Synthesis of Fe-TiO2 and Cu-TiO2 Based Materials by Olive Leaves Biotemplating—Application to Hydrogen Production from Glycerol Photoreforming

Abstract

:1. Introduction

2. Materials and Methods

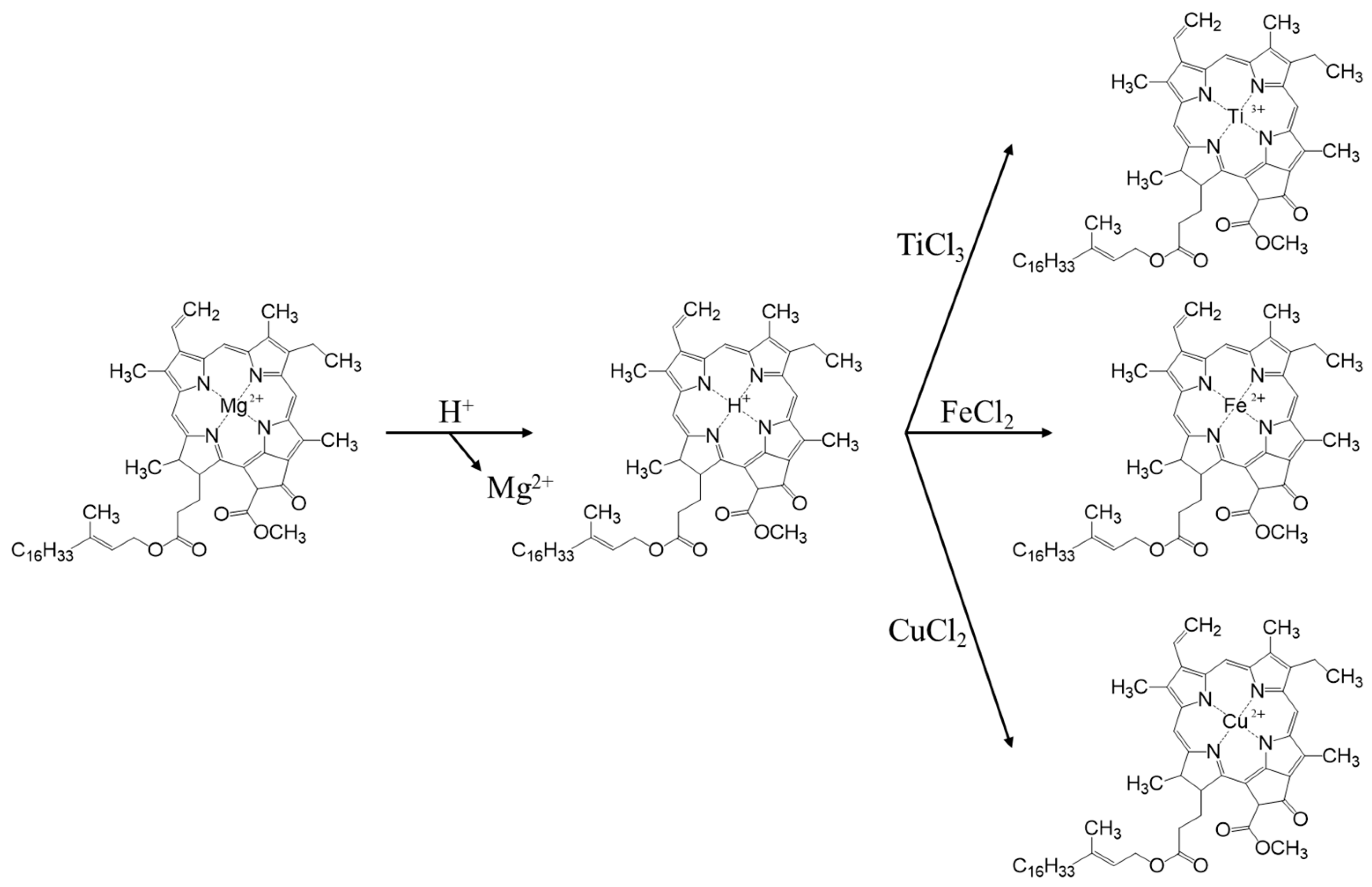

2.1. Catalyst Synthesis

2.2. Characterization of the Catalyst

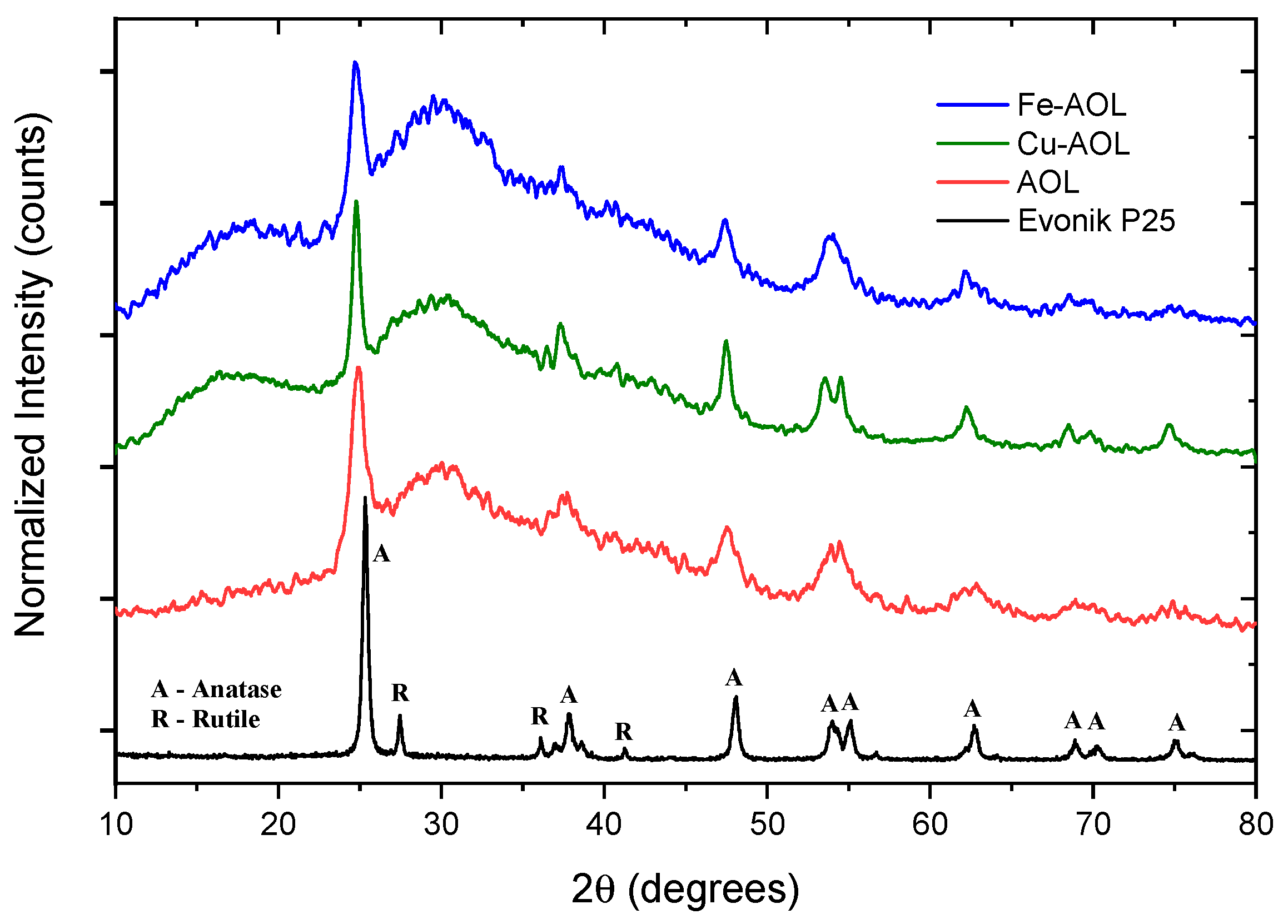

2.2.1. X-ray Diffraction (XRD)

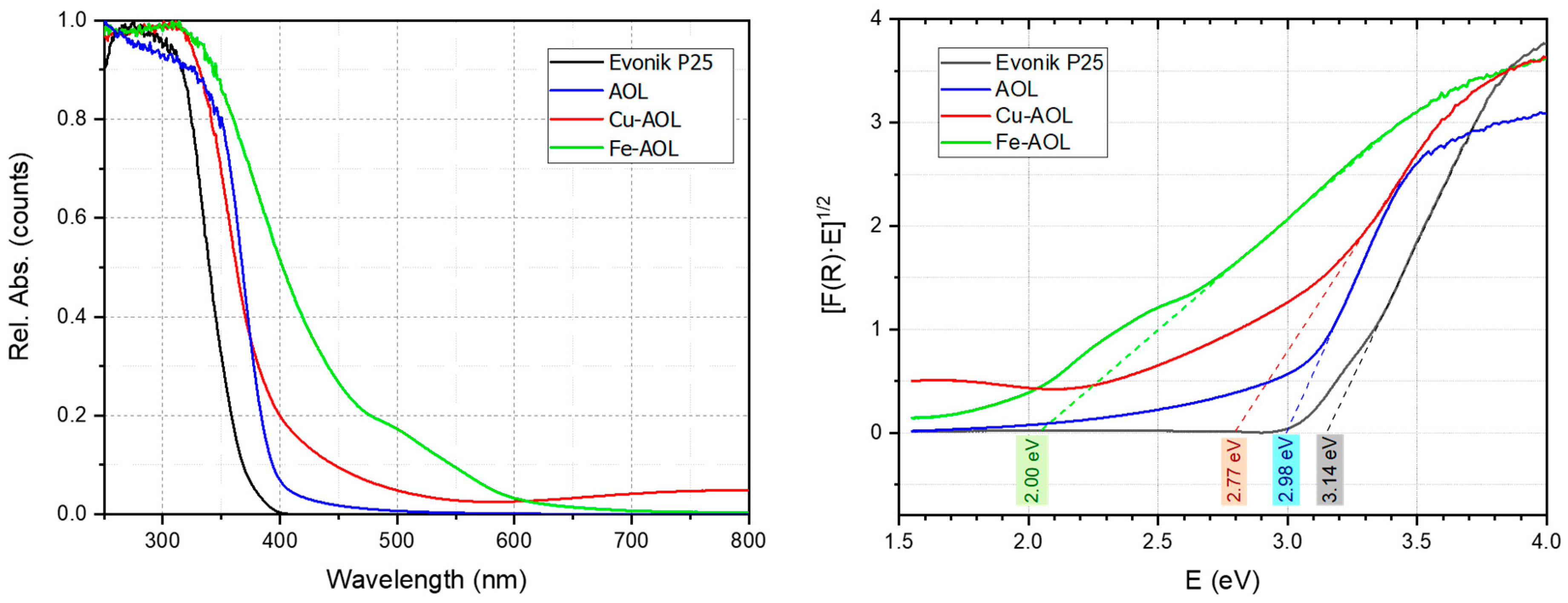

2.2.2. Ultraviolet-Visible Spectroscopy (UV-Vis)

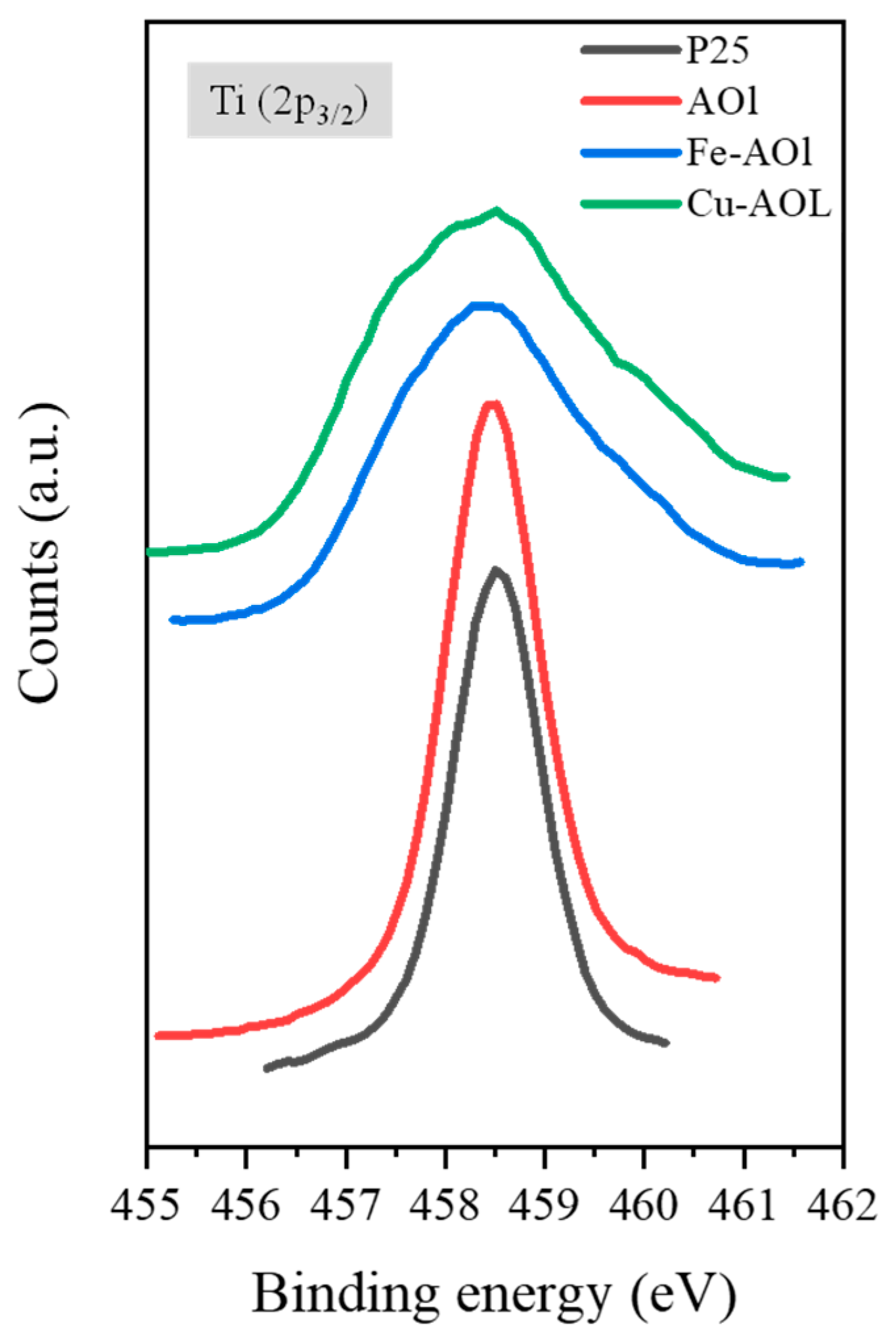

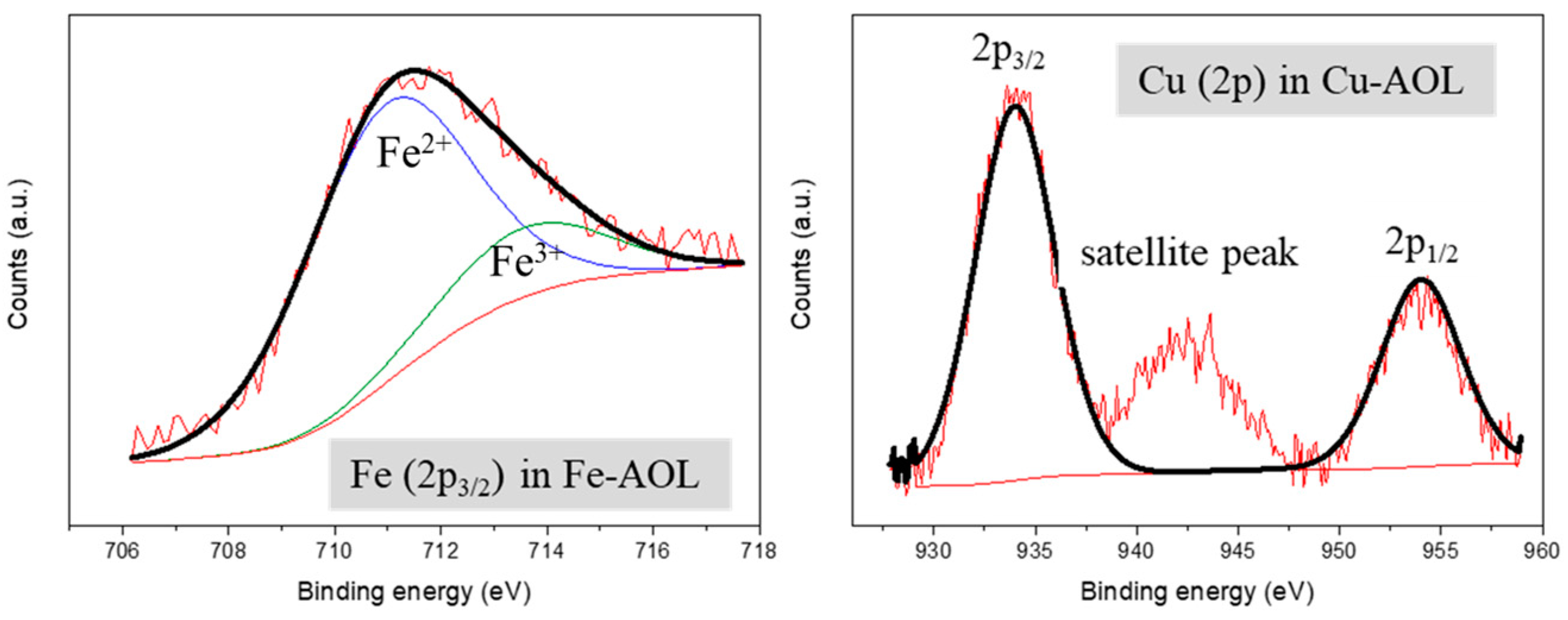

2.2.3. X-ray Photoelectron Spectroscopy (XPS)

2.2.4. Scanning Electron Microscopy (SEM)

2.2.5. X-ray Fluorescence (XRF)

