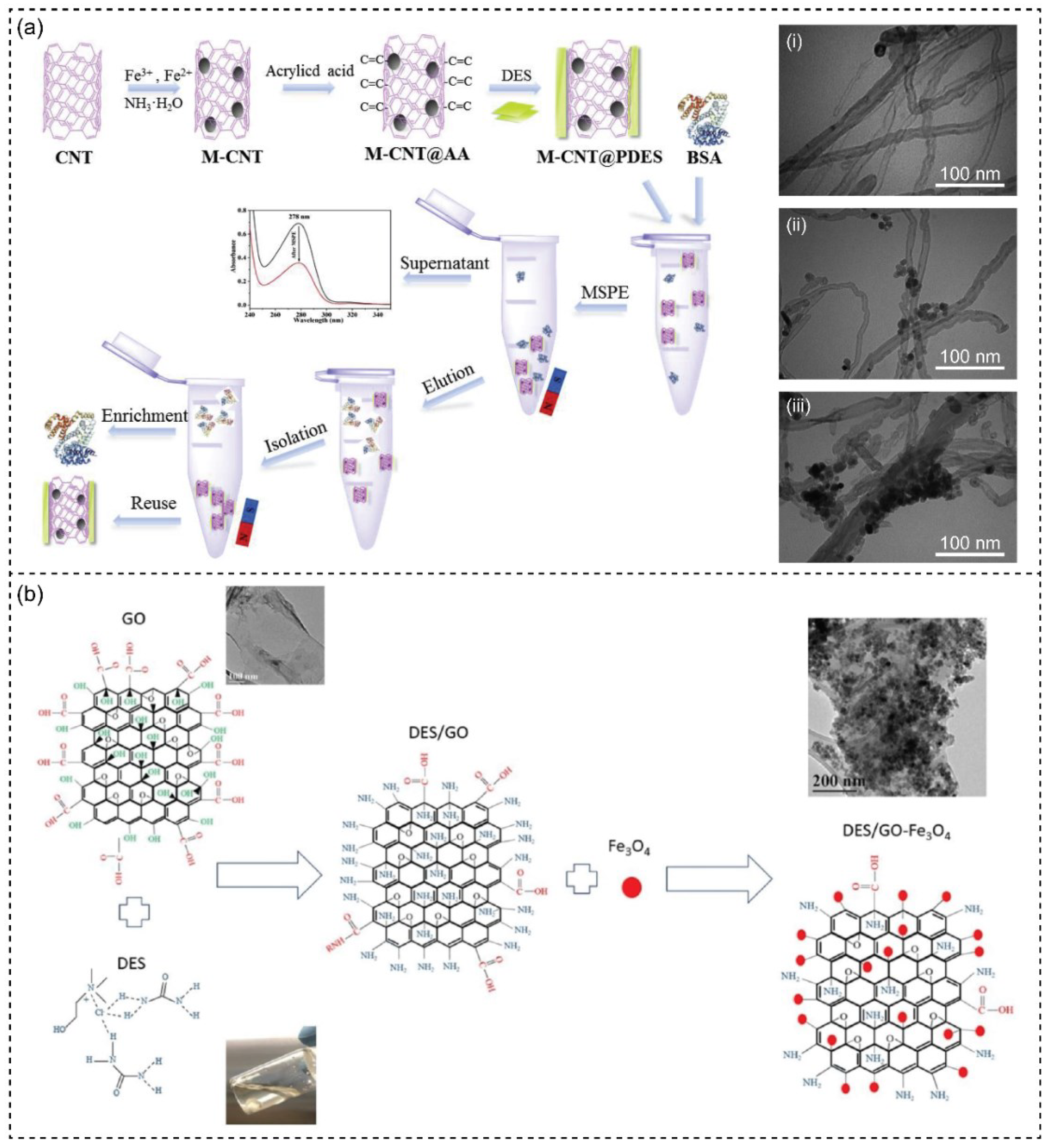

3.5. Nanostructure Functionalization

3.6. DES-Based Nano-Catalytic System

3.7. DES-Based Nanofluidic System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Clark, J.H.; Hunt, A.; Topi, C.; Paggiola, G.; Sherwood, J. Chapter 1. In troduction to Solvents and Sustainable Chemistry. In Sustainable Solvents: Perspectives from Research, Business and International Policy; Royal Society of Chemistry: London, UK, 2017; pp. 1–34. ISBN 978-1782623359. [Google Scholar]

- Wang, H.-Y.; Zhang, J.-T.; Zhang, S.-S.; Guo, Y.-L. The Remarkable Role of Solvent in Reaction Mechanism Studies by Electrospray Mass Spectrometry. Org. Chem. Front. 2015, 2, 990–994. [Google Scholar] [CrossRef]

- Jameel, F.; Stein, M. The Many Roles of Solvent in Homogeneous Catalysis—The Reductive Amination Showcase. J. Catal. 2022, 405, 24–34. [Google Scholar] [CrossRef]

- Ceballos, D.M.; Fellows, K.M.; Evans, A.E.; Janulewicz, P.A.; Lee, E.G.; Whittaker, S.G. Perchloroethylene and Dry Cleaning: It’s Time to Move the Industry to Safer Alternatives. Front. Public Health 2021, 9, 123. [Google Scholar] [CrossRef] [PubMed]

- Uzma, N.; Salar, B.M.K.M.; Santhosh Kumar, B.; Aziz, N.; David, M.A.; Reddy, V.D. Impact of Organic Solvents and Environmental Pollutants on the Physiological Function in Petrol Filling Workers. Int. J. Environ. Res. Public Health 2008, 5, 139–146. [Google Scholar] [CrossRef] [PubMed]

- Tobiszewski, M.; Namieśnik, J.; Pena-Pereira, F. Environmental Risk-Based Ranking of Solvents Using the Combination of a Multimedia Model and Multi-Criteria Decision Analysis. Green Chem. 2017, 19, 1034–1042. [Google Scholar] [CrossRef]

- Capello, C.; Hellweg, S.; Hungerbühler, K. Environmental Assessment of Waste-Solvent Treatment Options. J. Ind. Ecol. 2008, 12, 111–127. [Google Scholar] [CrossRef]

- Byrne, F.P.; Jin, S.; Paggiola, G.; Petchey, T.H.M.; Clark, J.H.; Farmer, T.J.; Hunt, A.J.; Robert McElroy, C.; Sherwood, J. Tools and Techniques for Solvent Selection: Green Solvent Selection Guides. Sustain. Chem. Process. 2016, 4, 1–24. [Google Scholar] [CrossRef]

- Fadel, C.; Tarabieh, K.; Brewing Company, E.; el Metn, J. Development of an Industrial Environmental Index to Assess the Sustainability of Industrial Solvent-Based Processes. Resources 2019, 8, 115. [Google Scholar] [CrossRef]

- Zhou, T.; Qi, Z.; Sundmacher, K. Model-Based Method for the Screening of Solvents for Chemical Reactions. Chem. Eng. Sci. 2014, 115, 177–185. [Google Scholar] [CrossRef]

- Lipshutz, B.H.; Gallou, F.; Handa, S. Evolution of Solvents in Organic Chemistry. ACS Sustain. Chem. Eng. 2016, 4, 5838–5849. [Google Scholar] [CrossRef]

- Horváth, I.T. Solvents from Nature. Green Chem. 2008, 10, 1024–1028. [Google Scholar] [CrossRef]

- Oklu, N.K.; Matsinha, L.C.; Makhubela, B.C.E.; Oklu, N.K.; Matsinha, L.C.; Makhubela, B.C.E. Bio-Solvents: Synthesis, Industrial Production and Applications. In Solvents, Ionic Liquids and Solvent Effects; Maciejewska, M., Ed.; IntechOpen: Rijeka, Croatia, 2019; ISBN 978-1-78985-282-0. [Google Scholar] [CrossRef]

- Jessop, P.G. Searching for Green Solvents. Green Chem. 2011, 13, 1391–1398. [Google Scholar] [CrossRef]

- Prasad, W.; Wani, A.D.; Khamrui, K.; Hussain, S.A.; Khetra, Y. Green Solvents, Potential Alternatives for Petroleum Based Products in Food Processing Industries. Clean. Chem. Eng. 2022, 3, 100052. [Google Scholar] [CrossRef]

- Kumaravel, S.; Thiruvengetam, P.; Kundu, S. Biosolvents as Green Solvents in the Pharmaceutical Industry. In Green Sustainable Process for Chemical and Environmental Engineering and Science, Solvents for the Pharmaceutical Industry; Inamuddin, Boddula, R., Ahamed, M.I., Asiri, A.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 105–149. ISBN 978-0-12-821885-3. [Google Scholar] [CrossRef]

- Brehm, M.; Pulst, M.; Kressler, J.; Sebastiani, D. Triazolium-Based Ionic Liquids: A Novel Class of Cellulose Solvents. J. Phys. Chem. B 2019, 123, 3994–4003. [Google Scholar] [CrossRef] [PubMed]

- Abbott, A.P.; Capper, G.; Davies, D.L.; Rasheed, R.K.; Tambyrajah, V. Novel Solvent Properties of Choline Chloride/Urea Mixtures. Chem. Commun. 2003, 1, 70–71. [Google Scholar] [CrossRef]

- Smith, E.L.; Abbott, A.P.; Ryder, K.S. Deep Eutectic Solvents (DESs) and Their Applications. Chem. Rev. 2014, 114, 11060–11082. [Google Scholar] [CrossRef]

- Khezeli, T.; Ghaedi, M.; Bahrani, S.; Daneshfar, A.; Soylak, M. Deep Eutectic Solvent in Separation and Preconcentration of Organic and Inorganic Species. In New Generation Green Solvents for Separation and Preconcentration of Organic and Inorganic Species; Mustafa, S., Erkan, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 381–423. ISBN 978-0-12-818569-8. [Google Scholar] [CrossRef]

- Ijardar, S.P.; Singh, V.; Gardas, R.L. Revisiting the Physicochemical Properties and Applications of Deep Eutectic Solvents. Molecules 2022, 27, 1368. [Google Scholar] [CrossRef]

