Oxygen Concentration Effect on Conductive Bridge Random Access Memory of InWZnO Thin Film

Abstract

:1. Introduction

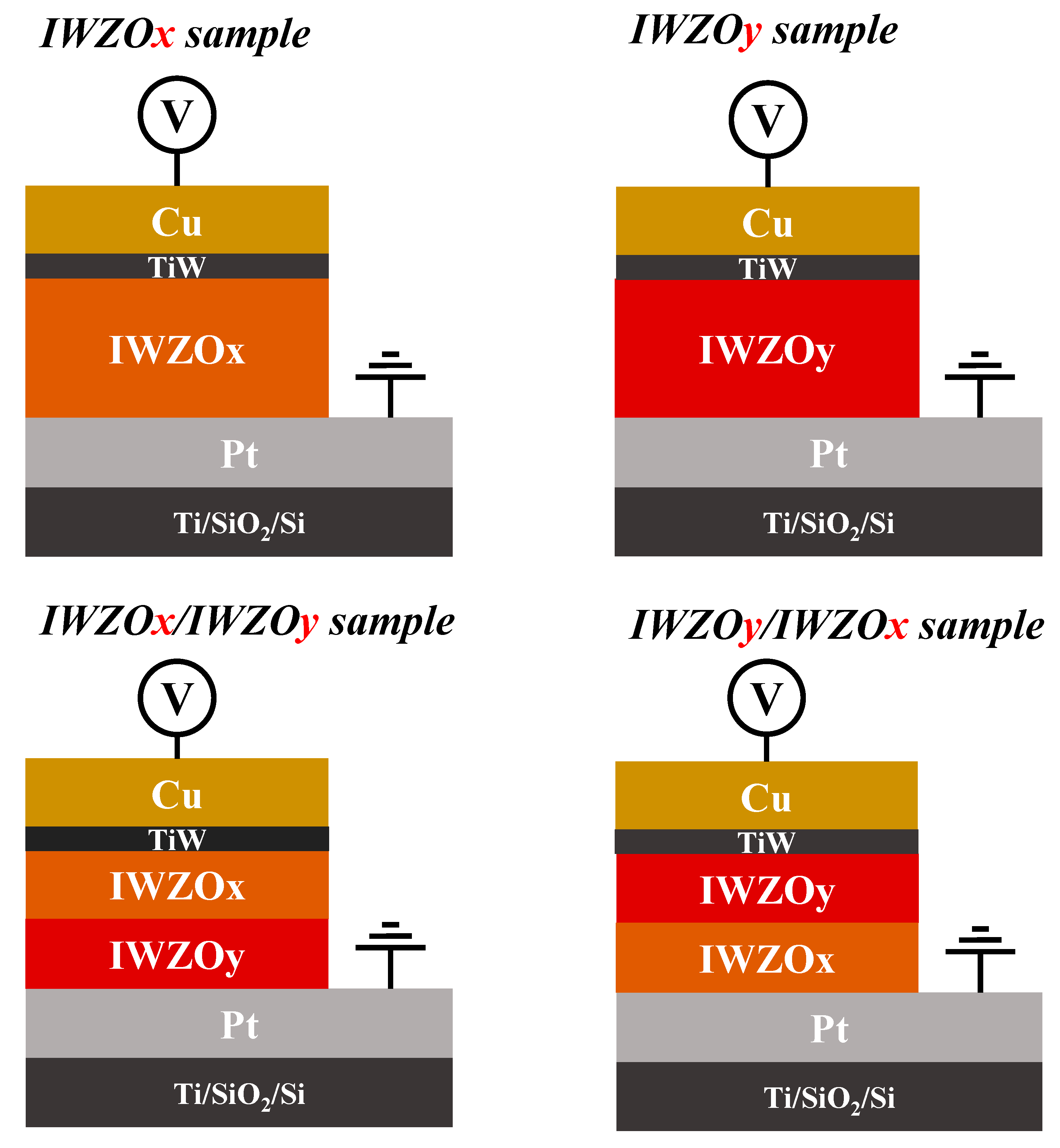

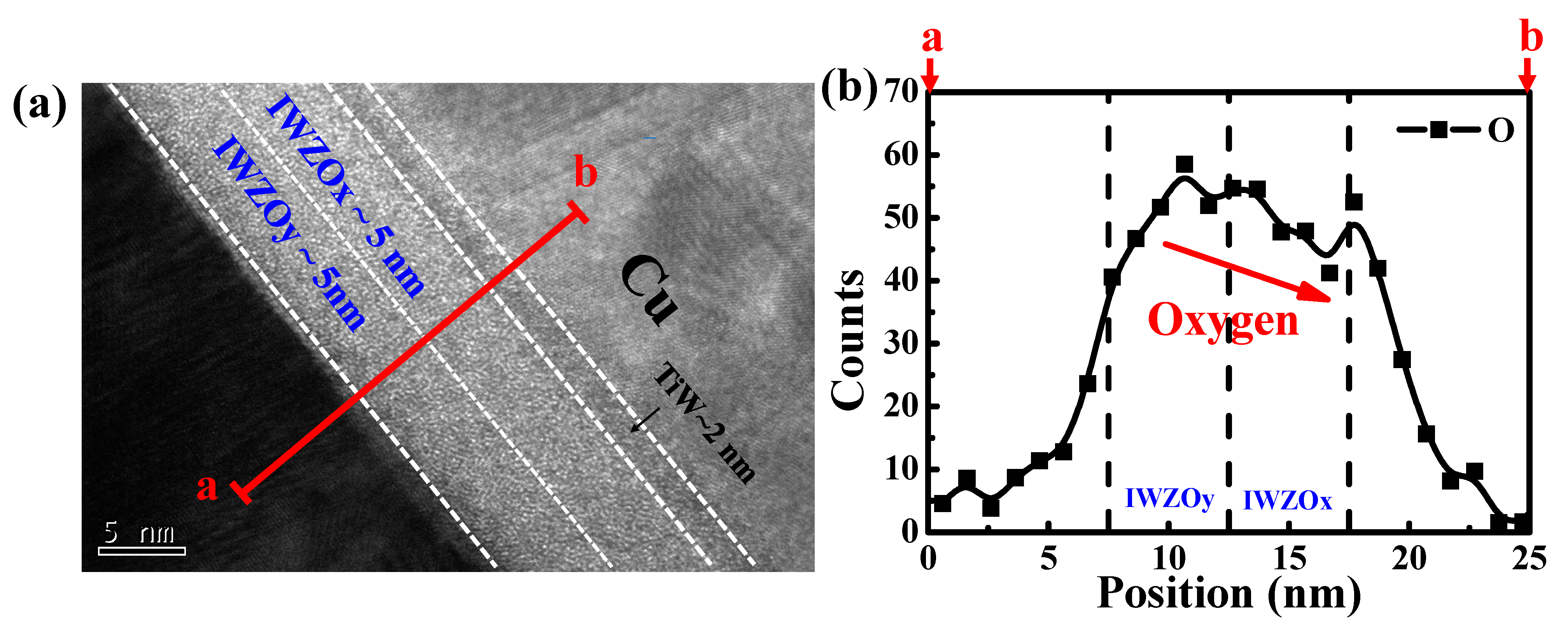

2. Materials and Methods

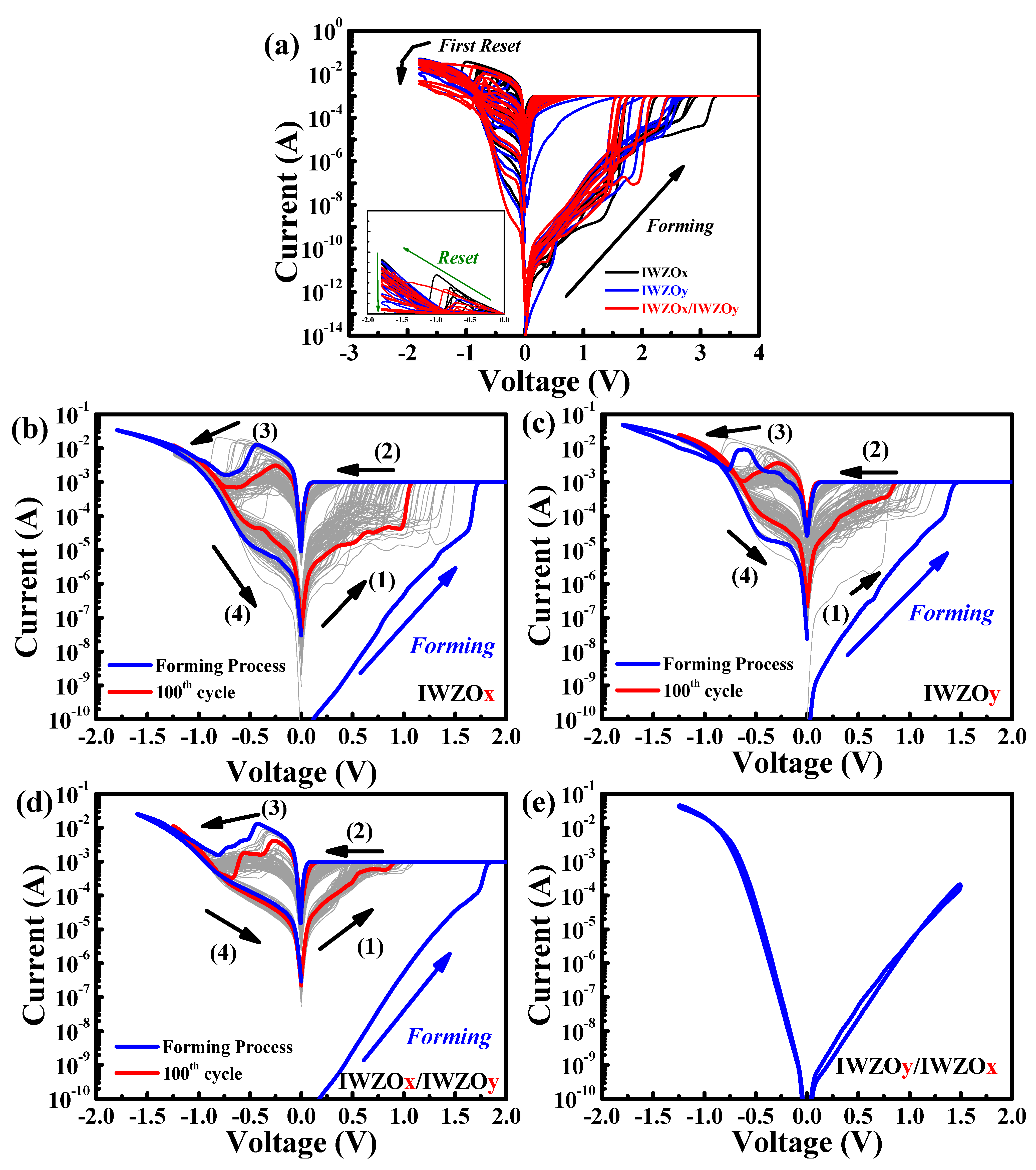

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wong, H.S.P.; Lee, H.-Y.; Yu, S.; Chen, Y.-S.; Wu, Y.; Chen, P.-S.; Lee, B.; Chen, F.T.; Tsai, M.-J. Metal–oxide RRAM. Proc. IEEE Inst. Electr. Electron. Eng. 2012, 100, 1951–1970. [Google Scholar]

- Kwon, J.Y.; Lee, D.J.; Kim, K.B. Transparent amorphous oxide semiconductor thin film transistor. Electron. Mater. Lett. 2011, 7, 1–11. [Google Scholar]

- Yen, T.J.; Chin, A.; Gritsenko, V. High-Performance Top-Gate Thin-Film Transistor with an Ultra-Thin Channel Layer. Nanomaterials 2020, 10, 2145. [Google Scholar] [CrossRef] [PubMed]

- Yen, T.J.; Chin, A.; Gritsenko, V. Exceedingly High Performance Top-Gate P-Type SnO Thin Film Transistor with a Nanometer Scale Channel Layer. Nanomaterials 2021, 11, 92. [Google Scholar] [CrossRef]

