Characteristics of the Colorless Polyimide-Based Flexible X-ray Detector with Non-Fullerene Acceptor Polymer

Abstract

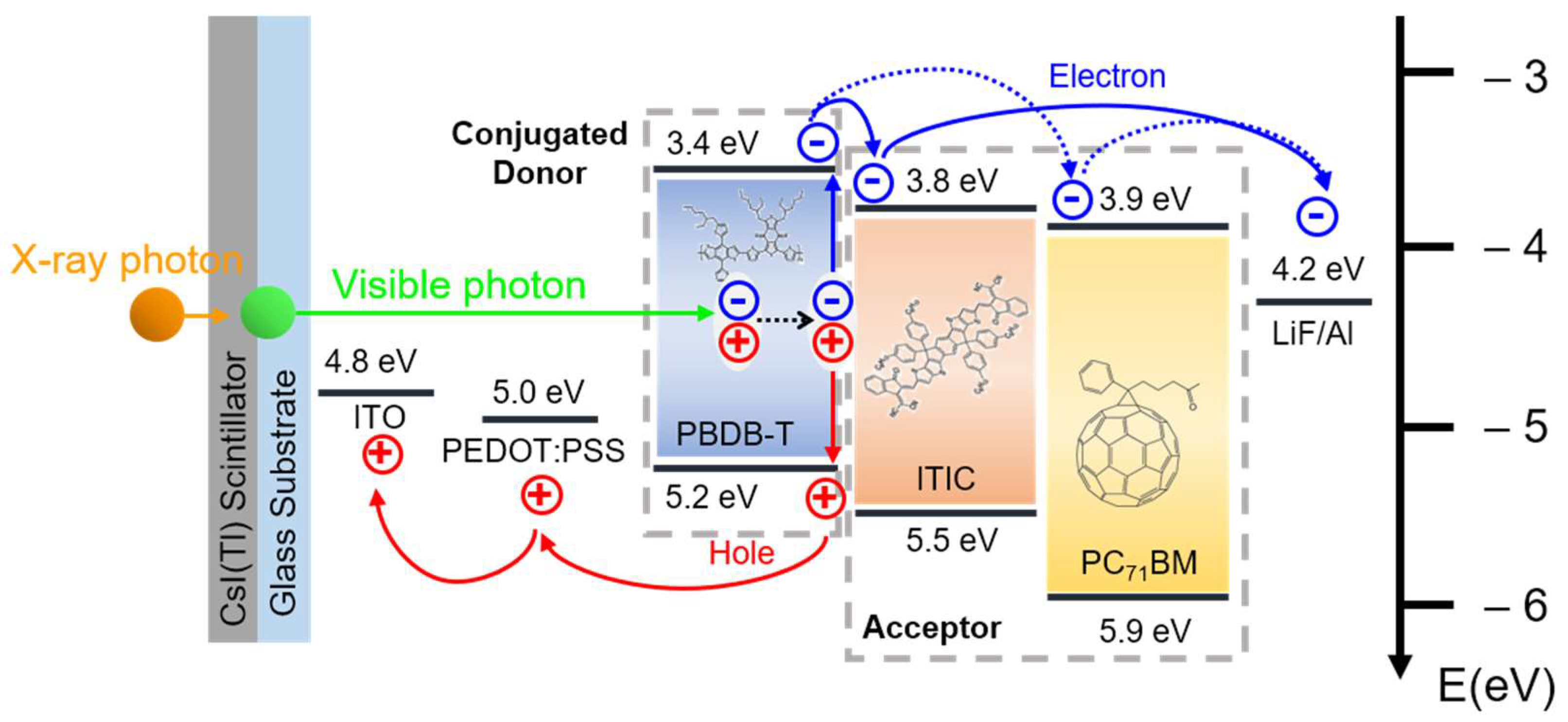

:1. Introduction

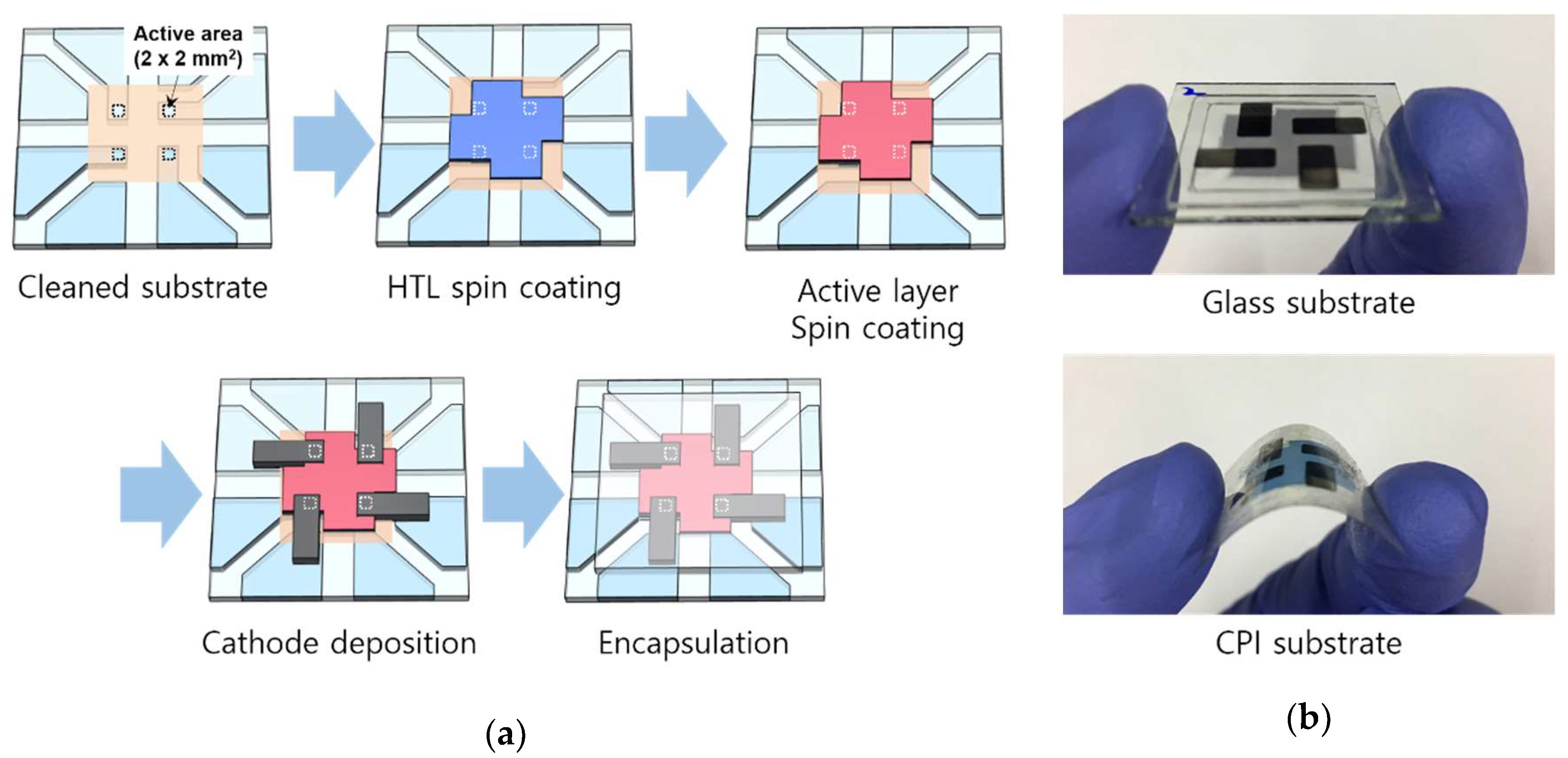

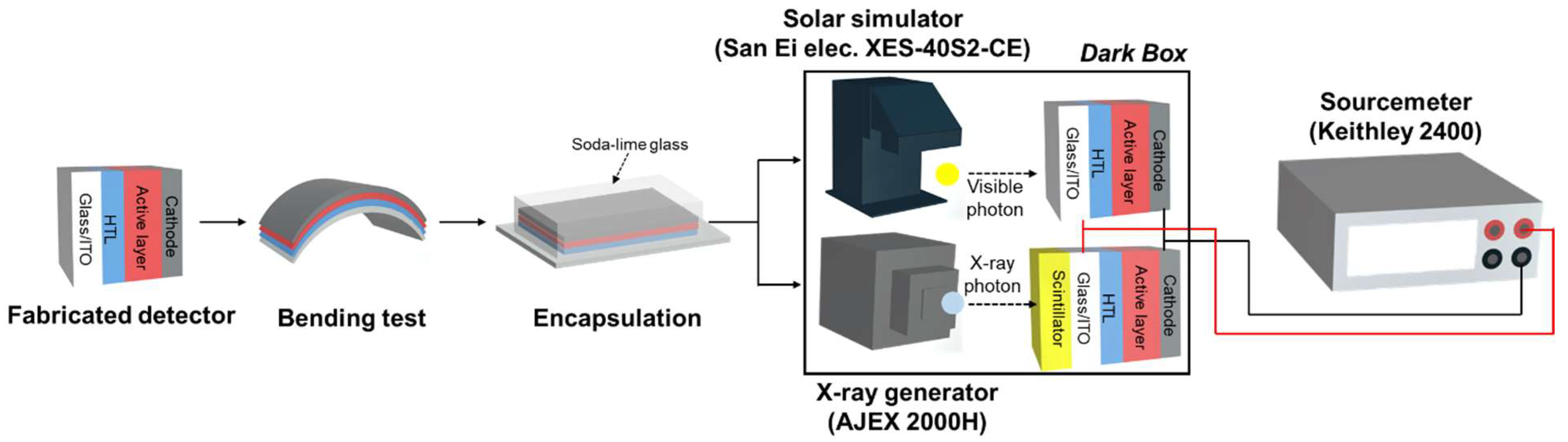

2. Experiment Set-Up

