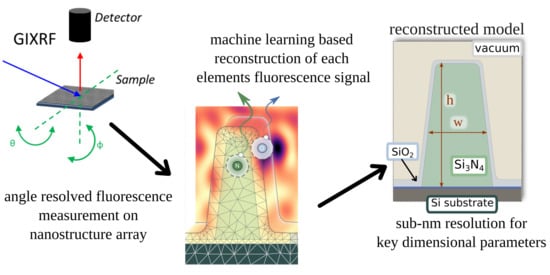

Shape- and Element-Sensitive Reconstruction of Periodic Nanostructures with Grazing Incidence X-ray Fluorescence Analysis and Machine Learning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental

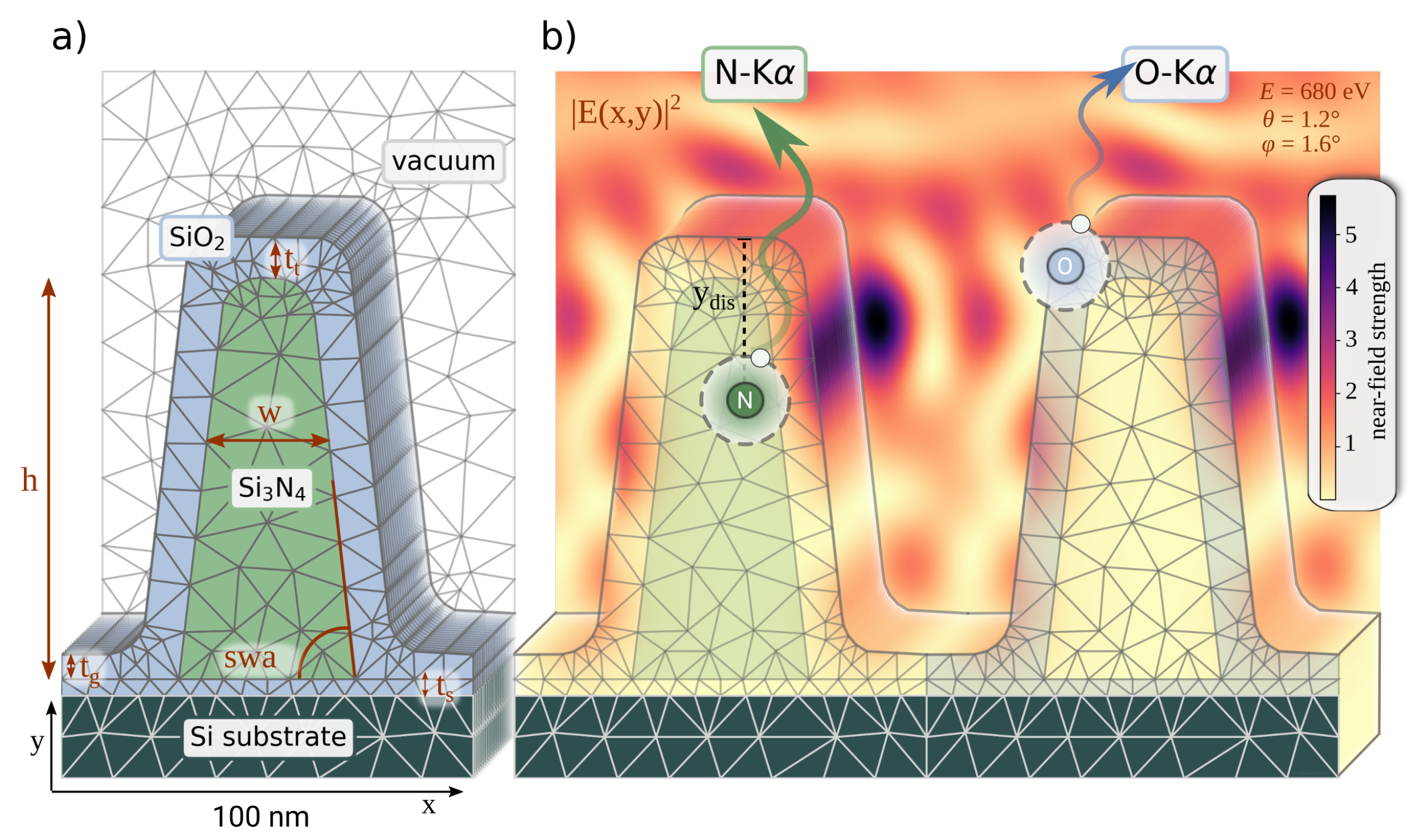

2.2. Simulation and Optimization of Fluorescence Intensities

3. Results and Discussion

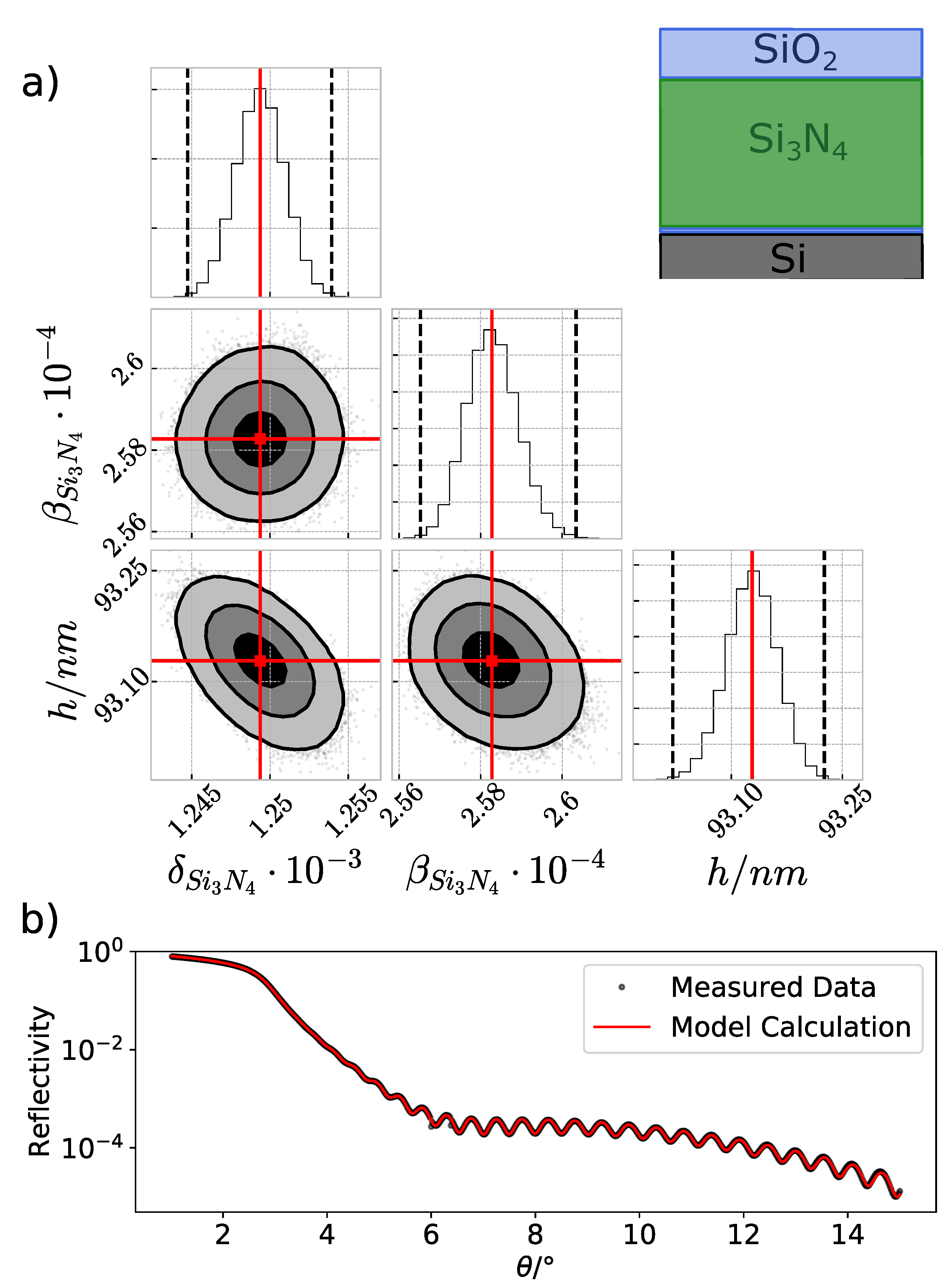

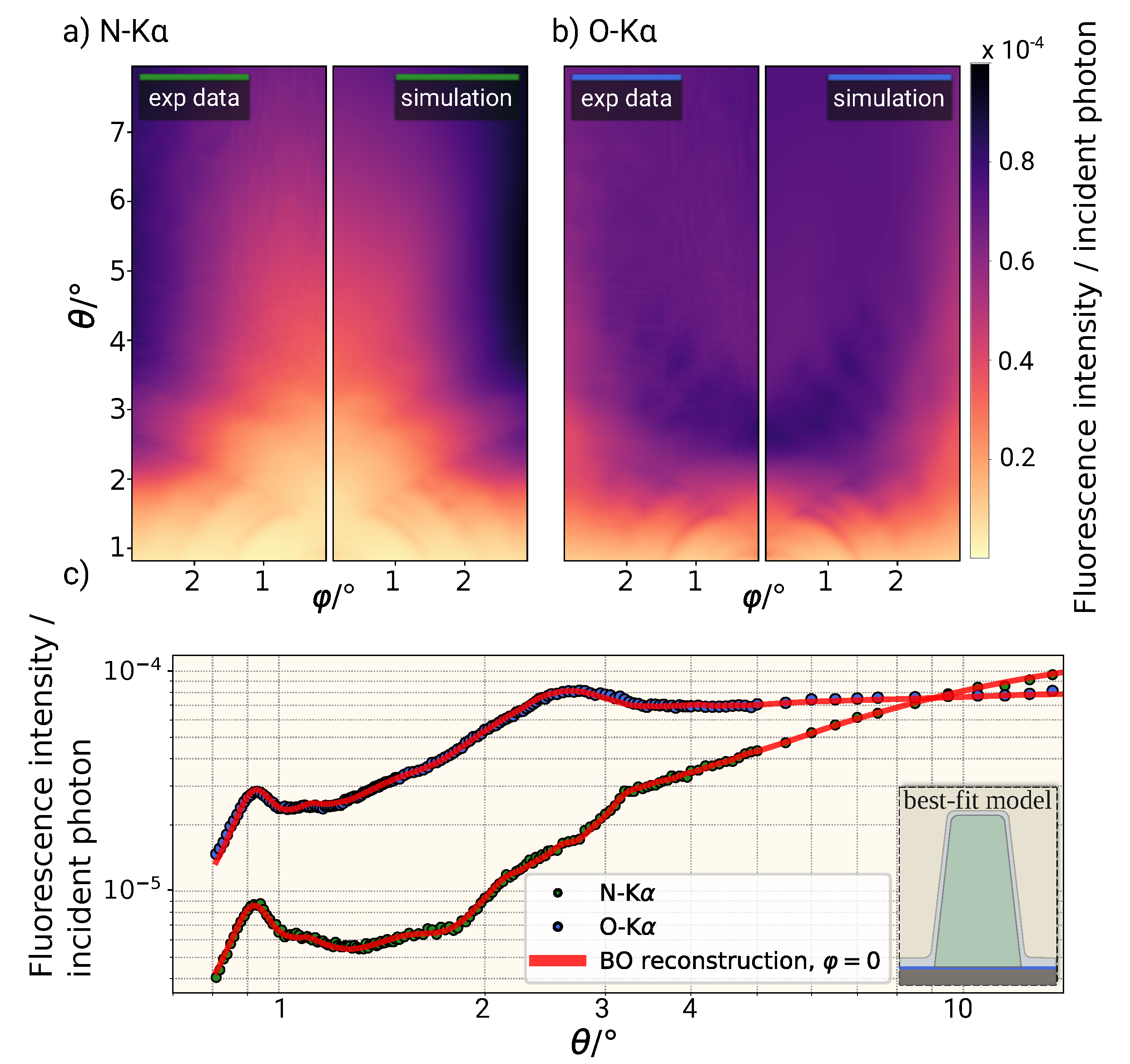

3.1. Validation of the Optical Material Parameters

3.2. GIXRF Reconstruction Results

