Cellulose Nanofiber Composite with Bimetallic Zeolite Imidazole Framework for Electrochemical Supercapacitors

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

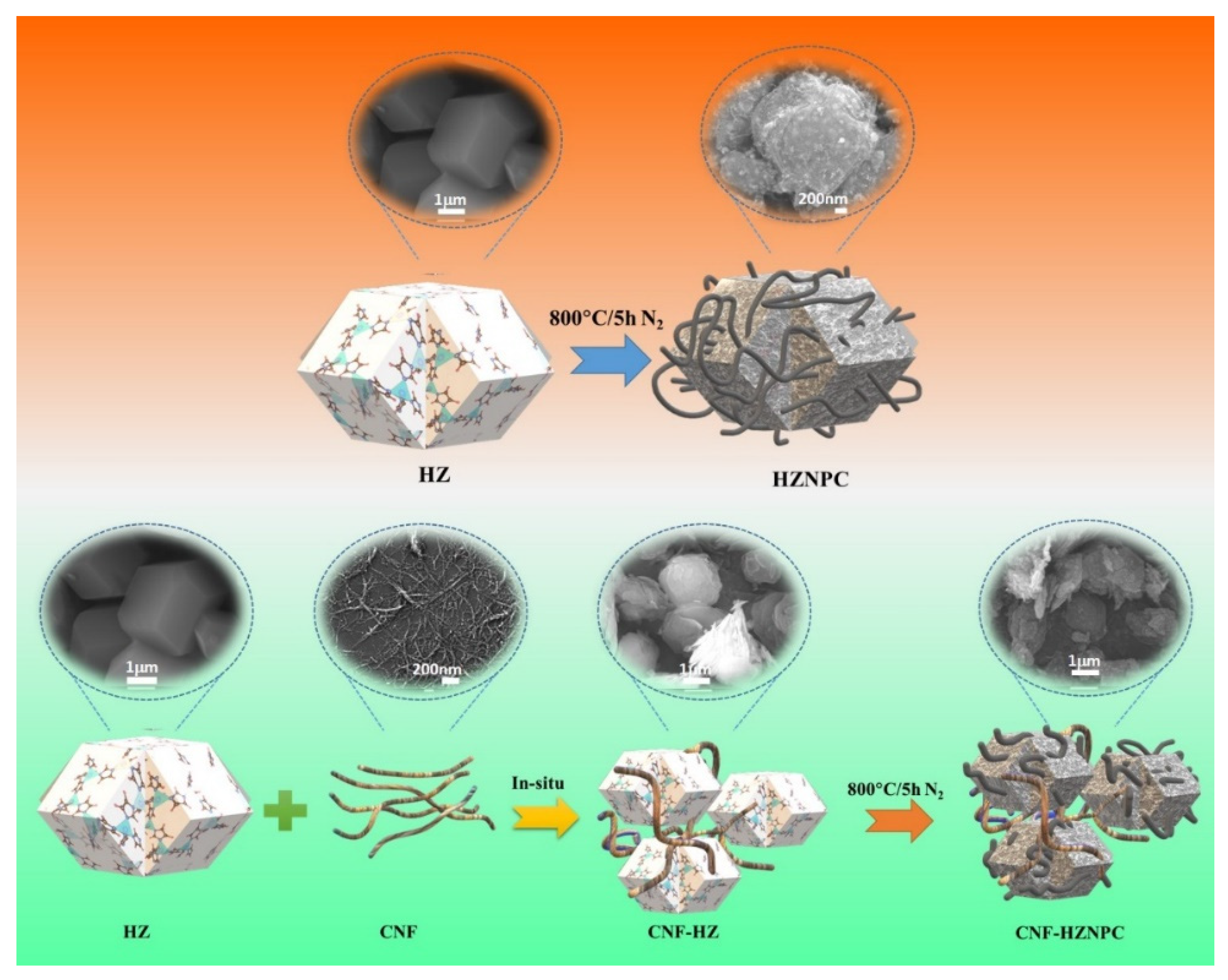

2.2. Synthesis of CNF–HZ Composites

2.3. Characterization

2.4. Electrochemical Study

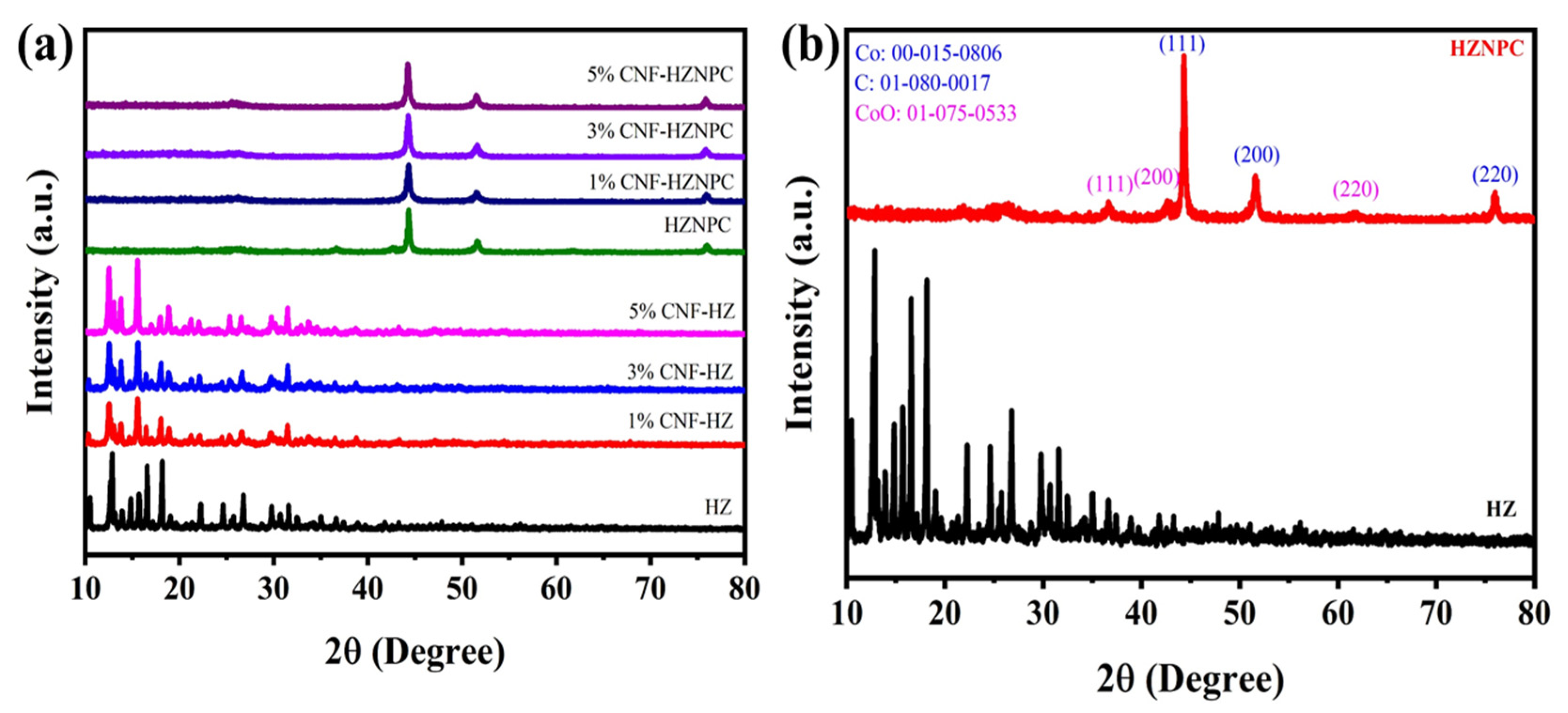

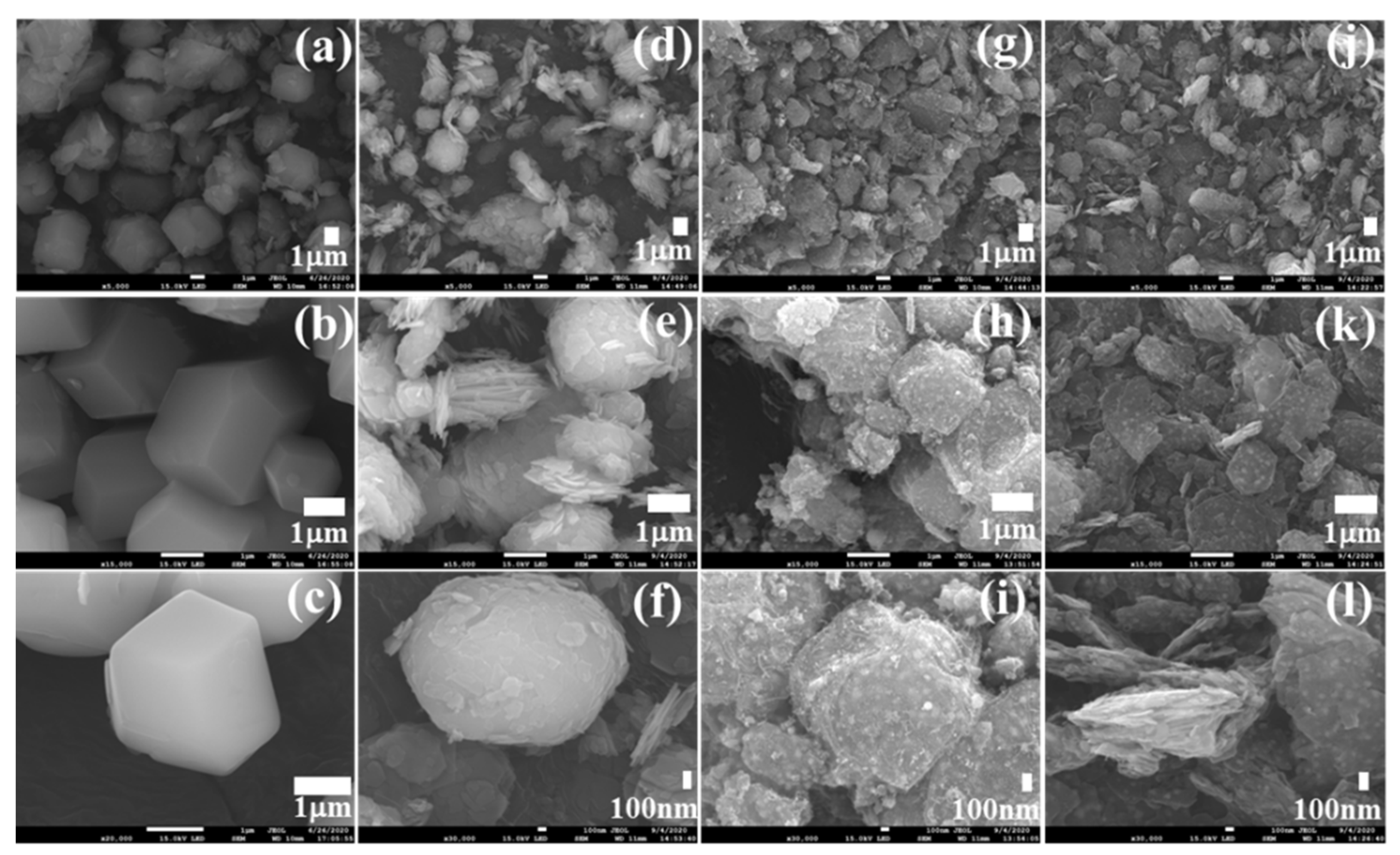

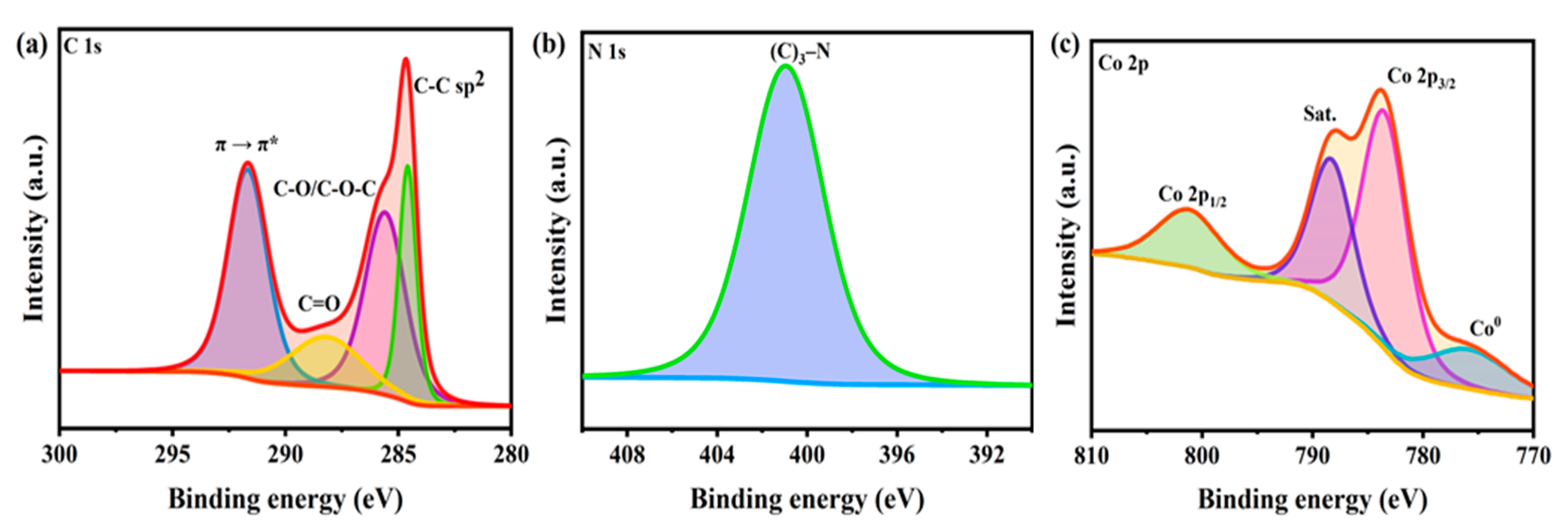

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, B.K.; Sy, S.; Yu, A.; Zhang, J. Electrochemical Supercapacitors for Energy Storage and