3. Results and Discussion

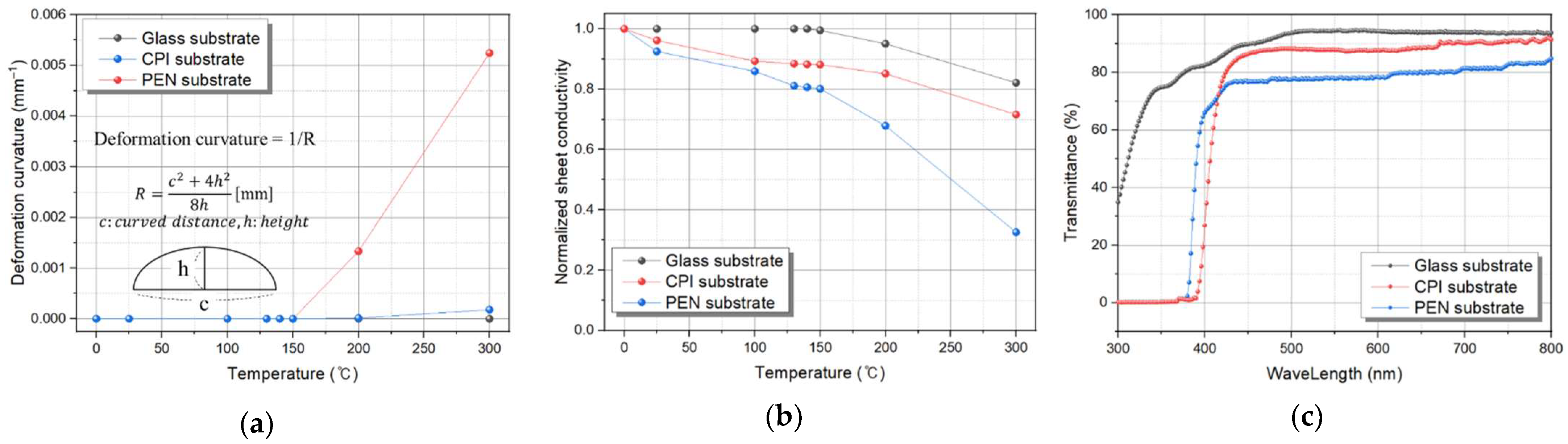

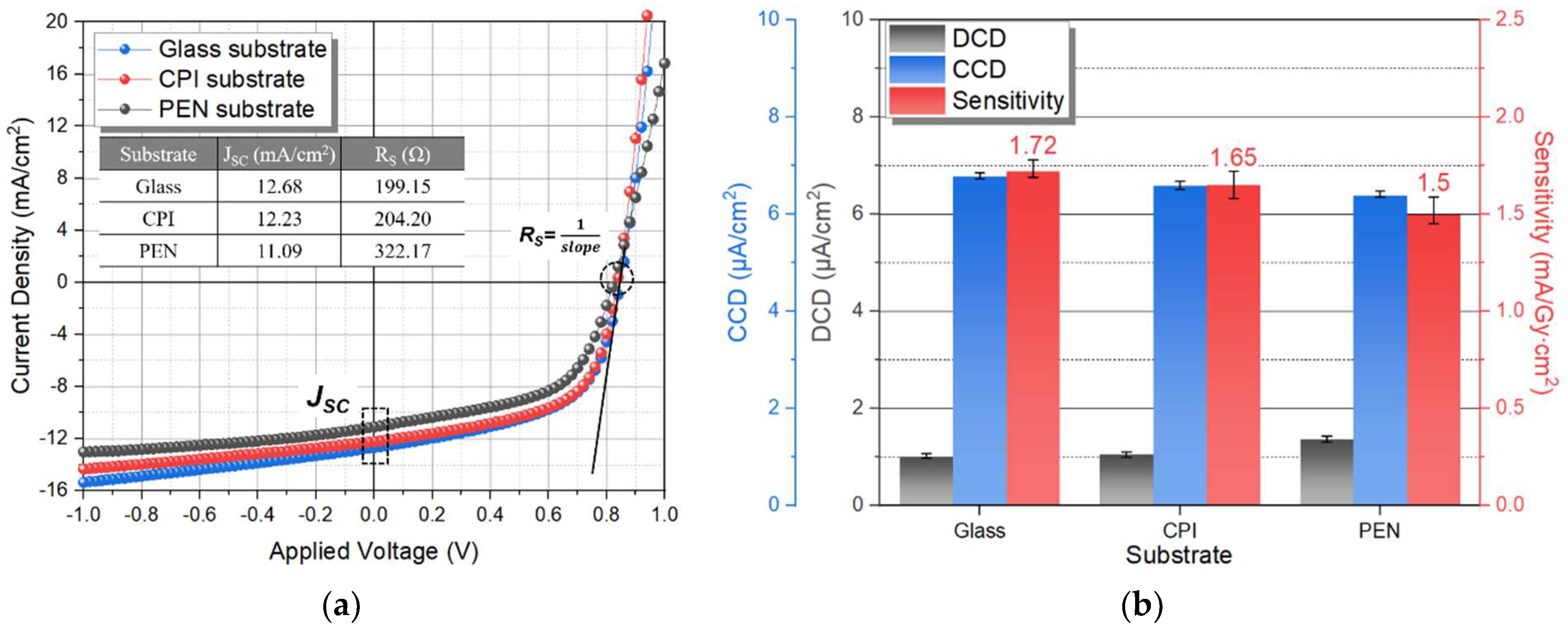

3.1. Experiments for Substrates Comparison

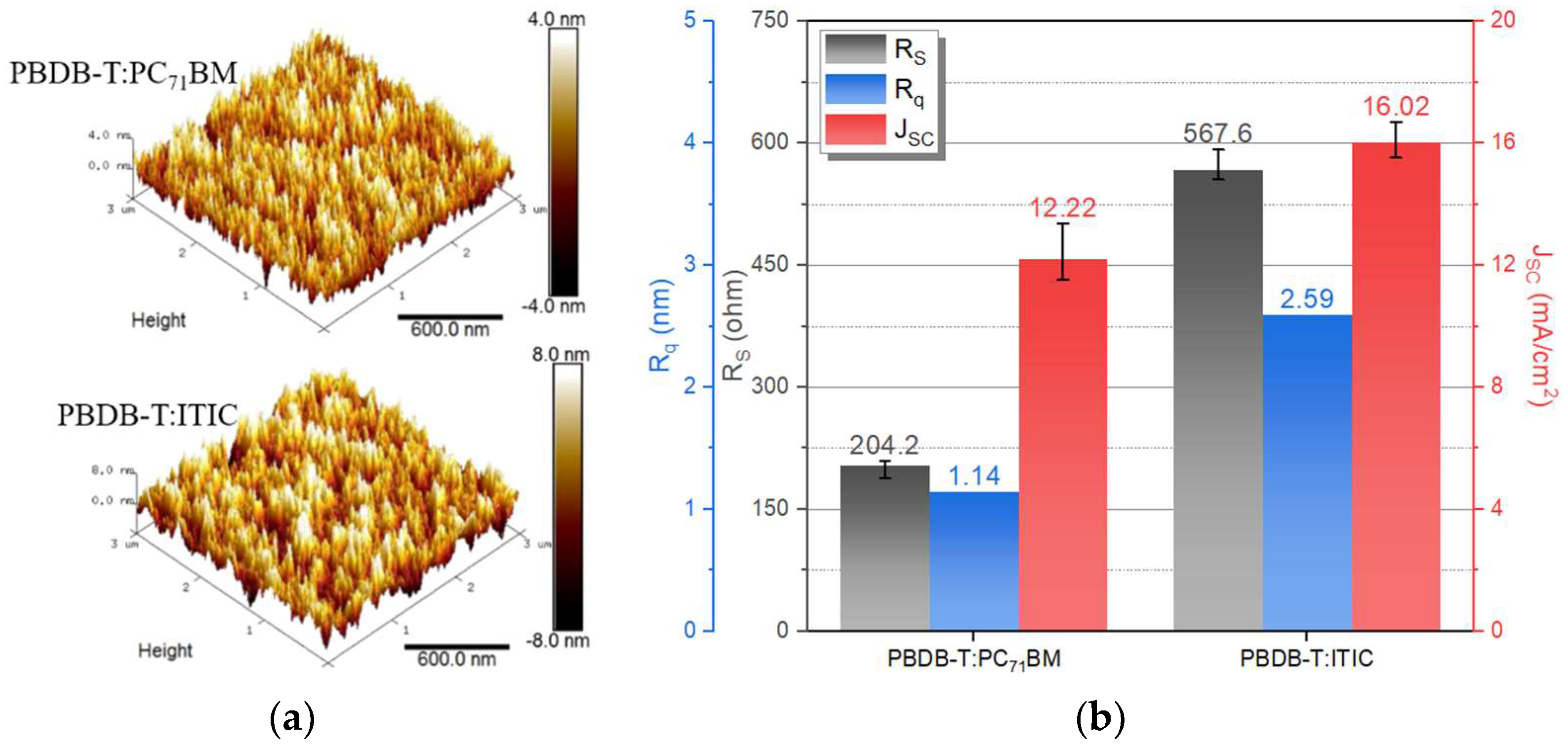

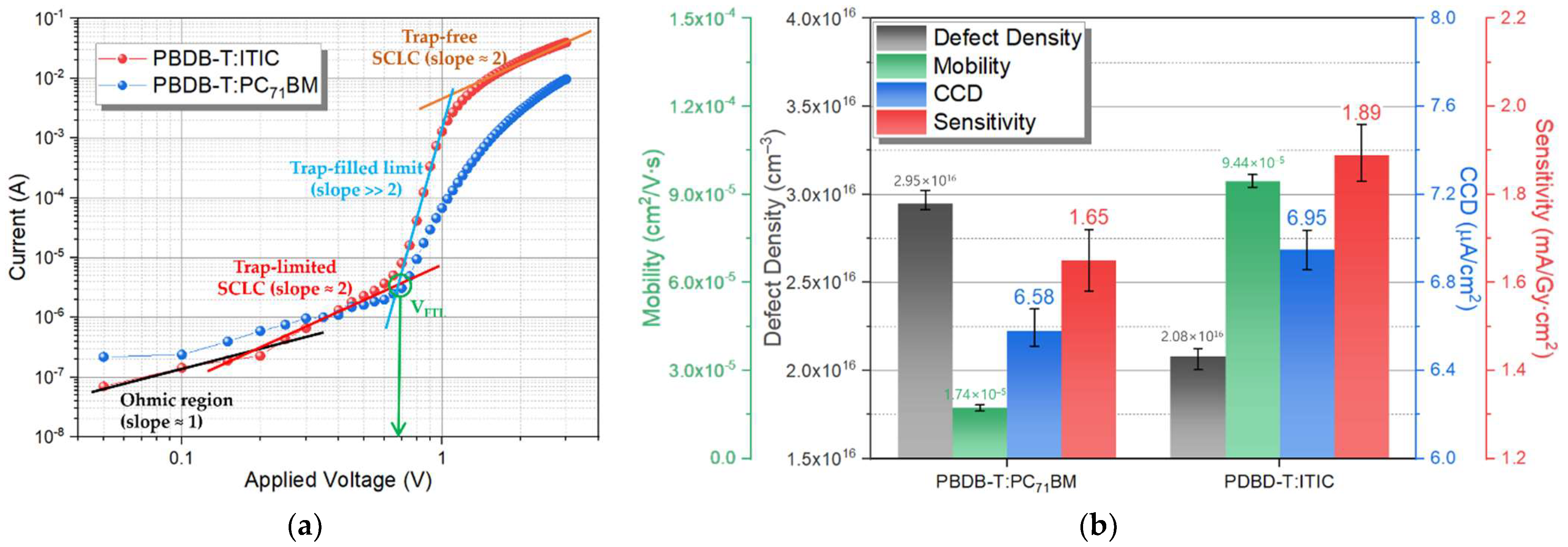

3.2. Characteristics Experiment According to the Type of Acceptor Materials