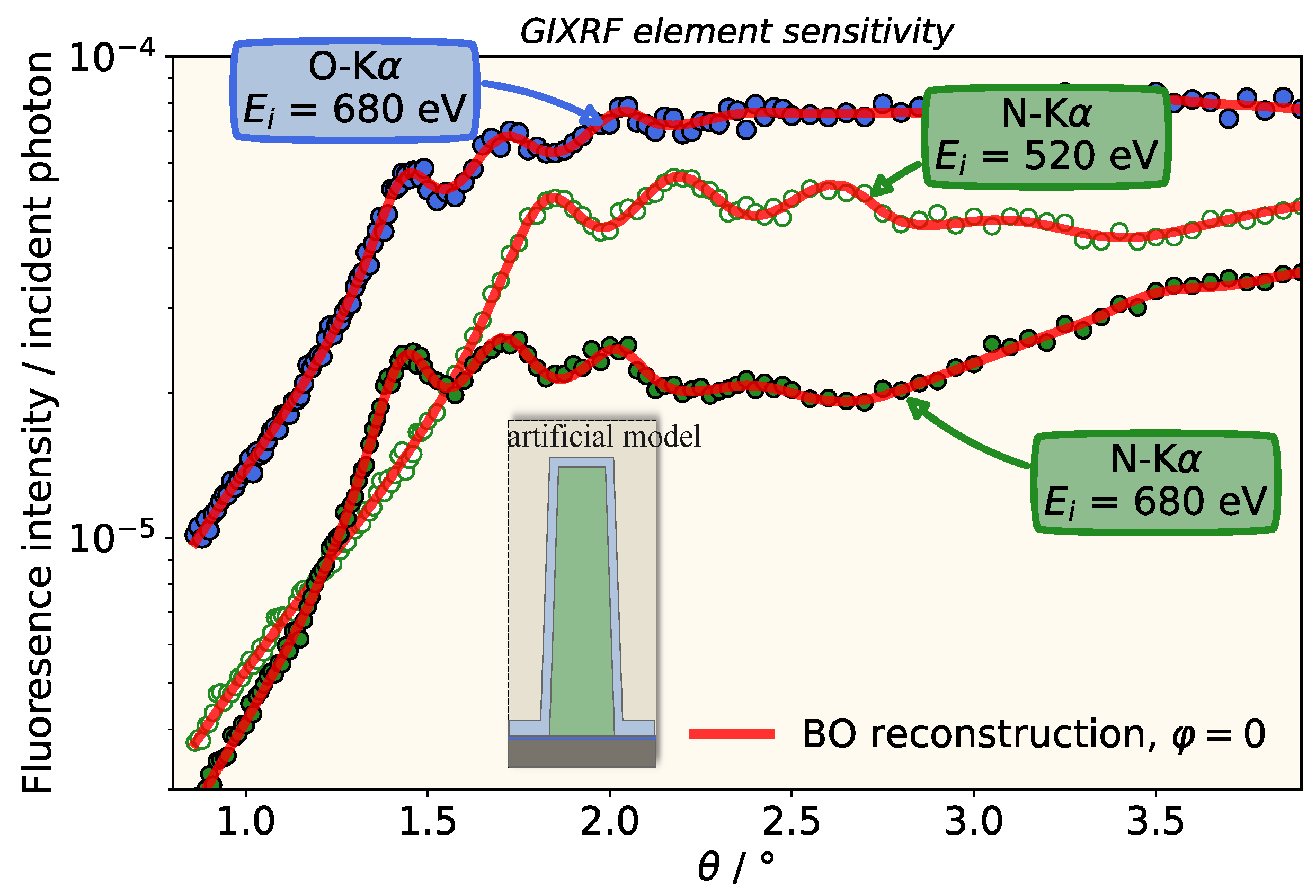

3.2.1. Virtual Experiment

3.2.2. Real Experimental Data

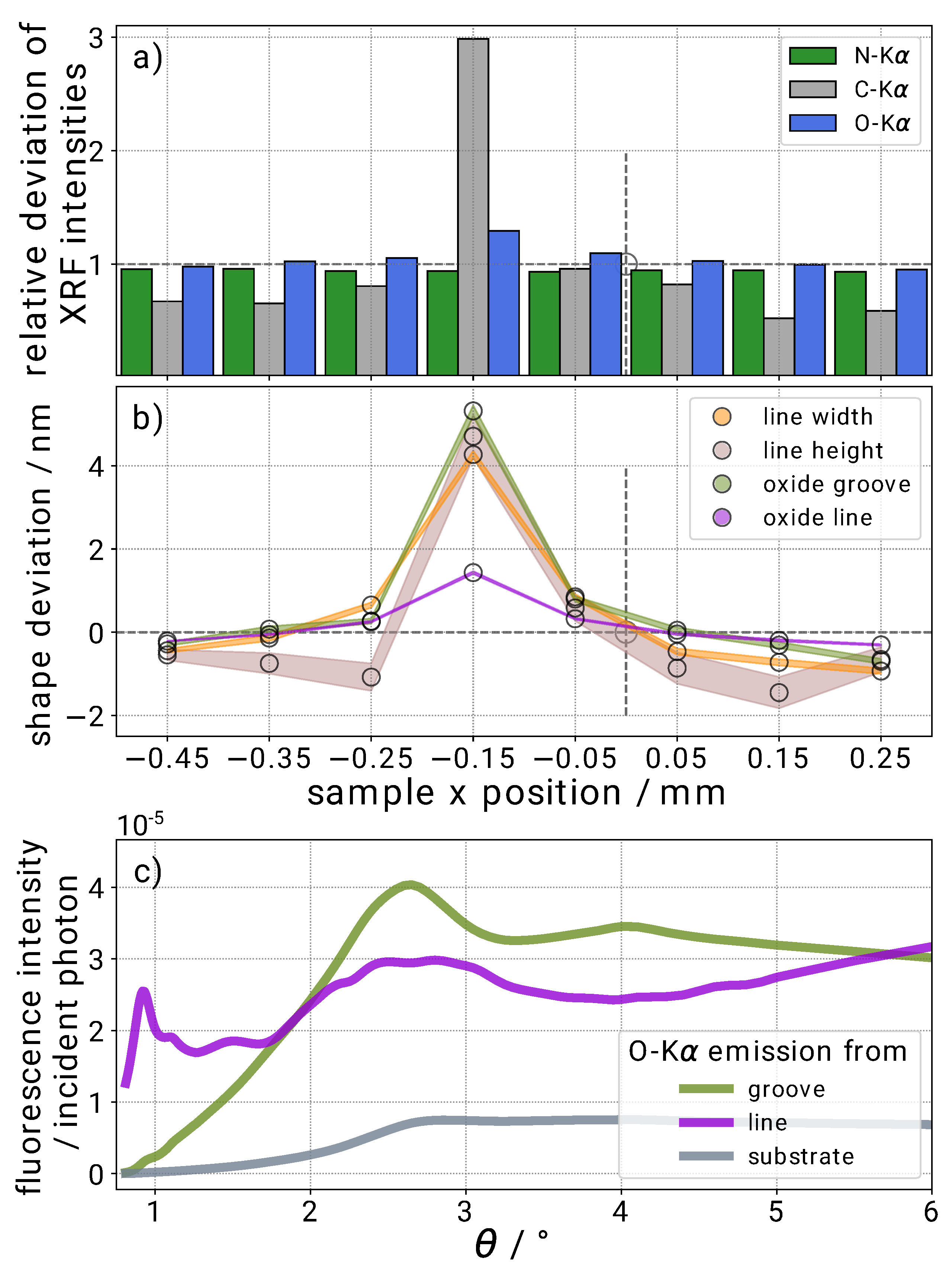

3.2.3. Influence of Model Errors

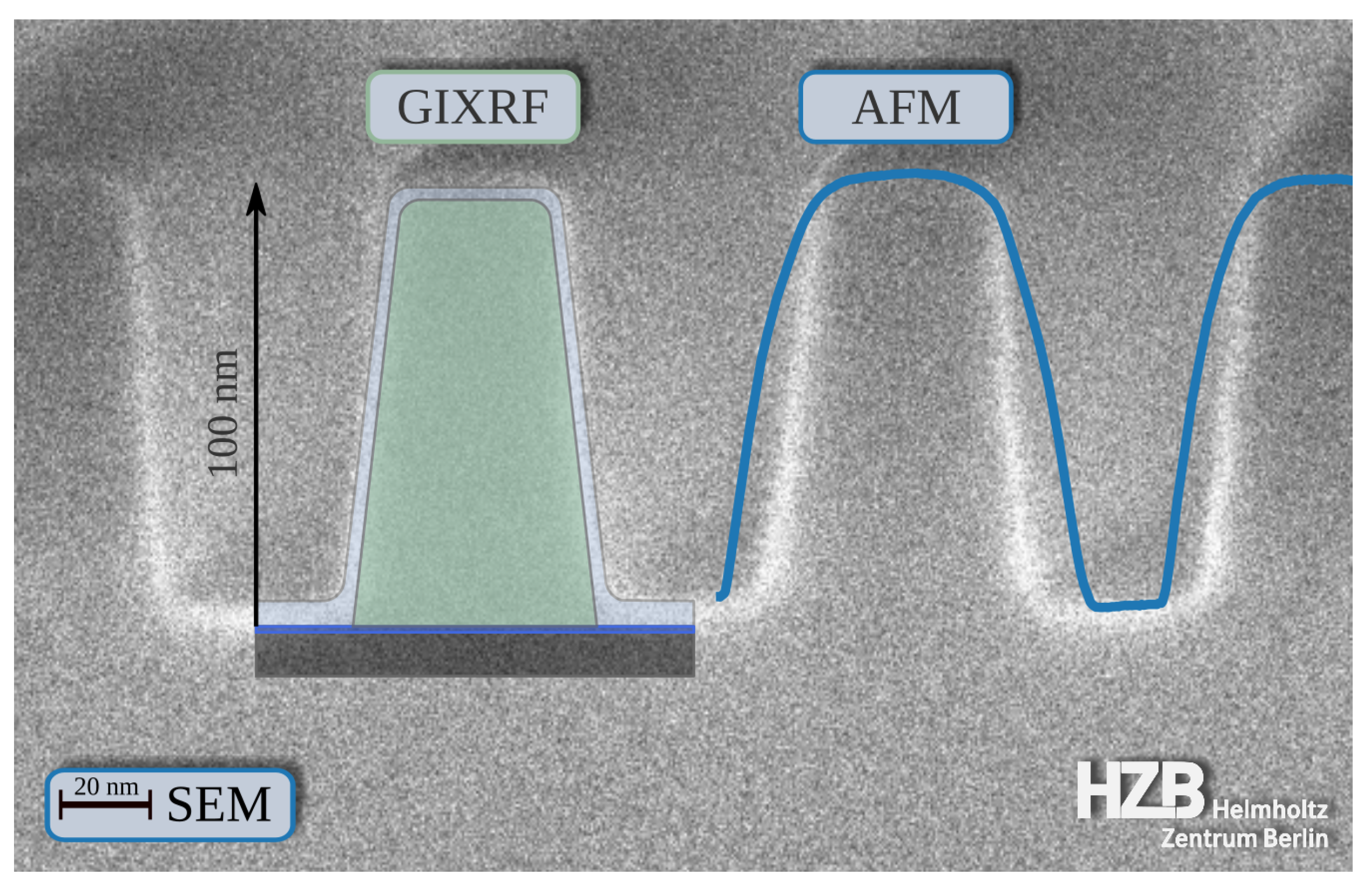

3.3. Comparison with SEM and AFM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Natarajan, S.; Agostinelli, M.; Akbar, S.; Bost, M.; Bowonder, A.; Chikarmane, V.; Chouksey, S.; Dasgupta, A.; Fischer, K.; Fu, Q.; et al. A 14nm logic technology featuring 2nd-generation FinFET, air-gapped interconnects, self-aligned