Size-Dependent Electroluminescence and Current-Voltage Measurements of Blue InGaN/GaN µLEDs down to the Submicron Scale

Abstract

:1. Introduction

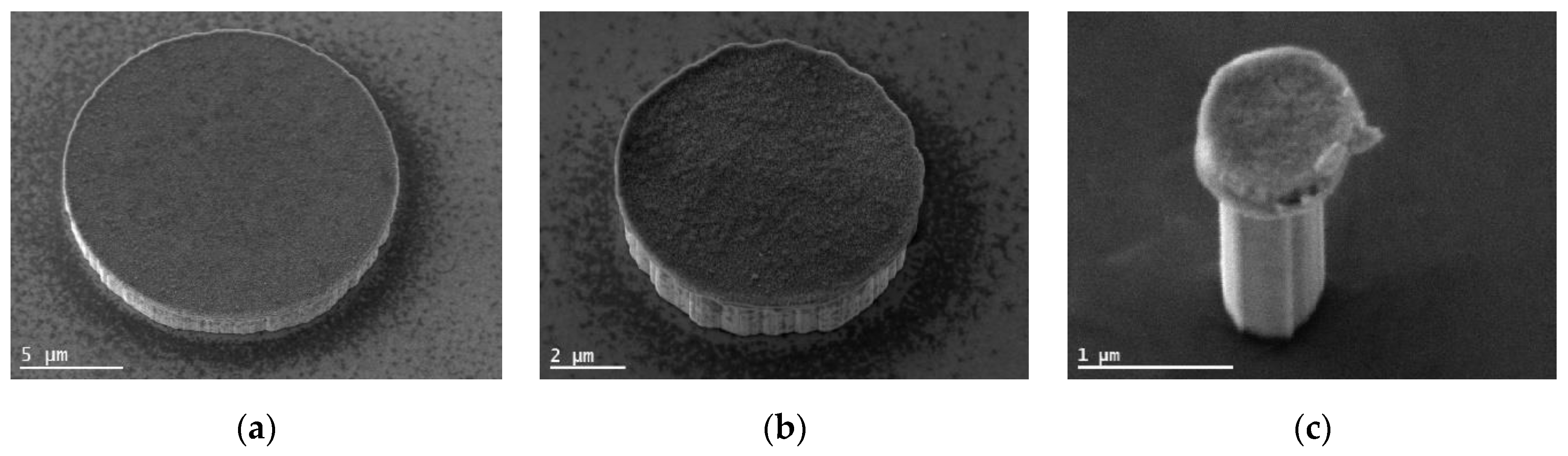

2. Materials and Methods

2.1. Samples and Fabrication

2.2. Instrumentation

2.3. Measurement Methods

3. Results and Discussion

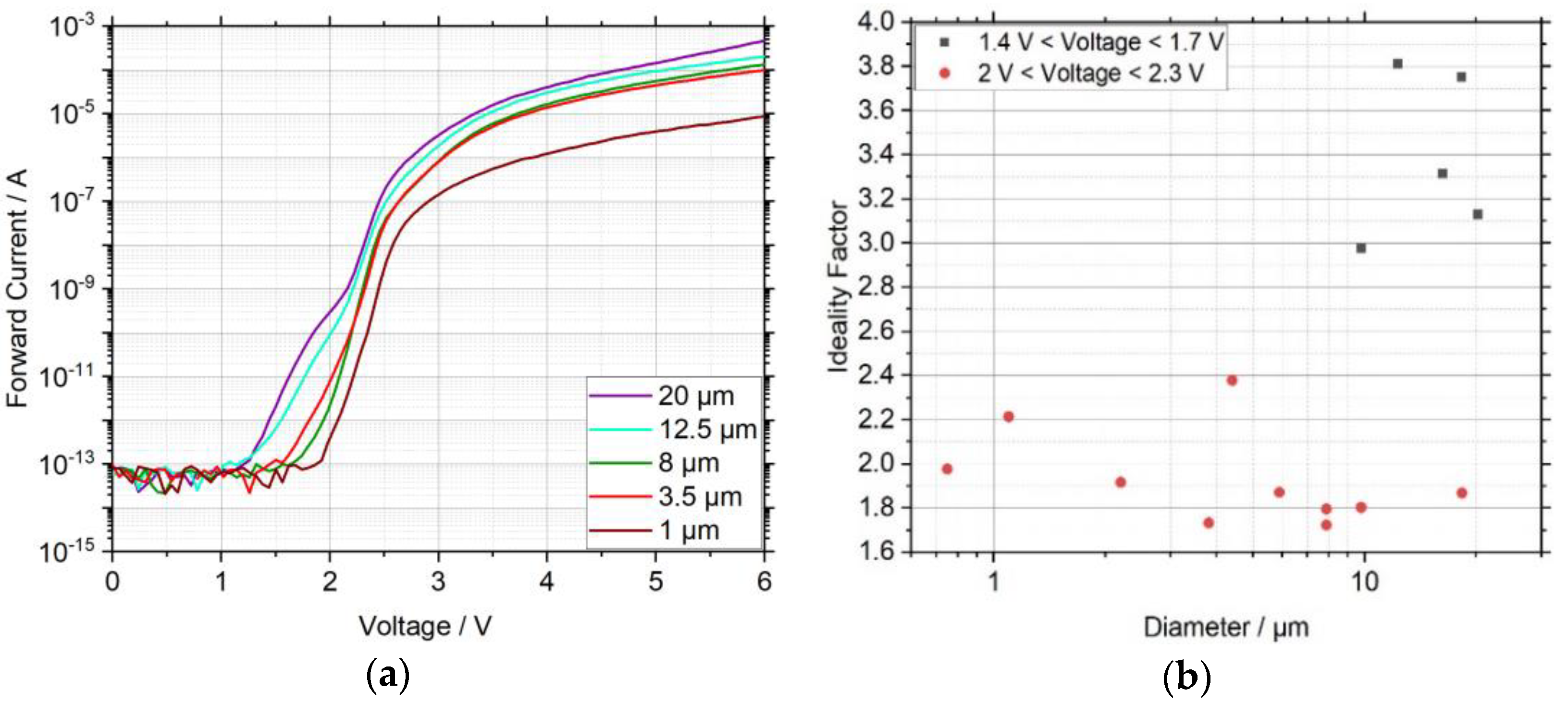

3.1. Electrical Properties

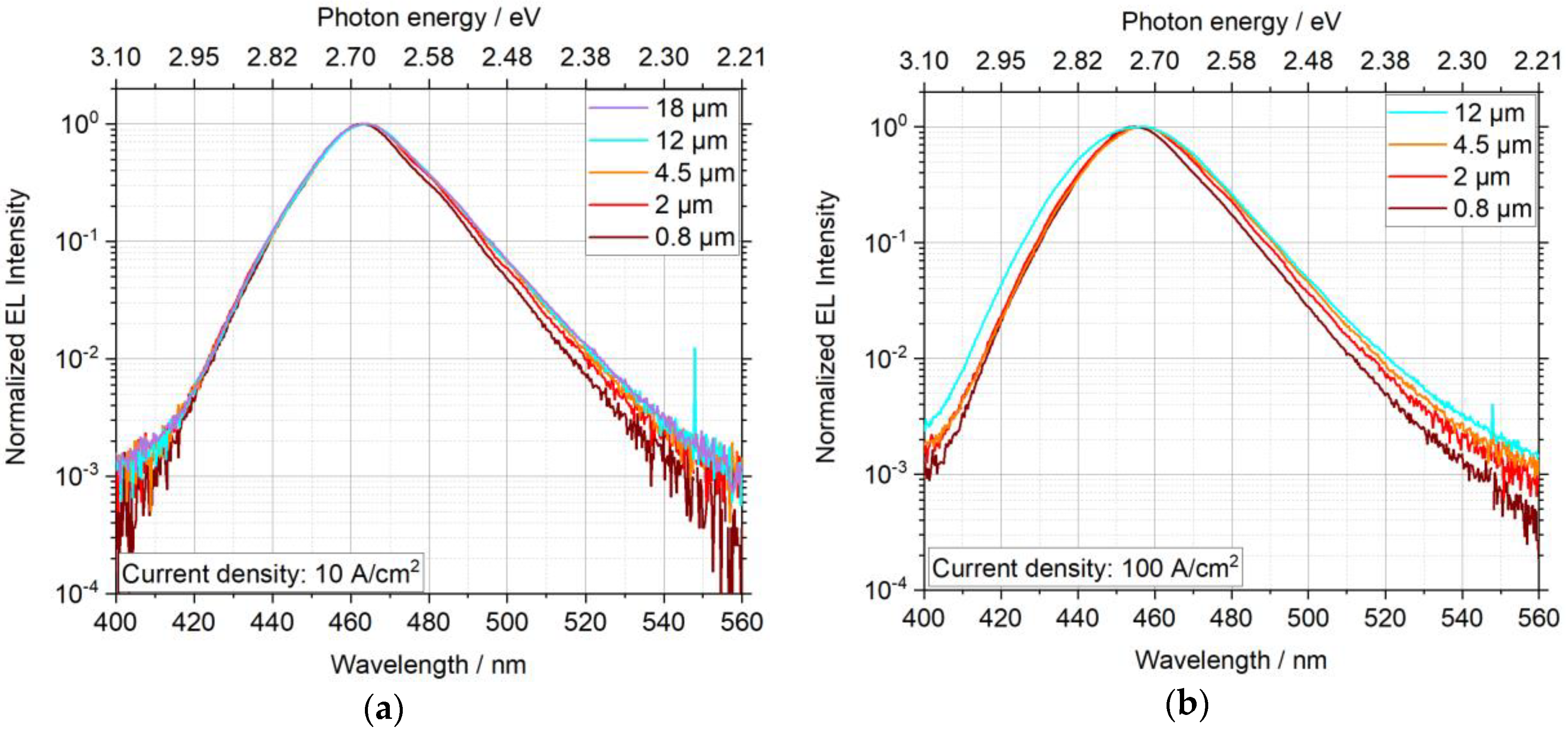

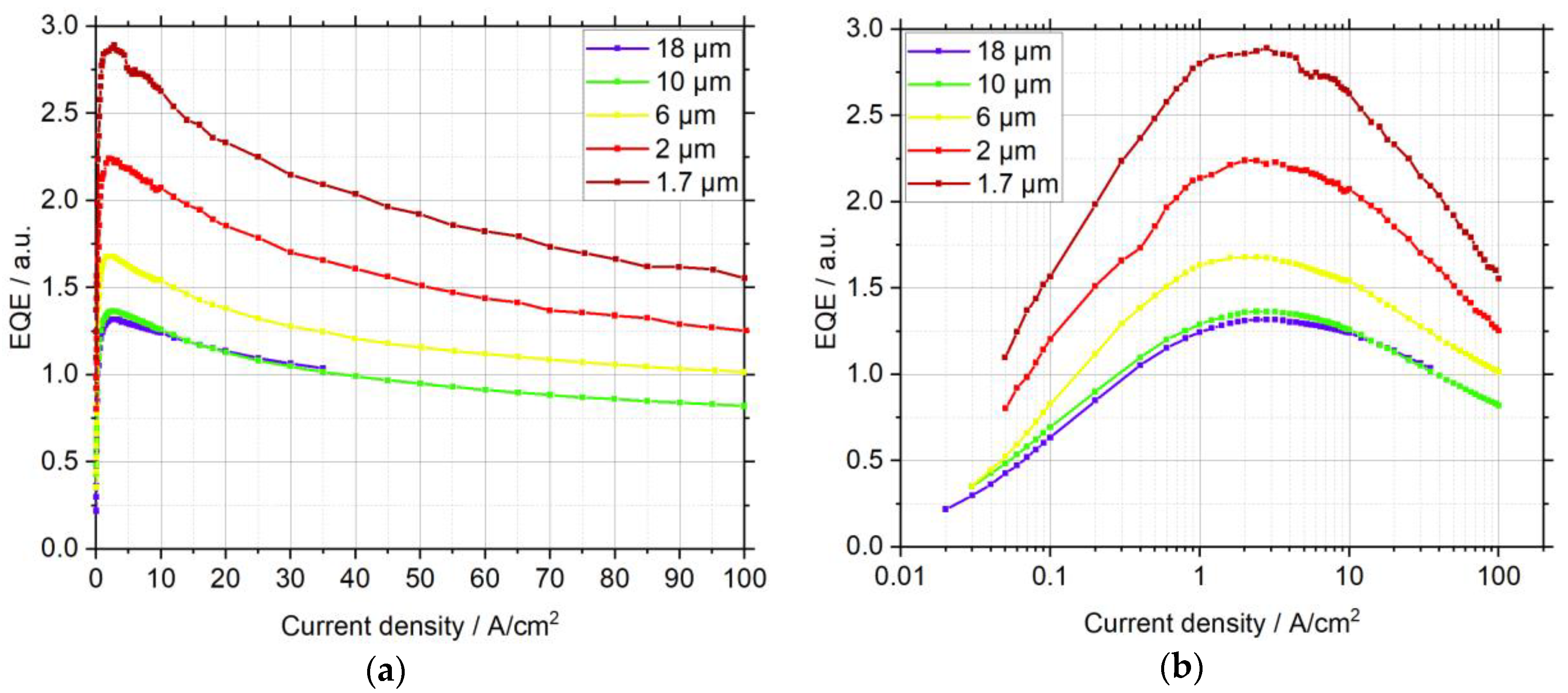

3.2. Optical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tao, Y.B.; Wang, S.Y.; Chen, Z.Z.; Gong, Z.; Xie, E.Y.; Chen, Y.J.; Zhang, Y.F.; Mckendry, J.; Massoubre, D.; Gu, E.D.; et