Conversion. In Handbook of Clean Energy Systms; John Wiley & Sons, Ltd.: Chichester, UK, 2015; pp. 1–25. [Google Scholar] [CrossRef]

- Chen, T.W.; Ramachandran, R.; Chen, S.M.; Kavitha, N.; Dinakaran, K.; Kannan, R.; Anushya, G.; Bhuvana, N.; Jeyapragasam, T.; Mariyappan, V.; et al. Developing low-cost, high performance, robust and sustainable perovskite electrocatalytic materials in the electrochemical sensors and energy sectors: “An overview”. Catalysts 2020, 10, 938. [Google Scholar] [CrossRef]

- Dubal, D.P.; Ayyad, O.; Ruiz, V.; Gómez-Romero, P. Hybrid energy storage: The merging of battery and supercapacitor chemistries. Chem. Soc. Rev. 2015, 44, 1777–1790. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Stoller, M.D.; Ganesh, K.J.; Cai, W.; Ferreira, P.J.; Pirkle, A.; Wallace, R.M.; Cychosz, K.A.; Thommes, M.; et al. Carbon-based supercapacitors produced by activation of grapheme. Science 2011, 332, 1537–1541. [Google Scholar] [CrossRef]

- Yi, T.F.; Pan, J.J.; Wei, T.T.; Li, Y.; Cao, G. NiCo2S4-based nanocomposites for energy storage in supercapacitors and batteries. Nano Today 2020, 33, 100894. [Google Scholar] [CrossRef]

- Shinde, S.K.; Ghodake, G.S.; Maile, N.C.; Yadav, H.M.; Jagadale, A.D.; Jalak, M.B.; Kadam, A.A.; Ramesh, S.; Bathula, C.; Kim, D.Y. Designing of nanoflakes anchored nanotubes-like MnCo2S4/halloysite composites for advanced battery like supercapacitor application. Electrochim. Acta 2020, 341, 135973. [Google Scholar] [CrossRef]

- Tian, S.; Li, B.; Zhang, B.; Wang, Y.; Yang, X.; Ye, H.; Xia, Z.; Zheng, G. Preparation of Co3O4/NF Anode for Lithium-ion Batteries. J. Electrochem. Sci. Technol. 2020, 2020, 384–391. [Google Scholar] [CrossRef]