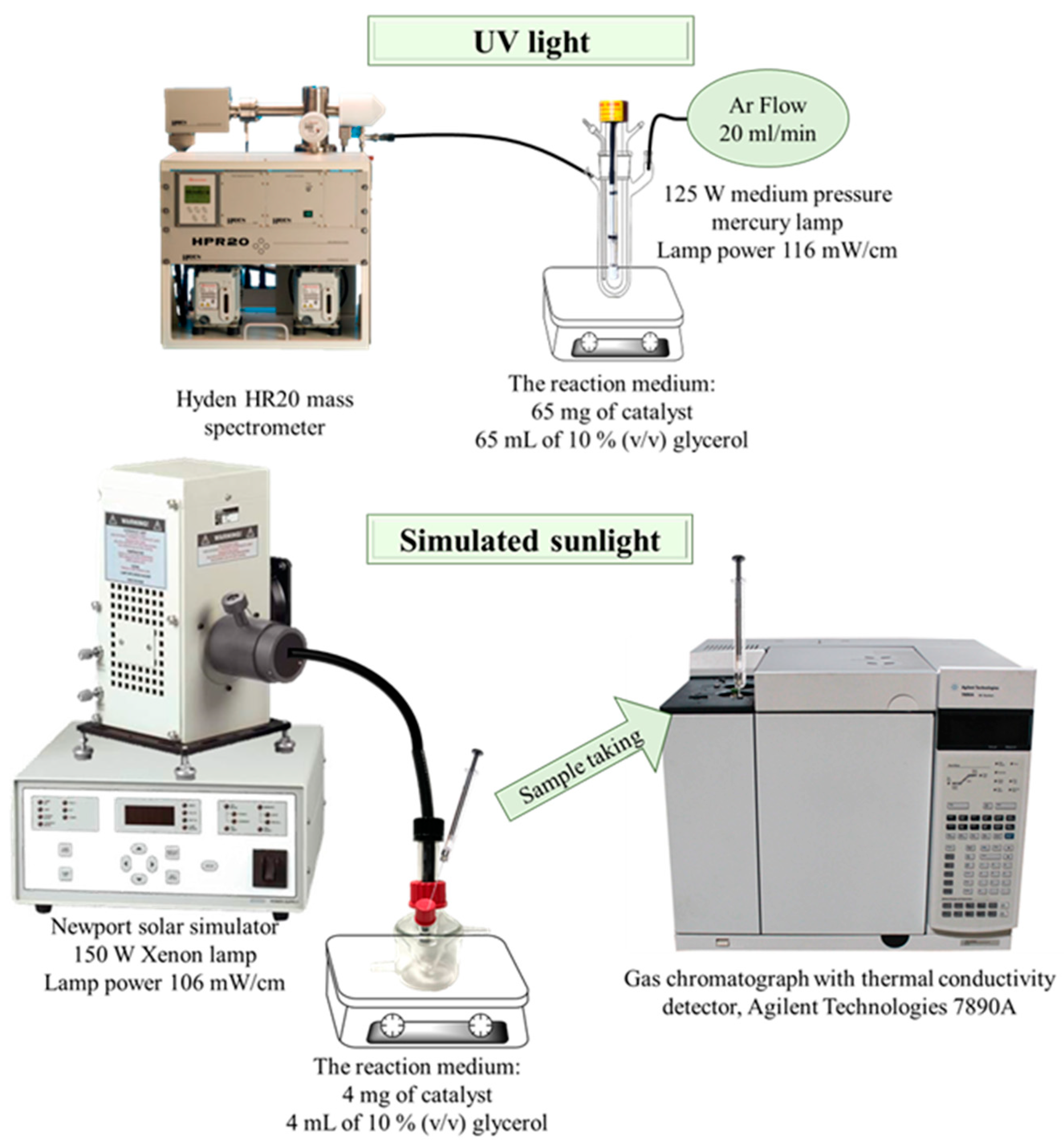

2.2.6. Glycerol Photo-Reforming Reaction

3. Results and Discussions

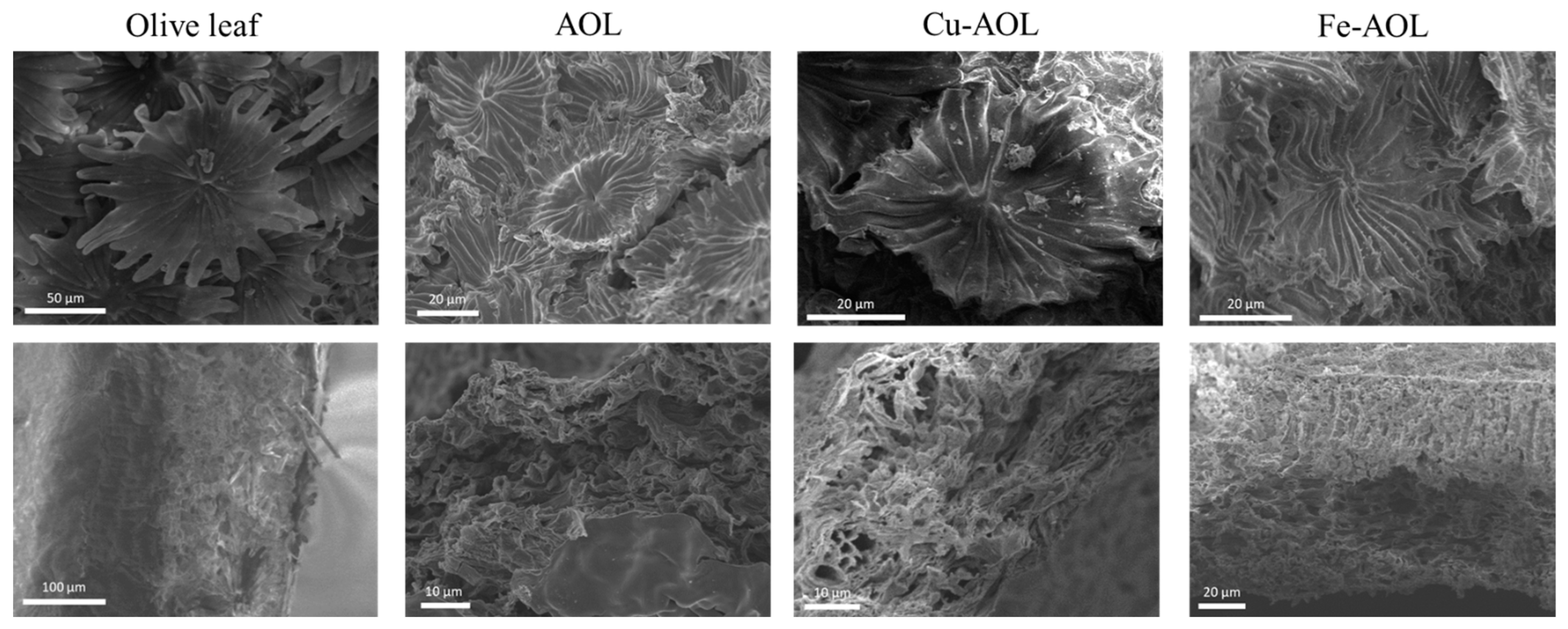

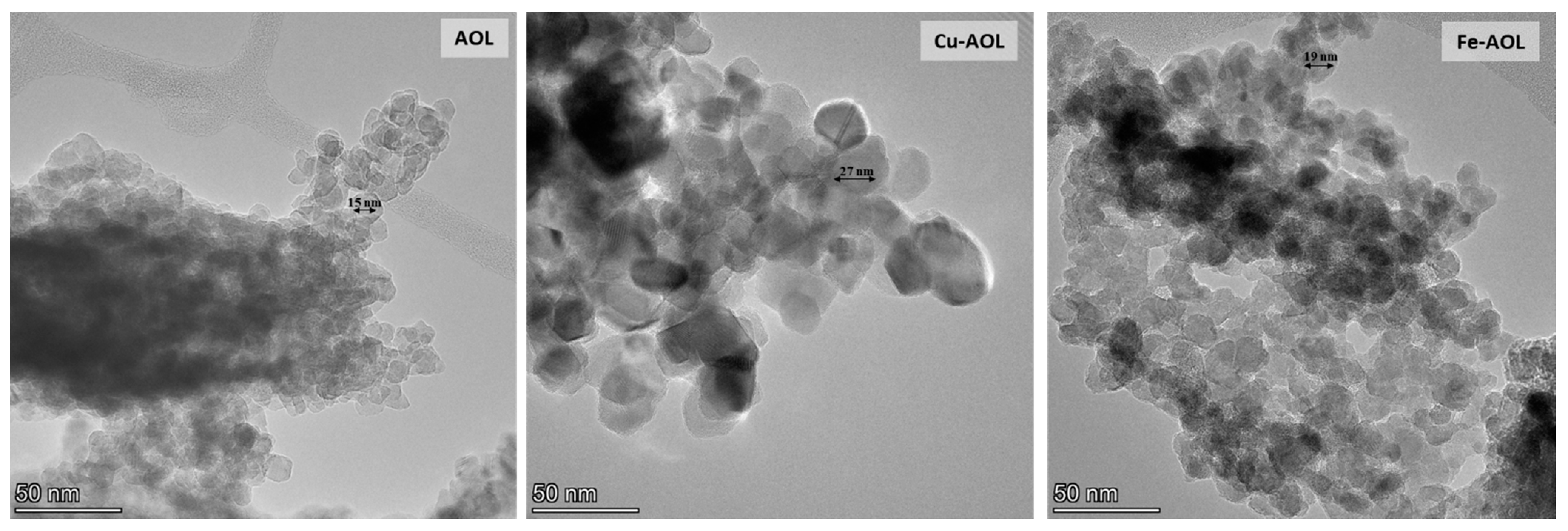

3.1. Synthesis of Catalysts and Morphological Analysis by SEM and TEM

3.2. Chemical Analysis of Catalysts

3.3. Structural Characterization of Catalyst

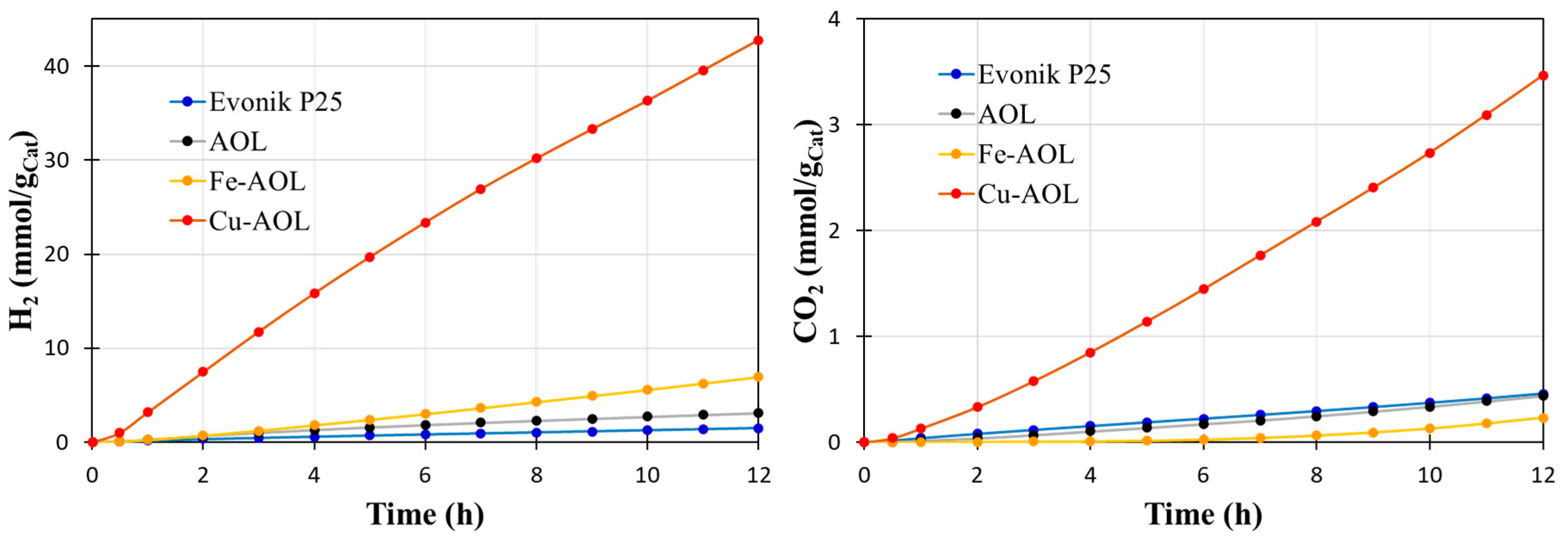

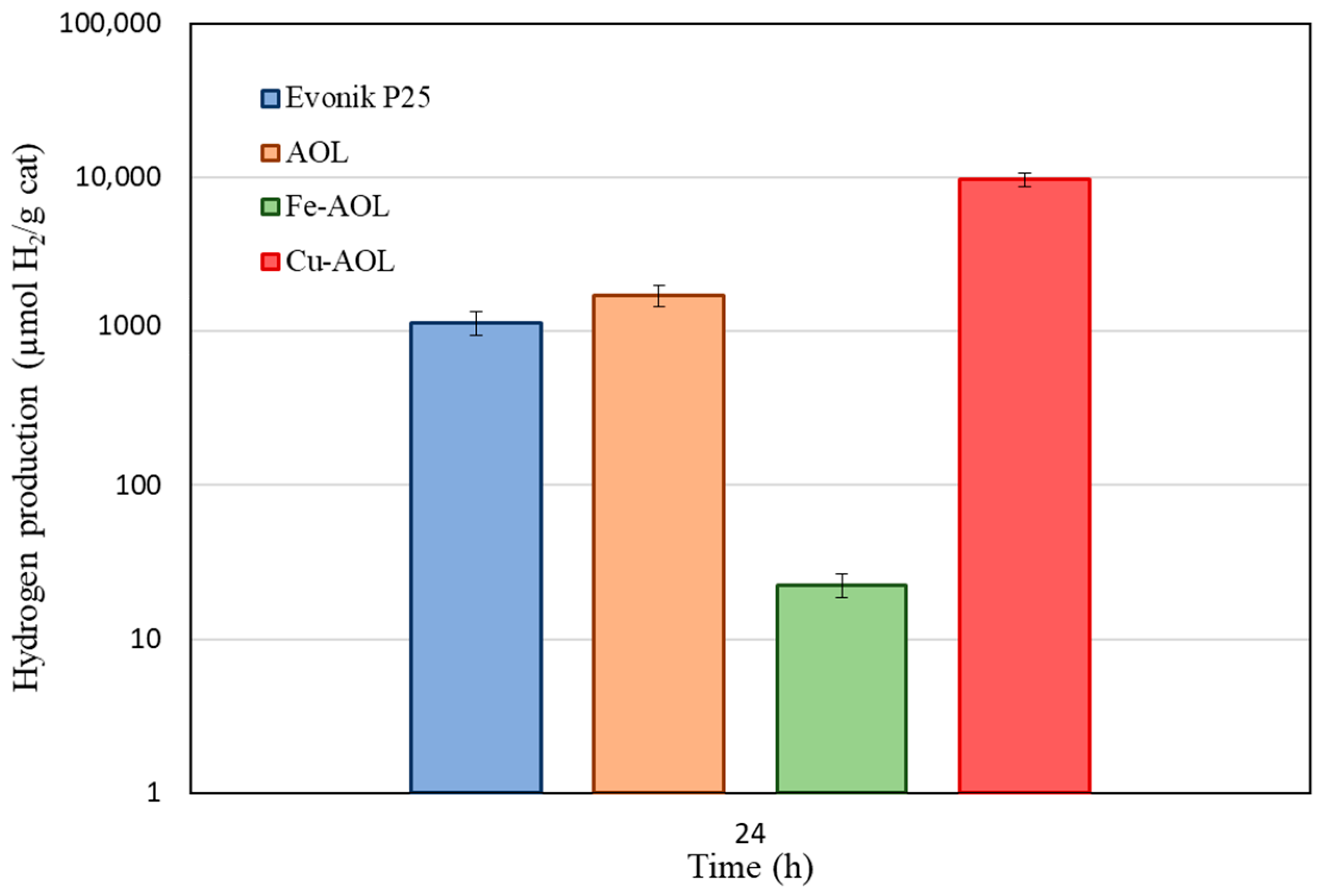

3.4. Photo-Catalytic Experiments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, Z.; Huang, X.; Zhang, G. TiO2-Based Catalysts for Photothermal Catalysis: Mechanisms, Materials and Applications. J. Clean. Prod. 2022, 381, 135156. [Google Scholar] [CrossRef]

