Preparation and Properties of Electrospun Phenylethynyl—Terminated Polyimide Nano-Fibrous Membranes with Potential Applications as Solvent-Free and High-Temperature Resistant Adhesives for Harsh Environments

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Measurements

2.3. Synthesis of PETI Resins

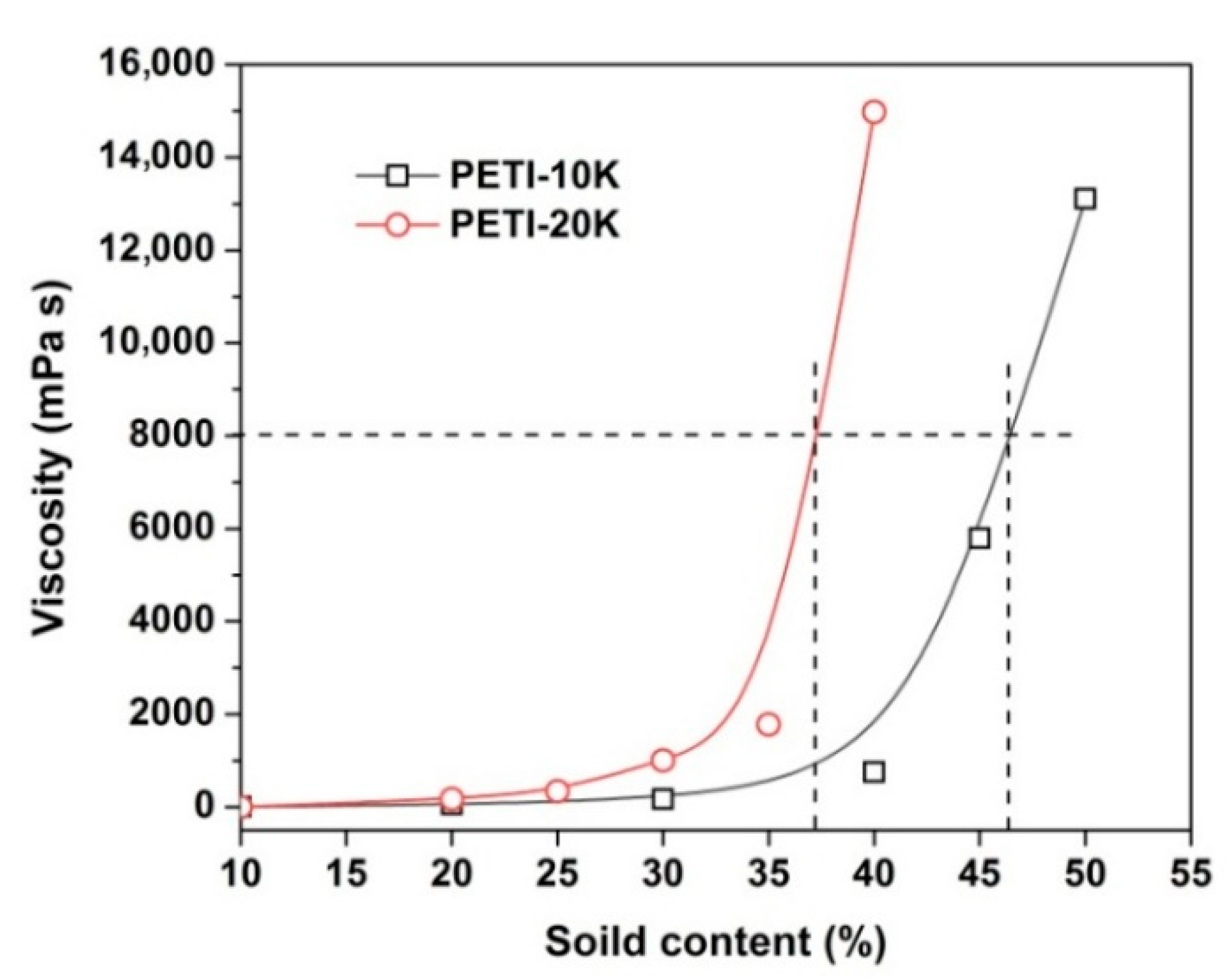

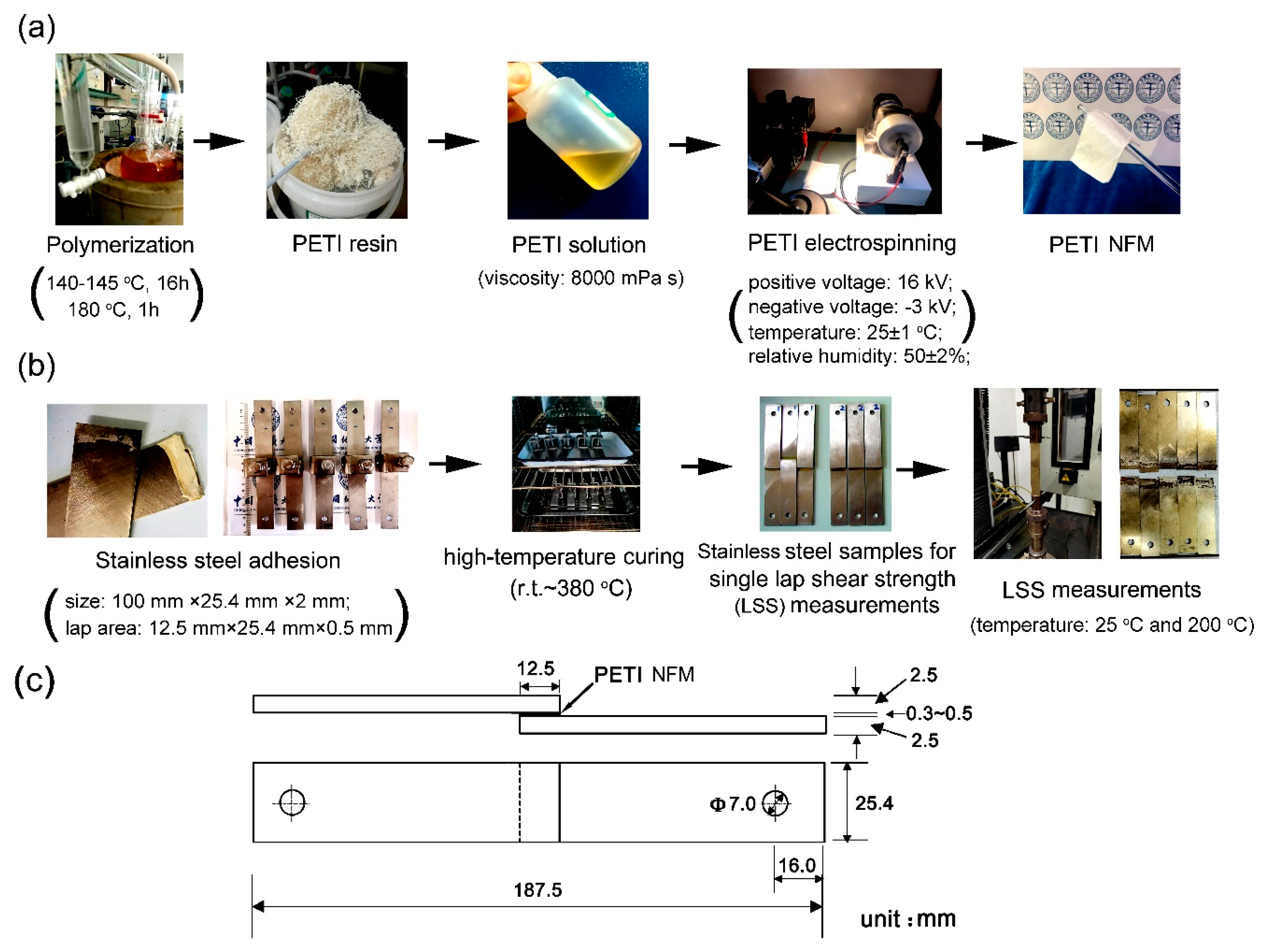

2.4. Electrospinning Preparation of PETI NFMs

2.5. Preparation of Stainless Steel Samples Adhered with the PETI NFMs

3. Results and Discussion

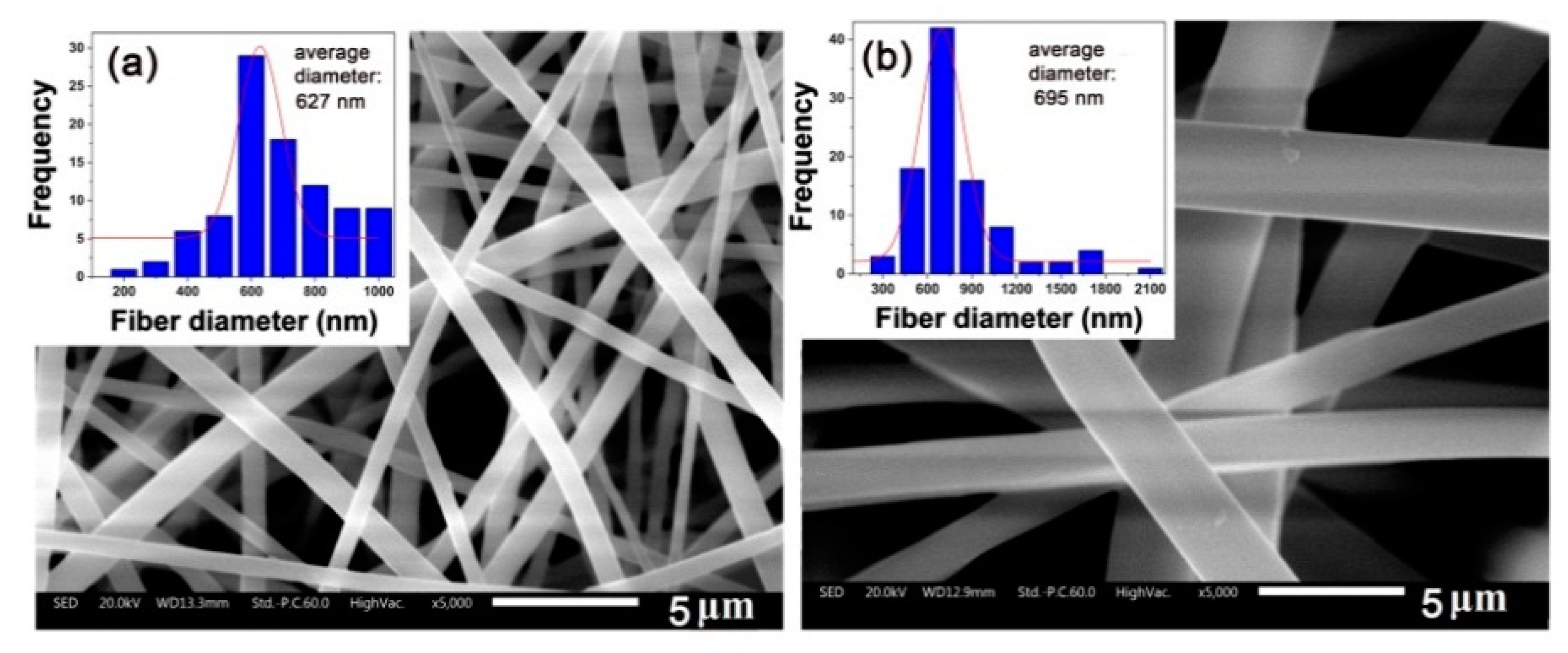