double patterning and a 0.0588 μm2 SRAM cell size. In Proceedings of the Electron Devices Meeting (IEDM), 2014 IEEE International, San Francisco, CA, USA, 15–17 December 2014; pp. 3.7.1–3.7.3. [Google Scholar] [CrossRef]

- Markov, I.L. Limits on fundamental limits to computation. Nature 2014, 512, 147–154. [Google Scholar] [CrossRef] [Green Version]

- Moore, G.E. Cramming more components onto integrated circuits, Reprinted from Electronics, volume 38, number 8, April 19, 1965, pp.114 ff. IEEE Solid State Circ. Soc. Newsl. 2006, 11, 33–35. [Google Scholar] [CrossRef]

- Orji, N.G.; Badaroglu, M.; Barnes, B.M.; Beitia, C.; Bunday, B.D.; Celano, U.; Kline, R.J.; Neisser, M.; Obeng, Y.; Vladar, A.E. Metrology for the next generation of semiconductor devices. Nat. Electron. 2018, 1, 532–547. [Google Scholar] [CrossRef]

- Takamasu, K.; Okitou, H.; Takahashi, S.; Konno, M.; Inoue, O.; Kawada, H. Sub-nanometer Line Width and Line Profile Measurement for CD-SEM Calibration by Using STEM. In Proceedings of the SPIE Advanced Lithography, San Jose, CA, USA, 27 February 2011; p. 797108. [Google Scholar] [CrossRef]

- Erni, R.; Rossell, M.D.; Kisielowski, C.; Dahmen, U. Atomic-Resolution Imaging with a Sub-50-pm Electron Probe. Phys. Rev. Lett. 2009, 102, 096101. [Google Scholar] [CrossRef] [Green Version]

- Ukraintsev, V.A.; Baum, C.; Zhang, G.; Hall, C.L. The Role of AFM in Semiconductor Technology Development: The 65 nm Technology Node and Beyond. In Proceedings of the Microlithography 2005, San Jose, CA, USA, 28 February–3 March 2005; p. 127. [Google Scholar] [CrossRef]

