Data Shepherding in Nanotechnology. The Exposure Field Campaign Template

Abstract

:1. Introduction

- The handling of research data during and after the end of the project;

- What data will be collected, processed and/or generated;

- Which methodology and standards will be applied;

- Whether data will be shared/made open access;

- How data will be curated and preserved.

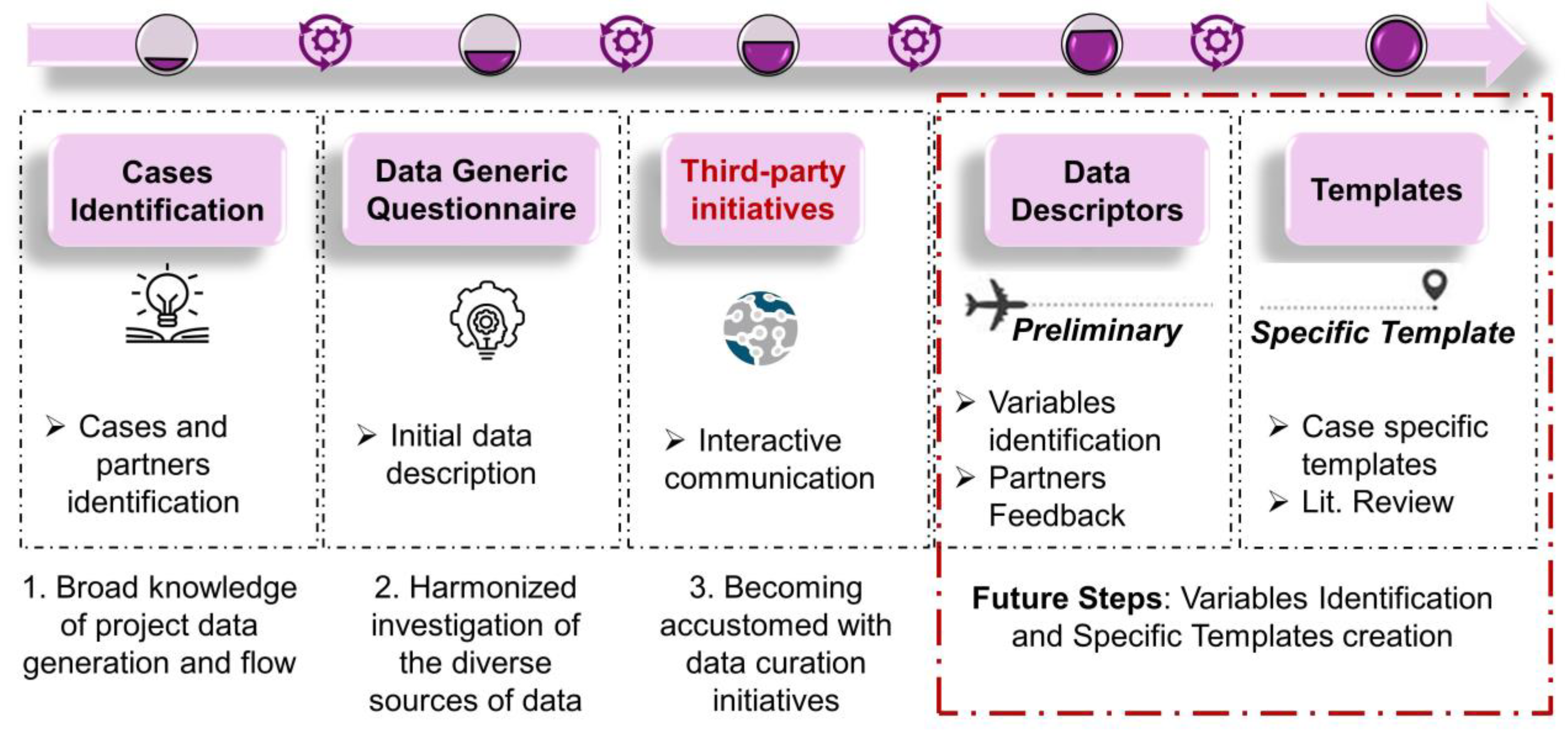

2. Materials and Methods

3. Results

3.1. Initial Data Description—Questionnaire

3.2. Preliminary Template from NIKC

3.3. Literature, Inner-Communication and Descriptors Identification

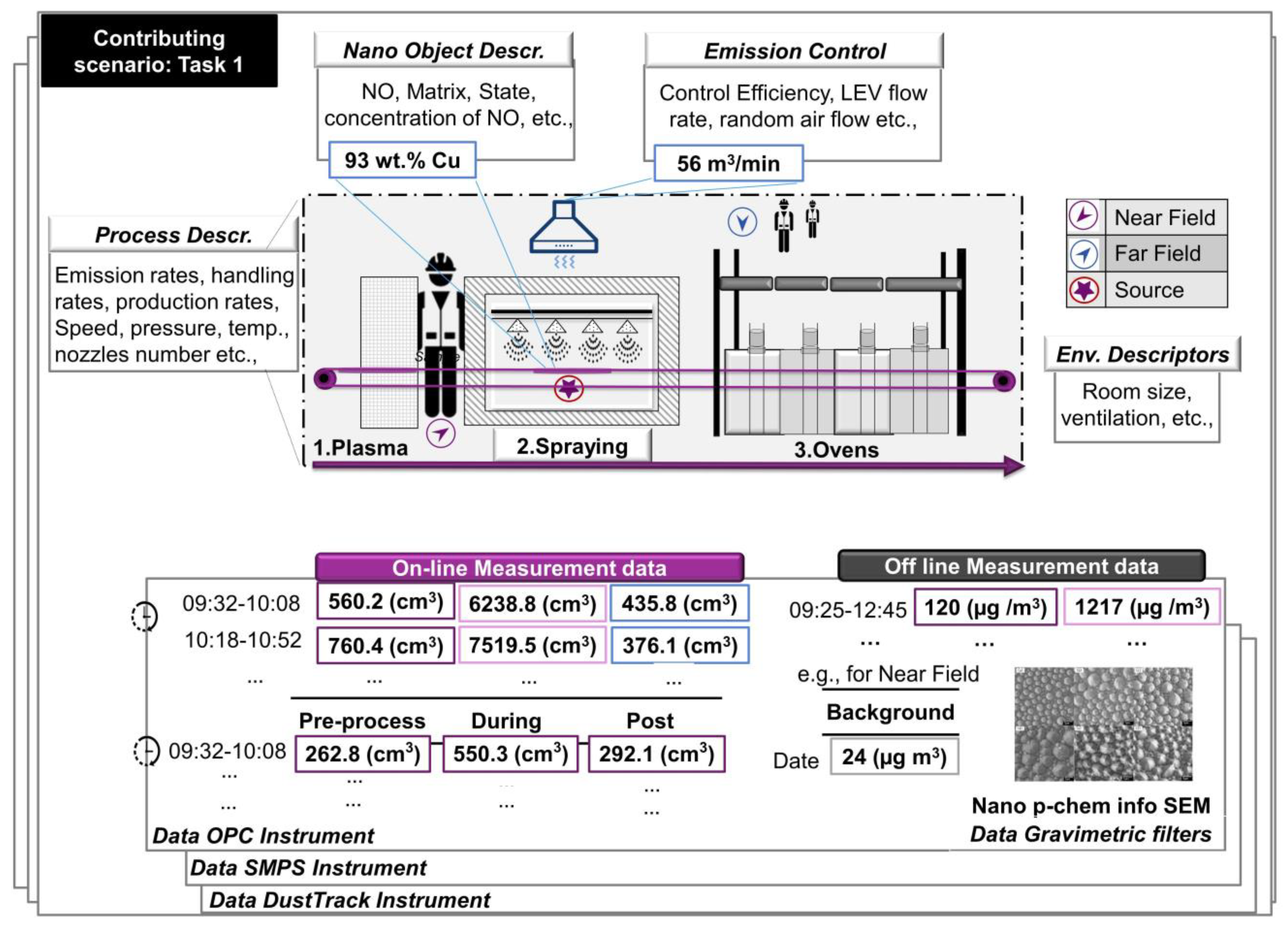

3.3.1. Work Shift and Process-Related Descriptors

3.3.2. Emission Control and Environmental Descriptors

3.3.3. Nanostructured Materials Descriptors

3.3.4. Time-Series Measurements

3.3.5. Instrumentation

3.4. Annotation

4. Discussion

4.1. Responsible Persons and Data Use

- For the data shepherd are facilitating the communication and understanding between the stakeholders of the process parameters, materials, working practices and the data to be captured.

- For the data creator are measurement of concentrations in relevant locations, evaluating the goodness of the concentration measurements, and reporting of the required metadata and underlying assumptions, such as identified sources and mixing of concentrations.

- For the data analysts are to link contextual information and concentration measurements, showing how the pre-process, process, and post-process levels are associated with the work activity to present assumptions in mass flow analysis, to evaluate links of regional concentrations and personal exposure and to report/justify uncertainty.

4.2. Comparison with GRACIOUS Data Collection Sheets

- −

- We dedicate a tab for the user to insert protocol information used during the sampling such as for TEM or SEM offline analysis, or the sampling of gravimetric filters. An increased availability of validated protocols is necessary to advance both computational studies and material characterization through homogeneous data [45,46]. Sample preparation (such as duration of sample preparation, and solvents use) is an important step of any chemical analysis. The data creator is responsible to report relevant steps in the sample collection and analysis.