- Si, A.; Misra, A.K. Perspective on the Transformation of Carbohydrates under Green and Sustainable Reaction Conditions. In Recent Trends in Carbohydrate Chemistry, Volume 1: Synthesis, Structure and Function of Carbohydrates; Amélia, P.R., Bjørn, E.C., László, S., Paul, K., Roberto, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–71. ISBN 978-0-12-817467-8. [Google Scholar] [CrossRef]

- Paiva, A.; Craveiro, R.; Aroso, I.; Martins, M.; Reis, R.L.; Duarte, A.R.C. Natural Deep Eutectic Solvents—Solvents for the 21st Century. ACS Sustain. Chem. Eng. 2014, 2, 1063–1071. [Google Scholar] [CrossRef]

- de Andrade, D.C.; Monteiro, S.A.; Merib, J. A Review on Recent Applications of Deep Eutectic Solvents in Microextraction Techniques for the Analysis of Biological Matrices. Adv. Sample Prep. 2022, 1, 100007. [Google Scholar] [CrossRef]

- Ling, J.K.U.; Hadinoto, K. Deep Eutectic Solvent as Green Solvent in Extraction of Biological Macromolecules: A Review. Int. J. Mol. Sci. 2022, 23, 3381. [Google Scholar] [CrossRef]

- el Achkar, T.; Greige-Gerges, H.; Fourmentin, S. Basics and Properties of Deep Eutectic Solvents: A Review. Env. Chem. Lett. 2021, 19, 3397–3408. [Google Scholar] [CrossRef]

- Hansen, B.B.; Spittle, S.; Chen, B.; Poe, D.; Zhang, Y.; Klein, J.M.; Horton, A.; Adhikari, L.; Zelovich, T.; Doherty, B.W.; et al. Deep Eutectic Solvents: A Review of Fundamentals and Applications. Chem. Rev. 2021, 121, 1232–1285. [Google Scholar] [CrossRef]

- Das, N.; Kumar, A.; Rayavarapu, R.G. The Role of Deep Eutectic Solvents and Carrageenan in Synthesizing Biocompatible Anisotropic Metal Nanoparticles. Beilstein. J. Nanotechnol. 2021, 12, 924. [Google Scholar] [CrossRef]

- Nie, L.; Toufouki, S.; Yao, S.; Guo, D. Rethinking the Applications of Ionic Liquids and Deep Eutectic Solvents in Innovative Nano-Sorbents. Front. Chem. 2021, 9, 192. [Google Scholar] [CrossRef] [PubMed]

- Gontrani, L.; Tagliatesta, P.; Donia, D.T.; Bauer, E.M.; Bonomo, M.; Carbone, M. Recent Advances in the Synthesis of Inorganic Materials Using Environmentally Friendly Media. Molecules 2022, 27, 2045. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, B.D.; Florindo, C.; Iff, L.C.; Coelho, M.A.Z.; Marrucho, I.M. Menthol-Based Eutectic Mixtures: Hydrophobic Low Viscosity Solvents. ACS Sustain. Chem. Eng. 2015, 3, 2469–2477. [Google Scholar] [CrossRef]

- Alshana, U.; Soylak, M. Deep Eutectic Solvents in Microextraction. In Analytical Sample Preparation with Nano- and Other High-Performance Materials; Rafael, L., Soledad, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 471–512. ISBN 978-0-12-822139-6. [Google Scholar] [CrossRef]

- Chen, J.; Liu, M.; Wang, Q.; Du, H.; Zhang, L. Deep Eutectic Solvent-Based Microwave-Assisted Method for Extraction of Hydrophilic and Hydrophobic Components from Radix Salviae Miltiorrhizae. Molecules 2016, 21, 1383. [Google Scholar] [CrossRef] [PubMed]

- Rozas, S.; Zamora, L.; Benito, C.; Atilhan, M.; Aparicio, S. A Study on Monoterpenoid-Based Natural Deep Eutectic Solvents. Green Chem. Eng. 2022, 4, 99–114. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, Q.; Zhu, T. Comparison of Hydrophilic and Hydrophobic Deep Eutectic Solvents for Pretreatment Determination of Sulfonamides from Aqueous Environments. Anal. Methods 2019, 11, 5901–5909. [Google Scholar] [CrossRef]

- Zhang, Q.; de Oliveira Vigier, K.; Royer, S.; Jérôme, F. Deep Eutectic Solvents: Syntheses, Properties and Applications. Chem. Soc. Rev. 2012, 41, 7108–7146. [Google Scholar] [CrossRef]

- Cao, J.; Su, E. Hydrophobic Deep Eutectic Solvents: The New Generation of Green Solvents for Diversified and Colorful Applications in Green Chemistry. J. Clean. Prod. 2021, 314, 127965. [Google Scholar] [CrossRef]

- van Osch, D.J.G.P.; Zubeir, L.F.; van den Bruinhorst, A.; Rocha, M.A.A.; Kroon, M.C. Hydrophobic Deep Eutectic Solvents as Water-Immiscible Extractants. Green Chem. 2015, 17, 4518–4521. [Google Scholar] [CrossRef]

- Ghaedi, H.; Ayoub, M.; Sufian, S.; Shariff, A.M.; Murshid, G.; Hailegiorgis, S.M.; Khan, S.N. Density, Excess and Limiting Properties of (Water and Deep Eutectic Solvent) Systems at Temperatures from 293.15 K to 343.15 K. J. Mol. Liq. 2017, 248, 378–390. [Google Scholar] [CrossRef]

- Wazeer, I.; AlNashef, I.M.; Al-Zahrani, A.A.; Hadj-Kali, M.K. The Subtle but Substantial Distinction between Ammonium- and Phosphonium-Based Deep Eutectic Solvents. J. Mol. Liq. 2021, 332, 115838. [Google Scholar] [CrossRef]

- Lemaoui, T.; Darwish, A.S.; Attoui, A.; Abu Hatab, F.; Hammoudi, N.E.H.; Benguerba, Y.; Vega, L.F.; Alnashef, I.M. Predicting the Density and Viscosity of Hydrophobic Eutectic Solvents: Towards the Development of Sustainable Solvents. Green Chem. 2020, 22, 8511–8530. [Google Scholar] [CrossRef]

- Yu, L.Y.; Hou, X.J.; Ren, G.P.; Wu, K.J.; He, C.H. Viscosity Model of Deep Eutectic Solvents from Group Contribution Method. AIChE J. 2022, 68, e17744. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, W.; Fu, L.; Yang, Y.; Wang, Y.; Hu, X.; Wang, F.; Mu, T. Surface Tension of 50 Deep Eutectic Solvents: Effect of Hydrogen-Bonding Donors, Hydrogen-Bonding Acceptors, Other Solvents, and Temperature. Ind. Eng. Chem. Res. 2019, 58, 12741–12750. [Google Scholar] [CrossRef]

- Tariq, M.; Freire, M.G.; Saramago, B.; Coutinho, J.A.P.; Lopes, J.N.C.; Rebelo, L.P.N. Surface Tension of Ionic Liquids and Ionic Liquid Solutions. Chem. Soc. Rev. 2012, 41, 829–868. [Google Scholar] [CrossRef]

- Zhao, Y.-P.; Wang, F.-C. Surface Tension Effects of Nanostructures. In Encyclopedia of Nanotechnology; Bhushan, B., Ed.; Springer: Dordrecht, The Netherlands, 2016; pp. 3976–3989. ISBN 978-94-017-9780-1. [Google Scholar] [CrossRef]

- Abbott, A.P.; Capper, G.; Gray, S. Design of Improved Deep Eutectic Solvents Using Hole Theory. ChemPhysChem 2006, 7, 803–806. [Google Scholar] [CrossRef]

- Juneidi, I.; Hayyan, M.; Hashim, M.A. Evaluation of Toxicity and Biodegradability for Cholinium-Based Deep Eutectic Solvents. RSC Adv. 2015, 5, 83636–83647. [Google Scholar] [CrossRef]

- Yang, Z. Toxicity and Biodegradability of Deep Eutectic Solvents. In Deep Eutectic Solvents: Synthesis, Properties, and Applications; Diego, J.R., Gabriela, G., Eds.; Wiley: Hoboken, NJ, USA, 2019; pp. 43–60. ISBN 9783527345182. [Google Scholar] [CrossRef]

- Mohd Fuad, F.; Mohd Nadzir, M.; Harun@Kamaruddin, A. Hydrophilic Natural Deep Eutectic Solvent: A Review on Physicochemical Properties and Extractability of Bioactive Compounds. J. Mol. Liq. 2021, 339, 116923. [Google Scholar] [CrossRef]

- Dai, Y.; van Spronsen, J.; Witkamp, G.J.; Verpoorte, R.; Choi, Y.H. Natural Deep Eutectic Solvents as New Potential Media for Green Technology. Anal. Chim. Acta 2013, 766, 61–68. [Google Scholar] [CrossRef] [PubMed]

- Harish, V.; Ansari, M.M.; Tewari, D.; Gaur, M.; Yadav, A.B.; García-Betancourt, M.L.; Abdel-Haleem, F.M.; Bechelany, M.; Barhoum, A. Nanoparticle and Nanostructure Synthesis and Controlled Growth Methods. Nanomaterials 2022, 12, 3226. [Google Scholar] [CrossRef] [PubMed]

- Thanh, N.T.K.; Maclean, N.; Mahiddine, S. Mechanisms of Nucleation and Growth of Nanoparticles in Solution. Chem. Rev. 2014, 114, 7610–7630. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Doert, T.; Wang, H.; Zhang, S.; Ruck, M. Inorganic Synthesis Based on Reactions of Ionic Liquids and Deep Eutectic Solvents. Angew. Chem. Int. Ed. 2021, 60, 22148–22165. [Google Scholar] [CrossRef]