- Ruan, D.-B.; Liu, P.-T.; Chen, Y.-H.; Chiu, Y.-C.; Chien, T.-C.; Yu, M.-C.; Gan, K.-J.; Sze, S.M. Photoresponsivity Enhancement and Extension of the Detection Spectrum for Amorphous Oxide Semiconductor Based Sensors. Adv. Electron. Mater. 2019, 5, 1800824. [Google Scholar] [CrossRef]

- Naqi, M.; Kwon, N.; Jung, S.H.; Pujar, P.; Cho, H.W.; Cho, Y.I.; Cho, H.K.; Lim, B.; Kim, S. High-Performance Non-Volatile InGaZnO Based Flash Memory Device Embedded with a Monolayer Au Nanoparticles. Nanomaterials 2021, 11, 5. [Google Scholar]

- Min, S.-Y.; Cho, W.-J. High-Performance Resistive Switching in Solution-Derived IGZO: N Memristors by Microwave-Assisted Nitridation. Nanomaterials 2021, 11, 1081. [Google Scholar] [CrossRef]

- Gan, K.-J.; Liu, P.-T.; Chien, T.-C.; Ruan, D.-B.; Sze, S.M. Highly durable and flexible gallium-based oxide conductive-bridging random access memory. Sci. Rep. 2019, 9, 14141. [Google Scholar] [CrossRef]

- Gan, K.-J.; Liu, P.-T.; Ruan, D.-B.; Hsu, C.-C.; Chiu, Y.-C.; Sze, S.M. Effect of tungsten doping on the variability of InZnO conductive-bridging random access memory. Nanotechnology 2020, 32, 035203. [Google Scholar] [CrossRef] [PubMed]

- Ruan, D.-B.; Liu, P.-T.; Yu, M.-C.; Chien, T.-C.; Chiu, Y.-C.; Gan, K.-J.; Sze, S.M. Performance Enhancement for Tungsten-Doped Indium Oxide Thin Film Transistor by Hydrogen Peroxide as Cosolvent in Room-Temperature Supercritical Fluid Systems. ACS Appl. Mater. Interfaces 2019, 11, 22521–22530. [Google Scholar]

- Ruan, D.-B.; Liu, P.-T.; Gan, K.-J.; Chiu, Y.-C.; Hsu, C.-C.; Sze, S.M. Role of tungsten dopants in indium oxide thin-film transistor on radiation hardness technology. Appl. Phys. Lett. 2020, 116, 182104. [Google Scholar] [CrossRef]

- Molas, G.; Vianello, E.; Dahmani, F.; Barci, M.; Blaise, P.; Guy, J.; Toffoli, A.; Bernard, M.; Roule, A.; Pierre, F. Controlling oxygen vacancies in doped oxide based CBRAM for improved memory performances. In Proceedings of the 2014 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2014. [Google Scholar]

- Liu, C.-F.; Tang, X.-G.; Wang, L.-Q.; Tang, H.; Jiang, Y.-P.; Liu, Q.-X.; Li, W.-H.; Tang, Z.-H. Resistive Switching Characteristics of HfO2 Thin Films on Mica Substrates Prepared by Sol-Gel Process. Nanomaterials 2019, 9, 1124. [Google Scholar] [CrossRef] [Green Version]

- Gismatulin, A.A.; Voronkovskii, V.A.; Kamaev, G.N.; Novikov, Y.N.; Kruchinin, V.N.; Krivyakin, G.K.; Gritsenko, V.A.; Prosvirin, I.P.; Chin, A. Electronic structure and charge transport mechanism in a forming-free SiOx-based memristor. Nanotechnology 2020, 31, 505704. [Google Scholar] [CrossRef]

- Gismatulin, A.A.; Kamaev, G.N.; Kruchinin, V.N.; Gritsenko, V.A.; Orlov, O.M.; Chin, A. Charge transport mechanism in the forming-free memristor based on silicon nitride. Sci. Rep. 2021, 11, 2417. [Google Scholar] [CrossRef] [PubMed]

- Hsu, C.-C.; Liu, P.-T.; Gan, K.-J.; Ruan, D.-B.; Chiu, Y.-C.; Sze, S.M. Impact of annealing environment on performance of InWZnO conductive bridge random access memory. Vacuum 2021, 191, 110321. [Google Scholar] [CrossRef]

