Icephobic Performance of Multi-Scale Laser-Textured Aluminum Surfaces for Aeronautic Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

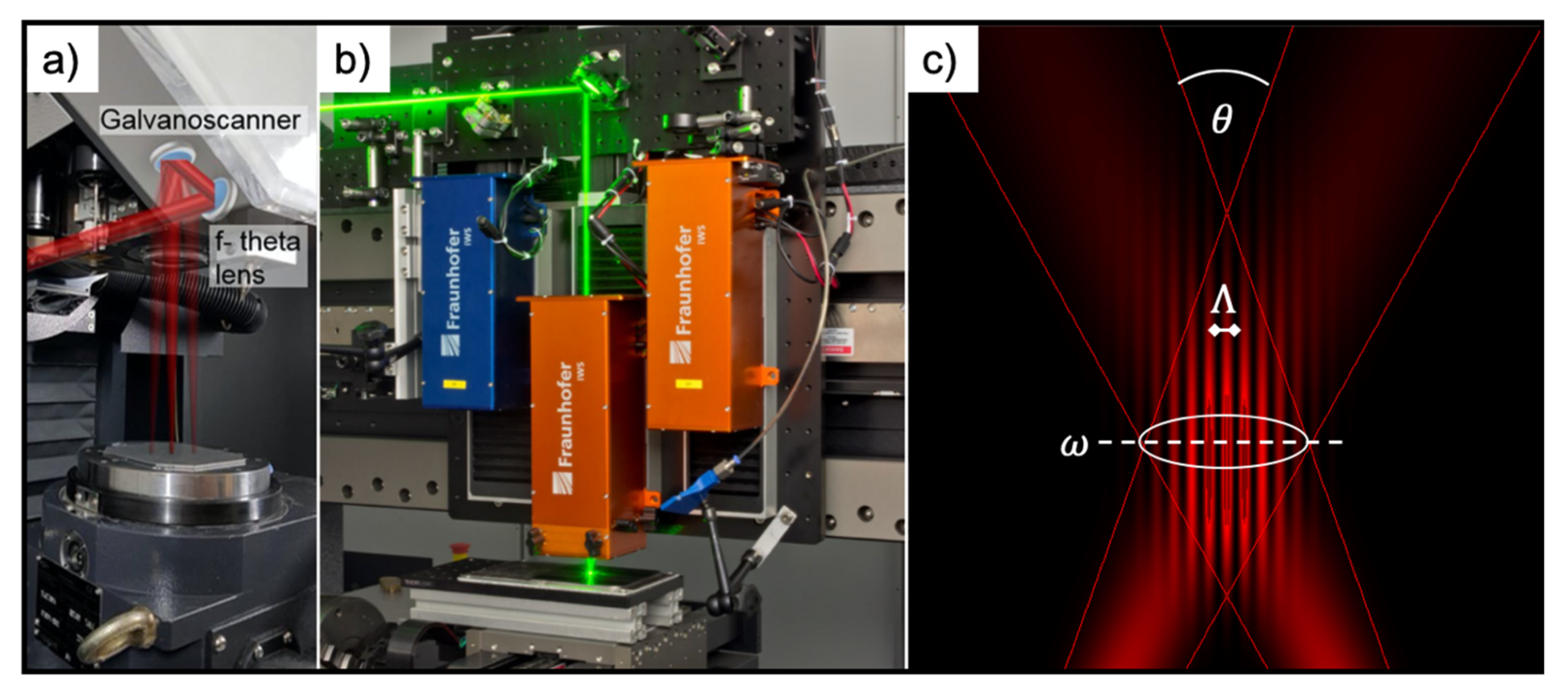

2.2. Laser Structuring Methods

2.3. Surface Characterization