- −

- Regarding the challenges of FAIRification, research institutions are often not sufficiently equipped with the specific knowhow and a number of researchers perceive these process requirements as additional paperwork that does not directly benefit their work [27]. Thus, the presented data collection sheet puts emphasis on the most essential elements to be captured, bypassing intense data reporting.

- −

- The GRACIOUS template requires detailed p-chem characterization—for example, the moisture of NOs or aspect ratio. Moisture content alone cannot be used to predict environmental effects, i.e., the powder dustiness, because storing conditions also affect the dustiness [47]. NOs’ length quantification is currently not feasible at sufficient accuracy from workplace air samples; only indicative dimensions and concentrations can be provided [7,48]. Thus, we focus our p-chem characterization data on emission determination of offline analysis and not as an integral part of material characterization per se [4]. The difference refers to timing; the GRACIOUS template focuses on the p-chem of NOs before they are incorporated into the matrix, while we are interested in the characterization of released airborne NOs from offline analysis. Measurements and analyses not only need to be standardized, but also need to be made simpler, feasible and to some extent, cost efficient [12].

- −

- A detail metadata description is provided to report the sampling strategy, measurement data and characterization part in an annotated manner to increase interoperability.

- −

- Some variables not found in the GRACIOUS template include random air speed, local control efficiency and production rate (work intensity). Random air speed related to the process should be considered when estimating the dispersion of particles between NF and FF. LEV integrated in the process machine should be evaluated separately (e.g., when air is returning to room or exhausted outdoors, etc.). In addition, we invite and encourage data creators to add pictures and visualization files to help the next users, such as schemes of process and location of instrumentations. This helps data users to apply the data accordingly for their purpose.