- Franquet, A.; Douhard, B.; Melkonyan, D.; Favia, P.; Conard, T.; Vandervorst, W. Self Focusing SIMS: Probing thin film composition in very confined volumes. Appl. Surf. Sci. 2016, 365, 143–152. [Google Scholar] [CrossRef]

- Vandervorst, W.; Schulze, A.; Kambham, A.K.; Mody, J.; Gilbert, M.; Eyben, P. Dopant/carrier profiling for 3D-structures: Dopant/carrier profiling for 3D-structures. Phys. Status Solidi (C) 2014, 11, 121–129. [Google Scholar] [CrossRef]

- Mertens, H.; Ritzenthaler, R.; Pena, V.; Santoro, G.; Kenis, K.; Schulze, A.; Litta, E.D.; Chew, S.A.; Devriendt, K.; Chiarella, R.; et al. Vertically stacked gate-all-around Si nanowire transistors: Key Process Optimizations and Ring Oscillator Demonstration. In 2017 IEEE International Electron Devices Meeting (IEDM); IEEE: San Francisco, CA, USA, 2017; pp. 37.4.1–37.4.4. [Google Scholar] [CrossRef]

- Silver, R.; Germer, T.; Attota, R.; Barnes, B.M.; Bunday, B.; Allgair, J.; Marx, E.; Jun, J. Fundamental Limits of Optical Critical Dimension Metrology: A Simulation Study. In Proceedings of the SPIE Advanced Lithography, San Jose, CA, USA, 25 February 2007; p. 65180U. [Google Scholar] [CrossRef]

- Sunday, D.F.; List, S.; Chawla, J.S.; Kline, R.J. Determining the shape and periodicity of nanostructures using small-angle X-ray scattering. J. Appl. Crystallogr. 2015, 48, 1355–1363. [Google Scholar] [CrossRef]

- Levine, J.R.; Cohen, J.B.; Chung, Y.W.; Georgopoulos, P. Grazing-incidence small-angle X-ray scattering: New tool for studying thin film growth. J. Appl. Cryst. 1989, 22, 528–532. [Google Scholar] [CrossRef]

- Renaud, G.; Lazzari, R.; Leroy, F. Probing surface and interface morphology with Grazing Incidence Small Angle X-Ray Scattering. Surf. Sci. 2009, 64, 255–380. [Google Scholar] [CrossRef]

- Soltwisch, V.; Fernández Herrero, A.; Pflüger, M.; Haase, A.; Probst, J.; Laubis, C.; Krumrey, M.; Scholze, F. Reconstructing detailed line profiles of lamellar gratings from GISAXS patterns with a Maxwell solver. J. Appl. Crystallogr. 2017, 50, 1524–1532. [Google Scholar] [CrossRef] [Green Version]

- Herrero, A.F.; Pflüger, M.; Probst, J.; Scholze, F.; Soltwisch, V. Applicability of the Debye-Waller damping factor for the determination of the line-edge roughness of lamellar gratings. Opt. Express 2019, 27, 32490–32507. [Google Scholar] [CrossRef] [Green Version]

- de Boer, D.; Leenaers, A.; van den Hoogenhof, W. Glancing-incidence x-ray analysis of thin-layered materials: A review. X-Ray Spectrom. 1995, 24, 91–102. [Google Scholar] [CrossRef]

- Bedzyk, M.J.; Bommarito, G.M.; Schildkraut, J.S. X-ray standing waves at a reflecting mirror surface. Phys. Rev. Lett. 1989, 62, 1376–1379. [Google Scholar] [CrossRef]

- Golovchenko, J.A.; Patel, J.R.; Kaplan, D.R.; Cowan, P.L.; Bedzyk, M.J. Solution to the Surface Registration Problem Using X-Ray Standing Waves. Phys. Rev. Lett. 1982, 49, 560–563. [Google Scholar] [CrossRef] [Green Version]

- Soltwisch, V.; Hönicke, P.; Kayser, Y.; Eilbracht, J.; Probst, J.; Scholze, F.; Beckhoff, B. Element sensitive reconstruction of nanostructured surfaces with finite-elements and grazing incidence soft X-ray fluorescence. Nanoscale 2018, 10, 6177–6185. [Google Scholar] [CrossRef] [Green Version]

- Nikolaev, K.V.; Soltwisch, V.; Hönicke, P.; Scholze, F.; de la Rie, J.; Yakunin, S.N.; Makhotkin, I.A.; van de Kruijs, R.W.E.; Bijkerk, F. A semi-analytical approach for the characterization of ordered 3D nano structures using grazing-incidence X-ray fluorescence. J. Synchrotron Radiat. 2020, 27, 386–395. [Google Scholar] [CrossRef] [PubMed]

- Hönicke, P.; Andrle, A.; Kayser, Y.; Nikolaev, K.; Probst, J.; Scholze, F.; Soltwisch, V.; Weimann, T.; Beckhoff, B. Grazing incidence-X-ray fluorescence for a dimensional and compositional characterization of well-ordered 2D and 3D nanostructures. Nanotechnology 2020, 31, 505709. [Google Scholar] [CrossRef] [PubMed]

