Investigation of Fast-Charging and Degradation Processes in 3D Silicon–Graphite Anodes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Electrode Material

2.2. Ultrafast Laser Processing

2.3. Cell Assembly

2.4. Electrochemical Analyses

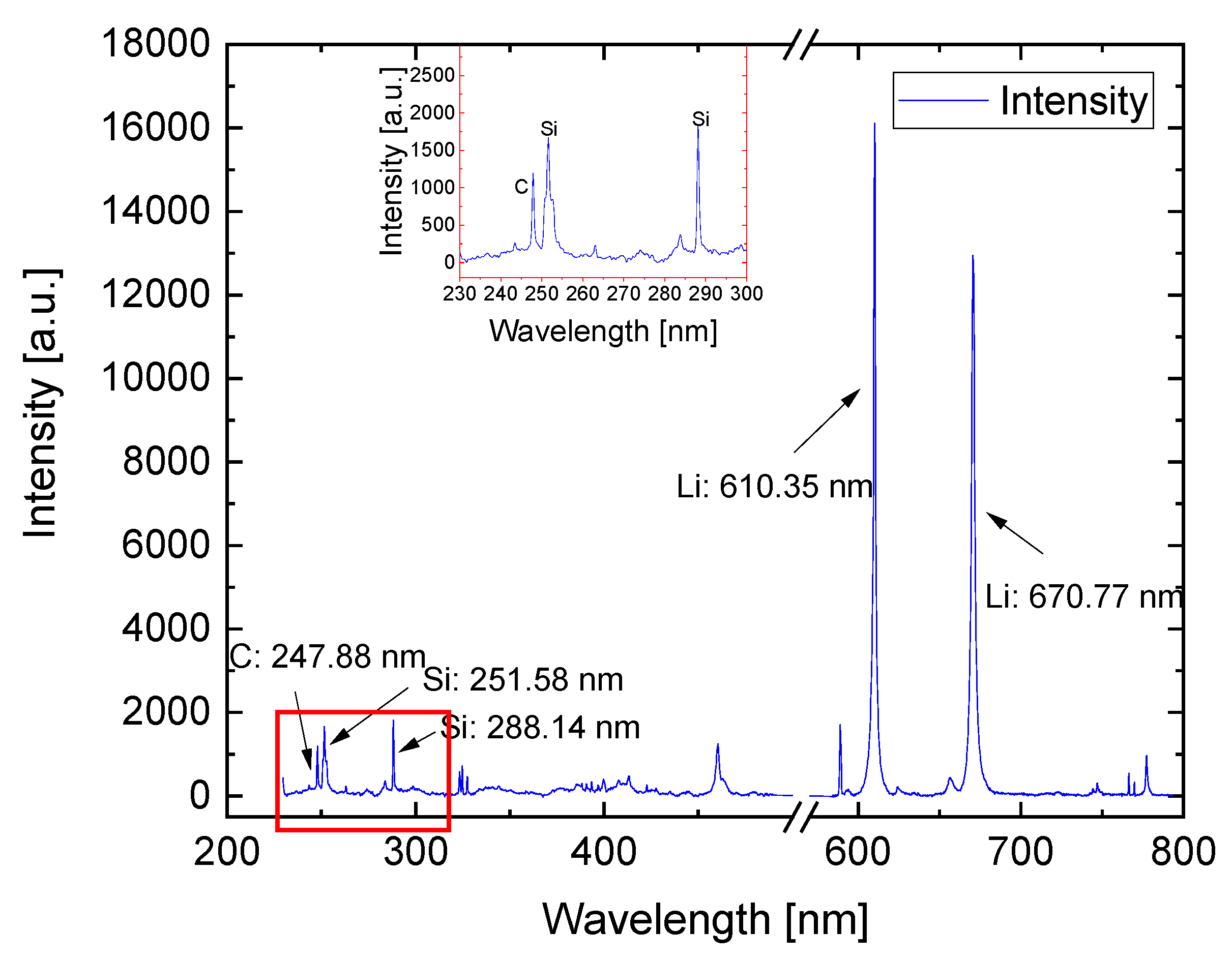

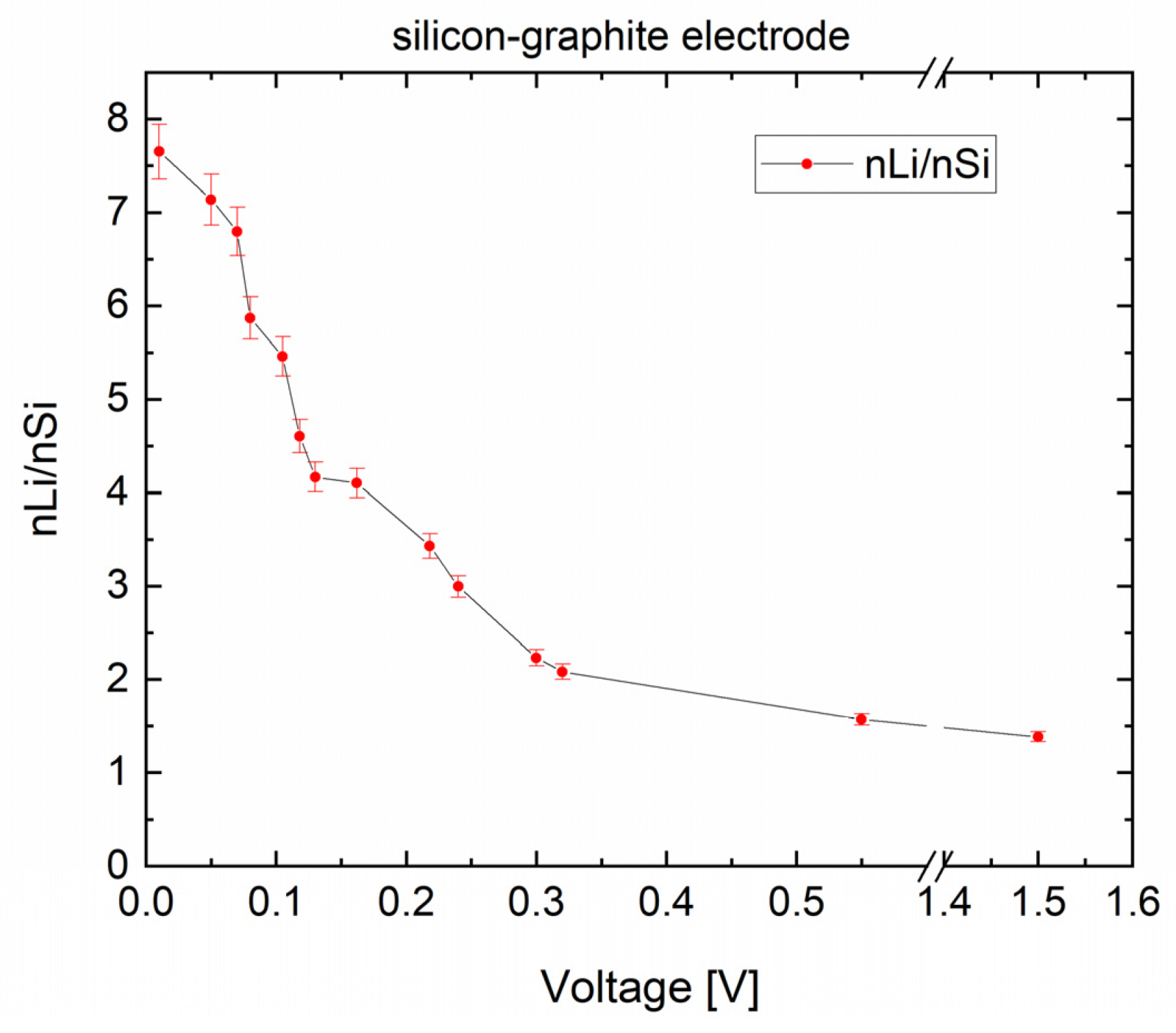

2.5. Laser-Induced Breakdown Spectroscopy and Creation of Calibration Data

3. Results

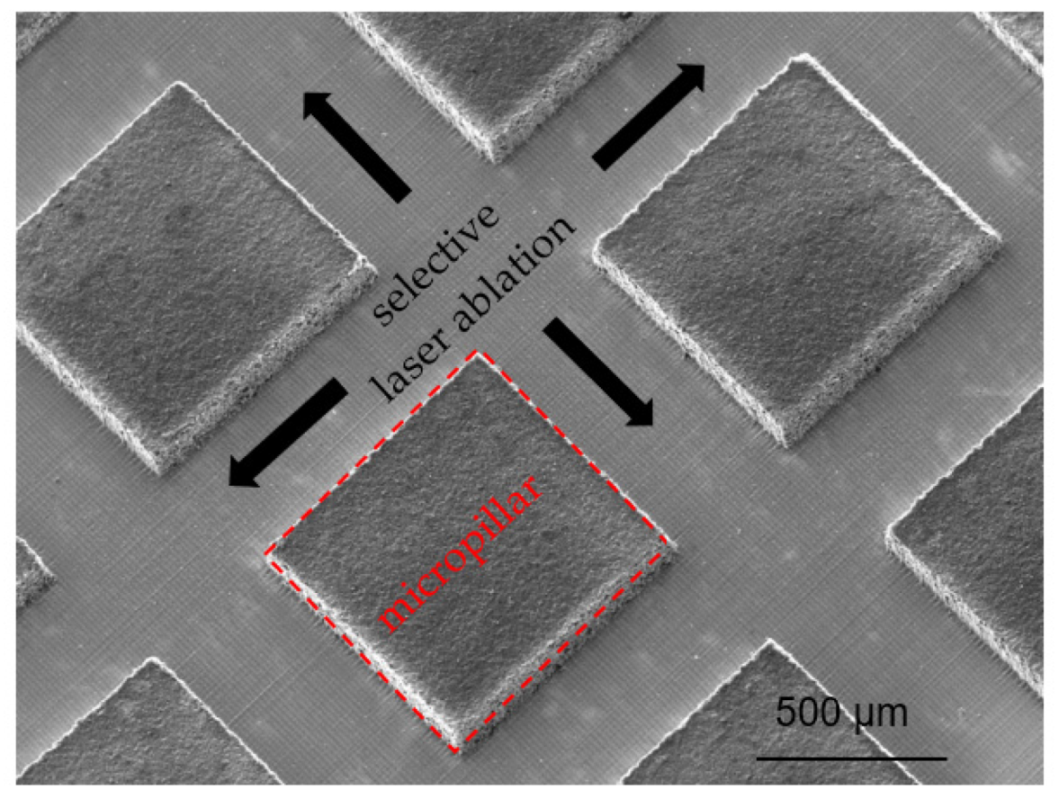

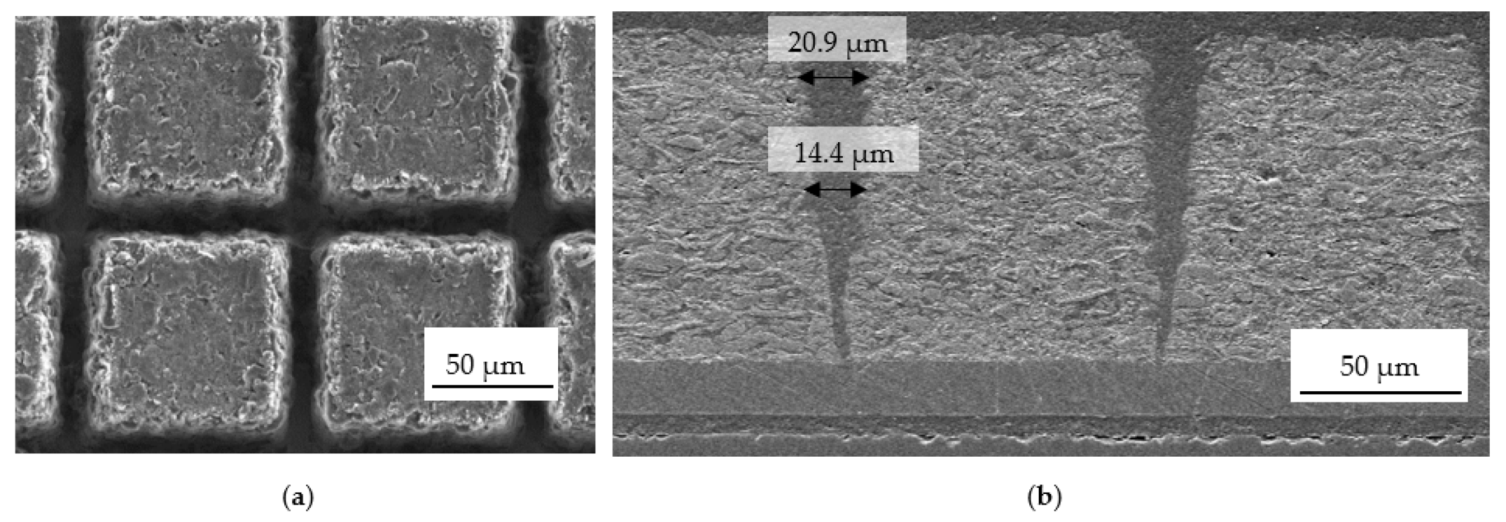

3.1. Laser Structuring

3.2. Electrochemical Properties of Silicon-Based Electrodes