- Vidal-García, G.; Guinto-Pano, C.E.; García-Hernández, I.; Rodríguez-Clemente, E.; Morales-Gil, P.; Ramírez-Silva, M.T.; Romero-Romo, M.; Palomar-Pardavé, M. Electrochemical Nucleation and Growth of Aluminum Nanoparticles and Leaf-like Flat Microstructures from Reline Deep Eutectic Solvent: Effect of Temperature and Angular Speed of Working Electrode. Trans. Nonferrous Met. Soc. China 2022, 32, 1050–1060. [Google Scholar] [CrossRef]

- Tomé, L.I.N.; Baião, V.; da Silva, W.; Brett, C.M.A. Deep Eutectic Solvents for the Production and Application of New Materials. Appl. Mater. Today 2018, 10, 30–50. [Google Scholar] [CrossRef]

- Pottathara, Y.B.; Grohens, Y.; Kokol, V.; Kalarikkal, N.; Thomas, S. Synthesis and Processing of Emerging Two-Dimensional Nanomaterials. In Nanomaterials Synthesis, Design, Fabrication and Applications; Yasir Beeran, P., Sabu, T., Nandakumar, K., Yves, G., Vanja, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–25. ISBN 978-0-12-815751-0. [Google Scholar] [CrossRef]

- Hammond, O.S.; Mudring, A.V. Ionic Liquids and Deep Eutectics as a Transformative Platform for the Synthesis of Nanomaterials. Chem. Commun. 2022, 58, 3865–3892. [Google Scholar] [CrossRef] [PubMed]

- Ul Haq, H.; Bibi, R.; Balal Arain, M.; Safi, F.; Ullah, S.; Castro-Muñoz, R.; Boczkaj, G. Deep Eutectic Solvent (DES) with Silver Nanoparticles (Ag-NPs) Based Assay for Analysis of Lead (II) in Edible Oils. Food Chem. 2022, 379, 132085. [Google Scholar] [CrossRef]

- Adhikari, L.; Larm, N.E.; Bhawawet, N.; Baker, G.A. Rapid Microwave-Assisted Synthesis of Silver Nanoparticles in a Halide-Free Deep Eutectic Solvent. ACS Sustain. Chem. Eng. 2018, 6, 5725–5731. [Google Scholar] [CrossRef]

- Sarjuna, K. Synthesis and Characterization of Silver Nanoparticles Using Zinc Chloride-Sugar-Amino Acids Based Novel Ternary Deep Eutectic Solvents. ECS Trans. 2022, 107, 4113–4127. [Google Scholar] [CrossRef]

- Raghuwanshi, V.S.; Ochmann, M.; Hoell, A.; Polzer, F.; Rademann, K. Deep Eutectic Solvents for the Self-Assembly of Gold Nanoparticles: A SAXS, UV-Vis, and TEM Investigation. Langmuir 2014, 30, 6038–6046. [Google Scholar] [CrossRef]

- Liao, H.G.; Jiang, Y.X.; Zhou, Z.Y.; Chen, S.P.; Sun, S.G. Shape-Controlled Synthesis of Gold Nanoparticles in Deep Eutectic Solvents for Studies of Structure–Functionality Relationships in Electrocatalysis. Angew. Chem. Int. Ed. 2008, 47, 9100–9103. [Google Scholar] [CrossRef]

- O’Neill, M.; Raghuwanshi, V.S.; Wendt, R.; Wollgarten, M.; Hoell, A.; Rademann, K. Gold Nanoparticles in Novel Green Deep Eutectic Solvents: Self-Limited Growth, Self-Assembly & Catalytic Implications. Z. Fur Phys. Chem. 2015, 229, 221–234. [Google Scholar] [CrossRef]

- Azizi, N.; Edrisi, M.; Manochehri, Z. Greener Synthesis of Magnetic Nanoparticles in an Aqueous Deep Eutectic Solvent. Sci. Iran. 2016, 23, 2750–2755. [Google Scholar] [CrossRef]

- Sakthi Sri, S.P.; Taj, J.; George, M. Facile Synthesis of Magnetite Nanocubes Using Deep Eutectic Solvent: An Insight to Anticancer and Photo-Fenton Efficacy. Surf. Interfaces 2020, 20, 100609. [Google Scholar] [CrossRef]

- Deng, Y.; Ouyang, J.; Wang, H.; Yang, C.; Zhu, Y.; Wang, J.; Li, D.; Ma, K. Magnetic Nanoparticles Prepared in Natural Deep Eutectic Solvent for Enzyme Immobilisation. Biocatal Biotransfor. 2021, 40, 450–460. [Google Scholar] [CrossRef]

- Dong, J.Y.; Hsu, Y.J.; Wong, D.S.H.; Lu, S.Y. Growth of ZnO Nanostructures with Controllable Morphology Using a Facile Green Antisolvent Method. J. Phys. Chem. C 2010, 114, 8867–8872. [Google Scholar] [CrossRef]

- Baum, T.P.F.; Santos, M.J.L. Deep Eutectic Solvent Assisted Sustainable Synthesis of ZnSe Nanoparticles by Hot Injection. Braz. MRS Meet. 2019, 51, 1217. [Google Scholar]

- Karimi, M.; Eshraghi, M.J.; Jahangir, V. A Facile and Green Synthetic Approach Based on Deep Eutectic Solvents toward Synthesis of CZTS Nanoparticles. Mater. Lett. 2016, 171, 100–103. [Google Scholar] [CrossRef]

- Furman, B.R.; Gutierrez, R.D.; Baker, C.K. Ionothermal Synthesis of Lanthanide Tetrafluoride Nanoparticles Using Deep Eutectic Solvents. MRS Online Proc. Libr. 2015, 1804, 25–30. [Google Scholar] [CrossRef]

- Murakami, Y.; Das, S.K.; Himuro, Y.; Maeda, S. Triplet-Sensitized Photon Upconversion in Deep Eutectic Solvents. Phys. Chem. Chem. Phys. 2017, 19, 30603–30615. [Google Scholar] [CrossRef] [PubMed]

- Luo, T.; Wang, C.; Ji, X.; Yang, G.; Chen, J.; Janaswamy, S.; Lyu, G. Preparation and Characterization of Size-Controlled Lignin Nanoparticles with Deep Eutectic Solvents by Nanoprecipitation. Molecules 2021, 26, 218. [Google Scholar] [CrossRef] [PubMed]

- Luo, T.; Wang, C.; Ji, X.; Yang, G.; Chen, J.; Yoo, C.G.; Janaswamy, S.; Lyu, G. Innovative Production of Lignin Nanoparticles Using Deep Eutectic Solvents for Multifunctional Nanocomposites. Int. J. Biol. Macromol. 2021, 183, 781–789. [Google Scholar] [CrossRef] [PubMed]

- Douard, L.; Bras, J.; Encinas, T.; Belgacem, M.N. Natural Acidic Deep Eutectic Solvent to Obtain Cellulose Nanocrystals Using the Design of Experience Approach. Carbohydr. Polym. 2020, 252, 117136. [Google Scholar] [CrossRef]

- Liu, Y.; Kang, S.; Li, K.; Chen, J.; Bae, B.; Hwang, I.; Ahn, E.Y.; Park, Y.; Chun, K.H.; Lee, J. Ecofriendly and Enhanced Biogenic Synthesis of Silver Nanoparticles Using Deep Eutectic Solvent-Based Green Tea Extracts. J. Clean. Prod. 2022, 379, 134655. [Google Scholar] [CrossRef]

- Sengul, A.B.; Asmatulu, E. Toxicity of Metal and Metal Oxide Nanoparticles: A Review. Environ. Chem. Lett. 2020, 18, 1659–1683. [Google Scholar] [CrossRef]

- Xiong, Q.Q.; Tu, J.P.; Ge, X.; Wang, X.L.; Gu, C.D. One-Step Synthesis of Hematite Nanospindles from Choline Chloride/Urea Deep Eutectic Solvent with Highly Powerful Storage versus Lithium. J. Power Sources 2015, 274, 1–7. [Google Scholar] [CrossRef]

- Hammond, O.S.; Edler, K.J.; Bowron, D.T.; Torrente-Murciano, L. Deep Eutectic-Solvothermal Synthesis of Nanostructured Ceria. Nat. Commun. 2017, 8, 1–7. [Google Scholar] [CrossRef]

- Ndlwana, L.; Raleie, N.; Dimpe, K.M.; Ogutu, H.F.; Oseghe, E.O.; Motsa, M.M.; Msagati, T.A.M.; Mamba, B.B. Sustainable Hydrothermal and Solvothermal Synthesis of Advanced Carbon Materials in Multidimensional Applications: A Review. Materials 2021, 14, 5094. [Google Scholar] [CrossRef]

- Zaib, Q.; Adeyemi, I.; Warsinger, D.M.; AlNashef, I.M. Deep Eutectic Solvent Assisted Dispersion of Carbon Nanotubes in Water. Front. Chem. 2020, 8, 808. [Google Scholar] [CrossRef]

- Banjare, R.K.; Banjare, M.K.; Behera, K.; Tandon, M.; Pandey, S.; Ghosh, K.K. Deep Eutectic Solvents as Modulator on the Micellization Behaviour of Cationic Surfactants and Potential Application in Human Serum Albumin Aggregation. J. Mol. Liq. 2021, 344, 117864. [Google Scholar] [CrossRef]

- Karimi, M.; Ramsheh, M.R.; Ahmadi, S.M.; Madani, M.R.; Shamsi, M.; Reshadi, R.; Lotfi, F. Reline-Assisted Green and Facile Synthesis of Fluorapatite Nanoparticles. Mater. Sci. Eng. C 2017, 77, 121–128. [Google Scholar] [CrossRef] [PubMed]

- Karimi, M.; Hesaraki, S.; Alizadeh, M.; Kazemzadeh, A. A Facile and Sustainable Method Based on Deep Eutectic Solvents toward Synthesis of Amorphous Calcium Phosphate Nanoparticles: The Effect of Using Various Solvents and Precursors on Physical Characteristics. J. Non Cryst. Solids 2016, 443, 59–64. [Google Scholar] [CrossRef]