- Xu, C.; Kong, X.; Zhou, S.; Zheng, B.; Huo, F.; Strømme, M. Interweaving metal-organic framework-templated Co-Ni layered double hydroxide nanocages with nanocellulose and carbon nanotubes to make flexible and foldable electrodes for energy storage devices. J. Mater. Chem. A 2018, 6, 24050–24057. [Google Scholar] [CrossRef]

- Yadav, H.M.; Nath, N.C.D.; Kim, J.; Shinde, S.K.; Ramesh, S.; Hossain, F.; Ibukun, O.; Lee, J.J. Nickel-Graphene nanoplatelet deposited on carbon fiber as binder-free electrode for electrochemical supercapacitor application. Polymers 2020, 12, 1666. [Google Scholar] [CrossRef]

- Zhuo, H.; Hu, Y.; Chen, Z.; Zhong, L. Cellulose carbon aerogel/PPy composites for high-performance supercapacitor. Carbohydr. Polym. 2019, 215, 322–329. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, S.; Yadav, H.M.; Lee, Y.-J.; Hong, G.-W.; Kathalingam, A.; Sivasamy, A.; Kim, H.-S.H.S.; Kim, H.-S.H.S.; Kim, J.-H. Porous materials of nitrogen doped graphene oxide@SnO2 electrode for capable supercapacitor application. Sci. Rep. 2019, 9, 12622. [Google Scholar] [CrossRef] [PubMed]

- Salunkhe, R.R.; Kaneti, Y.V.; Kim, J.; Kim, J.H.; Yamauchi, Y. Nanoarchitectures for Metal-Organic Framework-Derived Nanoporous Carbons toward Supercapacitor Applications. Acc. Chem. Res. 2016, 49, 2796–2806. [Google Scholar] [CrossRef]

- Bae, J. Recent advances on multi-dimensional nanocarbons for superapacitors: A review. J. Electrochem. Sci. Technol. 2018, 9, 251–259. [Google Scholar] [CrossRef]

- Xue, Q.; Sun, J.; Huang, Y.; Zhu, M.; Pei, Z.; Li, H.; Wang, Y.; Li, N.; Zhang, H.; Zhi, C. Recent Progress on Flexible and Wearable Supercapacitors. Small 2017, 13. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Yao, M.; Niu, Z. Smart supercapacitors from materials to devices. InfoMat 2020, 2, 113–125. [Google Scholar] [CrossRef]

- Wang, W.; Wang, A. Nanocomposite of carboxymethyl cellulose and attapulgite as a novel pH-sensitive superabsorbent: Synthesis, characterization and properties. Carbohydr. Polym. 2010, 82, 83–91. [Google Scholar] [CrossRef]

- Biswal, D.R.; Singh, R.P. Characterisation of carboxymethyl cellulose and polyacrylamide graft copolymer. Carbohydr. Polym. 2004, 57, 379–387. [Google Scholar] [CrossRef]

- Dutta, S.; Kim, J.; Ide, Y.; Ho Kim, J.; Hossain, M.S.A.; Bando, Y.; Yamauchi, Y.; Wu, K.C.W. 3D network of cellulose-based energy storage devices and related emerging applications. Mater. Horiz. 2017, 4, 522–545. [Google Scholar] [CrossRef]

- Xing, J.; Tao, P.; Wu, Z.; Xing, C.; Liao, X.; Nie, S. Nanocellulose-graphene composites: A promising nanomaterial for flexible supercapacitors. Carbohydr. Polym. 2019, 207, 447–459. [Google Scholar] [CrossRef] [PubMed]

- Caballero, Á.; Morales, J.; Sánchez, L. A simple route to high performance nanometric metallic materials for Li-ion batteries involving the use of cellulose: The case of Sb. J. Power Sources 2008, 175, 553–557. [Google Scholar] [CrossRef]

- Caballero, Á.; Morales, J.; Sánchez, L. Tin nanoparticles formed in the presence of cellulose fibers exhibit excellent electrochemical performance as anode materials in lithium-ion batteries. Electrochem. Solid-State Lett. 2005, 8, A464. [Google Scholar] [CrossRef][Green Version]

- Li, L.; Hou, L.; Cheng, J.; Simmons, T.; Zhang, F.; Zhang, L.T.; Linhardt, R.J.; Koratkar, N. A flexible carbon/sulfur-cellulose core-shell structure for advanced lithium–sulfur batteries. Energy Storage Mater. 2018, 15, 388–395. [Google Scholar] [CrossRef]