3.2.1. Cyclic Voltammetry of Cells with Silicon Electrodes

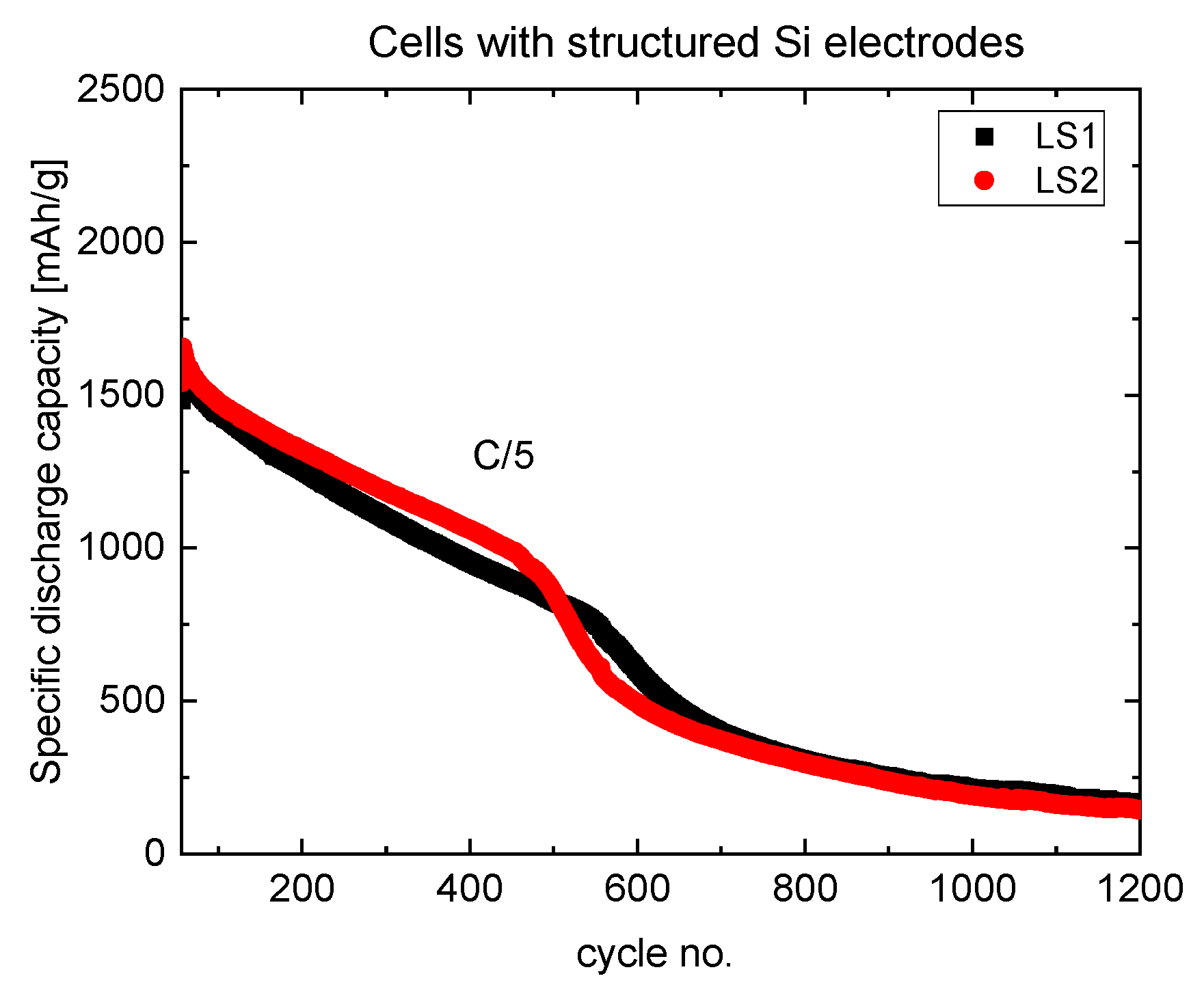

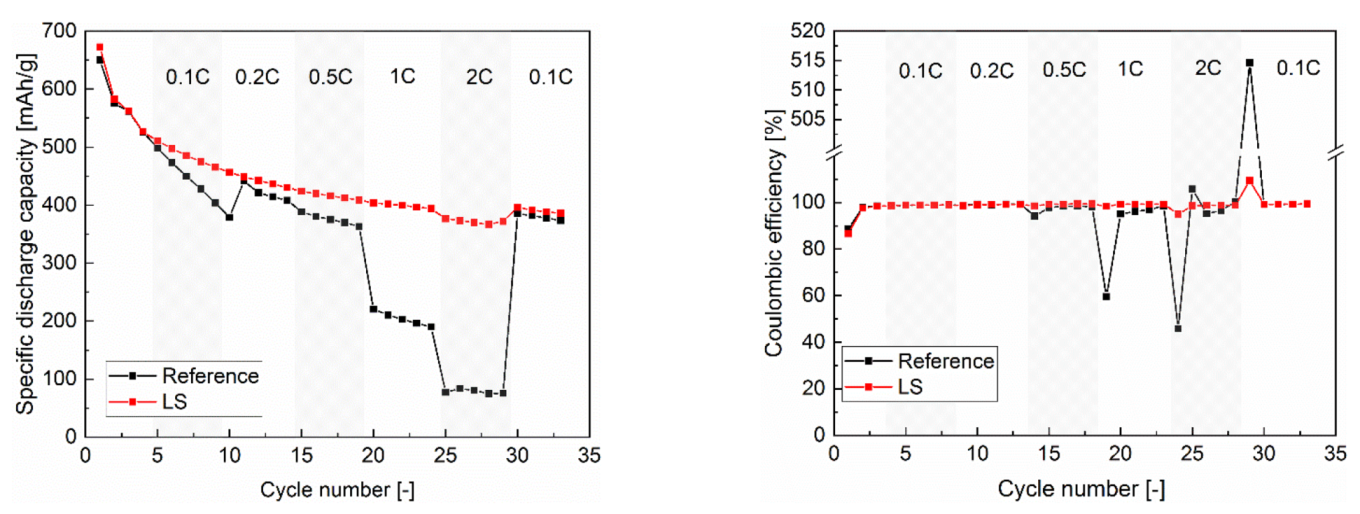

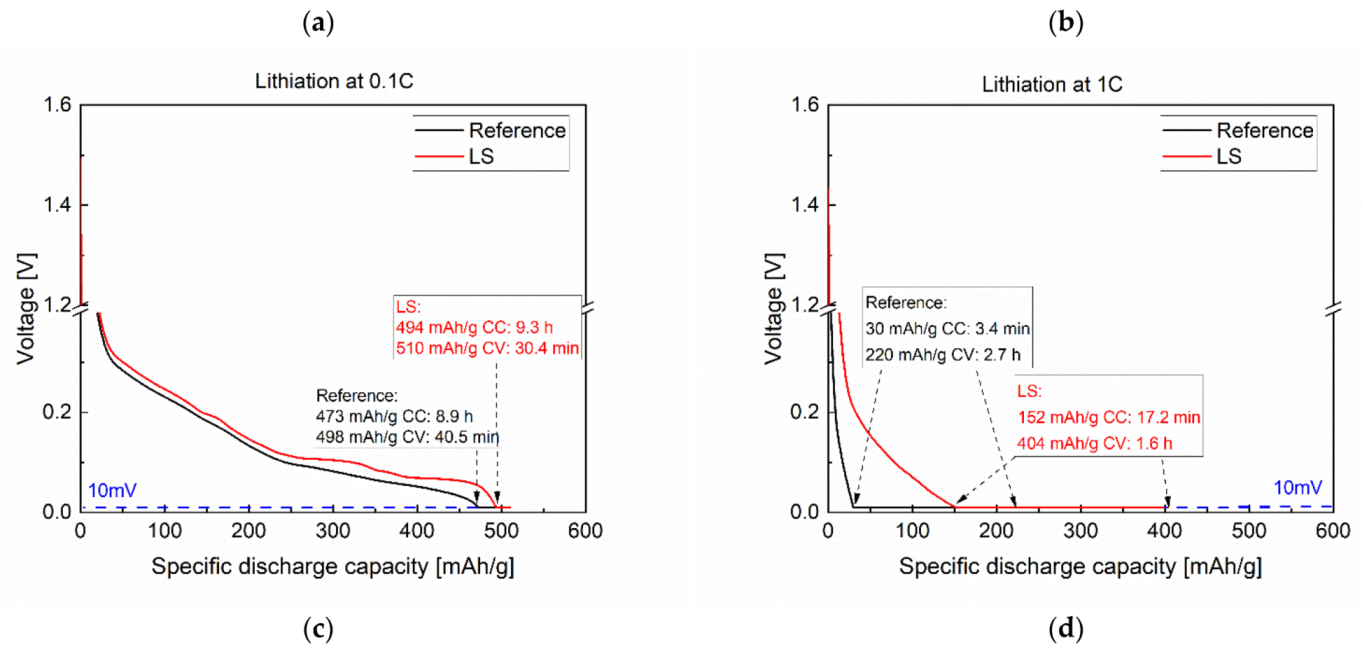

3.2.2. Galvanostatic Measurements of Cells with Si/C-Electrodes

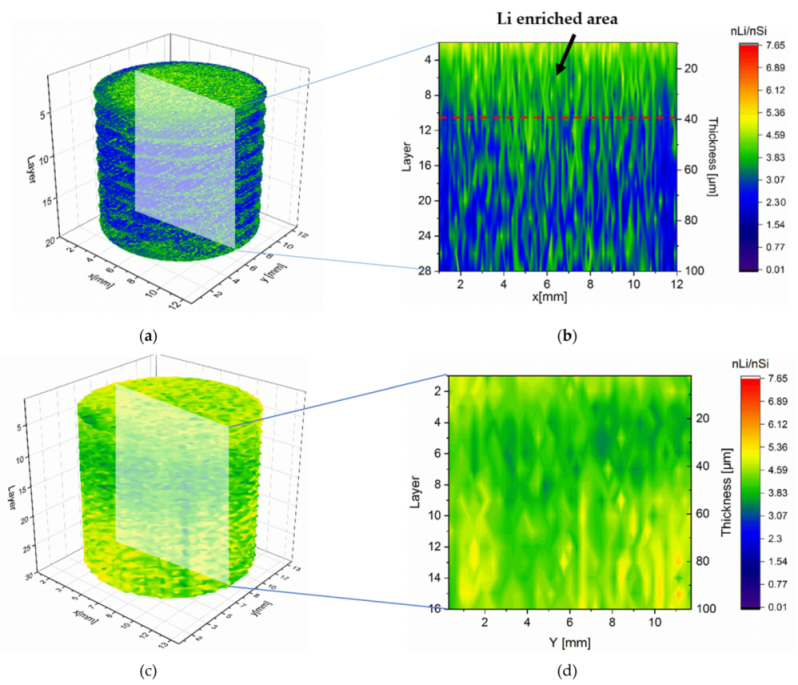

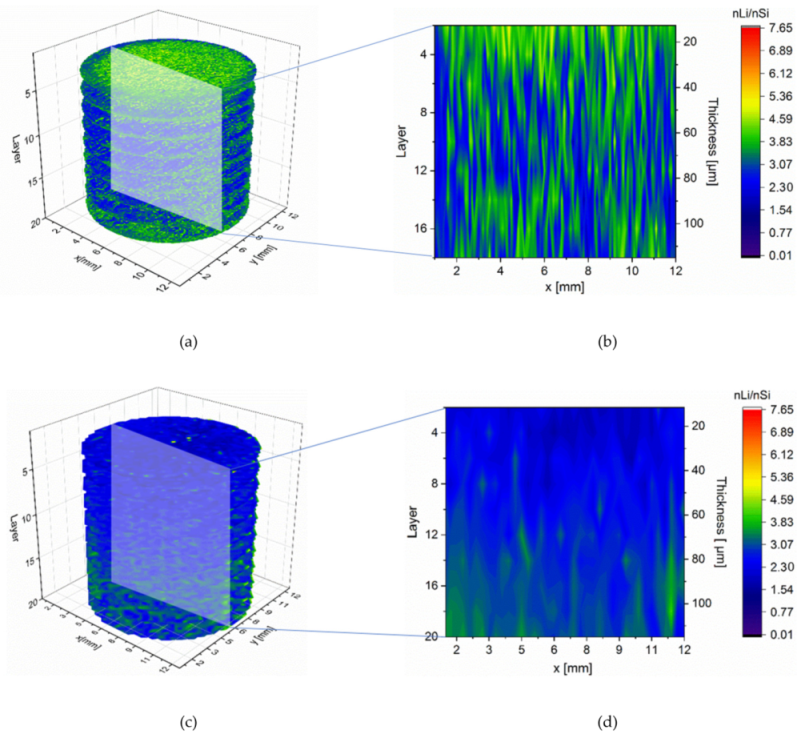

3.2.3. Lithium Distribution and Visualisation of Lithium Diffusion Pathway

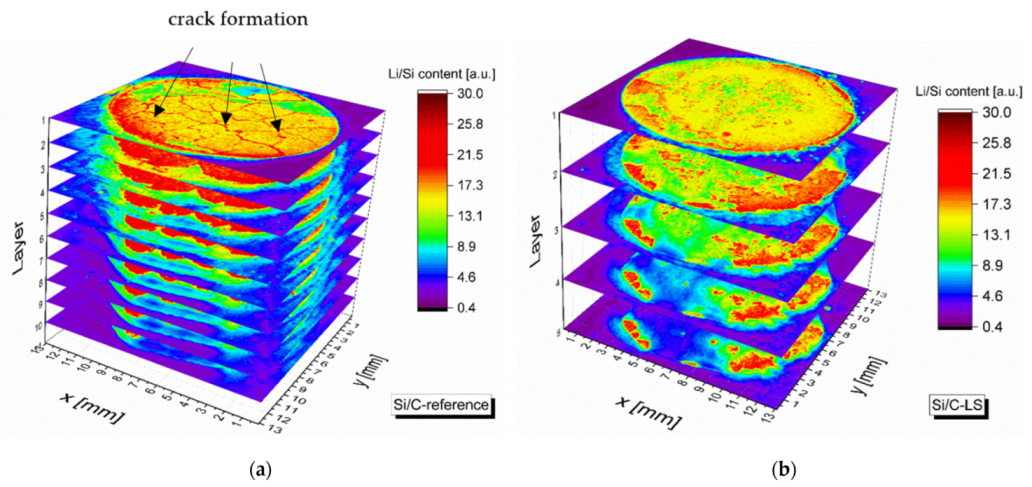

3.2.4. Post-Mortem Analysis

4. Discussion

4.1. Impact of Mechanical Stress on the Phase Change

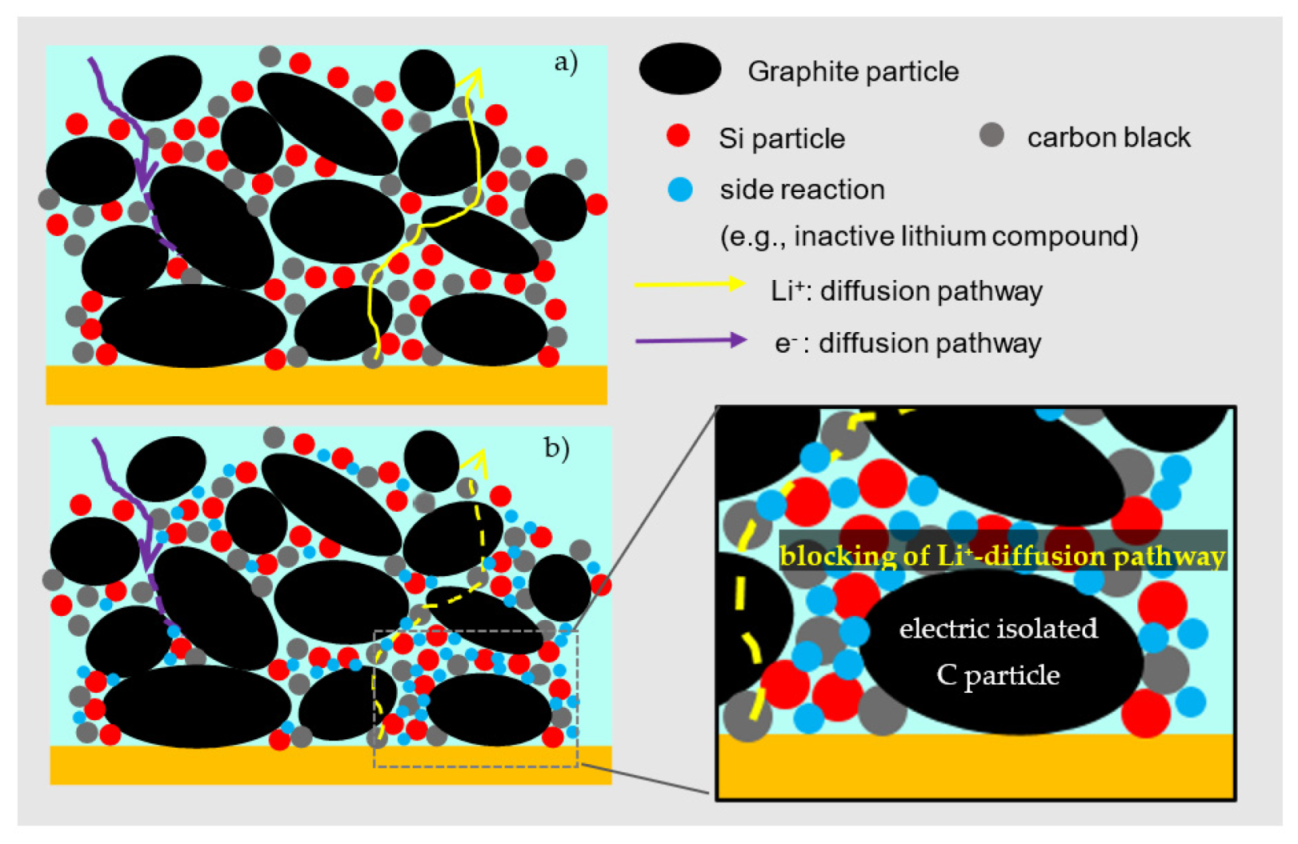