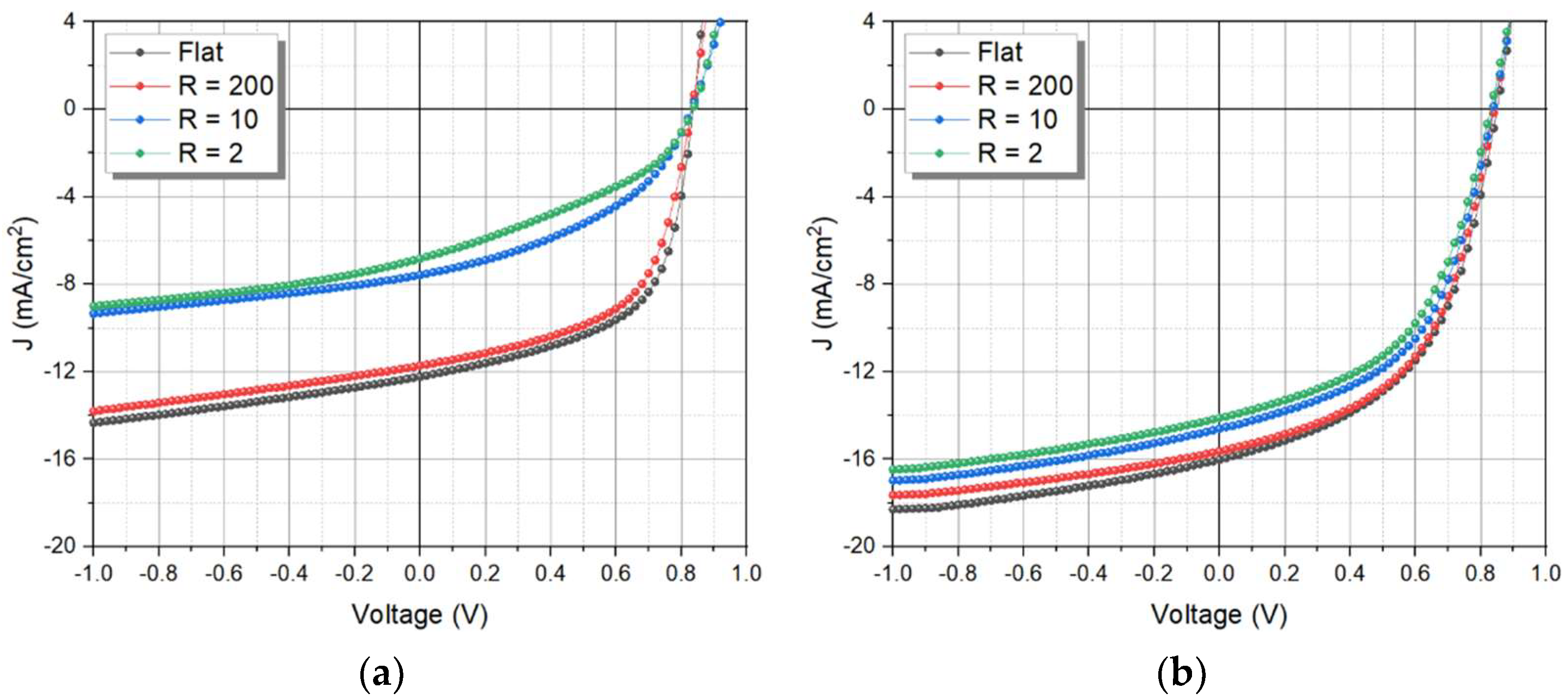

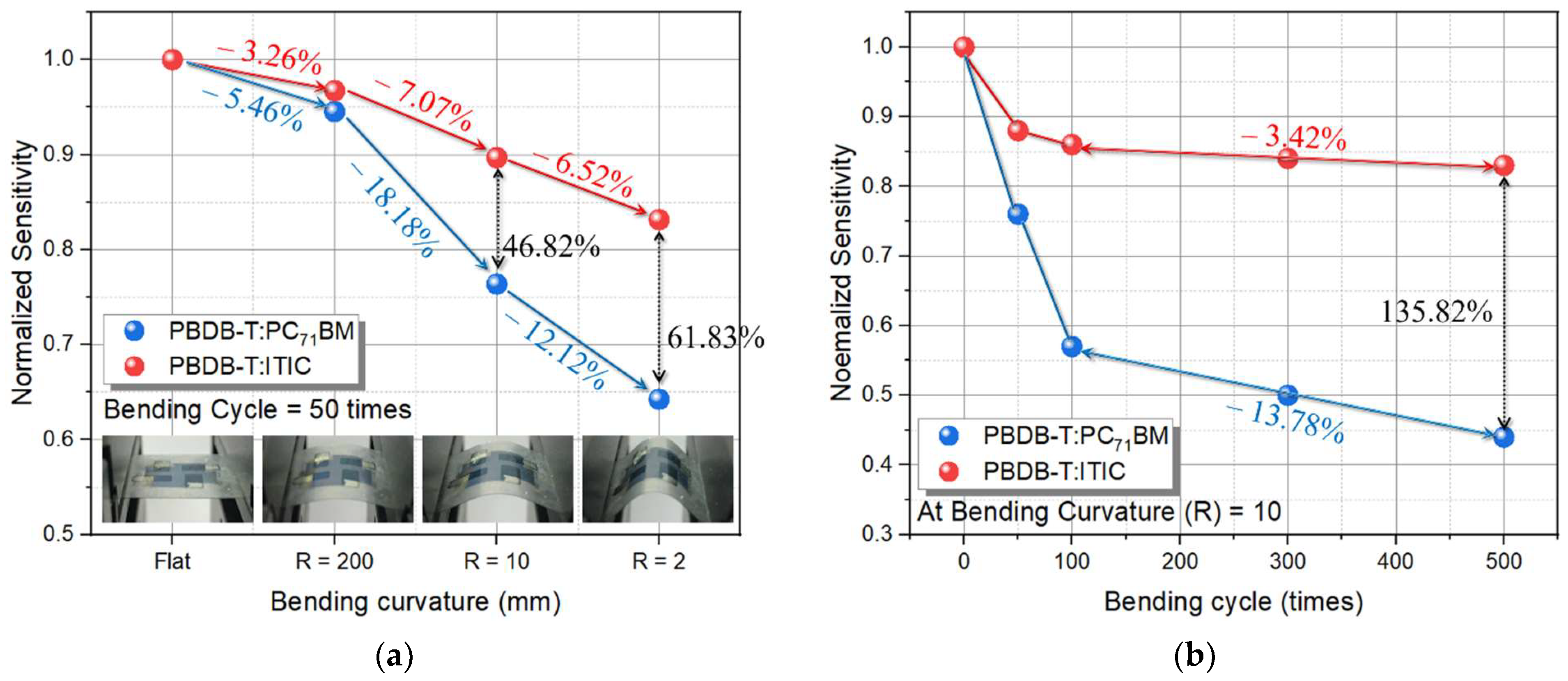

3.3. Bending Curvature and Bending Cycle Experiments for Flexibility Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, Y.; Chang, M.; Meng, L.; Wan, X.; Gao, H.; Zhang, Y.; Zhao, K.; Sun, Z.; Li, C.; Liu, S.; et al. Flexible organic photovoltaics based on water-processed silver nanowire electrodes. Nat. Electron. 2019, 2, 513–520. [Google Scholar] [CrossRef]

- Jeon, Y.; Choi, H.R.; Lim, M.; Choi, S.; Kim, H.; Kwon, J.H.; Park, K.C.; Choi, K.C. A Wearable Photobiomodulation Patch Using a Flexible Red-Wavelength OLED and Its In Vitro Differential Cell Proliferation Effects. Adv. Mater. Technol. 2018, 3, 1700391. [Google Scholar] [CrossRef]

- Pak, K.; Choi, J.; Lee, C.; Im, S.G. Low-Power, Flexible Nonvolatile Organic Transistor Memory Based on an Ultrathin Bilayer Dielectric Stack. Adv. Electron. Mater. 2019, 5, 1800799. [Google Scholar] [CrossRef]

- Liang, H.; Cui, S.; Su, R.; Guan, P.; He, Y.; Yang, L.; Chen, L.; Zhang, Y.; Mei, Z.; Du, X. Flexible X-ray Detectors Based on Amorphous Ga2O3 Thin Films. ACS Photon. 2019, 6, 351–359. [Google Scholar] [CrossRef]