- −

- A FEM template should be flexible enough to include not prescribed factors that are process-specific, such as speed, temperature, pressure, the number of nozzles during a spray coating process or the ink viscosity in screen printing processes. This should allow the user to adjust the template in a process-specific manner.

- −

- Concentration and emission data should be kept distinguishable. Emission depends on process parameters, while concentration depends both on emissions and environmental descriptors. We divide the process information-related data with the measurement requirements in clear and simple ways. We also limit the template to the FEM data without projecting assumptions to capture routes of exposure or potential of inhalation and dermal exposure. We provide a bottom-up designed template close to the raw data of exposure and emission assessments.

- −

- NO fragments’ properties depend on the release process described in the release experiment. We do not capture release experimentations. Products have intentional use applications, and the emissions are based on those. For example, Ag-NPs applied to textiles for clothes and toys have leaching to washing liquid, sweat and saliva as relevant release pathways but textiles for outdoor use have weathering (UV, abrasion, leaching) as a relevant release pathway. Thus, a template dedicated to release emissions and characterization of released fragments is more suitable.

- −

- GRACIOUS templates extend to regulatory requirements of chemical risk assessment. ECHA descriptors are designed mainly for traditional industry where the process categories (PROCS) can be difficult to associate with nanotechnology industry processes. Those features were not included in our template. The main ECHA descriptors are article category (AC), exposure scenarios (ESs), and PROCs. These are combined to contributing activities (CA) that are used to describe release from an AC in specific ESs by different PROCs. The CA, ES, and PROC descriptors with the quantitative NO release can be used for a “Lifecycle release and exposure” grouping strategy and parameterization of exposure and release models. AC defines where the substance has been processed (e.g., wood articles, plastic articles) and we maintained this information as the most relevant to the field campaign purpose. However, the categories are not well specified considering release. For example, ECHA AC1 is “Vehicles”, which is difficult to estimate where or for which vehicle the substance has been processed. Better sub-categories are needed which can be further grouped based on, e.g., matrix properties that behave in similar way under certain release circumstances (e.g., AC13 plastic articles: AC13.1 poly(methyl methacrylate), AC13.2 polypropylene, AC13.3 polyamide).

4.3. Comparison with the eNanoMapper and NECID Database

4.4. The Data Shepherd

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, H.; Jiang, S.; Chen, H.; Roco, M.C. International perspective on nanotechnology papers, patents, and NSF awards (2000–2016). J. Nanopart. Res. 2017, 19, 370. [Google Scholar] [CrossRef]

- Singh, N.A. Nanotechnology innovations, industrial applications and patents. Environ. Chem. Lett. 2017, 15, 185–191. [Google Scholar] [CrossRef]

- Vaquero, C.; Gutierrez-Cañas, C.; Galarza, N.; De Ipina, J.L. Exposure assessment to engineered nanoparticles handled in industrial workplaces: The case of alloying nano-TiO2 in new steel formulations. J. Aerosol Sci. 2016, 102, 1–15. [Google Scholar] [CrossRef]

- Kuhlbusch, T.A.J.; Wijnhoven, S.W.P.; Haase, A. Nanomaterial exposures for worker, consumer and the general public. NanoImpact 2018, 10, 11–25. [Google Scholar] [CrossRef]

- Huguet-Casquero, A.; Gainza, E.; Pedraz, J.L. Towards Green Nanoscience: From extraction to nanoformulation. Biotechnol. Adv. 2021, 46, 107657. [Google Scholar] [CrossRef]

- Saleem, H.; Zaidi, S.J. Sustainable Use of Nanomaterials in Textiles and Their Environmental Impact. Materials 2020, 13, 5134. [Google Scholar] [CrossRef]

- Koivisto, A.J.; Bluhme, A.B.; Kling, K.I.; Fonseca, A.S.; Redant, E.; Andrade, F.; Krepker, M.; Segal, E.; Vogel, U.; Koponen, I.K.; et al. Occupational exposure during handling and loading of halloysite nanotubes—A case study of counting nanofibers. NanoImpact 2018, 10, 153–160. [Google Scholar] [CrossRef]

- Viitanen, A.-K.; Uuksulainen, S.; Koivisto, A.J.; Hämeri, K.; Kauppinen, T. Workplace Measurements of Ultrafine Particles—A Literature Review. Ann. Work Expo. Health 2017, 61, 749–758. [Google Scholar] [CrossRef]

- OECD. Harmonized tiered approach to measure and assess the potential exposure to airborne emissions of engineered nano-objects and their agglomerates and aggregates at workplaces. In Series on the Safety of Manufactured Nanomaterials; OECD: Paris, France, 2015. [Google Scholar]

- Koivisto, A.; Spinazzè, A.; Verdonck, F.; Borghi, F.; Löndahl, J.; Koponen, I.K.; Jayjock, M.; Hussein, T.; Arnold, S.; Furxhi, I.; et al. Assessment of exposure determinants and exposure levels by using stationary concentration measurements and a probabilistic near-field/far-field exposure model [version 1; peer review: Awaiting peer review]. Open Res. Eur. 2021. [Google Scholar] [CrossRef]

- European Union. Revision of EU Legislation on Registration, Evaluation, Authorisation and Restriction of Chemicals; European Union: Brussels, Belgium, 2021; p. 4. [Google Scholar]

- Koivisto, A.J.; Kling, K.I.; Hänninen, O.; Jayjock, M.; Löndahl, J.; Wierzbicka, A.; Uhrbrand, K.; Viana, M.; Morawska, L.; Hussein, T.; et al. Source specific exposure and risk assessment for indoor aerosols. Sci. Total Environ. 2019, 668, 13–24. [Google Scholar] [CrossRef]