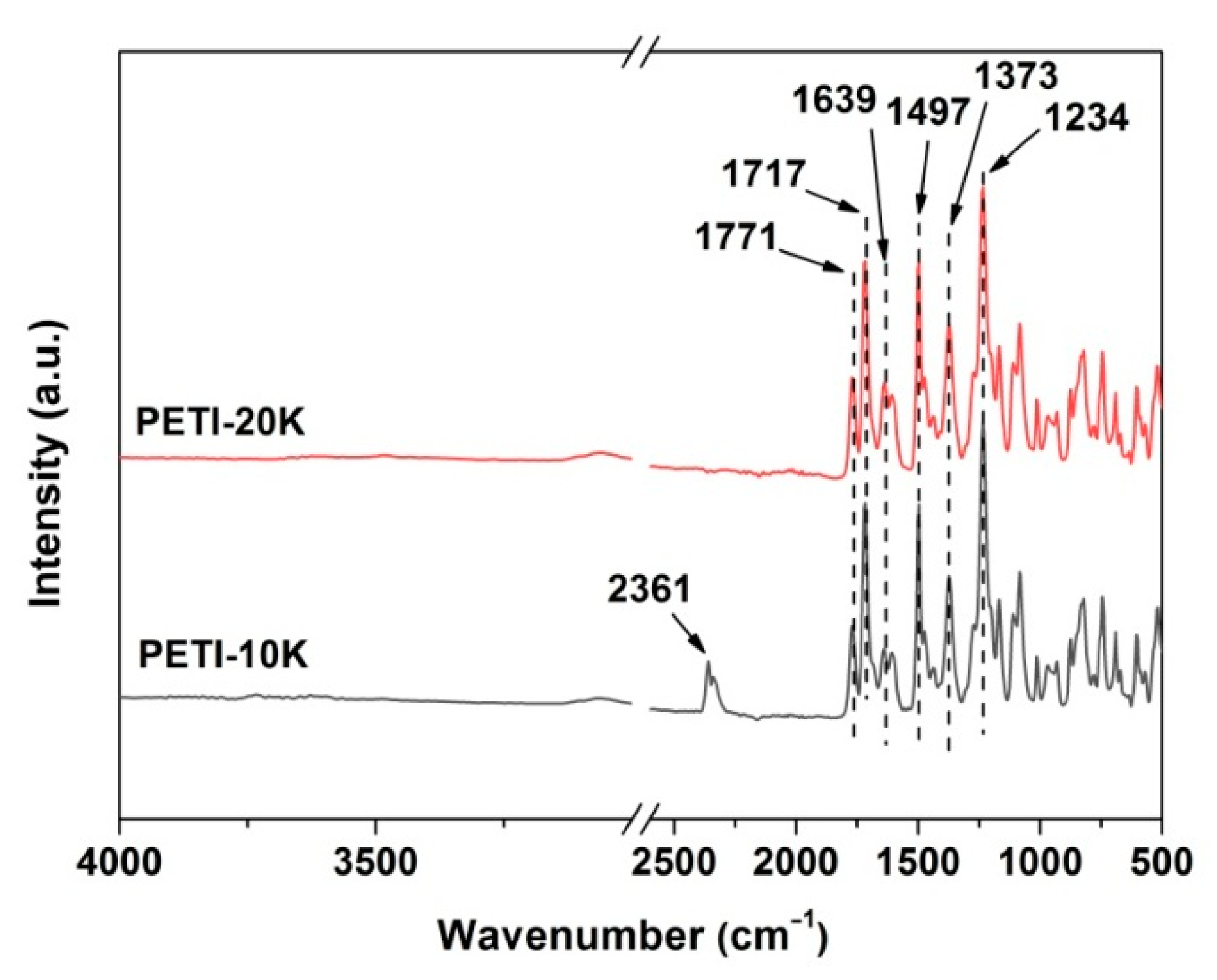

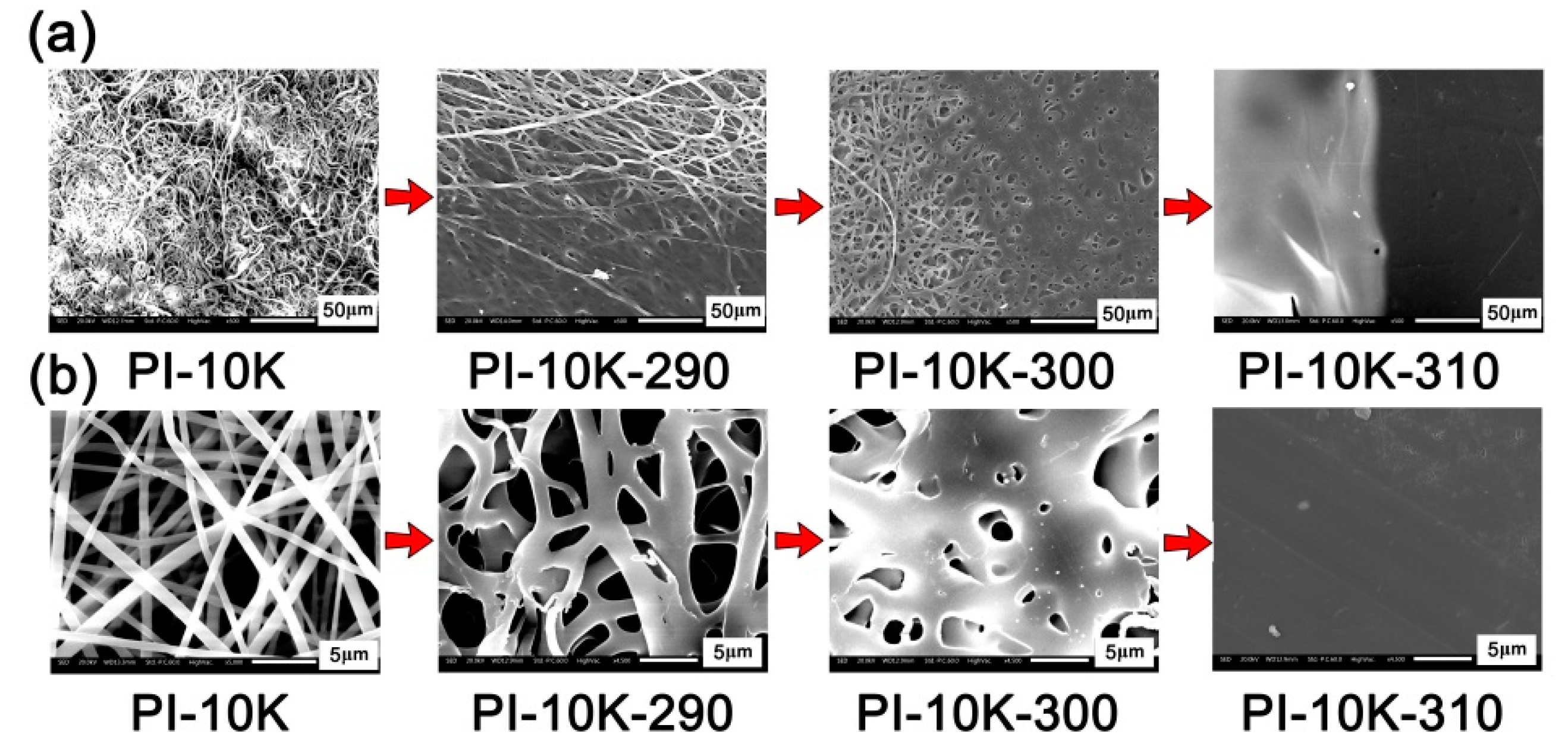

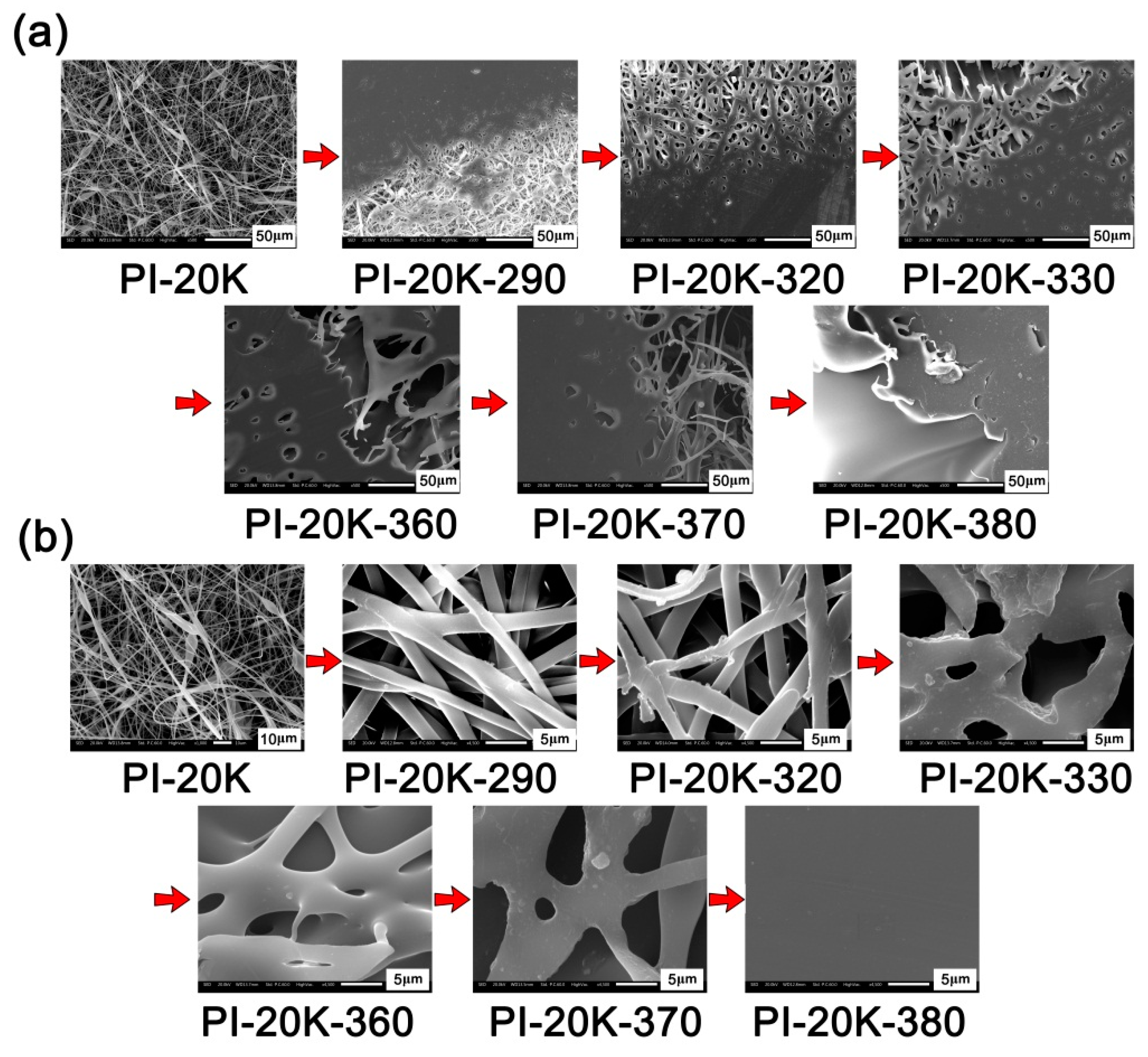

3.1. PI resins Synthesis and Electrospun PI NFMs Preparation

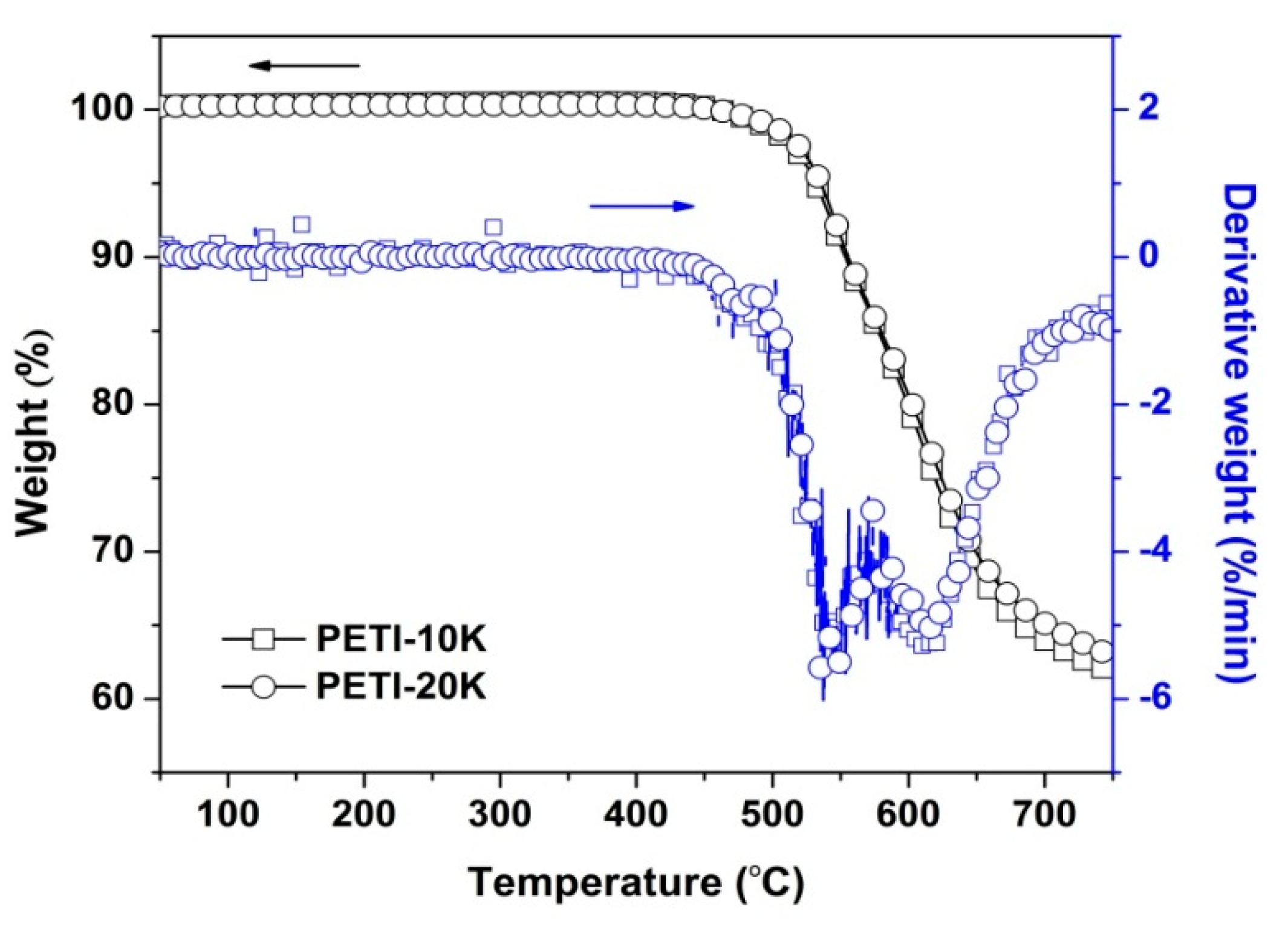

3.2. Thermal Properties

3.3. Adhesion Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bishopp, J. Adhesives for aerospace structures. In Handbook of Adhesives and Surface Preparation; Ebnesajjad, S., Ed.; Elsevier: Oxford, UK, 2011; pp. 301–344. [Google Scholar]