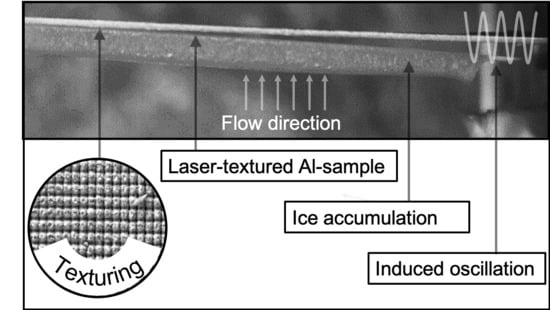

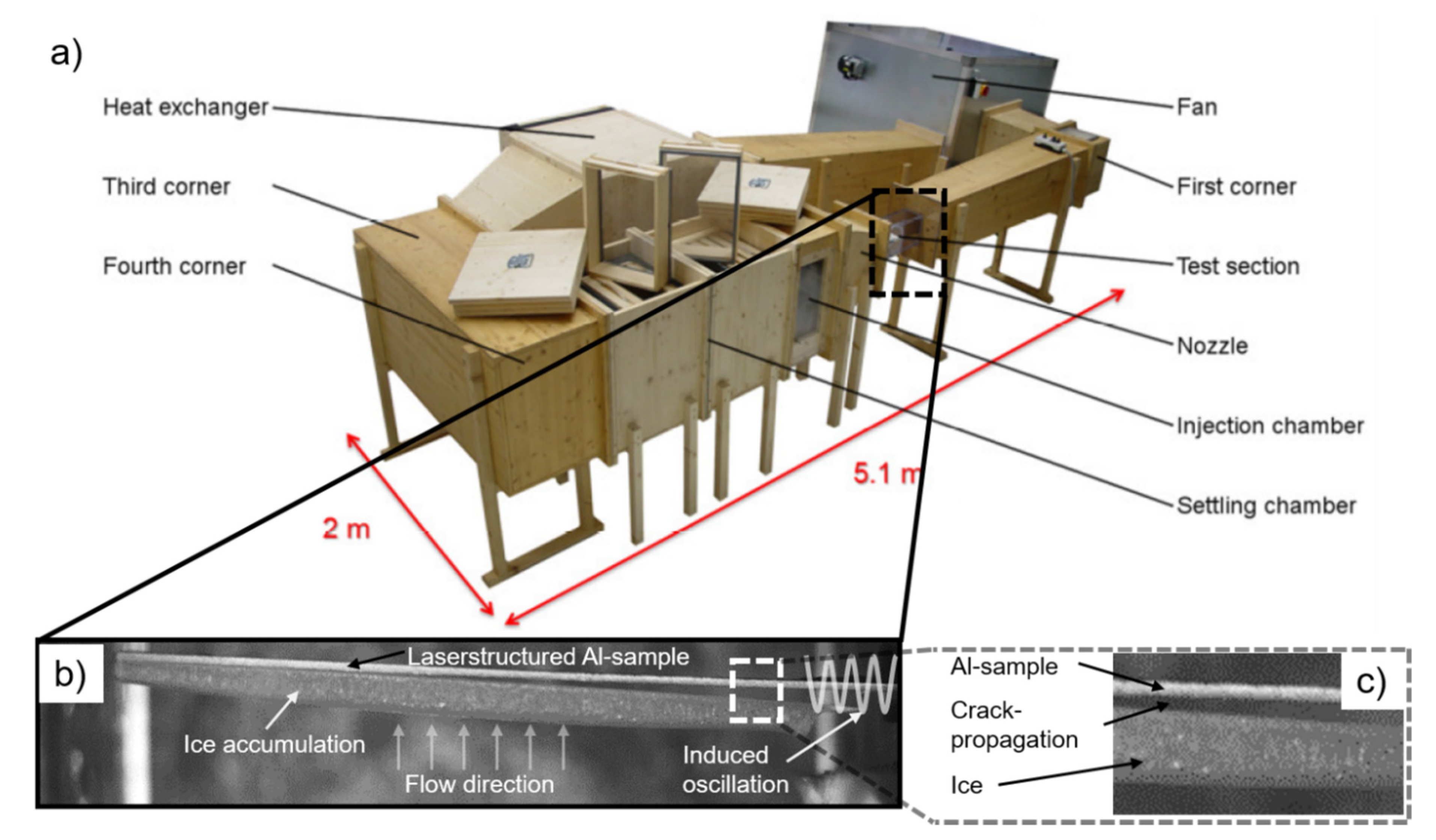

2.4. Ice Adhesion Test

3. Results and Discussion

3.1. Laser Structuring of Aluminum Substrates

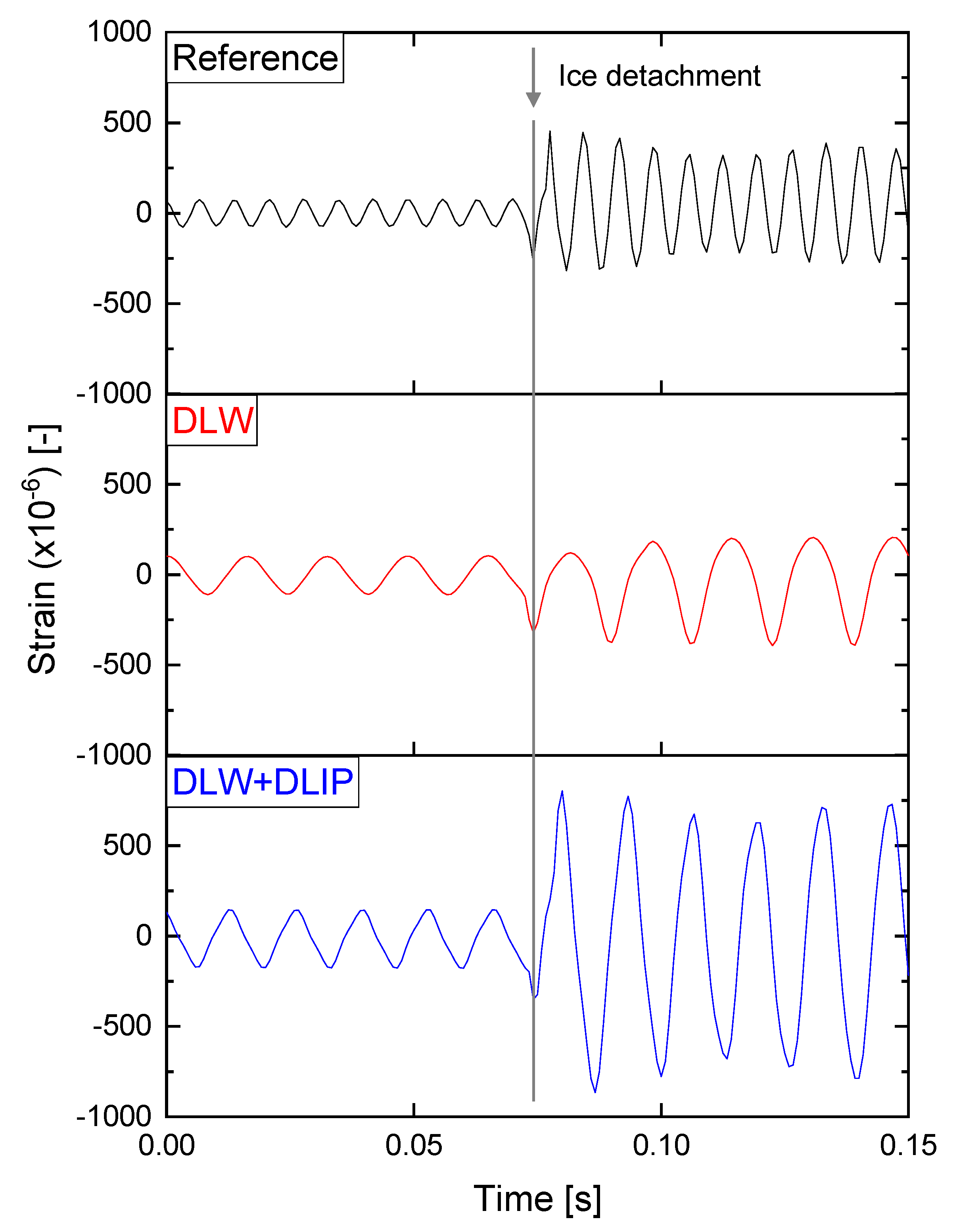