- Karimi, M.; Hesaraki, S.; Alizadeh, M.; Kazemzadeh, A. Synthesis of Calcium Phosphate Nanoparticles in Deep-Eutectic Choline Chloride–Urea Medium: Investigating the Role of Synthesis Temperature on Phase Characteristics and Physical Properties. Ceram. Int. 2016, 42, 2780–2788. [Google Scholar] [CrossRef]

- Yu, D.; Xue, Z.; Mu, T. Deep Eutectic Solvents as a Green Toolbox for Synthesis. Cell Rep. Phys. Sci. 2022, 3, 100809. [Google Scholar] [CrossRef]

- Exposito, A.J.; Barrie, P.J.; Torrente-Murciano, L. Fast Synthesis of CeO2 Nanoparticles in a Continuous Microreactor Using Deep Eutectic Reline As Solvent. ACS Sustain. Chem. Eng. 2020, 8, 18297–18302. [Google Scholar] [CrossRef]

- Hammond, O.S.; Bowron, D.T.; Edler, K.J. The Effect of Water upon Deep Eutectic Solvent Nanostructure: An Unusual Transition from Ionic Mixture to Aqueous Solution. Angew. Chem. Int. Ed. 2017, 56, 9782–9785. [Google Scholar] [CrossRef] [PubMed]

- Rozas, S.; Benito, C.; Alcalde, R.; Atilhan, M.; Aparicio, S. Insights on the Water Effect on Deep Eutectic Solvents Properties and Structuring: The Archetypical Case of Choline Chloride + Ethylene Glycol. J. Mol. Liq. 2021, 344, 117717. [Google Scholar] [CrossRef]

- Sreekanth, T.V.M.; Nagajyothi, P.C.; Reddy, G.R.; Shim, J.; Yoo, K. Urea Assisted Ceria Nanocubes for Efficient Removal of Malachite Green Organic Dye from Aqueous System. Sci. Rep. 2019, 9, 1–9. [Google Scholar] [CrossRef]

- Chavhan, M.P.; Lu, C.H.; Som, S. Urea and Surfactant Assisted Hydrothermal Growth of Ceria Nanoparticles. Colloids Surf. A Phys. Eng. Asp. 2020, 601, 124944. [Google Scholar] [CrossRef]

- Guzman, M.; Estrada, M.; Miridonov, S.; Simakov, A. Synthesis of Cerium Oxide (IV) Hollow Nanospheres with Tunable Structure and Their Performance in the 4-Nitrophenol Adsorption. Microporous Mesoporous Mater. 2019, 278, 241–250. [Google Scholar] [CrossRef]

- Li, H.; Meng, F.; Gong, J.; Fan, Z.; Qin, R. Structural, Morphological and Optical Properties of Shuttle-like CeO2 Synthesized by a Facile Hydrothermal Method. J. Alloys Compd. 2017, 722, 489–498. [Google Scholar] [CrossRef]

- Chen, J.; Kazzaz, A.E.; AlipoorMazandarani, N.; Feizi, Z.H.; Fatehi, P. Production of Flocculants, Adsorbents, and Dispersants from Lignin. Mol. A J. Synth. Chem. Nat. Prod. Chem. 2018, 23, 868. [Google Scholar] [CrossRef]

- Lai, P.-C.; Ren, Z.-F.; Yu, S.-S. Thermally Induced Gelation of Cellulose Nanocrystals in Deep Eutectic Solvents for 3D Printable and Self-Healable Ionogels. ACS Appl. Polym. Mater. 2022, 4, 9221–9230. [Google Scholar] [CrossRef]

- Seo, H.; Lee, I.; Sridhar, V.; Park, H. Metal-Organic Framework Reinforced Acrylic Polymer Marine Coatings. Materials 2022, 15, 27. [Google Scholar] [CrossRef]

- Nam, N.N.; Do, H.D.K.; Trinh, K.T.L.; Lee, N.Y. Recent Progress in Nanotechnology-Based Approaches for Food Monitoring. Nanomaterials 2022, 12, 4116. [Google Scholar] [CrossRef]

- Li, Y.; Karimi, M.; Gong, Y.N.; Dai, N.; Safarifard, V.; Jiang, H.L. Integration of Metal-Organic Frameworks and Covalent Organic Frameworks: Design, Synthesis, and Applications. Matter 2021, 4, 2230–2265. [Google Scholar] [CrossRef]

- Maia, R.A.; Louis, B.; Baudron, S.A. Deep Eutectic Solvents for the Preparation and Post-Synthetic Modification of Metal- and Covalent Organic Frameworks. CrystEngComm 2021, 23, 5016–5032. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, T.; Chen, S.; Feng, P.; Bu, X. Versatile Structure-Directing Roles of Deep-Eutectic Solvents and Their Implication in the Generation of Porosity and Open Metal Sites for Gas Storage. Angew. Chem. Int. Ed. 2009, 48, 3486–3490. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, J.; Wu, T.; Feng, P.; Bu, X. Zinc(II)-Boron(III)-Imidazolate Framework (ZBIF) with Unusual Pentagonal Channels Prepared from Deep Eutectic Solvent. Dalton Trans. 2009, 39, 697–699. [Google Scholar] [CrossRef]

- Parnham, E.R.; Morris, R.E. Ionothermal Synthesis of Zeolites, Metal–Organic Frameworks, and Inorganic–Organic Hybrids. Acc. Chem. Res. 2007, 40, 1005–1013. [Google Scholar] [CrossRef] [PubMed]

- Cooper, E.R.; Andrews, C.D.; Wheatley, P.S.; Webb, P.B.; Wormald, P.; Morris, R.E. Ionic Liquids and Eutectic Mixtures as Solvent and Template in Synthesis of Zeolite Analogues. Nature 2004, 430, 1012–1016. [Google Scholar] [CrossRef] [PubMed]

- Cheng, F.F.; Zhu, J.N.; Zhao, M.Y.; Ma, Z.J.; Xiong, W.W. Preparing Transition Metal-Organic Frameworks Based on Oxalate-Sulfate Anions in Deep Eutectic Solvents. J. Solid State Chem. 2019, 278, 120904. [Google Scholar] [CrossRef]

- Akbarian, M.; Sanchooli, E.; Oveisi, A.R.; Daliran, S. Choline Chloride-Coated UiO-66-Urea MOF: A Novel Multifunctional Heterogeneous Catalyst for Efficient One-Pot Three-Component Synthesis of 2-Amino-4H-Chromenes. J. Mol. Liq. 2021, 325, 115228. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Zhu, J.N.; Li, P.; Li, W.; Cai, T.; Cheng, F.F.; Xiong, W.W. Structural Variation of Transition Metal–Organic Frameworks Using Deep Eutectic Solvents with Different Hydrogen Bond Donors. Dalton Trans. 2019, 48, 10199–10209. [Google Scholar] [CrossRef]

- Dong, B.; Wang, W.J.; Xi, S.C.; Wang, D.Y.; Wang, R. A Carboxyl-Functionalized Covalent Organic Framework Synthesized in a Deep Eutectic Solvent for Dye Adsorption. Chem. A Eur. J. 2021, 27, 2692–2698. [Google Scholar] [CrossRef]

- Qiu, J.; Guan, P.; Zhao, Y.; Li, Z.; Wang, H.; Wang, J. Syntheses of Two- and Three-Dimensional Covalent Organic Frameworks in Deep Eutectic Solvents. Green Chem. 2020, 22, 7537–7542. [Google Scholar] [CrossRef]

- Gao, M.; Wang, D.; Deng, L.; Liu, S.; Zhang, K.; Quan, T.; Yang, L.; Kang, X.; Xia, Z.; Gao, D. High-Crystallinity Covalent Organic Framework Synthesized in Deep Eutectic Solvent: Potentially Effective Adsorbents Alternative to Macroporous Resin for Flavonoids. Chem. Mater. 2021, 33, 8036–8051. [Google Scholar] [CrossRef]

- Nasirpouri, F.; Alipour, K.; Daneshvar, F.; Sanaeian, M.-R. Electrodeposition of Anticorrosion Nanocoatings. In Corrosion Protection at the Nanoscale; Susai, R., Tuan ANH, N., Saeid, K., Mahdi, Y., Yongxin, L., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 473–497. ISBN 978-0-12-819359-4. [Google Scholar] [CrossRef]

- da Silva Ries, L.A.; de Brito, H.A.; Gasparin, F.P.; Muller, I.L. Additive-Free Electrodeposition of Cobalt on Silicon from 1-Butyl-3-Methylimidazolium Tetrafluoroborate Ionic Liquid. J. Mol. Liq. 2021, 325, 114787. [Google Scholar] [CrossRef]

- Sousa, N.G.; Salgueira, J.F.S.; Sousa, C.P.; Campos, O.S.; Salazar-Banda, G.R.; Eguiluz, K.I.B.; de Lima-Neto, P.; Correia, A.N. Silver Electrodeposition at Room Temperature Protic Ionic Liquid 1-H-Methylimidazolium Hydrogen Sulfate. J. Mol. Liq. 2020, 313, 113487. [Google Scholar] [CrossRef]

- Bhujbal, A.V.; Rout, A.; Venkatesan, K.A.; Bhanage, B.M. Electrochemical Behavior and Direct Electrodeposition of UO2 Nanoparticles from Uranyl Nitrate Dissolved in an Ammonium-Based Ionic Liquid. J. Mol. Liq. 2020, 307, 112975. [Google Scholar] [CrossRef]

- Banbur-Pawlowska, S.; Mech, K.; Kowalik, R.; Zabinski, P. Analysis of Electrodeposition Parameters Influence on Cobalt Deposit Roughness. Appl. Surf. Sci. 2016, 388, 805–808. [Google Scholar] [CrossRef]

- Protsenko, V.S.; Danilov, F.I. Current Trends in Electrodeposition of Electrocatalytic Coatings. In Methods for Electrocatalysis; Inamuddin, Rajender, B., Abdullah, M.A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 263–299. ISBN 978-3-030-27161-9. [Google Scholar] [CrossRef]