- Marques, E.A.S.; Da Silva, L.F.M.; Banea, M.D.; Carbas, R.J.C. Adhesive joints for low- and high-temperature use: An overview. J. Adhes. 2015, 91, 556–585. [Google Scholar] [CrossRef]

- Rabilloud, G. Heat-resistant adhesives. In Handbook of Adhesives and Surface Preparation; Ebnesajjad, S., Ed.; Elsevier: Oxford, UK, 2011; pp. 185–220. [Google Scholar]

- Clair, A.K.S.; Clair, T.L.S. Addition polyimide adhesives containing various end groups. Polym. Eng. Sci. 1982, 22, 9–14. [Google Scholar] [CrossRef]

- Xu, S.; Guo, S.; Dillard, D.A. Evaluation of the long-term durability of high-performance polyimide adhesives for bonding titanium. J. Adhes. 2004, 80, 1153–1172. [Google Scholar]

- An, H.Y.; Zhan, M.S.; Wang, K. Synthesis and properties of fluorene-based polyimide adhesives. Polym. Eng. Sci. 2011, 51, 1533–1540. [Google Scholar] [CrossRef]

- Ratta, V.; Stancik, E.J.; Ayambem, A.; Pavatareddy, H.; McGrath, J.E.; Wilkes, G.L. A melt-processable semicrystalline polyimide structural adhesive based on 1,3-bis(4-aminophenoxy)benzene and 3,3’,4,4’-biphenyltetracarboxylic dianhydride. Polymer 1999, 40, 1889–1902. [Google Scholar] [CrossRef]