- Tomboc, G.M.; Kwon, T.; Joo, J.; Lee, K. High entropy alloy electrocatalysts: A critical assessment of fabrication and performance. J. Mater. Chem. 2020, 8, 14844–14862. [Google Scholar] [CrossRef]

- Hardian, R.; Liang, Z.; Zhang, X.; Szekely, G. Artificial intelligence: The silver bullet for sustainable materials development. Green Chem. 2020, 22, 7521–7528. [Google Scholar] [CrossRef]

- Jia, Y.; Hou, X.; Wang, Z.; Hu, X. Machine Learning Boosts the Design and Discovery of Nanomaterials. ACS Sustain. Chem. Eng. 2021, 9, 6130–6147. [Google Scholar] [CrossRef]

- Shahriari, B.; Swersky, K.; Wang, Z.; Adams, R.P.; De Freitas, N. Taking the human out of the loop: A review of Bayesian optimization. Proc. IEEE 2016, 104, 148–175. [Google Scholar] [CrossRef] [Green Version]

- Schneider, P.I.; Garcia Santiago, X.; Soltwisch, V.; Hammerschmidt, M.; Burger, S.; Rockstuhl, C. Benchmarking five global optimization approaches for nano-optical shape optimization and parameter reconstruction. ACS Photonics 2019, 6, 2726–2733. [Google Scholar] [CrossRef]

- Zhang, D.X.; Zheng, Y.X.; Cai, Q.Y.; Lin, W.; Wu, K.N.; Mao, P.H.; Zhang, R.J.; Zhao, H.B.; Chen, L.Y. Thickness-dependence of optical constants for Ta2O5 ultrathin films. Appl. Phys. A 2012, 108, 975–979. [Google Scholar] [CrossRef]

- Beckhoff, B.; Gottwald, A.; Klein, R.; Krumrey, M.; Müller, R.; Richter, M.; Scholze, F.; Thornagel, R.; Ulm, G. A quarter-century of metrology using synchrotron radiation by PTB in Berlin. Phys. Status Solidi (B) 2009, 246, 1415–1434. [Google Scholar] [CrossRef]

- Senf, F.; Flechsig, U.; Eggenstein, F.; Gudat, W.; Klein, R.; Rabus, H.; Ulm, G. A plane-grating monochromator beamline for the PTB undulators at BESSY II. J. Synchrotron Rad. 1998, 5, 780–782. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lubeck, J.; Beckhoff, B.; Fliegauf, R.; Holfelder, I.; Hönicke, P.; Müller, M.; Pollakowski, B.; Reinhardt, F.; Weser, J. A novel instrument for quantitative nanoanalytics involving complementary X-ray methodologies. Rev. Sci. Instrum. 2013, 84, 045106. [Google Scholar] [CrossRef]

- Hönicke, P.; Detlefs, B.; Nolot, E.; Kayser, Y.; Mühle, U.; Pollakowski, B.; Beckhoff, B. Reference-free grazing incidence X-ray fluorescence and reflectometry as a methodology for independent validation of X-ray reflectometry on ultrathin layer stacks and a depth-dependent characterization. J. Vac. Sci. Technol. A 2019, 37, 041502. [Google Scholar] [CrossRef]

- Beckhoff, B. Reference-free X-ray spectrometry based on metrology using synchrotron radiation. J. Anal. At. Spectrom. 2008, 23, 845–853. [Google Scholar] [CrossRef]

- Scholze, F.; Procop, M. Modelling the response function of energy dispersive X-ray spectrometers with silicon detectors. X-Ray Spectrom. 2009, 38, 312–321. [Google Scholar] [CrossRef]

- Andrle, A.; Hönicke, P.; Vinson, J.; Quintanilha, R.; Saadeh, Q.; Heidenreich, S.; Scholze, F.; Soltwisch, V. The anisotropy in the optical constants of quartz crystals for soft X-rays. J. Appl. Crystallogr. 2021, 54, 402–408. [Google Scholar] [CrossRef]

- Siewert, F.; Löchel, B.; Buchheim, J.; Eggenstein, F.; Firsov, A.; Gwalt, G.; Kutz, O.; Lemke, S.; Nelles, B.; Rudolph, I.; et al. Gratings for synchrotron and FEL beamlines: A project for the manufacture of ultra-precise gratings at Helmholtz Zentrum Berlin. J. Synchrotron Radiat. 2018, 25, 91–99. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schoonjans, T.; Brunetti, A.; Golosio, B.; del Rio, M.S.; Solé, V.; Ferrero, C.; Vincze, L. The xraylib library for X-ray–matter interactions. Recent developments. Spectrochim. Acta B 2011, 66, 776–784. [Google Scholar] [CrossRef]

- Hönicke, P.; Kolbe, M.; Krumrey, M.; Unterumsberger, R.; Beckhoff, B. Experimental determination of the oxygen K-shell fluorescence yield using thin SiO2 and Al2O3 foils. Spectrochim. Acta B 2016, 124, 94–98. [Google Scholar] [CrossRef]

- Sherman, J. The theoretical derivation of fluorescent X-ray intensities from mixtures. Spectrochim. Acta 1955, 7, 283–306. [Google Scholar] [CrossRef]

- Garcia-Santiago, X.; Schneider, P.I.; Rockstuhl, C.; Burger, S. Shape design of a reflecting surface using Bayesian Optimization. J. Phys. Conf. Ser. 2018, 963. [Google Scholar] [CrossRef]

