Epitaxial Lateral Overgrowth of GaN on a Laser-Patterned Graphene Mask

Abstract

1. Introduction

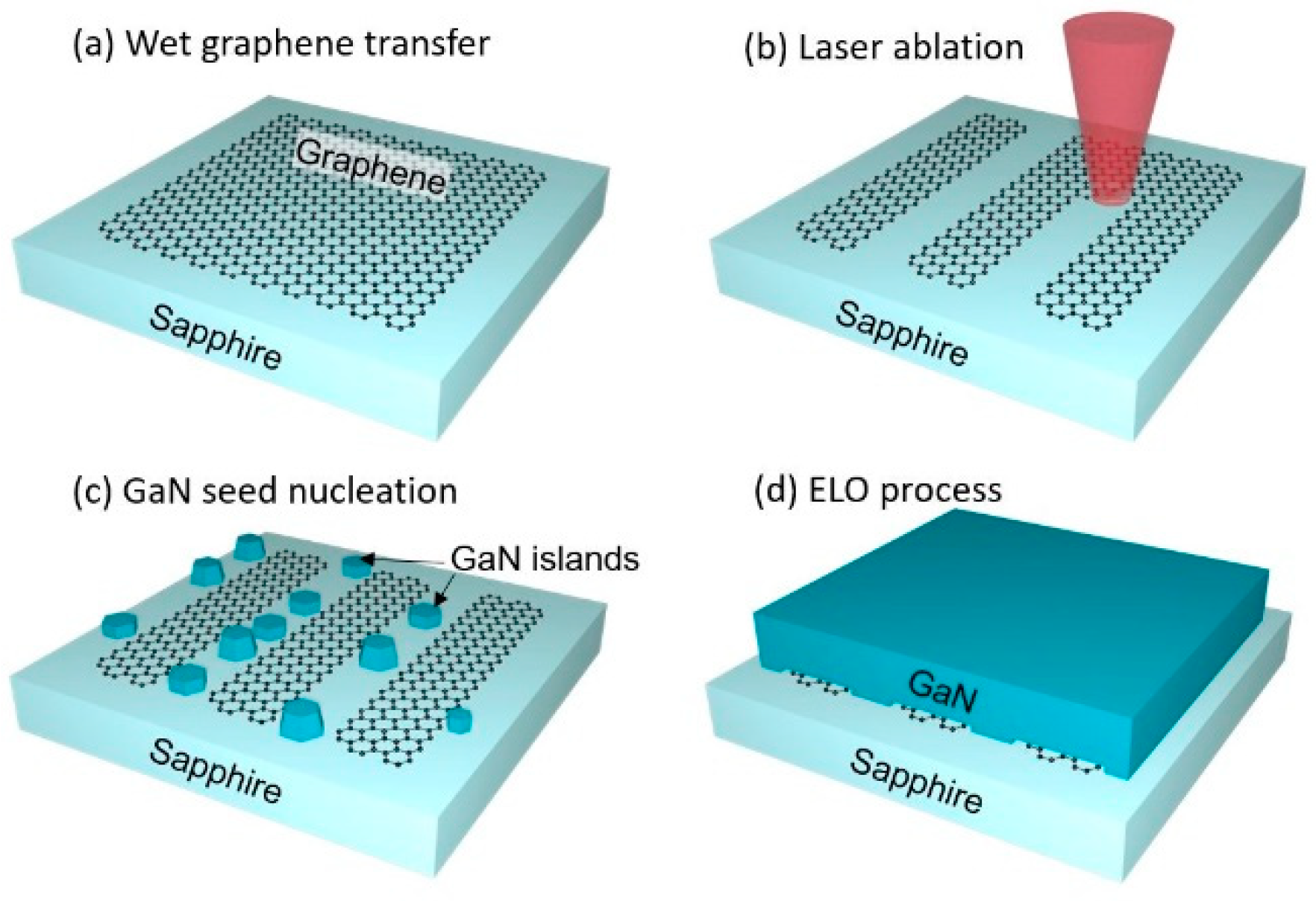

2. Materials and Methods

3. Results and Discussion

3.1. Graphene Layer Transfer

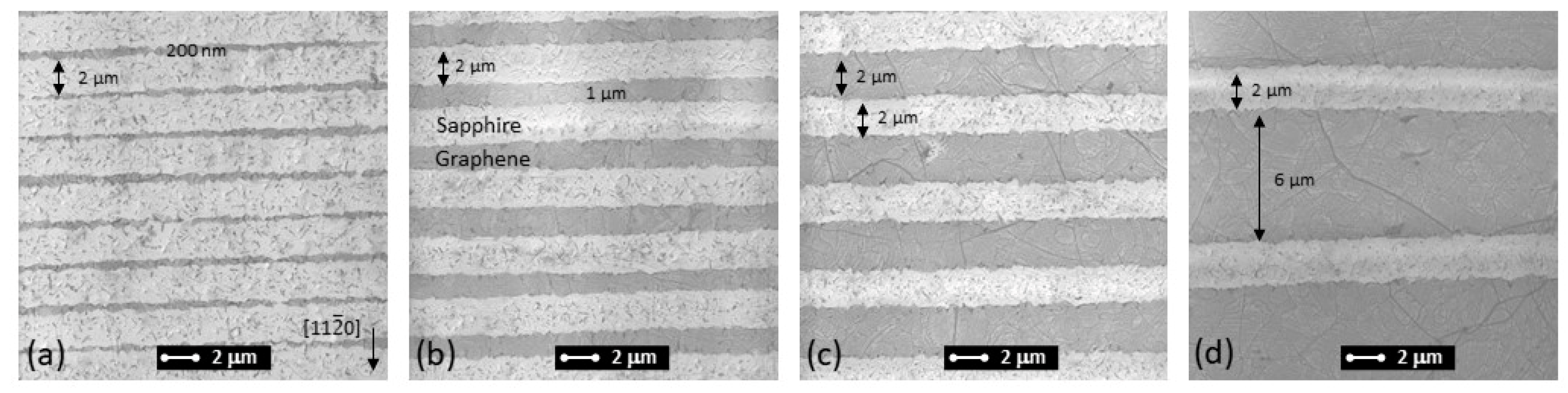

3.2. Graphene Lithography

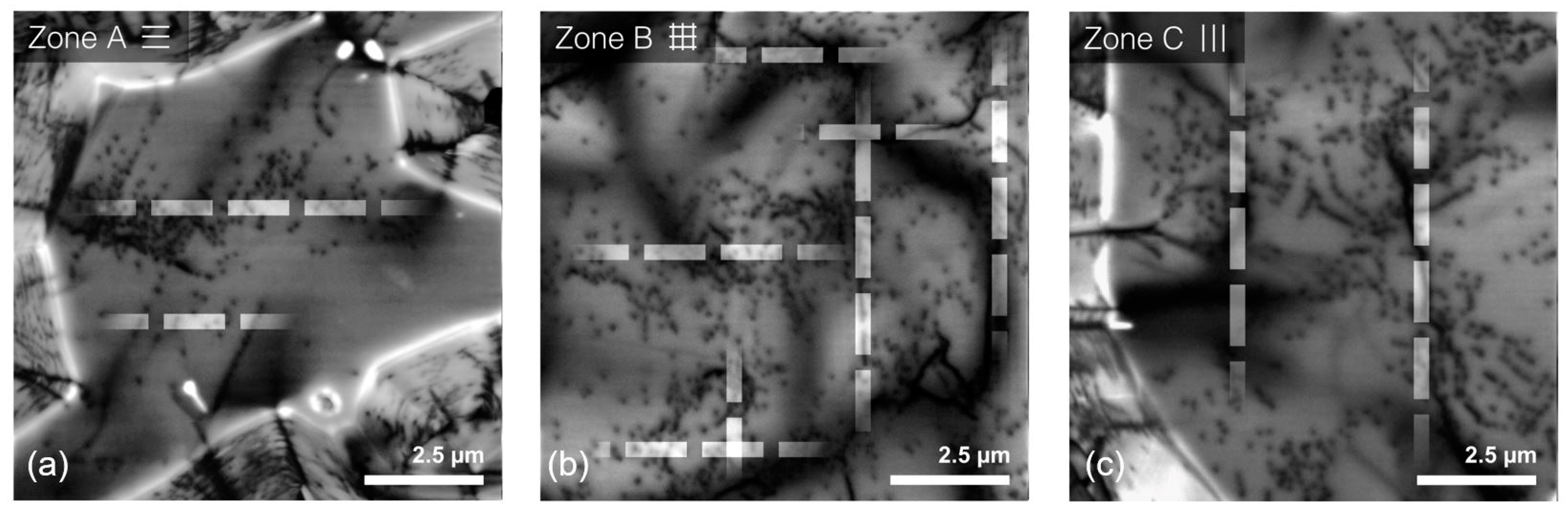

3.3. ELO of GaN Epilayers

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, L.; Edgar, J.H. Substrates for Gallium Nitride Epitaxy. Mater. Sci. Eng. R Rep. 2002, 37, 61–127. [Google Scholar] [CrossRef]

- Li, G.; Wang, W.; Yang, W.; Lin, Y.; Wang, H.; Lin, Z.; Zhou, S. GaN-Based Light-Emitting Diodes on Various Substrates: A Critical Review. Rep. Prog. Phys. 2016, 79, 056501. [Google Scholar] [CrossRef] [PubMed]

- Mickevičius, J.; Dobrovolskas, D.; Malinauskas, T.; Kolenda, M.; Kadys, A.; Tamulaitis, G. Improvement of Luminescence Properties of InN by Optimization of Multi-Step Deposition on Sapphire. Thin Solid Film. 2019, 680, 89–93. [Google Scholar] [CrossRef]

