Thickness Effects on the Martensite Transformations and Mechanical Properties of Nanocrystalline NiTi Wires

Abstract

1. Introduction

2. Materials and Methods

- Strand rolling of an ingot with a 20 mm diameter to a bar with a 7 mm thickness (20 cycles);

- Rotary forging of the bar from 7 mm to 3.5 mm (7 cycles);

- Cold wire drawing from 3.5 mm to 0.5 mm (25 cycles);

- Hot wire drawing with intermediate annealing at 450 °C was carried out for 50–70 cycles from a 500 µm diameter to 90, 60, and 40 µm thicknesses.

3. Results

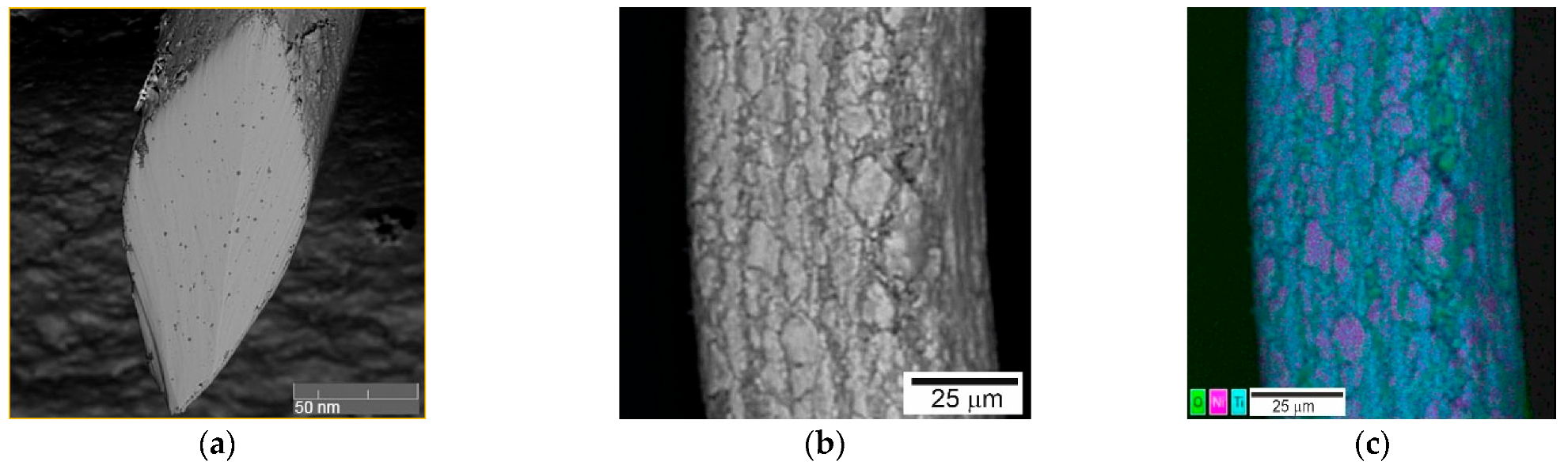

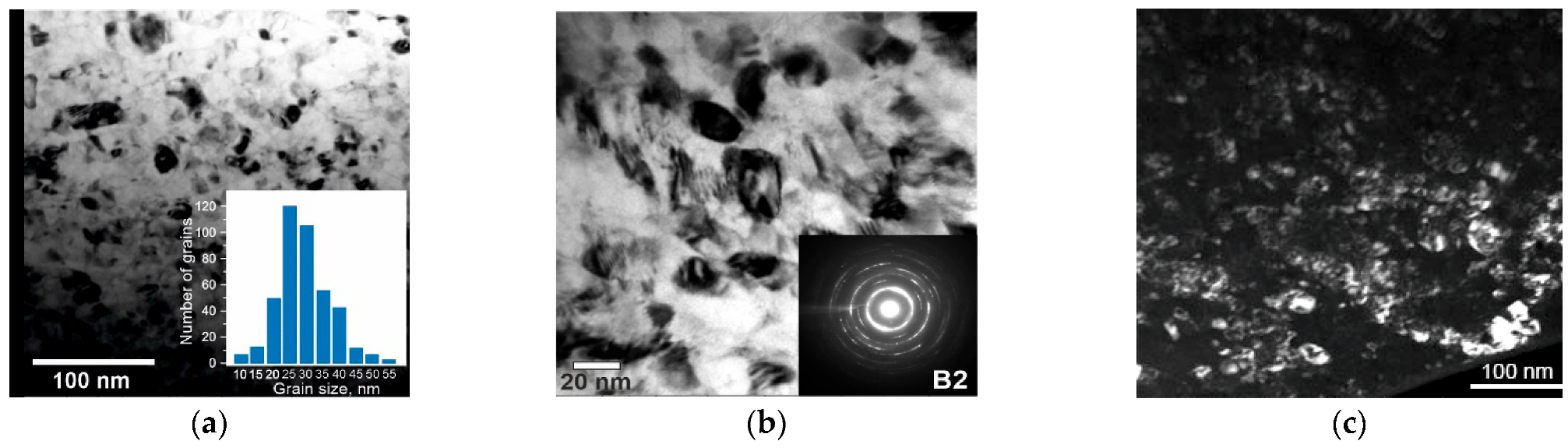

3.1. Structural Studies

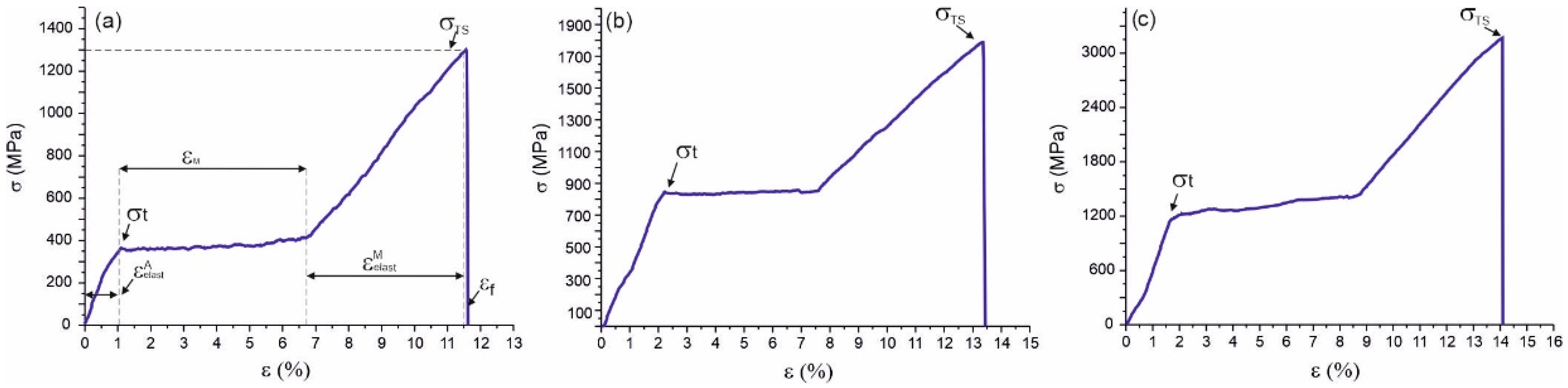

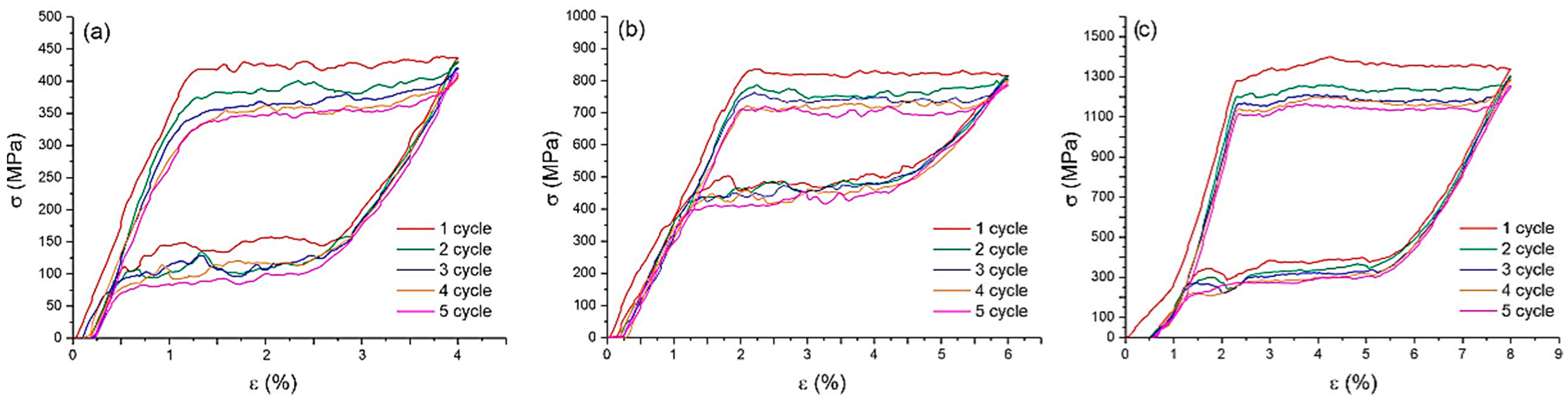

3.2. Mechanical Testing of NiTi Wires by Uniaxial Tension

3.3. Martensitic Transformations