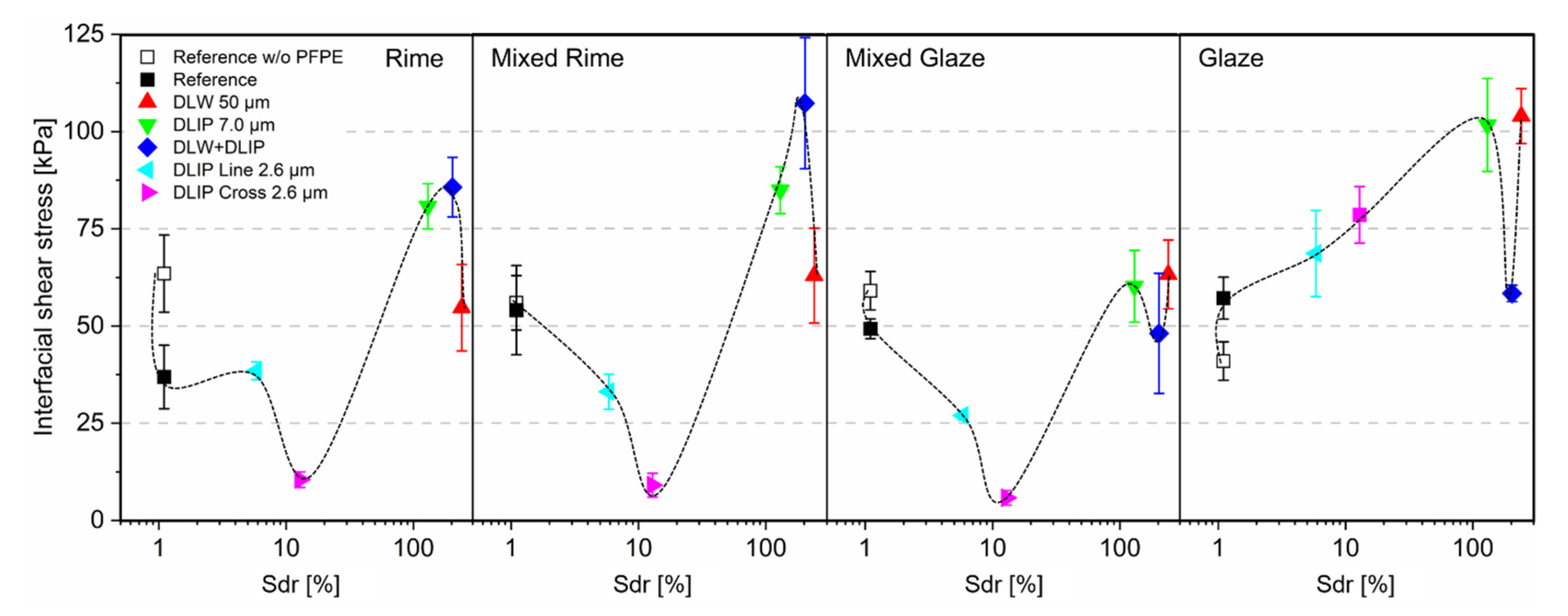

3.2. Ice Adhesion Analyzed by Mechanically Induced Stress

3.3. Influence of the Surface Topography on the Ice Adhesion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ω | Beam radius |