- Abd Rahman, N.; Choong, C.E.; Pichiah, S.; Nah, I.W.; Kim, J.R.; Oh, S.E.; Yoon, Y.; Choi, E.H.; Jang, M. Recent Advances in the TiO2 Based Photoreactors for Removing Contaminants of Emerging Concern in Water. Sep. Purif. Technol. 2023, 304, 122294. [Google Scholar] [CrossRef]

- Gaikwad, P.N.; Hankare, P.P.; Wandre, T.M.; Garadkar, K.M.; Sasikala, R. Photocatalytic Performance of Magnetically Separable Fe, N Co-Doped TiO2-Cobalt Ferrite Nanocomposite. Mater. Sci. Eng. B Solid. State. Mater. Adv. Technol. 2016, 205, 40–45. [Google Scholar] [CrossRef]

- Hsieh, C.-T.; Fan, W.-S.; Chen, W.-Y.; Lin, J.-Y. Adsorption and Visible-Light-Derived Photocatalytic Kinetics of Organic Dye on Co-Doped Titania Nanotubes Prepared by Hydrothermal Synthesis. Sep. Purif. Technol. 2009, 67, 312–318. [Google Scholar] [CrossRef]

- Lei, J.; Chen, Y.; Shen, F.; Wang, L.; Liu, Y.; Zhang, J. Surface Modification of TiO2 with G-C3N4 for Enhanced UV and Visible Photocatalytic Activity. J. Alloys Compd. 2015, 631, 328–334. [Google Scholar] [CrossRef]

- Lin, H.Y.; Shih, C.Y. Efficient One-Pot Microwave-Assisted Hydrothermal Synthesis of M (M=Cr, Ni, Cu, Nb) and Nitrogen Co-Doped TiO2 for Hydrogen Production by Photocatalytic Water Splitting. J. Mol. Catal. A Chem. 2015, 411, 128–137. [Google Scholar] [CrossRef]

- Malengreaux, C.M.; Pirard, S.L.; Léonard, G.; Mahy, J.G.; Herlitschke, M.; Klobes, B.; Hermann, R.; Heinrichs, B.; Bartlett, J.R. Study of the Photocatalytic Activity of Fe3+, Cr3+, La3+ and Eu3+ Single-Doped and Co-Doped TiO2 Catalysts Produced by Aqueous Sol-Gel Processing. J. Alloys Compd. 2017, 691, 726–738. [Google Scholar] [CrossRef]

- Mohini, R.; Lakshminarasimhan, N. Coupled Semiconductor Nanocomposite G-C3N4/TiO2 with Enhanced Visible Light Photocatalytic Activity. Mater. Res. Bull. 2016, 76, 370–375. [Google Scholar] [CrossRef]

- Rokhmat, M.; Wibowo, E.; Sutisna; Khairurrijal; Abdullah, M. Performance Improvement of TiO2/CuO Solar Cell by Growing Copper Particle Using Fix Current Electroplating Method. Procedia. Eng 2017, 170, 72–77. [Google Scholar] [CrossRef]