- Abbott, A.P. Deep Eutectic Solvents and Their Application in Electrochemistry. Curr. Opin. Green Sustain. Chem. 2022, 36, 100649. [Google Scholar] [CrossRef]

- Bhujbal, A.V.; Venkatesan, K.A.; Bhanage, B.M. Electrochemical Deposition of Nanocrystalline Aluminum from a Protic Ionic Liquid on Mild Steel. J. Mol. Liq. 2021, 326, 115275. [Google Scholar] [CrossRef]

- Bernasconi, R.; Panzeri, G.; Accogli, A.; Liberale, F.; Nobili, L. Electrodeposition from Deep Eutectic Solvents. In Progress and Developments in Ionic Liquids; Scott, H., Ed.; InTech: Rijeka, Croatia, 2017; pp. 235–261. ISBN 978-953-51-2902-8. [Google Scholar] [CrossRef]

- Abd El-Lateef, H.M.; Almulhim, N.F.; Mohamed, I.M.A. Physicochemical and Electrochemical Investigations of an Electrodeposited CeNi2@NiO Nanomaterial as a Novel Anode Electrocatalyst Material for Urea Oxidation in Alkaline Media. J. Mol. Liq. 2020, 297, 111737. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, J.; Höfft, O.; Endres, F. Electrodeposition of Indium from an Ionic Liquid Investigated by in Situ Electrochemical Xps. Metals 2022, 12, 59. [Google Scholar] [CrossRef]

- Lu, H.; Sha, S.; Li, T.; Wen, Q.; Yang, S.; Wu, J.; Wang, K.; Sheng, Z.; Ma, J. One-Step Electrodeposition of ZnO/Graphene Composites with Enhanced Capability for Photocatalytic Degradation of Organic Dyes. Front. Chem. 2022, 10, 1405. [Google Scholar] [CrossRef] [PubMed]

- Amani, S.; Sohrabi, N.; Mohammadi, R.; Ahadzadeh, I. Synthesis and Investigation of CoMnFeO4/Reduced Graphene Oxide as Ecofriendly Electrode Material for Supercapacitor and Its Electrochemical Performances. J. Alloys Compd. 2023, 937, 168020. [Google Scholar] [CrossRef]

- Zhang, Y.; An, M.; Yang, P.; Zhang, J. Electrochemical Behavior of Through-Hole Electrodeposition Inhibitor EO-PO under Periodic Pulse Reverse. Colloids Surf. A Phys. Eng. Asp. 2022, 655, 130238. [Google Scholar] [CrossRef]

- Barsan, M.M.; Ghica, M.E.; Brett, C.M.A. Electrochemical Sensors and Biosensors Based on Redox Polymer/Carbon Nanotube Modified Electrodes: A Review. Anal. Chim. Acta 2015, 881, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Hosu, O.; Bârsan, M.M.; Cristea, C.; Săndulescu, R.; Brett, C.M.A. Nanostructured Electropolymerized Poly(Methylene Blue) Films from Deep Eutectic Solvents. Optimization and Characterization. Electrochim. Acta 2017, 232, 285–295. [Google Scholar] [CrossRef]

- Hosu, O.; Barsan, M.M.; Cristea, C.; Săndulescu, R.; Brett, C.M.A. Nanocomposites Based on Carbon Nanotubes and Redox-Active Polymers Synthesized in a Deep Eutectic Solvent as a New Electrochemical Sensing Platform. Microchim. Acta 2017, 184, 3919–3927. [Google Scholar] [CrossRef]

- Fernandes, P.M.v.; Campiña, J.M.; Pereira, C.M.; Silva, F. Electrosynthesis of Polyaniline from Choline-Based Deep Eutectic Solvents: Morphology, Stability and Electrochromism. J. Electrochem. Soc. 2012, 159, G97–G105. [Google Scholar] [CrossRef]

- Prathish, K.P.; Carvalho, R.C.; Brett, C.M.A. Highly Sensitive Poly(3,4-Ethylenedioxythiophene) Modified Electrodes by Electropolymerisation in Deep Eutectic Solvents. Electrochem. Commun. 2014, 44, 8–11. [Google Scholar] [CrossRef]

- Prathish, K.P.; Carvalho, R.C.; Brett, C.M.A. Electrochemical Characterisation of Poly(3,4-Ethylenedioxythiophene) Film Modified Glassy Carbon Electrodes Prepared in Deep Eutectic Solvents for Simultaneous Sensing of Biomarkers. Electrochim. Acta 2016, 187, 704–713. [Google Scholar] [CrossRef]

- Ismail, H.K.; Alesary, H.F.; Juma, J.A.; Hillman, A.R.; Ryder, K.S. A Comparative Study of the Formation, and Ion and Solvent Transport of Polyaniline in Protic Liquid-Based Deep Eutectic Solvents and Aqueous Solutions Using EQCM. Electrochim. Acta 2022, 418, 140348. [Google Scholar] [CrossRef]

- Gamburg, Y.D.; Zangari, G. Theory and Practice of Metal Electrodeposition; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Mbugua, N.S.; Kang, M.; Zhang, Y.; Ndiithi, N.J.; Bertrand, G.V.; Yao, L. Electrochemical Deposition of Ni, NiCo Alloy and NiCo–Ceramic Composite Coatings—A Critical Review. Materials 2020, 13, 3475. [Google Scholar] [CrossRef]

- Torabinejad, V.; Aliofkhazraei, M.; Assareh, S.; Allahyarzadeh, M.H.; Rouhaghdam, A.S. Electrodeposition of Ni-Fe Alloys, Composites, and Nano Coatings–A Review. J. Alloys Compd. 2017, 691, 841–859. [Google Scholar] [CrossRef]

- Protsenko, V.S.; Kityk, A.A.; Shaiderov, D.A.; Danilov, F.I. Effect of Water Content on Physicochemical Properties and Electrochemical Behavior of Ionic Liquids Containing Choline Chloride, Ethylene Glycol and Hydrated Nickel Chloride. J. Mol. Liq. 2015, 212, 716–722. [Google Scholar] [CrossRef]

- Elsharkawya, S.; Hammad, S.; El-hallaga, I. Electrodeposition of Ni Nanoparticles from Deep Eutectic Solvent and Aqueous Solution Promoting High Stability Electrocatalyst for Hydrogen and Oxygen Evolution Reactions. J. Solid. State Electrochem. 2022, 26, 1501–1517. [Google Scholar] [CrossRef]

- Gu, C.; Tu, J. One-Step Fabrication of Nanostructured Ni Film with Lotus Effect from Deep Eutectic Solvent. Langmuir 2011, 27, 10132–10140. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zou, X.; Lu, Y.; Rao, S.; Xie, X.; Pang, Z.; Lu, X.; Xu, Q.; Zhou, Z. Electrodeposition of Nano-Nickel in Deep Eutectic Solvents for Hydrogen Evolution Reaction in Alkaline Solution. Int. J. Hydrogen Energy 2018, 43, 15673–15686. [Google Scholar] [CrossRef]

- Leal-Duaso, A.; Akkari, S.; Fajardo, A.S.; Sánchez-Sánchez, C.M. Bio-Based Deep Eutectic Solvents Applied In Nanoparticles Electrosynthesis for Water Decontamination. In Proceedings of the XXXVIII Reunión Bienal de la Real Sociedad Española de Química, Granada, Spain, 27–30 June 2022; ISBN 978-84-09-42159-6. [Google Scholar]

- Gu, C.D.; You, Y.H.; Yu, Y.L.; Qu, S.X.; Tu, J.P. Microstructure, Nanoindentation, and Electrochemical Properties of the Nanocrystalline Nickel Film Electrodeposited from Choline Chloride-Ethylene Glycol. Surf. Coat. Technol. 2011, 205, 4928–4933. [Google Scholar] [CrossRef]

- Li, R.; Hou, Y.; Liang, J. Electro-Codeposition of Ni-SiO2 Nanocomposite Coatings from Deep Eutectic Solvent with Improved Corrosion Resistance. Appl. Surf. Sci. 2016, 367, 449–458. [Google Scholar] [CrossRef]

- Mernissi Cherigui, E.A.; Sentosun, K.; Bouckenooge, P.; Vanrompay, H.; Bals, S.; Terryn, H.; Ustarroz, J. Comprehensive Study of the Electrodeposition of Nickel Nanostructures from Deep Eutectic Solvents: Self-Limiting Growth by Electrolysis of Residual Water. J. Phys. Chem. C 2017, 121, 9337–9347. [Google Scholar] [CrossRef]

- dos Santos, L.P.M.; Freire, R.M.; Michea, S.; Denardin, J.C.; Araújo, D.B.; Barros, E.B.; Correia, A.N.; de Lima-Neto, P. Electrodeposition of 1-D Tellurium Nanostructure on Gold Surface from Choline Chloride-Urea and Choline Chloride-Ethylene Glycol Mixtures. J. Mol. Liq. 2019, 288, 111038. [Google Scholar] [CrossRef]

- Hammons, J.A.; Muselle, T.; Ustarroz, J.; Tzedaki, M.; Raes, M.; Hubin, A.; Terryn, H. Stability, Assembly, and Particle/Solvent Interactions of Pd Nanoparticles Electrodeposited from a Deep Eutectic Solvent. J. Phys. Chem. C 2013, 117, 14381–14389. [Google Scholar] [CrossRef]

- Manolova, M.; Böck, R. Electrodeposition of Pd from a Deep Eutectic Solvent System: Effect of Additives and Hydrodynamic Conditions. Trans. IMF 2019, 97, 161–168. [Google Scholar] [CrossRef]

- Wei, L.; Xu, C.D.; Huang, L.; Zhou, Z.Y.; Chen, S.P.; Sun, S.G. Electrochemically Shape-Controlled Synthesis of Pd Concave-Disdyakis Triacontahedra in Deep Eutectic Solvent. J. Phys. Chem. C 2016, 120, 15569–15577. [Google Scholar] [CrossRef]