- Yin, Z.; Sun, S.; Salim, T.; Huang, X.; He, Q.; Lam, Y.M.; Zhang, H. Organic Photovoltaic Devices Using Highly Flexible Re-duced Graphene Oxide Films as Transparent Electrodes. ACS Nano 2010, 4, 5263–5268. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Kang, J. Characteristics of a Flexible Radiation Detector Fabricated with Non-Fullerene Acceptor for an Indirect-type X-ray Imaging. J. Instrum. 2019, 14, C03008. [Google Scholar] [CrossRef]

- Lee, D.H.; Yun, H.; Jung, E.D.; Chu, J.H.; Nam, Y.S.; Song, S.; Seok, S.H.; Song, M.H.; Kwon, S.Y. Ultrathin Graphene Inter-calation in PEDOT:PSS/Colorless Polyimide-Based Transparent Electrodes for Enhancement of Optoelectronic Performance and Operational Stability of Organic Devices. ACS Appl. Mater. Interfaces 2019, 11, 21069–21077. [Google Scholar] [CrossRef]

- Kim, B.; Lee, J.; Kang, J. Improving the sensitivity of indirect-type organic X-ray detector by blending with CdSe quantum dots. J. Instrum. 2017, 12, C01009. [Google Scholar] [CrossRef]

- Liu, H.; Lee, J.; Kang, J. Characteristics of A Hybrid Detector Combined with A Perovskite Active Layer for Indirect X-ray Detection. Sensors 2020, 20, 6872. [Google Scholar] [CrossRef]

- Elandaloussi, E.H.; Frère, P.; Richomme, P.; Orduna, J.; Garin, J.; Roncali, J. Effect of Chain Extension on the Electrochemical and Electronic Properties of π-Conjugated Soluble Thienylenevinylene Oligomers. J. Am. Chem. Soc. 1997, 119, 10774–10784. [Google Scholar] [CrossRef]

- Ma, Z.; Geng, H.; Wang, D.; Shuai, Z. Influence of alkyl side-chain length on the carrier mobility in organic semiconductors: Herringbone vs. pi–pi stacking. J. Mater. Chem. C 2016, 4, 4546–4555. [Google Scholar] [CrossRef]

- Kleinhenz, N.; Yang, L.; Zhou, H.; Price, S.C.; You, W. Low-Band-Gap Polymers That Utilize Quinoid Resonance Structure Stabilization by Thienothiophene: Fine-Tuning of HOMO Level. Macromology 2011, 44, 872–877. [Google Scholar] [CrossRef]

- Kadem, B.; Al-Hashimi, M.K.; Hassan, A. The Effect of Solution Processing on the Power Conversion Efficiency of P3HT-based Organic Solar Cells. Energy Procedia 2014, 50, 237–245. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.; Kim, J.-H.; Kang, T.E.; Lee, C.; Kang, H.; Shin, M.; Wang, C.; Ma, B.; Jeong, U.; Kim, T.-S.; et al. Flexible, highly efficient all-polymer solar cells. Nat. Commun. 2015, 6, 8547. [Google Scholar] [CrossRef] [Green Version]

- Holliday, S.; Ashraf, R.S.; Wadsworth, A.; Baran, D.; Yousaf, S.A.; Nielsen, C.B.; Tan, C.-H.; Dimitrov, S.D.; Shang, Z.; Gasparini, N.; et al. High-efficiency and air-stable P3HT-based polymer solar cells with a new non-fullerene acceptor. Nat. Commun. 2016, 7, 11585. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.; Wang, J.; Zhang, Z.-G.; Bai, H.; Li, Y.; Zhu, D.; Zhan, X. An Electron Acceptor Challenging Fullerenes for Efficient Polymer Solar Cells. Adv. Mater. 2015, 27, 1170–1174. [Google Scholar] [CrossRef]

- Bai, Y.; Yang, B.; Chen, X.; Wang, F.; Hayat, T.; Alsaedi, A.; Tan, Z. Constructing Desired Vertical Component Distribution Within a PBDB-T:ITIC-M Photoactive Layer via Fine-Tuning the Surface Free Energy of a Titanium Chelate Cathode Buffer Layer. Front. Chem. 2018, 6, 292. [Google Scholar] [CrossRef]

- Xu, Y.; Yuan, J.; Zhou, S.; Seifrid, M.; Ying, L.; Li, B.; Huang, F.; Bazan, G.C.; Ma, W. Ambient Processable and Stable All-Polymer Organic Solar Cells. Adv. Funct. Mater. 2019, 29, 1806747. [Google Scholar] [CrossRef]

- Won, J.; Liu, H.; Kang, J. Improvement of Indirect X-ray Detector Performance by Applying Additive Solvent to the Organic Active-Layer. J. Nanosci. Nanotech. 2021, 21, 2998–3003. [Google Scholar] [CrossRef]

- Ban, D.; Yoo, K.; Kang, J. Characteristics of an organic photodetector with a conjugated donor and non-fullerene acceptor for indirect X-ray detection. J. Instrum. 2019, 14, P12012. [Google Scholar] [CrossRef]

- Wei, J.; Tu, Q.; Zheng, Q. Heteroheptacene-cored semiconducting molecules for non-fullerene organic solar cells. Dye. Pigment. 2017, 144, 133–141. [Google Scholar] [CrossRef]