- Szkoda, M.; Siuzdak, K.; Lisowska-Oleksiak, A. Non-Metal Doped TiO2 Nanotube Arrays for High Efficiency Photocatalytic Decomposition of Organic Species in Water. Physica. E Low. Dimens. Syst. Nanostruct. 2016, 84, 141–145. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, M.; Zhu, X.; Hong, B.; Wang, W.; Qi, Z.; Xie, W.; Ding, J.; Bao, J.; Sun, S.; et al. Effect of Surface Modification with H2S and NH3 on TiO2 for Adsorption and Photocatalytic Degradation of Gaseous Toluene. Appl. Catal. B 2015, 170–171, 215–224. [Google Scholar] [CrossRef]

- Zhou, H.; Fan, T.; Zhang, D. Biotemplated Materials for Sustainable Energy and Environment: Current Status and Challenges. ChemSusChem 2011, 4, 1344–1387. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, M.A.; Salleh, W.N.W.; Jaafar, J.; Mohd Hir, Z.A.; Rosmi, M.S.; Mutalib, M.A.; Ismail, A.F.; Tanemura, M. Regenerated Cellulose Membrane as Bio-Template for in-Situ Growth of Visible-Light Driven C-Modified Mesoporous Titania. Carbohydr. Polym. 2016, 146, 166–173. [Google Scholar] [CrossRef] [PubMed]

- Xiao, G.; Huang, X.; Liao, X.; Shi, B. One-Pot Facile Synthesis of Cerium-Doped TiO2 Mesoporous Nanofibers Using Collagen Fiber as the Biotemplate and Its Application in Visible Light Photocatalysis. J. Phys. Chem. C 2013, 117, 9739–9746. [Google Scholar] [CrossRef]

- Bu, D.; Zhuang, H. Synthesis, Characterization, and Photocatalytic Studies of Copper-Doped TiO2 Hollow Spheres Using Rape Pollen as a Novel Biotemplate. Catal. Commun. 2012, 29, 24–28. [Google Scholar] [CrossRef]

- Li, J.; Shi, J.; Li, Y.; Ding, Z.; Huang, J. A Biotemplate Synthesized Hierarchical Sn-Doped TiO2 with Superior Photocatalytic Capacity under Simulated Solar Light. Ceram. Int. 2020, 47, 8218–8227. [Google Scholar] [CrossRef]

- Berbel, J.; Gutiérrez-Martín, C.; Antonio La Cal, J. Valorización de Los Subproductos de La Cadena Del Aceite de Oliva. Mediterr. Econ. 2018, 31, 273–289. [Google Scholar]

- Council, O. Olive Leaf Characterisation, Chemical Composition of Olive Oils from Different Origins, Olive Oil Traceability; Official Journal of the International Olive Council: Madrid, Spain, 2014. [Google Scholar]

- Hidalgo-Carrillo, J.; Martín-Gómez, J.; Herrera-Beurnio, M.C.; Estévez, R.C.; Urbano, F.J.; Marinas, A. Olive Leaves as Biotemplates for Enhanced Solar-Light Harvesting by a Titania-Based Solid. Nanomaterials 2020, 10, 1057. [Google Scholar] [CrossRef]

- Martín-Gómez, J.; Hidalgo-Carrillo, J.; Estévez, R.C.; Urbano, F.J.; Marinas, A. Hydrogen Photoproduction on TiO2-CuO Artificial Olive Leaves. Appl. Catal. A Gen. 2021, 620, 118178. [Google Scholar] [CrossRef]

- Barranco, D.; Fernández-Escobar, R.; Rallo, L. El Cultivo Del Olivo; Wikifarmer: Madrid, Spain, 2017. [Google Scholar]

- Gharagozlou, M.; Bayati, R. Photocatalytic Activity and Formation of Oxygen Vacancies in Cation Doped Anatase TiO2 Nanoparticles. Ceram. Int. 2014, 40, 10247–10253. [Google Scholar] [CrossRef]

- Hernández Enríquez, J.M.; Alamilla, R.G.; García Serrano, L.A.; Hernández, C. Síntesis, Caracterización y Actividad Fotocatalítica de Óxido de Titanio Modificado Con Nitrógeno. Bol. Soc. Esp. Ceram. Y Vidr. 2011, 50, 245–252. [Google Scholar] [CrossRef]

- Si, Z.; Zhang, X.; Liu, Y.; Zhou, H.; Chen, X.; Yang, X.; Chen, H.; Zhan, J. Revisiting the Preparation of Titanium Dioxide: Aerosol-Assisted Production of Photocatalyst with Higher Catalytic Activity than P25. J. Mater. Sci. 2020, 55, 565–576. [Google Scholar] [CrossRef]

- Cheng, G.; Liu, X.; Song, X.; Chen, X.; Dai, W.; Yuan, R.; Fu, X. Visible-Light-Driven Deep Oxidation of NO over Fe Doped TiO2 Catalyst: Synergic Effect of Fe and Oxygen Vacancies. Appl. Catal. B 2020, 277, 119196. [Google Scholar] [CrossRef]

- Pennington, A.M.; Yang, R.A.; Munoz, D.T.; Celik, F.E. Metal-Free Hydrogen Evolution over Defect-Rich Anatase Titanium Dioxide. Int. J. Hydrogen Energy 2018, 43, 15176–15190. [Google Scholar] [CrossRef]

- Temperton, R.H.; Gibson, A.; O’Shea, J.N. In Situ XPS Analysis of the Atomic Layer Deposition of Aluminium Oxide on Titanium Dioxide. Phys. Chem. Chem. Phys. 2019, 21, 1393–1398. [Google Scholar] [CrossRef]

- Wang, N.; Lin, H.; Li, J.B.; Yang, X.Z.; Chi, B. Synthesis of Titanium Dioxide Nanotubes by Ion Exchange Approach. Mater. Sci. Forum 2005, 475–479, 1235–1238. [Google Scholar] [CrossRef]

- Xiong, L.B.; Li, J.L.; Yang, B.; Yu, Y. Ti3+ in the Surface of Titanium Dioxide: Generation, Properties and Photocatalytic Application. J. Nanomater. 2012, 2012, 831524. [Google Scholar] [CrossRef]

- Mohamed Racik, K.; Manikandan, A.; Mahendiran, M.; Prabakaran, P.; Madhavan, J.; Victor Antony Raj, M. Fabrication of Manganese Oxide Decorated Copper Oxide (MnO2/CuO) Nanocomposite Electrodes for Energy Storage Supercapacitor Devices. Physica. E Low Dimens. Syst. Nanostruct. 2020, 119, 114033. [Google Scholar] [CrossRef]

- Feng, Z.; Chen, N.; Feng, C.; Fan, C.; Wang, H.; Deng, Y.; Gao, Y. Roles of Functional Groups and Irons on Bromate Removal by FeCl3 Modified Porous Carbon. Appl. Surf. Sci. 2019, 488, 681–687. [Google Scholar] [CrossRef]

- Shang, C.; Zhang, X.; Shui, L.; Chen, Z.; Liao, H.; Li, M.; Wang, X.; Zhou, G. Fe3O4 @CoO Mesospheres with Core-Shell Nanostructure as Catalyst for Li-O2 Batteries. Appl. Surf. Sci 2018, 457, 804–808. [Google Scholar] [CrossRef]

- Aguilar, T.; Navas, J.; Alcántara, R.; Fernández-Lorenzo, C.; Gallardo, J.J.; Blanco, G.; Martín-Calleja, J. A Route for the Synthesis of Cu-Doped TiO2 Nanoparticles with a Very Low Band Gap. Chem. Phys. Lett. 2013, 571, 49–53. [Google Scholar] [CrossRef]

- Anwar, D.I.; Mulyadi, D. Synthesis of Fe-TiO2 Composite as a Photocatalyst for Degradation of Methylene Blue. Procedia Chem. 2015, 17, 49–54. [Google Scholar] [CrossRef]