- Andrle, A.; Hönicke, P.; Schneider, P.I.; Kayser, Y.; Hammerschmidt, M.; Burger, S.; Scholze, F.; Beckhoff, B.; Soltwisch, V. Grazing incidence x-ray fluorescence based characterization of nanostructures for element sensitive profile reconstruction. Proc. SPIE Model. Asp. Opt. Metrol. VII 2019, 11057, 110570M. [Google Scholar] [CrossRef]

- Schneider, P.I.; Hammerschmidt, M.; Zschiedrich, L.; Burger, S. Using Gaussian process regression for efficient parameter reconstruction. Proc. SPIE 2019, 10959, 1095911. [Google Scholar]

- JCMwave GmbH. Paramter Reference. 2020. Available online: https://docs.jcmwave.com/JCMsuite/html/ParameterReference/index.html?version=4.0.3 (accessed on 17 September 2020).

- Henn, M.A.; Gross, H.; Scholze, F.; Wurm, M.; Elster, C.; Bär, M. A maximum likelihood approach to the inverse problem of scatterometry. Optics Express 2012, 20, 12771. [Google Scholar] [CrossRef]

- Chason, E.; Mayer, T.M. Thin film and surface characterization by specular X-ray reflectivity. Crit. Rev. Solid State Mater. Sci. 1997, 22, 1–67. [Google Scholar] [CrossRef]

- Kennedy, G.P.; Buiu, O.; Taylor, S. Oxidation of silicon nitride films in an oxygen plasma. J. Appl. Phys. 1999, 85, 3319–3326. [Google Scholar] [CrossRef]

- Foreman-Mackey, D.; Hogg, D.W.; Lang, D.; Goodman, J. emcee: The MCMC Hammer. PASP 2013, 125, 306–312. [Google Scholar] [CrossRef] [Green Version]

- Haase, A.; Bajt, S.; Hönicke, P.; Soltwisch, V.; Scholze, F. Multiparameter characterization of subnanometre Cr/Sc multilayers based on complementary measurements. J. Appl. Crystallogr. 2016, 49, 2161–2171. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Henke, B.L.; Gullikson, E.M.; Davis, J.C. X-Ray Interactions: Photoabsorption, Scattering, Transmission, and Reflection at E = 50–30,000 eV, Z = 1–92. At. Data Nucl. Data Tables 1993, 54, 181–342. [Google Scholar] [CrossRef] [Green Version]

- Andrle, A.; Farchmin, N.; Hagemann, P.; Heidenreich, S.; Soltwisch, V.; Steidl, G. Invertible Neural Networks versus MCMC for Posterior Reconstruction in Grazing Incidence X-Ray Fluorescence. Available online: https://arxiv.org/abs/2102.03189 (accessed on 2 June 2021).

- Martin, Y.; Wickramasinghe, H.K. Method for imaging sidewalls by atomic force microscopy. Appl. Phys. Lett. 1994, 64, 2498–2500. [Google Scholar] [CrossRef]

| Parameter | Intial | Config. | Ratio | |||

|---|---|---|---|---|---|---|

| Name | Value | A | B | |||

| nm | 90 | 0.67 | ||||

| nm | 25 | 0.85 | ||||

| 88 | 1.0 | |||||

| nm | 3 | 0.83 | ||||

| nm | 5 | 0.17 | ||||

| 1 | 1 | |||||

| 1 | - | |||||

| Parameter | Reconstructed | Confidence Intervals |

|---|---|---|

| Name | Value | Value |

| nm | ||

| nm | ||

| nm | ||

| nm | ||

| nm | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrle, A.; Hönicke, P.; Gwalt, G.; Schneider, P.-I.; Kayser, Y.; Siewert, F.; Soltwisch, V. Shape- and Element-Sensitive Reconstruction of Periodic Nanostructures with Grazing Incidence X-ray Fluorescence Analysis and Machine Learning. Nanomaterials 2021, 11, 1647. https://doi.org/10.3390/nano11071647

Andrle A, Hönicke P, Gwalt G, Schneider P-I, Kayser Y, Siewert F, Soltwisch V. Shape- and Element-Sensitive Reconstruction of Periodic Nanostructures with Grazing Incidence X-ray Fluorescence Analysis and Machine Learning. Nanomaterials. 2021; 11(7):1647. https://doi.org/10.3390/nano11071647

Chicago/Turabian StyleAndrle, Anna, Philipp Hönicke, Grzegorz Gwalt, Philipp-Immanuel Schneider, Yves Kayser, Frank Siewert, and Victor Soltwisch. 2021. "Shape- and Element-Sensitive Reconstruction of Periodic Nanostructures with Grazing Incidence X-ray Fluorescence Analysis and Machine Learning" Nanomaterials 11, no. 7: 1647. https://doi.org/10.3390/nano11071647

APA StyleAndrle, A., Hönicke, P., Gwalt, G., Schneider, P.-I., Kayser, Y., Siewert, F., & Soltwisch, V. (2021). Shape- and Element-Sensitive Reconstruction of Periodic Nanostructures with Grazing Incidence X-ray Fluorescence Analysis and Machine Learning. Nanomaterials, 11(7), 1647. https://doi.org/10.3390/nano11071647