- Mickevičius, J.; Grinys, T.; Kadys, A.; Tamulaitis, G. Optimization of Growing Green-Emitting InGaN/GaN Multiple Quantum Wells on Stress-Relieving Superlattices. Opt. Mater. 2018, 82, 71–74. [Google Scholar] [CrossRef]

- Koleske, D.D.; Fischer, A.J.; Bryant, B.N.; Kotula, P.G.; Wierer, J.J. On the Increased Efficiency in InGaN-Based Multiple Quantum Wells Emitting at 530–590nm with AlGaN Interlayers. J. Cryst. Growth 2015, 415, 57–64. [Google Scholar] [CrossRef]

- Du, C.; Ma, Z.; Zhou, J.; Lu, T.; Jiang, Y.; Zuo, P.; Jia, H.; Chen, H. Enhancing the Quantum Efficiency of InGaN Yellow-Green Light-Emitting Diodes by Growth Interruption. Appl. Phys. Lett. 2014, 105, 071108. [Google Scholar] [CrossRef]

- Dmukauskas, M.; Kadys, A.; Malinauskas, T.; Grinys, T.; Reklaitis, I.; Badokas, K.; Skapas, M.; Tomašiūnas, R.; Dobrovolskas, D.; Stanionytė, S.; et al. Influence