- Bashiri, R.; Mohamed, N.M.; Kait, C.F.; Sufian, S. Hydrogen Production from Water Photosplitting Using Cu/TiO2 Nanoparticles: Effect of Hydrolysis Rate and Reaction Medium. Int. J. Hydrogen Energy 2015, 40, 6021–6037. [Google Scholar] [CrossRef]

- George, S.; Pokhrel, S.; Ji, Z.; Henderson, B.L.; Xia, T.; Li, L.; Zink, J.I.; Nel, A.E.; Mädler, L. Role of Fe Doping in Tuning the Band Gap of TiO2 for the Photo-Oxidation-Induced Cytotoxicity Paradigm. J. Am. Chem. Soc. 2011, 133, 11270–11278. [Google Scholar] [CrossRef]

- Sasikala, R.; Shirole, A.; Sudarsan, V.; Sakuntala, T.; Sudakar, C.; Naik, R.; Bharadwaj, S.R. Highly Dispersed Phase of SnO2 on TiO2 Nanoparticles Synthesized by Polyol-Mediated Route: Photocatalytic Activity for Hydrogen Generation; Elsevier: Amsterdam, The Netherlands, 2009; Volume 34. [Google Scholar]

- Mancuso, A.; Sacco, O.; Vaiano, V.; Bonelli, B.; Esposito, S.; Freyria, F.S.; Blangetti, N.; Sannino, D. Visible Light-Driven Photocatalytic Activity and Kinetics of Fe-Doped TiO2 Prepared by a Three-Block Copolymer Templating Approach. Materials 2021, 14, 3105. [Google Scholar] [CrossRef] [PubMed]

- Kanjana, N.; Maiaugree, W.; Laokul, P. Photocatalytic Activity of Nanocrystalline Fe3+-Doped Anatase TiO2 Hollow Spheres in a Methylene Blue Solution under Visible-Light Irradiation. J. Mater. Sci. Mater. Electron. 2022, 33, 4659–4680. [Google Scholar] [CrossRef]

- Schubert, J.S.; Kalantari, L.; Lechner, A.; Giesriegl, A.; Nandan, S.P.; Alaya, P.; Kashiwaya, S.; Sauer, M.; Foelske, A.; Rosen, J.; et al. Elucidating the Formation and Active State of Cu Co-Catalysts for Photocatalytic Hydrogen Evolution. J. Mater. Chem. A 2021, 9, 21958–912971. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.M.; Tripathi, M. A Review of TiO2 Nanoparticles. Chin. Sci. Bull. 2011, 56, 1639–1657. [Google Scholar] [CrossRef]

- Zedek, R.; Djedjiga, H.; Megherbi, M.; Belkaid, M.S.; Ntsoenzok, E. Effects of Slight Fe (III)-Doping on Structural and Optical Properties of TiO2 Nanoparticles. J. Solgel. Sci. Technol. 2021, 100, 44–54. [Google Scholar] [CrossRef]

- Fan, X.; Fan, J.; Hu, X.; Liu, E.; Kang, L.; Tang, C.; Ma, Y.; Wu, H.; Li, Y. Preparation and Characterization of Ag Deposited and Fe Doped TiO2 Nanotube Arrays for Photocatalytic Hydrogen Production by Water Splitting. Ceram. Int. 2014, 40, 15907–15917. [Google Scholar] [CrossRef]

- Ismael, M. Enhanced Photocatalytic Hydrogen Production and Degradation of Organic Pollutants from Fe (III) Doped TiO2 Nanoparticles. J. Environ. Chem. Eng. 2020, 8, 103676. [Google Scholar] [CrossRef]

- Khan, M.A.; Woo, S.I.; Yang, O.B. Hydrothermally Stabilized Fe(III) Doped Titania Active under Visible Light for Water Splitting Reaction. Int. J. Hydrogen Energy 2008, 33, 5345–5351. [Google Scholar] [CrossRef]

- Sadanandam, G.; Zhang, L.; Scurrell, M.S. Enhanced Photocatalytic Hydrogen Formation over Fe-Loaded TiO2 and g-C3N4 Composites from Mixed Glycerol and Water by Solar Irradiation. J. Renew. Sustain. Energy 2018, 10. [Google Scholar] [CrossRef]

- Wang, F.; Shen, T.; Fu, Z.; Lu, Y.; Chen, C. Enhanced Photocatalytic Water-Splitting Performance Using Fe-Doped Hierarchical TiO2 Ball-Flowers. Nanotechnology 2017, 29, 035702. [Google Scholar] [CrossRef] [PubMed]

- Jung, M.; Scott, J.; Ng, Y.H.; Jiang, Y.; Amal, R. CuOx Dispersion and Reducibility on TiO2 and Its Impact on Photocatalytic Hydrogen Evolution. Int. J. Hydrogen Energy 2014, 39, 12499–12506. [Google Scholar] [CrossRef]

- Martín-Gómez, J.; Hidalgo-Carrillo, J.; Montes, V.; Estévez-Toledano, R.C.; Escamilla, J.C.; Marinas, A.; Urbano, F.J. EPR and CV Studies Cast Further Light on the Origin of the Enhanced Hydrogen Production through Glycerol Photoreforming on CuO:TiO2 physical Mixtures. J Environ. Chem. Eng. 2021, 9, 105336. [Google Scholar] [CrossRef]

- Reddy, N.L.; Emin, S.; Kumari, V.D.; Muthukonda Venkatakrishnan, S. CuO Quantum Dots Decorated TiO2 Nanocomposite Photocatalyst for Stable Hydrogen Generation. Ind. Eng. Chem. Res 2018, 57, 568–577. [Google Scholar] [CrossRef]

- Yu, J.; Hai, Y.; Jaroniec, M. Photocatalytic Hydrogen Production over CuO-Modified Titania. J. Colloid. Interface Sci. 2011, 357, 223–228. [Google Scholar] [CrossRef]

- Hinojosa-Reyes, M.; Camposeco-Solís, R.; Zanella, R.; Rodríguez González, V. Hydrogen Production by Tailoring the Brookite and Cu2O Ratio of Sol-Gel Cu-TiO2 Photocatalysts. Chemosphere 2017, 184, 992–1002. [Google Scholar] [CrossRef] [PubMed]

- Valášková, M.; Kočí, K.; Madejová, J.; Matějová, L.; Pavlovský, J.; Barrocas, B.T.; Klemencová, K. α-Fe2O3 Nanoparticles/Iron-Containing Vermiculite Composites: Structural, Textural, Optical and Photocatalytic Properties. Minerals 2022, 12, 607. [Google Scholar] [CrossRef]

- Bootluck, W.; Chittrakarn, T.; Techato, K.; Jutaporn, P.; Khongnakorn, W. S-Scheme α-Fe2O3/TiO2 Photocatalyst with Pd Cocatalyst for Enhanced Photocatalytic H2 Production Activity and Stability. Catal. Lett. 2022, 152, 2590–2606. [Google Scholar] [CrossRef]

- Kurenkova, A.Y.; Yakovleva, A.Y.; Saraev, A.A.; Gerasimov, E.Y.; Kozlova, E.A.; Kaichev, V. Copper-Modified Titania-Based Photocatalysts for the Efficient Hydrogen Production under UV and Visible Light from Aqueous Solutions of Glycerol. Nanomaterials 2022, 12, 3106. [Google Scholar] [CrossRef] [PubMed]

- Pollap, A.; Serafin, J.; Serrano, I.; Sreńscek-Nazzal, J.; Llorca, J. Promising Photocatalysts Based on Nanoshaped TiO2–RGO Composite Doped with Metals (Pt and Cu) for Hydrogen Photoproduction. J. Environ. Chem. Eng. 2022, 10, 108877. [Google Scholar] [CrossRef]