- Abbott, A.P.; McKenzie, K.J. Application of Ionic Liquids to the Electrodeposition of Metals. Phys. Chem. Chem. Phys. 2006, 8, 4265–4279. [Google Scholar] [CrossRef] [PubMed]

- Tsuda, T.; Boyd, L.E.; Kuwabata, S.; Hussey, C.L. Electrochemistry of Copper(I) Oxide in the 66.7–33.3 Mol % Urea–Choline Chloride Room-Temperature Eutectic Melt. J. Electrochem. Soc. 2010, 157, F96. [Google Scholar] [CrossRef]

- Wang, R.; Hua, Y.; Zhang, Q. Electrochemical Preparation of Copper Nanoparticles in Choline Chloride-Urea Deep Eutectic Solvent. ECS Trans. 2014, 59, 505–511. [Google Scholar] [CrossRef]

- Wright, A.C.; Faulkner, M.K.; Harris, R.C.; Goddard, A.; Abbott, A.P. Nanomagnetic Domains of Chromium Deposited on Vertically-Aligned Carbon Nanotubes. J. Magn. Magn. Mater. 2012, 324, 4170–4174. [Google Scholar] [CrossRef]

- Cvetković, V.S.; Vukićević, N.M.; Jovićević, N.; Stevanović, J.S.; Jovićević, J.N. Aluminium Electrodeposition under Novel Conditions from AlCl3–Urea Deep Eutectic Solvent at Room Temperature. Trans. Nonferrous Met. Soc. China 2020, 30, 823–834. [Google Scholar] [CrossRef]

- Huynh, T.C.; Dao, Q.P.D.; Truong, T.-N.; Doan, N.-G.; Ho, S.-L. Electrodeposition of Aluminum on Cathodes in Ionic Liquid Based Choline Chloride/Urea/ALCL3. Environ. Pollut. 2014, 3, 60–69. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Zhang, X.; Yu, Y.; Wang, S. Electrochemical Nucleation and Growth Mechanism of Aluminum on AZ31 Magnesium Alloys. Coatings 2021, 11, 46. [Google Scholar] [CrossRef]

- Popescu, A.M.; Soare, V.; Demidenko, O.; Calderon Moreno, J.M.; Neacşu, E.I.; Donath, C.; Burada, M.; Constantin, I.; Constantin, V. Recovery of Silver and Gold from Electronic Waste by Electrodeposition in Ethaline Ionic Liquid. Rev. De Chim. 2020, 71, 122–132. [Google Scholar] [CrossRef]

- Sides, W.D.; Huang, Q. Electrodeposition of Manganese Thin Films on a Rotating Disk Electrode from Choline Chloride/Urea Based Ionic Liquids. Electrochim. Acta 2018, 266, 185–192. [Google Scholar] [CrossRef]

- Palomar-Pardavé, M.; Mostany, J.; Muñoz-Rizo, R.; Botello, L.E.; Aldana-González, J.; Arce-Estrada, E.M.; de Oca-Yemha, M.G.M.; Ramírez-Silva, M.T.; Romo, M.R. Electrochemical Study and Physicochemical Characterization of Iron Nanoparticles Electrodeposited onto HOPG from Fe(III) Ions Dissolved in the Choline Chloride-Urea Deep Eutectic Solvent. J. Electroanal. Chem. 2019, 851, 113453. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, T.; Geng, X.; Ru, J.; Hua, Y.; Bu, J.; Xue, Y.; Wang, D. The Role of Electrolyte Ratio in Electrodeposition of Nanoscale FeCr Alloy from Choline Chloride-Ethylene Glycol Ionic Liquid: A Suitable Layer for Corrosion Resistance. J. Mol. Liq. 2022, 346, 117059. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, T.; Ru, J.; Hua, Y.; Bu, J.; Wang, D. Eco-Friendly Preparation of Nanocrystalline Fe-Cr Alloy Coating by Electrodeposition in Deep Eutectic Solvent without Any Additives for Anti-Corrosion. Surf. Coat. Technol. 2021, 406, 126636. [Google Scholar] [CrossRef]

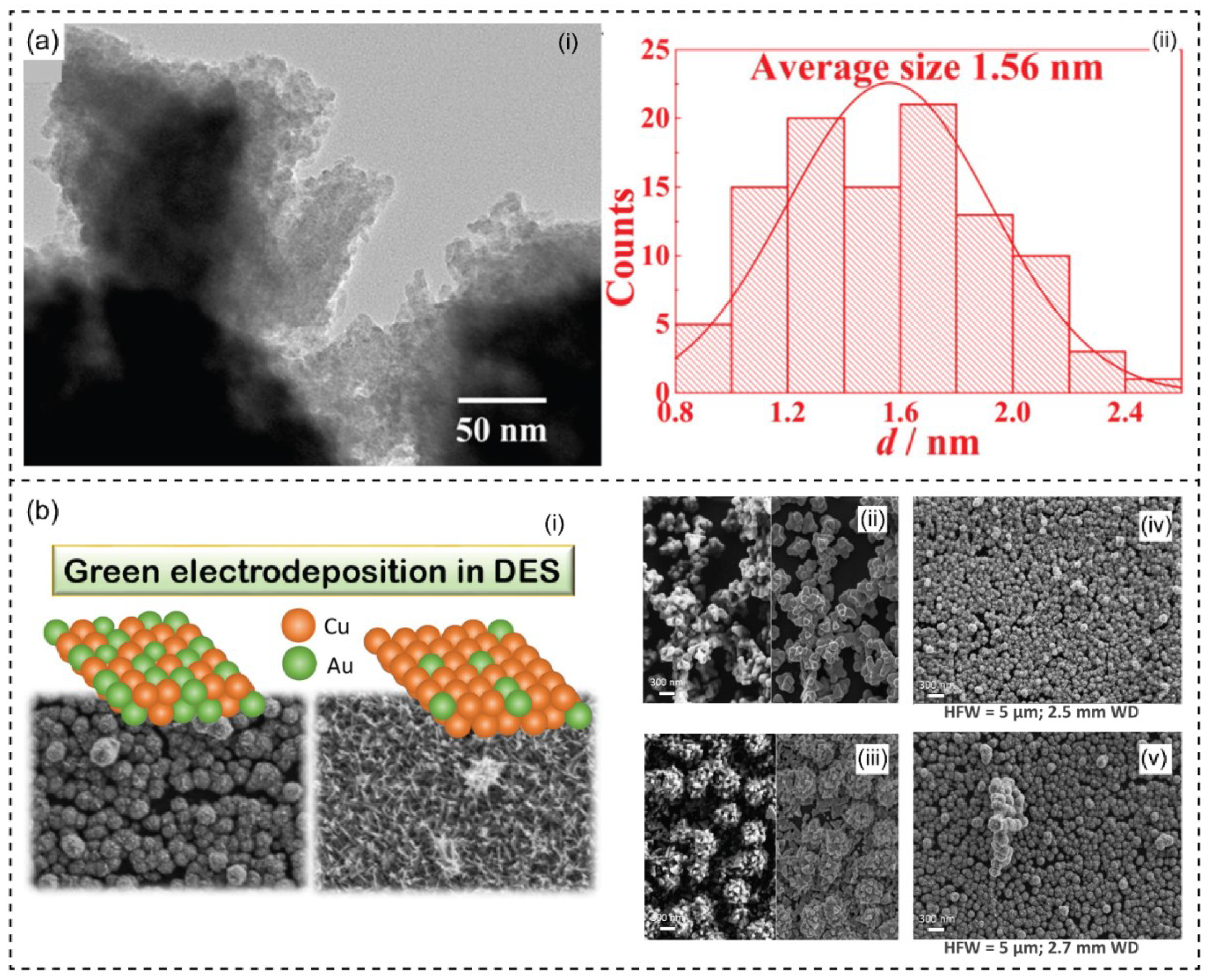

- Plaza-Mayoral, E.; Sebastián-Pascual, P.; Nicole Dalby, K.; Degn Jensen, K.; Chorkendorff, I.; Falsig, H.; Escudero-Escribano, M.; Topsøe, H.A.; Allé, H.T. Green Preparation of High Surface Area Cu-Au Bimetallic Nanostructured Materials by Co-Electrodeposition in a Deep Eutectic Solvent. ChemRxiv 2021. [Google Scholar] [CrossRef]

- Niciejewska, A.; Ajmal, A.; Pawlyta, M.; Marczewski, M.; Winiarski, J. Electrodeposition of Ni–Mo Alloy Coatings from Choline Chloride and Propylene Glycol Deep Eutectic Solvent Plating Bath. Sci. Rep. 2022, 12, 1–15. [Google Scholar] [CrossRef]

- Li, A.; Duan, W.; Liu, J.; Zhuo, K.; Chen, Y.; Wang, J. Electrochemical Synthesis of AuPt Nanoflowers in Deep Eutectic Solvent at Low Temperature and Their Application in Organic Electro-Oxidation. Sci. Rep. 2018, 8, 1–9. [Google Scholar] [CrossRef] [PubMed]

- You, Y.H.; Gu, C.D.; Wang, X.L.; Tu, J.P. Electrodeposition of Ni–Co Alloys from a Deep Eutectic Solvent. Surf. Coat. Technol. 2012, 206, 3632–3638. [Google Scholar] [CrossRef]

- Landa-Castro, M.; Romero-Romo, M.; Arce-Estrada, E.; Morales-Gil, P.; de Oca-Yemha, M.G.M.; Palomar-Pardavé, M. Electrochemical Nucleation and Growth of Pd-Co Alloy Nanoparticles from the Reline Deep Eutectic Solvent. J. Electrochem. Soc. 2022, 169, 092521. [Google Scholar] [CrossRef]

- Guillamat, P.; Cortés, M.; Vallés, E.; Gómez, E. Electrodeposited CoPt Films from a Deep Eutectic Solvent. Surf. Coat. Technol. 2012, 206, 4439–4448. [Google Scholar] [CrossRef]