- Kwan, C.-P.; Street, M.; Mahmood, A.; Echtenkamp, W.; Randle, M.; He, K.; Nathawat, J.; Arabchigavkani, N.; Barut, B.; Yin, S.; et al. Space-charge limited conduction in epitaxial chromia films grown on elemental and oxide-based metallic substrates. AIP Adv. 2019, 9, 055018. [Google Scholar] [CrossRef] [Green Version]

- Jhamba, L.; Wamwangi, D.; Chiguvare, Z. Dependence of mobility and charge injection on active layer thickness of bulk het-erojunction organic solar cells: PCBM:P3HT. Opt. Quantum Electron. 2020, 52, 245. [Google Scholar] [CrossRef]

- Haneef, H.F.; Zeidell, A.M.; Jurchescu, O.D. Charge carrier traps in organic semiconductors: A review on the underlying physics and impact on electronic devices. J. Mater. Chem. C 2020, 8, 759–787. [Google Scholar] [CrossRef]

- Jahandar, M.; Khan, N.; Lee, H.K.; Lee, S.K.; Shin, W.S.; Lee, J.-C.; Song, C.E.; Moon, S.-J. High-Performance CH3NH3PbI3-Inverted Planar Perovskite Solar Cells with Fill Factor Over 83% via Excess Organic/Inorganic Halide. ACS Appl. Mater. Interfaces 2017, 9, 35871–35879. [Google Scholar] [CrossRef]

- Sareni, B.; Krähenbühl, L.; Brosseau, C.; Beroual, A. Effective dielectric constant of random composite materials. J. Appl. Phys. 1997, 81, 2375–2383. [Google Scholar] [CrossRef] [Green Version]

- Heo, J.H.; Park, J.K.; Yang, Y.; Lee, D.S.; Im, S.H. Self-powered flexible all-perovskite X-ray detectors with high sensitivity and fast response. iSci. 2021, 24, 102927. [Google Scholar]

- Li, Z.; Chang, S.; Hu, Y.; Huang, Y.; Au, L.; Ren, S. Flexible Lead-Free X-ray Detector from Metal-Organic Frameworks. Nano Lett. 2021, 21, 6983–6989. [Google Scholar]

- Guo, J.; Chang, S.; Xu, Y.; Yang, W.; Xiao, B.; Sun, Q.; Zhang, X.; Zhang, B.; Zhu, M.; Jie, W. High-Stability Flexible X-ray Detectors Based on Lead-Free Halide Perovskite Cs2TeI6 Films. ACS Appl. Mater. Interfaces 2021, 13, 23928–23935. [Google Scholar]

- Mao, L.; Li, Y.; Chen, H.; Yu, L.; Zhang, J. A high-sensitivity flexible direct x-ray detector based on bi2o3/pdms nanocomposite thin film. Nanomaterials 2021, 11, 1832. [Google Scholar]

- Shrestha, S.; Fischer, R.; Matt, G.J.; Feldner, P.; Michel, T.; Osvet, A.; Levchuk, I.; Merle, B.; Chen, H.; Tedde, S.F.; et al. High-performance direct conversion X-ray detectors based on sintered hybrid lead triiodide perovskite wafers. Nat. Photonic. 2017, 11, 436–440. [Google Scholar]

| Active Layer | Bending Curvature | JSC (mA/cm2) | RS (ohm) |

|---|---|---|---|

| PBDB-T:PC71BM | Flat | 12.22 | 204.20 |

| R = 200 | 11.72 | 479.43 | |

| R = 10 | 7.57 | 1925.18 | |

| R = 2 | 6.83 | 2604.55 | |

| PBDB-T:ITIC | Flat | 16.02 | 567.60 |

| R = 200 | 15.64 | 617.41 | |

| R = 10 | 14.61 | 851.14 | |

| R = 2 | 14.11 | 1169.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Won, J.; Lee, D.; Liu, H.; Kang, J. Characteristics of the Colorless Polyimide-Based Flexible X-ray Detector with Non-Fullerene Acceptor Polymer. Nanomaterials 2022, 12, 918. https://doi.org/10.3390/nano12060918

Lee J, Won J, Lee D, Liu H, Kang J. Characteristics of the Colorless Polyimide-Based Flexible X-ray Detector with Non-Fullerene Acceptor Polymer. Nanomaterials. 2022; 12(6):918. https://doi.org/10.3390/nano12060918

Chicago/Turabian StyleLee, Jehoon, Jongkyu Won, Duhee Lee, Hailiang Liu, and Jungwon Kang. 2022. "Characteristics of the Colorless Polyimide-Based Flexible X-ray Detector with Non-Fullerene Acceptor Polymer" Nanomaterials 12, no. 6: 918. https://doi.org/10.3390/nano12060918

APA StyleLee, J., Won, J., Lee, D., Liu, H., & Kang, J. (2022). Characteristics of the Colorless Polyimide-Based Flexible X-ray Detector with Non-Fullerene Acceptor Polymer. Nanomaterials, 12(6), 918. https://doi.org/10.3390/nano12060918