- Akram, M.; Jansen, K.M.B.; Ernst, L.J.; Bhowmik, S. Atmospheric plasma modification of polyimide sheet for jointing to titanium with high temperature adhesive. Int. J. Adhes. Adhes. 2016, 65, 63–69. [Google Scholar] [CrossRef]

- Naito, K.; Onta, M.; Kogo, Y. The effect of adhesive thickness on tensile and shear strength of polyimide adhesive. Int. J. Adhes. Adhes. 2012, 36, 77–85. [Google Scholar] [CrossRef]

- Saeed, M.B.; Zhan, M.S. Adhesive strength of partially imidized thermoplastic polyimide films in bonded joints. Int. J. Adhes. Adhes. 2007, 27, 9–19. [Google Scholar] [CrossRef]

- Liu, C.; Sun, M.; Zhang, B.; Zhang, X.; Li, J.; Xue, G.; Zhang, X.; Zhou, H. Synthesis and characterization of bisphthalonitrile-terminated polyimide precursors with unique advantages in processing and adhesive properties. Polymer 2021, 212, 123290. [Google Scholar] [CrossRef]

- Acar, O.; Varis, S.; Isik, T.; Tirkes, S.; Demir, M.M. Synthesis and characterization of novel high temperature structural adhesives based on nadic end capper MDA-BTDA-ODA copolyimide. Mater. Res. Express 2018, 5, 105305. [Google Scholar] [CrossRef]