4.2. Degradation Mechanisms of Silicon–Graphite Electrodes

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Nishi, Y. Lithium ion secondary batteries; past 10 years and the future. J. Power Sources 2001, 100, 101–106. [Google Scholar] [CrossRef]

- Dühnen, S.; Betz, J.; Kolek, M.; Schmuch, R.; Winter, M.; Placke, T. Toward green battery cells: Perspective on materials and technologies. Small Methods 2020, 4, 2000039. [Google Scholar] [CrossRef]

- Nykvist, B.; Nilsson, M. Rapidly falling costs of battery packs for electric vehicles. Nat. Clim. Change 2015, 5, 329–332. [Google Scholar] [CrossRef]

- Wood, D.L., III; Li, J.; Daniel, C. Prospects for reducing the processing cost of lithium ion batteries. J. Power Sources 2015, 275, 234–242. [Google Scholar] [CrossRef] [Green Version]

- Mauler, L.; Duffner, F.; Zeier, W.G.; Leker, J. Battery cost forecasting: A review of methods and results with an outlook to 2050. Energy Environ. Sci. 2021, 14, 4712–4739. [Google Scholar] [CrossRef]

- Andre, D.; Kim, S.-J.; Lamp, P.; Lux, S.F.; Maglia, F.; Paschos, O.; Stiaszny, B. Future generations of cathode materials: An automotive industry perspective. J. Mater. Chem. A 2015, 3, 6709–6732. [Google Scholar] [CrossRef]