of Metalorganic Precursors Flow Interruption Timing on Green InGaN Multiple Quantum Wells. J. Phys. Appl. Phys. 2016, 49, 505101. [Google Scholar] [CrossRef]

- Badokas, K.; Kadys, A.; Mickevičius, J.; Ignatjev, I.; Skapas, M.; Stanionytė, S.; Radiunas, E.; Juška, G.; Malinauskas, T. Remote Epitaxy of GaN via Graphene on GaN/Sapphire Templates. J. Phys. Appl. Phys. 2021, 54, 205103. [Google Scholar] [CrossRef]

- Bae, S.-H.; Kum, H.; Kong, W.; Kim, Y.; Choi, C.; Lee, B.; Lin, P.; Park, Y.; Kim, J. Integration of Bulk Materials with Two-Dimensional Materials for Physical Coupling and Applications. Nat. Mater. 2019, 18, 550–560. [Google Scholar] [CrossRef]

- Alaskar, Y.; Arafin, S.; Wickramaratne, D.; Zurbuchen, M.A.; He, L.; McKay, J.; Lin, Q.; Goorsky, M.S.; Lake, R.K.; Wang, K.L. Towards van Der Waals Epitaxial Growth of GaAs on Si Using a Graphene Buffer Layer. Adv. Funct. Mater. 2014, 24, 6629–6638. [Google Scholar] [CrossRef]