- Boccuni, F.; Ferrante, R.; Tombolini, F.; Lega, D.; Antonini, A.; Alvino, A.; Pingue, P.; Beltram, F.; Sorba, L.; Iavicoli, S.; et al. Workers’ Exposure to Nano-Objects with Different Dimensionalities in R&D Laboratories: Measurement Strategy and Field Studies. Int. J. Mol. Sci. 2018, 19, 349. [Google Scholar]

- Fonseca, A.S.; Viitanen, A.K.; Kanerva, T.; Säämänen, A.; Aguerre-Chariol, O.; Fable, S.; Dermigny, A.; Karoski, N.; Fraboulet, I.; Koivisto, J.; et al. Occupational Exposure and Environmental Release: The Case Study of Pouring TiO2 and Filler Materials for Paint Production. Int. J. Environ. Res. Public Health 2021, 18, 418. [Google Scholar] [CrossRef] [PubMed]

- Shahzad, R.; Veronique, A.; Ana, S.F.; Socorro, V.; Camila, D.; Araceli, S.J.; Nina, J. GRACIOUS Release and Exposure Templates. Available online: https://zenodo.org/record/4665253#.YOlza-hKguU (accessed on 5 June 2021).

- van Vlijmen, H.; Mons, A.; Waalkens, A.; Franke, W.; Baak, A.; Ruiter, G.; Kirkpatrick, C.; da Silva Santos, L.O.B.; Meerman, B.; Jellema, R.; et al. The Need of Industry to Go FAIR. Data Intell. 2020, 2, 276–284. [Google Scholar] [CrossRef]

- Wise, J.; de Barron, A.G.; Splendiani, A.; Balali-Mood, B.; Vasant, D.; Little, E.; Mellino, G.; Harrow, I.; Smith, I.; Taubert, J.; et al. Implementation and relevance of FAIR data principles in biopharmaceutical R&D. Drug Discov. Today 2019, 24, 933–938. [Google Scholar]

- European Union. Chemicals Strategy for Sustainability Towards a Toxic-Free Environment. In Communication from the Com-mission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Union: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions a New Industrial Strategy for Europe; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Boeckhout, M.; Zielhuis, G.A.; Bredenoord, A.L. The FAIR guiding principles for data stewardship: Fair enough? Eur. J. Hum. Genet. 2018, 26, 931–936. [Google Scholar] [CrossRef] [Green Version]

- European Commission. H2020 Programme: Guidelines on FAIR Data Management in Horizon 2020; Directorate-General for Re-search & Innovation. 2016. Available online: https://ec.europa.eu/research/participants/data/ref/h2020/grants_manual/hi/oa_pilot/h2020-hi-oa-data-mgt_en.pdf (accessed on 13 July 2021).

- Romanos, N.; Kalogerini, M.; Koumoulos, E.P.; Morozinis, A.K.; Sebastiani, M.; Charitidis, C. Innovative Data Management in advanced characterization: Implications for materials design. Mater. Today Commun. 2019, 20, 100541. [Google Scholar] [CrossRef]

- Wilkinson, M.D.; Dumontier, M.; Aalbersberg, I.J.; Appleton, G.; Axton, M.; Baak, A.; Zhao, J.; Wittenburg, P.; Waagmeester, A.; Mons, B.; et al. The FAIR Guiding Principles for scientific data management and stewardship. Sci. Data 2016, 3, 160018. [Google Scholar] [CrossRef] [Green Version]

- Jacobsen, A.; de Miranda Azevedo, R.; Juty, N.; Batista, D.; Coles, S.; Cornet, R.; Strawn, G.; Thompson, M.; Roos, M.; Schultes, E.; et al. FAIR Principles: Interpretations and Implementation Considerations. Data Intell. 2020, 2, 10–29. [Google Scholar] [CrossRef]

- Bloemers, M.; Montesanti, A. The FAIR Funding Model: Providing a Framework for Research Funders to Drive the Transition toward FAIR Data Management and Stewardship Practices. Data Intell. 2020, 2, 171–180. [Google Scholar] [CrossRef]

- Papadiamantis, A.G.; Klaessig, F.C.; Exner, T.E.; Hofer, S.; Hofstaetter, N.; Himly, M.; Doganis, P.; Afantitis, A.; Melagraki, G.; Lynch, I.; et al. Metadata Stewardship in Nanosafety Research: Community-Driven Organisation of Metadata Schemas to Support FAIR Nanoscience Data. Nanomaterials 2020, 10, 2033. [Google Scholar] [CrossRef]

- Furxhi, I.; Arvanitis, A.; Murphy, F.; Costa, A.; Blosi, M. Data Shepherding in Nanotechnology. The Initiation. Nanomaterials 2021, 11, 1520. [Google Scholar] [CrossRef]

- Powers, C.M.; Mills, K.A.; Morris, S.A.; Klaessig, F.; Gaheen, S.; Lewinski, N.; Hendren, C.O. Nanocuration workflows: Establishing best practices for identifying, inputting, and sharing data to inform decisions on nanomaterials. Beilstein J. Nanotechnol. 2015, 6, 1860–1871. [Google Scholar] [CrossRef] [Green Version]

- Koivisto, J. Source Specific Risk Assessment of Indoor Aerosol Particles. Ph.D. Thesis, University of Helsinki (Helsingin yliopisto), Helsinki, Finland, 2013. [Google Scholar]

- Koivisto, A.J.; Kling, K.I.; Fonseca, A.S.; Bluhme, A.B.; Moreman, M.; Yu, M.; Costa, A.L.; Giovanni, B.; Ortelli, S.; Jensen, K.A.; et al. Dip coating of air purifier ceramic honeycombs with photocatalytic TiO2 nanoparticles: A case study for occupational exposure. Sci. Total Environ. 2018, 630, 1283–1291. [Google Scholar] [CrossRef] [PubMed]

- European Chemicals Agency. Guidance on Information Requirements and Chemical Safety Assessment Chapter R.14: Occupational Exposure Assessment; European Chemicals Agency: Helsinki, Finland. 2016. Available online: https://echa.europa.eu/documents/10162/13632/information_requirements_r14_en.pdf/bb14b581-f7ef-4587-a171-17bf4b332378 (accessed on 13 July 2021).