al. Size effect on efficiency droop of blue light emitting diode. Phys. Status Solidi Curr. Top. Solid State Phys. 2012, 9, 616–619. [Google Scholar] [CrossRef]

- Tian, P.; McKendry, J.J.D.; Gong, Z.; Guilhabert, B.; Watson, I.M.; Gu, E.; Chen, Z.; Zhang, G.; Dawson, M.D. Size-dependent efficiency and efficiency droop of blue InGaN micro-light emitting diodes. Appl. Phys. Lett. 2012, 101. [Google Scholar] [CrossRef]

- Olivier, F.; Tirano, S.; Dupré, L.; Aventurier, B.; Largeron, C.; Templier, F. Influence of size-reduction on the performances of GaN-based micro-LEDs for display application. J. Lumin. 2017, 191, 112–116. [Google Scholar] [CrossRef]

- Olivier, F.; Daami, A.; Licitra, C.; Templier, F. Shockley-Read-Hall and Auger non-radiative recombination in GaN based LEDs: A size effect study. Appl. Phys. Lett. 2017, 111. [Google Scholar] [CrossRef]

- Daami, A.; Olivier, F.; Dupré, L.; Henry, F.; Templier, F. 59-4: Invited Paper: Electro-optical size-dependence investigation in GaN micro-LED devices. SID Symp. Dig. Tech. Pap. 2018, 49, 790–793. [Google Scholar] [CrossRef]

- Konoplev, S.S.; Bulashevich, K.A.; Karpov, S.Y. From Large-Size to Micro-LEDs: Scaling Trends Revealed by Modeling. Phys. Status Solidi Appl. Mater. Sci. 2018, 215, 1700508. [Google Scholar] [CrossRef]

- Wong, M.S.; Lee, C.; Myers, D.J.; Hwang, D.; Kearns, J.A.; Li, T.; Speck, J.S.; Nakamura, S.; Denbaars, S.P. Size-independent peak efficiency of III-nitride micro-light-emitting-diodes using chemical treatment and sidewall passivation. Appl. Phys. Express 2019, 12, 097004. [Google Scholar] [CrossRef]

- Wasisto, H.S.; Prades, J.D.; Gülink, J.; Waag, A. Beyond solid-state lighting: Miniaturization, hybrid integration, and applications of GaN nano-and micro-LEDs. Appl. Phys. Rev. 2019, 6. [Google Scholar] [CrossRef] [Green Version]