4. Conclusions

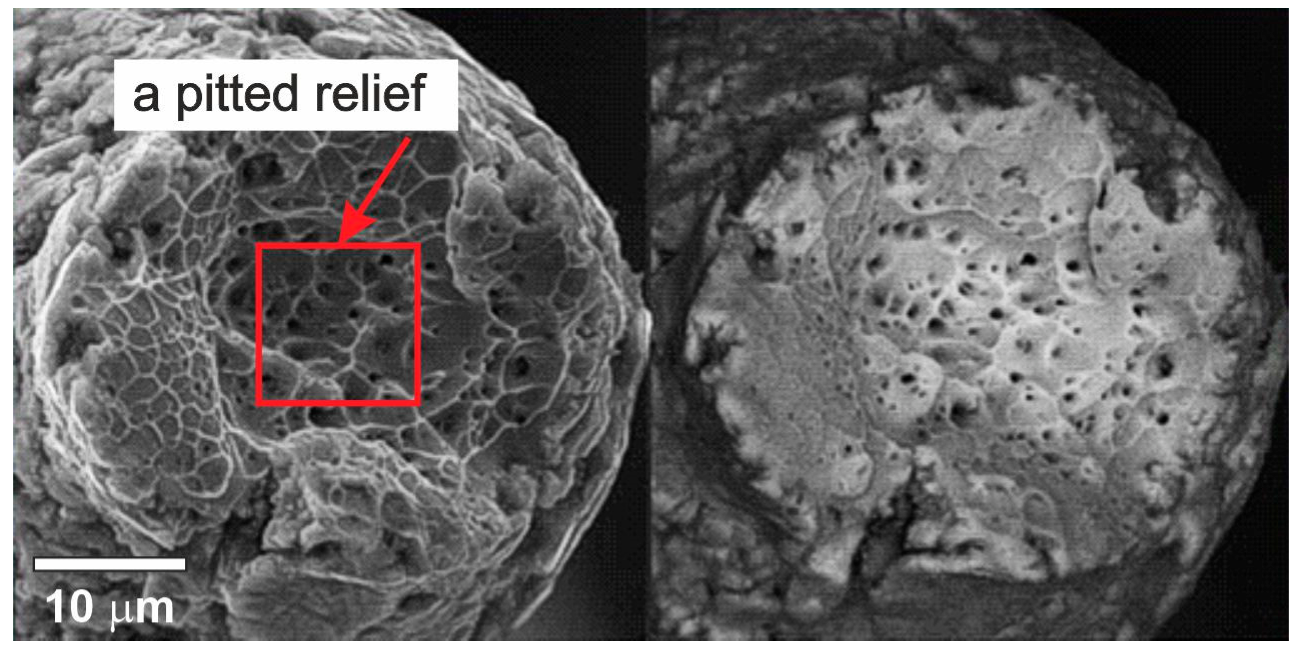

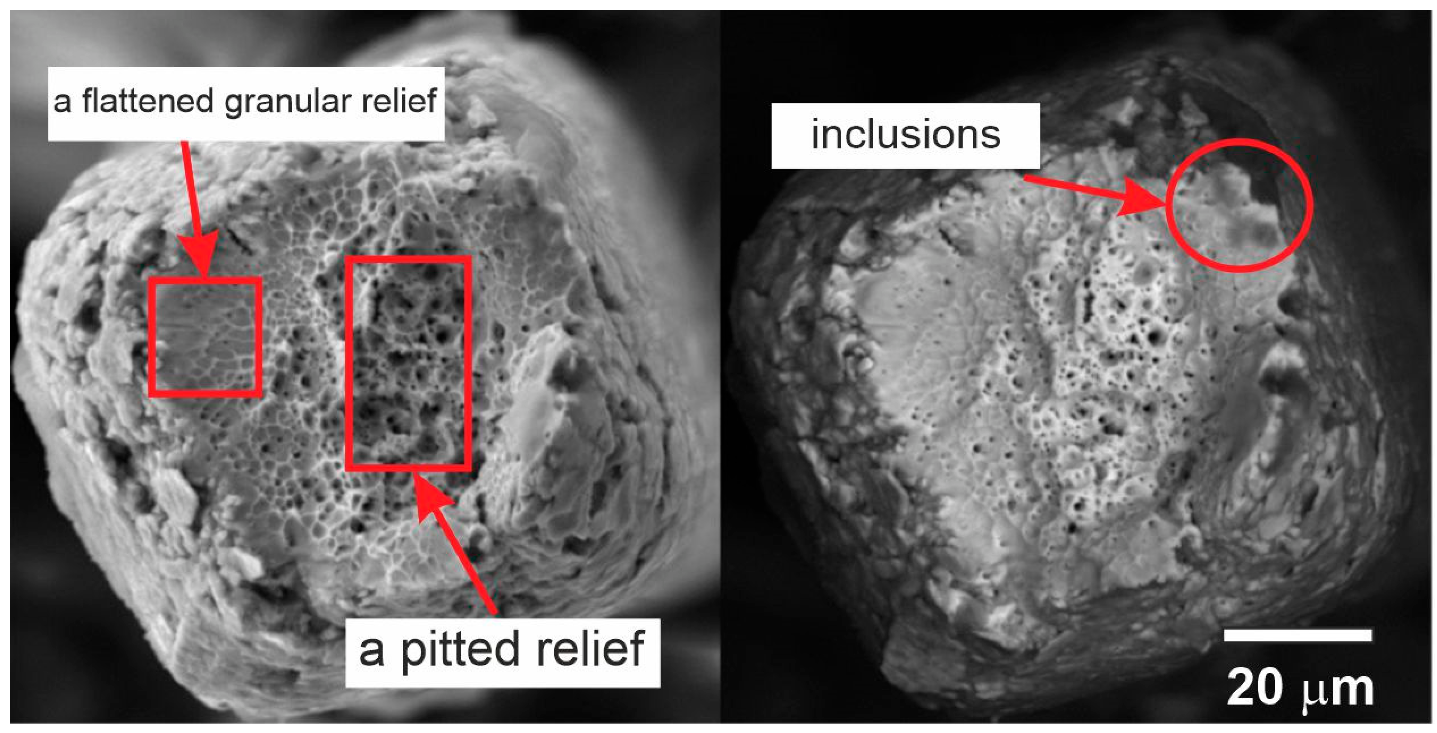

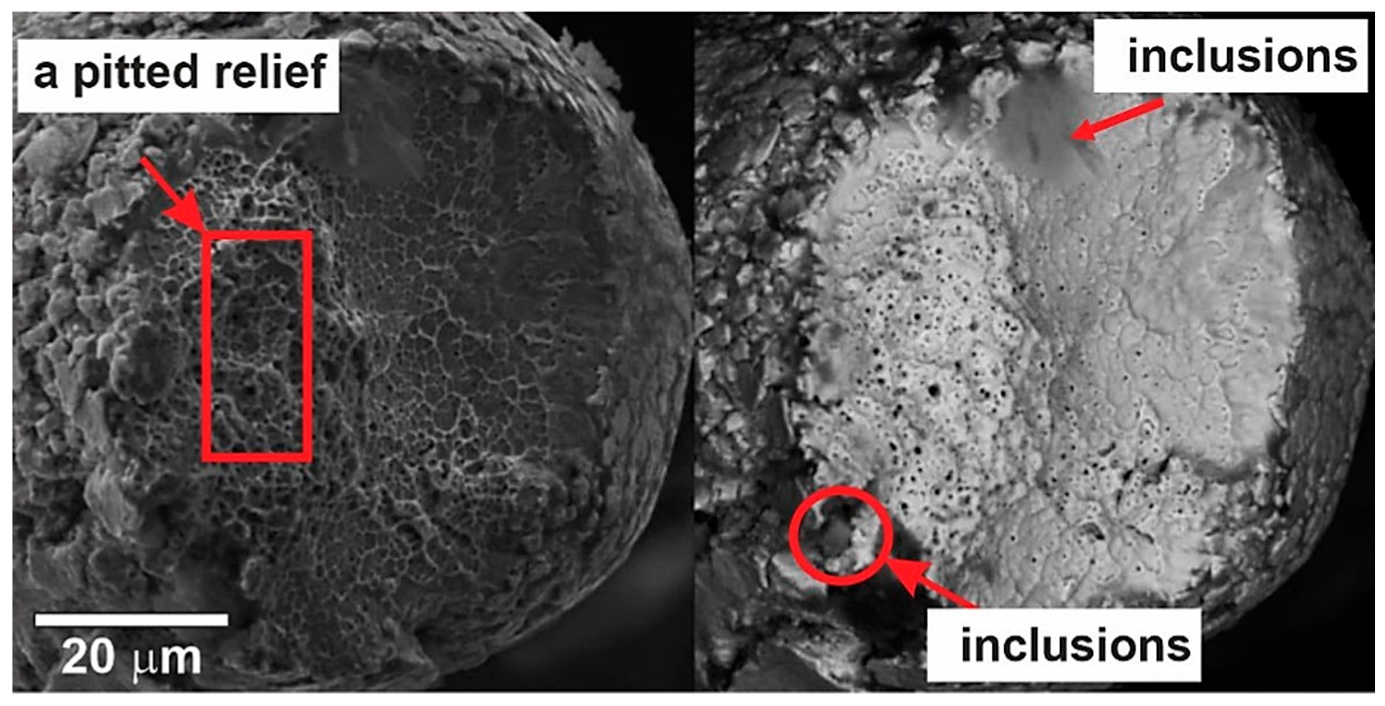

- The microscopic studies showed that on the surface of the samples with a thickness of 60 μm, the interaction of interstitial impurities with the decomposition products of the TiNi matrix formed a surface layer of TiO2 oxides and TiNi3 intermetallic fragments of the decomposition of the TiNi matrix phase. During wire drawing, the impact of intensive plastic deformation in the presence of hydrocarbon lubricants and intermediate annealing in the air led to the formation of fragmented TiO2 surface layers mixed with fragmented TiNi3 intermetallic layers.

- It was established that the main phase of the nitinol samples at room temperature before uniaxial tension was TiNi(B2) austenite.