- Koivisto, A.J.; Jensen, A.C.Ø.; Kling, K.I.; Nørgaard, A.; Brinch, A.; Christensen, F.; Jensen, K.A. Quantitative material releases from products and articles containing manufactured nanomaterials: Towards a release library. NanoImpact 2017, 5, 119–132. [Google Scholar] [CrossRef]

- Fransman, W.; Schinkel, J.; Meijster, T.; Van Hemmen, J.; Tielemans, E.; Goede, H. Development and evaluation of an exposure control efficacy library (ECEL). Ann. Occup. Hyg. 2008, 52, 567–575. [Google Scholar] [PubMed] [Green Version]

- Goede, H.; Christopher-de Vries, Y.; Kuijpers, E.; Fransman, W. A Review of Workplace Risk Management Measures for Nanomaterials to Mitigate Inhalation and Dermal Exposure. Ann. Work Exp. Health 2018, 62, 907–922. [Google Scholar] [CrossRef]

- Baldwin, P.E.; Maynard, A.D. A Survey of Wind Speeds in Indoor Workplaces. Ann. Occup. Hyg. 1998, 42, 303–313. [Google Scholar] [CrossRef]

- Organisation for Economic Co-Operation and Development. Strategies, techniques and sampling protocols for determining the concentrations of manufactured nanomaterials in air at the workplace. In Series on the Safety of Manufactured Nanomaterials; Organisation for Economic Co-Operation and Development: Paris, France, 2017; p. 155. [Google Scholar]

- Harper, M. Recent Advances in Occupational Exposure Assessment of Aerosols. Int. J. Environ. Res. Public Health 2020, 17, 6820. [Google Scholar] [CrossRef]

- Levin, M.; Witschger, O.; Bau, S.; Jankowska, E.; Koponen, I.K.; Koivisto, A.J.; Clausen, P.A.; Jensen, A.; Mølhave, K.; Asbach, C.; et al. Can We Trust Real Time Measurements of Lung Deposited Surface Area Concentrations in Dust from Powder Nanomaterials? Aerosol Air Qual. Res. 2016, 16, 1105–1117. [Google Scholar] [CrossRef] [Green Version]

- Huanyu, L.; Armiento, R.; Lambrix, P. Method for Extending Ontologies with Application to the Materials Science Domain. Data Sci. J. 2019, 18, 50. [Google Scholar]

- Kochev, N.; Jeliazkova, N.; Paskaleva, V.; Tancheva, G.; Iliev, L.; Ritchie, P.; Jeliazkov, V. Your Spreadsheets Can Be FAIR: A Tool and FAIRification Workflow for the eNanoMapper Database. Nanomaterials 2020, 10, 1908. [Google Scholar] [CrossRef]

- Clark, K.; van Tongeren, M.; Christensen, F.M.; Brouwer, D.; Nowack, B.; Gottschalk, F.; Micheletti, C.; Schmid, K.; Gerritsen, R.; Aitken, R.; et al. Limitations and information needs for engineered nanomaterial-specific exposure estimation and scenarios: Recommendations for improved reporting practices. J. Nanopart. Res. 2012, 14, 970. [Google Scholar] [CrossRef]

- Shockey, T.M.; Babik, K.R.; Wurzelbacher, S.J.; Moore, L.L.; Bisesi, M.S. Occupational exposure monitoring data collection, storage, and use among state-based and private workers’ compensation insurers. J. Occup. Environ. Hyg. 2018, 15, 502–509. [Google Scholar] [CrossRef] [PubMed]

- Karcher, S.; Willighagen, E.L.; Rumble, J.; Ehrhart, F.; Evelo, C.T.; Fritts, M.; Gaheen, S.; Harper, S.L.; Hoover, M.D.; Jeliazkova, N.; et al. Integration among databases and data sets to support productive nanotechnology: Challenges and recommendations. NanoImpact 2018, 9, 85–101. [Google Scholar] [CrossRef]

- Samuel, J. Collaborative Approach to Developing a Multilingual Ontology: A Case Study of Wikidata; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

- Johnston, L.J.; Gonzalez-Rojano, N.; Wilkinson, K.J.; Xing, B. Key challenges for evaluation of the safety of engineered nanomaterials. NanoImpact 2020, 18, 100219. [Google Scholar] [CrossRef]

- Furxhi, I.; Murphy, F. Predicting In Vitro Neurotoxicity Induced by Nanoparticles Using Machine Learning. Int. J. Mol. Sci. 2020, 21, 5280. [Google Scholar] [CrossRef] [PubMed]

- Levin, M.; Rojas, E.; Vanhala, E.; Vippola, M.; Liguori, B.; Kling, K.I.; Koponen, I.K.; Mølhave, K.; Tuomi, T.; Gregurec, D.; et al. Influence of relative humidity and physical load during storage on dustiness of inorganic nanomaterials: Implications for testing and risk assessment. J. Nanopart. Res. 2015, 17, 337. [Google Scholar] [CrossRef] [Green Version]