| θ | Intersection angle |

| Λ | Spatial period |

| Eice | Young’s modulus of the ice layer |

| Young’s Modulus of the bulk cantilever material | |

| Rz | Maximum peak to valley roughness |

| Sdr | Real area to projected area ratio |

| Interfacial shear stress | |

| Amplitude of the strain | |

| Thickness of the ice | |

| Thickness of the cantilever | |

| Distance of the strain gauge to the fixed end of the cantilever | |

| Length of the cantilever | |

| Eccentricity of the neutral axis of the ice/metal beam |

Appendix A

| Ice Type | TAT (°C) | Airspeed (m/s) | LWC (g/m3) | MVD (µm) | AFF (–) |

|---|---|---|---|---|---|

| Rime | −20 | 50 | 0.3 | 20 | 1.0 |

| Mixed/Rime | −20 | 50 | 0.8 | 20 | 0.7 |

| Mixed/Glaze | −5 | 50 | 0.3 | 20 | 0.5 |

| Glaze | −5 | 80 | 1.0 | 20 | 0.2 |

References

- Makkonen, L.; Lehtonen, P.; Hirviniemi, M. Determining ice loads for tower structure design. Eng. Struct. 2014, 74, 229–232. [Google Scholar] [CrossRef]

- Jelle, B.P. The challenge of removing snow downfall on photovoltaic solar cell roofs in order to maximize solar energy efficiency—Research opportunities for the future. Energy Build. 2013, 67, 334–351. [Google Scholar] [CrossRef]

- Cao, Y.; Tan, W.; Wu, Z. Aircraft icing: An ongoing threat to aviation safety. Aerosp. Sci. Technol. 2018, 75, 353–385. [Google Scholar] [CrossRef]

- Li, Q.; Guo, Z. Fundamentals of icing and common strategies for designing biomimetic anti-icing surfaces. J. Mater. Chem. A 2018, 6, 13549–13581. [Google Scholar] [CrossRef]

- Stankov, B.B.; Bedard, A.J.; Edard, A.J. Remote sensing observations of winter aircraft icing conditions—A case study. J. Aircr. 1994, 31, 79–89. [Google Scholar] [CrossRef]

- Cebeci, T.; Kafyeke, F. Aircrafticing. Annu. Rev. Fluid Mech. 2003, 35, 11–21. [Google Scholar] [CrossRef]

- Mao, Y.; Liming, K.; Chunping, H.; Fencheng, L.; Qiang, L. Formation characteristic, microstructure, and mechanical performances of aluminum-based components by friction stir additive manufacturing. Int. J. Adv. Manuf. Technol. 2015, 83, 1637–1647. [Google Scholar] [CrossRef]

- Sasse, C.; Brühl, F.; Schäfer, M. Thermal Treatment of Aviation Aluminum Alloys in Strip Processing Lines. Available online: /KEM.746.168 (accessed on 2 April 2020).

- Zhang, X.; Ma, J.; Jia, Z.; Song, D. Machining parameter optimisation for aviation aluminium-alloy thin-walled parts in high-speed milling. Int. J. Mach. Mach. Mater. 2018, 20, 180–192. [Google Scholar] [CrossRef]

- Thomas, S.K.; Cassoni, R.P.; MacArthur, C.D. Aircraft anti-icing and de-icing techniques and modeling. J. Aircr. 1996, 33, 841–854. [Google Scholar] [CrossRef]

- Masiulaniec, K.C. A Numerical Simulation of the Full Two-Dimensional Electrothermal De-Icer Pad; National Aeronautics and Space Administration, Scientific and Technical Information Division. In Proceedings of the 21st Aerospace Sciences Meeting Conference, Reno, NV, USA, 10–13 January 1983; pp. 1–7. [Google Scholar]

- Yaslik, A.D.; De Witt, K.J.; Keith, T.G.; Boronow, W. Three-dimensional simulation of electrothermal deicing systems. J. Aircr. 1992, 29, 1035–1042. [Google Scholar] [CrossRef]

- Work, A.; Lian, Y. A critical review of the measurement of ice adhesion to solid substrates. Prog. Aerosp. Sci. 2018, 98, 1–26. [Google Scholar] [CrossRef]

- Rønneberg, S.; Laforte, C.; He, J.; Zhang, Z. Comparison of Icephobic Materials through Interlaboratory Studies. In Ice Adhesion; John Wiley & Sons: Hoboken, NJ, USA, 2020; pp. 285–324. [Google Scholar]

- Huang, X.; Tepylo, N.; Pommier-Budinger, V.; Budinger, M.; Bonaccurso, E.; Villedieu, P.; Bennani, L. A survey of icephobic coatings and their potential use in a hybrid coating/active ice protection system for aerospace applications. Prog. Aerosp. Sci. 2019, 105, 74–97. [Google Scholar] [CrossRef]