- Kadiyala, A.K.; Sharma, M.; Bijwe, J. Exploration of thermoplastic polyimide as high temperature adhesive and understanding the interfacial chemistry using XPS, TOF-SIMS and Raman spectroscopy. Mater. Des. 2016, 109, 622–633. [Google Scholar] [CrossRef]

- Progar, D.J. Evaluation of polyimide films as adhesives. J. Adhes. Sci. Tech. 1987, 1, 53–68. [Google Scholar] [CrossRef]

- Kim, Y.; Wu, X.; Oh, J.H. Fabrication of triboelectric nanogenerators based on electrospun polyimide nanofibers membrane. Sci. Rep. 2020, 10, 2742. [Google Scholar] [CrossRef] [PubMed]

- Yi, B.; Zhao, Y.; Tian, E.; Li, J.; Ren, Y. High-performance polyimide nanofiber membranes prepared by electrospinning. High Perform. Polym. 2019, 31, 438–448. [Google Scholar] [CrossRef]

- Rogalski, J.J.; Zhang, H.; Yao, J.; Bastiaansen, C.W.M.; Peijs, T. High-modulus rotary jet spun co-polyimide nanofibers and their composites. Nanocomposites 2020, 6, 1–11. [Google Scholar] [CrossRef]

- Ding, Y.; Hou, H.; Zhao, Y.; Zhu, Z.; Fong, H. Electrospun polyimide nanofibers and their applications. Prog. Polym. Sci. 2016, 61, 67–103. [Google Scholar] [CrossRef]

- Kausar, A. Holistic insights on polyimide nanocomposite nanofiber. Polym. Plast. Technol. Mater. 2020, 59, 1621–1639. [Google Scholar]

- Fuat, T.; Tibor, H.; Gyorgy, S. Scavenging organic micropollutants from water with nanofibrous hypercrosslinked cyclodextrin membranes derived from green resources. Chem. Eng. J. 2021, 419, 129443. [Google Scholar]

- Wang, H.T.; Xu, H.; Li, H.; Liu, X.; Du, Z.Q.; Yu, W.D. Electrospun polyurethane/zeolitic imidazolate framework nanofibrous membrane with superior stability for filtering performance. ACS Appl. Polym. Mater. 2021, 3, 710–719. [Google Scholar] [CrossRef]

- Levente, C.; Fuat, T.; Mahmoud, A.A.; Abdulaziz, A.; Peter, M.B.; Gyorgy, S. Electrospun adsorptive nanofibrous membranes from ion exchange polymers to snare textile dyes from wastewater. Adv. Mater. Technol. 2021, 2000955. [Google Scholar]

- Zhao, C.; Si, Y.; Zhu, S.; Kevin, B.; Ameer, Y.T.; Pan, T.; Sun, G. Diffusion of protein molecules through microporous nanofibrous polyacrylonitrile membranes. ACS Appl. Polym. Mater. 2021, 3, 1618–1627. [Google Scholar] [CrossRef]

- Hao, Z.; Wu, J.; Wang, C.; Liu, J. Electrospun polyimide.metal-organic framework nanofibrous membrane with superior thermal stability for efficient PM2.5 capture. ACS Appl. Mater. Interfaces 2019, 11, 11904–11909. [Google Scholar] [CrossRef]

- Guo, C.Y.; Wang, Q.W.; Liu, J.G.; Huangfu, M.G.; Wu, X.; Zhang, Y.; Zhang, X.M. Electrospun polyimide ultrafine non-woven fabrics with high whiteness and good thermal stability from organo-soluble semi-alicyclic polyimides: Preparation and properties. Express Polym. Lett. 2019, 13, 724–738. [Google Scholar] [CrossRef]

- Qi, L.; Guo, C.Y.; Huangfu, M.G.; Zhang, Y.; Yin, L.M.; Wu, L.; Liu, J.G.; Zhang, X.M. Enhancement of solvent resistance of polyimide electrospun mat via the UV-assisted electrospinning and photosensitive varnish. Polymers 2019, 11, 2055. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.Y.; Liu, J.G.; Yin, L.M.; Huangfu, M.G.; Zhang, Y.; Wu, X.; Zhang, X.M. Preparation and characterization of electrospun polyimide microfibrous mats with high whiteness and high thermal stability from organo-soluble polyimides containing rigid-rod moieties. Fibers Polym. 2018, 19, 1706–1714. [Google Scholar] [CrossRef]

- Qi, L.; Guo, C.Y.; Huangfu, M.G.; Zhang, Y.; Wu, L.; Zhi, X.X.; Liu, J.G.; Zhang, X.M. Highly solvent-stable polyimide ultrafine fibrous membranes fabricated by a novel ultraviolet-assisted electrospinning technique via organo-soluble intrinsically negative photosensitive varnishes. Express Polym. Lett. 2021, 15, 72–87. [Google Scholar] [CrossRef]