- Vijayakumar, J.; Mohan, S.; Anand Kumar, S.; Suseendiran, S.R.; Pavithra, S. Electrodeposition of Ni–Co–Sn Alloy from Choline Chloride-Based Deep Eutectic Solvent and Characterization as Cathode for Hydrogen Evolution in Alkaline Solution. Int. J. Hydrogen Energy 2013, 38, 10208–10214. [Google Scholar] [CrossRef]

- Ghosh, S.; Roy, S. Codeposition of Cu-Sn from Ethaline Deep Eutectic Solvent. Electrochim. Acta 2015, 183, 27–36. [Google Scholar] [CrossRef]

- Fashu, S.; Gu, C.D.; Zhang, J.L.; Bai, W.Q.; Wang, X.L.; Tu, J.P. Electrodeposition and Characterization of Zn–Sn Alloy Coatings from a Deep Eutectic Solvent Based on Choline Chloride for Corrosion Protection. Surf. Interface Anal. 2015, 47, 403–412. [Google Scholar] [CrossRef]

- dos Reis da Costa, J.G.; Costa, J.M.; de Almeida Neto, A.F. Progress on Electrodeposition of Metals and Alloys Using Ionic Liquids as Electrolytes. Metals 2022, 12, 2095. [Google Scholar] [CrossRef]

- Tian, Y.; Ma, L.; Xi, X.; Nie, Z. Induced Electrodeposition of Alloy Coatings from Baths Containing Different Systems of Complexing Agents: Preparation and Enhanced Properties of Co-Mo-Ni-W Coatings. J. Electroanal. Chem. 2022, 921, 116700. [Google Scholar] [CrossRef]

- Wang, Z.; Ru, J.; Hua, Y.; Wang, D.; Bu, J. Morphology-Controlled Preparation of Sn Powders by Electrodeposition in Deep Eutectic Solvent as Anodes for Lithium Ion Batteries. J. Electrochem. Soc. 2020, 167, 082504. [Google Scholar] [CrossRef]

- Plaza-Mayoral, E.; Sebastián-Pascual, P.; Dalby, K.N.; Jensen, K.D.; Chorkendorff, I.; Falsig, H.; Escudero-Escribano, M. Preparation of High Surface Area Cu-Au Bimetallic Nanostructured Materials by Co-electrodeposition in a Deep Eutectic Solvent. Electrochim. Acta 2021, 398, 139309. [Google Scholar] [CrossRef]

- Winiarski, J.; Niciejewska, A.; Ryl, J.; Darowicki, K.; Baśladyńska, S.; Winiarska, K.; Szczygiel, B. Ni/Cerium Molybdenum Oxide Hydrate Microflakes Composite Coatings Electrodeposited From Choline Chloride: Ethylene Glycol Deep Eutectic Solvent. Materials 2020, 13, 924. [Google Scholar] [CrossRef] [PubMed]

- Ansari, M.I.; Julka, S.; Thakur, D.G. Enhancement of Surface Properties with Influence of Bath PH on Electroless Ni-P-ZnO/Al2O3 Nano-Composite Deposits for Defence Applications. J. Mol. Liq. 2017, 247, 22–33. [Google Scholar] [CrossRef]

- Belakhmima, R.A.; Errahmany, N.; Ebn Touhami, M.; Larhzil, H.; Touir, R. Preparation and Characterization of Electroless Cu–P Deposition Protection for Mild Steel Corrosion in Molar Hydrochloric Solution. J. Assoc. Arab Univ. Basic Appl. Sci. 2017, 24, 46–53. [Google Scholar] [CrossRef]

- Lahiri, A.; Pulletikurthi, G.; Endres, F. A Review on the Electroless Deposition of Functional Materials in Ionic Liquids for Batteries and Catalysis. Front. Chem. 2019, 7, 85. [Google Scholar] [CrossRef]

- Sudagar, J.; Lian, J.; Sha, W. Electroless Nickel, Alloy, Composite and Nano Coatings—A Critical Review. J. Alloys Compd. 2013, 571, 183–204. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, X.; Wang, W.; Mitsuzak, N.; Chen, Z. Immersion Gold Deposition from a Chloroauric Acid–Choline Chloride Solution: Deposition Kinetics and Coating Performances. Surf. Coat. Technol. 2015, 265, 62–67. [Google Scholar] [CrossRef]

- Jayakumar, M.; Murugesan, C.; Andrew, C.; Natarajan, K.; Sekar, R. Electro- and Electroless Deposition of Rhenium from Reline Deep Eutectic Solvent. J. Electrochem. Soc. 2022, 169, 032510. [Google Scholar] [CrossRef]

- Abbott, A.P.; Nandhra, S.; Postlethwaite, S.; Smith, E.L.; Ryder, K.S. Electroless Deposition of Metallic Silver from a Choline Chloride-Based Ionic Liquid: A Study Using Acoustic Impedance Spectroscopy, SEM and Atomic Force Microscopy. Phys. Chem. Chem. Phys. 2007, 9, 3735–3743. [Google Scholar] [CrossRef] [PubMed]

- Abbott, A.P.; Griffith, J.; Nandhra, S.; O’Connor, C.; Postlethwaite, S.; Ryder, K.S.; Smith, E.L. Sustained Electroless Deposition of Metallic Silver from a Choline Chloride-Based Ionic Liquid. Surf. Coat. Technol. 2008, 202, 2033–2039. [Google Scholar] [CrossRef]

- Kang, R.; Peng, Z.; Liu, B.; Wang, D.; Liang, J. A Protocol for Fast Electroless Ni-P on Al Alloy at Medium-Low Temperature Accelerated by Hierarchically Structured Cu Immersion Layer. Surf. Coat. Technol. 2017, 309, 67–74. [Google Scholar] [CrossRef]

- Lahiri, A.; Borisenko, N.; Olschewski, M.; Gustus, R.; Zahlbach, J.; Endres, F. Electroless Deposition of III–V Semiconductor Nanostructures from Ionic Liquids at Room Temperature. Angew. Chem. Int. Ed. 2015, 54, 11870–11874. [Google Scholar] [CrossRef]

- Ali, M.R.; Rahman, M.Z.; Saha, S.S. Electroless and Electrolytic Deposition of Nickel from Deep Eutectic Solvents Based on Choline Chloride. Indian J. Chem. Technol. 2014, 21, 127–133. [Google Scholar]

- Yang, Q.; Ru, J.; Song, P.; Hu, M.; Feng, J. Fabrication and Characterization of Ni-Decorated h-BN Powders with ChCl-EG Ionic Liquid as Addition by Electroless Deposition. R Soc. Open Sci. 2018, 5, 180146. [Google Scholar] [CrossRef]

- Bibi, S.; Sarfaraz, S.; Yar, M.; Zaman, M.I.; Niaz, A.; Khan, A.; Hashmi, M.A.; Ayub, K. Structure and Electronic Characterization of Pristine and Functionalized Single Wall Carbon Nanotube Interacting with Sulfide Ion: A Density Functional Theory Approach. J. Mol. Liq. 2022, 366, 120144. [Google Scholar] [CrossRef]

- Mahendiran, B.; Azeez, N.A.; Muthusamy, S.; Krishnakumar, G.S. Polymer-Based Bionanomaterials for Targeted Drug Delivery. In Fundamentals of Bionanomaterials; Ahmed, B., Jaison, J., Michael, K.D., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 241–271. ISBN 978-0-12-824147-9. [Google Scholar] [CrossRef]

- Plastiras, O.E.; Andreasidou, E.; Samanidou, V. Microextraction Techniques with Deep Eutectic Solvents. Molecules 2020, 25, 6026. [Google Scholar] [CrossRef]

- Cvetanovi’c, A.; Kljaki´ckljaki´c, C.; Bodo, E.; Plastiras, O.-E.; Samanidou, V. Applications of Deep Eutectic Solvents in Sample Preparation and Extraction of Organic Molecules. Molecules 2022, 27, 7699. [Google Scholar] [CrossRef]

- Ramon, D.J.; Guillena, G. Deep Eutectic Solvents Synthesis, Properties, and Applications; Wiley: Hoboken, NJ, USA, 2020; ISBN 978-3-527-34518-2. [Google Scholar]

- Jablonský, M.; Škulcová, A.; Šima, J. Use of Deep Eutectic Solvents in Polymer Chemistry–A Review. Molecules 2019, 24, 3978. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, S.; Shanti, R.; Morris, E. Studies on the Plasticization Efficiency of Deep Eutectic Solvent in Suppressing the Crystallinity of Corn Starch Based Polymer Electrolytes. Carbohydr. Polym. 2012, 87, 701–706. [Google Scholar] [CrossRef] [PubMed]

- Sousa, A.M.M.; Souza, H.K.S.; Latona, N.; Liu, C.K.; Gonçalves, M.P.; Liu, L. Choline Chloride Based Ionic Liquid Analogues as Tool for the Fabrication of Agar Films with Improved Mechanical Properties. Carbohydr. Polym. 2014, 111, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Favero, J.; Belhabib, S.; Guessasma, S.; Decaen, P.; Reguerre, A.L.; Lourdin, D.; Leroy, E. On the Representative Elementary Size Concept to Evaluate the Compatibilisation of a Plasticised Biopolymer Blend. Carbohydr. Polym. 2017, 172, 120–129. [Google Scholar] [CrossRef] [PubMed]

- Pereira, P.F.; Andrade, C.T. Optimized PH-Responsive Film Based on a Eutectic Mixture-Plasticized Chitosan. Carbohydr. Polym. 2017, 165, 238–246. [Google Scholar] [CrossRef]

- Li, L.; Liu, K.; Xing, H.; Li, X.; Zhang, Q.; Han, D.; He, H.; Yan, H.; Tang, B. Deep Eutectic Solvents Functionalized Polymers for Easily and Efficiently Promoting Biocatalysis. J. Catal. 2019, 374, 306–319. [Google Scholar] [CrossRef]