- Liu, J.; Bao, Z.; Cui, Y.; Dufek, E.J.; Goodenough, J.B.; Khalifah, P.; Li, Q.; Liaw, B.Y.; Liu, P.; Manthiram, A. Pathways for practical high-energy long-cycling lithium metal batteries. Nat. Energy 2019, 4, 180–186. [Google Scholar] [CrossRef]

- Tarascon, J.-M.; Armand, M. Issues and Challenges Facing Rechargeable Lithium Batteries. In Materials for Sustainable Energy: A Collection of Peer-Reviewed Research and Review Articles from Nature Publishing Group; Nature Publishing Group: London, UK, 2011; pp. 171–179. [Google Scholar]

- Maruyama, H.; Nakano, H.; Ogawa, M.; Nakamoto, M.; Ohta, T.; Sekiguchi, A. Improving battery safety by reducing the formation of Li dendrites with the use of amorphous silicon polymer anodes. Sci. Rep. 2015, 5, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oumellal, Y.; Delpuech, N.; Mazouzi, D.; Dupre, N.; Gaubicher, J.; Moreau, P.; Soudan, P.; Lestriez, B.; Guyomard, D. The failure mechanism of nano-sized Si-based negative electrodes for lithium ion batteries. J. Mater. Chem. 2011, 21, 6201–6208. [Google Scholar] [CrossRef]