- Fonseca, A.S.; Viitanen, A.K.; Koivisto, A.J.; Kangas, A.; Huhtiniemi, M.; Hussein, T.; Vanhala, E.; Viana, M.; Querol, X.; Hämeri, K.; et al. Characterization of exposure to carbon nanotubes in an industrial setting. Ann. Occup. Hyg. 2015, 59, 586–599. [Google Scholar] [PubMed]

- Jeliazkova, N.; Apostolova, M.D.; Andreoli, C.; Barone, F.; Barrick, A.; Battistelli, C.; Bossa, C.; Botea-Petcu, A.; Châtel, A.; De Angelis, I.; et al. Towards FAIR nanosafety data. Nat. Nanotechnol. 2021, 16, 644–654. [Google Scholar] [CrossRef]

| Field Monitoring Campaigns for Exposure Assessment in Pilot Plants | ||

|---|---|---|

| Element | Response—Data Creators | Response—Data Analysts |

| Data Identification | ||

| Dataset description | Assessment of process emission rates and setting conditions of use. | Design field monitoring campaigns to quantify exposure determinants and workers exposure. |

| Source | Experimental measurement data. | Computational data |

| Partner’s activities and responsibilities | ||

| Partner owner of the data; copyright holder | Each partner is responsible for the data provided to the data set. | Each partner is responsible for the data provided to the data set. |

| Partner in charge of data collection/analysis/storage/related WP (s) | Data collection: Data creators and Shepherd. Development of measurement matrix with stakeholders and reporting plan. | Data analysis: Data analyst, Data creators and Shepherd. Bridging information. |

| Expected input variables | ||

| Description of the information required (WPs and/or Tasks) in order to move forward. | -NOs used in the processes and their use amounts per task/shift. -Pilot plants characteristics: dimensions, aspiration hood (position, size, flow rate). | Design of the measurement’s matrix with contextual information. |

| Expected outcomes | ||

| Description of the specific endpoint measurement variables/outcomes. | -Particle concentration. -Particle size distribution. -Samples for off-line SEM particle characterization. | -Quantification of workstation concentrations, exposure levels, and other relevant exposure determinants. |

| Standards | ||

| Detailed description of the methods/protocols | Set up of an experimental sampling station composed of: -SMPS to obtain the particle size distribution from 0.01 µm to 0.7 µm. -Optical Particle Counter to obtain the particle size distribution from 0.3 µm to 20 µm. -Monitors to obtain the LDSA (Partector-Naneos and MiniDisc-Testo) -Total filter samplers. Measurement standards (e.g., CEN EN 17058:2018; EN689) | -Analysis of mass flows, process emission rates and other relevant exposure determinants. -Validate mechanistic model against personal exposure. -Apply probabilistic model to evaluate exposure. -Set conditions of use. |

| Category | Variables | Metrics | Metadata Description |

|---|---|---|---|

| Work Shift Descriptors | Task Identifier | Text | Short identifier, e.g., Task 1 |

| Use/Task name | Text | Task name, e.g., Powder pouring | |

| Description | Text | Task descriptions linked to process descriptors. If sampling is performed over multiple tasks each task should be described separately, e.g., Task 1.1 and 1.2 | |

| Task duration | [min] | Task duration | |

| Time spent near process | [min] | Specify what is considered as near the source. For example, near the source is when distance is <2 m, for point emission sources and <10 m for diffusive sources (well mixed concentrations). The distances here are based on authors decisions. | |

| Process Definition | Process Diagram | Picture (sketches, photos) | Process visualization including identified exposure determinants, such as source, process closures, LEVs and worker location. |

| Life Cycle Stage (LCS) | List | LCS code according to ECHA use descriptor | |

| Sector of use (SU) | List | SU code according to ECHA use descriptor | |

| Process category (PROC) | List | PROC code according to ECHA use descriptor | |

| Description | Text | General description of the process, equipment, relevant process parameters, material chemical compositions and form (solid, liquid, gas). It is recommended to provide process machine manufacturer and model and material safety data sheets. |

| Category | Variables | Metric | Metadata Description |

|---|---|---|---|

| Generic Process Descriptors | Process parameters | Text | Factors that have an effect on the process emissions including materials. This is relevant for other users so that they can apply the process emissions reliably for their case. Data creators and partners are responsible for identifying relevant process parameters affecting the emission. Koivisto et al. [32] show some examples of relevant process parameters for specific processes and materials. Example: Temperature, speed, pressure. The user has the freedom to insert process parameters relevant to the case. |

| Level of automation | List | If workers’ time use is not known, the level of process automation can be used to estimate the worker exposure time as: Fully—Workers are only involved in supervision and control walks. Worker exposure time < 30 min during an 8 h work shift. Highly—Very limited manual invention is required to run. Contact with the substance may be possible for a very limited duration. Worker exposure time between 30 and 90 min during an 8 h work shift. Semi—Manual intervention is repeatedly required, although large parts of the process are machinery assisted. Worker exposure time between 90 and 240 min during an 8 h work shift. Manual—This process requires an operator, who is conducting a task manually. Worker exposure time is over 240 min during an 8 h work shift. The time intervals here are based on authors’ selections. | |

| Process duration | [min] | Equal or smaller than task duration, depending on if the process is continuous or not. Process duration and rate should equal to the production amount during work shift. | |

| Material process /handling rate | [e.g., kg/min] | This describes the intensity of process during the task and should be expressed in units, such as: - Material transfer, handling or synthesis (e.g., kg/min; m3/min) - Surface treatment (e.g., m2/min) - Component production or processing (e.g., pieces/min, m2/min) | |