- Qiu, P.; Lu, M.; Cheng, G.; Li, W.; Liu, L.; Xiong, J. Co-Implantation of Oxygen Vacancy and Well-Dispersed Cu Cocatalyst into TiO2 Nanoparticles for Promoting Solar-to-Hydrogen Evolution. Int. J. Hydrogen Energy 2022, 48, 933–942. [Google Scholar] [CrossRef]

- Barrocas, B.T.; Ambrožová, N.; Kočí, K. Photocatalytic Reduction of Carbon Dioxide on TiO2 Heterojunction Photocatalysts—A Review. Materials 2022, 15, 967. [Google Scholar] [CrossRef]

- Yu, F.; Wang, W.; Li, Y.; Du, M.; Liu, F.; Liang, D. Ultralow Fe Doping Induced High Photocatalytic Activity toward Ciprofloxacin Degradation and CO2 Reduction. J Mol. Struct. 2023, 1273, 134344. [Google Scholar] [CrossRef]

- Liang, C.; Li, C.; Zhu, Y.; Du, X.; Zeng, Y.; Zhou, Y.; Zhao, J.; Li, S.; Liu, X.; Yu, Q.; et al. Light-Driven Photothermal Catalysis for Degradation of Toluene on CuO/TiO2 Composite: Dominating Photocatalysis and Auxiliary Thermalcatalysis. Appl. Surf. Sci. 2022, 601, 154144. [Google Scholar] [CrossRef]

- Sassi, S.; Trabelsi, K.; el Jery, A.; Abidi, M.; Hajjaji, A.; Khezami, L.; Karrech, A.; Gaidi, M.; Soucase, B.M.; Bessais, B. Synergistic Effect of CuxOy-NPs/TiO2-NTs Heterostructure on the Photodegradation of Amido Black Staining. Optik 2022, 272, 170234. [Google Scholar] [CrossRef]

- Hao, B.; Guo, J.; Zhang, L.; Ma, H. Magnetron Sputtered TiO2/CuO Heterojunction Thin Films for Efficient Photocatalysis of Rhodamine B. J. Alloys Compd. 2022, 903, 163851. [Google Scholar] [CrossRef]

- Mohamed, H.H.; Besisa, D.H.A. Eco-Friendly and Solar Light-Active Ti-Fe2O3 Ellipsoidal Capsules’ Nanostructure for Removal of Herbicides and Organic Dyes. Environ. Sci. Pollut. Res. 2022, 1–11. [Google Scholar] [CrossRef]

- Waheed, A.; Shi, Q.; Maeda, N.; Meier, D.M.; Qin, Z.; Li, G.; Baiker, A. Strong Activity Enhancement of the Photocatalytic Degradation of an Azo Dye on Au/TiO2 Doped with Feox. Catal. 2020, 10, 933. [Google Scholar] [CrossRef]

- Hernández-Gordillo, A.; Arriaga, S. Mesoporous TiO2 Monoliths Impregnated with CdS and CuO Nanoparticles for Airborne Bacteria Inactivation Under Visible Light. Catal. Lett. 2022, 152, 629–640. [Google Scholar] [CrossRef] [PubMed]

- Espinoza-Villalobos, N.; Rojas, S.; Salazar, R.A.; Contreras, D.; Escalona, N.; Vergara, E.; Laguna-Bercero, M.A.; Mendizabal, F.; Barrientos, L. Role of β-CD Macromolecule Anchored to α-Fe2O3/TiO2 on the Selectivity and Partial Oxidation of Guaiacol to Add-Value Products. ACS Sustain. Chem. Eng. 2021, 9, 11427–11438. [Google Scholar] [CrossRef]

| Elements | Olive Leaf (% Weight) | AOL (% Weight) | Cu-AOL (% Weight) | Fe-AOL (% Weight) |

|---|---|---|---|---|

| Ti | 0 | 53.20 | 44.00 | 42.13 |

| Fe | 0.40 | 0.05 | 0.04 | 5.80 |

| Cu | 0 | 0 | 2.78 | 0 |

| Mg | 0.10 | 0.12 | 0.07 | 0.08 |

| Al | 0.03 | 0.08 | 0.03 | 0.06 |

| Si | 0.06 | 0.38 | 0.10 | 0.53 |

| P | 0.16 | 1.09 | 0.11 | 0.22 |

| S | 0.17 | 0.73 | 0.61 | 0.76 |

| Cl | 0.11 | 0.01 | 0.48 | 0.27 |

| K | 1.27 | 0.95 | 0.84 | 0.72 |

| Ca | 1.59 | 1.83 | 1.04 | 0.88 |

| C | 53.23 | 2.28 | 1.99 | 2.81 |

| Catalyst | Sacrificial Agent | Light Source | Hydrogen Production (TiO2) (mmol/h·gCat) | Hydrogen Production (Catalyst) (mmol/h·gCat) | Reference |

|---|---|---|---|---|---|

| Cu-AOL | Glycerol at 10% | UV | 1.4 | 42.8 | This study |

| 5% CuO-TiO2 | Glycerol at 10% | UV | 0.4 | 3.24 | [49] |

| 1% Cu-TiO2 | Ethanol at 50% | UV | 0.96 | 3.86 | [52] |

| Fe-AOL | Glycerol at 10% | UV | 1.4 | 6.94 | This study |

| Fe2O3-TiO2 | Methanol at 30% | UV | 0.04 | 0.74 | [54] |

| Fe2O3-TiO2 | Methanol at 50% | UV | 1 | 1.3 | [53] |

| Cu-AOL | Glycerol at 10% | Solar | 1.1 | 9.7 | This study |

| 5% CuO-TiO2 | Glycerol at 2.8% | Visible | 0.2 | 0.6 | [55] |

| CuO-TiO2 | Ethanol at 10% | Solar | 1.9 | 7 | [56] |

| CuO-TiO2 | Methanol at 20% | Solar | 3.4 | 7.2 | [57] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Gómez, J.; Reca-Expósito, S.; López-Tenllado, F.J.; Hidalgo-Carrillo, J.; Marinas, A.; Urbano, F.J. Synthesis of Fe-TiO2 and Cu-TiO2 Based Materials by Olive Leaves Biotemplating—Application to Hydrogen Production from Glycerol Photoreforming. Nanomaterials 2023, 13, 664. https://doi.org/10.3390/nano13040664

Martín-Gómez J, Reca-Expósito S, López-Tenllado FJ, Hidalgo-Carrillo J, Marinas A, Urbano FJ. Synthesis of Fe-TiO2 and Cu-TiO2 Based Materials by Olive Leaves Biotemplating—Application to Hydrogen Production from Glycerol Photoreforming. Nanomaterials. 2023; 13(4):664. https://doi.org/10.3390/nano13040664

Chicago/Turabian StyleMartín-Gómez, Juan, Susana Reca-Expósito, Francisco J. López-Tenllado, Jesús Hidalgo-Carrillo, Alberto Marinas, and Francisco J. Urbano. 2023. "Synthesis of Fe-TiO2 and Cu-TiO2 Based Materials by Olive Leaves Biotemplating—Application to Hydrogen Production from Glycerol Photoreforming" Nanomaterials 13, no. 4: 664. https://doi.org/10.3390/nano13040664

APA StyleMartín-Gómez, J., Reca-Expósito, S., López-Tenllado, F. J., Hidalgo-Carrillo, J., Marinas, A., & Urbano, F. J. (2023). Synthesis of Fe-TiO2 and Cu-TiO2 Based Materials by Olive Leaves Biotemplating—Application to Hydrogen Production from Glycerol Photoreforming. Nanomaterials, 13(4), 664. https://doi.org/10.3390/nano13040664