- Yoon, T.; Nguyen, C.C.; Seo, D.M.; Lucht, B.L. Capacity fading mechanisms of silicon nanoparticle negative electrodes for lithium ion batteries. J. Electrochem. Soc. 2015, 162, A2325. [Google Scholar] [CrossRef] [Green Version]

- Tariq, F.; Yufit, V.; Eastwood, D.S.; Merla, Y.; Biton, M.; Wu, B.; Chen, Z.; Freedman, K.; Offer, G.; Peled, E. In-operando X-ray tomography study of lithiation induced delamination of Si based anodes for lithium-ion batteries. ECS Electrochem. Lett. 2014, 3, A76. [Google Scholar] [CrossRef]

- Obrovac, M.N.; Krause, L.J. Reversible Cycling of Crystalline Silicon Powder. J. Electrochem. Soc. 2007, 154, A103. [Google Scholar] [CrossRef]

- Leveau, L.; Laïk, B.; Pereira-Ramos, J.-P.; Gohier, A.; Tran-Van, P.; Cojocaru, C.-S. Silicon nano-trees as high areal capacity anodes for lithium-ion batteries. J. Power Sources 2016, 316, 1–7. [Google Scholar] [CrossRef]

- Peng, K.; Jie, J.; Zhang, W.; Lee, S.-T. Silicon nanowires for rechargeable lithium-ion battery anodes. Appl. Phys. Lett. 2008, 93, 033105. [Google Scholar] [CrossRef]

- Mishra, K.; Zheng, J.; Patel, R.; Estevez, L.; Jia, H.; Luo, L.; El-Khoury, P.Z.; Li, X.; Zhou, X.-D.; Zhang, J.-G. High performance porous Si@ C anodes synthesized by low temperature aluminothermic reaction. Electrochim. Acta 2018, 269, 509–516. [Google Scholar] [CrossRef]

- Yoon, T.; Bok, T.; Kim, C.; Na, Y.; Park, S.; Kim, K.S. Mesoporous silicon hollow nanocubes derived from metal–organic framework template for advanced lithium-ion battery anode. ACS Nano 2017, 11, 4808–4815. [Google Scholar] [CrossRef]

- Tang, H.; Zhang, Y.; Xiong, Q.; Cheng, J.; Zhang, Q.; Wang, X.; Gu, C.; Tu, J. Self-assembly silicon/porous reduced graphene oxide composite film as a binder-free and flexible anode for lithium-ion batteries. Electrochim. Acta 2015, 156, 86–93. [Google Scholar] [CrossRef]

- Tang, H.; Zhang, J.; Zhang, Y.; Xiong, Q.; Tong, Y.; Li, Y.; Wang, X.; Gu, C.; Tu, J. Porous reduced graphene oxide sheet wrapped silicon composite fabricated by steam etching for lithium-ion battery application. J. Power Sources 2015, 286, 431–437. [Google Scholar] [CrossRef]

- Shen, X.; Tian, Z.; Fan, R.; Shao, L.; Zhang, D.; Cao, G.; Kou, L.; Bai, Y. Research progress on silicon/carbon composite anode materials for lithium-ion battery. J. Energy Chem. 2018, 27, 1067–1090. [Google Scholar] [CrossRef] [Green Version]

- Dou, F.; Shi, L.; Chen, G.; Zhang, D. Silicon/carbon composite anode materials for lithium-ion batteries. Electrochem. Energy Rev. 2019, 2, 149–198. [Google Scholar] [CrossRef]

- Kwade, A.; Haselrieder, W.; Leithoff, R.; Modlinger, A.; Dietrich, F.; Droeder, K. Current status and challenges for automotive battery production technologies. Nat. Energy 2018, 3, 290–300. [Google Scholar] [CrossRef]

- Schmuch, R.; Wagner, R.; Hörpel, G.; Placke, T.; Winter, M. Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat. Energy 2018, 3, 267–278. [Google Scholar] [CrossRef]

- Pfleging, W. Recent Progress in Laser Texturing of Battery Materials: A Review of Tuning Electrochemical Performances, Related Material Development, and Prospects for Large-Scale Manufacturing. Int. J. Extrem. Manuf. 2020, 3, 1. [Google Scholar] [CrossRef]

- Zheng, Y.; Seifert, H.; Shi, H.; Zhang, Y.; Kübel, C.; Pfleging, W. 3D silicon/graphite composite electrodes for high-energy lithium-ion batteries. Electrochim. Acta 2019, 317, 502–508. [Google Scholar] [CrossRef]

- Smyrek, P.; Pröll, J.; Seifert, H.; Pfleging, W. Laser-induced breakdown spectroscopy of laser-structured Li (NiMnCo) O2 electrodes for lithium-ion batteries. J. Electrochem. Soc. 2015, 163, A19. [Google Scholar] [CrossRef]

- Levi, M.; Levi, E.; Aurbach, D. The mechanism of lithium intercalation in graphite film electrodes in aprotic media. Part 2. Potentiostatic intermittent titration and in situ XRD studies of the solid-state ionic diffusion. J. Electroanal. Chem. 1997, 421, 89–97. [Google Scholar] [CrossRef]

- Levi, M.D.; Aurbach, D. The mechanism of lithium intercalation in graphite film electrodes in aprotic media. Part 1. High resolution slow scan rate cyclic voltammetric studies and modeling. J. Electroanal. Chem. 1997, 421, 79–88. [Google Scholar] [CrossRef]

- Datta, M.K.; Kumta, P.N. In situ electrochemical synthesis of lithiated silicon–carbon based composites anode materials for lithium ion batteries. J. Power Sources 2009, 194, 1043–1052. [Google Scholar] [CrossRef]