| Process emission rate/factor | [e.g., μg/min] | Process emission described in scalable quantities to calculate emission in different exposure scenarios. For example, emission factor can be expressed for surface treatment as mg/m2, material removal/additive processes as mg/kg, component production as mg/component, welding as mg/cm of welding, etc. | |

| Production Rates | [e.g., m2/min, pieces/min] | Similarly, as for emission rate, the production rate is described in scalable quantities. |

| Category | Variables | Metric | Metadata Description |

|---|---|---|---|

| Emission Control descriptors in process machine | Emission control type | List | It is recommended to report the distance from the source and extraction funnel surface area for LEV and, for closures, the open surface area to evaluate LEV capturing efficiency (e.g., https://www.hse.gov.uk/lev/calculator.htm (accessed on 8 June 2021)). Emission control categorization helps to describe control techniques [33,34]: 1. Enclosure (automation): physical containment or enclosure of the source of emission; 2. LEV: exhaust ventilation systems located in close proximity of and directed at the source of emission; 3. Specialized ventilation systems: mechanical ventilation systems specifically designed for displacement of air contaminants in small, designated areas or systems intended to supply fresh air to workers; 4. Suppression techniques: techniques where an additive is added to an activity or process in an attempt to suppress emissions; 5. Segregation sources: isolation or segregation of sources from the work environment without containment of the emission source itself; 6. Worker separation: a personal enclosure within a work environment. It is recommended to provide the emission control’s manufacturer, model and efficiency. Note that emission control efficacies should be reported as well and in worker separation, the time that the worker spends in a separated area and close to the process. |

| Local Control Efficiency | [%] | Efficiency is 100% for perfect local control capturing all emissions and 0% when it acts as a ventilation exhaust near the source. | |

| LEV flow rate | [m3/min] | LEV air extraction and exhaust locations should be specified (e.g., mechanically assisted LEV where replacement air is partially from outdoors or LEV circulating the room air through a filter). |

| Category | Variables | Metric | Metadata Description |

|---|---|---|---|

| Environmental descriptors | Room size | [m3] | An approximate of the room volume where air exchange is considered to follow the room ventilation rate. |

| Room ventilation | [m3/min or 1/h] | Ventilation by LEV should be treated separately from the general ventilation. | |

| Other possible emissions sources | Text | Emissions from other processes in the same room as the sampler can increase the concentration level. Incoming ventilation air may also transport pollutants depending on the ventilation design and location of the facility. All active processes during the task that could impact measurements should be mentioned. | |

| Workstation closure | Text | The workstation closure where the worker performs the task is used to estimate how much air mixing between near and far field is limited. This is relevant mainly for point sources. Workstation closure is expressed as a side of a cube/rectangle, where sides may be closed in combination of back, one side, both sides and top. | |

| Random Air flow at workstation | [m/min] | Random air speed gives information about pollution dispersion near the source [35]. Near is defined as the distance within the worker breathing zone and the source. Typically, this varies from 30 cm to 1 m. |

| Category | Variables | Metric | Metadata Description |

|---|---|---|---|

| Nanostructured material Descriptors | Article Category (AC) and sub-category | List | AC code according to ECHA use descriptors |

| Substrate (Matrix type) | Text | Description of the matrix (Polyester fibers, Polymethylmethacrylate, clay, epoxy, fil, liquid) and chemical composition | |

| NO name and core | Text | Name, ID code (i.e., JRCxxx) CAS and or ES number and chemical composition, i.e., TiO2 pigment (93% rutile), (Tioxid TR81; CAS-Nr. 13463-67-7) | |

| External Layer | Text | NO name in surface layer 1 (more external layer) | |

| Inner Layer | Text | NO name in surface layer 2 (inner layer) | |

| NO Provider/Supplier | Text | NO manufacturer provider (partner related to the project ASINA) or supplier | |

| Concentration | [wt.%] | NO concentration in material mass unit, e.g., wt.%, µg/g, etc. Usually, this information is provided by a different partner, but the final concentration of NOs in a product is of paramount importance and should be captured when known. | |

| Form of NO in matrix | Text | State of NO (s) in the matrix/media: embedded into, surface bound, incorporated, impregnated, in liquid, dispersion, powder, solid, paste |

| Category | Variables | Metrics | Metadata Description |

|---|---|---|---|

| On-line Measurements based on Location and Phase | Collection Interval | hh:mm-hh:mm | Start–End Time of the measurement |

| Instrument | Instrument name. Detailed information regarding instruments is inserted in a different tab (Instrument Tab) | ||

| Ventilation | [m3/min or 1/h] | Incoming/outgoing ventilation air | |

| Source | Metric: P Numb (cm−3), Lung Deposited (µm2 cm−3), Size Distribution (dN/d(Dp)), Mass (µg m−3) AND Variations: Average, Geometric mean (GM), Geometric standard deviation (GSD), Arithmetic mean (AM), Standard deviation (SD) | Very close to the source or at the source (e.g., tailpipe, inside the process closure or inside fume chamber). Report average and standard deviation | |

| NF | NF—Close to the source where pollution is mixed to the rest of the room. At working station, NF should cover the worker’s breathing zone and source, and provide the distance from the source. | ||

| FF | FF—Typically 5 to 10 m from the NF measured in the same room (same room where the source is). | ||

| BZ | Breathing zone measured within 30 cm from the worker’s nose and mouth (EN 689) | ||