- Palacios, J.; Smith, E.; Rose, J.; Royer, R. Ultrasonic De-Icing of Wind-Tunnel Impact Icing. J. Aircr. 2011, 48, 1020–1027. [Google Scholar] [CrossRef]

- Wang, Z. Recent progress on ultrasonic de-icing technique used for wind power generation, high-voltage transmission line and aircraft. Energy Build. 2017, 140, 42–49. [Google Scholar] [CrossRef]

- Meuler, A.J.; Smith, J.D.; Varanasi, K.K.; Mabry, J.M.; McKinley, G.H.; Cohen, R.E. Relationships between Water Wettability and Ice Adhesion. ACS Appl. Mater. Interfaces 2010, 2, 3100–3110. [Google Scholar] [CrossRef]

- Yan, W.; Liu, H.; Chen, T.; Sun, Q.; Zhu, W. Fast and low-cost method to fabricate large-area superhydrophobic surface on steel substrate with anticorrosion and anti-icing properties. J. Vac. Sci. Technol. A 2016, 34, 041401. [Google Scholar] [CrossRef]

- Alizadeh, A.; Yamada, M.; Li, R.; Shang, W.; Otta, S.; Zhong, S.; Ge, L.; Dhinojwala, A.; Conway, K.R.; Bahadur, V.; et al. Dynamics of Ice Nucleation on Water Repellent Surfaces. Langmuir 2012, 28, 3180–3186. [Google Scholar] [CrossRef]

- Schutzius, T.M.; Jung, S.; Maitra, T.; Eberle, P.; Antonini, C.; Stamatopoulos, C.; Poulikakos, D. Physics of Icing and Rational Design of Surfaces with Extraordinary Icephobicity. Langmuir 2015, 31, 4807–4821. [Google Scholar] [CrossRef]

- Alamri, S.; Vercillo, V.; Aguilar-Morales, A.I.; Schell, F.; Wetterwald, M.; Lasagni, A.F.; Bonaccurso, E.; Kunze, T. Self-Limited Ice Formation and Efficient De-Icing on Superhydrophobic Micro-Structured Airfoils through Direct Laser Interference Patterning. Adv. Mater. Interfaces 2020, 7. [Google Scholar] [CrossRef]

- De Pauw, D.; Dolatabadi, A. Effect of Superhydrophobic Coating on the Anti-Icing and Deicing of an Airfoil. J. Aircr. 2017, 54, 490–499. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Hejazi, V. Why Superhydrophobic Surfaces Are Not Always Icephobic. ACS Nano 2012, 6, 8488–8491. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Wang, C.; Dong, X.; Yin, K.; Zhang, F.; Xie, Z.; Chu, D.; Duan, J. Controllable superhydrophobic aluminum surfaces with tunable adhesion fabricated by femtosecond laser. Opt. Laser Technol. 2018, 102, 25–31. [Google Scholar] [CrossRef]

- Waller, E.H.; Dix, S.; Gutsche, J.; Widera, A.; Von Freymann, G. Functional Metallic Microcomponents via Liquid-Phase Multiphoton Direct Laser Writing: A Review. Micromachines 2019, 10, 827. [Google Scholar] [CrossRef] [PubMed]

- Alqattan, B.; Yetisen, A.K.; Butt, H. Direct Laser Writing of Nanophotonic Structures on Contact Lenses. ACS Nano 2018, 12, 5130–5140. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhou, Y.; Fan, F.; Du, F.; Yu, H. Controlling surface wettability and adhesive properties by laser marking approach. Opt. Laser Technol. 2019, 115, 160–165. [Google Scholar] [CrossRef]

- Huerta-Murillo, D.; Morales, A.I.A.; Alamri, S.; Cardoso, J.; Jagdheesh, R.; Lasagni, A.-F.; Ocaña, J.L. Fabrication of multi-scale periodic surface structures on Ti-6Al-4V by direct laser writing and direct laser interference patterning for modified wettability applications. Opt. Lasers Eng. 2017, 98, 134–142. [Google Scholar] [CrossRef]

- Milles, S.; Soldera, M.; Kuntze, T.; Lasagni, A.F. Characterization of self-cleaning properties on superhydrophobic aluminum surfaces fabricated by direct laser writing and direct laser interference patterning. Appl. Surf. Sci. 2020, 525, 146518. [Google Scholar] [CrossRef]

- Samanta, A.; Wang, Q.; Shaw, S.K.; Ding, H. Roles of chemistry modification for laser textured metal alloys to achieve extreme surface wetting behaviors. Mater. Des. 2020, 192, 108744. [Google Scholar] [CrossRef]

- Li, J.; Du, F.; Zhao, Y.; Zhao, S.; Yu, H. Two–step fabrication of superhydrophobic surfaces with anti–adhesion. Opt. Laser Technol. 2019, 113, 273–280. [Google Scholar] [CrossRef]

- Milles, S.; Voisiat, B.; Nitschke, M.; Lasagni, A.F. Influence of roughness achieved by periodic structures on the wettability of aluminum using direct laser writing and direct laser interference patterning technology. J. Mater. Process. Technol. 2019, 270, 142–151. [Google Scholar] [CrossRef]