- Li, J.; Dahn, J. An in situ X-ray diffraction study of the reaction of Li with crystalline Si. J. Electrochem. Soc. 2007, 154, A156. [Google Scholar] [CrossRef]

- Reyes Jiménez, A.; Klöpsch, R.; Wagner, R.; Rodehorst, U.C.; Kolek, M.; Nölle, R.; Winter, M.; Placke, T. A Step toward High-Energy Silicon-Based Thin Film Lithium Ion Batteries. ACS Nano 2017, 11, 4731–4744. [Google Scholar] [CrossRef]

- Baggetto, L.; Niessen, R.A.H.; Roozeboom, F.; Notten, P.H.L. High Energy Density All-Solid-State Batteries: A Challenging Concept Towards 3D Integration. Adv. Funct. Mater. 2008, 18, 1057–1066. [Google Scholar] [CrossRef]

- Obrovac, M.; Christensen, L. Structural changes in silicon anodes during lithium insertion/extraction. Electrochem. Solid State Lett. 2004, 7, A93. [Google Scholar] [CrossRef]

- Habedank, J.B.; Kraft, L.; Rheinfeld, A.; Krezdorn, C.; Jossen, A.; Zaeh, M.F. Increasing the discharge rate capability of lithium-ion cells with laser-structured graphite anodes: Modeling and simulation. J. Electrochem. Soc. 2018, 165, A1563–A1573. [Google Scholar] [CrossRef]

- Zhang, N.; Zheng, Y.; Trifonova, A.; Pfleging, W. Laser structured Cu foil for high-performance lithium-ion battery anodes. J. Appl. Electrochem. 2017, 47, 829–837. [Google Scholar] [CrossRef] [Green Version]

- Yuan, G.; Li, X.; Dong, Z.; Westwood, A.; Cui, Z.; Cong, Y.; Du, H.; Kang, F. Graphite blocks with preferred orientation and high thermal conductivity. Carbon 2012, 50, 175–182. [Google Scholar] [CrossRef]

- Zheng, Y.; Pfäffl, L.; Seifert, H.J.; Pfleging, W. Lithium Distribution in Structured Graphite Anodes Investigated by Laser-Induced Breakdown Spectroscopy. Appl. Sci. 2019, 9, 4218. [Google Scholar] [CrossRef] [Green Version]

- Hatchard, T.; Dahn, J. In situ XRD and electrochemical study of the reaction of lithium with amorphous silicon. J. Electrochem. Soc. 2004, 151, A838. [Google Scholar] [CrossRef]

- Markevich, E.; Salitra, G.; Aurbach, D. Fluoroethylene Carbonate as an Important Component for the Formation of an Effective Solid Electrolyte Interphase on Anodes and Cathodes for Advanced Li-Ion Batteries. ACS Energy Lett. 2017, 2, 1337–1345. [Google Scholar] [CrossRef] [Green Version]

| Type | Composition (wt%) | Areal Capacity * (mAh/cm²) | Thickness (µm) | Analytics | ||||

|---|---|---|---|---|---|---|---|---|

| Si | Graphite | Carbon | CMC | SBR | ||||

| 1 | 40 | 0 | 30 | 15 | 15 | 2.42 ± 0.13 | 25 ± 2 | CV |

| 2 | 20 | 60 | 10 | 5 | 5 | 3.09 ± 0.20 | 55 ± 2 | LIBS |

| 3 | 10 | 70 | 10 | 5 | 5 | 4.03 ± 0.05 | 70 ± 2 | Calibration |

| 4 | 10 | 70 | 10 | 5 | 5 | 6.44 ± 0.10 | 100 ± 2 | LIBS and GM |

| Electrochemical Titration Voltages (V) | ||||||

|---|---|---|---|---|---|---|

| 0.01 | 0.05 | 0.08 | 0.105 | 0.118 | 0.13 | 0.162 |

| 0.2 | 0.218 | 0.24 | 0.3 | 0.32 | 0.55 | 1.5 |

| Samples | Cell State for LIBS | Step 1 (formation) | Step 2 | Step 3 |

|---|---|---|---|---|

| (a) Unstructured Si/C electrode (b) LS Si/C electrode (c) Si/C model electrode | lithiated state at 0.01 V (0.05C) | discharging/charging: 0.02C; cycles: 1 | - | discharging: 0.05C cv at 0.01 V for 10 min |

| delithiated state at 1.5 V (0.05C) | discharging: 0.05C | charging: 0.05C, cv at 1.5 V for 10 min | ||

| lithiated state at 0.01 V (1C) | discharging/charging: 0.05C; cycles: 2 | - | discharging: 1C, cv at 0.01 V for 10 min | |

| delithiated state at 1.5 V (1C) | discharging: 0.2C | charging: 1C, cv at 1.5 V for 10 min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Yin, D.; Seifert, H.J.; Pfleging, W. Investigation of Fast-Charging and Degradation Processes in 3D Silicon–Graphite Anodes. Nanomaterials 2022, 12, 140. https://doi.org/10.3390/nano12010140

Zheng Y, Yin D, Seifert HJ, Pfleging W. Investigation of Fast-Charging and Degradation Processes in 3D Silicon–Graphite Anodes. Nanomaterials. 2022; 12(1):140. https://doi.org/10.3390/nano12010140

Chicago/Turabian StyleZheng, Yijing, Danni Yin, Hans Jürgen Seifert, and Wilhelm Pfleging. 2022. "Investigation of Fast-Charging and Degradation Processes in 3D Silicon–Graphite Anodes" Nanomaterials 12, no. 1: 140. https://doi.org/10.3390/nano12010140

APA StyleZheng, Y., Yin, D., Seifert, H. J., & Pfleging, W. (2022). Investigation of Fast-Charging and Degradation Processes in 3D Silicon–Graphite Anodes. Nanomaterials, 12(1), 140. https://doi.org/10.3390/nano12010140