- Yen, T.-J.; Chin, A.; Gritsenko, V. Improved Device Distribution in High-Performance SiNx Resistive Random Access Memory via Arsenic Ion Implantation. Nanomaterials 2021, 11, 1401. [Google Scholar] [CrossRef] [PubMed]

- Gan, K.-J.; Liu, P.-T.; Ruan, D.-B.; Hsu, C.-C.; Chiu, Y.-C.; Sze, S.M. Effect of Annealing Treatment on Performance of Ga2O3 Conductive-Bridging Random-Access Memory. J. Electron. Mater. 2020, 49, 6817–6822. [Google Scholar] [CrossRef]

- Gan, K.-J.; Chang, W.-C.; Liu, P.-T.; Sze, S.M. Investigation of resistive switching in copper/InGaZnO/Al2O3-based memristor. Appl. Phys. Lett. 2019, 115, 143501. [Google Scholar] [CrossRef]

- Yang, Y.; Gao, P.; Gaba, S.; Chang, T.; Pan, X.; Liu, W. Observation of conducting filament growth in nanoscale resistive memories. Nat. Commun. 2012, 3, 732. [Google Scholar] [CrossRef]

- Shatma, Y.; Misra, P.; Pavunny, S.P.; Katiyar, R.S. Multilevel unipolar resistive memory switching in amorphous SmGdO3 thin film. Appl. Phys. Lett. 2014, 104, 073501. [Google Scholar]

- Waser, R.; Aono, M. Nanoionics-based resistive switching memories. Nat. Mater. 2007, 6, 833. [Google Scholar] [CrossRef]

- Cho, H.; Kim, S. Emulation of Biological Synapse Characteristics from Cu/AlN/TiN Conductive Bridge Random Access Memory. Nanomaterials 2020, 10, 1709. [Google Scholar] [CrossRef]

- Mahata, C.; An, Y.; Choi, S.; Kim, Y.C.B.D.K.; Lee, T.; Kim, J.; Cho, M.H.; Kim, H. Electrical properties of the HfO2-Al2O3 nanolaminates with homogeneous and graded compositions on InP. Curr. Appl. Phys. 2016, 16, 294. [Google Scholar] [CrossRef]

- Gan, K.-J.; Liu, P.-T.; Ruan, D.-B.; Chiu, Y.-C.; Sze, S.M. Annealing effects on resistive switching of IGZO-based CBRAM devices. Vacuum 2020, 180, 109630. [Google Scholar] [CrossRef]

- Mahata, C.; Kim, S. Modified resistive switching performance by increasing Al concentration in HfO2 on transparent indium tin oxide electrode. Ceram. Int. 2020, 47, 1199. [Google Scholar] [CrossRef]

- Mahata, C.; Kang, M.; Kim, S. Multi-Level analog resistive switching characteristics in tri-layer HfO2/Al2O3/HfO2 based memristor on ITO electrode. Nanomateirals 2020, 10, 2069. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, C.-C.; Liu, P.-T.; Gan, K.-J.; Ruan, D.-B.; Sze, S.M. Oxygen Concentration Effect on Conductive Bridge Random Access Memory of InWZnO Thin Film. Nanomaterials 2021, 11, 2204. https://doi.org/10.3390/nano11092204

Hsu C-C, Liu P-T, Gan K-J, Ruan D-B, Sze SM. Oxygen Concentration Effect on Conductive Bridge Random Access Memory of InWZnO Thin Film. Nanomaterials. 2021; 11(9):2204. https://doi.org/10.3390/nano11092204

Chicago/Turabian StyleHsu, Chih-Chieh, Po-Tsun Liu, Kai-Jhih Gan, Dun-Bao Ruan, and Simon M. Sze. 2021. "Oxygen Concentration Effect on Conductive Bridge Random Access Memory of InWZnO Thin Film" Nanomaterials 11, no. 9: 2204. https://doi.org/10.3390/nano11092204

APA StyleHsu, C.-C., Liu, P.-T., Gan, K.-J., Ruan, D.-B., & Sze, S. M. (2021). Oxygen Concentration Effect on Conductive Bridge Random Access Memory of InWZnO Thin Film. Nanomaterials, 11(9), 2204. https://doi.org/10.3390/nano11092204