- Kim, Y.; Cruz, S.S.; Lee, K.; Alawode, B.O.; Choi, C.; Song, Y.; Johnson, J.M.; Heidelberger, C.; Kong, W.; Choi, S.; et al. Remote Epitaxy through Graphene Enables Two-Dimensional Material-Based Layer Transfer. Nature 2017, 544, 340–343. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhang, Y.; Abidi, N.; Cabrales, L. Wettability and Surface Free Energy of Graphene Films. Langmuir 2009, 25, 11078–11081. [Google Scholar] [CrossRef] [PubMed]

- Al Balushi, Z.Y.; Miyagi, T.; Lin, Y.-C.; Wang, K.; Calderin, L.; Bhimanapati, G.; Redwing, J.M.; Robinson, J.A. The Impact of Graphene Properties on GaN and AlN Nucleation. Surf. Sci. 2015, 634, 81–88. [Google Scholar] [CrossRef]

- Kovács, A.; Duchamp, M.; Dunin-Borkowski, R.E.; Yakimova, R.; Neumann, P.L.; Behmenburg, H.; Foltynski, B.; Giesen, C.; Heuken, M.; Pécz, B. Graphoepitaxy of High-Quality GaN Layers on Graphene/6H–SiC. Adv. Mater. Interfaces 2015, 2, 1400230. [Google Scholar] [CrossRef]

- Xu, Y.; Cao, B.; He, S.; Qi, L.; Li, Z.; Cai, D.; Zhang, Y.; Ren, G.; Wang, J.; Wang, C.; et al. Evolution of Threading Dislocations in GaN Epitaxial Laterally Overgrown on GaN Templates Using Self-Organized Graphene as a Nano-Mask. Appl. Phys. Lett. 2017, 111, 102105. [Google Scholar] [CrossRef]

- Kasischke, M.; Subaşı, E.; Bock, C.; Pham, D.-V.; Gurevich, E.L.; Kunze, U.; Ostendorf, A. Femtosecond Laser Patterning of Graphene Electrodes for Thin-Film Transistors. Appl. Surf. Sci. 2019, 478, 299–303. [Google Scholar] [CrossRef]

- Katsiaounis, S.; Chourdakis, N.; Michail, E.; Fakis, M.; Polyzos, I.; Parthenios, J.; Papagelis, K. Graphene Nano-Sieves by Femtosecond Laser Irradiation. Nanotechnology 2022, 34, 105302. [Google Scholar] [CrossRef]

- Zhang, H.; Mischke, J.; Mertin, W.; Bacher, G. Graphene as a Transparent Conductive Electrode in GaN-Based LEDs. Materials 2022, 15, 2203. [Google Scholar] [CrossRef]

- Tang, P.; Xiong, F.; Du, Z.; Li, K.; Mei, Y.; Guo, W.; Sun, J. Nickel-Assisted Transfer-Free Technology of Graphene Chemical Vapor Deposition on GaN for Improving the Electrical Performance of Light-Emitting Diodes. Crystals 2022, 12, 1497. [Google Scholar] [CrossRef]

- Pirkle, A.; Chan, J.; Venugopal, A.; Hinojos, D.; Magnuson, C.W.; McDonnell, S.; Colombo, L.; Vogel, E.M.; Ruoff, R.S.; Wallace, R.M. The Effect of Chemical Residues on the Physical and Electrical Properties of Chemical Vapor Deposited Graphene Transferred to SiO2. Appl. Phys. Lett. 2011, 99, 122108. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Basko, D.M. Raman Spectroscopy as a Versatile Tool for Studying the Properties of Graphene. Nat. Nanotechnol. 2013, 8, 235–246. [Google Scholar] [CrossRef]

- Nebogatikova, N.A.; Antonova, I.V.; Gutakovskii, A.K.; Smovzh, D.V.; Volodin, V.A.; Sorokin, P.B. Visualization of Swift Ion Tracks in Suspended Local Diamondized Few-Layer Graphene. Materials 2023, 16, 1391. [Google Scholar] [CrossRef]