- Chen, K.; Sun, T. Effects of microstructure design on aluminum surface hydrophobic and ice-retarding properties. Asia-Pacific J. Chem. Eng. 2017, 12, 307–312. [Google Scholar] [CrossRef]

- Milles, S.; Soldera, M.; Voisiat, B.; Lasagni, A.F. Fabrication of superhydrophobic and ice-repellent surfaces on pure aluminium using single and multiscaled periodic textures. Sci. Rep. 2019, 9, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Bieda, M.; Siebold, M.; Lasagni, A.F. Fabrication of sub-micron surface structures on copper, stainless steel and titanium using picosecond laser interference patterning. Appl. Surf. Sci. 2016, 387, 175–182. [Google Scholar] [CrossRef]

- Indrišiūnas, S.; Voisiat, B.; Žukauskas, A.; Račiukaitis, G. Direct laser beam interference patterning technique for fast high aspect ratio surface structuring. Proc. SPIE 2015, 9350, 935003. [Google Scholar] [CrossRef]

- Fang, S.; Hsu, C.-J.; Klein, S.; Llanes, L.; Bähre, D.; Mücklich, F. Influence of Laser Pulse Number on the Ablation of Cemented Tungsten Carbides (WC-CoNi) with Different Grain Size. Lubricants 2018, 6, 11. [Google Scholar] [CrossRef]

- Roitero, E.; Lasserre, F.; Anglada, M.; Mücklich, F.; Jimenez-Pique, E. A parametric study of laser interference surface patterning of dental zirconia: Effects of laser parameters on topography and surface quality. Dent. Mater. 2017, 33, e28–e38. [Google Scholar] [CrossRef] [PubMed]

- König, F.; Rosenkranz, A.; Grützmacher, P.G.; Mücklich, F.; Jacobs, G. Effect of single- and multi-scale surface patterns on the frictional performance of journal bearings—A numerical study. Tribol. Int. 2020, 143, 106041. [Google Scholar] [CrossRef]

- Aguilar-Morales, A.I.; Alamri, S.; Voisiat, B.; Kunze, T.; Lasagni, A.F. The Role of the Surface Nano-Roughness on the Wettability Performance of Microstructured Metallic Surface Using Direct Laser Interference Patterning. Materials 2019, 12, 2737. [Google Scholar] [CrossRef]

- Zwahr, C.; Helbig, R.; Werner, C.; Lasagni, A.F. Fabrication of multifunctional titanium surfaces by producing hierarchical surface patterns using laser based ablation methods. Sci. Rep. 2019, 9, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, J.; Aguilar-Morales, A.; Alamri, S.; Huerta-Murillo, D.; Cordovilla, F.; Lasagni, A.; Ocaña, J. Superhydrophobicity on hierarchical periodic surface structures fabricated via direct laser writing and direct laser interference patterning on an aluminium alloy. Opt. Lasers Eng. 2018, 111, 193–200. [Google Scholar] [CrossRef]

- Vercillo, V.; Tonnicchia, S.; Romano, J.; García-Girón, A.; Aguilar-Morales, A.I.; Alamri, S.; Dimov, S.S.; Kunze, T.; Lasagni, A.F.; Bonaccurso, E. Design Rules for Laser-Treated Icephobic Metallic Surfaces for Aeronautic Applications. Adv. Funct. Mater. 2020, 30. [Google Scholar] [CrossRef]

- Strobl, T.; Raps, D.; Hornung, M. Comparative Evaluation of Ice Adhesion Behavior. Mater. Sci. 2012, 6, 1622–1627. [Google Scholar]

- Portet, D.; Lecollinet, G.; Hindre, F.; Bejanin, S.; Chappard, D.; Denizot, B. Procede de Recouvrement de Surfaces Metalliques ou Minerales par des Monocouches Autoassemblees de Composes gem-Bisphosphoniques et Leurs Utilisations. Patent WO2008017721A2, 14 February 2008. [Google Scholar]

- Choi, J.; Kawaguchi, M.; Kato, T. Self-assembled monolayer formation on magnetic hard disk surface and friction measurements. J. Appl. Phys. 2002, 91, 7574. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; Von Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Aguilar-Morales, A.I.; Alamri, S.; Lasagni, A.F. Micro-fabrication of high aspect ratio periodic structures on stainless steel by picosecond direct laser interference patterning. J. Mater. Process. Technol. 2018, 252, 313–321. [Google Scholar] [CrossRef]

- Vercillo, V.; Cardoso, J.T.; Huerta-Murillo, D.; Tonnicchia, S.; Laroche, A.; Guillén, J.M.; Ocaña, J.L.; Lasagni, A.F.; Bonaccurso, E. Durability of superhydrophobic laser-treated metal surfaces under icing conditions. Mater. Lett. X 2019, 3, 100021. [Google Scholar] [CrossRef]

- DIN EN ISO 4287:2010-07, Geometrische Produktspezifikation (GPS)_- Oberflächenbeschaffenheit: Tastschnittverfahren_- Benennungen, Definitionen Und Kenngrößen Der Oberflächenbeschaffenheit (ISO_4287:1997_+ Cor_1:1998_+ Cor_2:2005_+ Amd_1:2009); Deutsche Fassung EN_ISO_4287:1998_+ AC:2008_+ A1:2009; Beuth Verlag GmbH: Berlin, Germany, 2009.