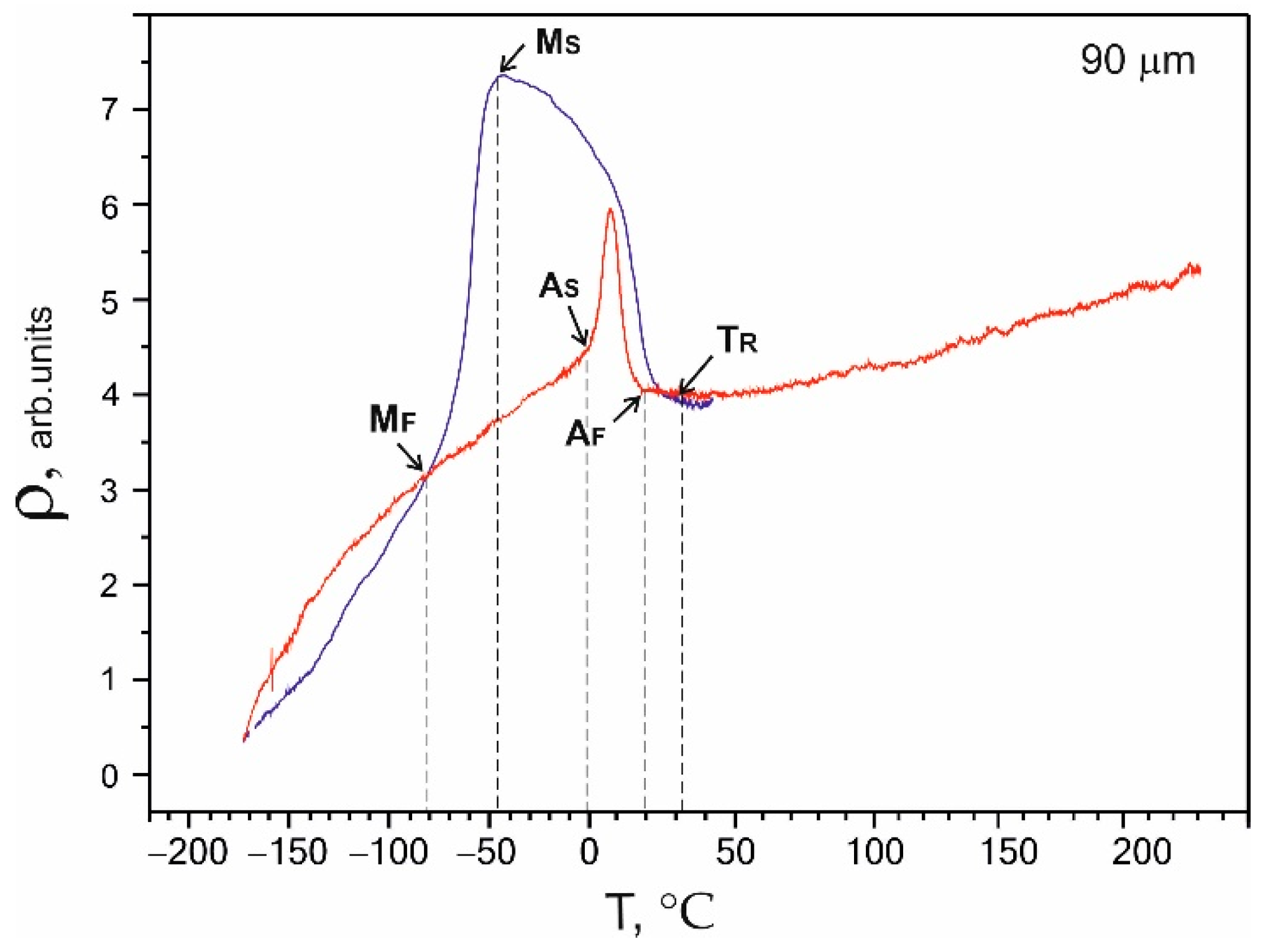

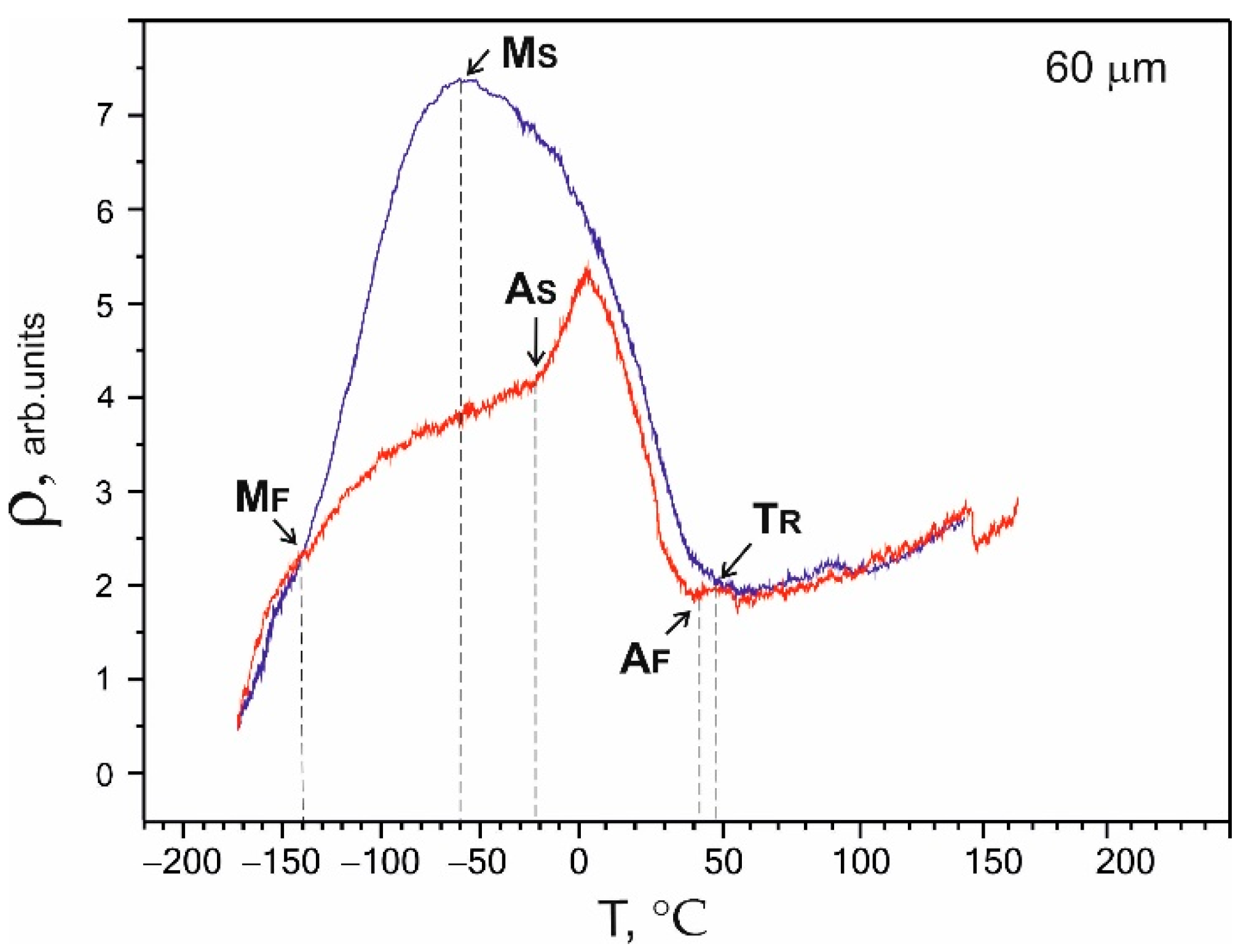

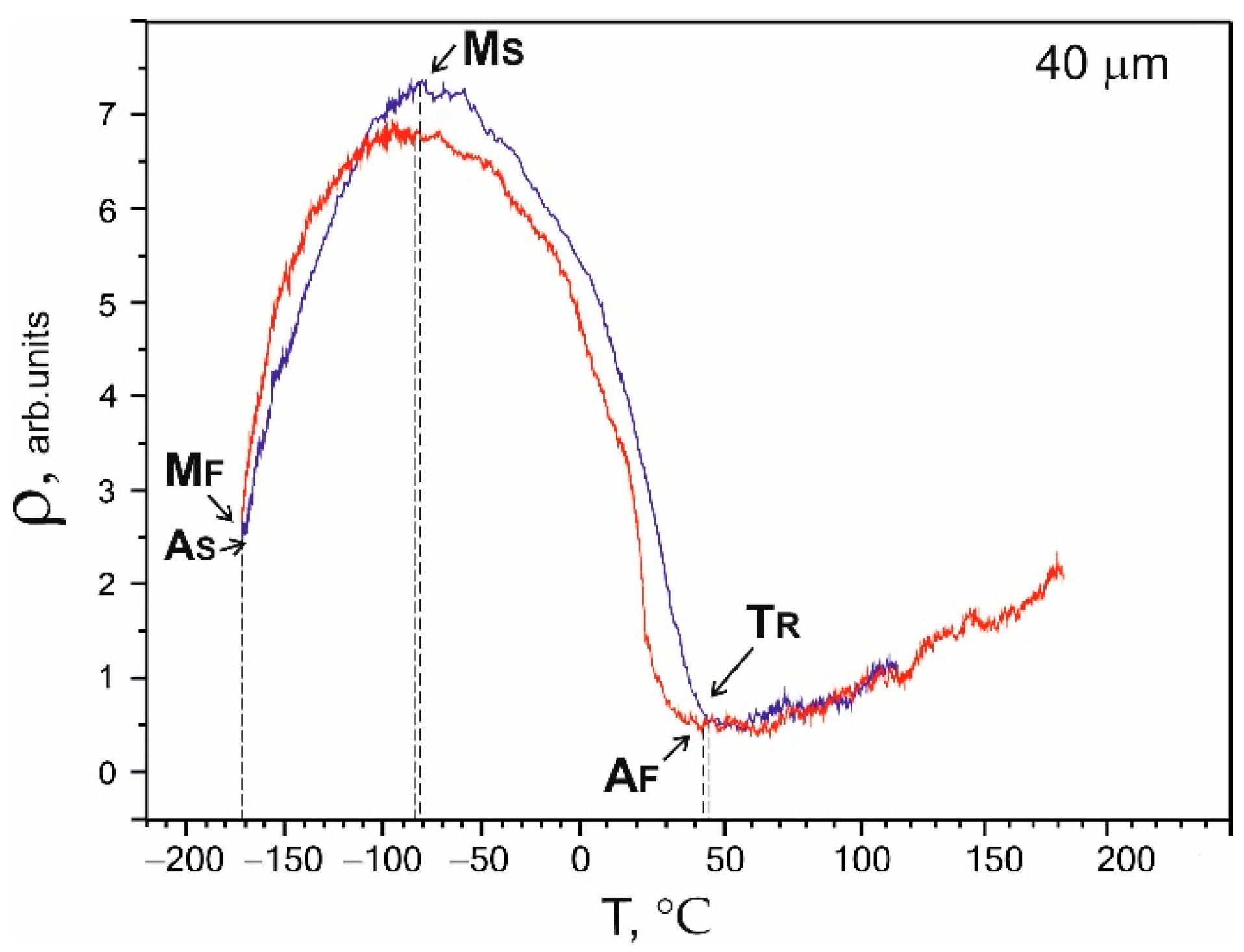

- The obtained temperature dependencies of electrical resistivity ρ(Т) for the NiTi samples with thicknesses of 40, 60, and 90 μm were characteristic of a two-stage martensitic transformation В2↔R↔B19′. It was established that the characteristic temperatures, MS, MF, and AS, shifted to lower temperatures, and AF shifted to a higher temperature as the sample thickness decreased to 40 μm.