- Patel, M.U.M.; Luong, N.D.; Seppälä, J.; Tchernychova, E.; Dominko, R. Low surface area graphene/cellulose composite as a host matrix for lithium sulphur batteries. J. Power Sources 2014, 254, 55–61. [Google Scholar] [CrossRef]

- Cai, Z.X.; Wang, Z.L.; Kim, J.; Yamauchi, Y. Hollow Functional Materials Derived from Metal–Organic Frameworks: Synthetic Strategies, Conversion Mechanisms, and Electrochemical Applications. Adv. Mater. 2019, 31. [Google Scholar] [CrossRef]

- Wang, C.; Kim, J.; Tang, J.; Na, J.; Kang, Y.; Kim, M.; Lim, H.; Bando, Y.; Li, J.; Yamauchi, Y. Large-Scale Synthesis of MOF-Derived Superporous Carbon Aerogels with Extraordinary Adsorption Capacity for Organic Solvents. Angew. Chem. 2020, 132, 2082–2086. [Google Scholar] [CrossRef]

- Young, C.; Wang, J.; Kim, J.; Sugahara, Y.; Henzie, J.; Yamauchi, Y. Controlled Chemical Vapor Deposition for Synthesis of Nanowire Arrays of Metal-Organic Frameworks and Their Thermal Conversion to Carbon/Metal Oxide Hybrid Materials. Chem. Mater. 2018, 30, 3379–3386. [Google Scholar] [CrossRef]

- Wang, J.; Luo, X.; Young, C.; Kim, J.; Kaneti, Y.V.; You, J.; Kang, Y.M.; Yamauchi, Y.; Wu, K.C.W. A Glucose-Assisted Hydrothermal Reaction for Directly Transforming Metal-Organic Frameworks into Hollow Carbonaceous Materials. Chem. Mater. 2018, 30, 4401–4408. [Google Scholar] [CrossRef]

- Marpaung, F.; Kim, M.; Khan, J.H.; Konstantinov, K.; Yamauchi, Y.; Hossain, M.S.A.; Na, J.; Kim, J. Metal–Organic Framework (MOF)-Derived Nanoporous Carbon Materials. Chem. Asian J. 2019, 14, 1331–1343. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Kim, J.; Tang, J.; Kim, M.; Lim, H.; Malgras, V.; You, J.; Xu, Q.; Li, J.; Yamauchi, Y. New Strategies for Novel MOF-Derived Carbon Materials Based on Nanoarchitectures. Chem 2020, 6, 19–40. [Google Scholar] [CrossRef]

- Li, Y.; Kim, J.; Wang, J.; Liu, N.L.; Bando, Y.; Alshehri, A.A.; Yamauchi, Y.; Hou, C.H.; Wu, K.C.W. High performance capacitive deionization using modified ZIF-8-derived, N-doped porous carbon with improved conductivity. Nanoscale 2018, 10, 14852–14859. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Lim, H.; Wang, C.; Kani, K.; Kwon, G.; You, J.; Park, H.; Alshehri, A.A.; Alghamidi, Y.G.; Alzahrani, K.A.; et al. Core-shell structured metal-organic framework-derived carbon with redox-active polydopamine nanothin film. Mater. Lett. 2019, 253, 178–182. [Google Scholar] [CrossRef]

- Marpaung, F.; Park, T.; Kim, M.; Yi, J.W.; Lin, J.; Wang, J.; Ding, B.; Lim, H.; Konstantinov, K.; Yamauchi, Y.; et al. Gram-Scale Synthesis of Bimetallic ZIFs and Their Thermal Conversion to Nanoporous Carbon Materials. Nanomaterials 2019, 9, 1796. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Kim, J.; Malgras, V.; Na, J.; Lin, J.; You, J.; Zhang, M.; Li, J.; Yamauchi, Y. Metal–Organic Frameworks and Their Derived Materials: Emerging Catalysts for a Sulfate Radicals-Based Advanced Oxidation Process in Water Purification. Small 2019, 15, 1900744. [Google Scholar] [CrossRef]