- Hauk, T.; Strobl, T.; Raps, D. Implementation and Calibration of the Icing and Contamination Research Facility (ICORE). In Proceedings of the 25th European Conference on Liquid Atomization and Spray Systems (ILASS), Chania, Greece, 1–4 September 2013; p. 8. [Google Scholar]

- Thompson, D.S.; Meng, D.; Afshar, A.; Bassou, R.; Zong, J.; Bonaccurso, E.; Laroche, A.; Vercillo, V. Initial Development of a Model to Predict Impact Ice Adhesion Stress. In Proceedings of the 2018 Atmospheric and Space Environments Conference; American Institute of Aeronautics and Astronautics (AIAA), Atlanta, GA, USA, 25–29 June 2018. [Google Scholar]

- Jeck, R.K. Icing Design Envelopes (14 CFR Parts 25 and 29, Appenddix C) Converted to a Distance-Based Format; Federal Aviation Administration Technical Center: Atlantic City, NJ, USA, 2002.

- Ruff, G.A. Analysis and Verification of the Icing Scaling Equations; Arnold Engineering Development Center: Tullahoma, TN, USA, 1986; Volume 1. [Google Scholar]

- Garcia-Giron, A.; Romano, J.-M.; Batal, A.; Dashtbozorg, B.; Dong, H.; Solanas, E.M.; Angos, D.U.; Walker, M.; Penchev, P.; Dimov, S.S. Durability and Wear Resistance of Laser-Textured Hardened Stainless Steel Surfaces with Hydrophobic Properties. Langmuir 2019, 35, 5353–5363. [Google Scholar] [CrossRef]

- Eral, H.B.; Mannetje, D.J.C.M.; Oh, J.M. Contact angle hysteresis: A review of fundamentals and applications. Colloid Polym. Sci. 2013, 291, 247–260. [Google Scholar] [CrossRef]

- Su, C.; Li, Y.; Dai, Y.-Z.; Gao, F.; Tang, K.; Cao, H. Fabrication of three-dimensional superhydrophobic membranes with high porosity via simultaneous electrospraying and electrospinning. Mater. Lett. 2016, 170, 67–71. [Google Scholar] [CrossRef]

- Subramanyam, S.B.; Kondrashov, V.; Rühe, J.; Varanasi, K.K. Low Ice Adhesion on Nano-Textured Superhydrophobic Surfaces under Supersaturated Conditions. ACS Appl. Mater. Interfaces 2016, 8, 12583–12587. [Google Scholar] [CrossRef]

- Dehkordi, H.B.; Farzaneh, M.; Van Dyke, P.; Kollár, L.E. The effect of droplet size and liquid water content on ice accretion and aerodynamic coefficients of tower legs. Atmos. Res. 2013, 362–374. [Google Scholar] [CrossRef]

- Hassan, M.F.; Lee, H.P.; Lim, S.P. The variation of ice adhesion strength with substrate surface roughness. Meas. Sci. Technol. 2010, 21, 075701. [Google Scholar] [CrossRef]

- Bharathidasan, T.; Kumar, S.V.; Bobji, M.; Chakradhar, R.; Basu, B.J. Effect of wettability and surface roughness on ice-adhesion strength of hydrophilic, hydrophobic and superhydrophobic surfaces. Appl. Surf. Sci. 2014, 314, 241–250. [Google Scholar] [CrossRef]

- Eskandarian, M.; Jennings, R.; Coté, M.; Arsenault, B. Fracture Behavior of Typical Structural Adhesive Joints Under Quasi-Static and Cyclic Loadings. SAE Int. J. Mater. Manuf. 2010, 3, 622–627. [Google Scholar] [CrossRef][Green Version]

- Ginnings, D.; Corruccini, R. An improved ice calorimeter—The determination of its calibration factor and the density of ice at 0 degrees C. J. Res. Natl. Inst. Stand. Technol. 1947, 38, 583. [Google Scholar] [CrossRef]

- Golovin, K.; Kobaku, S.P.R.; Lee, D.H.; DiLoreto, E.T.; Mabry, J.M.; Tuteja, A. Designing durable icephobic surfaces. Sci. Adv. 2016, 2, e1501496. [Google Scholar] [CrossRef]

- Saleema, N.; Farzaneh, M.; Paynter, R.W.; Sarkar, D. Prevention of Ice Accretion on Aluminum Surfaces by Enhancing Their Hydrophobic Properties. J. Adhes. Sci. Technol. 2011, 25, 27–40. [Google Scholar] [CrossRef]

- Kulinich, S.A.; Farzaneh, M. On ice-releasing properties of rough hydrophobic coatings. Cold Reg. Sci. Technol. 2011, 65, 60–64. [Google Scholar] [CrossRef]