- The tests of the NiTi microwires with thicknesses of 40, 60, and 90 µm by uniaxial tension-to-failure and cyclic tension testing within the limits of reversible martensitic deformation showed that the NiTi samples with a thickness of 40–90 µm were characterized by superelastic behavior. An increase in the sample thickness led to an increase in the critical stresses of martensitic transformation from 300 to 1200 MPa, an increase in the ultimate tensile strength from 1300 to 3150 MPa, and an increase in the stress hysteresis width from 250 to 400 MPa. Such a correlation was due to a change in the composition of the TiNi matrix during wire drawing and annealing in air, the formation of a surface TiO2 oxide layer, and an intermetallic TiNi3 sublayer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fu, Y.Q.; Du, H.J.; Huang, W.; Zhang, S.; Hu, M. TiNi based thin films in MEMS applications: A review. Sens. Actuators A 2004, 112, 395–408. [Google Scholar] [CrossRef]

- Chernyshova, A.; Kolomiets, L.; Chekalkin, T.; Chernov, V.; Sinilkin, I.; Gunther, V.; Marchenko, E.; Baigonakova, G.; Kang, J.H. Fertility-Sparing Surgery Using Knitted TiNi Mesh Implants and Sentinel Lymph Nodes: A 10-Year Experience. J. Investig. Surg. 2021, 34, 1110–1118. [Google Scholar] [CrossRef] [PubMed]

- Margan, N.B. Medical shape memory alloy applications—The market and its products. Mater. Sci. Eng. A 2004, 378, 16–23. [Google Scholar] [CrossRef]

- Marchenko, E.S.; Yasenchuk, Y.F.; Gunter, S.V.; Yasenchuk, Y.F.; Gunther, S.V.; Kokorev, O.V.; Baigonakova, G.A.; Gunther, V.E.; Chekalkin, T.L.; Chumlyakov, Y.I.; et al. Viscoelastic Behavior of Biocompatible TiNi Alloys; Tomsk State University Publishing House: Tomsk, Russia, 2020; 102p. [Google Scholar]

- Heller, L.; Seiner, H.; Šittner, P.; Sedlák, P.; Tyc, O.; Kadeřávek, L. On the plastic deformation accompanying cyclic martensitic transformation in thermomechanically loaded NiTi. Int. J. Plast. 2018, 111, 53–71. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Pushin, V.G.; Prokoshkin, S.D.; Valiev, R.Z. Part 1. Structure, phase transformations and properties. In TiNi Shape Memory Alloys; Ural Branch of the Russian Academy of Sciences: Ekaterinburg, Russia, 2006; 438p. [Google Scholar]

- Miyazaki, S. The shape memory mechanism associated with the martensitic transformation in Ti-Ni alloys—I. Self-accommodation. Acta Metall. 1989, 37, 1873–1884. [Google Scholar] [CrossRef]

- Jenko, M.; Godec, M.; Kocijan, A.; Rudolf, R.; Dolinar, D.; Ovsenik, M.; Gorenšek, M.; Mozetic, M. A new route to biocompatible Nitinol based on a rapid treatment with H2/O2 gaseous plasma. Appl. Surf. Sci. 2019, 473, 976–984. [Google Scholar] [CrossRef]

- Nasakina, E.O.; Sevostyanov, M.A.; Baikin, A.S.; Seryogin, A.V.; Konushkin, S.V.; Sergienko, K.V.; Leonov, A.V.; Kolmakov, A.G. Applications of nanostructural NiTi alloys for medical devices. In Shape Memory Alloys—Fundamentals and Applications; IntechOpen: London, UK, 2017. [Google Scholar]

- Marandi, L.; Sen, I. In-vitro mechanical behavior and high cycle fatigue characteristics of NiTi-based shape memory alloy wire. Int. J. Fatigue 2021, 148, 106226. [Google Scholar] [CrossRef]

- Racek, J.; Stora, M.; Šittner, P.; Heller, L.; Kopeček, J.; Petrenec, M. Monitoring Tensile Fatigue of Superelastic NiTi Wire in Liquids by Electrochemical Potential. Shape Mem. Superelast. 2015, 1, 204–230. [Google Scholar] [CrossRef][Green Version]

- James, B.; Foulds, J.; Eiselstein, L. Failure analysis of NiTi wires used in medical applications. J. Fail. Anal. Prev. 2005, 5, 82–87. [Google Scholar] [CrossRef]

- Tsuchiya, K.; Hada, Y.; Koyano, T.; Nakajima, K.; Ohnuma, M.; Koike, T.; Todaka, Y.; Umemoto, M. Production of TiNi amorphous/nanocrystalline wires with high strength and elastic modulus by severe cold drawing. Scr. Mater. 2009, 60, 749–752. [Google Scholar] [CrossRef]

- Mahmud, A.; Wu, Z.; Zhang, J.; Liu, Y.; Yang, H. Surface oxidation of NiTi and its effects on thermal and mechanical properties. Intermetallics 2018, 103, 52–62. [Google Scholar] [CrossRef]