- Wang, C.; Kim, J.; Kim, M.; Lim, H.; Zhang, M.; You, J.; Yun, J.H.; Bando, Y.; Li, J.; Yamauchi, Y. Nanoarchitectured metal-organic framework-derived hollow carbon nanofiber filters for advanced oxidation processes. J. Mater. Chem. A 2019, 7, 13743–13750. [Google Scholar] [CrossRef]

- Dutta, S.; Kim, J.; Hsieh, P.; Hsu, Y.; Kaneti, Y.V.; Shieh, F.; Yamauchi, Y.; Wu, K.C.-W. Nanoarchitectonics of Biofunctionalized Metal–Organic Frameworks with Biological Macromolecules and Living Cells. Small Methods 2019, 3, 1900213. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.; Kim, J.H.; Park, H.S. Hierarchically open-porous nitrogen-incorporated carbon polyhedrons derived from metal-organic frameworks for improved CDI performance. Chem. Eng. J. 2020, 382, 122996. [Google Scholar] [CrossRef]

- Choi, I.; Jung, Y.E.; Yoo, S.J.; Kim, J.Y.; Kim, H.J.; Lee, C.Y.; Jang, J.H. Facile synthesis of M-MOF-74 (M=Co, Ni, Zn) and its application as an electrocatalyst for electrochemical CO2 conversion and H2 production. J. Electrochem. Sci. Technol. 2017, 8, 61–68. [Google Scholar] [CrossRef]

- Dias, O.A.T.; Konar, S.; Leão, A.L.; Yang, W.; Tjong, J.; Sain, M. Current State of Applications of Nanocellulose in Flexible Energy and Electronic Devices. Front. Chem. 2020, 8, 420. [Google Scholar] [CrossRef] [PubMed]

- Nyström, G.; Marais, A.; Karabulut, E.; Wågberg, L.; Cui, Y.; Hamedi, M.M. Self-assembled three-dimensional and compressible interdigitated thin-film supercapacitors and batteries. Nat. Commun. 2015, 6, 1–8. [Google Scholar] [CrossRef]

- Kuzmenko, V.; Wang, N.; Haque, M.; Naboka, O.; Flygare, M.; Svensson, K.; Gatenholm, P.; Liu, J.; Enoksson, P. Cellulose-derived carbon nanofibers/graphene composite electrodes for powerful compact supercapacitors. RSC Adv. 2017, 7, 45968–45977. [Google Scholar] [CrossRef]

- Zhou, S.; Kong, X.; Zheng, B.; Huo, F.; Strømme, M.; Xu, C. Cellulose Nanofiber @ Conductive Metal–Organic Frameworks for High-Performance Flexible Supercapacitors. ACS Nano 2019, 13, 9578–9586. [Google Scholar] [CrossRef]

- Kwon, G.; Kim, J.; Kim, D.; Ko, Y.; Yamauchi, Y.; You, J. Nanoporous cellulose paper-based SERS platform for multiplex detection of hazardous pesticides. Cellulose 2019, 26, 4935–4944. [Google Scholar] [CrossRef]

- Kim, J.; Young, C.; Lee, J.; Heo, Y.U.; Park, M.S.; Hossain, M.S.A.; Yamauchi, Y.; Kim, J.H. Nanoarchitecture of MOF-derived nanoporous functional composites for hybrid supercapacitors. J. Mater. Chem. A 2017, 5, 15065–15072. [Google Scholar] [CrossRef]

- Kim, J.; Young, C.; Lee, J.; Park, M.S.; Shahabuddin, M.; Yamauchi, Y.; Kim, J.H. CNTs grown on nanoporous carbon from zeolitic imidazolate frameworks for supercapacitors. Chem. Commun. 2016, 52, 13016–13019. [Google Scholar] [CrossRef]

- Lee, S.H.; Choi, S. Bimetallic zeolitic imidazolate frameworks for symmetric electrical double-layer supercapacitors with aqueous electrolytes. Mater. Lett. 2017, 207, 129–132. [Google Scholar] [CrossRef]

- Malas, A.; Bharati, A.; Verkinderen, O.; Goderis, B.; Moldenaers, P.; Cardinaels, R. Effect of the GO Reduction Method on the Dielectric Properties, Electrical Conductivity and Crystalline Behavior of PEO/rGO Nanocomposites. Polymers 2017, 9, 613. [Google Scholar] [CrossRef]