- Deng, T.; Varanasi, K.K.; Hsu, M.; Bhate, N.; Keimel, C.; Stein, J.; Blohm, M.L. Nonwetting of impinging droplets on textured surfaces. Appl. Phys. Lett. 2009, 94, 133109. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, C.; Liu, K.; Jiang, Y.; Song, Y.; Francisco, J.S.; Zeng, X.C.; Wang, J. Distinct ice patterns on solid surfaces with various wettabilities. Proc. Natl. Acad. Sci. USA 2017, 114, 11285–11290. [Google Scholar] [CrossRef]

- Lo, C.-W.; Sahoo, V.; Lu, M.-C. Control of Ice Formation. ACS Nano 2017, 11, 2665–2674. [Google Scholar] [CrossRef] [PubMed]

- Varanasi, K.K.; Deng, T.; Smith, J.D.; Hsu, M.; Bhate, N. Frost formation and ice adhesion on superhydrophobic surfaces. Appl. Phys. Lett. 2010, 97, 234102. [Google Scholar] [CrossRef]

- Kulinich, S.A.; Farzaneh, M. Ice adhesion on super-hydrophobic surfaces. Appl. Surf. Sci. 2009, 255, 8153–8157. [Google Scholar] [CrossRef]

- Memon, H.; Liu, J.; De Focatiis, D.S.; Choi, K.-S.; Hou, X. Intrinsic dependence of ice adhesion strength on surface roughness. Surf. Coat. Technol. 2020, 385, 125382. [Google Scholar] [CrossRef]

- Momen, G.; Jafari, R.; Farzaneh, M. Ice repellency behaviour of superhydrophobic surfaces: Effects of atmospheric icing conditions and surface roughness. Appl. Surf. Sci. 2015, 349, 211–218. [Google Scholar] [CrossRef]

- Sarshar, M.A.; Song, D.; Swarctz, C.; Lee, J.; Choi, C.-H. Anti-Icing or Deicing: Icephobicities of Superhydrophobic Surfaces with Hierarchical Structures. Langmuir 2018, 34, 13821–13827. [Google Scholar] [CrossRef]

- He, Y.; Jiang, C.; Cao, X.; Chen, J.; Tian, W.; Yuan, W. Reducing ice adhesion by hierarchical micro-nano-pillars. Appl. Surf. Sci. 2014, 305, 589–595. [Google Scholar] [CrossRef]

| Parameter | Untreated Reference | Reference with PFPE | DLW 50 µm | DLIP 7.0 µm | DLW/DLIP 50/7.0 µm | DLIP Line 2.6 µm | DLIP Cross 2.6 µm |

|---|---|---|---|---|---|---|---|

| Geometry | - | - | Mesh-like | Pillar-like | Hierarchical | Line-like | Cross-like |

| Spatial period (µm) | - | - | 50 | 7 | 50/7 | 2.6 | 2.6 |

| Static contact angle (°) | 59 ± 2 | 122 ± 2 | 171 ± 2 | 165 ± 1 | 172 ± 1 | 166 ± 1 | 164 ± 3 |

| Sliding angle (°) | No sliding | No sliding | 2 ± 1 | 4 ± 2 | 2 ± 1 | 3 ± 1 | 9 ± 4 |

| Roughness Rz (µm) | 0.15 ± 0.04 | 0.18 ± 0.04 | 43.15 ± 0.32 | 4.16 ± 0.39 | 38.16 ± 2.33 | 0.61 ± 0.03 | 0.96 ± 0.17 |

| Real area to projected area ratio Sdr (%) | 1.1 | 1.1 | 240 | 130 | 203 | 5.9 | 12.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Milles, S.; Vercillo, V.; Alamri, S.; Aguilar-Morales, A.I.; Kunze, T.; Bonaccurso, E.; Lasagni, A.F. Icephobic Performance of Multi-Scale Laser-Textured Aluminum Surfaces for Aeronautic Applications. Nanomaterials 2021, 11, 135. https://doi.org/10.3390/nano11010135

Milles S, Vercillo V, Alamri S, Aguilar-Morales AI, Kunze T, Bonaccurso E, Lasagni AF. Icephobic Performance of Multi-Scale Laser-Textured Aluminum Surfaces for Aeronautic Applications. Nanomaterials. 2021; 11(1):135. https://doi.org/10.3390/nano11010135

Chicago/Turabian StyleMilles, Stephan, Vittorio Vercillo, Sabri Alamri, Alfredo I. Aguilar-Morales, Tim Kunze, Elmar Bonaccurso, and Andrés Fabián Lasagni. 2021. "Icephobic Performance of Multi-Scale Laser-Textured Aluminum Surfaces for Aeronautic Applications" Nanomaterials 11, no. 1: 135. https://doi.org/10.3390/nano11010135

APA StyleMilles, S., Vercillo, V., Alamri, S., Aguilar-Morales, A. I., Kunze, T., Bonaccurso, E., & Lasagni, A. F. (2021). Icephobic Performance of Multi-Scale Laser-Textured Aluminum Surfaces for Aeronautic Applications. Nanomaterials, 11(1), 135. https://doi.org/10.3390/nano11010135