- Ryu, H.Y.; Ha, K.H.; Chae, J.H.; Kim, K.S.; Son, J.K.; Nam, O.H.; Park, Y.J.; Shim, J.I. Evaluation of radiative efficiency in InGaN blue-violet laser-diode structures using electroluminescence characteristics. Appl. Phys. Lett. 2006, 89, 171106. [Google Scholar] [CrossRef]

- Schubert, M.F.; Chhajed, S.; Kim, J.K.; Schubert, E.F.; Koleske, D.D.; Crawford, M.H.; Lee, S.R.; Fischer, A.J.; Thaler, G.; Banas, M.A. Effect of dislocation density on efficiency droop in GaInNGaN light-emitting diodes. Appl. Phys. Lett. 2007, 91. [Google Scholar] [CrossRef] [Green Version]

- Ryu, H.Y.; Kim, H.S.; Shim, J.I. Rate equation analysis of efficiency droop in InGaN light-emitting diodes. Appl. Phys. Lett. 2009, 95, 2007–2010. [Google Scholar] [CrossRef]

- Dai, Q.; Shan, Q.; Wang, J.; Chhajed, S.; Cho, J.; Schubert, E.F.; Crawford, M.H.; Koleske, D.D.; Kim, M.H.; Park, Y. Carrier recombination mechanisms and efficiency droop in GaInN/GaN light-emitting diodes. Appl. Phys. Lett. 2010, 97. [Google Scholar] [CrossRef] [Green Version]

- Piprek, J. Efficiency droop in nitride-based light-emitting diodes. Phys. Status Solidi Appl. Mater. Sci. 2010, 207, 2217–2225. [Google Scholar] [CrossRef]

- Dai, Q.; Shan, Q.; Cho, J.; Schubert, E.F.; Crawford, M.H.; Koleske, D.D.; Kim, M.H.; Park, Y. On the symmetry of efficiency-versus-carrier-concentration curves in GaInN/GaN light-emitting diodes and relation to droop-causing mechanisms. Appl. Phys. Lett. 2011, 98, 96–99. [Google Scholar] [CrossRef]

- Cho, J.; Schubert, E.F.; Kim, J.K. Efficiency droop in light-emitting diodes: Challenges and countermeasures. Laser Photon. Rev. 2013, 7, 408–421. [Google Scholar] [CrossRef]

- Karpov, S. ABC-model for interpretation of internal quantum efficiency and its droop in III-nitride LEDs: A review. Opt. Quantum Electron. 2015, 47, 1293–1303. [Google Scholar] [CrossRef]

- Nippert, F.; Karpov, S.; Pietzonka, I.; Galler, B.; Wilm, A.; Kure, T.; Nenstiel, C.; Callsen, G.; Straburg, M.; Lugauer, H.J.; et al. Determination of recombination coefficients in InGaN quantum-well light-emitting diodes by small-signal time-resolved photoluminescence. Jpn. J. Appl. Phys. 2016, 55. [Google Scholar] [CrossRef] [Green Version]

- Bezshlyakh, D.D.; Spende, H.; Weimann, T.; Hinze, P.; Bornemann, S.; Gülink, J.; Canals, J.; Prades, J.D.; Dieguez, A.; Waag, A.; et al. Accepted Article Preview: Published ahead of advance online publication Directly addressable GaN-based Nano-LED arrays: Fabrication and electro-optical characterization. Nature 2020. [Google Scholar] [CrossRef]

- Yu, F.; Strempel, K.; Fatahilah, M.F.; Zhou, H.; Romer, F.; Bakin, A.; Witzigmann, B.; Schumacher, H.W.; Wasisto, H.S.; Waag, A. Normally off Vertical 3-D GaN Nanowire MOSFETs with Inverted p-GaN Channel. IEEE Trans. Electron Devices 2018, 65, 2439–2445. [Google Scholar] [CrossRef]

- Mariana, S.; Gülink, J.; Hamdana, G.; Yu, F.; Strempel, K.; Spende, H.; Yulianto, N.; Granz, T.; Prades, J.D.; Peiner, E.; et al. Vertical GaN Nanowires and Nanoscale Light-Emitting-Diode Arrays for Lighting and Sensing Applications. ACS Appl. Nano Mater. 2019, 2, 4133–4142. [Google Scholar] [CrossRef]