| BG | Other spaces where ventilation replacement air flows are potentially carrying pollutants to the process room. Background can be estimated from pre- and post-process measurements or by measuring background concentration from FF that is not affected by the source emissions. | ||

| Pre-process | Pre- and post-process concentrations are one way to estimate the concentrations from the process. This shows how much the concentration is increased by the process, when assuming background concentration as constant (as average of pre- and post-concentrations). Specified for NF, FF, or source depending on the assessment objective (e.g., worker or co-worker exposure to process particles or emissions from the process, respectively); (2) Specified for any instrument. Local background particle exposure: local work area eight-hour time-weighted average particle number or mass concentration that excludes any contribution of particles from the nanotechnology process. This value is specific to each work environment. This value should be determined following repeated measurement of the particle number and mass concentration when the nanotechnology process is not in operation. The results of such measurement should be converted to an 8-hour time-weighted average value and the median of all values used as the basis for the recommended local particle reference value. | ||

| Post-Process concentration | |||

| Process concentration | Concentration during the process. | ||

| Log-normal size distribution Descr. | Instrument | ||

| Location and Phase | NF, FF, BG, etc., Post-/During/Pre-process | ||

| X | [N (cm3)] | P number concentration (>10 nm) | |

| GMD | [nm] | geometric mean diameter, AND information such as: particle diameter corresponding to 50% of the cumulative distribution | |

| GSD | [-] | geometric standard deviation, AND information such as: particle diameter corresponding to 84% of the cumulative |

| Category | Variables | Metrics | Metadata Description |

|---|---|---|---|

| Offline Measurements and Analysis | Collection Interval | hh:mm-hh:mm | |

| Instrument | Text | Instrument name. Detailed information regarding instruments is inserted in a different tab (Instrument Tab) | |

| Sample collection/description | Text | A description of the sample collection, e.g., gravimetric, surface dust sample | |

| Ventilation | [m3/min or 1/h] | ||

| Source | Metric: P Numb (cm−3), Lung Deposited (µm2 cm−3), Size Distri (dN/d(dp)), Mass (µg m−3) AND Variations: AVEG, SD, GM, AM, GSD, | Same as Table 7 | |

| NF | |||

| FF | |||

| BZ | |||

| BG | |||

| Chemical Information | Instrument | Text | I.e., ICP-MS, EDX |

| E.g., Elemental composition (wt.%), Impurities, Crystallinity phase | Elemental composition, i.e., Major: Ti, O Minor: Si, Al, Zr, P, and organic coating | ||

| Impurities: Any unwanted organic, inorganic, and residual solvents in drug substances and final products. | |||

| The detection and quantification of the amount of amorphous material within a highly crystalline substance. | |||

| StructuralInformation | Instrument | Text | I.e., SEM, TEM, BET |

| E.g., Pristine size (nm), Shape, Specific surface area (m2/g), Bulk density (g/cm3), Zeta potential (mV), Dissolution rate (mass/time unit), Solubility(g/L) | Specific surface area total surface area of a material per unit of mass, or solid or bulk volume | ||

| Bulk density | |||

| Zeta: The measurement of the overall charge a particle acquires in a specific medium | |||

| Dissolution rate actual release rate of the compound at the given particle size, etc. | |||

| Solubility: capacity of a solute to dissolve in a pure solvent | |||

| Category | Variables | Metadata Description |

|---|---|---|

| Instrument | Instrument Name | e.g., FESEX, EDX, ICP-MS, OPC, SMPS, DustTrack, INSPEC, etc., |

| Model | e.g., Sigma, DISCMini, Partector, DusttRACK, Bravo, Pump | |

| Measured Metric (Outputs) | e.g., Mobility/aerodynamic/optical particle Number concentration (1/cm3), Lung Deposited Surface Area (µm2/cm3), Particle Size Distribution (dN/d(dp)), Particle Mass concentration (µg/m3) | |

| Detection Technique | e.g., light scattering, particle mobility classification and single particle counting, particle aerodynamic classification and current induced by moving charge particle | |

| Size Range | e.g., 30 nm–~700 nm, 250 nm–20 μm, 11.1 nm–1082 nm, >30 µg | |

| Detection Limits | Lower and upper detection limit | |

| Total Flow (L/min) | Instrument sampling flow? | |

| Manufacturer Information | e.g., Agilent technology, Santa Clara, USA. TSI, Shoreview, USA, Grimm Aerodol Technik, Airnring, Germany. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Furxhi, I.; Koivisto, A.J.; Murphy, F.; Trabucco, S.; Del Secco, B.; Arvanitis, A. Data Shepherding in Nanotechnology. The Exposure Field Campaign Template. Nanomaterials 2021, 11, 1818. https://doi.org/10.3390/nano11071818

Furxhi I, Koivisto AJ, Murphy F, Trabucco S, Del Secco B, Arvanitis A. Data Shepherding in Nanotechnology. The Exposure Field Campaign Template. Nanomaterials. 2021; 11(7):1818. https://doi.org/10.3390/nano11071818

Chicago/Turabian StyleFurxhi, Irini, Antti Joonas Koivisto, Finbarr Murphy, Sara Trabucco, Benedetta Del Secco, and Athanasios Arvanitis. 2021. "Data Shepherding in Nanotechnology. The Exposure Field Campaign Template" Nanomaterials 11, no. 7: 1818. https://doi.org/10.3390/nano11071818

APA StyleFurxhi, I., Koivisto, A. J., Murphy, F., Trabucco, S., Del Secco, B., & Arvanitis, A. (2021). Data Shepherding in Nanotechnology. The Exposure Field Campaign Template. Nanomaterials, 11(7), 1818. https://doi.org/10.3390/nano11071818