- Sun, H.; Huo, H.; Nie, K.; Yang, S.; Fan, L. Phenylethynyl terminated oligoimides derived from 3,3’,4,4’-diphenylsulfonetetracarboxylic dianhydride and their adhesive properties. Eur. Polym. J. 2009, 45, 1169–1178. [Google Scholar] [CrossRef]

- Yu, P.; Wang, Y.; Yu, J.; Zhu, J.; Hu, Z. Influence of different ratios of a-ODPA/a-BPDA on the properties of phenylethynyl terminated polyimide. J. Polym. Res. 2018, 25, 110. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, B.; Li, P. Thermal oxidative crosslinking of phenolphthalein-based cardo polyimides with enhanced gas permeability and selectivity. J. Membr. Sci. 2018, 546, 90–99. [Google Scholar] [CrossRef]

- Xu, R.; Li, X.; Jin, X.; Hou, M.; He, J.; Lu, Y.; Song, C.; Wang, T. Thermal crosslinking of a novel membrane derived from phenolphthalein-based cardo poly(arylene ether ketone) to enhance CO2/CH4 separation performance and plasticization resistance. J. Membr. Sci. 2019, 586, 306–317. [Google Scholar] [CrossRef]

- Yang, C.P.; Lin, J.H. Preparation and properties of aromatic polyamides and polyimides derived from 3,3-bis[4-(4-aminophenoxy)phenyl]phthalide. J. Polym. Sci. Part A Polym. Chem. 1994, 32, 423–433. [Google Scholar] [CrossRef]

- Yuan, L.; Ji, M.; Yang, S. Molecular weight controlled poly(amic acid) resins end-capped with phenylethynyl groups for manufacturing advanced polyimide films. J. Appl. Polym. Sci. 2017, 134, 45168. [Google Scholar] [CrossRef]

| PI | [ƞ]inh 1 (dL g−1) | Molecular Weight 2 (×104 g mol−1) | Solubility 3 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mn | Mw | PDI | NMP | DMAc | DMF | DMSO | CHCl3 | THF | ||

| PETI-10K | 0.43 | 2.36 | 3.48 | 1.47 | ++ | ++ | ++ | ++ | +− | +− |

| PETI-20K | 0.62 | 3.63 | 5.95 | 1.64 | ++ | ++ | ++ | ++ | +− | +− |

| PI-ref 4 | 1.21 | 19.0 | 25.8 | 1.36 | ++ | ++ | ++ | ++ | +− | − |

| Samples | T5% 1 (°C) | T10% 1 (°C) | Rw700 1 (%) | Tg 1 (°C) | LSS25 2 (MPa) | LSS200 2 (MPa) |

|---|---|---|---|---|---|---|

| PETI-10K | 531.7 | 553.3 | 64.0 | 270.6 | 26.4 ± 1.2 | 23.2 ± 1.3 |

| PETI-20K | 535.3 | 555.2 | 65.1 | 274.8 | 24.4 ± 1.3 | 21.2 ± 1.4 |

| PI-ref | 514.1 | 527.6 | 59.0 | 288.7 | 18.6 ± 0.8 | 16.7 ± 1.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, H.-r.; Shen, D.-x.; Jia, Y.-j.; An, Y.-c.; Wu, H.; Wei, X.-y.; Zhang, Y.; Zhi, X.-x.; Liu, J.-g. Preparation and Properties of Electrospun Phenylethynyl—Terminated Polyimide Nano-Fibrous Membranes with Potential Applications as Solvent-Free and High-Temperature Resistant Adhesives for Harsh Environments. Nanomaterials 2021, 11, 1525. https://doi.org/10.3390/nano11061525

Qi H-r, Shen D-x, Jia Y-j, An Y-c, Wu H, Wei X-y, Zhang Y, Zhi X-x, Liu J-g. Preparation and Properties of Electrospun Phenylethynyl—Terminated Polyimide Nano-Fibrous Membranes with Potential Applications as Solvent-Free and High-Temperature Resistant Adhesives for Harsh Environments. Nanomaterials. 2021; 11(6):1525. https://doi.org/10.3390/nano11061525

Chicago/Turabian StyleQi, Hao-ran, Deng-xiong Shen, Yan-jiang Jia, Yuan-cheng An, Hao Wu, Xin-ying Wei, Yan Zhang, Xin-xin Zhi, and Jin-gang Liu. 2021. "Preparation and Properties of Electrospun Phenylethynyl—Terminated Polyimide Nano-Fibrous Membranes with Potential Applications as Solvent-Free and High-Temperature Resistant Adhesives for Harsh Environments" Nanomaterials 11, no. 6: 1525. https://doi.org/10.3390/nano11061525

APA StyleQi, H.-r., Shen, D.-x., Jia, Y.-j., An, Y.-c., Wu, H., Wei, X.-y., Zhang, Y., Zhi, X.-x., & Liu, J.-g. (2021). Preparation and Properties of Electrospun Phenylethynyl—Terminated Polyimide Nano-Fibrous Membranes with Potential Applications as Solvent-Free and High-Temperature Resistant Adhesives for Harsh Environments. Nanomaterials, 11(6), 1525. https://doi.org/10.3390/nano11061525