- Schubert, E.F. Light-Emitting Diodes; Cambridge University Press: Cambridge, UK, 2006; ISBN 9780511790546. [Google Scholar]

- Perlin, P.; Osiński, M.; Eliseev, P.G.; Smagley, V.A.; Mu, J.; Banas, M.; Sartori, P. Low-temperature study of current and electroluminescence in InGaN/AlGaN/GaN double-heterostructure blue light-emitting diodes. Appl. Phys. Lett. 1996, 69, 1680–1682. [Google Scholar] [CrossRef] [Green Version]

- Cao, X.A.; Stokes, E.B.; Sandvik, P.M.; LeBoeuf, S.F.; Kretchmer, J.; Walker, D. Diffusion and tunneling currents in GaN/InGaN multiple quantum well light-emitting diodes. IEEE Electron Device Lett. 2002, 23, 535–537. [Google Scholar] [CrossRef]

- Lee, S.W.; Oh, D.C.; Goto, H.; Ha, J.S.; Lee, H.J.; Hanada, T.; Cho, M.W.; Yao, T.; Hong, S.K.; Lee, H.Y.; et al. Origin of forward leakage current in GaN-based light-emitting devices. Appl. Phys. Lett. 2006, 89. [Google Scholar] [CrossRef]

- Yan, D.; Lu, H.; Chen, D.; Zhang, R.; Zheng, Y. Forward tunneling current in GaN-based blue light-emitting diodes. Appl. Phys. Lett. 2010, 96, 94–97. [Google Scholar] [CrossRef]

- Boroditsky, M.; Gontijo, I.; Jackson, M.; Vrijen, R.; Yablonovitch, E.; Krauss, T.; Cheng, C.C.; Scherer, A.; Bhat, R.; Krames, M. Surface recombination measurements on III-V candidate materials for nanostructure light-emitting diodes. J. Appl. Phys. 2000, 87, 3497–3504. [Google Scholar] [CrossRef] [Green Version]

- Choi, H.W.; Jeon, C.W.; Dawson, M.D.; Edwards, P.R.; Martin, R.W.; Tripathy, S. Mechanism of enhanced light output efficiency in InGaN-based microlight emitting diodes. J. Appl. Phys. 2003, 93, 5978–5982. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wolter, S.; Spende, H.; Gülink, J.; Hartmann, J.; Wehmann, H.-H.; Waag, A.; Lex, A.; Avramescu, A.; Lugauer, H.-J.; Malm, N.v.; et al. Size-Dependent Electroluminescence and Current-Voltage Measurements of Blue InGaN/GaN µLEDs down to the Submicron Scale. Nanomaterials 2021, 11, 836. https://doi.org/10.3390/nano11040836

Wolter S, Spende H, Gülink J, Hartmann J, Wehmann H-H, Waag A, Lex A, Avramescu A, Lugauer H-J, Malm Nv, et al. Size-Dependent Electroluminescence and Current-Voltage Measurements of Blue InGaN/GaN µLEDs down to the Submicron Scale. Nanomaterials. 2021; 11(4):836. https://doi.org/10.3390/nano11040836

Chicago/Turabian StyleWolter, Stefan, Hendrik Spende, Jan Gülink, Jana Hartmann, Hergo-Heinrich Wehmann, Andreas Waag, Andreas Lex, Adrian Avramescu, Hans-Jürgen Lugauer, Norwin von Malm, and et al. 2021. "Size-Dependent Electroluminescence and Current-Voltage Measurements of Blue InGaN/GaN µLEDs down to the Submicron Scale" Nanomaterials 11, no. 4: 836. https://doi.org/10.3390/nano11040836

APA StyleWolter, S., Spende, H., Gülink, J., Hartmann, J., Wehmann, H.-H., Waag, A., Lex, A., Avramescu, A., Lugauer, H.-J., Malm, N. v., Drolet, J.-J., & Strassburg, M. (2021). Size-Dependent Electroluminescence and Current-Voltage Measurements of Blue InGaN/GaN µLEDs down to the Submicron Scale. Nanomaterials, 11(4), 836. https://doi.org/10.3390/nano11040836