- Chu, C.; Wu, S.; Yen, Y. Oxidation behavior of equiatomic TiNi alloy in high temperature air environment. Mater. Sci. Eng. A 1996, 216, 193–200. [Google Scholar] [CrossRef]

- Dagdelen, F.; Ercan, E. The surface oxidation behavior of Ni–45.16%Ti shape memory alloys at different temperatures. J. Therm. Anal. Calorim. 2013, 115, 561–565. [Google Scholar] [CrossRef]

- Chen, X.; Shen, Y.; Fu, S.; Yu, D.; Zhang, Z.; Chen, G. Size effects on uniaxial tension and multiaxial ratcheting of oligo-crystalline stainless steel thin wires. Int. J. Fatigue 2018, 116, 163–171. [Google Scholar] [CrossRef]

- Baturin, A.; Lotkov, A.; Grishkov, V.; Rodionov, I.; Kudiiarov, V. Effect of hydrogen redistribution during aging on the structure and phase state of nanocrystalline and coarse-grained TiNi alloys. J. Alloys Compd. 2018, 751, 359–363. [Google Scholar] [CrossRef]

- Cong, D.; Saha, G.; Barnett, M. Thermomechanical properties of Ni–Ti shape memory wires containing nanoscale precipitates induced by stress-assisted ageing. Acta Biomater. 2014, 10, 5178–5192. [Google Scholar] [CrossRef] [PubMed]

- Liang, X.; Xiao, F.; Chen, H.; Li, Z.; Jin, X.; Fukuda, T. Growth of B2 parent phase grain assisted by martensitic transformation in a nanocrystalline Ti-50.8Ni (at.%) shape memory alloy. Scr. Mater. 2019, 159, 37–40. [Google Scholar] [CrossRef]

- Buslaeva, E.M. Materials Science: Textbook, 2nd ed.; IPR Media: Saratov, Russia, 2019; 149p. [Google Scholar]

- Maziz, A.; Concas, A.; Khaldi, A.; Stålhand, J.; Persson, N.K.; Jager, E.W.H. Knitting and weaving artificial muscles. Sci. Adv. 2017, 3, e1600327. [Google Scholar] [CrossRef] [PubMed]

| Element | Atomic % | ||

|---|---|---|---|

| Spectrum 1 | Spectrum 2 | Spectrum 3 | |

| O | 65.7 | 67.39 | 5.71 |

| Ti | 33.33 | 31.98 | 20.81 |

| Ni | 1.97 | 0.63 | 73.48 |

| Total | 100 | 100 | 100 |

| Wire Thickness µm | σt MPa | σTS MPa | εf % | εelast % | εм % |

|---|---|---|---|---|---|

| 40 ± 5 | 350 ± 35 | 1300 ± 130 | 11.5 ± 1 | 4.5 ± 0.4 | 5.5 ± 0.6 |

| 60 ± 5 | 800 ± 35 | 1800 ± 130 | 13.5 ± 1 | 5.9 ± 0.4 | 5.5 ± 0.6 |

| 90 ± 5 | 1200 ± 35 | 3150 ± 130 | 14 ± 1 | 5.4 ± 0.4 | 7.1 ± 0.6 |

| Wire Thickness µm | TR °C | MS °C | MF °C | AS °C | AF °C |

|---|---|---|---|---|---|

| 40 ± 5 | 45 ± 3 | −80 ± 3 | – | – | 42 ± 3 |

| 60 ± 5 | 49 ± 3 | −60 ± 3 | −140 ± 3 | −21 ± 3 | 40 ± 3 |

| 90 ± 5 | 31 ± 3 | −49 ± 3 | −80 ± 3 | −2 ± 3 | 20 ± 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baigonakova, G.A.; Marchenko, E.S.; Kovaleva, M.A.; Chudinova, E.A.; Volinsky, A.A.; Zhang, Y. Thickness Effects on the Martensite Transformations and Mechanical Properties of Nanocrystalline NiTi Wires. Nanomaterials 2022, 12, 4442. https://doi.org/10.3390/nano12244442

Baigonakova GA, Marchenko ES, Kovaleva MA, Chudinova EA, Volinsky AA, Zhang Y. Thickness Effects on the Martensite Transformations and Mechanical Properties of Nanocrystalline NiTi Wires. Nanomaterials. 2022; 12(24):4442. https://doi.org/10.3390/nano12244442

Chicago/Turabian StyleBaigonakova, Gulsharat A., Ekaterina S. Marchenko, Marina A. Kovaleva, Ekaterina A. Chudinova, Alex A. Volinsky, and Yi Zhang. 2022. "Thickness Effects on the Martensite Transformations and Mechanical Properties of Nanocrystalline NiTi Wires" Nanomaterials 12, no. 24: 4442. https://doi.org/10.3390/nano12244442

APA StyleBaigonakova, G. A., Marchenko, E. S., Kovaleva, M. A., Chudinova, E. A., Volinsky, A. A., & Zhang, Y. (2022). Thickness Effects on the Martensite Transformations and Mechanical Properties of Nanocrystalline NiTi Wires. Nanomaterials, 12(24), 4442. https://doi.org/10.3390/nano12244442