- Ni, R.; Wang, Y.; Wei, X.; Chen, J.; Meng, J.; Xu, F.; Liu, Z.; Zhou, Y. Magnetic Carbon Nanotube Modified with Polymeric Deep Eutectic Solvent for the Solid Phase Extraction of Bovine Serum Albumin. Talanta 2020, 206, 120215. [Google Scholar] [CrossRef]

- AlOmar, M.K.; Alsaadi, M.A.; Hayyan, M.; Akib, S.; Ibrahim, R.K.; Hashim, M.A. Lead Removal from Water by Choline Chloride Based Deep Eutectic Solvents Functionalized Carbon Nanotubes. J. Mol. Liq. 2016, 222, 883–894. [Google Scholar] [CrossRef]

- Abo-Hamad, A.; Hayyan, M.; AlSaadi, M.A.H.; Mirghani, M.E.S.; Hashim, M.A. Functionalization of Carbon Nanotubes Using Eutectic Mixtures: A Promising Route for Enhanced Aqueous Dispersibility and Electrochemical Activity. Chem. Eng. J. 2017, 311, 326–339. [Google Scholar] [CrossRef]

- AlOmar, M.K.; Alsaadi, M.A.; Hayyan, M.; Akib, S.; Ibrahim, M.; Hashim, M.A. Allyl Triphenyl Phosphonium Bromide Based DES-Functionalized Carbon Nanotubes for the Removal of Mercury from Water. Chemosphere 2017, 167, 44–52. [Google Scholar] [CrossRef]

- AlOmar, M.K.; Alsaadi, M.A.; Hayyan, M.; Akib, S.; Hashim, M.A. Functionalization of CNTs Surface with Phosphonuim Based Deep Eutectic Solvents for Arsenic Removal from Water. Appl. Surf. Sci. 2016, 389, 216–226. [Google Scholar] [CrossRef]

- Mehrabi, N.; Abdul Haq, U.F.; Reza, M.T.; Aich, N. Application of Deep Eutectic Solvent for Conjugation of Magnetic Nanoparticles onto Graphene Oxide for Lead(II) and Methylene Blue Removal. J. Environ. Chem. Eng. 2020, 8, 104222. [Google Scholar] [CrossRef]

- Hayyan, M.; Abo-Hamad, A.; AlSaadi, M.A.H.; Hashim, M.A. Functionalization of Graphene Using Deep Eutectic Solvents. Nanoscale Res. Lett. 2015, 10, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Häckl, K.; Li, H.; Aldous, I.M.; Tsui, T.; Kunz, W.; Abbott, A.P.; Warr, G.G.; Atkin, R. Potential Dependence of Surfactant Adsorption at the Graphite Electrode/Deep Eutectic Solvent Interface. J. Phys. Chem. Lett. 2019, 10, 5331–5337. [Google Scholar] [CrossRef] [PubMed]

- Zamani, P.; Ozdemir, J.; Ha, Y.; Benamara, M.; Kuchuk, A.V.; Wang, T.; Chen, J.; Khosropour, A.R.; Beyzavi, M.H. Magnetic Nanoparticle Anchored Deep Eutectic Solvents as a Catalyst for the Etherification and Amination of Naphthols. Adv. Synth. Catal. 2018, 360, 4372–4380. [Google Scholar] [CrossRef]

- Marullo, S.; Rizzo, C.; D’anna, F. Activity of a Heterogeneous Catalyst in Deep Eutectic Solvents: The Case of Carbohydrate Conversion into 5-Hydroxymethylfurfural. ACS Sustain. Chem. Eng. 2019, 7, 13359–13368. [Google Scholar] [CrossRef]

- Abdullah, L.W.; Saied, S.M.; Saleh, M.Y. Deep Eutectic Solvents (Reline) and Gold Nanoparticles Supported on Titanium Oxide (Au–TiO2) as New Catalysts for Synthesis Some Substituted Phenyl(Substituted-3-Phenyloxiran)Methanone Enantioselective Peroxidation. Egypt J. Chem. 2021, 64, 4381–4389. [Google Scholar] [CrossRef]

- Minea, A.A.; Murshed, S.M.S. A Review on Development of Ionic Liquid Based Nanofluids and Their Heat Transfer Behavior. Renew. Sustain. Energy Rev. 2018, 91, 584–599. [Google Scholar] [CrossRef]

- Zhang, X.; Pan, L.; Wang, L.; Zou, J.J. Review on Synthesis and Properties of High-Energy-Density Liquid Fuels: Hydrocarbons, Nanofluids and Energetic Ionic Liquids. Chem. Eng. Sci. 2018, 180, 95–125. [Google Scholar] [CrossRef]

- Jafari, K.; Fatemi, M.H.; Estellé, P. Deep Eutectic Solvents (DESs): A Short Overview of the Thermophysical Properties and Current Use as Base Fluid for Heat Transfer Nanofluids. J. Mol. Liq. 2021, 321, 114752. [Google Scholar] [CrossRef]

- Walvekar, R.; Chen, Y.Y.; Saputra, R.; Khalid, M.; Panchal, H.; Chandran, D.; Muabrak, N.M.; Sadasivuni, K.K. Deep Eutectic Solvents-Based CNT Nanofluid—A Potential Alternative to Conventional Heat Transfer Fluids. J. Taiwan Inst. Chem. Eng. 2021, 128, 314–326. [Google Scholar] [CrossRef]

- Abbott, A.P.; Ahmed, E.I.; Harris, R.C.; Ryder, K.S. Evaluating Water Miscible Deep Eutectic Solvents (DESs) and Ionic Liquids as Potential Lubricants. Green Chem. 2014, 16, 4156–4161. [Google Scholar] [CrossRef]

- Domínguez de María, P.; Maugeri, Z. Ionic Liquids in Biotransformations: From Proof-of-Concept to Emerging Deep-Eutectic-Solvents. Curr. Opin. Chem. Biol. 2011, 15, 220–225. [Google Scholar] [CrossRef]

- Boldrini, C.L.; Quivelli, A.F.; Manfredi, N.; Capriati, V.; Abbotto, A. Deep Eutectic Solvents in Solar Energy Technologies. Molecules 2022, 27, 709. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.Y.; Walvekar, R.; Khalid, M.; Shahbaz, K.; Gupta, T.C.S.M. Stability and Thermophysical Studies on Deep Eutectic Solvent Based Carbon Nanotube Nanofluid. Mater. Res. Express 2017, 4, 075028. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Y.; Li, M.; Dong, X.; Wang, B. The Effect of ZIF-67 Nanoparticles on the Desulfurization Performance of Deep Eutectic Solvent Based Nanofluid System. J. Hazard Mater. 2022, 426, 128098. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Fang, H.; Liu, X.; Xu, B.; Rao, Z. Novel Silica Filled Deep Eutectic Solvent Based Nanofluids for Energy Transportation. ACS Sustain. Chem. Eng. 2019, 7, 20159–20169. [Google Scholar] [CrossRef]

- Fan, C.; Wang, H.; Liu, Y.; Cao, X. New Deep Eutectic Solvent Based Superparamagnetic Nanofluid for Determination of Perfluoroalkyl Substances in Edible Oils. Talanta 2021, 228, 122214. [Google Scholar] [CrossRef]

- Liu, X.; Wang, B.; Lv, X.; Meng, Q.; Li, M. Enhanced Removal of Hydrogen Sulfide Using Novel Nanofluid System Composed of Deep Eutectic Solvent and Cu Nanoparticles. J. Hazard Mater. 2021, 405, 124271. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Fang, H.; Qiao, Y.; Zhao, J.; Rao, Z. Properties and Heat Transfer Mechanistic Study of Glycerol/Choline Chloride Deep Eutectic Solvents Based Nanofluids. Int. J. Heat Mass Transf. 2019, 138, 690–698. [Google Scholar] [CrossRef]

- Fang, Y.K.; Osama, M.; Rashmi, W.; Shahbaz, K.; Khalid, M.; Mjalli, F.S.; Farid, M.M. Synthesis and Thermo-Physical Properties of Deep Eutectic Solvent-Based Graphene Nanofluids. Nanotechnology 2016, 27, 075702. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Jiang, P.; Huo, Y.; Zhang, T.; Rao, Z. Experimental Study on Ethylene Glycol/Choline Chloride Deep Eutectic Solvent System Based Nanofluids. Heat Mass Transfer. 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Jafari, K.; Hossein Fatemi, M.; Lugo, L. An Experimental Study of Novel Nanofluids Based on Deep Eutectic Solvents (DESs) by Choline Chloride and Ethylene Glycol. J. Mol. Liq. 2022, 360, 119521. [Google Scholar] [CrossRef]

- Liu, C.; Sun, W.; Huo, Y.; Zhao, J.; Said, Z. Thermophysical Study of Glycerol/Choline Chloride Deep Eutectic Solvent Based Nanofluids. J. Mol. Liq. 2022, 363, 119862. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nam, N.N.; Do, H.D.K.; Trinh, K.T.L.; Lee, N.Y. Design Strategy and Application of Deep Eutectic Solvents for Green Synthesis of Nanomaterials. Nanomaterials 2023, 13, 1164. https://doi.org/10.3390/nano13071164

Nam NN, Do HDK, Trinh KTL, Lee NY. Design Strategy and Application of Deep Eutectic Solvents for Green Synthesis of Nanomaterials. Nanomaterials. 2023; 13(7):1164. https://doi.org/10.3390/nano13071164

Chicago/Turabian StyleNam, Nguyen Nhat, Hoang Dang Khoa Do, Kieu The Loan Trinh, and Nae Yoon Lee. 2023. "Design Strategy and Application of Deep Eutectic Solvents for Green Synthesis of Nanomaterials" Nanomaterials 13, no. 7: 1164. https://doi.org/10.3390/nano13071164

APA StyleNam, N. N., Do, H. D. K., Trinh, K. T. L., & Lee, N. Y. (2023). Design Strategy and Application of Deep Eutectic Solvents for Green Synthesis of Nanomaterials. Nanomaterials, 13(7), 1164. https://doi.org/10.3390/nano13071164