- Chen, R.; Zhao, T.; Tian, T.; Cao, S.; Coxon, P.R.; Xi, K.; Fairen-Jimenez, D.; Vasant Kumar, R.; Cheetham, A.K. Graphene-wrapped sulfur/metal organic framework-derived microporous carbon composite for lithium sulfur batteries. APL Mater. 2014, 2, 124109. [Google Scholar] [CrossRef]

- Xu, M.; He, G.; Li, Z.; He, F.; Gao, F.; Su, Y.; Zhang, L.; Yang, Z.; Zhang, Y. A green heterogeneous synthesis of N-doped carbon dots and their photoluminescence applications in solid and aqueous states. Nanoscale 2014, 6, 10307–10315. [Google Scholar] [CrossRef]

- Aghavnian, T.; Moussy, J.B.; Stanescu, D.; Belkhou, R.; Jedrecy, N.; Magnan, H.; Ohresser, P.; Arrio, M.A.; Sainctavit, P.; Barbier, A. Determination of the cation site distribution of the spinel in multiferroic CoFe2O4/BaTiO3 layers by X-ray photoelectron spectroscopy. J. Electron. Spectros. Relat. Phenom. 2015, 202, 16–21. [Google Scholar] [CrossRef]

- Ramesh, S.; Karuppasamy, K.; Yadav, H.M.; Lee, J.-J.; Kim, H.-S.; Kim, H.-S.; Kim, J.-H. Ni(OH)2-decorated nitrogen doped MWCNT nanosheets as an efficient electrode for high performance supercapacitors. Sci. Rep. 2019, 91, 6034. [Google Scholar] [CrossRef]

- Gui, Z.; Zhu, H.; Gillette, E.; Han, X.; Rubloff, G.W.; Hu, L.; Lee, S.B. Natural cellulose fiber as substrate for supercapacitor. ACS Nano 2013, 7, 6037–6046. [Google Scholar] [CrossRef]

- Zhu, J.; Shen, X.; Kong, L.; Zhu, G.; Ji, Z.; Xu, K.; Li, B.; Zhou, H.; Yue, X. MOF derived CoP-decorated nitrogen-doped carbon polyhedrons/reduced graphene oxide composites for high performance supercapacitors. Dalt. Trans. 2019, 48, 10661–10668. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Wang, H.; Yang, W.; Wu, S.; Han, W. Sustainable nitrogen-rich hierarchical porous carbon nest for supercapacitor application. Carbohydr. Polym. 2018, 198, 364–374. [Google Scholar] [CrossRef] [PubMed]

- Shu, Y.; Bai, Q.; Fu, G.; Xiong, Q.; Li, C.; Ding, H.; Shen, Y.; Uyama, H. Hierarchical porous carbons from polysaccharides carboxymethyl cellulose, bacterial cellulose, and citric acid for supercapacitor. Carbohydr. Polym. 2020, 227, 115346. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yadav, H.M.; Park, J.D.; Kang, H.C.; Kim, J.; Lee, J.-J. Cellulose Nanofiber Composite with Bimetallic Zeolite Imidazole Framework for Electrochemical Supercapacitors. Nanomaterials 2021, 11, 395. https://doi.org/10.3390/nano11020395

Yadav HM, Park JD, Kang HC, Kim J, Lee J-J. Cellulose Nanofiber Composite with Bimetallic Zeolite Imidazole Framework for Electrochemical Supercapacitors. Nanomaterials. 2021; 11(2):395. https://doi.org/10.3390/nano11020395

Chicago/Turabian StyleYadav, Hemraj M., Jong Deok Park, Hyeong Cheol Kang, Jeonghun Kim, and Jae-Joon Lee. 2021. "Cellulose Nanofiber Composite with Bimetallic Zeolite Imidazole Framework for Electrochemical Supercapacitors" Nanomaterials 11, no. 2: 395. https://doi.org/10.3390/nano11020395

APA StyleYadav, H. M., Park, J. D., Kang, H. C., Kim, J., & Lee, J.-J. (2021). Cellulose Nanofiber Composite with Bimetallic Zeolite Imidazole Framework for Electrochemical Supercapacitors. Nanomaterials, 11(2), 395. https://doi.org/10.3390/nano11020395