- Bleu, Y.; Bourquard, F.; Loir, A.-S.; Barnier, V.; Garrelie, F.; Donnet, C. Raman Study of the Substrate Influence on Graphene Synthesis Using a Solid Carbon Source via Rapid Thermal Annealing. J. Raman Spectrosc. 2019, 50, 1630–1641. [Google Scholar] [CrossRef]

- Kefer, S.; Zettl, J.; Esen, C.; Hellmann, R. Femtosecond Laser-Based Micromachining of Rotational-Symmetric Sapphire Workpieces. Materials 2022, 15, 6233. [Google Scholar] [CrossRef] [PubMed]

- Arnatkevičiūtė, A.; Reklaitis, I.; Kadys, A.; Malinauskas, T.; Stanionytė, S.; Juška, G.; Rzheutski, M.V.; Tomašiūnas, R. Relationships Between Strain and Recombination in Intermediate Growth Stages of GaN. J. Electron. Mater. 2014, 43, 2667–2675. [Google Scholar] [CrossRef]

- Park, J.-H.; Lee, J.-Y.; Park, M.-D.; Min, J.-H.; Lee, J.-S.; Yang, X.; Kang, S.; Kim, S.-J.; Jeong, W.-L.; Amano, H.; et al. Influence of Temperature-Dependent Substrate Decomposition on Graphene for Separable GaN Growth. Adv. Mater. Interfaces 2019, 6, 1900821. [Google Scholar] [CrossRef]

- Badokas, K.; Kadys, A.; Augulis, D.; Mickevičius, J.; Ignatjev, I.; Skapas, M.; Šebeka, B.; Juška, G.; Malinauskas, T. MOVPE Growth of GaN via Graphene Layers on GaN/Sapphire Templates. Nanomaterials 2022, 12, 785. [Google Scholar] [CrossRef]

- Hiramatsu, K.; Nishiyama, K.; Motogaito, A.; Miyake, H.; Iyechika, Y.; Maeda, T. Recent Progress in Selective Area Growth and Epitaxial Lateral Overgrowth of III-Nitrides: Effects of Reactor Pressure in MOVPE Growth. Phys. Status Solidi A 1999, 176, 535–543. [Google Scholar] [CrossRef]

- Beaumont, B.; Vennéguès, P.; Gibart, P. Epitaxial Lateral Overgrowth of GaN. Phys. Status Solidi B 2001, 227, 1–43. [Google Scholar] [CrossRef]

- Shen, X.Q.; Okumura, H. Surface Step Morphologies of GaN Films Grown on Vicinal Sapphire (0001) Substrates by Rf-MBE. J. Cryst. Growth 2007, 300, 75–78. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kadys, A.; Mickevičius, J.; Badokas, K.; Strumskis, S.; Vanagas, E.; Podlipskas, Ž.; Ignatjev, I.; Malinauskas, T. Epitaxial Lateral Overgrowth of GaN on a Laser-Patterned Graphene Mask. Nanomaterials 2023, 13, 784. https://doi.org/10.3390/nano13040784

Kadys A, Mickevičius J, Badokas K, Strumskis S, Vanagas E, Podlipskas Ž, Ignatjev I, Malinauskas T. Epitaxial Lateral Overgrowth of GaN on a Laser-Patterned Graphene Mask. Nanomaterials. 2023; 13(4):784. https://doi.org/10.3390/nano13040784

Chicago/Turabian StyleKadys, Arūnas, Jūras Mickevičius, Kazimieras Badokas, Simonas Strumskis, Egidijus Vanagas, Žydrūnas Podlipskas, Ilja Ignatjev, and Tadas Malinauskas. 2023. "Epitaxial Lateral Overgrowth of GaN on a Laser-Patterned Graphene Mask" Nanomaterials 13, no. 4: 784. https://doi.org/10.3390/nano13040784

APA StyleKadys, A., Mickevičius, J., Badokas, K., Strumskis, S., Vanagas, E., Podlipskas, Ž., Ignatjev, I., & Malinauskas, T. (2023). Epitaxial Lateral Overgrowth of GaN on a Laser-Patterned Graphene Mask. Nanomaterials, 13(4), 784. https://doi.org/10.3390/nano13040784